Transmission and Reflection Properties of Iron Pyrite-Epoxy Resin Composite for Electromagnetic Applications

Abstract

:1. Introduction

- The proposed study characterizes the iron pyrite-epoxy composite, which exhibits fine electromagnetic properties, revealing a transmission coefficient of 90% over a very wide range of frequency from 1 GHz to 15 GHz. Furthermore, for the application of substrate materials in antennas, the reflection losses were relatively small. This implies that clear and strong signal transmission is possible for electromagnetic applications.

- This composite also presents a band gap tunable to 1.3 eV, thus enabling the selective absorption and emission of electromagnetic radiation. Characteristics like these increase its utility in diverse applications requiring a specific interaction of electromagnetic waves, such as UV-Vis spectroscopy and advanced antenna systems.

- The epoxy resin binder ensured that the composite possessed mechanical strength and improved dielectric properties at the same time. This ensured that the transmission efficiency was enhanced and quite stable in high-performance electromagnetic systems. The product could therefore be relied on for highly complex applications such as antennas that demanded transmission with high-quality reliability and minimal attenuations of signal.

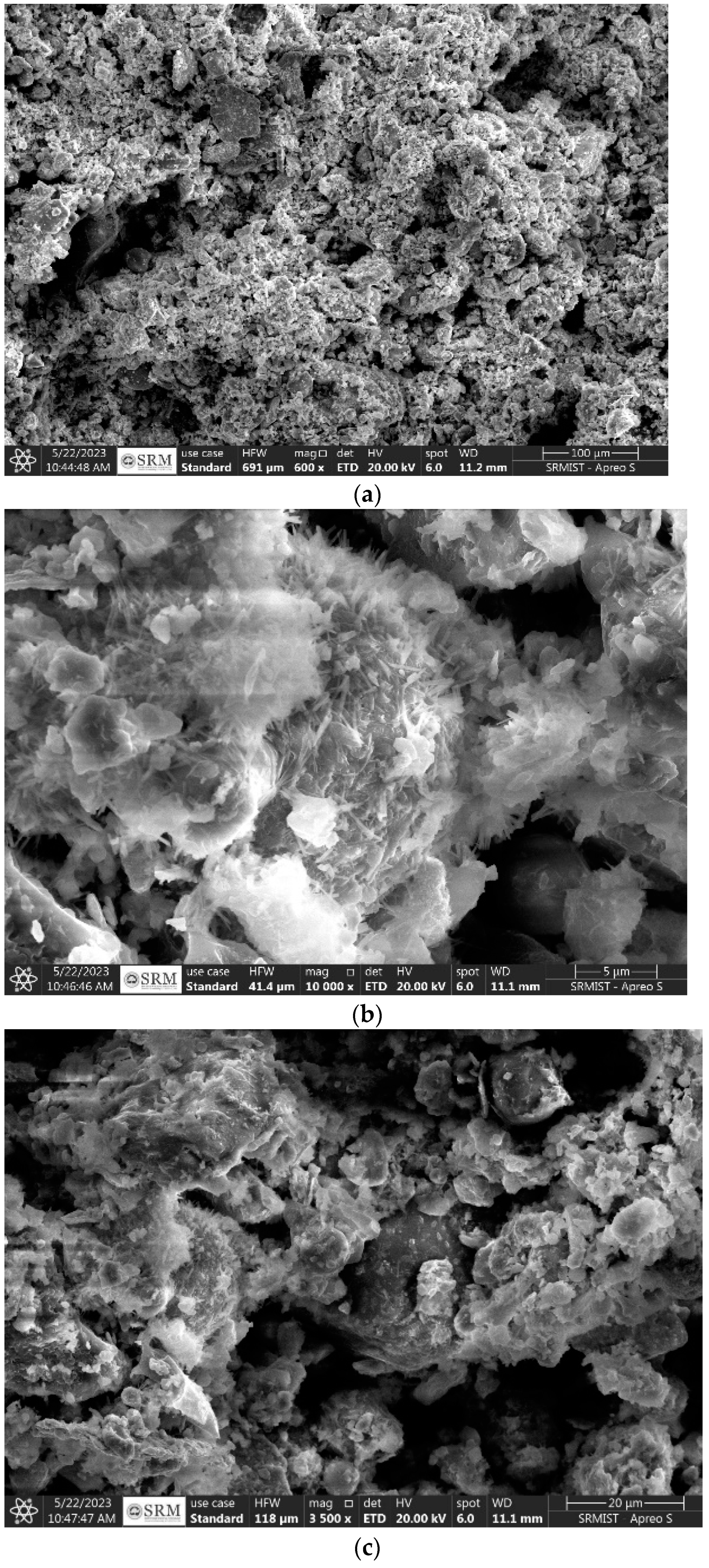

2. Materials Selection and Characterization

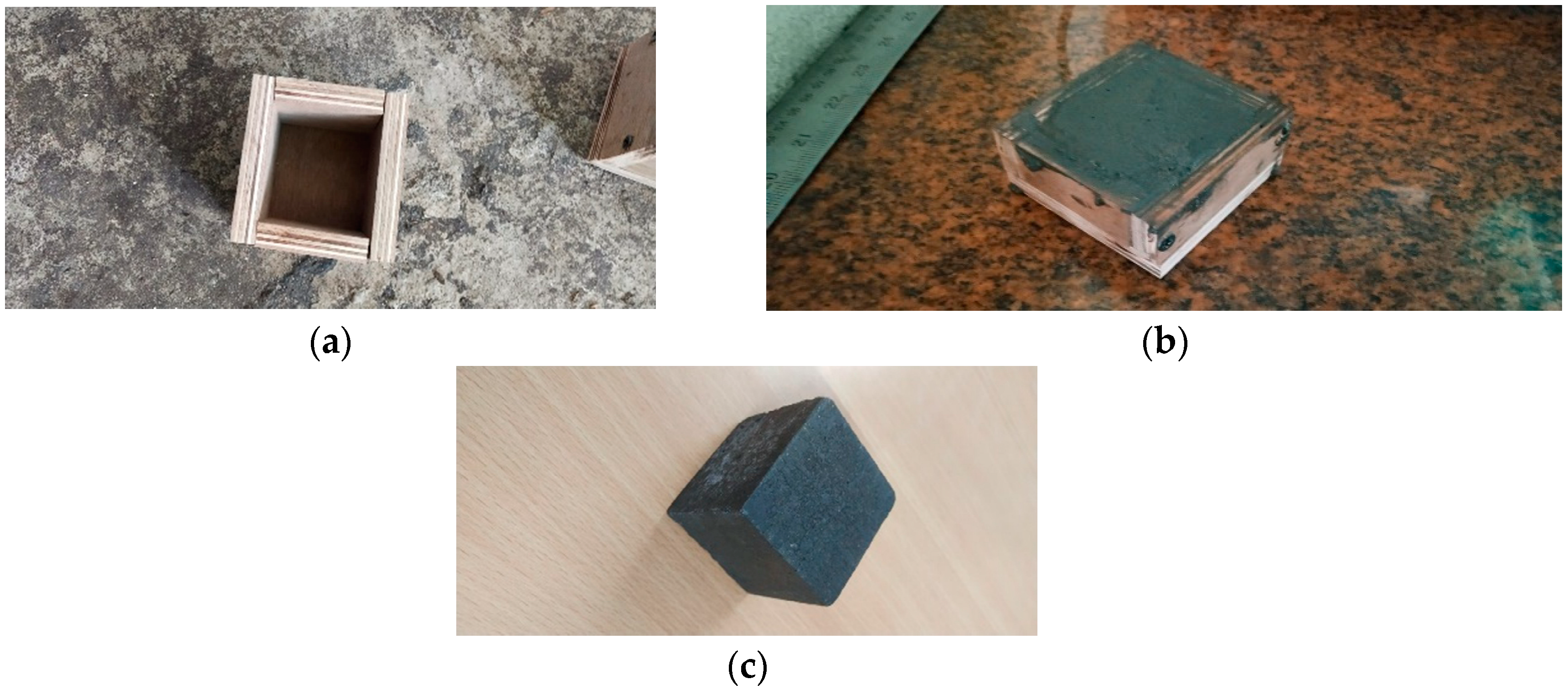

3. Performance Analysis of iPyroxy Block

