Effect of Nanosecond Laser Texturization on Tribological Behavior of AISI 321 Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

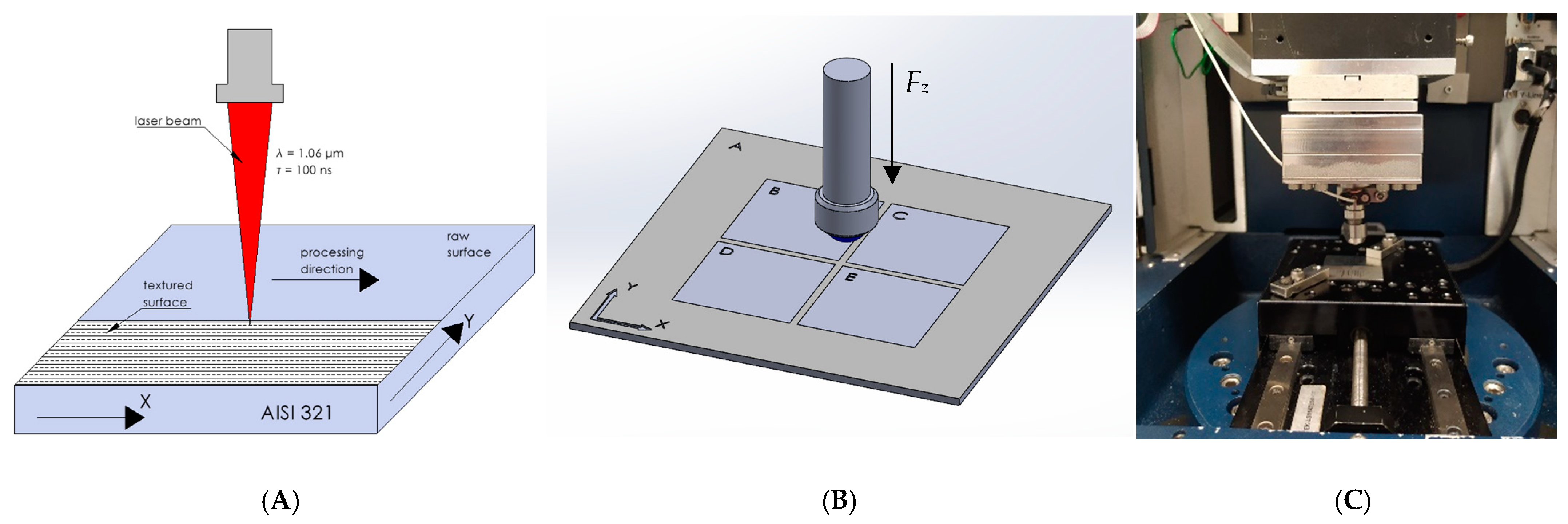

2.1. Laser Surface Texturing of AISI 321

2.2. Surface Characteristics Measurement

2.3. Wettability Test

2.4. Tribology Test

3. Results and Discussion

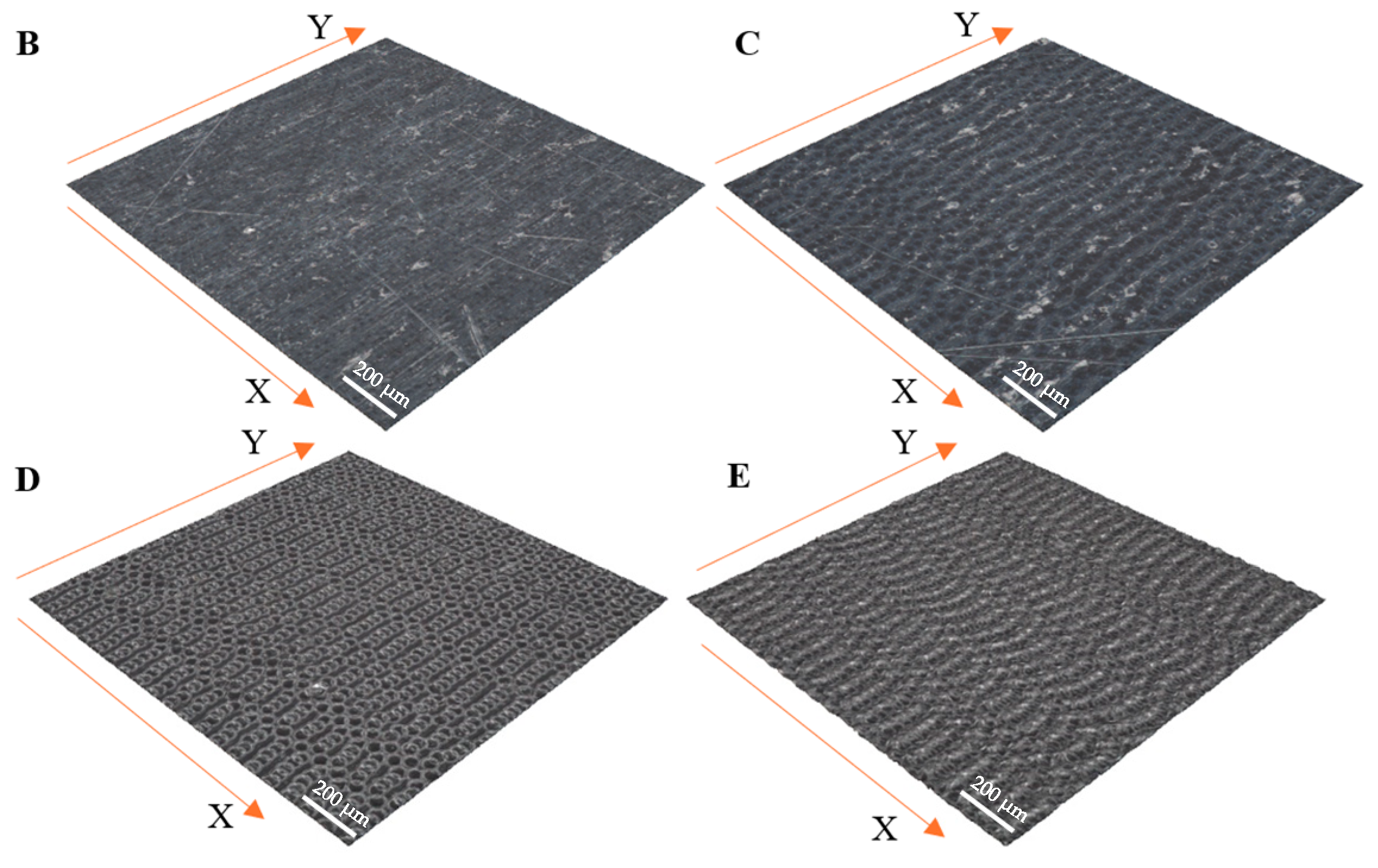

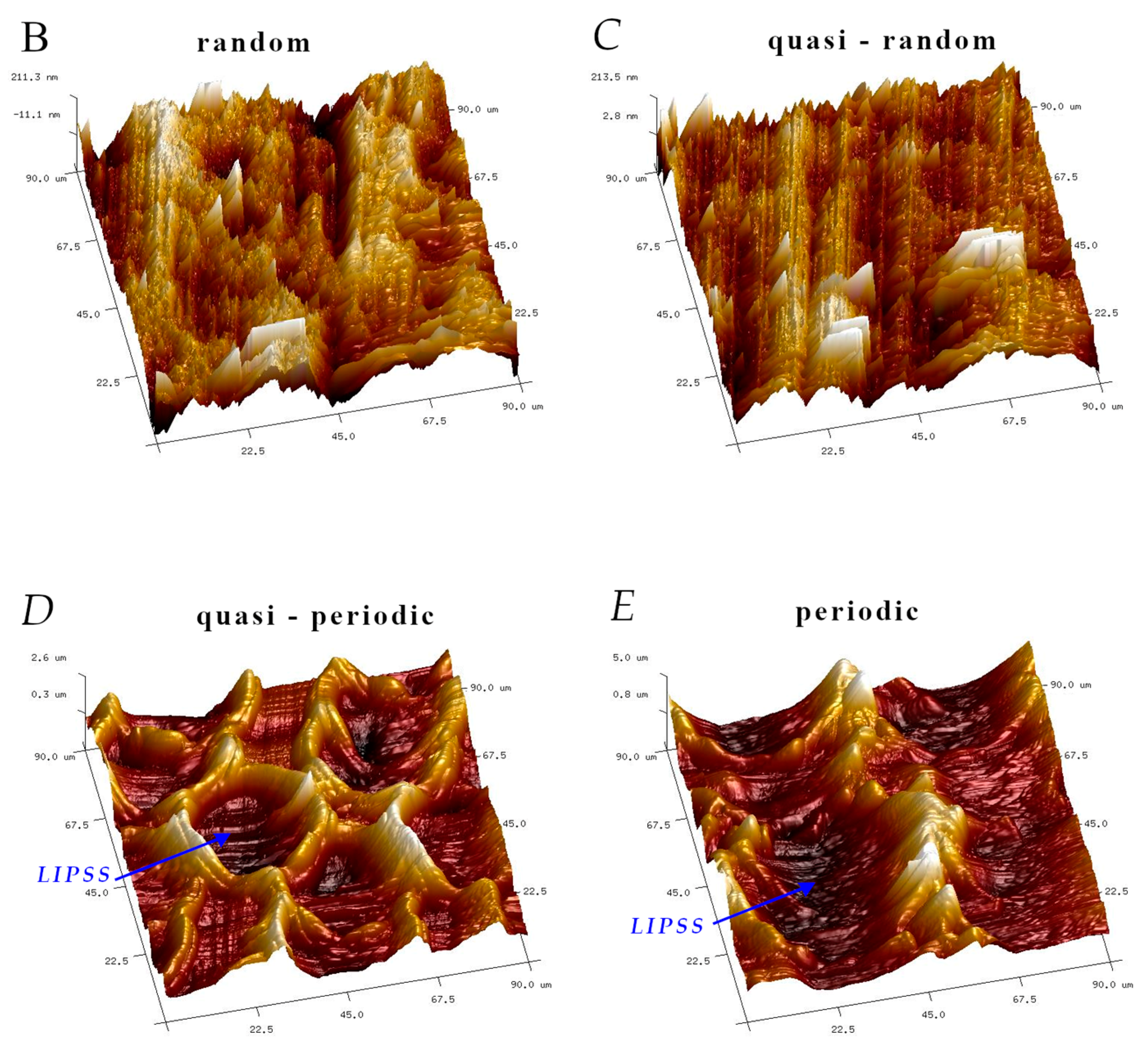

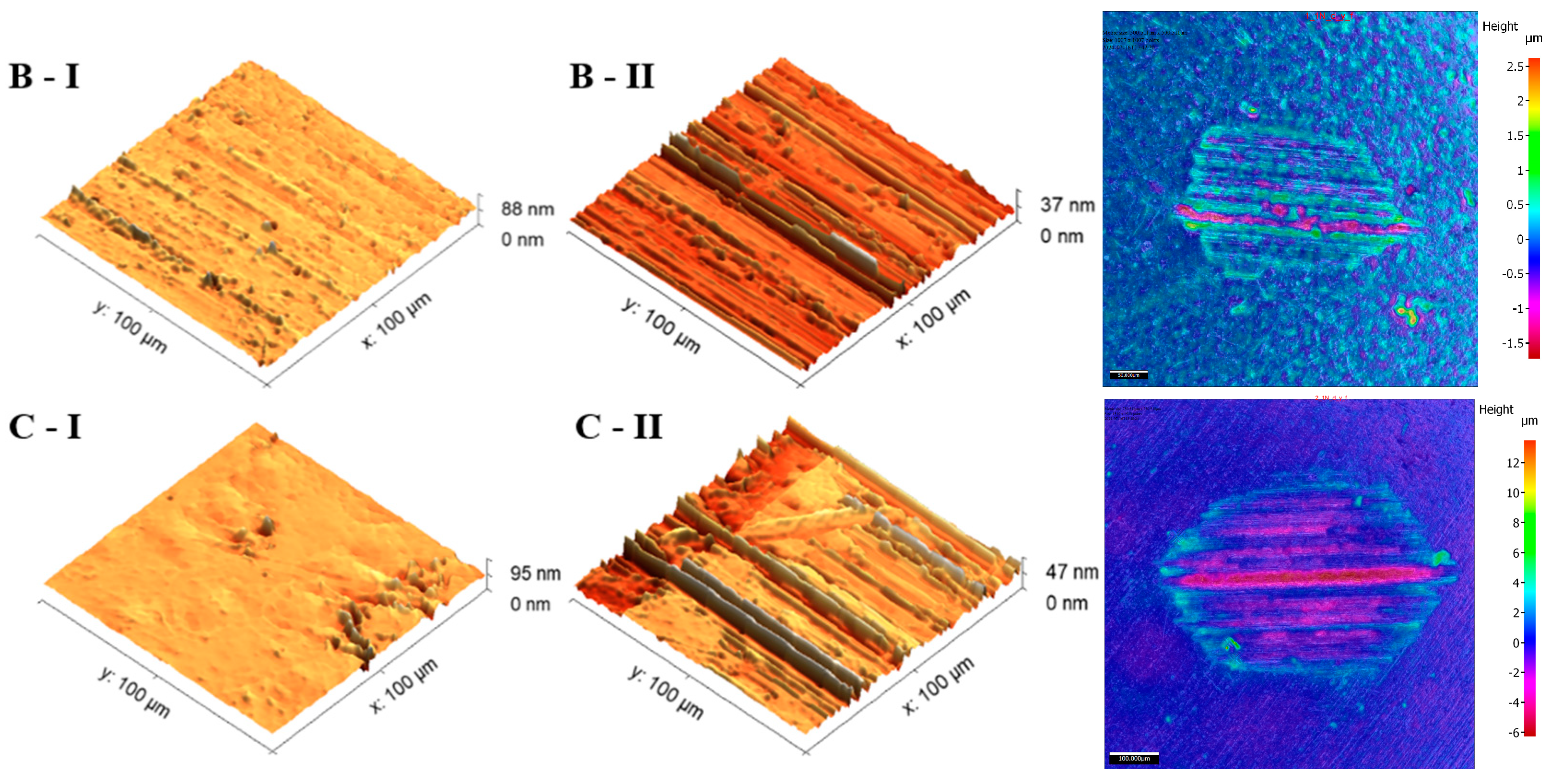

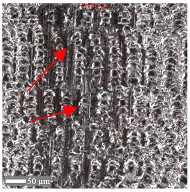

3.1. Surface Topography Evaluation

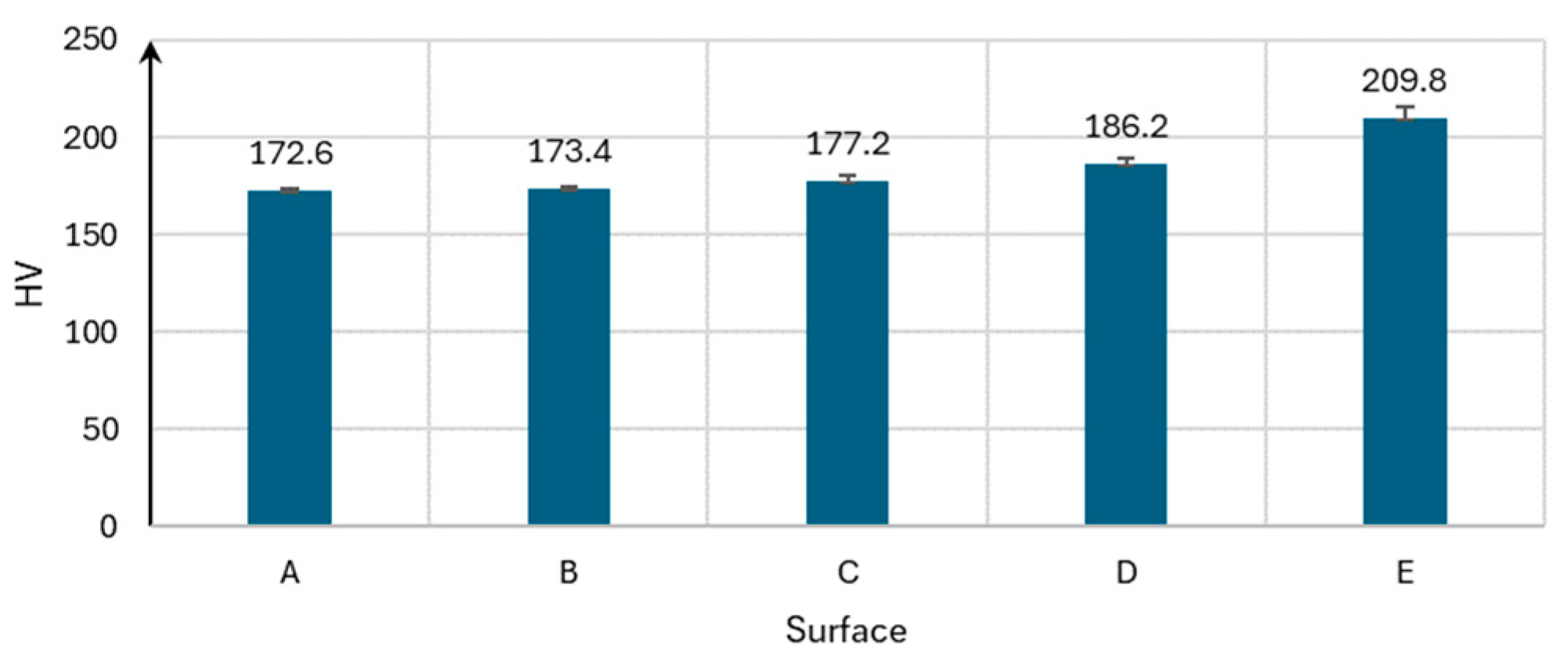

3.2. Hardness

3.3. Wettability

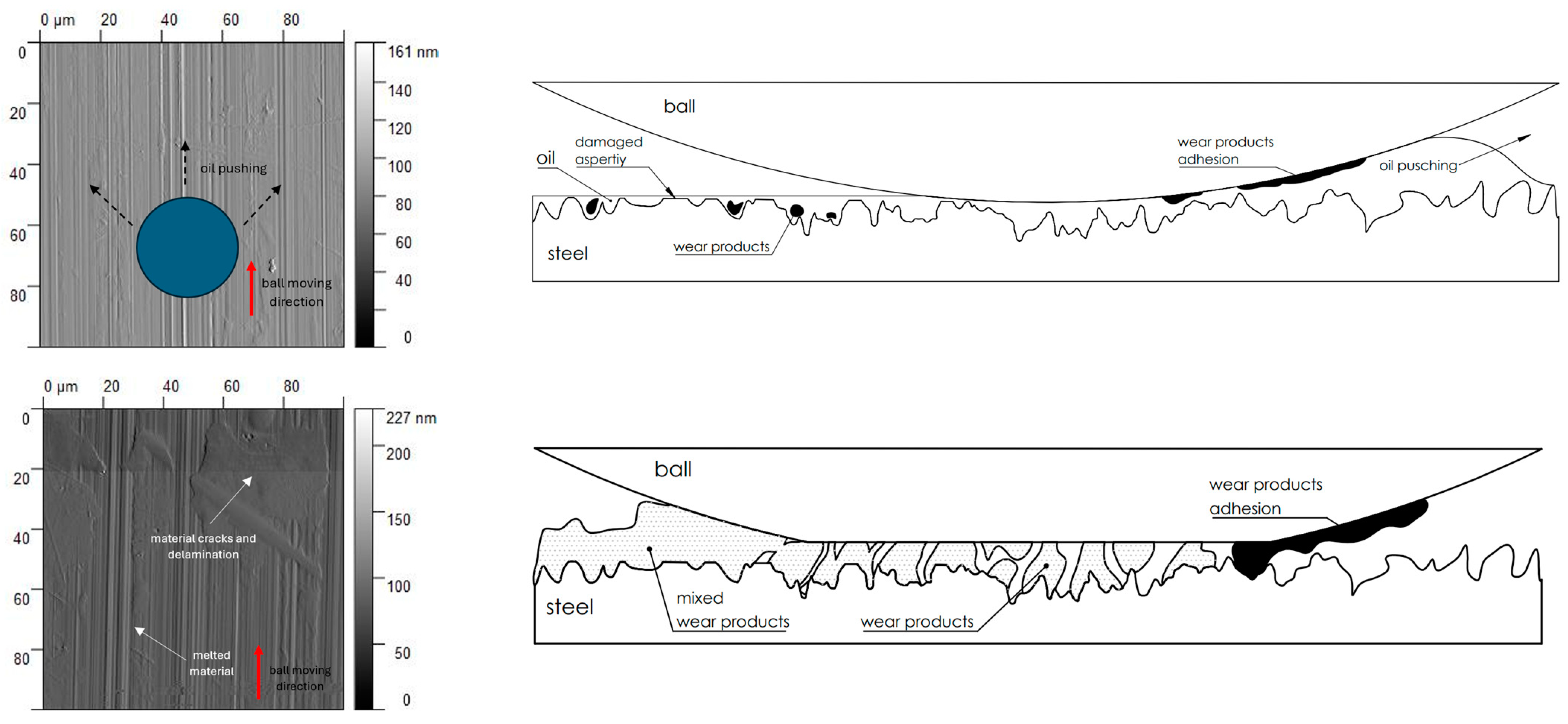

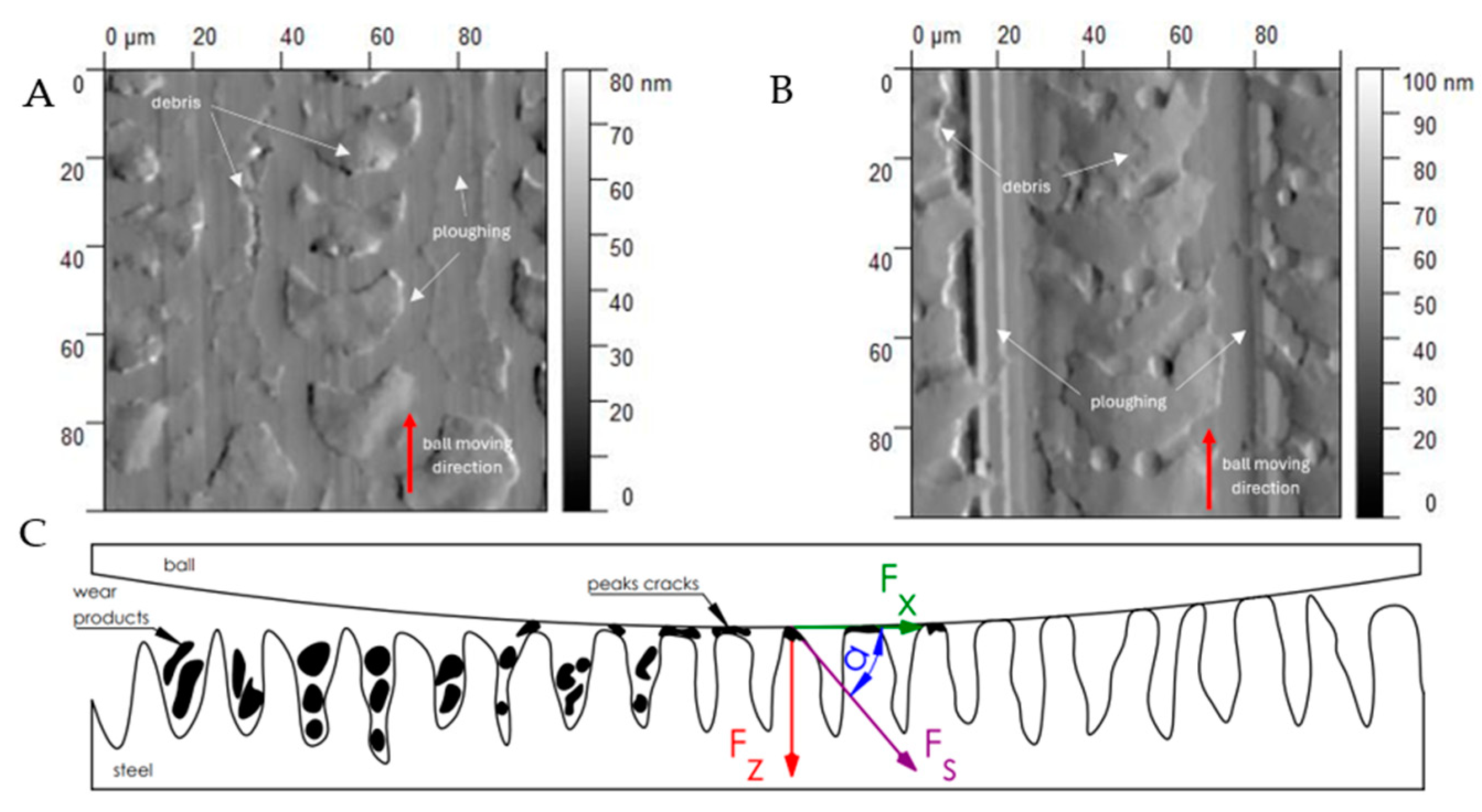

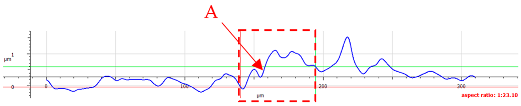

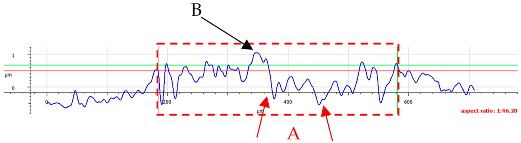

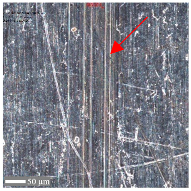

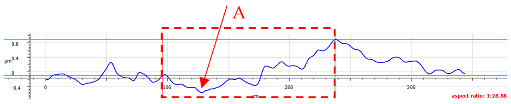

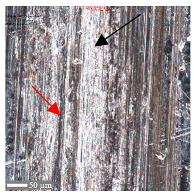

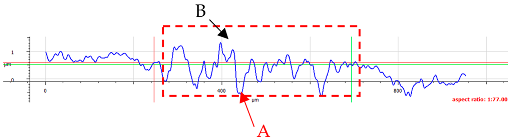

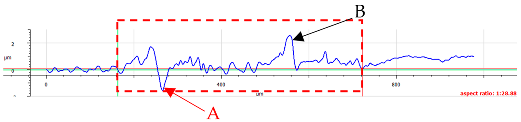

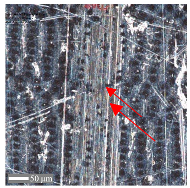

3.4. Surface Topography After Test Evaluation

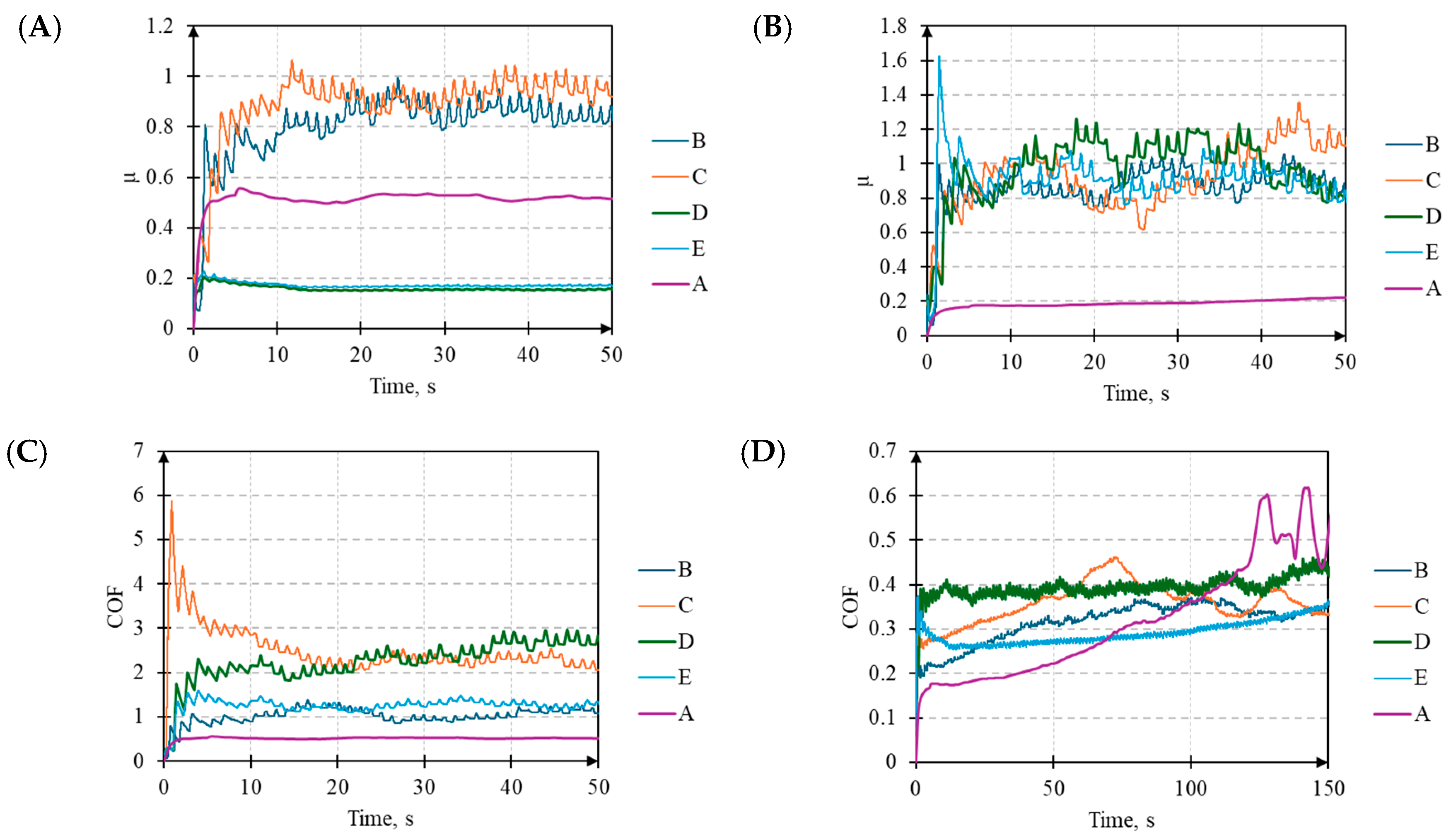

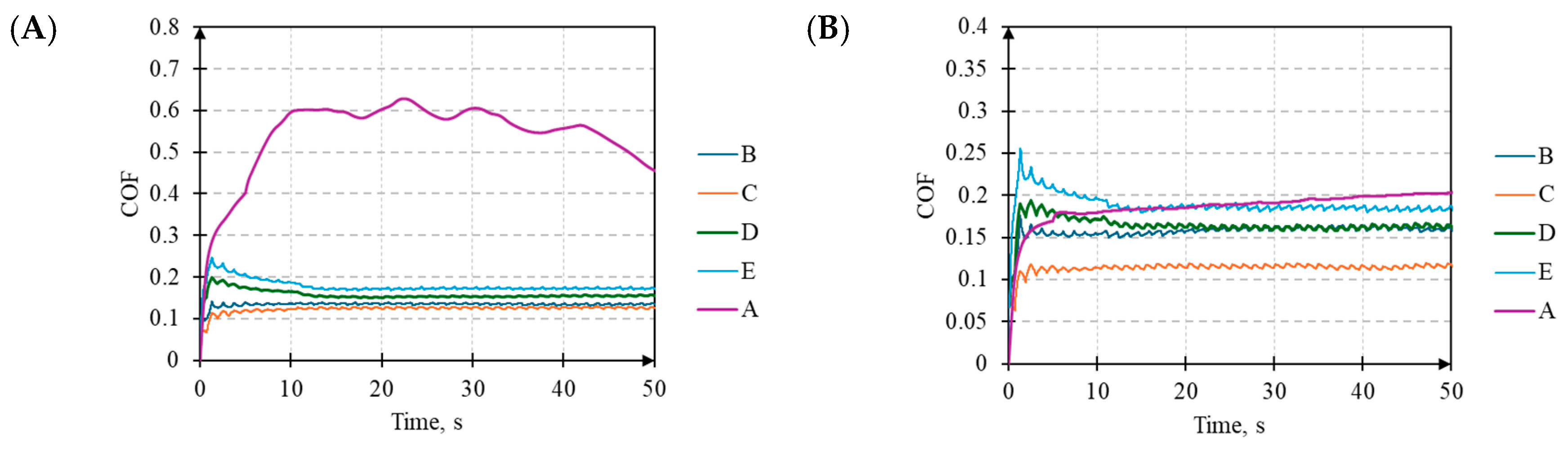

3.5. Coefficient of Friction

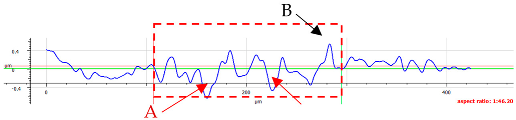

