Study of the Microstructure and Mechanical Properties of Steel Grades for Ship Hull Construction

Abstract

1. Introduction

2. Experimental Procedure

2.1. The Chemical Composition of the Steel Grades

2.2. The Steel Fabrication Processes

2.3. The Microstructure Characterization Methods

2.4. The Evaluation Procedures for Mechanical Properties

2.5. Corrosion Resistance Measurement Method

3. Results and Discussions

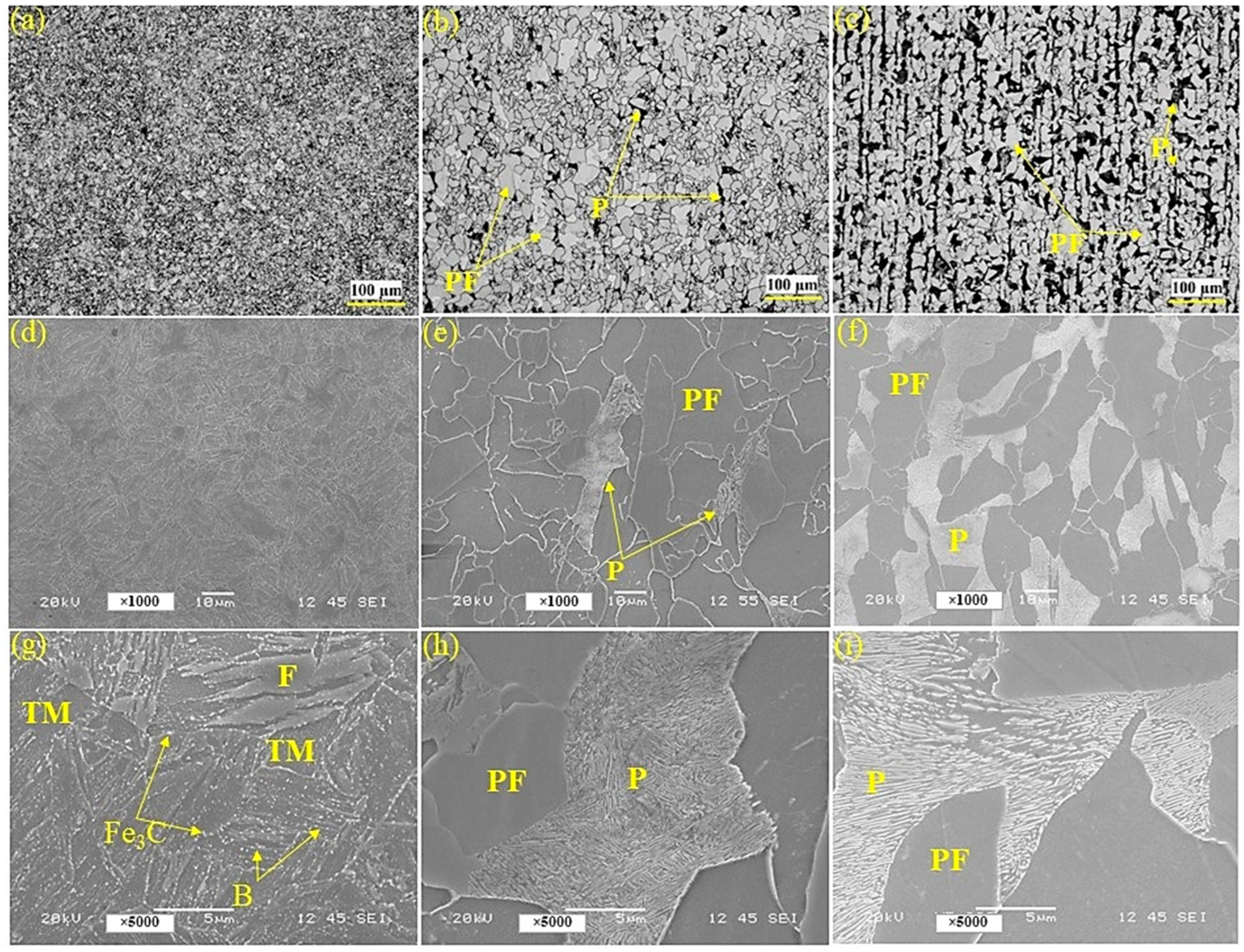

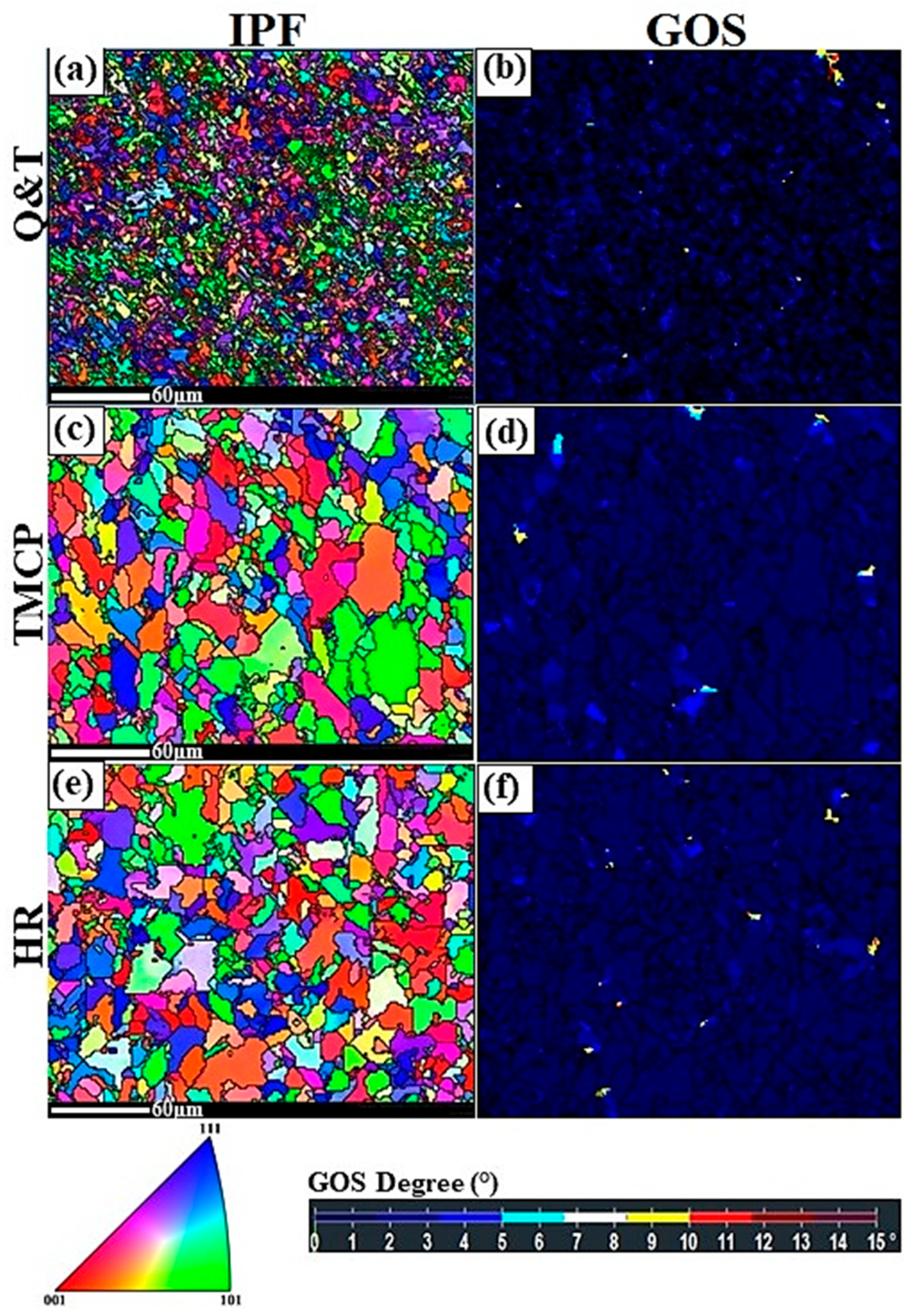

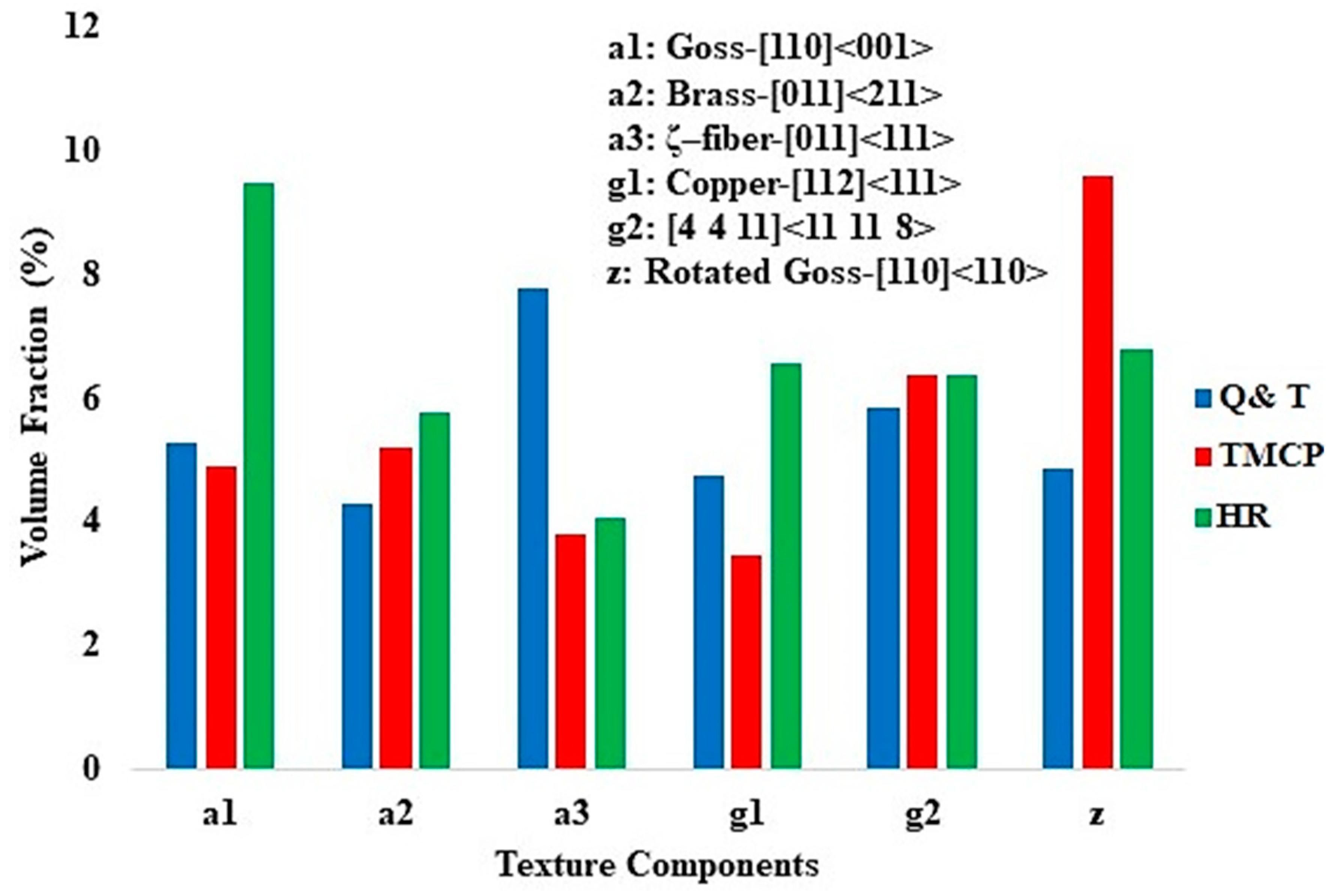

3.1. Microstructure Characterization

3.2. Mechanical Properties

3.2.1. Hardness and Tensile Properties and Fracture Mechanisms

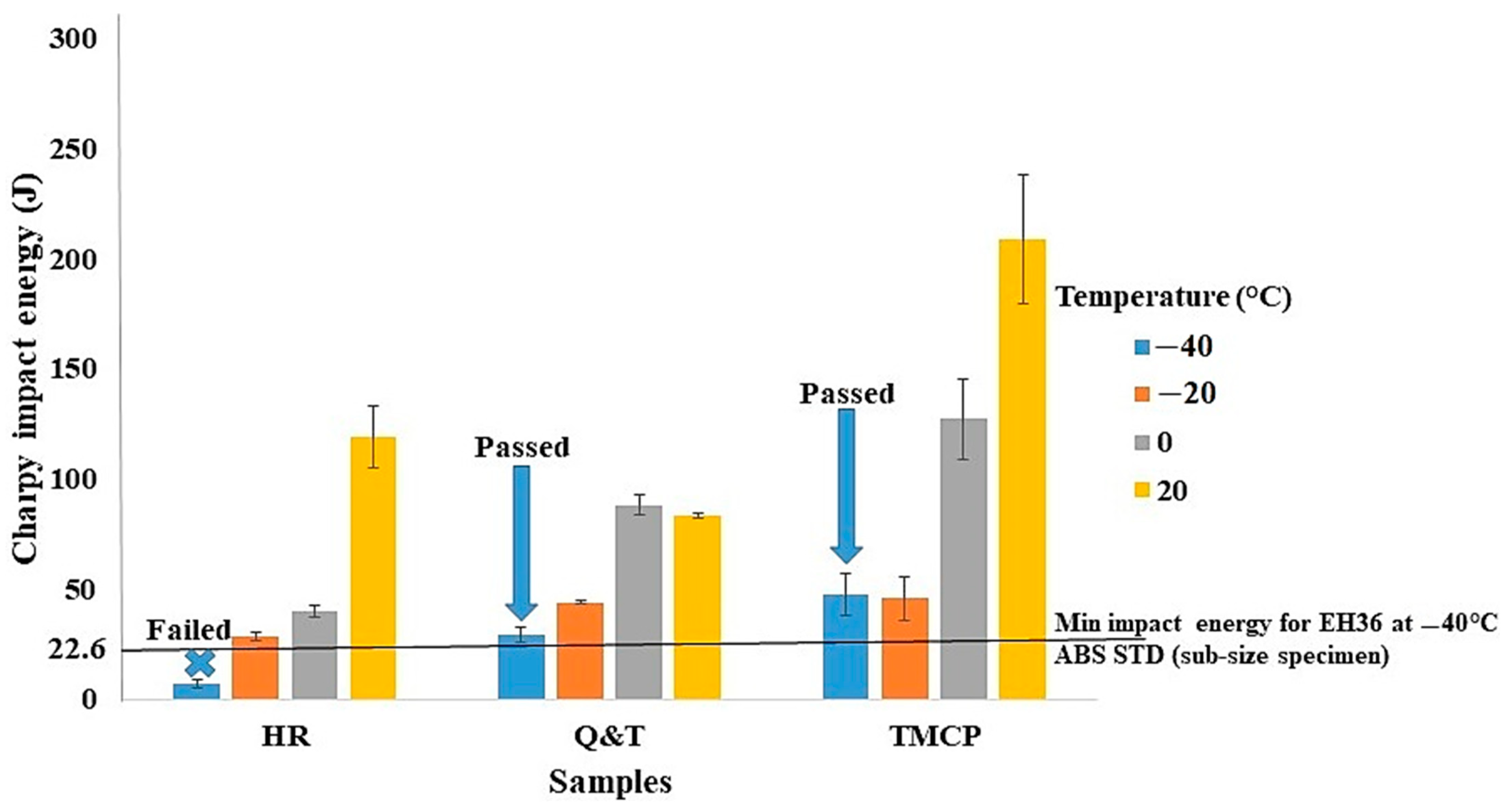

3.2.2. Charpy Impact Test

3.3. Corrosion Test

4. Conclusions