3.1. Electromagnetic Wave Transmission Rate

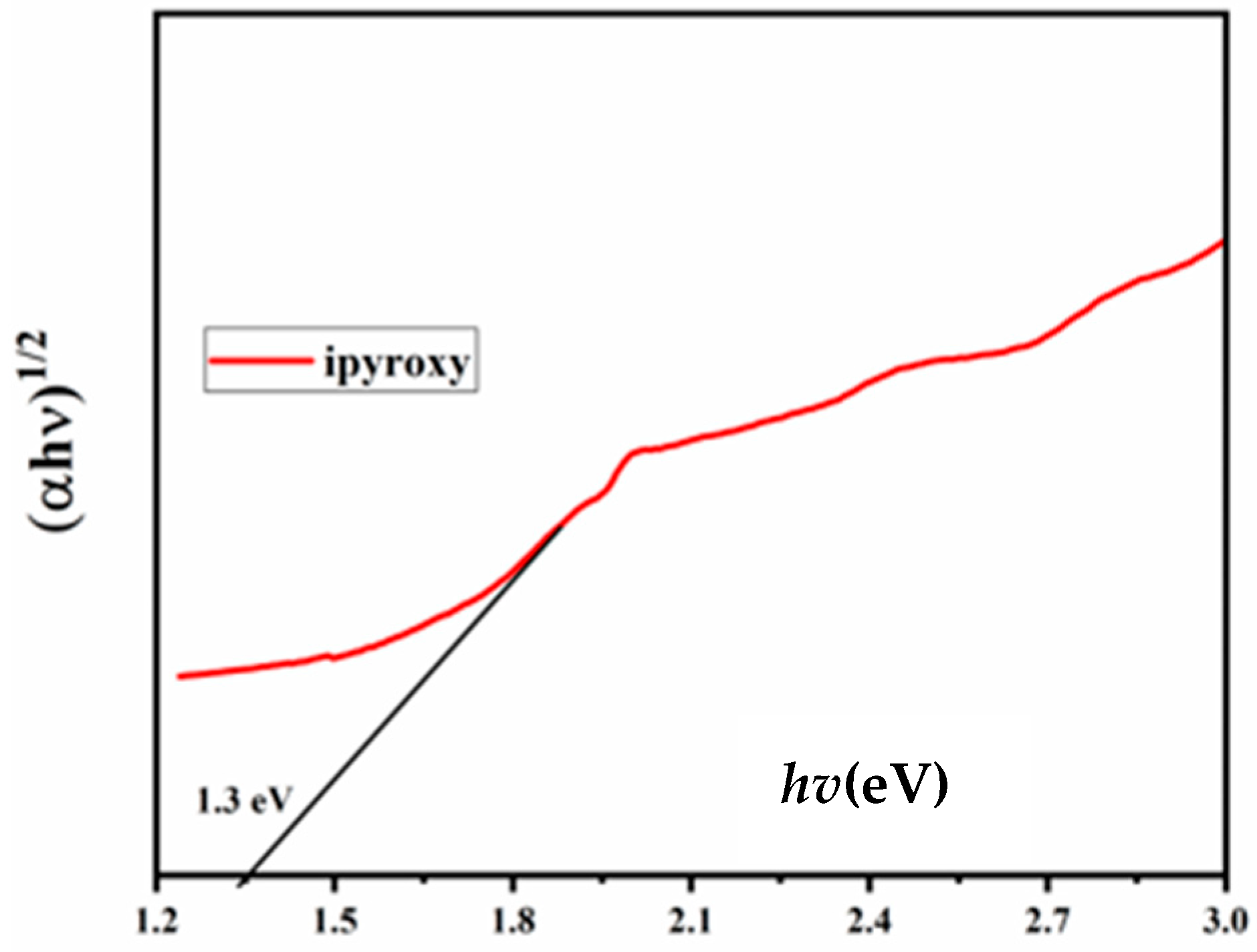

3.2. UV Absorption and Band Gap

3.3. Absorption Value

3.4. Antenna Specification

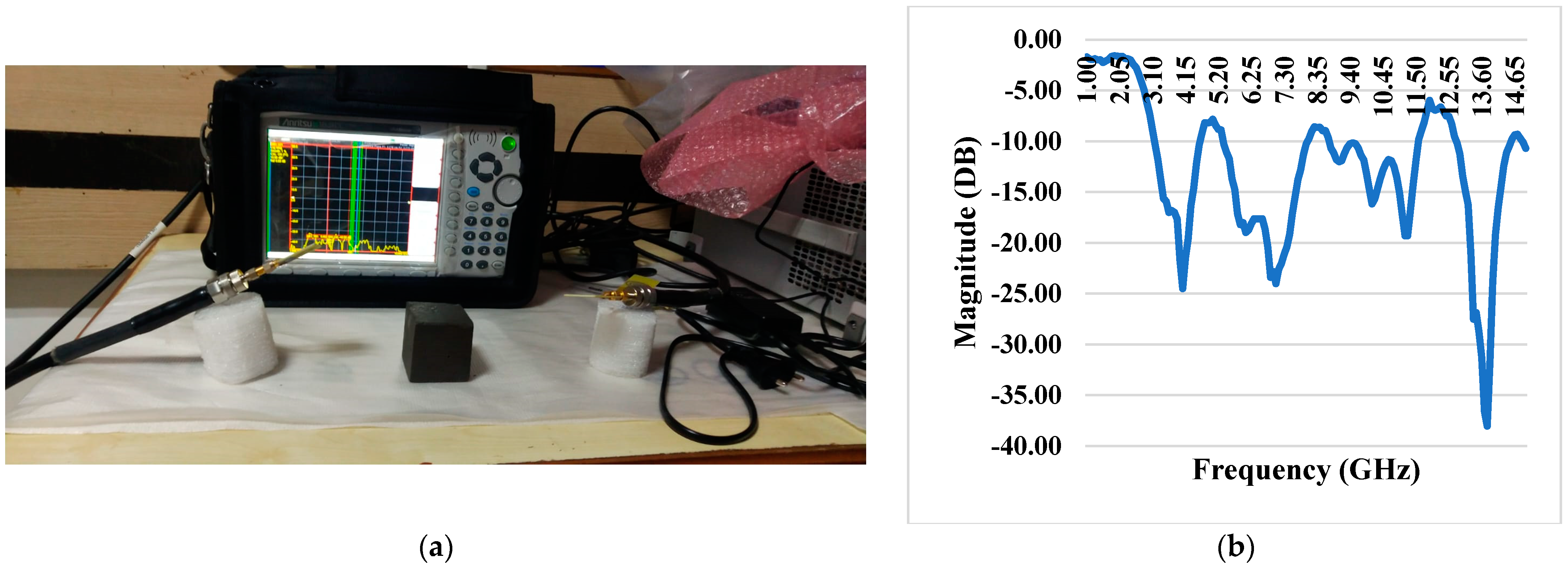

3.5. S Parameter Using Vector Network Analyser

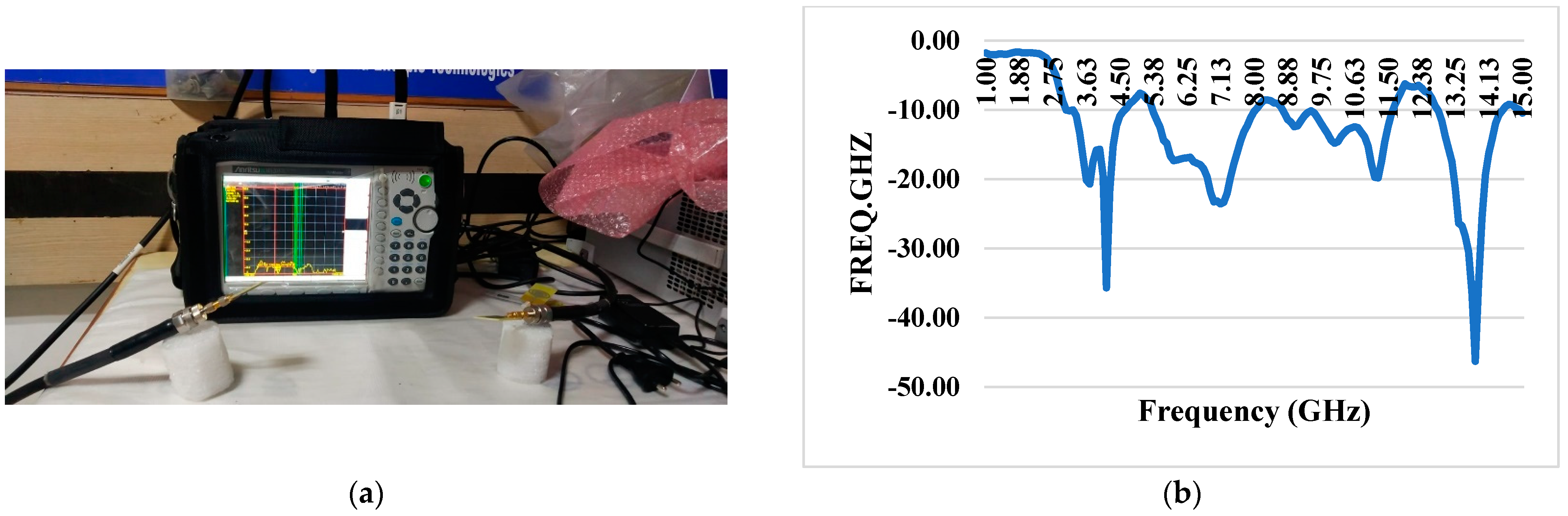

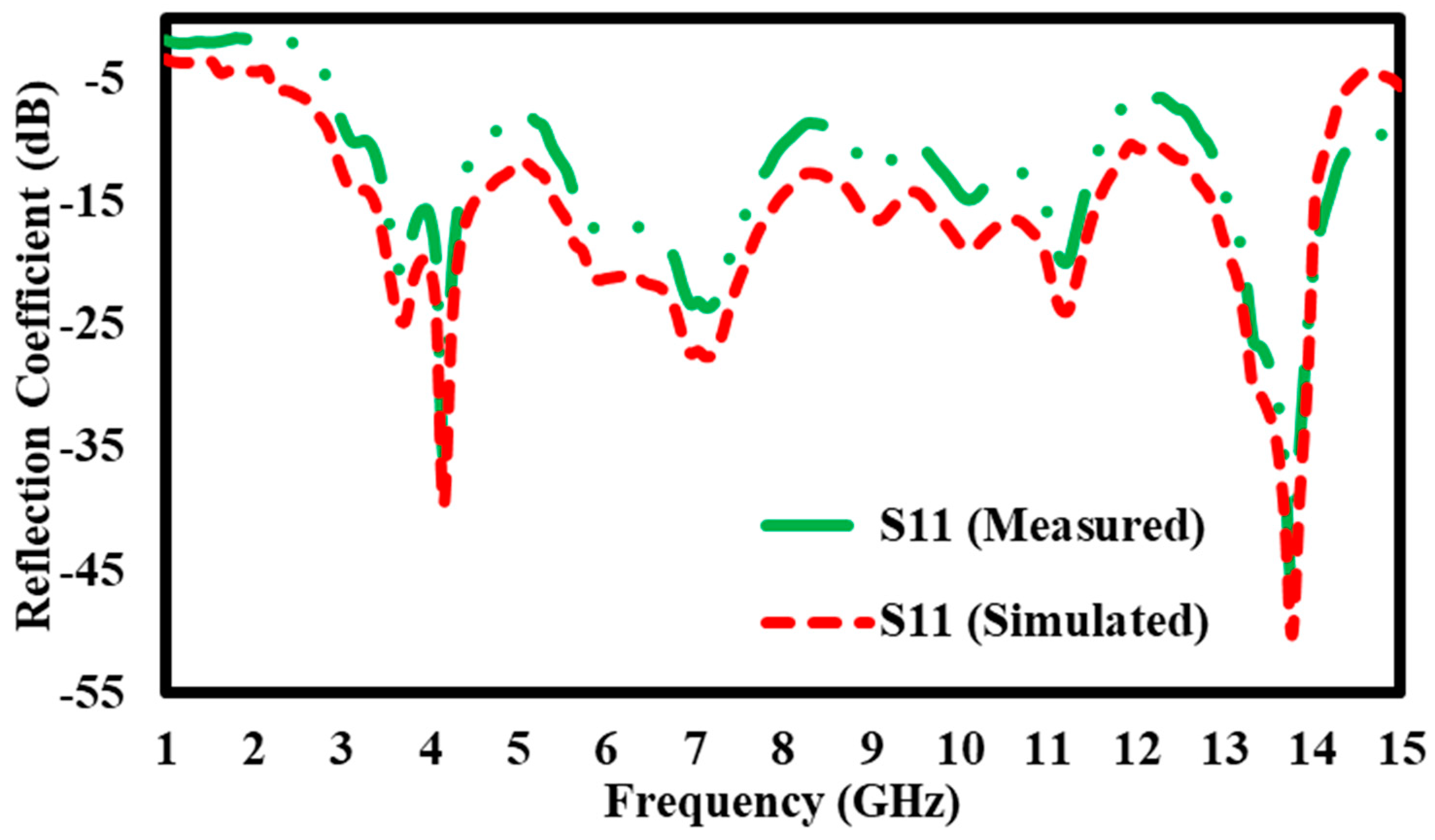

3.6. S11 Reflection Coefficient

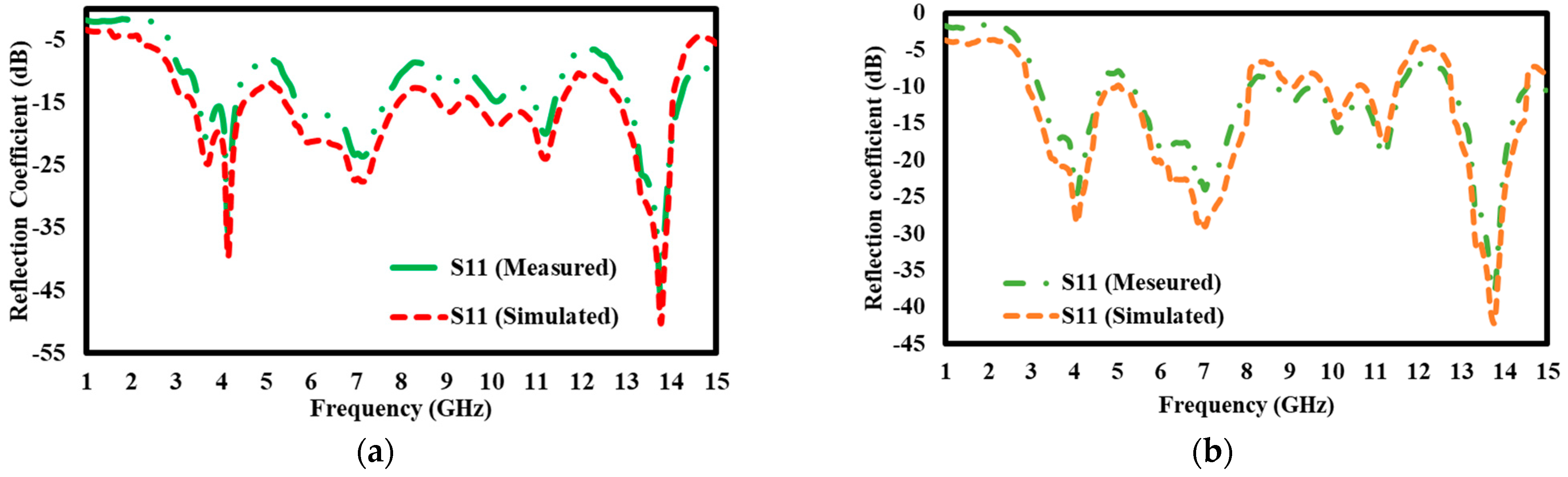

3.7. S11 Reflection Coefficient with iPyroxy Block

3.8. S11 Reflection Coefficient Without iPyroxy Block

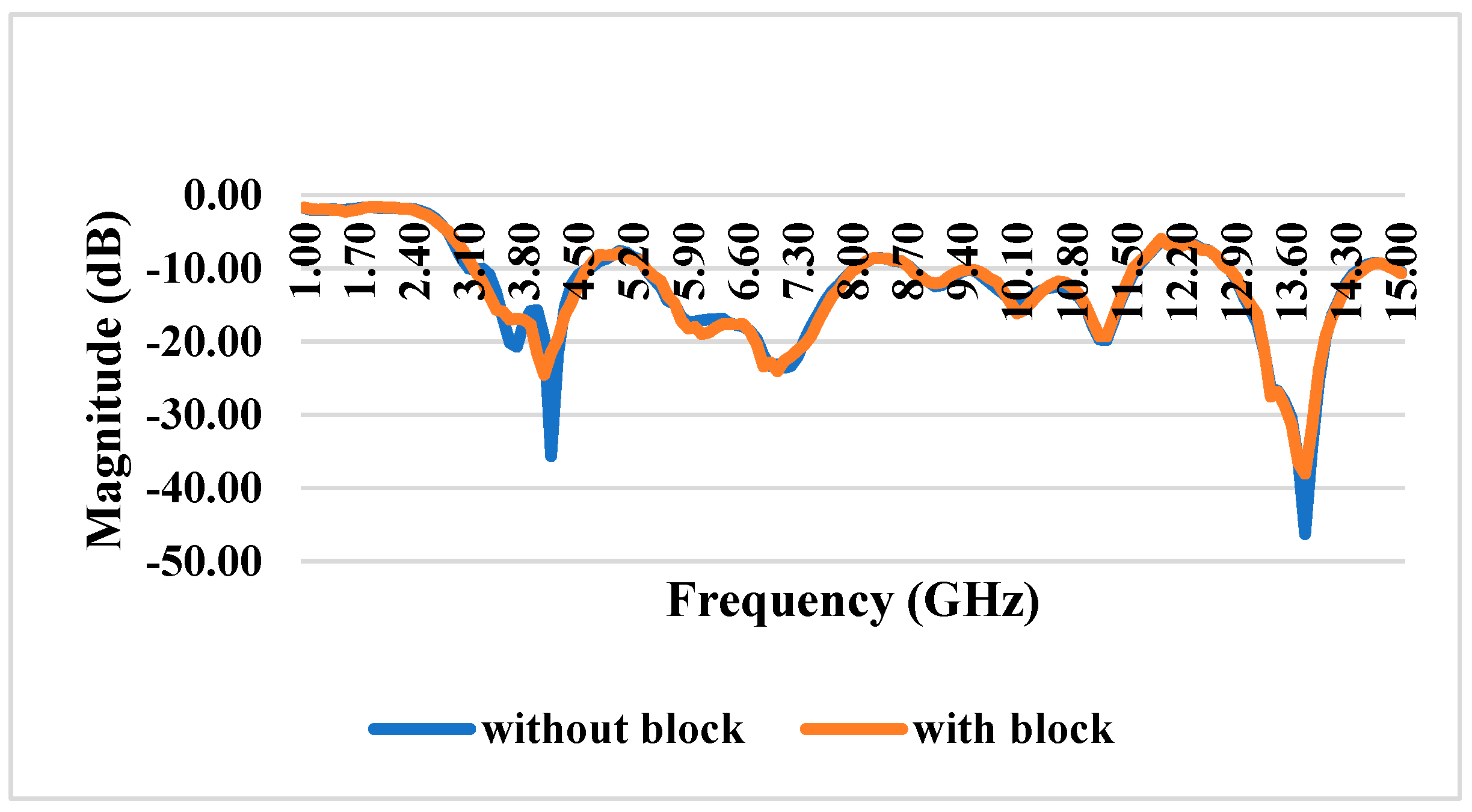

3.9. S11 Reflection Coefficient With and Without iPyroxy Block

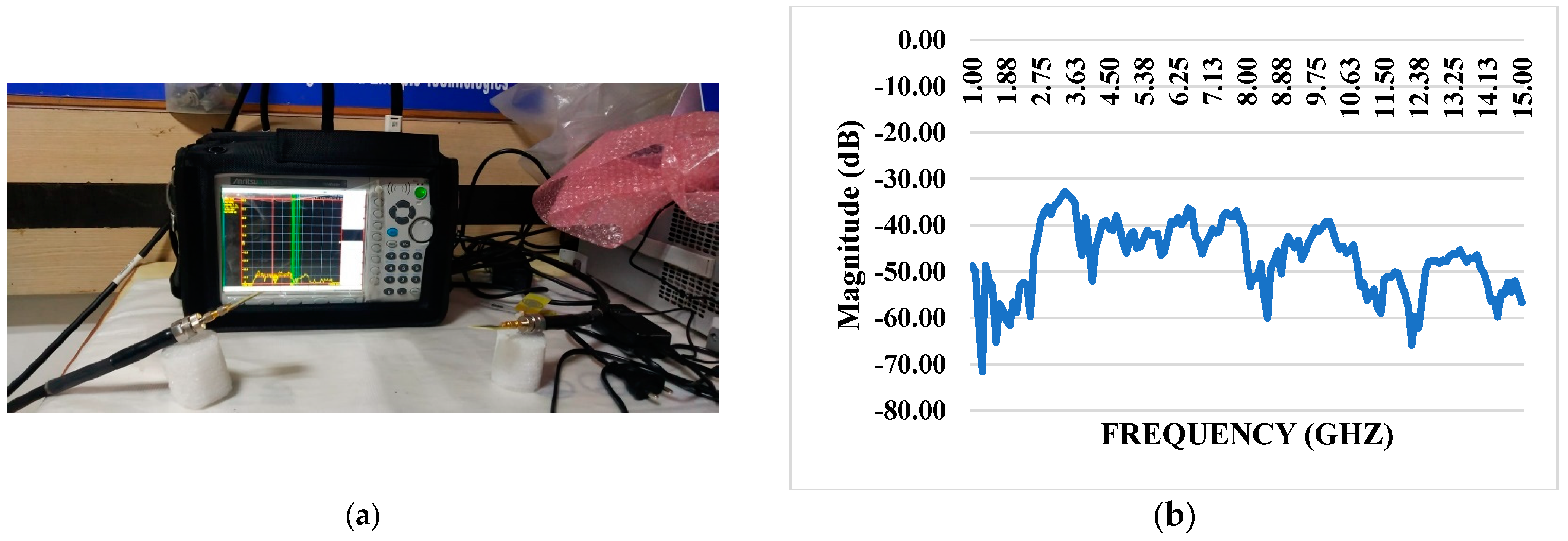

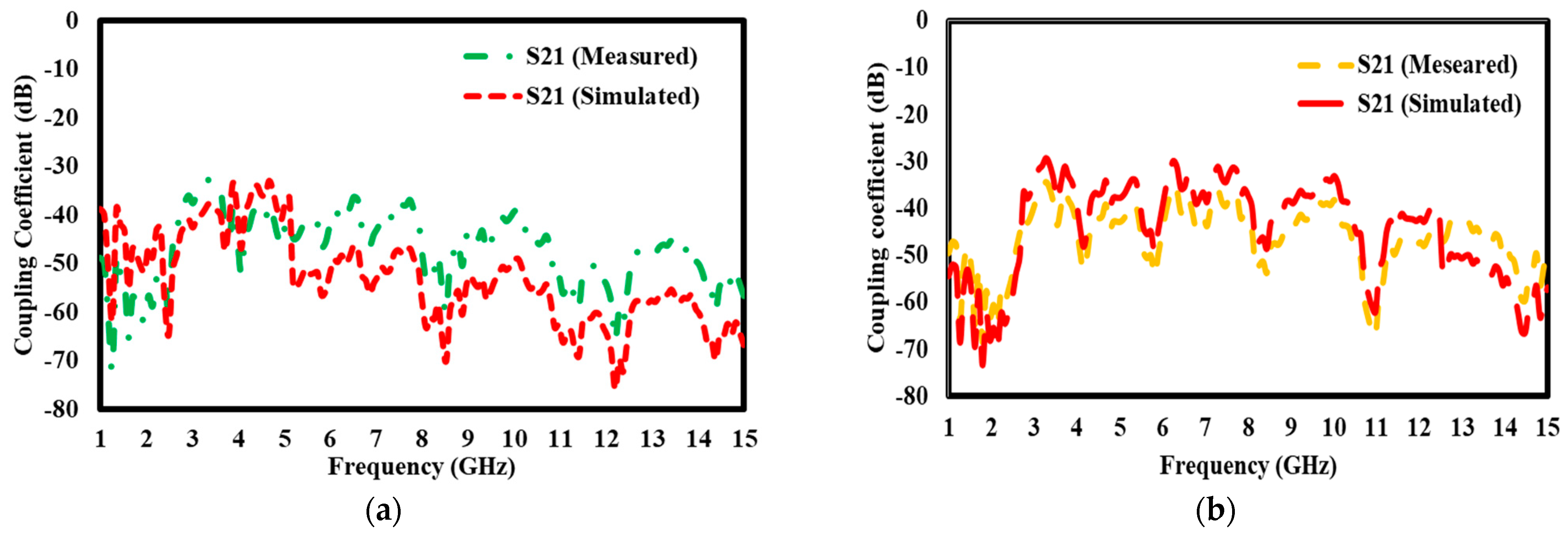

