Microwave Heating and Self-Healing Performance of Asphalt Mixtures Containing Metallic Fibres from Recycled Tyres

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

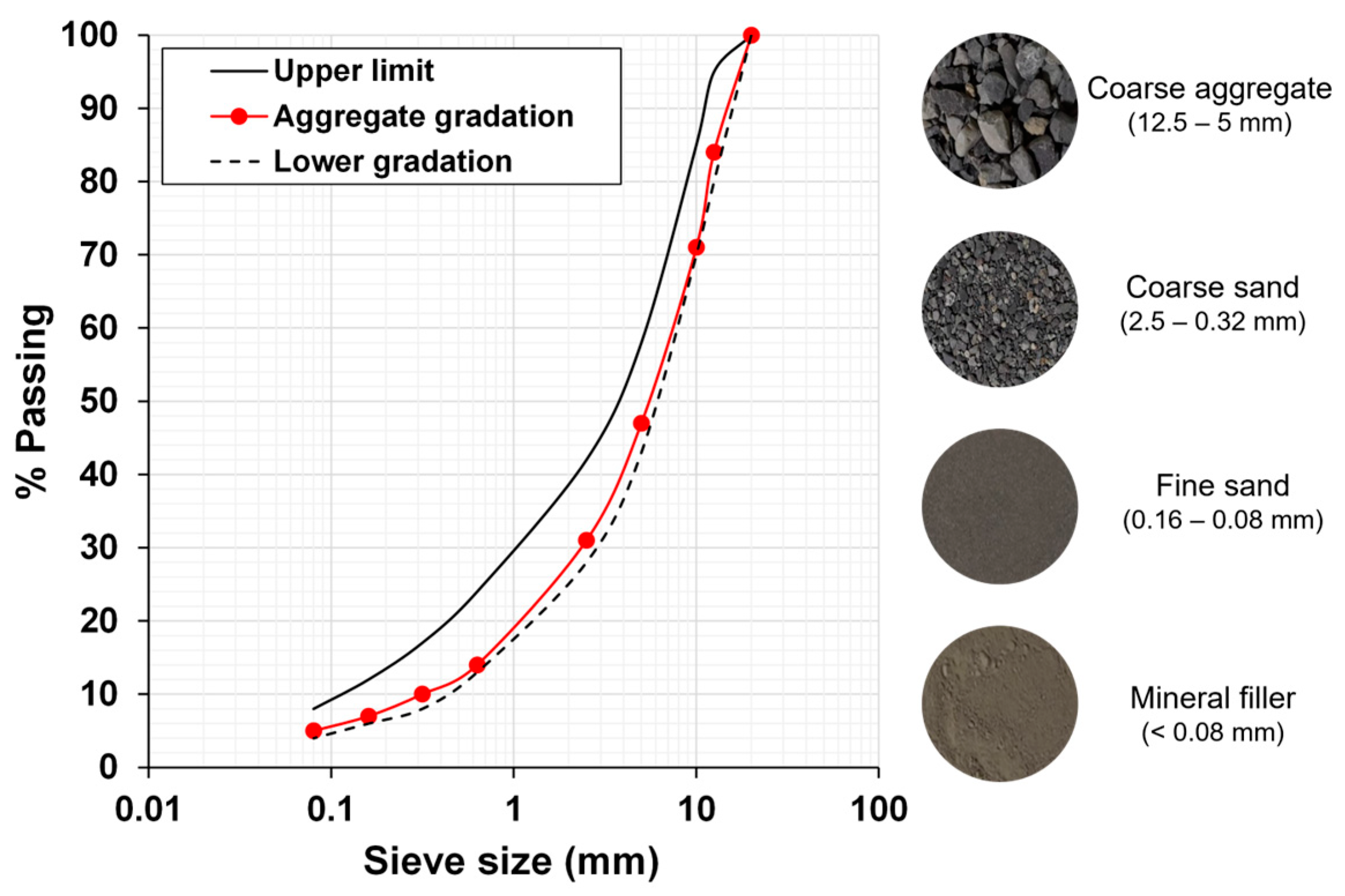

- (1)

- coarse aggregate (CA size 12.5–5 mm),

- (2)

- coarse sand (CS size 2.5–0.32 mm),

- (3)

- fine sand (FS size 0.16–0.08 mm), and

- (4)

- mineral filler (MF size <0.08 mm).