- The microstructural investigations revealed that Q and T steel exhibited the finest microstructure, characterized by a complex mixture of ferrite, tempered martensite, upper bainite, and Fe3C phases. TMCP steel demonstrated a balanced microstructure with polygonal ferrite and pearlite. HR displayed an anisotropic microstructure with polygonal ferrite and aligned pearlite.

- The texture analysis highlighted that Q and T steel contained significant ζ-fiber and [4 4 11]<11 11 8> shear textures, indicative of its quenched and tempered nature. TMCP steel displayed a predominance of rotated Goss and [4 4 11]<11 11 8> shear textures, consistent with its thermomechanical processing, while HR steel showed Goss, rotated Goss, and copper textures, reflecting its hot rolled processing history.

- Tensile testing revealed that Q and T steel exhibited the highest hardness, YS, and UTS but the lowest El% among the steel grades. TMCP steel demonstrated tensile properties that met all the ABS standards for marine steels, including optimal YS, UTS, and El%, making it the most suitable for shipbuilding applications. HR steel, while showing superior strength, did not fully meet the required criteria for the UTS range. The fracture surface analysis via SEM further verified these findings, showing fewer coarse dimples and microvoids in Q and T steel, indicative of its lower ductility and higher strength, whereas TMCP and HR steel exhibited coarser dimples, aligning with their higher ductility.

- As temperatures dropped, the impact energy of all the steel grades decreased, indicating a reduced ability to absorb energy before fracturing. TMCP steel consistently exhibited the highest impact energy across the temperatures due to its favorable microstructure, which includes a significant amount of ductile polygonal ferrite and pearlite that help resist crack propagation. Q and T steel ranked second, with its fine microstructure aiding in energy absorption, although the presence of harder phases like tempered martensite and bainite slightly reduced its impact energy. HR steel did not perform well at sub-zero temperatures, due to its anisotropic microstructure and lower ferrite content. Among the grades, only TMCP steel fully meets the ABS standard requirements for tensile and impact energy properties for EH36 grade, making it the most suitable grade for ship hull construction.

