Powder Metallurgy Processing to Enhance Superelasticity and Shape Memory in Polycrystalline Cu–Al–Ni Alloys: Reference Material for Additive Manufacturing

Abstract

1. Introduction

2. The State of the Art in Powder Metallurgy of Shape Memory Alloys

2.1. Powder Metallurgy of NiTi Alloys

2.2. Powder Metallurgy of Cu–Al–Based Alloys

2.3. Conclusions from the Review on Powder Metallurgy of SMAs

- Powders should be produced by gas atomization.

- The use of pre-alloyed powders is practically compulsory to obtain the required control and homogeneity of the martensitic transformation temperatures.

- The best compaction method seems to be hot isostatic pressing (HIP).

- Hot rolling breaks the oxide film surrounding the powder particles, improving the compaction and the texture of the material.

- The use of grain refiners in the pre-alloyed powders is recommended in order to avoid a large recrystallization during hot rolling and during the required standard solid solution thermal treatment.

3. Materials and Methods

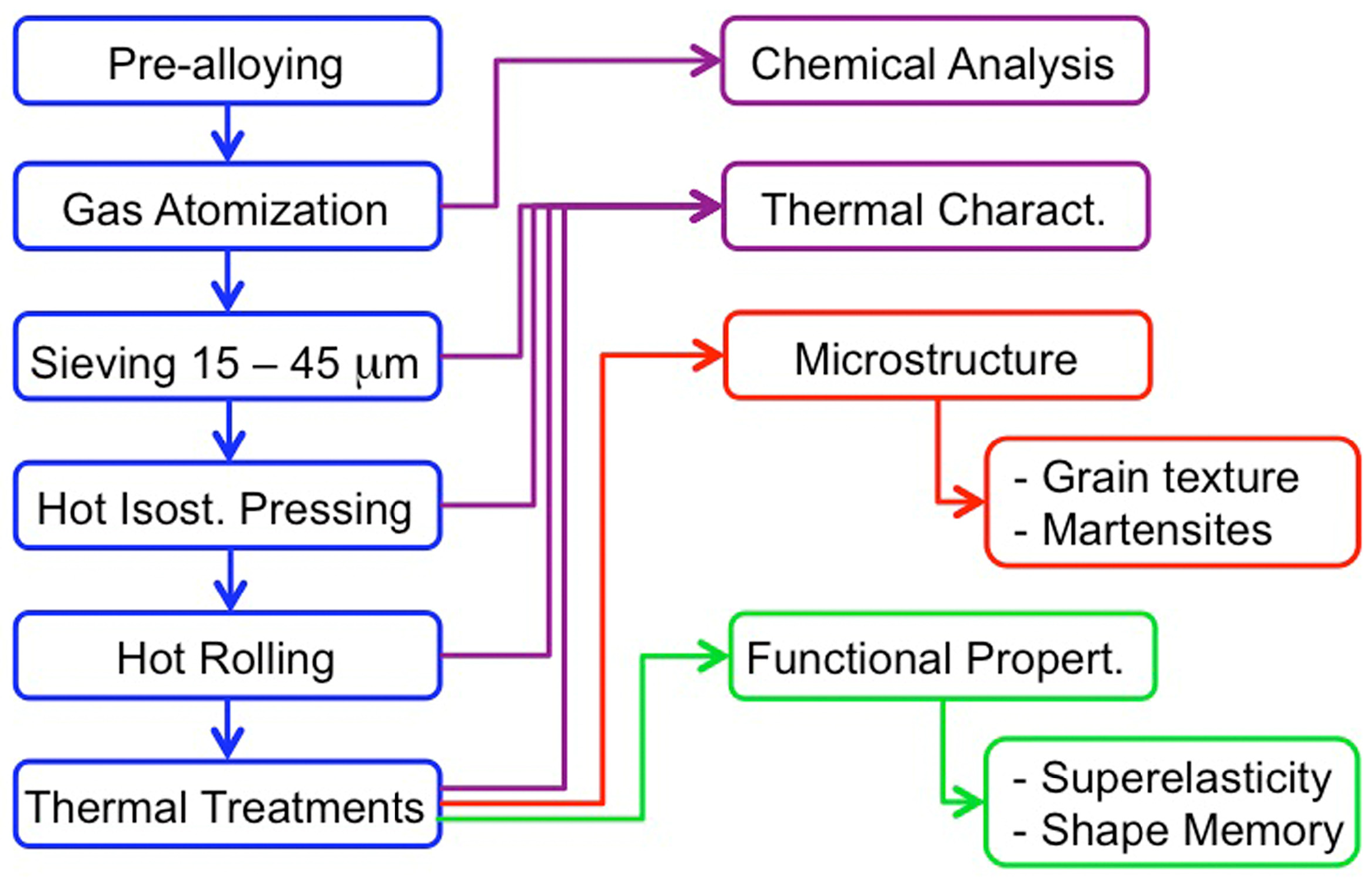

3.1. Experimental Methodology

3.2. Selected Alloy and Powder Preparation

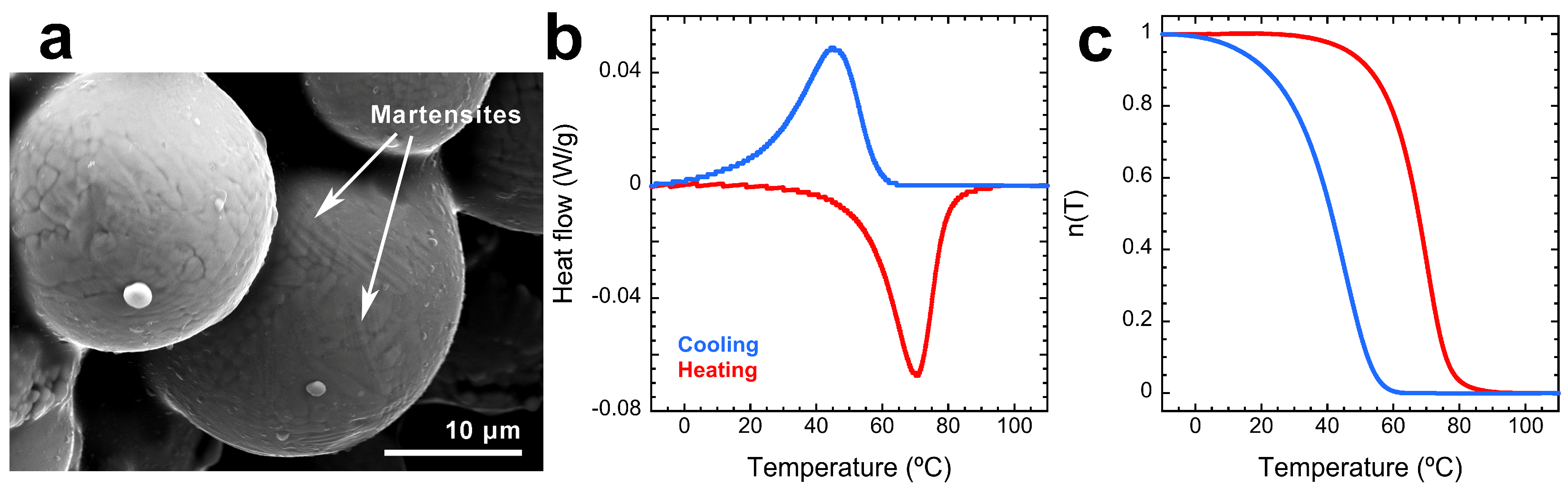

3.3. Chemical and Thermal Powders Characterization

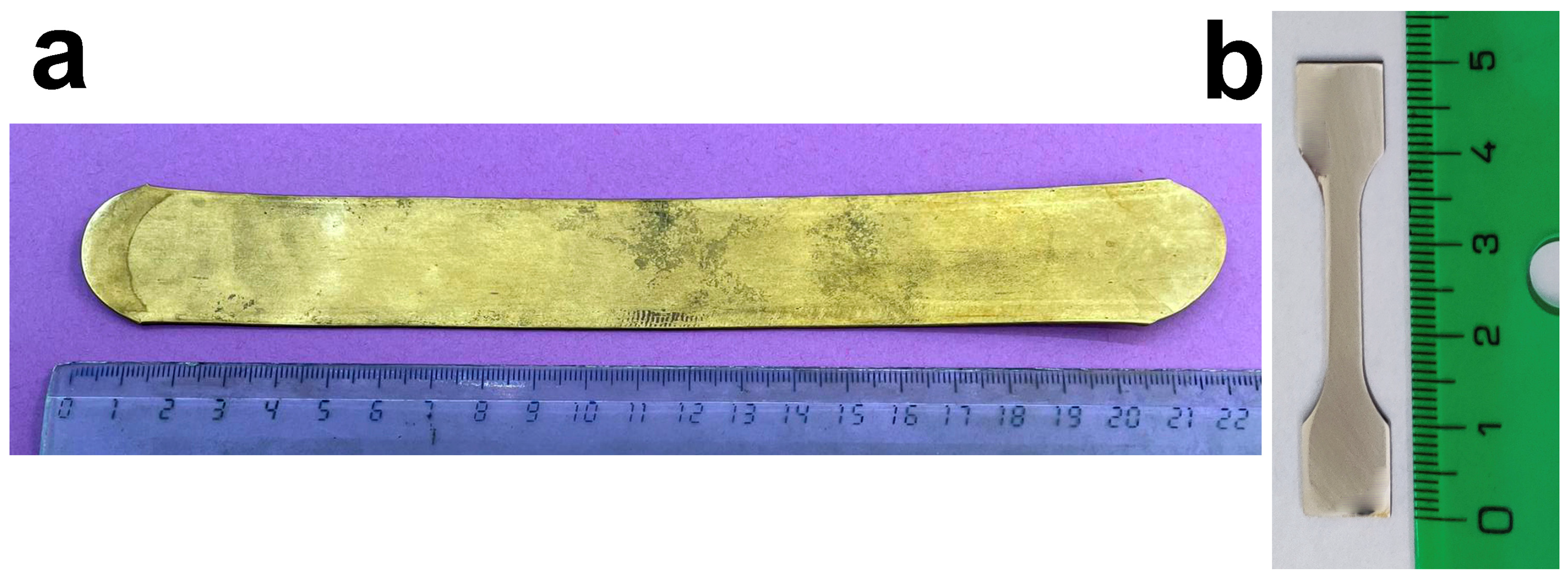

3.4. Fabrication of the Powder Metallurgy Samples

3.5. Thermal Treatments