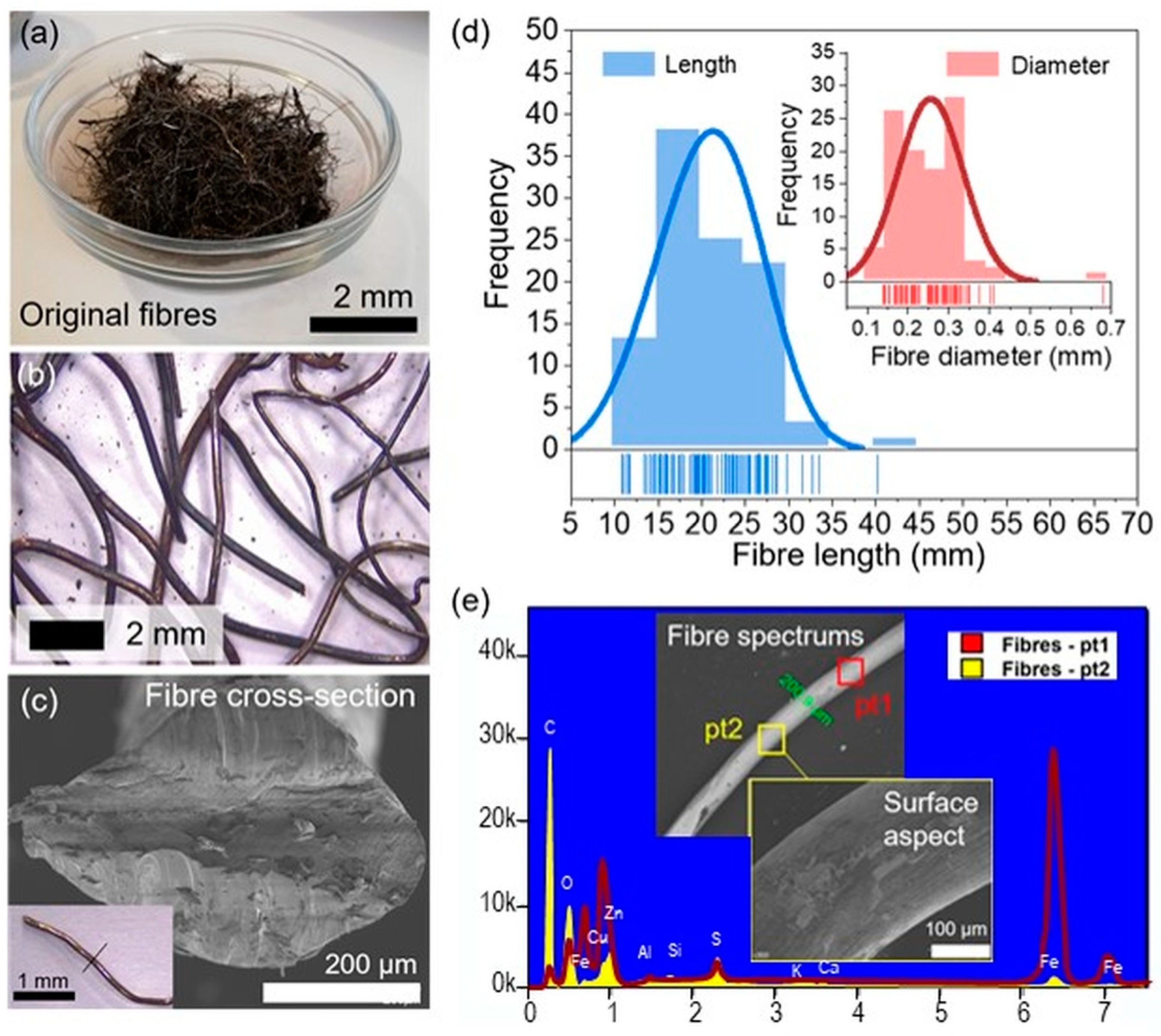

2.2. Elemental Characterisation of Aggregates and Metallic Fibres

2.3. Manufacturing and Physical Characterisation of Asphalt Mixture Specimens

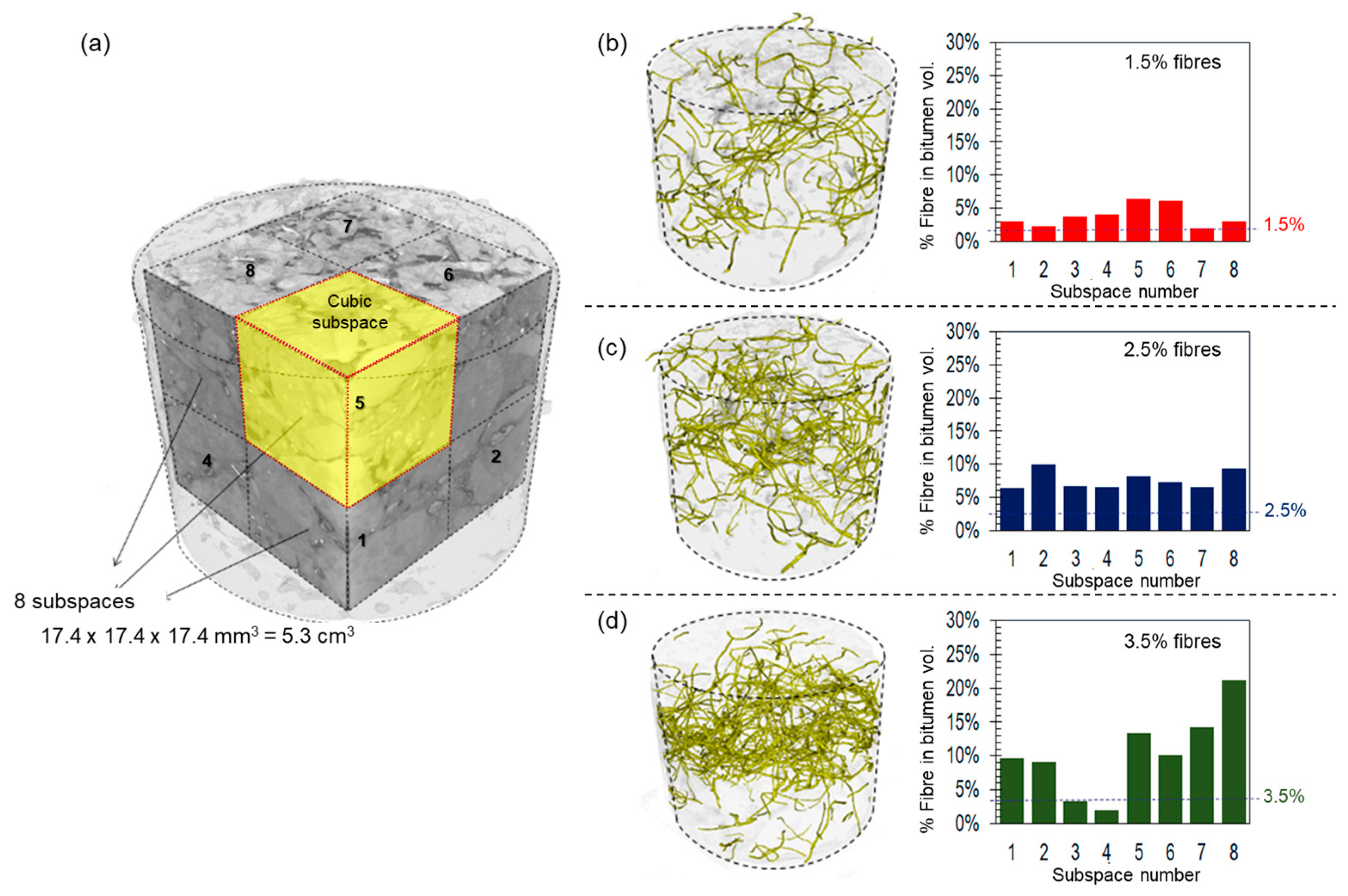

2.4. Fibre Distribution Examined Using X-Ray Computed Tomography

2.5. Microwave Heating of Asphalt Mixtures and Their Components

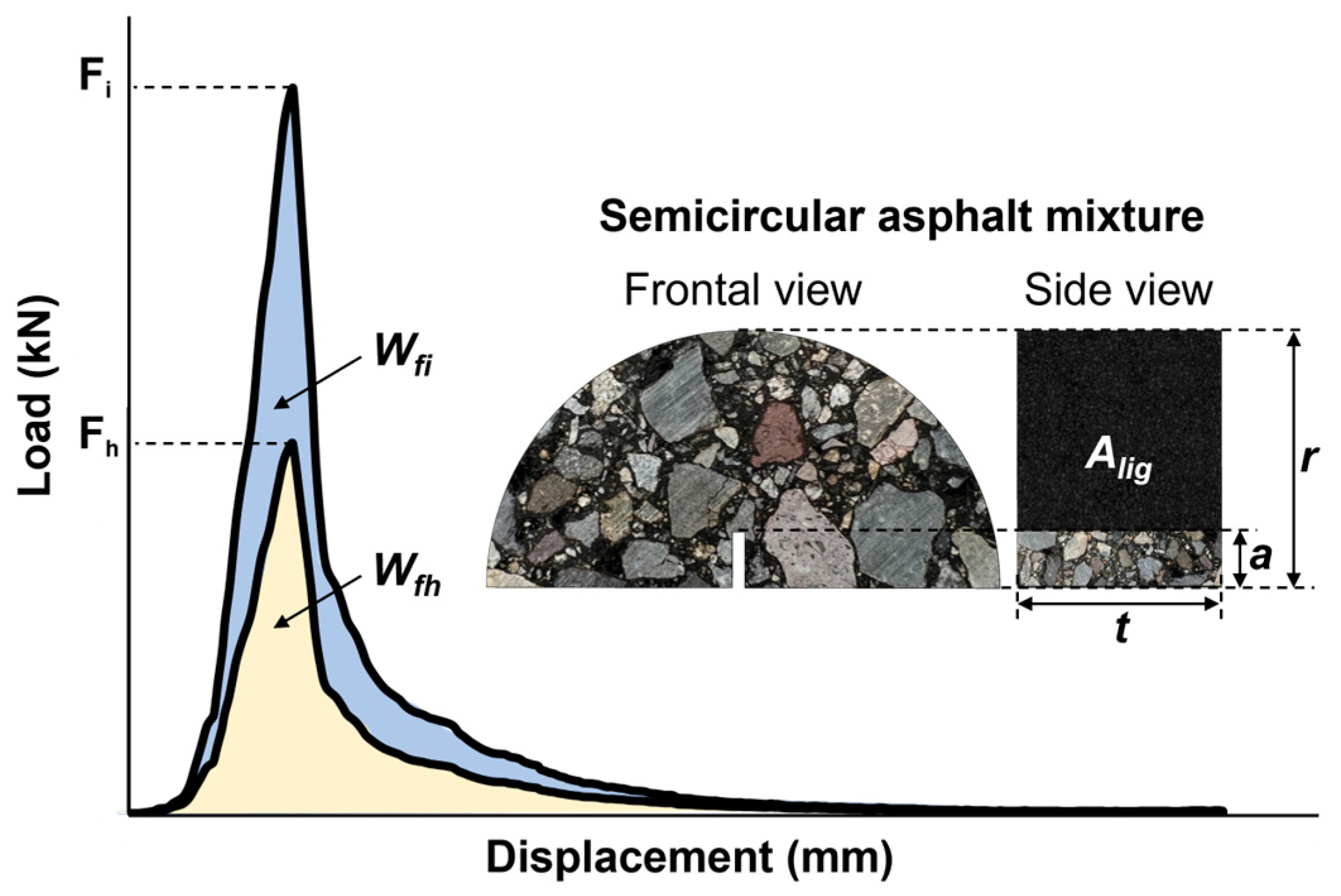

2.6. Measurements of Crack-Healing Properties of Asphalt Mixtures

- (S-1) Semi-circular samples were positioned on two support rollers, 80 mm apart. A monotonic vertical load was applied at 0.5 mm/min until failure at the midpoint of the semi-circular arc. As a result, two sections of the semi-circular sample were obtained.

- (S-2) Following the bending test, the cracked samples were left at room temperature for 2 h to reach 20 °C, allowing the surface moisture to fully evaporate.

- (S-3) The two broken sections were realigned and subjected to microwave radiation at three intervals: 30 s, 40 s, and 50 s. Surface temperature changes were monitored using a thermographic camera connected to the PIX Connect software version 2.6.2125.0 (Optris, Berlin, Germany).

- (S-4) After microwave heating, the samples were allowed to cool at room temperature for 2 h followed by conditioning at 5 °C for 24 h. Then, they were subjected to the 3-PBT once more, completing a crack-healing cycle.

2.7. Statistical Analysis of the Measured Variables

3. Results and Discussion

3.1. Thermal Contribution of Asphalt Mixture Components Under Microwave Heating

- (i)

- 12.5–0.32 mm,

- (ii)

- 0.16–0.08 mm, and

- (iii)

- <0.08 mm (filler).