- The potentiodynamic polarization curves showed that Q and T steel demonstrated superior corrosion resistance with the lowest corrosion current and rate, attributed to its higher Cr and Mo content, which helps form a protective oxide layer. Its uniform Fe3C dispersion further blocked corrosion pathways. In addition, during tempering, stress relief further minimizes corrosion risks by reducing residual stresses, which can act as corrosion initiation sites. In contrast, the TMCP grade, with its two rolling cycles, retains higher residual stresses, lowering its corrosion resistance compared to HR steel, which undergoes a less stressful single rolling cycle.

- Consequently, this study underscores the critical role of processing techniques in tailoring the microstructure and mechanical properties of shipbuilding steel grades. Among the steel grades, TMCP grade steel emerged as the optimal choice for shipbuilding applications due to its balanced combination of strength, ductility, and impact energy, meeting all ABS requirements. These insights provide valuable guidelines for the selection and optimization of steel grades for enhanced performance and durability in marine environments, ensuring the safety and efficiency of vessel operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM A131/A131M-19; Standard Specification for Structural Steel for Ships. ASTM International: West Conshohocken, PA, USA, 2019.

- Ghazanlou, S.I.; Amini, A.M.; Carrier, F.-A.; Javidani, M. Innovations and challenges in marine steels for polar icebreaker manufacturing–a comprehensive review. Ships Offshore Struct. 2024, 1–25. [Google Scholar] [CrossRef]

- Nam, W.; Hopperstad, O.S.; Amdahl, J. Modelling of the ductile-brittle fracture transition in steel structures with large shell elements: A numerical study. Mar. Struct. 2018, 62, 40–59. [Google Scholar] [CrossRef]

- Sumpter, J.; Kent, J. Prediction of ship brittle fracture casualty rates by a probabilistic method. Mar. Struct. 2004, 17, 575–589. [Google Scholar] [CrossRef]

- Hayat, F.; Uzun, H. Effect of heat treatment on microstructure, mechanical properties and fracture behaviour of ship and dual phase steels. J. Iron Steel Res. Int. 2011, 18, 65–72. [Google Scholar] [CrossRef]

- Li, X.; Yu, W.; Wan, D.; Zhang, J.; Wu, H.; Cai, Q. Effect of heat treatment process on microstructure and mechanical properties of F550 ship plate steel. J. Iron Steel Res. 2011, 23, 114–118. [Google Scholar]

- Luo, X.D.; Zhu, Y.X.; Liu, H. Effect of Subcritical Quenching on Microstructure and Mechanical Properties of EH36 Alloy. Adv. Mater. Res. 2014, 886, 59–62. [Google Scholar] [CrossRef]

- Zhang, H.; Huo, M.; Ma, Z.; Wu, H.; Su, G.; Li, L.; Zhang, T.; Lin, F.; Chen, F.; Jiang, Z. Effects of quenching and tempering heat treatment processing on the microstructure and properties of high-strength hull steel. Metals 2022, 12, 914. [Google Scholar] [CrossRef]

- Byun, J.-S.; Shim, J.-H.; Suh, J.-Y.; Oh, Y.-J.; Cho, Y.W.; Lee, D.N. Inoculated acicular ferrite microstructure and mechanical properties. Mater. Sci. Eng. A 2001, 319, 326–331. [Google Scholar] [CrossRef]

- Sung, H.K.; Shin, S.Y.; Cha, W.; Oh, K.; Lee, S.; Kim, N.J. Effects of acicular ferrite on charpy impact properties in heat affected zones of oxide-containing API X80 linepipe steels. Mater. Sci. Eng. A 2011, 528, 3350–3357. [Google Scholar] [CrossRef]

- Um, K.-K.; Kim, S.-H.; Kang, K.-B.; Park, Y.-H.; Kwon, O. High performance steel plates for shipbuilding applications. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 July 2008; OnePetro: Richardson, TX, USA, 2008. [Google Scholar]

- Gao, X.-H.; Qiu, C.-L.; Du, L.-X. Effect of Rolling Process on Microstructure and Mechanical Properties of EH 36 Ship Plate Steel. Jixie Gongcheng Cailiao Mater. Mech. Eng. 2010, 34, 5–7. [Google Scholar]