3.6. Wear on a Cross-Section of Steel

3.7. Frictional Performance of the Carbon Steel Ball

3.8. Frictional Performance of Laser-Textured Steel

4. Conclusions

- The phase transformation of austenite into martensite, occurring during the process, increases the surface hardness, significantly improving the wear resistance.

- The texturing enhances the surface’s hydrophobicity, minimizing the direct contact between bodies and thereby reducing the material wear.

- The creation of regular structures and their periodicity stabilizes the contact and alters the distribution of contact stresses, which is crucial for improving the durability of components operating under demanding conditions.

- The periodic structures promote the formation of oil reservoirs, enabling operation in mixed lubrication (ML) or hydrodynamic lubrication (HL) regimes, further enhancing the lubrication efficiency and extending the service life of components.

- The change in the friction from sliding to rolling due to the influence of the surface texture on the hydrodynamic effects, as evidenced by the changes in the friction coefficient value.

- Laser-induced periodic surface structures (LIPSSs) further optimize the tribological properties, making this technology a promising tool for surface modification in various industrial applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, L.; Li, Y. Reduction of Friction and Wear for AISI321 Stainless Steel through Surface Modification Using Nanocrystallization. Materials 2023, 16, 5303. [Google Scholar] [CrossRef] [PubMed]

- Kato, K. Industrial Tribology in the Past and Future. Tribol. Online 2011, 6, 1–9. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Montoya, V.L.; Cairns, E.; Eskandari, M.; Liu, S.; Chung, Y.-W.; Wang, Q.J.; Berkebile, S.P.; Aouadi, S.M.; Voevodin, A.A.; et al. Tribological Analysis of Steels in Fuel Environments: Impact of Alloy Content and Hardness. Appl. Sci. 2024, 14, 1898. [Google Scholar] [CrossRef]

- Kharlamov, Y.; Sokolov, V.; Krol, O.; Romanchenko, O. Experimental Research of the Tribological Properties of D-Gun Sprayed WC—Co Coatings. In Innovations in Mechanical Engineering; Springer: Cham, Switzerland, 2022; pp. 34–45. [Google Scholar]

- Shimada, H.; Kato, S.; Watanabe, T.; Yamaguchi, M. Direct Laser Processing of Two-Scale Periodic Structures for Superhydrophobic Surfaces Using a Nanosecond Pulsed Laser. Lasers Manuf. Mater. Process. 2020, 7, 496–512. [Google Scholar] [CrossRef]