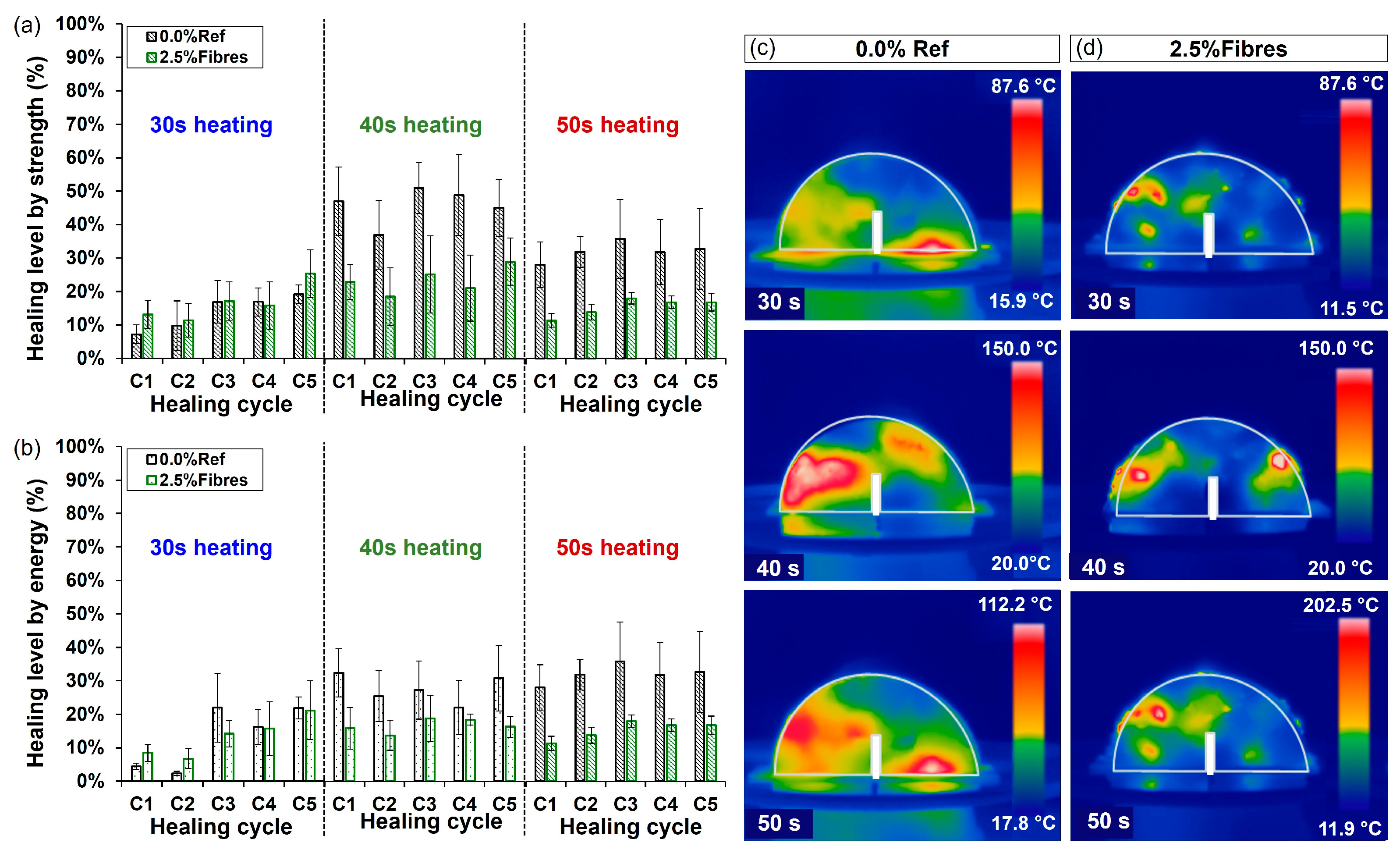

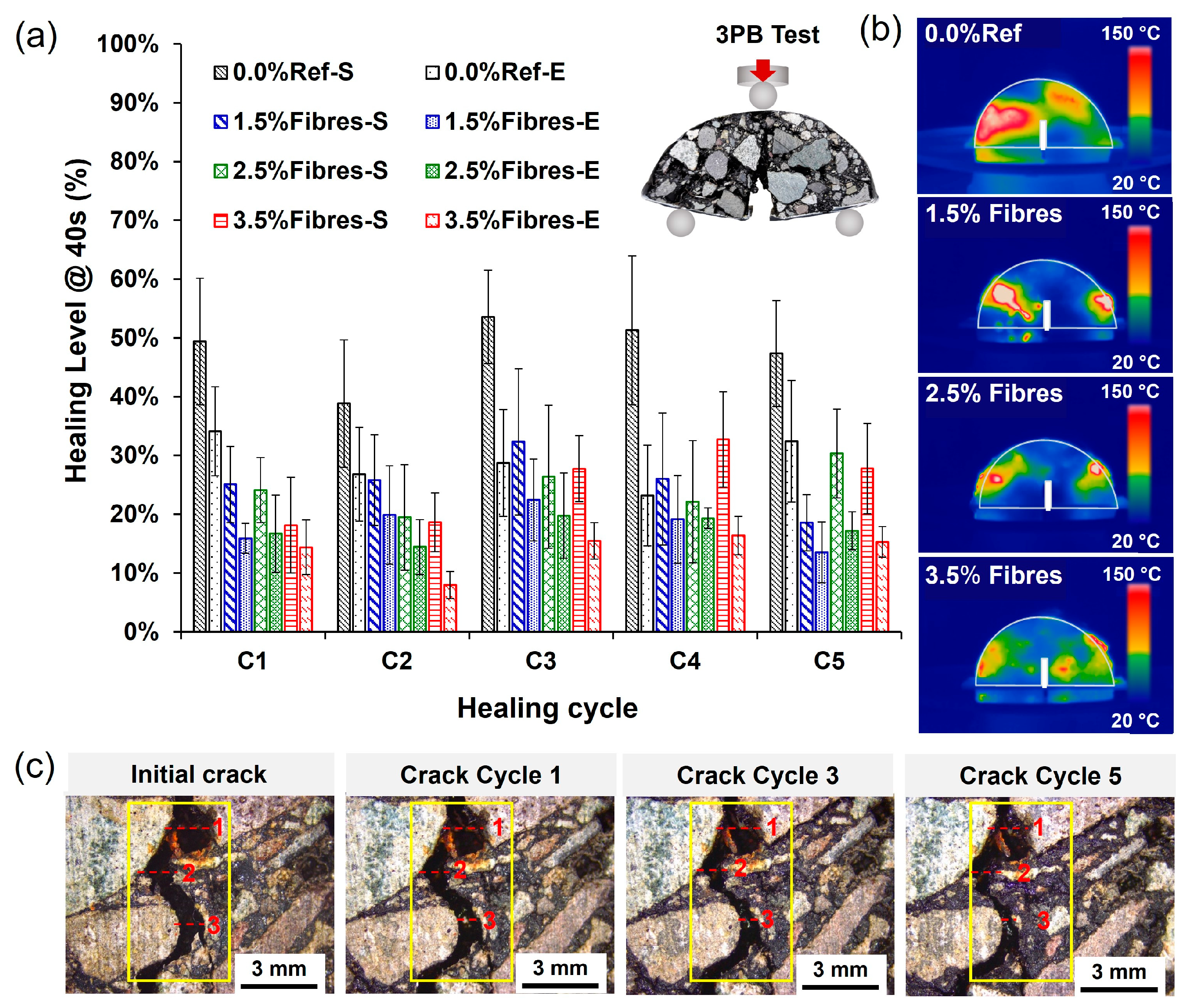

3.2. Effects of Fibres and Heating Time on Crack Healing

- (i)

- were higher for the reference asphalt mixture without fibres,

- (ii)

- tended to increase with the number of healing cycles, and

- (iii)

- increased for a heating time of up to 40 s.