3.6. Microstructural Characterization Techniques

3.7. Thermomechanical Tests

4. Results and Discussion

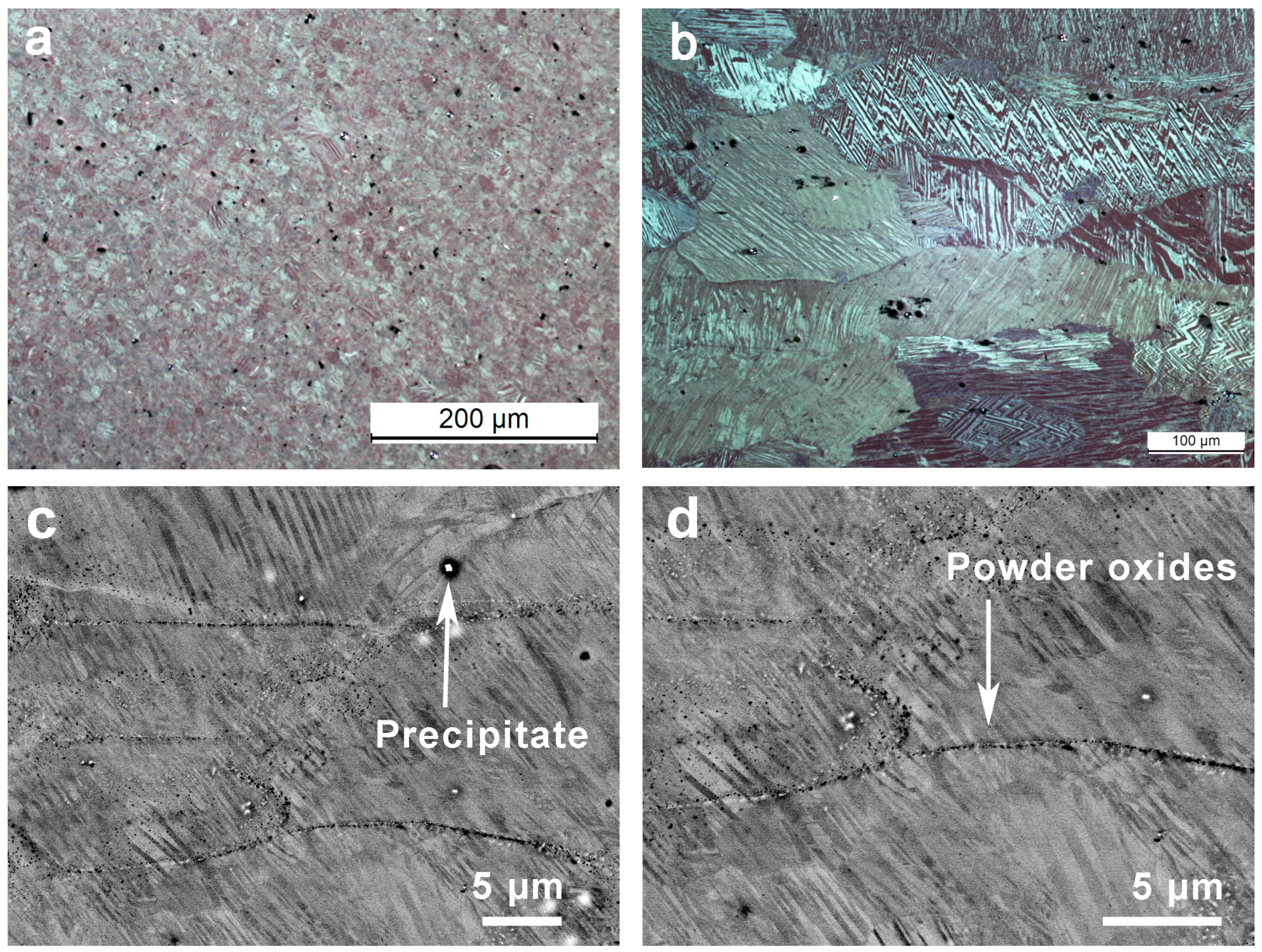

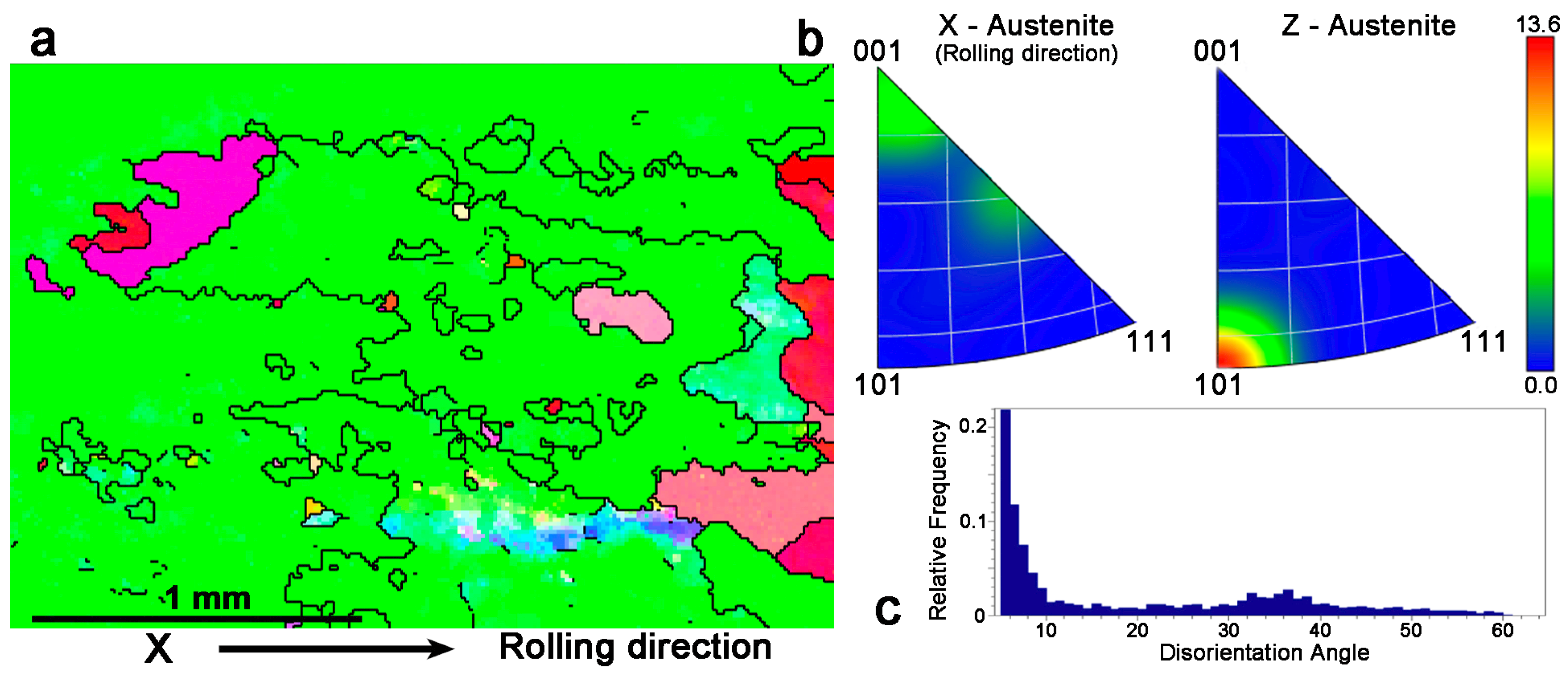

4.1. Microstructural Characterization

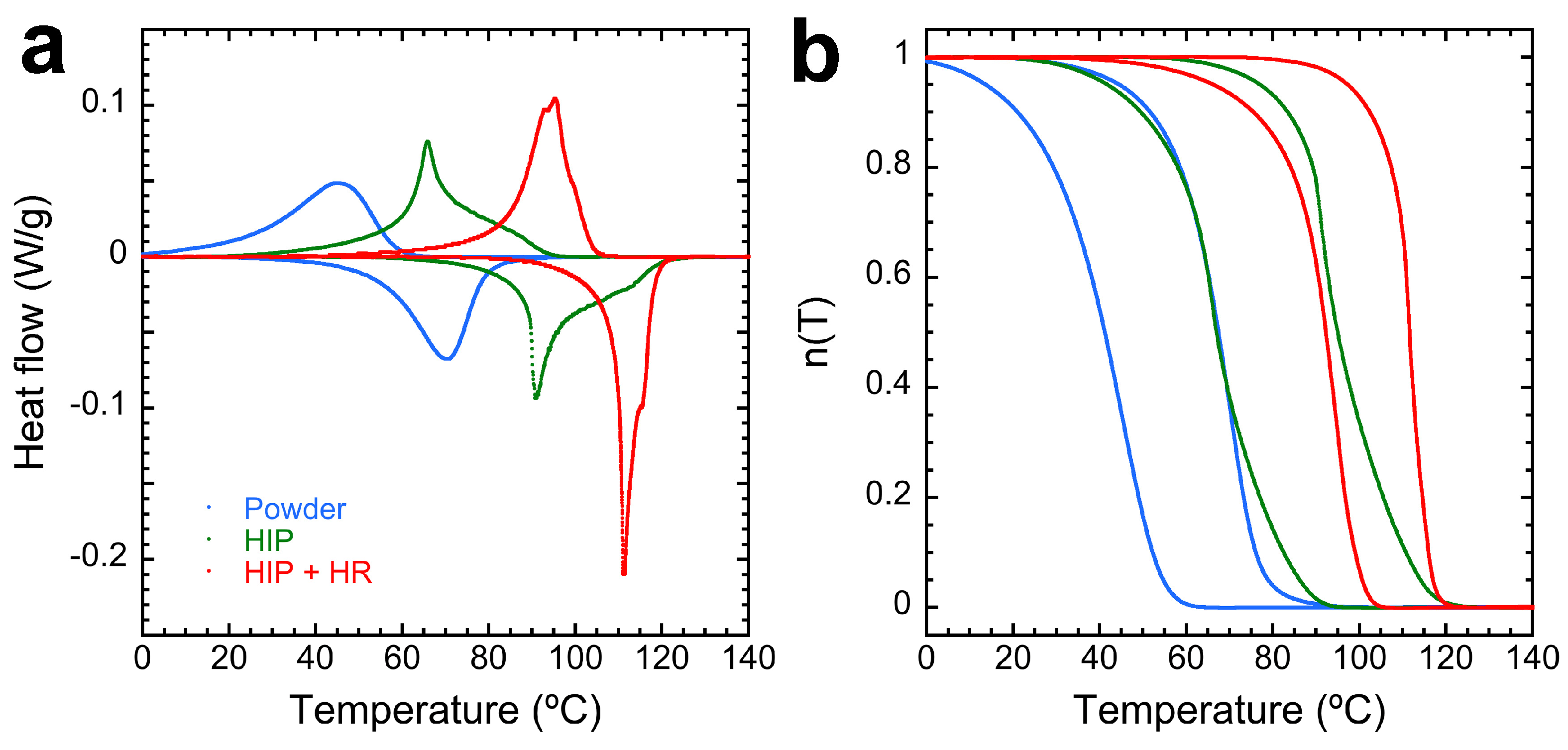

4.2. Thermal Characterization

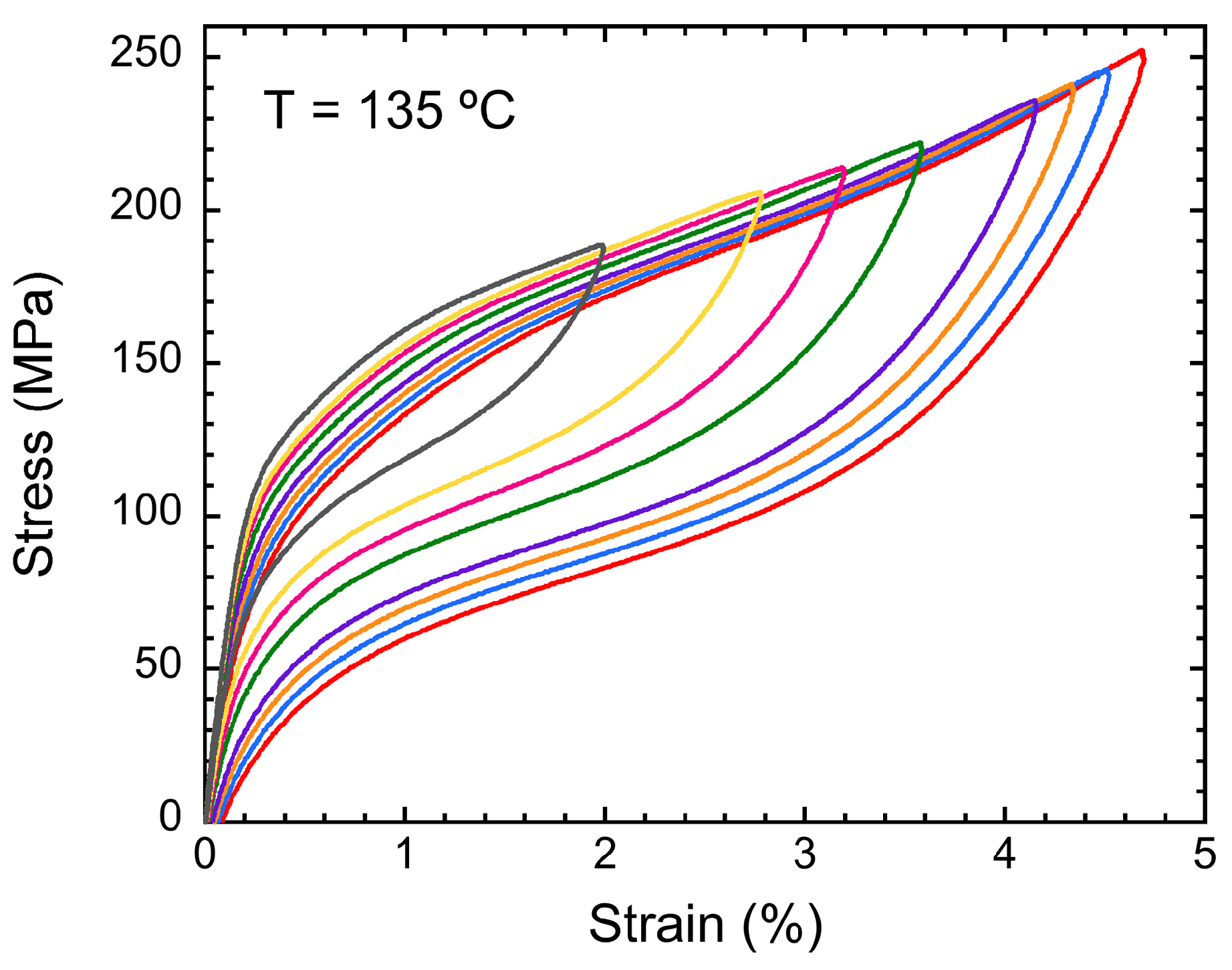

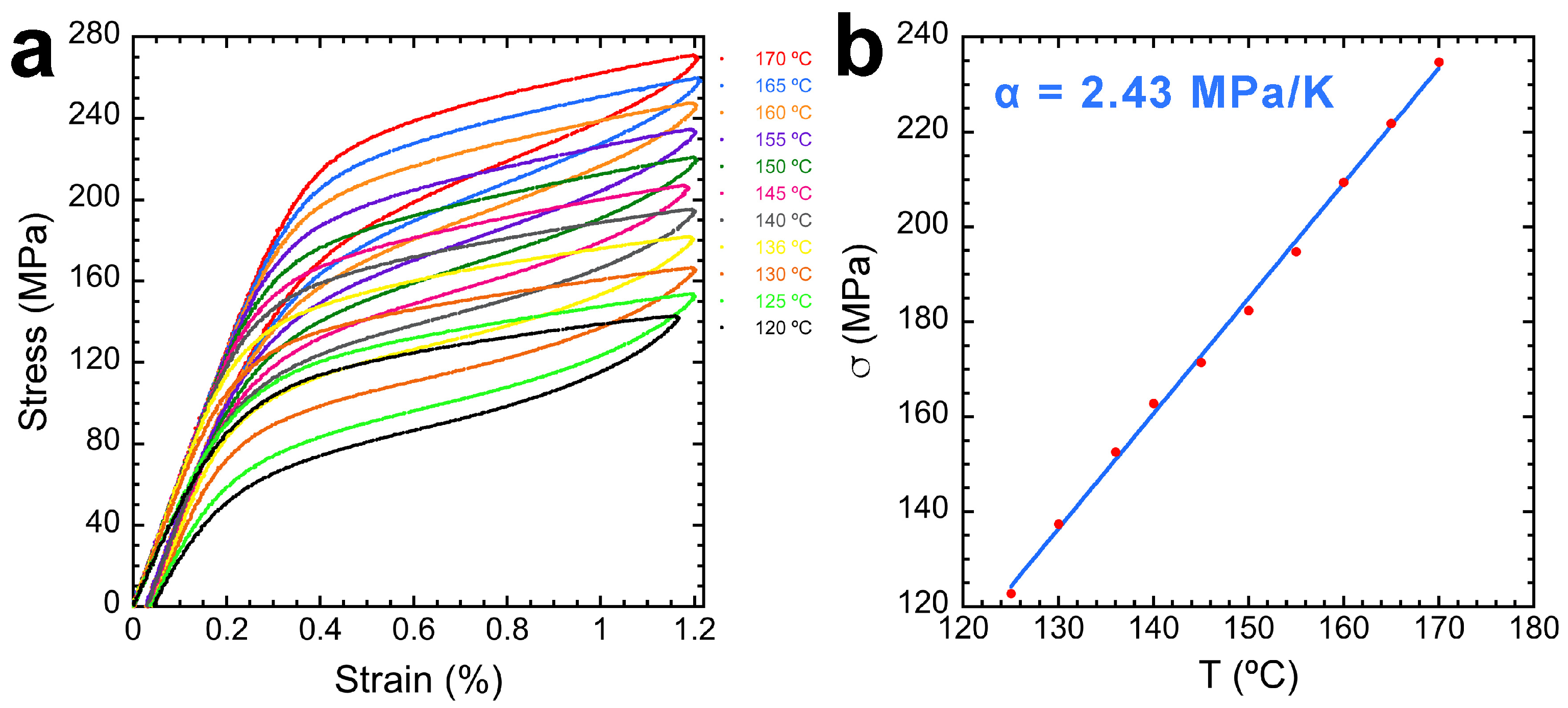

4.3. Functional Behavior

5. Conclusions

- The presented powder metallurgy processing route based on pre-alloying before gas atomization, compaction by hot isostatic pressing (HIP), and hot rolling through small rolling steps, was revealed as an optimal process to improve the functional behavior of the alloy.