- Liu, C.; Peng, Q.; Xue, Z. Study on rolling process and heat treatment of high strength ship plate steel EH40. Metall. Mater. Eng. 2018, 24, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Zhang, P.; Peng, X.; Yan, L.; Li, G. Fatigue Crack Growth Behavior and Fracture Toughness of EH36 TMCP Steel. Materials 2021, 14, 6621. [Google Scholar] [CrossRef] [PubMed]

- Xue, C.; Yan, L.; Shang, X.; Ren, X. Effects of microstructure and specimen size on the fracture toughness of EH47 shipbuilding steel at low temperature. Eng. Fract. Mech. 2022, 276, 108938. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, P.; Peng, X.; Yan, L.; Li, G. Comparison of microstructure and mechanical properties of high strength and toughness ship plate steel. Materials 2021, 14, 5886. [Google Scholar] [CrossRef]

- Li, C.; Peng, C.; Li, X.; Liu, Y.; Liu, Y.; Wang, Z.; Pai, J.; Wang, C. Initial Corrosion Behavior of EH36 Marine Steel in Simulated Polar Marine Environment. Int. J. Electrochem. Sci. 2022, 17, 22126. [Google Scholar] [CrossRef]

- Silionis, N.E.; Anyfantis, K.N. Optimal sensor placement for corrosion induced thickness loss monitoring in ship structures. Mar. Struct. 2024, 93, 103524. [Google Scholar] [CrossRef]

- Tekgoz, M.; Garbatov, Y.; Soares, C.G. Review of ultimate strength assessment of ageing and damaged ship structures. J. Mar. Sci. Appl. 2020, 19, 512–533. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, L.; Zhu, Y.; Ai, F.; Li, H.; Li, Y.; Jiang, Z. The effect of immersion corrosion time on electrochemical corrosion behavior and the corrosion mechanism of EH47 ship steel in seawater. Metals 2021, 11, 1317. [Google Scholar] [CrossRef]

- Plaza, A. Materials and Welding 2018. 2017. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=8fc885fe3f3dc9ade4195f434e8cd5e027589545 (accessed on 8 March 2018).

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM A370-24; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2024.

- Field, D.; Bradford, L.; Nowell, M.; Lillo, T. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Eghbali, B.; Petrov, R. Microstructural evolution and strengthening mechanisms in Al7075/graphene nano-plates/carbon nano-tubes composite processed through accumulative roll bonding. Mater. Sci. Eng. A 2021, 807, 140877. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Mokdad, F.; Wells, M.; Chen, D. A new grain orientation spread approach to analyze the dynamic recrystallization behavior of a cast-homogenized Mg-Zn-Zr alloy using electron backscattered diffraction. Mater. Sci. Eng. A 2018, 709, 285–289. [Google Scholar] [CrossRef]

- Park, S.; Kim, W. Texture and microstructure of pure Nb fabricated by cross rolling combined with differential speed rolling. J. Mater. Res. Technol. 2023, 22, 2704–2719. [Google Scholar] [CrossRef]

- Raabe, D. Crystallographic Textures of Hot Rolled Steels. 2003. Available online: https://pure.mpg.de/rest/items/item_2018381/component/file_2018380/content (accessed on 8 March 2018).

- Nguyen-Minh, T.; Sidor, J.; Petrov, R.; Kestens, L. Occurrence of shear bands in rotated Goss ({1 1 0} <1 1 0>) orientations of metals with bcc crystal structure. Scr. Mater. 2012, 67, 935–938. [Google Scholar] [CrossRef]

- Cho, C.-H.; Son, K.; Ch, H.O. Experimental analysis of deformation texture evolutions in pure Cu, Cu-37Zn, Al-6Mg, and −8Mg alloys at cold-rolling processes. J. Alloys Compd. 2023, 934, 167879. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Eghbali, B.; Petrov, R. EBSD characterization of Al7075/graphene nanoplates/carbon nanotubes composites processed through post-deformation annealing. Trans. Nonferrous Met. Soc. China 2021, 31, 2250–2263. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Eghbali, B.; Petrov, R. Study on the microstructural and texture evolution of Hot Rolled Al7075/graphene/carbon nanotubes reinforced composites. Mater. Chem. Phys. 2021, 257, 123766. [Google Scholar] [CrossRef]

- Li, X.; Yu, R.; Wang, P.; Kang, R.; Shu, Z.; Yue, Z.; Zhao, Z.; Wang, X.; Lu, T.J. Plastic deformation and ductile fracture of L907A ship steel at increasing strain rate and temperature. Int. J. Impact Eng. 2023, 174, 104515. [Google Scholar] [CrossRef]