4. S21 Transmission Coefficient

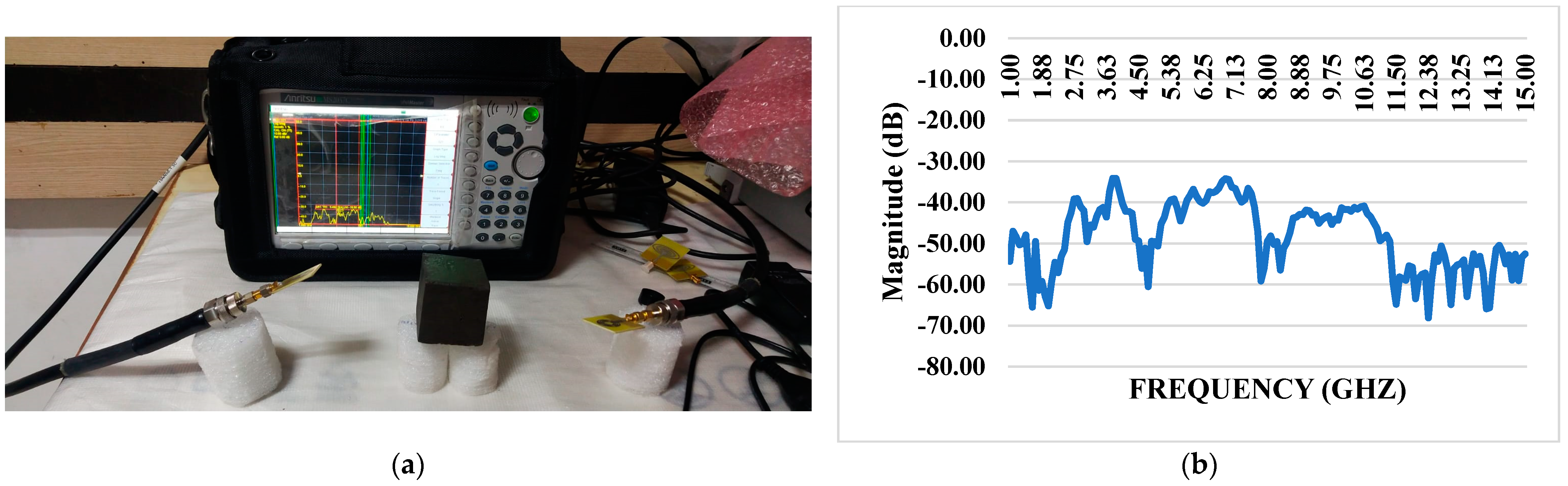

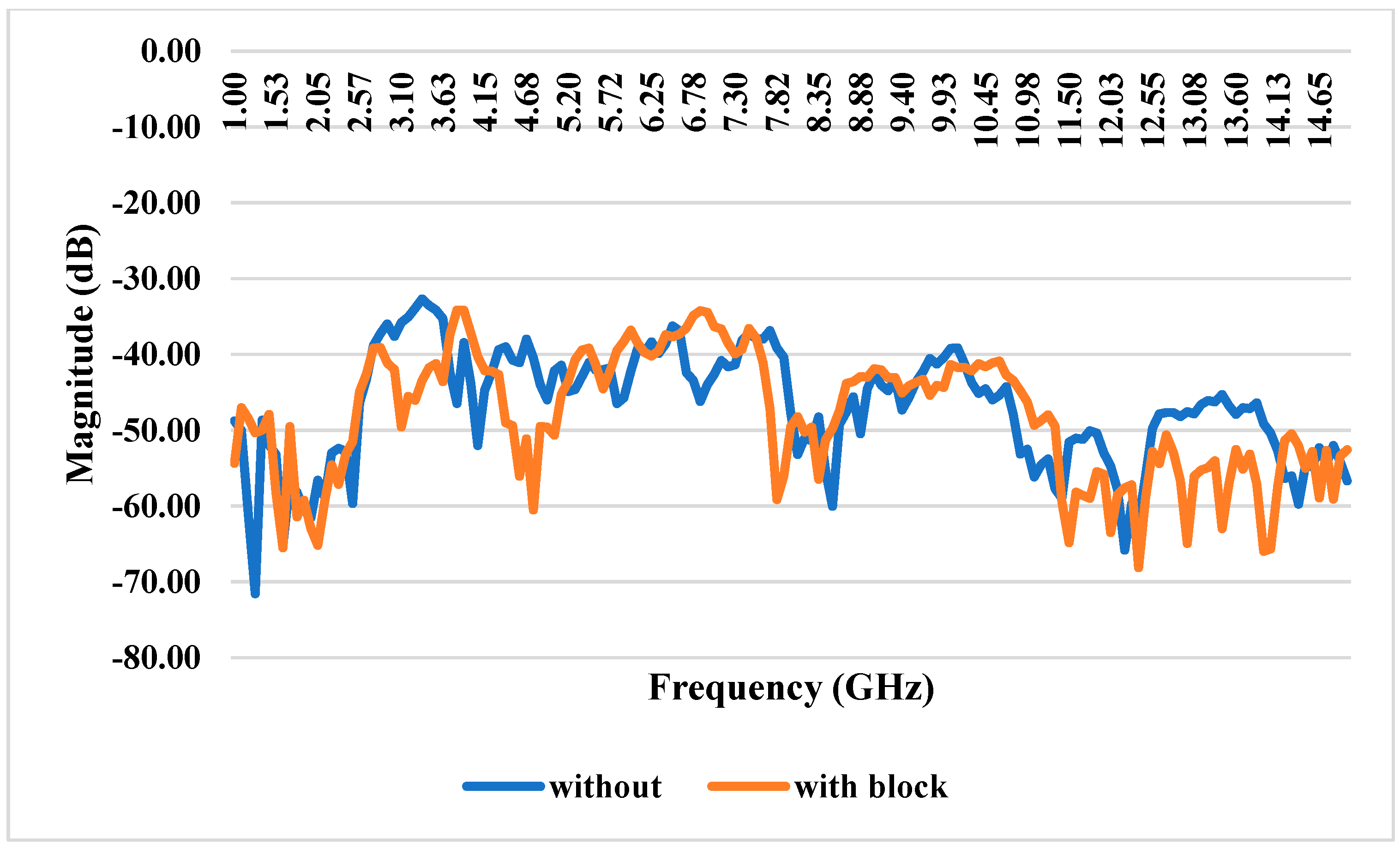

4.1. S21 Transmission Coefficient With and Without Block

4.2. S21 Transmission Coefficient with Block

4.3. S21 Transmission Coefficient With and Without Block

5. Simulation Analysis

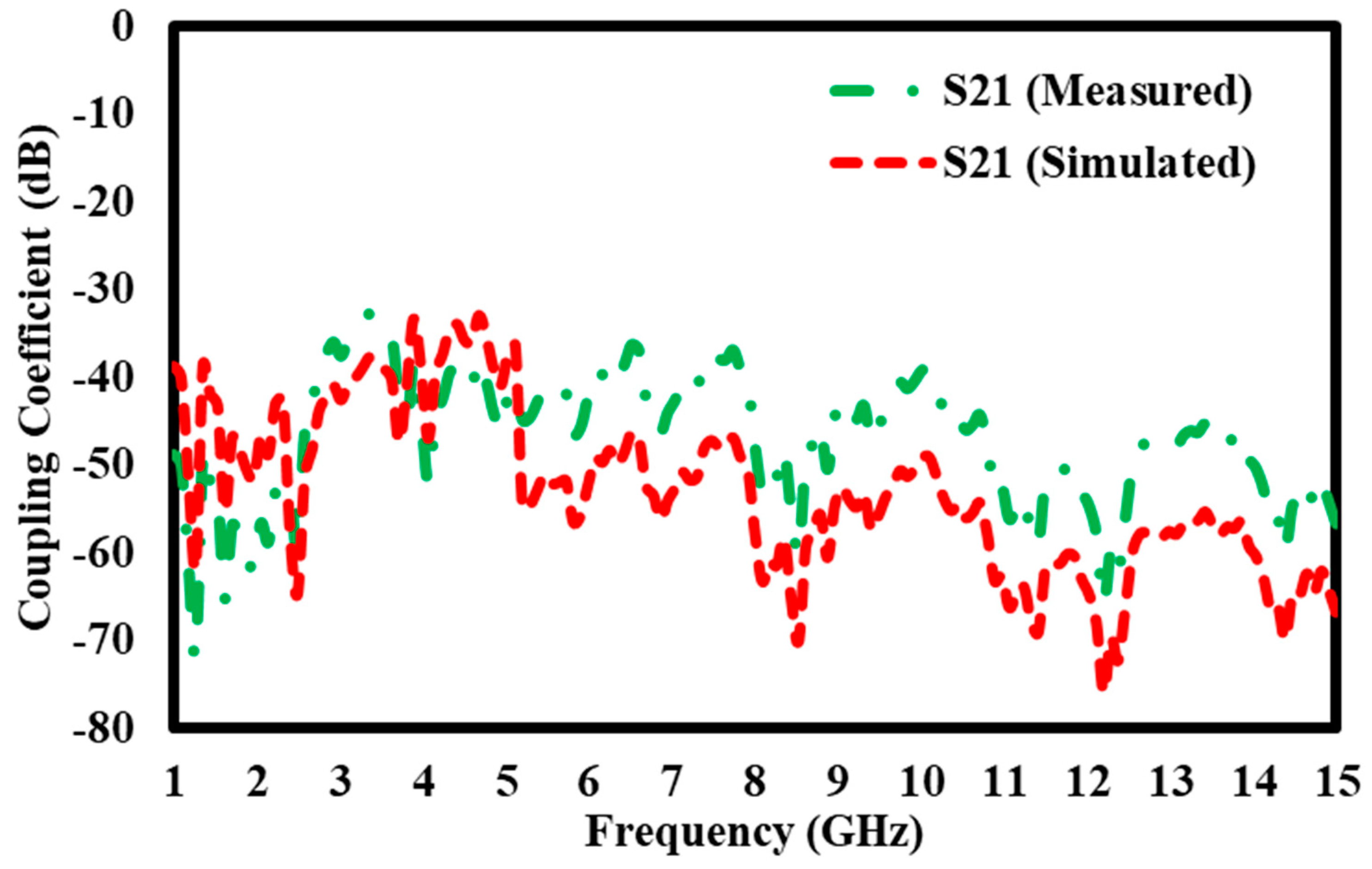

5.1. Simulation Results of S21 Transmission Coefficient Without Block

5.2. Simulation Results of S11 Reflection Coefficient for Without Block

5.3. Simulation Results of S11 Reflection Coefficient for Block

5.4. Simulation Results of S21 Transmission Coefficient with Block

5.5. Simulation Results of S11 Reflection Coefficient With and Without

5.6. Simulation Results of S21 Transmission Coefficient With and Without Block