- Once the functionalization thermal treatments were applied to the material, the processed Cu–Al–Ni samples exhibited a highly reproducible martensitic transformation with a low hysteresis associated with the β’3 martensite.

- Even though polycrystalline Cu–Al–Ni SMAs tend to be fragile, the presented powder metallurgy processing route allowed obtaining samples with a specific [001] texture that contributed to their good functional properties.

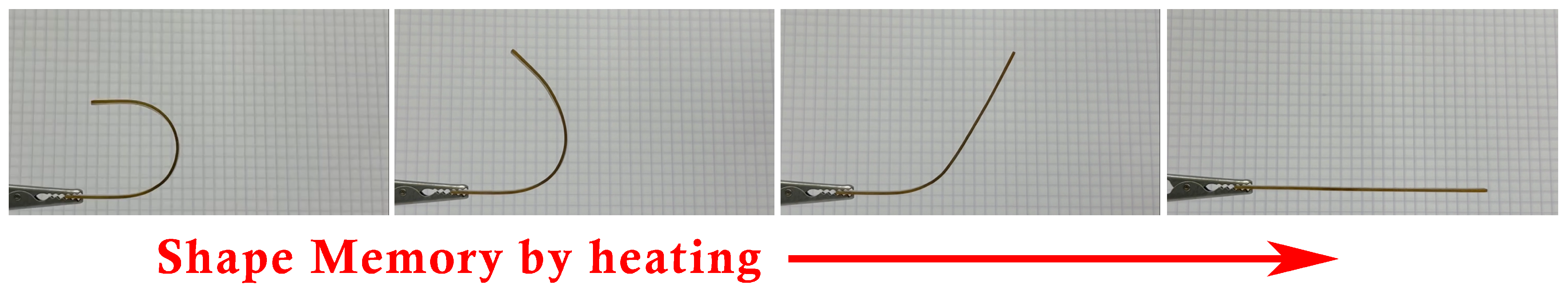

- An impressive recoverable 4.75% superelastic deformation can be achieved in tensile experiments, as well as a ±5% fully recoverable shape memory effect, which was tested in bending.