- Peng, Z.; Zhao, H.; Li, X.; Yuan, L.; Zhu, T. Ductile fracture of X80 pipeline steel over a wide range of stress triaxialities and Lode angles. Eng. Fract. Mech. 2023, 289, 109470. [Google Scholar] [CrossRef]

- Yu, R.; Li, X.; Yue, Z.; Li, A.; Zhao, Z.; Wang, X.; Zhou, H.; Lu, T.J. Stress state sensitivity for plastic flow and ductile fracture of L907A low-alloy marine steel: From tension to shear. Mater. Sci. Eng. A 2022, 835, 142689. [Google Scholar] [CrossRef]

- Rushd, S.; Ismail, M. Pipeline Engineering: Design, Failure, and Management; BoD–Books on Demand: Norderstedt, Germany, 2023. [Google Scholar]

- Das, A. Fracture complexity of pressure vessel steels. Philos. Mag. 2017, 97, 3084–3141. [Google Scholar] [CrossRef]

- Wilsdorf, H.G. The ductile fracture of metals: A microstructural viewpoint. Mater. Sci. Eng. 1983, 59, 1–39. [Google Scholar] [CrossRef]

- Laukkanen, A.; Uusikallio, S.; Lindroos, M.; Andersson, T.; Kömi, J.; Porter, D. Micromechanics driven design of ferritic–austenitic duplex stainless steel microstructures for improved cleavage fracture toughness. Eng. Fract. Mech. 2021, 253, 107878. [Google Scholar] [CrossRef]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals I: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef]

- Shukla, R.; Ghosh, S.; Chakrabarti, D.; Chatterjee, S. Microstructure, texture, property relationship in thermo-mechanically processed ultra-low carbon microalloyed steel for pipeline application. Mater. Sci. Eng. A 2013, 587, 201–208. [Google Scholar] [CrossRef]

- Korda, A.A.; Mutoh, Y.; Miyashita, Y.; Sadasue, T. Effects of pearlite morphology and specimen thickness on fatigue crack growth resistance in ferritic–pearlitic steels. Mater. Sci. Eng. A 2006, 428, 262–269. [Google Scholar] [CrossRef]

- Guan, M.; Yu, H. Fatigue crack growth behaviors in hot-rolled low carbon steels: A comparison between ferrite–pearlite and ferrite–bainite microstructures. Mater. Sci. Eng. A 2013, 559, 875–881. [Google Scholar] [CrossRef]

- Ji, X.-B.; Zhao, S.-X.; Fu, L.-M.; Peng, J.; Gao, J.-Q.; Yu, D.-J.; Huang, Z.-Z.; Shan, A.-D. High cycle rotating bending fatigue performance and fracture behavior in a pearlite–ferrite dual-phase steel. J. Iron Steel Res. Int. 2022, 29, 519–528. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, M.; Zhang, Y.; Wu, Y.; Yang, Y.; Jiang, H.; Bai, L.; Zhang, Y.; Mi, Z. Fatigue crack initiation and competitive crack propagation behavior in 500 MPa grade automobile beam steel. J. Mater. Res. Technol. 2023, 24, 2595–2610. [Google Scholar] [CrossRef]

- Mousavinasab, S.; Blais, C. Role of microstructure heterogeneity on fatigue crack propagation of low-alloyed PM steels in the as-sintered condition. Metals 2017, 7, 60. [Google Scholar] [CrossRef]

- Ghosh, S.; Mula, S.; Malakar, A.; Somani, M.; Kömi, J. High cycle fatigue performance, crack growth and failure mechanisms of an ultrafine-grained Nb+ Ti stabilized, low-C microalloyed steel processed by multiphase controlled rolling and forging. Mater. Sci. Eng. A 2021, 825, 141883. [Google Scholar] [CrossRef]

- De Oliveira, R.K.; Correa, O.V.; de Oliveira, M.C.L.; Antunes, R.A. Surface chemistry and semiconducting properties of passive film and corrosion resistance of annealed surgical stainless steel. J. Mater. Eng. Perform. 2020, 29, 6085–6100. [Google Scholar] [CrossRef]

- Sun, H.; Xu, Z.; Zhang, D.; Peng, L.; Lai, X. Corrosion behavior of passivation layer Cr2O3 of uncoated stainless steel under the anodic and cathodic conditions: A first-principles study. Chem. Eng. J. 2024, 493, 152658. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Ghazanlou, S.I.; Ghazanlou, S.I.; Mohammadzadeh, R. The multifunctional performance of the laser powder bed fusion 316L stainless steel matrix composite reinforced with the CNT-ZrO2 nanohybrid. Mater. Chem. Phys. 2024, 313, 128693. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Ghazanlou, S.I.; Ghazanlou, S.I.; Hosseinpour, S.; Liao, Y.; Javidani, M. Improving the properties of an Al matrix composite fabricated by laser powder bed fusion using graphene–TiO2 nanohybrid. J. Alloys Compd. 2023, 938, 168596. [Google Scholar] [CrossRef]