6. Application

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kwe, N.B.; Yadav, V.; Kumar, M.; Savilov, S.V.; Yahya, M.Z.A.; Singh, S.K. A Comparative Study of Dielectric Substrate Materials Effects on the Performance of Microstrip Patch Antenna for 5G/6G Application. J. Mater. Sci. Mater. Electron. 2024, 35, 1617. [Google Scholar] [CrossRef]

- Kedze, K.E.; Wang, H.; Park, Y.B.; Park, I. Substrate Dielectric Constant Effects on the Performances of a Metasurface-Based Circularly Polarized Microstrip Patch Antenna. Int. J. Antennas Propag. 2022, 2022, 3026677. [Google Scholar] [CrossRef]

- Abdel Halim, A.S.; Abdel-Salam, Z.; Abdel-Harith, M.; Hamdy, O. Investigating the Effect of Changing the Substrate Material Analyzed by Laser-Induced Breakdown Spectroscopy on the Antenna Performance. Sci. Rep. 2024, 14, 1964. [Google Scholar] [CrossRef]

- Qin, M.; Zhang, L.; Wu, H. Dielectric Loss Mechanism in Electromagnetic Wave Absorbing Materials. Adv. Sci. 2022, 9, 2105553. [Google Scholar] [CrossRef] [PubMed]

- Tütüncü, B.; Kösem, M. Substrate Analysis on the Design of Wide-Band Antenna for Sub-6 GHz 5G Communication. Wirel. Pers. Commun. 2022, 125, 1523–1535. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wei, J.; Luo, Y.; Clark, K.A.; Sillekens, E.; Deakin, C.; Sohanpal, R.; Slavík, R.; Liu, Z. Communications with Guaranteed Bandwidth and Low Latency Using Frequency-Referenced Multiplexing. Nat. Electron. 2023, 6, 694–702. [Google Scholar] [CrossRef]