- These outstanding results in polycrystalline Cu–Al–Ni SMAs pave the road for further advanced works and applications of these types of polycrystalline materials.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Milewski, J.O. Additive Manufacturing of Metals; Springer: Cham, Switzerland, 2017; ISBN 978-3-319-58204-7. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998; ISBN 052144487X. [Google Scholar]

- Yamauchi, K.; Ohkata, I.; Tsuchiya, K.; Miyazaki, S. Shape Memory and Superelastic Alloys; Woodhead Publishing: Cambridge, UK, 2011; ISBN 9780081017012. [Google Scholar]

- Jani, J.M.; Leary, M.; Subic, A.M.; Gibson, A. A review of shape memory alloy research, applications and opportunities. Mater Design 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E. Shape Memory Alloys for Aerospace, Recent Developments, and New Applications: A Short Review. Materials 2020, 13, 1856. [Google Scholar] [CrossRef]

- Rodríguez-Aseguinolaza, J.; Ruiz-Larrea, I.; Nó, M.L.; López-Echarri, A.; San Juan, J. A new quantitative approach to the thermoelastic martensitic transformation: The density of elastic states. Acta Mater. 2008, 56, 6283–6290. [Google Scholar] [CrossRef]

- Ruiz-Larrea, I.; López-Echarri, A.; Gómez-Cortés, J.F.; Nó, M.L.; Brown, D.W.; Balogh, L.; Breczewski, T.; San Juan, J. Strain relaxation in Cu–Al–Ni shape memory alloys studied by in situ neutron diffraction experiments. J. Appl. Phys. 2019, 125, 082536. [Google Scholar] [CrossRef]

- Elahinia, M.; Moghaddam, N.S.; Andani, M.T.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Additive Manufacturing of Shape Memory Alloys. Shape Mem. Superelasticity 2018, 4, 309–312. [Google Scholar] [CrossRef]

- Xue, L.; Atli, K.C.; Zhang, C.; Hite, N.; Srivastava, A.; Leff, A.C.; Wilson, A.A.; Sharar, D.J.; Elvany, A.; Arroyave, R.; et al. Laser Powder Bed Fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity. Acta Mater. 2022, 229, 117781. [Google Scholar] [CrossRef]

- Ferretto, I.; Kim, D.; Della-Ventura, N.M.; Shahverdi, M.; Lee, W.; Leinenbach, C. Laser powder bed fusion of a Fe–Mn–Si shape memory alloy. Add. Manuf. 2021, 46, 102071. [Google Scholar] [CrossRef]

- Ferretto, I.; Borzi, À.; Kim, D.; Della Ventura, N.M.; Hosseini, E.; Lee, W.J.; Leinenbach, C. Control of microstructure and shape memory properties of a Fe-Mn-Si-based shape memory alloy during laser powder bed fusion. Add. Manuf. Lett. 2022, 3, 100091. [Google Scholar] [CrossRef]

- Del-Río, L.; Nó, M.L.; Gómez, R.; García-Sesma, L.; Urionabarrenetxea, E.; Ortega, P.; Mancisidor, A.M.; San Sebastian, M.; Burgos, N.; San Juan, J.M. Additive Manufacturing of Fe-Mn-Si-based Shape Memory Alloys: State of the Art, Challenges and Opportunities. Materials 2023, 16, 7517. [Google Scholar] [CrossRef] [PubMed]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef]

- Laitinen, V.; Sozinov, A.; Saren, A.; Salminen, A.; Ullakko, K. Laser powder bed fusion of Ni-Mn-Ga magnetic shape memory alloy. Addit. Manuf. 2019, 30, 100891. [Google Scholar] [CrossRef]

- Rittinghaus, S.-K.; Shokri, H.; Shkodich, N.; Bruder, E.; Farle, M.; Gökce, B. Comparative insights into microstructure and magnetism of Ni-Mn-Sn Heusler alloys manufactured by electron beam and laser beam powder bed fusion. Addit. Manuf. Let. 2023, 7, 100159. [Google Scholar] [CrossRef]

- Alagha, A.N.; Hussain, S.; Zaki, W. Additive manufacturing of shape memory alloys: A review with emphasis on powder bed systems. Mater. Des. 2021, 204, 109654. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I.; Noebe, R.D. High temperature shape memory alloys. Inter. Mater. Rev. 2010, 55, 257–315. [Google Scholar] [CrossRef]

- López-Ferreño, I.; Gómez-Cortés, J.F.; Breczewski, T.; Ruiz-Larrea, I.; Nó, M.L.; San Juan, J.M. High-temperature shape memory alloys based on the Cu–Al–Ni system: Design and thermomechanical characterization. J. Mater. Res. Technol. 2020, 9, 9972–9984. [Google Scholar] [CrossRef]

- San Juan, J.; Nó, M.L.; Schuh, C.A. Thermomechanical behavior at the nanoscale and size effects in shape memory alloys. J. Mater. Res. 2011, 26, 2461–2469. [Google Scholar] [CrossRef]

- Gómez-Cortés, J.F.; Nó, M.L.; López-Ferreño, I.; Hernandez-Saz, J.; Molina, S.I.; Chuvilin, A.; San Juan, J.M. Size effect and scaling power-law for superelasticity in shape-memory alloys at the nanoscale. Nat. Nanotechnol. 2017, 12, 790–796. [Google Scholar] [CrossRef] [PubMed]

- Karami, M.; Chen, X. Nanomechanics of shape memory alloys. Mater. Today Adv. 2021, 10, 100141. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Biffi, C.A.; Lemke, J.N.; Bregoli, C.; Fiocchi, J.; Mohajerani, S.; Tuissi, A.; Elahinia, M. Additive manufacturing of architected shape memory alloys: A review. Virtual Phys. Prot. 2024, 19, e2414395. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, X.; Sun, H.; Shao, Z.; Fang, Y.; Shu, R. Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al–based alloys: A review. Nanotechnol. Rev. 2021, 10, 1560–1591. [Google Scholar] [CrossRef]

- Gargarella, P.; Kiminami, C.S.; Mazzer, E.M.; Cava, R.D.; Basilio, L.A.; Bolfarini, C.; Botta, W.J.; Eckert, J.; Gustmann, T.; Pauly, S. Phase Formation, Thermal Stability and Mechanical Properties of a Cu–Al–Ni-Mn Shape Memory Alloy Prepared by Selective Laser Melting. Mater. Res. 2015, 18, 35–38. [Google Scholar] [CrossRef]

- Gustmann, T.; Neves, A.; Kühn, U.; Gargarella, P.; Kiminami, C.S.; Bolfarini, C.; Eckert, J.; Pauly, S. Influence of processing parameters on the fabrication of a Cu–Al–Ni-Mn shape-memory alloy by selective laser melting. Addit. Manuf. 2016, 11, 23–31. [Google Scholar] [CrossRef]

- Gustmann, T.; dos Santos, J.M.; Gargarella, P.; Kühn, U.; Van Humbeeck, J.; Pauly, S. Properties of Cu-Based Shape-Memory Alloys Prepared by Selective Laser Melting. Shape Mem. Superelasticity 2017, 3, 24–36. [Google Scholar] [CrossRef]

- Gustmann, T.; Schwab, H.; Kühn, U.; Pauly, S. Selective laser remelting of an additively manufactured Cu–Al–Ni-Mn shape-memory alloy. Mater. Des. 2018, 153, 129–138. [Google Scholar] [CrossRef]

- Tian, J.; Zhu, W.; Wei, Q.; Wen, S.; Li, S.; Song, B.; Shi, Y. Process optimization, microstructures and mechanical properties of a Cu-based shape memory alloy fabricated by selective laser melting. J. Alloys Comp. 2019, 785, 754–764. [Google Scholar] [CrossRef]

- Babacan, N.; Pauly, S.; Gustmann, T. Laser powder bed fusion of a superelastic Cu-Al-Mn shape memory alloy. Mater. Des. 2021, 203, 109625. [Google Scholar] [CrossRef]