- Li, W.X.; Liu, Y.; Duan, H.T.; Wang, Y.H.; Zhan, S.P.; Zhang, W.L.; Yang, T.; Li, G.Z.; Dan, J. Effect of Laser Texturing Bulges on Tribological Properties of 316L Stainless Steel. Surf. Topogr. 2023, 11, 015004. [Google Scholar] [CrossRef]

- Simões, J.G.A.B.; Riva, R.; Miyakawa, W. High-Speed Laser-Induced Periodic Surface Structures (LIPSS) Generation on Stainless Steel Surface Using a Nanosecond Pulsed Laser. Surf. Coat. Technol. 2018, 344, 423–432. [Google Scholar] [CrossRef]

- Conradi, M.; Podgornik, B.; Remškar, M.; Klobčar, D.; Kocijan, A. Tribological Evaluation of Vegetable Oil/MoS2 Nanotube-Based Lubrication of Laser-Textured Stainless Steel. Materials 2023, 16, 5844. [Google Scholar] [CrossRef]

- Lawrence, J.; Waugh, D.G. Creating Superhydrophobic Surface Structures via the Rose Petal Effect on Stainless Steel with a Picosecond Laser. Lasers Eng. 2017, 37, 125–134. [Google Scholar]

- Gnilitskyi, I.; Rota, A.; Gualtieri, E.; Valeri, S.; Orazi, L. Tribological Properties of High-Speed Uniform Femtosecond Laser Patterning on Stainless Steel. Lubricants 2019, 7, 83. [Google Scholar] [CrossRef]