- (i)

- decreased with the incorporation of metallic fibres;

- (ii)

- was lower for the energy criterion compared to the strength one; and

- (iii)

- did not clearly vary with the healing cycles.

4. Conclusions and Outlook

- Key factors affecting healing levels: The main influential factors were the heating time and the addition of metallic fibres, regardless of the fibre content.

- Aggregate grain size and energy consumption: Smaller aggregates required approximately three times more energy to reach the same temperature as larger aggregates. However, there were no significant differences in heating efficiency between the two. Additionally, bitumen was found to be transparent to microwaves.

- Heating time and fibre content on surface temperature: In general, the longer the microwave heating time and the lower the metallic fibre content in the asphalt mixture, the higher the average surface temperature reached by the test samples.

- Heating efficiency: The addition of fibres reduced the required heating energy for the fibre-reinforced mixtures. This positive effect could lower both the environmental footprint and operational costs of asphalt pavement maintenance, aligning with sustainability goals in civil infrastructure.

- Time and fibre influence on healing: Microwave heating facilitated the self-healing of cracked asphalt mixtures, regardless of the presence of metallic fibres. Furthermore, the healing levels of the asphalt mixtures improved with heating times of up to 40 s; this value was selected as the optimal healing time. Longer heating times led to reduced healing levels of the asphalt mixtures with fibres. This can be attributed to changes in the internal structure of the heated samples and potential ageing damage to the bitumen exposed to high temperatures. All healing cycles evaluated in this study achieved similar average healing levels for asphalt mixtures with and without metallic fibres. However, higher amounts of metallic fibres can introduce heterogeneities in the thermal behaviour of the asphalt mixture, creating hot spots that may cause the bitumen to flow away from the fracture zone, thereby affecting the healing process.

- Implications for practical application: Overall, the high stiffness and uneven volumetric distribution of the metallic fibres were found to reduce the mechanical properties of the mixtures. Consequently, in their current form, the use of these fibres in asphalt pavements may not be technically advantageous for enhancing crack-healing behaviour through microwave heating. Furthermore, as this research was conducted in a controlled laboratory environment, additional investigations are needed to scale up and validate these findings for field applications.

- Outlook: Although these findings may discourage the use of ELT recycled metallic fibres in their present form, their potential could improve with advancements in fibre processing techniques to achieve better distribution within the mixture matrix. Future research should therefore explore different fibre processing methods to optimize their performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- González, A.; Norambuena-Contreras, J.; Poulikakos, L.; Varela, M.J.; Valderrama, J.; Flisch, A.; Arraigada, M. Evaluation of Asphalt Mixtures Containing Metallic Fibers from Recycled Tires to Promote Crack-Healing. Materials 2020, 13, 5731. [Google Scholar] [CrossRef] [PubMed]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- European Tire & Rubber Manufacturer’s Association. In Europe 95% of All End of Life Tyres Were Collected and Treated in 2019. Press Release. Available online: https://www.etrma.org/wp-content/uploads/2021/05/20210520_ETRMA_PRESS-RELEASE_ELT-2019.pdf (accessed on 22 September 2024).

- Tran, T.Q.; Thomas, B.S.; Zhang, W.; Ji, B.; Li, S.; Brand, A.S. A comprehensive review on treatment methods for end-of-life tire rubber used for rubberized cementitious materials. Constr. Build. Mater. 2022, 359, 129365. [Google Scholar] [CrossRef]

- Ajam, H.; Gomez-Meijide, B.; Artamendi, I.; Garcia, A. Mechanical and healing properties of asphalt mixes reinforced with different types of waste and commercial metal particles. J. Clean. Prod. 2018, 192, 138–150. [Google Scholar] [CrossRef]

- Winternitz, K.; Heggie, M.; Baird, J. Extended producer responsibility for waste tyres in the EU: Lessons learnt from three case studies—Belgium, Italy and the Netherlands. Waste Manag. 2019, 89, 386–396. [Google Scholar] [CrossRef]

- Formela, K. Sustainable development of waste tires recycling technologies—Recent advances, challenges and future trends. Int. J. Polym. Sci. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Recycled Rubber Facts. Available online: https://www.recycledrubberfacts.org/uses/ (accessed on 22 September 2024).