- Pérez-Cerrato, M.; Fraile, I.; Gómez-Cortés, J.F.; Urionabarrenetxea, E.; Ruiz-Larrea, I.; Gonzalez, I.; Nó, M.L.; Burgos, N.; San Juan, J.M. Designing for Shape Memory in Additive Manufacturing of Cu–Al–Ni Shape Memory Alloy Processed by Laser Powder Bed Fusion. Materials 2022, 15, 6284. [Google Scholar] [CrossRef] [PubMed]

- Babacan, N.; Pilz, S.; Pauly, S.; Hufenbach, J.; Gustmann, T. Tailoring the superelastic properties of an additively manufactured Cu–Al–Mn shape memory alloy via adjusting the scanning strategy. Mater. Sci. Eng. A 2023, 862, 144412. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, L.; Zhao, L.; Lin, D.; Liu, M.; Qi, X.; Han, Y. Process-microstructure-properties of CuAlNi shape memory alloys fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2023, 152, 1–15. [Google Scholar] [CrossRef]

- Gao, Y.; Jian, Z.; Wang, B.; Zhang, Z.; Jian, J.; Gao, Q. 4D forming shape memory component of Cu-13Al-5Fe alloy based on laser powder bed fusion of metal powders. Mater. Sci. Eng. A 2023, 866, 144693. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, L.; Zhao, L.; Lin, D.; Liu, M.; Chen, W.; Han, Y. Deformation mechanism of Cu–Al–Ni shape memory alloys fabricated via laser powder bed fusion: Tension-compression asymmetry. J. Mater. Sci. Technol. 2023, 167, 14–26. [Google Scholar] [CrossRef]

- Babacan, N.; Pilz, S.; Hufenbach, J.; Gustmann, T. Effects of Remelting on the Properties of a superelastic Cu-Al-Mn Shape Memory Alloy Fabricated by Laser Powder Bed Fusion. Shape Mem. Superelasticity 2023, 9, 447–459. [Google Scholar] [CrossRef]

- Dang, M.; Xiang, H.; Li, J.; Cai, C.; Wei, Q. Laser powder bed fusion of full martensite Cu-Al-Mn-Ti alloy with good superelasticity and shape memory effect. Mater. Sci. Eng. A 2023, 884, 145475. [Google Scholar] [CrossRef]

- Gao, Y.; Jian, Z.; Wang, B. Effect of laser power on the microstructure, shape memory effect and mechanical properties of Cu-13Al-5Fe high temperature shape memory alloy by laser powder bed fusion. Appl. Phys. A Mater. Sci. Proc. 2023, 129, 836. [Google Scholar] [CrossRef]

- Xu, D.; Wang, H.; Yuan, X.; Sun, H.; Feng, J. Comparison of shape memory properties between Cu-12.5Al-3Mn and Cu-12.5Al-3Mn-1Ni produced by additive manufacturing technology. J. Mater. Res. Technol. 2023, 26, 4070–4077. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Sáez, R.B.; Bocanegra, E.H.; Nó, M.L.; San Juan, J. Dependence of the martensitic transformation characteristics on concentration on Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 380–384. [Google Scholar] [CrossRef]

- Lawley, A. Atomization: The Production of Metal Powders; MPIF: Princeton, NJ, USA, 1992. [Google Scholar]

- Yule, A.J.; Dunkey, J.J. Atomization of Melts for Powder Production and Spray Deposition; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

- German, R.M. Powder Metallurgy and Particulate Materials Processing; MPIF: Princeton, NJ, USA, 2005. [Google Scholar]

- Mehta, A.; Singh, G.; Vasudev, H. Processing of shape memory alloys research, applications and opportunities: A review. Phys. Scr. 2024, 99, 062006. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.C.; Moore, J.J. SHS synthesized Ni-Ti based shape memory alloys for both low- and high-temperature applications. J. Mater. Sci. Lett. 1989, 8, 1182–1184. [Google Scholar] [CrossRef]

- Salvetr, P.; Kubatik, T.F.; Pignol, D.; Novak, P. Fabrication of Ni-Ti Alloy by Self-Propagating High-Temperature Synthesis and Spark Plasma Sintering Technique. Met. Mater. Trans. B 2017, 48, 772–778. [Google Scholar] [CrossRef]

- Soba, R.; Tanabe, Y.; Yonezawa, T.; Umeda, J.; Kondoh, K. Microstructure and Mechanical Properties of Shape Memory Alloys Using Pre-Mixed TiNi Powders with TiO2 Particles. Mater. Trans. 2018, 59, 117–122. [Google Scholar] [CrossRef]

- Soba, R.; Tanabe, Y.; Yonezawa, T.; Umeda, J.; Kondoh, K. Effect of Shape Memory Heat Treatment on Microstructure and Mechanical Properties of Powder Metallurgy TiNi Shape Memory Alloy. Mater. Trans. 2018, 59, 805–810. [Google Scholar] [CrossRef]

- Monastyrsky, G.E.; Odnosum, V.; Van Humbeeck, J.; Kolomytsev, V.I.; Koval, Y.N. Powder metallurgical processing of Ni-Ti-Zr alloys undergoing martensitic transformation: Part I. Intermetallics 2002, 10, 95–103. [Google Scholar] [CrossRef]

- Goryczka, T.; Van Humbeeck, J. NiTiCu shape memory alloy produced by powder technology. J. Alloys Comp. 2008, 456, 194–200. [Google Scholar] [CrossRef]

- Parida, J.; Mishra, S.C.; Marupalli, B.C.G.; Behera, A. Fabrication of nickel-titanium-iron shape memory alloys by powder metallurgy route and analyses of their physical and mechanical behavior. Powder Metall. 2023, 66, 557–570. [Google Scholar] [CrossRef]

- McNeese, M.D.; Lagoudas, D.; Pollock, T.C. Processing from elemental powders by hot isostatic pressing. Mater. Sci. Eng. A 2000, 280, 334–348. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P.; Stöver, D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. A 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Krone, L.; Schüller, E.; Bram, M.; Hamed, O.; Buchkremer, H.P.; Stöver, D. Mechanical behaviour of NiTi parts prepared by poder metallurgical methods. Mater. Sci. Eng. A 2004, 378, 185–190. [Google Scholar] [CrossRef]

- Morris, D.G.; Morris, M.A. NiTi intermetallic by mixing, milling and interdiffusion elemental components. Mater. Sci. Eng. A 1989, 110, 139–149. [Google Scholar] [CrossRef]

- Terayama, A.; Nagai, K.; Kyogoku, H. Fabrication of Ti-Ni-Zr shape memory alloy by P/M process. Mater. Trans. 2009, 50, 2446–2450. [Google Scholar] [CrossRef]

- Terayama, A.; Kyogoku, H. Shape memory characteristics of the P/M-processed Ti-Ni-Cu alloys. Mater. Sci. Eng. A 2010, 527, 5484–5491. [Google Scholar] [CrossRef]

- Valeanu, M.; Lucaci, M.; Crisan, A.D.; Sofronie, M.; Leonat, L.; Kuncser, V. Martensitic transformation of Ti50Ni30Cu20 alloy prepared by poder metallurgy. J. Alloys Comp. 2011, 509, 4495–4498. [Google Scholar] [CrossRef]

- Novák, P.; Moravec, H.; Salvetr, P.; Prusa, F.; Drahokoupil, J.; Kopecek, J.; Karlík, M.; Kubatík, T.F. Preparation of nitinol by non-conventional powder metallurgy techniques. Mater. Sci. Technol. 2016, 31, 1886–1893. [Google Scholar] [CrossRef]

- Goryczka, T.; Salwa, P.; Zubko, M. High-Energy Ball Milling Conditions in Formation of NiTiCu Shape Memory Alloys. Microsc. Microanal. 2022, 28, 939–945. [Google Scholar] [CrossRef]

- Parida, J.; Mishra, S.C.; Behera, A. Microstructure and Mechanical Properties of Ti50Ni(50−X)FeX Alloys Fabricated by Powder Metallurgy Process. Metall. Mater. Trans. A 2023, 54, 2585–2604. [Google Scholar] [CrossRef]