- Alnusirat, W.; Kyrychok, M.; Bellucci, S.; Gnilitskyi, I. Impact of Ultrashort Laser Nanostructuring on Friction Properties of AISI 314 LVC. Symmetry 2021, 13, 1049. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Rotundo, F.; Martini, C.; Pavlov, I.; Ilday, S.; Vovk, E.; Ilday, F.Ö.; Orazi, L. Nano Patterning of AISI 316L Stainless Steel with Nonlinear Laser Lithography: Sliding under Dry and Oil-Lubricated Conditions. Tribol. Int. 2016, 99, 67–76. [Google Scholar] [CrossRef]

- Zhan, X.; Yi, P.; Liu, Y.; Xiao, P.; Zhu, X.; Ma, J. Effects of Single- and Multi-Shape Laser-Textured Surfaces on Tribological Properties under Dry Friction. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2020, 234, 1382–1392. [Google Scholar] [CrossRef]

- Jähnig, T.; Lasagni, A.F. Laser Interference Patterned Ta-C-Coated Dry Forming Tools. Ind. Lubr. Tribol. 2020, 72, 1001–1005. [Google Scholar] [CrossRef]

- Onufrijevs, P.; Grase, L.; Padgurskas, J.; Rukanskis, M.; Durena, R.; Willer, D.; Iesalnieks, M.; Lungevics, J.; Kaupuzs, J.; Rukuiža, R.; et al. Anisotropy of the Tribological Performance of Periodically Oxidated Laser-Induced Periodic Surface Structures. Coatings 2023, 13, 1199. [Google Scholar] [CrossRef]

- Ji, X.; Sun, Y. Special Issue on Laser Surface Engineering for Tribology. Lubricants 2024, 12, 98. [Google Scholar] [CrossRef]