- País, J.C.; Ferreira, A.; Santos, C.; Pereira, P.; Lo Presti, D. Preliminary studies to use textile fibers obtained from recycled tires to reinforce asphalt mixtures. Rom. J. Transp. Infrastruct. 2018, 7, 14–30. [Google Scholar] [CrossRef]

- Dobrota, D.; Dobrota, G.; Dobrescu, T. Improvement of waste tyre recycling technology based on a new tyre markings. J. Clean. Prod. 2020, 260, 121141. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of Steel Fibres Recovered from Waste Tyres as Reinforcement in Concrete: Pull-out Behaviour, Compressive and Flexural Strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2018, 159, 164–174. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; González, A.; Concha, J.L.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Serpell, R.; Valdés Vidal, G.; González, A.; Schlangen, E. Effect of fibres addition on the physical and mechanical properties of asphalt mixtures with crack-healing purposes by microwave radiation. Constr. Build. Mater. 2016, 127, 369–382. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez-Torre, I. Influence of the Microwave Heating Time on the Self-Healing Properties of Asphalt Mixtures. Appl. Sci. 2017, 7, 1076. [Google Scholar] [CrossRef]

- Pang, Q.; Zhang, J.; Gao, L.; Sun, B.; Yao, S. Evaluation of Induction Heating Effects on Asphalt Concretes Containing Waste Steel Shavings and Iron-based Particles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 787, 012033. [Google Scholar] [CrossRef]

- Yıldız, K.; Atakan, M. Improving microwave healing characteristic of asphalt concrete by using fly ash as a filler. Constr. Build. Mater. 2020, 262, 120448. [Google Scholar] [CrossRef]

- Gallego, J.; Gulisano, F.; Picado, L.; Crucho, J. Optimising asphalt mixtures to be heated by microwaves. In Proceedings of the 17th International Conference on Microwave and High Frecuency Heating, Valencia, Spain, 9–12 September 2019. [Google Scholar]

- Trigos, L.; Juan Gallego, J.; Escavy, J.I. Heating potential of aggregates in asphalt mixtures exposed to microwaves radiation. Constr. Build. Mater. 2020, 230, 117035. [Google Scholar] [CrossRef]

- Menozzi, A.; Garcia, A.; Partl, M.N.; Tebaldi, G.; Schuetz, P. Induction healing of fatigue damage in asphalt test samples. Constr. Build. Mater. 2015, 74, 162–168. [Google Scholar] [CrossRef]

- García, A.; Schlangen, E.; van de Ven, M.; Liua, Q. A simple model to define induction heating in asphalt mastic. Constr. Build. Mater. 2012, 31, 38–46. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Ajam, H.; Garcia, A.; Vansteenkiste, S. Effect of bitumen properties in the induction healing capacity of asphalt mixes. Constr. Build. Mater. 2018, 190, 131–139. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; Gonzáelz, A. Analysis of the scientific evolution of self-healing asphalt pavements: Toward sustainable road materials. J. Clean. Prod. 2021, 293, 126107. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; González, A. Assessment of the sustainability of asphalt pavement maintenance using the microwave heating self-healing technique. J. Clean. Prod. 2022, 365, 132859. [Google Scholar] [CrossRef]

- Flores, G.; Gallego, J.; Giuliani, F.; Autelitano, F. Aging of asphalt binder in hot pavement rehabilitation. Constr. Build. Mater. 2018, 187, 214–219. [Google Scholar] [CrossRef]

- Gulisano, F.; Gallego, J. Microwave heating of asphalt paving materials: Principles, current status and next steps. Constr. Build. Mater. 2021, 278, 121993. [Google Scholar] [CrossRef]

- Maliszewski, M.; Zofka, A.; Maliszewska, D.; Sybilski, D.; Salski, B.; Karpisz, T.; Rembelski, R. Full-Scale Use of Microwave Heating in Construction of Longitudinal Joints and Crack Healing in Asphalt Pavements. Materials 2021, 14, 5159. [Google Scholar] [CrossRef]

- Gallego, J.; Del Val, M.A.; Contreras, V.; Páez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, D.; Jain, V.; Sharma, A.K. Microwave processing of materials and applications in manufacturing industries: A review. Mater. Manuf. Process. 2015, 30, 1–29. [Google Scholar] [CrossRef]

- Phan, T.M.; Park, D.-W.; Le, T.H.M. Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Constr. Build. Mater. 2018, 180, 503–511. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Bocci, E.; Germani, M. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Environ. Manag. 2019, 248, 119295. [Google Scholar] [CrossRef]

- Ministerio de Obras Públicas. Manual de Carreteras. Volumen No 5. Especificaciones Técnicas Generales de Construcción; Ministerio de Obras Públicas: Santiago, Chile, 2022.

- Pan, C.; Tang, P.; Riara, M.; Mo, L.; Li, M.; Guo, M. Effect of healing agents on crack healing of asphalt and asphalt mortar. Materials 2018, 11, 1373. [Google Scholar] [CrossRef]

- Al-Ohaly, A.A.; Terrel, R.L. Effect of Microwave Heating on Adhesion and Moisture Damage of Asphalt Mixtures; National Research Council, Transportation Research Board: Washington, DC, USA, 1988; pp. 27–36. [Google Scholar]

- Trigos, L.; Escavy, J.I.; Gallego, J.; Gulisano, F. Natural factors related to the differential heating of aggregates exposed to microwaves. Constr. Build. Mater. 2002, 314, 125654. [Google Scholar] [CrossRef]

- Gallego, J.; Del Val, M.A.; Contreras, V.; Páez, A. Use of additives to improve the capacity of bituminous mixtures to be heated by means of microwaves. Mater. Constr. 2017, 67, e110. [Google Scholar] [CrossRef]