- Parida, J.; Mishra, S.C.; Behera, A. Synthesis and Characterization of Ti50Ni(50−X)FeX Alloy Produced by Mechanical Alloying and Pressure-Less Sintering. Metals Mater. Int. 2023, 29, 1145–1164. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.P.; Du, Z.; Chandra, S.; Sun, Z.; Lim, C.W.J.; Tor, S.B.; Lim, C.S.; Wong, C.H. Additive manufacturing of NiTi shape memory alloys using pre-mixed powders. J. Mater. Process. Technol. 2019, 271, 152–161. [Google Scholar] [CrossRef]

- Chmielewska, A.; Wysocki, B.; Kwasniak, P.; Kruszewski, M.J.; Michalski, B.; Zielinska, A.; Adamczyk-Cieslak, B.; Krawczybska, A.; Buhagiar, J.; Swieszkowski, W. Heat Treatment of NiTi Alloys Fabricated Using Laser Powder Bed Fusion (LPBF) from Elementally Blended Powders. Materials 2022, 15, 3304. [Google Scholar] [CrossRef]

- Wei, Z.G.; Tang, C.Y.; Lee, W.B.; Cui, L.S.; Yang, D.Z. Preparation of Smart composite material with TiNiCu shape memory particulates in an aluminium matrix. Mater. Let. 1997, 32, 313–317. [Google Scholar] [CrossRef]

- Mentz, J.; Bram, M.; Buchkremer, H.P.; Stöver, D. Influence of heat treatments on the mechanical properties of high-quality Ni-rich NiTi produced by powder metallurgical methods. Mater. Sci. Eng. A 2008, 481–482, 630–634. [Google Scholar] [CrossRef]

- Mentz, J.; Frenzel, J.; Wagner, M.F.X.; Neuking, K.; Eggeler, G.; Buchkremer, H.P.; Stöver, D. Powder metallurgical processing of NiTi shape memory alloys with elevated transformation temperatures. Mater. Sci. Eng. A 2008, 491, 270–278. [Google Scholar] [CrossRef]

- Kim, Y.W.; Chung, Y.S.; Choi, E.; Nam, T.H. Microstructure and shape memory characteristics of Powder–Metallurgical-Processing Ti-Ni-Cu Alloys. Metall. Mater. Trans. A 2012, 43, 2932–2938. [Google Scholar] [CrossRef]

- Zheng, H.X.; Mentz, J.; Bram, M.; Buchkremer, H.P.; Stöver, D. Powder metallurgical production of TiNiNb and TiNiCu shape memory alloys by combination of pre-alloyed and elemental powders. J. Alloys Comp. 2008, 463, 250–256. [Google Scholar] [CrossRef]

- Bram, M.; Bitzer, M.; Buchkremer, H.P.; Stöver, D. Reproducibility Study of NiTi Parts Made by Metal Injection Molding. J. Mater. Eng. Perform. 2012, 21, 2701–2712. [Google Scholar] [CrossRef]

- Parvizi, S.; Hashemi, S.M.; Asgarinia, F.; Nematollahi, M.; Elahinia, M. Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review. Prog. Mater. Sci. 2021, 117, 100739. [Google Scholar] [CrossRef]

- Horikawa, H.; Ichinose, S.; Morii, K.; Miyazaki, S.; Otsuka, K. Orientation dependence of β1 → β1′ stress-induced martensitic transformation in Cu–Al–Ni alloy. Metall. Trans. A 1988, 19, 915–923. [Google Scholar] [CrossRef]

- Mañosa, L.; Jurado, M.; Planes, A.; Zarestky, J.; Lograsso, T.; Stassis, C. Elastic constants of bcc Cu–Al–Ni alloys. Phys. Rev. B 1994, 49, 9969–9972. [Google Scholar] [CrossRef]

- Pérez-Landazabal, J.I.; Recarte, V.; Ezpeleta, J.M.; Rodríguez, P.P.; San Juan, J.; Nó, M.L. Vibrational behavior of the β phase near martensitic transformation in Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 2004, 378, 243–247. [Google Scholar] [CrossRef]

- Graczykowski, B.; Mroz, B.; Mielcarek, S.; Breczewski, T.; Nó, M.L.; San Juan, J. Surface acoustic waves and elastic constants of Cu14%Al4%Ni shape memory alloys studied by Brillouin light scattering. J. Phys. D Appl. Phys. 2011, 44, 455307. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kawai, T.; Otsuka, K. On the origin of intergranular fracture in β phase shape memory alloys. Scripta Metall. 1982, 16, 431–436. [Google Scholar] [CrossRef]

- Otsuka, K.; Sakamoto, H.; Shimizu, K. Successive stress-induced martensitic transformations and associated transformation pseudoelasticity in Cu–Al–Ni alloys. Acta Metall. 1979, 27, 585–601. [Google Scholar] [CrossRef]

- Novák, V.; Sittner, P.; Zárubová, N. Anisotropy of transformation characteristics of Cu-base shape memory alloys. Mater. Sci. Eng. A 1997, 234–236, 414–417. [Google Scholar] [CrossRef]

- Sittner, P.; Novák, V. Anisotropy of martensitic transformations in modeling of shape memory alloy polycrystals. Int. J. Plast. 2000, 16, 1243–1268. [Google Scholar] [CrossRef]

- Gastien, R.; Corbellani, C.E.; Alvarez-Villar, H.N.; Sade, M.; Lovey, F.C. Pseudoelastic cycling in Cu–14.3Al–4.1Ni (wt.%) single crystals. Mater. Sci. Eng. A 2003, 349, 191–196. [Google Scholar] [CrossRef]

- Ibarra, A.; San Juan, J.; Bocanegra, E.H.; Nó, M.L. Evolution of microstructure and thermomechanical properties during superelastic compression cycling in Cu–Al–Ni single crystals. Acta Mater. 2007, 55, 4789–4798. [Google Scholar] [CrossRef]

- Nó, M.L.; Ibarra, A.; Caillard, D.; San Juan, J. Quantitative analysis of stress-induced martensites by in-situ transmission electron microscopy superelastic tests in Cu–Al–Ni shape memory alloys. Acta Mater. 2010, 58, 6181–6193. [Google Scholar] [CrossRef]

- Tadaki, T. Cu-Based Shape Memory Alloys; Cambridge University Press: Cambridge, UK, 1998; Chapter 4; pp. 97–116. [Google Scholar]

- Sure, G.N.; Brown, L.C. The mechanical properties of grain refined β-CuAlNi strain-memory alloys. Metall. Trans. A 1984, 15, 1613–1621. [Google Scholar] [CrossRef]

- Sugimoto, K.; Kamei, K.; Matsumoto, H.; Somatsu, S.; Akamatsu, K.; Sugimoto, T. Grain refinement and the related phenomena in quaternary Cu–Al–Ni-Ti shape memory alloys. J. Phys. Colloq. 1982, C4, 761–766. [Google Scholar] [CrossRef]

- Lee, J.S.; Wayman, C.M. Grain refinement of a Cu–Al–Ni shape memory alloy by Ti and Zr additions. Trans. Jpn. Inst. Met. 1986, 27, 584–591. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseuoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Lu, X.; Chen, F.; Li, W.; Zheng, Y. Effect of Ce addition on the microstructure and damping properties of Cu-Al-Mn shape memory alloys. J. Alloys Comp. 2009, 480, 608–611. [Google Scholar] [CrossRef]

- Zhang, X.; Sui, J.; Liu, Q.; Cai, W. Effects of Gd addition on the microstructure, mechanical properties and shape memory effect of polycrystalline Cu–Al–Ni shape memory alloy. Mater. Lett. 2016, 180, 223–227. [Google Scholar] [CrossRef]

- Tang, S.M.; Chung, C.Y.; Liu, W.G. Preparation of Cu–Al–Ni-based Shape memory Alloys by Mechanical Alloying and Powder Metallurgy Method. J. Mater. Process. Technol. 1997, 63, 307–312. [Google Scholar] [CrossRef]