- Ali, S.Z.; Ahsan, K.; ul Khairi, D.; Alhalabi, W.; Anwar, M.S. Advancements in FR4 Dielectric Analysis: Free Space Approach and Measurement Validation. PLoS ONE 2024, 19, e0305614. [Google Scholar] [CrossRef]

- Chaimool, S.; Prasert, N.; Rakluea, C. Low-Cost FR-4 Metasurface-Enhanced Microstrip Patch Antenna Array for Wideband 5G Millimeter-Wave Applications. In Proceedings of the 2024 IEEE International Workshop on Antenna Technology (iWAT 2024), Sendai, Japan, 15–18 April 2024; pp. 118–121. [Google Scholar] [CrossRef]

- Zahidul Islam, M.D.; Fu, Y.; Deb, H.; Khalid Hasan, M.D.; Dong, Y.; Shi, S. Polymer-Based Low Dielectric Constant and Loss Materials for High-Speed Communication Network: Dielectric Constants and Challenges. Eur. Polym. J. 2023, 200, 112543. [Google Scholar] [CrossRef]

- Aleem, A.; Ghaffar, A.; Kiani, N.M.; Irshad, M.; Mehmood, I.; Shahzad, M.; Shahbaz, A. Broad-Band Dielectric Properties of Teflon, Bakelite, and Air: Simulation and Experimental Study. Mater. Sci. Eng. B 2021, 272, 115347. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable Biobased Composites for Advanced Applications: Recent Trends and Future Opportunities—A Critical Review. Compos. Part. C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. NPJ Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Ayode Otitoju, T.; Ugochukwu Okoye, P.; Chen, G.; Li, Y.; Onyeka Okoye, M.; Li, S. Advanced Ceramic Components: Materials, Fabrication, and Applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-Entropy Ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Omar, A.A. An Expert-Based Model for Selecting the Most Suitable Substrate Material Type for Antenna Circuits. Int. J. Electron. 2015, 102, 1044–1055. [Google Scholar] [CrossRef]

- Koziel, S.; Pietrenko-Dabrowska, A. On Nature-Inspired Design Optimization of Antenna Structures Using Variable-Resolution EM Models. Sci. Rep. 2023, 13, 8373. [Google Scholar] [CrossRef]

- Xu, Z.; Hui, J.; Lv, J.; Wei, D.; Yan, Z.; Zhang, H.; Wang, J. An Investigation of Methods to Enhance Adhesion of Conductive Layer and Dielectric Substrate for Additive Manufacturing of Electronics. Sci. Rep. 2024, 14, 10351. [Google Scholar] [CrossRef] [PubMed]

- De Guzman, J.L.A.; Guzman, A.C.C.V. Design and Optimization of Micro-Strip Patch Antennas for Wireless Communication Systems—A Literature Review. Int. J. Res. Publ. Rev. 2024, 5, 573–580. [Google Scholar] [CrossRef]

- Koziel, S.; Pietrenko-Dabrowska, A. High-Efficacy Global Optimization of Antenna Structures by Means of Simplex-Based Predictors. Sci. Rep. 2023, 13, 17109. [Google Scholar] [CrossRef]

- Marasco, I.; Niro, G.; De Marzo, G.; Rizzi, F.; D’orazio, A.; Grande, M.; De Vittorio, M. Design and Fabrication of a Plastic-Free Antenna on a Sustainable Chitosan Substrate. IEEE Electron. Device Lett. 2023, 44, 341–344. [Google Scholar] [CrossRef]

- Aileen, A.; Suwardi, A.D.; Prawiranata, F. Wi-Fi Signal Strength Degradation over Different Building Materials. Eng. Math. Comput. Sci. J. 2021, 3, 109–113. [Google Scholar] [CrossRef]

- Suherman, S. Wifi-Friendly Building to Enable Wi-Fi Signal Indoor. Bull. Electr. Eng. Inform. 2018, 7, 264–271. [Google Scholar] [CrossRef]

- Dambal, V.A.; Mohadikar, S.; Kumbhar, A.; Guvenc, I. Improving LoRa Signal Coverage in Urban and Sub-Urban Environments with UAVs. In Proceedings of the 2019 International Workshop on Antenna Technology iWAT, Miami, FL, USA, 3–6 March 2019; pp. 210–213. [Google Scholar] [CrossRef]

- Di Giacomo, R.; Neitzert, H.C.; Vertuccio, L.; Sorrentino, A.; Sabbatino, S. Lecture Notes in Electrical Engineering: Foreword. Lect. Notes Electr. Eng. 2011, 91, 455–459. [Google Scholar] [CrossRef]

- Wang, B.; Wei, J.; Yang, Y.; Wang, T.; Li, F. Investigation on Peak Frequency of the Microwave Absorption for Carbonyl Iron/Epoxy Resin Composite. J. Magn. Magn. Mater. 2011, 323, 1101–1103. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, L.; Yan, J.; Wu, Z. Room-to-low temperature thermo-mechanical behavior and corresponding constitutive model of liquid oxygen compatible epoxy composites. Compos. Sci. Technol. 2024, 245, 110357. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Hua, W.; Zhang, A.; Bao, J. Lightweight Silver Plating Foam and Carbon Nanotube Hybridized Epoxy Composite Foams with Exceptional Conductivity and Electromagnetic Shielding Property. ACS Appl. Mater. Interfaces 2016, 8, 24131–24142. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, C.; Yang, X. Simultaneous measurement of trace dimethyl methyl phosphate and temperature using all fiber Michaelson interferometer cascaded FBG. Opt. Express 2023, 31, 6203–6216. [Google Scholar] [CrossRef]

- Gao, X.; Yang, W.; Cheng, L.; Ding, Y.; Zhan, J.; Tan, J. Epoxy Resin Composite Containing Nanocarbon-Coated Glass Fiber and Cloth for Electromagnetic Interference Shielding. J. Mater. Res. Technol. 2021, 13, 1759–1766. [Google Scholar] [CrossRef]

- Cui, M.; Xiong, S.; Yang, N.; Wang, Y.; Wang, Z.; Luo, M.; Deguchi, Y. Applications of laser-induced breakdown spectroscopy in industrial measurement and monitoring: Multi-technology combination. Appl. Spectrosc. Rev. 2024, 1–49. [Google Scholar] [CrossRef]

- Bian, W.; Yao, T.; Chen, M.; Zhang, C.; Shao, T.; Yang, Y. The Synergistic Effects of the Micro-BN and Nano-Al2O3 in Micro-Nano Composites on Enhancing the Thermal Conductivity for Insulating Epoxy Resin. Compos. Sci. Technol. 2018, 168, 420–428. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.; Zhou, Y.; Wang, C.; Zhu, H. Design of a Simultaneous Information and Power Transfer System Based on a Modulating Feature of Magnetron. IEEE Trans. Microw. Theory Tech. 2023, 71, 907–915. [Google Scholar] [CrossRef]

- Wang, J.; Jiao, J.; Sun, G.; Yuan, K.; Guan, Z.; Wei, X. Preparation and Microwave Absorption Performance of a Flexible Fe3O4/Nanocarbon Hybrid Buckypaper and Its Application in Composite Materials. RSC Adv. 2019, 9, 37870–37881. [Google Scholar] [CrossRef] [PubMed]

- Zha, S.; Qu, Z.; Zhang, J.; Zheng, D.; Liu, P. A Gain-Reconfigurable Reflector Antenna with Surface-Mounted Field-Induced Artificial Magnetic Conductor for Adaptive HIRF Prevention. IEEE Trans. Antennas Propag. 2024, 72, 7252–7260. [Google Scholar] [CrossRef]