- Kohutiar, M.; Krbata, M.; Escherova, J.; Eckert, M.; Mikus, P.; Jus, M.; Polášek, M.; Janík, R.; Dubec, A. The Influence of the Geometry of Movement during the Friction Process on the Change in the Tribological Properties of 30CrNiMo8 Steel in Contact with a G40 Steel Ball. Materials 2023, 17, 127. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Madej, M.; Kowalski, M. Influence of Surface Roughness on Tribologicalproperties of Hs6-5-2c Steel with An Altin Coating. Tribologia 2024, 307, 67–78. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Mathia, T.G. Impact of Roughness. In Fretting Wear and Fretting Fatigue; Elsevier: Amsterdam, The Netherlands, 2023; pp. 153–171. [Google Scholar]

- Wang, P.; Liang, H.; Jiang, L.; Qian, L. Effect of Nanoscale Surface Roughness on Sliding Friction and Wear in Mixed Lubrication. Wear 2023, 530–531, 204995. [Google Scholar] [CrossRef]

- Wang, D.; Chen, X.; Li, F.; Wan, B.; Liu, B.; Zhao, Y.; Qing, X. Effect of Surface Texture on the Tribological Behavior of Sliding Electrical Contact Interface. Surf. Topogr. 2023, 11, 025008. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, Z.; Zhang, H.; Shi, Z.; Gu, F. Tribology and Characterization of Dynamically-Loaded Crankshaft Main Bearings with Surface Roughness. In Proceedings of the UNIfied Conference of DAMAS, IncoME and TEPEN Conferences (UNIfied 2023), Huddersfield, UK, 29 August–1 September 2023; pp. 47–62. [Google Scholar]

- G133; Standard Test Method for Lineay Reciprocating Ball-on-Flat Sliding Wear. ASTM Interntional: West Conshohocken, PA, USA, 2013.

- Liang, G.; Schmauder, S.; Lyu, M.; Schneider, Y.; Zhang, C.; Han, Y. An Investigation of the Influence of Initial Roughness on the Friction and Wear Behavior of Ground Surfaces. Materials 2018, 11, 237. [Google Scholar] [CrossRef]

- Dobrotvorskiy, S.; Aleksenko, B.A.; Kościński, M.; Basova, Y.; Prykhodko, V.; Dobrovolska, L.; Mižáková, J. The Relief of the Structured by Nanosecond Laser Stainless Steel Surface Inspection by Sliding Reflection of a Laser Beam. In Proceedings of the EAI International Conference on Automation and Control in Theory and Practice, EAI ARTEP 2023, Stará Lesná, Slovakia, 8–10 February 2023; pp. 65–77. [Google Scholar]

- Dobrotvorskiy, S.; Aleksenko, B.A.; Yepifanov, V.; Basova, Y.; Prykhodko, V.; Dobrovolska, L.; Kościński, M. Computer Modelling and Comparative Analysis of Surface Microrelief Inspection by the Method of Scattering of a Laser Beam During Its Small-Angle Sliding Incidence. In Proceedings of the International Conference on Reliable Systems Engineering (ICoRSE)–2023, Bucharest, Romania, 7–8 September 2023; pp. 237–252. [Google Scholar]

- Dobrotvorskiy, S.; Aleksenko, B.A.; Kościński, M.; Basova, Y.; Prykhodko, V. Modeling and Surface Modification of AISI 321 Stainless Steel by Nanosecond Laser Radiation. In Advances in Design, Simulation and Manufacturing VI: Proceedings of the 6th International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2023, June 6–9, 2023, High Tatras, Slovak Republic—Volume 1: Manufacturing Engineering; Springer: Cham, Switzerland, 2023; pp. 205–215. [Google Scholar]

- Chen, L.; Liu, Z.; Wang, X.; Wang, Q.; Liang, X. Effects of Surface Roughness Parameters on Tribological Performance for Micro-Textured Eutectic Aluminum-Silicon Alloy. J. Tribol. 2020, 142, 021702. [Google Scholar] [CrossRef]

- Gupta, M.K.; Niesłony, P.; Sarikaya, M.; Korkmaz, M.E.; Kuntoğlu, M.; Królczyk, G.M. Studies on Geometrical Features of Tool Wear and Other Important Machining Characteristics in Sustainable Turning of Aluminium Alloys. Int. J. Precis. Eng. Manuf.—Green. Technol. 2023, 10, 943–957. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Sun, C.; Bao, Y.; Zhou, Q. How Surface Roughness Reduces Heat Transport for Small Roughness Heights in Turbulent Rayleigh-Bénard Convection. J. Fluid. Mech. 2018, 836, R2. [Google Scholar] [CrossRef]

- Zhong, Z.; Xing, W.; Zhang, B. Fabrication of Ceramic Membranes with Controllable Surface Roughness and Their Applications in Oil/Water Separation. Ceram. Int. 2013, 39, 4355–4361. [Google Scholar] [CrossRef]

- Matikainen, V.; Rubio Peregrina, S.; Ojala, N.; Koivuluoto, H.; Schubert, J.; Houdková; Vuoristo, P. Erosion Wear Performance of WC-10Co4Cr and Cr3C2-25NiCr Coatings Sprayed with High-Velocity Thermal Spray Processes. Surf. Coat. Technol. 2019, 370, 196–212. [Google Scholar] [CrossRef]

- Breukelman, H.J.; Hermans, M.J.M.; Santofimia, M.J.; Hidalgo, J. Engineering Austenite/Martensite Mesostructured Materials by Controlled Localised Laser Treatments in a Fe–Ni–C Alloy. Mater. Des. 2023, 227, 111772. [Google Scholar] [CrossRef]

- Li, C.; Feng, L.; Sun, H.; Han, X. Phase-Field Simulation and High-Temperature Confocal Laser Scanning Microscope Experimental Study of Martensite Transformation during the Disk Laser Quenching Process. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 1605–1622. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kim, Y.-K.; Lee, K.-A. Effect of Repeated Laser Scanning on the Microstructure Evolution of Carbon-Bearing Martensitic Steel Manufactured by Laser Powder Bed Fusion: Quenching-Partitioning Drives Carbon-Stabilized Austenite Formation. Addit. Manuf. 2022, 60, 103262. [Google Scholar] [CrossRef]

- Piasecki, A.; Kulka, M.; Kotkowiak, M. Wear Resistance Improvement of 100CrMnSi6-4 Bearing Steel by Laser Boriding Using CaF2 Self-Lubricating Addition. Tribol. Int. 2016, 97, 173–191. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.-W.; Wang, M.; Zhao, Q.-Z. Manipulation of Tribological Properties of Stainless Steel by Picosecond Laser Texturing and Quenching. Tribol. Int. 2016, 99, 14–22. [Google Scholar] [CrossRef]

- Rabiei, A.; Ghadami, F.; Malek, F. Microstructural Characteristics and Tribological Properties of the Localized Laser Surface Treatment of AISI 420 Stainless Steel. Tribol. Int. 2023, 177, 107969. [Google Scholar] [CrossRef]

- Bonek, M.; Tillová, E. Tribological Characteristic of Tool Steel Surface Layer Alloyed Using Laser. Solid State Phenom. 2020, 308, 110–118. [Google Scholar] [CrossRef]

- Huang, J.; Cai, L.; Zhang, W.; Zhang, L.; Jiang, B.; Kong, L. Influence of Surface Structure/Wettability on Tribological Properties of Titanium. Tribol. Int. 2022, 174, 107747. [Google Scholar] [CrossRef]

- Sarath, P.S.; Reghunath, R.; Haponiuk, J.T.; Thomas, S.; George, S.C. Introduction: A Journey to the Tribological Behavior of Polymeric Materials. In Tribology of Polymers, Polymer Composites, and Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–16. [Google Scholar]

- Murakami, T. Biotribology of Artificial Joints. In Biotribology of Natural and Artificial Joints; Elsevier: Amsterdam, The Netherlands, 2023; pp. 151–207. [Google Scholar]

- Rahman, M.; Haider, J.; Hashmi, M.S.J. Health and Safety Issues in Emerging Surface Engineering Techniques. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 35–47. [Google Scholar]