- Hu, Q.; He, Y.; Wang, F.; Wu, J.; Ci, Z.; Chen, L.; Xu, R.; Yang, M.; Lin, J.; Han, L.; et al. Microwave technology: A novel approach to the transformation of natural metabolites. Chin. Med. 2021, 16, 87. [Google Scholar] [CrossRef] [PubMed]

- Nejati, H. Analysis of Physical Properties and Thermo–Mechanical Induced Fractures of Rocks Subjected to Microwave Radiation. Doctoral Thesis, Universidad McGill, Montreal, QC, Canada, 2014. [Google Scholar]

- Peinsitt, T.; Kuchar, F.; Hartlieb, P.; Moser, P.; Kargl, H.; Restner, U.; Sifferlinger, N. Microwave heating of dry and water saturated basalt, granite and sandstone. Int. J. Min. Miner. Eng. 2010, 2, 18–29. [Google Scholar] [CrossRef]

- Chamchong, M.; Datta, A.K. Thawing of foods in a microwave oven: II. Effect of load geometry and dielectric properties. J. Microw. Power Electromagn. Energy 1999, 34, 22–32. [Google Scholar] [CrossRef]

- Talens, C.; Arboleya, J.C.; Castro-Giraldez, M.; Fito, P.J. Effect of microwave power coupled with hot air drying on process efficiency and physico-chemical properties of a new dietary fibre ingredient obtained from orange peel. LWT Food Sci. Technol. 2017, 77, 110–118. [Google Scholar] [CrossRef]

| Fibre Content (%vol. Bitumen) | Bulk Density (g/cm3) | Air Void Content (%) |

|---|---|---|

| Ref. 0% | 2.38 ± 0.20 (1) | 4.7 ± 0.43 (1) |

| 1.5% | 2.31 ± 0.24 (3) | 7.7 ± 0.81 (4) |

| 2.5% | 2.33 ± 0.31 (4) | 6.1 ± 0.52 (2) |

| 3.5% | 2.30 ± 0.26 (2) | 7.7 ± 0.71 (3) |

| Sample n° (See Figure 5a) | Components of the Mixture | Size (mm) | Mass of Fraction in Marshall Specimen (g) | Testing Mass (g) |

|---|---|---|---|---|

| 1 | Coarse aggregate | 12.5–5.0 | 583 | 200 |

| 2 | Coarse sand | 2.5–0.32 | 407 | 200 |

| 3 | Fine sand | 0.16–0.08 | 52 | 46 |

| 4 | Mineral filler | <0.08 | 58 | 56 |

| 5 | Bitumen | - | 58 | 60 |

| Fibre Content (%vol. bit.) | Heating Speed (°C/s) | Surface Temp. (°C) | Heating Efficiency °C/(Wh/kg) | Microwave Energy (Wh/kg) |

|---|---|---|---|---|

| Ref. 0% | 1.25 (4) | 89.1 (4) | 0.95 (4) | 58 (4) |

| 1.5% | 1.60 (1) | 107.9 (1) | 1.20 (1) | 45 (1) |

| 2.5% | 1.31 (3) | 92.8 (3) | 1.01 (3) | 54 (3) |

| 3.5% | 1.45 (2) | 95.7 (2) | 1.14 (2) | 55 (2) |

| Variable | p-Value | Statistically Significant Differences? | Tukey HSD Mean Comparisons |

|---|---|---|---|

| Heating | <0.001 | Yes | CA-B; CS-B; FS-B; MF-B |

| Energy | <0.001 | Yes | CA-FS; CA-MF; CA-B CS-FS; CS-MF; CS-B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norambuena-Contreras, J.; Concha, J.L.; Varela, M.J.; Trigos, L.; Poulikakos, L.; González, A.; Arraigada, M. Microwave Heating and Self-Healing Performance of Asphalt Mixtures Containing Metallic Fibres from Recycled Tyres. Materials 2024, 17, 5950. https://doi.org/10.3390/ma17235950

Norambuena-Contreras J, Concha JL, Varela MJ, Trigos L, Poulikakos L, González A, Arraigada M. Microwave Heating and Self-Healing Performance of Asphalt Mixtures Containing Metallic Fibres from Recycled Tyres. Materials. 2024; 17(23):5950. https://doi.org/10.3390/ma17235950

Chicago/Turabian StyleNorambuena-Contreras, Jose, Jose L. Concha, María J. Varela, Laura Trigos, Lily Poulikakos, Alvaro González, and Martín Arraigada. 2024. "Microwave Heating and Self-Healing Performance of Asphalt Mixtures Containing Metallic Fibres from Recycled Tyres" Materials 17, no. 23: 5950. https://doi.org/10.3390/ma17235950

APA StyleNorambuena-Contreras, J., Concha, J. L., Varela, M. J., Trigos, L., Poulikakos, L., González, A., & Arraigada, M. (2024). Microwave Heating and Self-Healing Performance of Asphalt Mixtures Containing Metallic Fibres from Recycled Tyres. Materials, 17(23), 5950. https://doi.org/10.3390/ma17235950