- Faruque, M.R.; Islam, M.T.; Islam, S.S. Space Science and Communication for Sustainability; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, S.; Liu, X.; Lin, B.; Huang, Y. Experimental study of a composite beam externally bonded with a carbon fiber-reinforced plastic plate. J. Build. Eng. 2023, 71, 106522. [Google Scholar] [CrossRef]

- Lyubutin, I.S.; Starchikov, S.S.; Lin, C.R.; Lu, S.Z.; Shaikh, M.O.; Funtov, K.O.; Dmitrieva, T.V.; Ovchinnikov, S.G.; Edelman, I.S.; Ivantsov, R. Magnetic, Structural, and Electronic Properties of Iron Sulfide Fe 3S4 Nanoparticles Synthesized by the Polyol Mediated Process. J. Nanoparticle Res. 2013, 15, 1397. [Google Scholar] [CrossRef]

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, mechanical and microstructural properties of alkali-activated composites incorporating nanomaterials: A comprehensive review. J. Clean. Prod. 2023, 384, 135390. [Google Scholar] [CrossRef]

- Qin, H.; Jia, J.; Lin, L.; Ni, H.; Wang, M.; Meng, L. Pyrite FeS2 Nanostructures: Synthesis, Properties and Applications. Mater. Sci. Eng. B 2018, 236–237, 104–124. [Google Scholar] [CrossRef]

- Buyukozturk, O. Electromagnetic Properties of Concrete and Their Significance in Nondestructive Testing. Transp. Res. Rec. 1997, 1574, 10–17. [Google Scholar] [CrossRef]

- Xie, S.; Ji, Z.; Zhu, L.; Zhang, J.; Cao, Y.; Chen, J.; Liu, R.; Wang, J. Recent Progress in Electromagnetic Wave Absorption Building Materials. J. Build. Eng. 2020, 27, 100963. [Google Scholar] [CrossRef]

- Liu, T.T.; Cao, M.Q.; Fang, Y.S.; Zhu, Y.H.; Cao, M.S. Green Building Materials Lit Up by Electromagnetic Absorption Function: A Review. J. Mater. Sci. Technol. 2022, 112, 329–344. [Google Scholar] [CrossRef]

- Zhou, M.; Gu, W.; Wang, G.; Zheng, J.; Pei, C.; Fan, F.; Ji, G. Sustainable Wood-Based Composites for Microwave Absorption and Electromagnetic Interference Shielding. J. Mater. Chem. A 2020, 8, 24267–24283. [Google Scholar] [CrossRef]

- Herron, D. Electromagnetic Wave Absorbing Materials; SciTech Publishing: New York, NY, USA, 2004. [Google Scholar]

- Richalot, E.; Bonilla, M.; Wong, M.F.; Fouad-Hanna, V.; Baudrand, H.; Wiart, J. Electromagnetic Propagation into Reinforced-Concrete Walls. IEEE Trans. Microw. Theory Tech. 2000, 48, 357–366. [Google Scholar] [CrossRef]

- Wei, M.; Song, D.; He, X.; Li, Z.; Qiu, L.; Lou, Q. Effect of Rock Properties on Electromagnetic Radiation Characteristics Generated by Rock Fracture During Uniaxial Compression. Rock. Mech. Rock. Eng. 2020, 53, 5223–5238. [Google Scholar] [CrossRef]

- Dos Santos, E.C.; Lourenço, M.P.; Pettersson, L.G.M.; Duarte, H.A. Stability, Structure, and Electronic Properties of the Pyrite/Arsenopyrite Solid-Solid Interface-A DFT Study. J. Phys. Chem. C 2017, 121, 8042–8051. [Google Scholar] [CrossRef]

- Lou, J.; Bhobe, A.; Shu, Y.; Yu, J. Analytical Calculation of Transformer Parameters by S-Parameters. In Proceedings of the 2018 IEEE International Symposium on Electromagnetic Compatibility and 2018 IEEE Asia-Pacific Symposium on Electromagnetic Compatibility (EMC/APEMC), Suntec City, Singapore, 14–18 May 2018; pp. 1310–1313. [Google Scholar] [CrossRef]

- Kaur, K.; Malhotra, S. Analyzing the Impedance of Reflection Coefficient of S-Parameters S11 and S22 Using Vector Network Analyzer & Recognization of Hand Gesture Using DTW. JETIR 2017, 4, 61–65. [Google Scholar]

- Yang, C.; Wang, J.; Yang, C. Estimation Methods to Extract Complex Permittivity from Transmission Coefficient in the Terahertz Band. Opt. Quantum Electron. 2021, 53, 433. [Google Scholar] [CrossRef]

- Ozturk, T.; Hudlička, M.; Uluer, İ. Development of Measurement and Extraction Technique of Complex Permittivity Using Transmission Parameter S 21 for Millimeter Wave Frequencies. J. Infrared Millim. Terahertz Waves 2017, 38, 1510–1520. [Google Scholar] [CrossRef]

- Fezai, N.; Ben Amor, A. Measure of Reflection Factor S11 High Frequency. In Proceedings of the International Conference on Advanced Systems and Electric Technologies (IC_ASET 2017), Hammamet, Tunisia, 14–17 January 2017; pp. 384–388. [Google Scholar] [CrossRef]

| Materials Value | Electromagnetic Wave Absorption dB | References |

|---|---|---|

| Concrete | 10–20 | [40] |

| Brick | 5–15 | [41] |

| Gypsum board | 8–25 | [42] |

| Wood | 5–12 | [43] |

| Composite material | 10–30 | [44] |

| steel | 20–40 | [45] |

| Natural stone | 20–40 | [46] |

| Element | Net Counts | Weight % | Atom % | Atom % Error | Formula |

|---|---|---|---|---|---|

| C | 131 | 8.21 | 16.10 | ±1.11 | C |

| O | 449 | 33.63 | 49.48 | ±2.87 | O |

| F | 17 | 1.49 | 1.84 | ±2.49 | F |

| Mg | 58 | 1.28 | 1.24 | ±0.23 | Mg |

| Al | 260 | 4.24 | 3.70 | ±0.24 | Al |

| Si | 495 | 7.15 | 5.99 | ±0.38 | Si |

| S | 93 | 1.10 | 0.81 | ±0.12 | S |

| Ca | 1079 | 16.62 | 9.76 | ±0.29 | Ca |

| Fe | 713 | 26.28 | 11.08 | ±0.71 | Fe |

| Total | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poyyamozhi, M.; Murugesan, B.; Rajamanickam, N.; Pandey, D.K.; Emara, A. Transmission and Reflection Properties of Iron Pyrite-Epoxy Resin Composite for Electromagnetic Applications. Materials 2024, 17, 5456. https://doi.org/10.3390/ma17225456

Poyyamozhi M, Murugesan B, Rajamanickam N, Pandey DK, Emara A. Transmission and Reflection Properties of Iron Pyrite-Epoxy Resin Composite for Electromagnetic Applications. Materials. 2024; 17(22):5456. https://doi.org/10.3390/ma17225456

Chicago/Turabian StylePoyyamozhi, Mukilan, Balasubramanian Murugesan, Narayanamoorthi Rajamanickam, Devesh Kr Pandey, and Ahmed Emara. 2024. "Transmission and Reflection Properties of Iron Pyrite-Epoxy Resin Composite for Electromagnetic Applications" Materials 17, no. 22: 5456. https://doi.org/10.3390/ma17225456

APA StylePoyyamozhi, M., Murugesan, B., Rajamanickam, N., Pandey, D. K., & Emara, A. (2024). Transmission and Reflection Properties of Iron Pyrite-Epoxy Resin Composite for Electromagnetic Applications. Materials, 17(22), 5456. https://doi.org/10.3390/ma17225456