- Jażdżewska, M.; Bartmański, M.; Zieliński, A.; Kwidzińska, D.B. Effect of Laser Treatment on Intrinsic Mechanical Stresses in Titanium and Some of Its Alloys. Appl. Sci. 2023, 13, 6276. [Google Scholar] [CrossRef]

- Popescu, A.; Olaru, D.N. Influence of Lubricant on the Friction in an Angular Contact Ball Bearing under Low Load Conditions. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 012040. [Google Scholar] [CrossRef]

- Hirayama, T.; Shiotani, H.; Yamada, K.; Yamashita, N.; Matsuoka, T.; Sawada, H.; Kawahara, K. Hydrodynamic Performance Produced by Nanotexturing in Submicrometer Clearance with Surface Roughness. J. Tribol. 2015, 137, 011704. [Google Scholar] [CrossRef]

- Meddah, S.; Bourebia, M.; Achouri, S.; Oulabbas, A.; Kahloul, L.; Lemboub, S. Numerical Simulation of the Evolution of Roughness Parameter During Friction. In Proceedings of the 2023 International Conference on Decision Aid Sciences and Applications, DASA 2023, Annaba, Algeria, 16–17 September 2023. [Google Scholar]

- Bahshwan, M.; Myant, C.W.; Reddyhoff, T.; Pham, M.S. The Role of Microstructure on Wear Mechanisms and Anisotropy of Additively Manufactured 316L Stainless Steel in Dry Sliding. Mater. Des. 2020, 196, 109076. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- la Monaca, A.; Murray, J.W.; Liao, Z.; Speidel, A.; Robles-Linares, J.A.; Axinte, D.A.; Hardy, M.C.; Clare, A.T. Surface Integrity in Metal Machining—Part II: Functional Performance. Int. J. Mach. Tools Manuf. 2021, 164, 103718. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Lubricated Sliding Wear of Textured Surfaces. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; ASMEDC: New York, NY, USA, 2005; Volume 2, pp. 431–432. [Google Scholar]

- Khosla, T.; Cremaldi, J.; Erickson, J.S.; Pesika, N.S. Load-Induced Hydrodynamic Lubrication of Porous Films. ACS Appl. Mater. Interfaces 2015, 7, 17587–17591. [Google Scholar] [CrossRef]

- Liu, X.; Guo, Z.; Lu, Z.; Qin, L. Tribological Behavior of the Wear-Resistant and Self-Lubrication Integrated Interface Structure with Ordered Micro-Pits. Surf. Coat. Technol. 2023, 454, 129159. [Google Scholar] [CrossRef]

| Parameter | Fz [N] | pmax [MPa] | τmax [MPa] | z [µm] | d [µm] | v [mm/s] | s [mm] | t [s] |

| Value | 1 | 744 | 230 | 12 | 51 | 10 | 5 | 360 |

| 3 | 1073 | 332 | 18 | 73 | 10 | 5 | 360 |

| Name | Unit | Sample | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | ||

| Sa | µm | 0.24 | 0.25 | 0.28 | 0.38 | 1.00 |

| Sq | µm | 0.31 | 0.34 | 0.34 | 0.49 | 1.23 |

| Sp | µm | 6.04 | 3.23 | 1.32 | 2.96 | 9.38 |

| Sv | µm | 42.4 | 33.8 | 1.6 | 7.7 | 3.1 |

| Sz | µm | 48.5 | 37.0 | 3.0 | 10.6 | 12.5 |

| S10z | µm | 4.44 | 9.52 | 2.48 | 5.60 | 9.29 |

| Ssk | −2.01 | −5.25 | −0.06 | −0.96 | 0.44 | |

| Sku | 412 | 494 | 3 | 14 | 3 | |

| Sdq | 0.04 | 0.10 | 0.04 | 0.10 | 0.22 | |

| Sdr | % | 0.10 | 0.34 | 0.08 | 0.45 | 2.42 |

| Surface | Random | Quasi-Random | Quasi-Periodic | Periodic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameter | Fz | Lubricant | Y | X | Raw | Y | X | Raw | Y | X | Raw | Y | X | Raw |

| Sa | 3 | dry | 0.30 | 0.23 | 0.17 | 0.32 | 0.23 | 0.18 | 0.47 | 0.32 | 0.46 | 0.82 | 0.76 | 1.00 |

| oil | 0.13 | 0.28 | 0.14 | 0.22 | 0.49 | 0.47 | 0.98 | 0.95 | ||||||

| 1 | dry | 0.24 | 0.22 | 0.34 | 0.21 | 0.33 | 0.48 | 1.04 | 1.00 | |||||

| oil | 0.15 | 0.27 | 0.14 | 0.18 | 0.38 | 0.46 | 0.62 | 0.98 | ||||||

| Sq | 3 | dry | 0.45 | 0.30 | 0.21 | 0.47 | 0.28 | 0.23 | 0.59 | 0.44 | 0.65 | 1.00 | 0.93 | 1.22 |

| oil | 0.17 | 0.35 | 0.18 | 0.29 | 0.61 | 0.58 | 1.14 | 1.10 | ||||||

| 1 | dry | 0.33 | 0.27 | 0.43 | 0.35 | 0.43 | 0.60 | 1.23 | 1.23 | |||||

| oil | 0.20 | 0.34 | 0.18 | 0.25 | 0.48 | 0.59 | 0.82 | 1.18 | ||||||

| Sz | 3 | dry | 9.67 | 1.80 | 2.00 | 3.00 | 1.17 | 3.90 | 5.38 | 6.60 | 13.60 | 10.90 | 4.90 | 7.67 |

| oil | 1.22 | 1.39 | 1.60 | 1.68 | 3.10 | 4.22 | 6.38 | 3.34 | ||||||

| 1 | dry | 3.36 | 1.05 | 3.40 | 2.2 | 1.55 | 5.62 | 3.79 | 7.70 | |||||

| oil | 1.70 | 1.29 | 0.65 | 4.94 | 3.36 | 3.90 | 12.00 | 3.34 | ||||||

| Ssk | 3 | dry | 3.23 | 0.52 | 0.52 | 0.76 | 0.13 | 0.36 | −0.18 | 1.18 | 1.76 | 0.47 | 2.55 | 0.31 |

| oil | 0.44 | 0.23 | −0.20 | 0.98 | −0.58 | −0.33 | −0.04 | 0.08 | ||||||

| 1 | dry | 0.93 | 0.09 | 0.33 | 1.2 | −0.54 | −0.15 | 0.75 | 0.24 | |||||

| oil | 0.94 | 0.26 | −0.51 | 1.52 | −0.47 | −0.02 | 1.37 | 0.20 | ||||||

| Sku | 3 | dry | 48.10 | 3.70 | 4.00 | 8.70 | 3.00 | 7.00 | 3.38 | 13.00 | 24.00 | 6.35 | −0.07 | 2.68 |

| oil | 4.87 | 2.92 | 3.80 | 4.84 | 3.00 | 2.94 | 2.33 | 2.14 | ||||||

| 1 | dry | 9.27 | 2.95 | 4.20 | 4.6 | 3.29 | 4.39 | 2.10 | 2.25 | |||||

| oil | 6.69 | 2.91 | 4.22 | 24.00 | 3.30 | 3.43 | 17.80 | 2.17 | ||||||

| Vvc | 3 | dry | 0.46 | 0.25 | 0.25 | 0.48 | 0.35 | 0.27 | 0.67 | 0.51 | 0.67 | 1.16 | 1.16 | 1.65 |