- Caines, S.; Khan, F.; Shirokoff, J. Analysis of pitting corrosion on steel under insulation in marine environments. J. Loss Prev. Process Ind. 2013, 26, 1466–1483. [Google Scholar] [CrossRef]

- Fairfax, E.; Steinzig, M. A summary of failures caused by residual stresses. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems, Volume 9: Proceedings of the 2015 Annual Conference on Experimental and Applied Mechanics; Springer: Cham, Switzerland, 2016; pp. 209–214. [Google Scholar]

| Steel Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Cu |

|---|---|---|---|---|---|---|---|---|---|

| A | 0.21 max | 2.5 × C min | 0.035 max | 0.035 max | 0.5 max | - | - | - | - |

| B | 0.21 max | 0.8 max | 0.035 max | 0.035 max | 0.35 max | - | - | - | - |

| D | 0.21 max | 0.60–0.90 | 0.035 max | 0.035 max | 0.10–0.35 | - | - | - | - |

| E | 0.18 max | 0.70–0.90 | 0.035 max | 0.035 max | 0.10–0.35 | - | - | - | - |

| AH/DH/EH | 0.18 max | 0.90–1.6 | 0.035 max | 0.035 max | 0.1–0.5 | 0.4 max | 0.2 max | 0.08 max | 0.35 max |

| FH | 0.16 max | 0.90–1.6 | 0.025 max | 0.025 max | 0.1–0.5 | 0.8 max | 0.2 max | 0.08 max | 0.35 max |

| Element/Steel Grade | C | Mn | P | S | Si | Cr | Ni | Cu | Mo | Al | Nb | V | B | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q and T | 0.18 | 1.25 | 0.011 | 0.002 | 0.19 | 0.12 | 0.02 | 0.03 | 0.120 | 0.025 | 0.000 | 0.007 | 0.0021 | 0.048 |

| TMCP | 0.05 | 1.37 | 0.009 | 0.002 | 0.31 | 0.08 | 0.08 | 0.08 | 0.060 | 0.033 | 0.038 | 0.043 | 0.0001 | 0.002 |

| HR | 0.19 | 1.50 | 0.012 | 0.000 | 0.31 | 0.02 | 0.02 | 0.02 | 0.000 | 0.032 | 0.009 | 0.062 | 0.0001 | 0.002 |

| Sample | βa (mV/dec) | βc (mV/dec) | Ecorr (mV vs. Ag/AgCl) | Icorr (μA/cm2) | Rp (kΩ·cm2) | Corrosion Rate (µm/year) |

|---|---|---|---|---|---|---|

| Q and T | 54 | −115 | −337 | 1.04 | 12.90 | 11 |

| HR | 106 | −148 | −443 | 8.13 | 2.80 | 88 |

| TMCP | 131 | −189 | −478 | 10.39 | 2.63 | 113 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imanian Ghazanlou, S.; Mobasher Amini, A.; Carrier, F.-A.; Sarkar, D.K.; Rehman, K.; Javidani, M. Study of the Microstructure and Mechanical Properties of Steel Grades for Ship Hull Construction. Materials 2024, 17, 5687. https://doi.org/10.3390/ma17235687

Imanian Ghazanlou S, Mobasher Amini A, Carrier F-A, Sarkar DK, Rehman K, Javidani M. Study of the Microstructure and Mechanical Properties of Steel Grades for Ship Hull Construction. Materials. 2024; 17(23):5687. https://doi.org/10.3390/ma17235687

Chicago/Turabian StyleImanian Ghazanlou, Siavash, Ahmad Mobasher Amini, Félix-Antoine Carrier, Dilip K. Sarkar, Kashif Rehman, and Mousa Javidani. 2024. "Study of the Microstructure and Mechanical Properties of Steel Grades for Ship Hull Construction" Materials 17, no. 23: 5687. https://doi.org/10.3390/ma17235687

APA StyleImanian Ghazanlou, S., Mobasher Amini, A., Carrier, F.-A., Sarkar, D. K., Rehman, K., & Javidani, M. (2024). Study of the Microstructure and Mechanical Properties of Steel Grades for Ship Hull Construction. Materials, 17(23), 5687. https://doi.org/10.3390/ma17235687