| oil | 0.20 | 0.34 | 0.21 | 0.36 | 0.62 | 0.63 | 1.40 | 1.45 | ||||||

| 1 | dry | 0.36 | 0.26 | 0.48 | 0.29 | 0.48 | 0.68 | 1.60 | 1.70 | |||||

| oil | 0.23 | 0.45 | 0.20 | 0.26 | 0.50 | 0.66 | 0.93 | 1.66 | ||||||

| Fz [N] | 1 | 3 | |||

|---|---|---|---|---|---|

| Lubricant | Dry | Oil | Dry | Oil | |

| Surface | B | ||||

| Direction | Y | 0.34 ± 0.04 | 0.9 ± 0.23 | 0.12 ± 0.01 | 0.27 ± 0.05 |

| X | 0.85 ± 0.08 | 0.79 ± 0.08 | 0.15 ± 0.01 | 0.13 ± 0.01 | |

| Surface | C | ||||

| Direction | Y | 0.37 ± 0.04 | 2.29 ± 0.4 | 0.17 ± 0.04 | 0.33 ± 0.08 |

| X | 0.93 ± 0.15 | 0.85 ± 0.08 | 0.12 ± 0.01 | 0.12 ± 0.01 | |

| Surface | D | ||||

| Direction | Y | 0.41 ± 0.03 | 2.15 ± 0.25 | 0.15 ± 0.01 | 0.26 ± 0.06 |

| X | 1.14 ± 0.15 | 0.15 ± 0.01 | 0.16 ± 0.01 | 0.16 ± 0.01 | |

| Surface | E | ||||

| Direction | Y | 1.33 ± 0.52 | 1.22 ± 0.1 | 0.16 ± 0.008 | 0.24 ± 0.06 |

| X | 0.92 ± 0.14 | 0.17 ± 0.01 | 0.19 ± 0.02 | 0.17 ± 0.02 | |

| Surface | A | ||||

| Direction | Y | 0.28 ± 0.1 | 0.58 ± 0.05 | 0.76 ± 0.08 | 0.46 ± 0.11 |

| X | |||||

| Fz [N] | 3 | 1 | |||

|---|---|---|---|---|---|

| Surface | Direction | Lubricant | |||

| Dry | Oil | Dry | Oil | ||

| Width, µm | |||||

| B | X | 325 | 117 | 188 | 72 |

| Y | 366 | 141 | 155 | 110 | |

| C | X | 299 | 139 | 135 | 93 |

| Y | 305 | 156 | 180 | 93 | |

| D | X | 278 | 228 | 222 | 160 |

| Y | 271 | 216 | 266 | 161 | |

| E | X | 312 | 297 | 240 | 227 |

| Y | 367 | 308 | 204 | 169 | |

| A | 431 | 357 | 387 | 120 | |

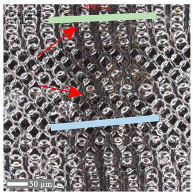

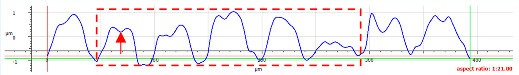

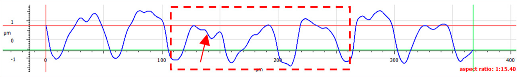

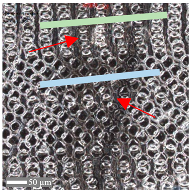

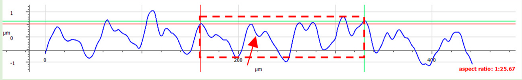

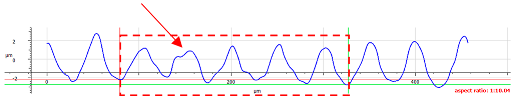

| Scratch View | Surface Roughness Profile | Conditions |

|---|---|---|

|  | Fz = 1 N dry |

|  | Fz = 1 N oil |

|  | Fz = 3 N dry |

|  | Fz = 3 N oil |

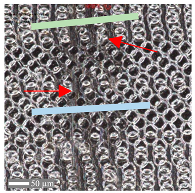

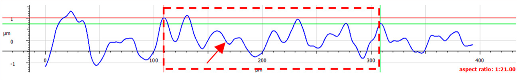

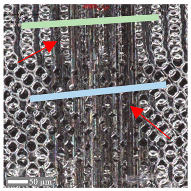

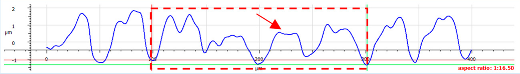

| Scratch View | Surface Roughness Profile | Conditions |

|---|---|---|

|  | Fz = 1 N dry |

|  | Fz = 1 N oil |

|  | Fz = 3 N dry |

|  | Fz = 3 N oil |

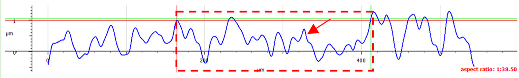

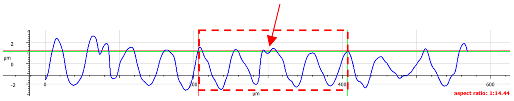

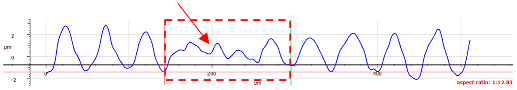

| Scratch View | Surface Roughness Profile | Conditions |

|---|---|---|

|  | Fz = 1 N dry |

| ||

|  | Fz = 1 N oil |

| ||

|  | Fz = 3 N dry |

| ||

|  | Fz = 3 N oil |

|

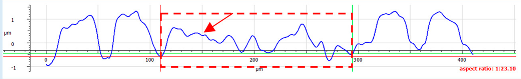

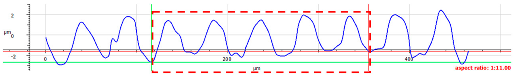

| Scratch View | Surface Roughness Profile | Conditions |

|---|---|---|

|  | Fz = 1 N dry |

|  | Fz = 1 N oil |

|  | Fz = 3 N dry |

|  | Fz = 3 N oil |

| Fz [N] | 3 | 1 | 3 | 1 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Surface | Direction | Lubricant | |||||||

| Dry | Oil | Dry | Oil | Dry | Oil | Dry | Oil | ||

| A, µm × 105 | d, µm | ||||||||

| B | X | 1.59 | 0.21 | 0.48 | 0.11 | 450 | 162 | 247 | 121 |

| Y | 1.21 | 0.20 | 0.25 | 0.18 | 392 | 160 | 180 | 150 | |

| C | X | 3.19 | 0.47 | 0.88 | 0.18 | 637 | 245 | 334 | 151 |

| Y | 2.98 | 0.18 | 0.17 | 0.23 | 616 | 150 | 146 | 483 | |

| D | X | 0.75 | 0.44 | 0.33 | 0.31 | 309 | 236 | 205 | 199 |

| Y | 0.39 | 0.46 | 0.30 | 0.52 | 223 | 241 | 194 | 257 | |

| E | X | 0.96 | 0.83 | 0.60 | 0.61 | 350 | 326 | 276 | 279 |

| Y | 0.76 | 0.81 | 0.55 | 0.84 | 311 | 321 | 264 | 328 | |

| A | 3.67 | 1.11 | 1.38 | 1.42 | 342 | 683 | 377 | 419 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zawadzki, P.; Dobrotvorskiy, S.; Aleksenko, B.; Talar, R. Effect of Nanosecond Laser Texturization on Tribological Behavior of AISI 321 Stainless Steel. Materials 2024, 17, 5870. https://doi.org/10.3390/ma17235870

Zawadzki P, Dobrotvorskiy S, Aleksenko B, Talar R. Effect of Nanosecond Laser Texturization on Tribological Behavior of AISI 321 Stainless Steel. Materials. 2024; 17(23):5870. https://doi.org/10.3390/ma17235870

Chicago/Turabian StyleZawadzki, Paweł, Sergey Dobrotvorskiy, Borys Aleksenko, and Rafał Talar. 2024. "Effect of Nanosecond Laser Texturization on Tribological Behavior of AISI 321 Stainless Steel" Materials 17, no. 23: 5870. https://doi.org/10.3390/ma17235870

APA StyleZawadzki, P., Dobrotvorskiy, S., Aleksenko, B., & Talar, R. (2024). Effect of Nanosecond Laser Texturization on Tribological Behavior of AISI 321 Stainless Steel. Materials, 17(23), 5870. https://doi.org/10.3390/ma17235870