- Xiao, Z.; Fang, M.; Li, Z.; Xiao, T.; Lei, Q. Structure and properties of ductile CuAlMn shape memory alloy synthesized by mechanical alloying and powder metallurgy. Mater. Des. 2014, 58, 451–456. [Google Scholar] [CrossRef]

- Shafeeq, M.; Gupta, G.K.; Hirshikesh; Malik, M.M.; Modi, O.P. Effect of milling parameters on processing, microstructure and properties of Cu–Al–Ni–Ti shape memory alloys. Powder Metall. 2015, 58, 265–272. [Google Scholar] [CrossRef]

- Saud, S.N.; Hamzah, E.; Abubakar, T.; Bakhsheshi-Rad, H.R.; Mohammed, M.N. Influence of Tin additions on the phase transformation characteristics of mechanical alloyed Cu–Al–Ni shape memory alloy. Metall. Mater. Trans. A 2016, 47, 5242–5255. [Google Scholar] [CrossRef]

- Deng, Z.; Yin, H.; Zhang, C.; Zhang, G.; Li, W.; Zhang, T.; Zhang, R.; Jiang, X.; Qu, X. Microstructure and mechanical properties of Cu-12Al-xNi alloy prepared using powder metallurgy. Mater. Sci. Eng. A 2019, 759, 241–251. [Google Scholar] [CrossRef]

- Gohar, G.A.; Manzoor, T.; Ahmad, A.; Raza, H.; Farooq, A.; Karim, I.; Iftikhar, W.; Umar, M.; Asad, F. Synthesis and investigate the properties of Cu–Al–Ni alloys with Ag addition using powder metallurgy technique. J. Alloys Comp. 2020, 817, 153281. [Google Scholar] [CrossRef]

- Gómez, A.P.; Urretavizcaya, G.; Baruj, A.L.; Malachevsky, M.T. Consolidation and properties of porous Cu–Al–Ni shape memory alloys manufactured by powder metallurgy. Powder Metall. 2023, 66, 548–556. [Google Scholar] [CrossRef]

- Shafeeq, M.M.; Hirshikesh; Gupta, G.K.; Mondal, D.P. Influence of Mn on the Mechanical and Shape memory Transformation Behaviors of Powder Metallurgy Processed Cu–Al–Ni SMAs. Met. Mater. Int. 2024, 30, 211–219. [Google Scholar] [CrossRef]

- Li, Z.; Pan, Z.Y.; Tang, N.; Jiang, Y.B.; Liu, N.; Fang, M.; Zheng, F. Cu–Al–Ni-Mn shape memory alloys processed by mechanical alloying and powder metallurgy. Mater. Sci. Eng. A 2006, 417, 225–229. [Google Scholar] [CrossRef]

- Xiao, Z.; Li, Z.; Fang, M.; Xiong, S.; Sheng, X.; Zhou, M. Effect of processing of mechanical alloying and powder metallurgy on microstructure and properties of Cu–Al–Ni–Mn alloy. Mater. Sci. Eng. A 2008, 488, 266–272. [Google Scholar] [CrossRef]

- Sharma, M.; Vajpai, S.K.; Dube, R.K. Processing and characterization of Cu–Al–Ni shape memory alloy strips prepared from elemental powder via a novel powder metallurgy route. Metall. Mater. Trans. A 2010, 41, 2905–2913. [Google Scholar] [CrossRef]

- Sharma, M.; Vajpai, S.K.; Dube, R.K. Synthesis and properties of Cu–Al–Ni shape memory alloy strips prepared via hot densification rolling of powder preforms. Powder Metall. 2011, 54, 620–627. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Parvin, N.; Kenevisi, M.S.; Naeimi, M.; Khaniki, H.E. A study on the microstructure and properties of Cu-based shape memory alloy produced by hot extrusion of mechanically alloyed powders. Mater. Sci. Eng. A 2012, 556, 658–663. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Dube, R.K.; Chatterjee, P.; Sangal, S. A novel Powder Metallurgy processing Approach to prepare Fine-Grained Cu–Al–Ni Shape Memory Alloy Strips from Elemental Powders. Metall. Mater. Trans. A 2012, 43, 2484–2499. [Google Scholar] [CrossRef]

- Rezvani, M.R.; Shokuhfar, A. Synthesis and characterization of nano structures Cu-Al-Mn shape memory alloy by mechanical alloying. Mater. Sci. Eng. A 2012, 532, 282–286. [Google Scholar] [CrossRef]

- Yavuzer, B.; Bicakci, U.; Simsek, D.; Ozyurek, D. Effect of alloying time and heat treatment on microstructure and tribological properties of mechanical alloyed Cu–Al–Ni shape memory alloy. J. Mater. Eng. Perform. 2024, 33, 11176–11187. [Google Scholar] [CrossRef]

- Thiruppathi, K.; Raj-Mohan, R.; Raghuraman, S. Study of the densification behaviour of copper with aluminum & nickel powders though spark plasma sintering. J. Mech. Sci. Technol. 2020, 34, 3233–3237. [Google Scholar] [CrossRef]

- Duerig, T.W.; Albrecht, J.; Gessinger, G.H. A Shape-Memory Alloy for High-Temperature Applications. J. Metals 1982, 34, 14–20. [Google Scholar] [CrossRef]

- Duerig, T.W.; Albrecht, J. Reverse springback: A curious manifestation of thermoelasticity. Acta Metall. 1983, 31, 1013–1018. [Google Scholar] [CrossRef]

- Jean, R.D.; Wu, T.Y.; Leu, S.S. The effect of powder metallurgy on Cu–Al–Ni shape memory alloys. Scripta Metall. Mater. 1991, 25, 883–888. [Google Scholar] [CrossRef]

- San Juan, J.; Pérez-Sáez, R.B.; Recarte, V.; Nó, M.L.; Caruana, G.; Lieblich, M.; Ruano, O. Martensitic Transformation in Cu–Al–Ni Shape Memory Alloys Processed by Powder Metallurgy. J. Phys. IV 1995, 5, 919–924. [Google Scholar] [CrossRef]

- Pérez-Sáez, R.B.; Recarte, V.; Nó, M.L.; Ruano, O.A.; San Juan, J. Advanced Shape Memory Alloys Processed by Powder Metallurgy. Adv. Eng. Mater. 2000, 2, 49–53. [Google Scholar] [CrossRef]

- Ibarra, A.; Rodriguez, P.P.; Recarte, V.; Pérez-landazabal, J.I.; Nó, M.L.; San Juan, J. Internal friction behavior during martensitic transformation in shape memory alloys processed by poder metallurgy. Mater. Sci. Eng. A 2004, 370, 492–496. [Google Scholar] [CrossRef]

- Rodriguez, P.P.; Ibarra, A.; Iza-Mendia, A.; Recarte, V.; Pérez-Landazabal, J.I.; San Juan, J.; Nó, M.L. Influence of thermomechanical processing on the microstructure of Cu-based shape memory alloys produced by powder metallurgy. Mater. Sci. Eng. A 2004, 378, 263–268. [Google Scholar] [CrossRef]

- Ibarra, A.; San Juan, J.M.; Bocanegra, E.H.; Nó, M.L. Thermo-mechanical characterization of Cu–Al–Ni shape memory alloys elaborated by powder metallurgy. Mater. Sci. Eng. A 2006, 438–440, 782–786. [Google Scholar] [CrossRef]

- Gera, D.B.; Soyama, J.; Cava, R.D.; Spinelli, J.E.; Kiminami, C.S. The influence of Sintering Parameters in the Microstructure and Mechanical Properties of a Cu–Al–Ni-Mn-Zr Shape Memory Alloy. Adv. Eng. Mater. 2018, 20, 1800372. [Google Scholar] [CrossRef]

- Urionabarrenetxea, E.; Avello, A.; Rivas, A.; Martín, J.M. Experimental study of the influence of operational and geometric variables on the powders produced by close-coupled gas atomization. Mater. Des. 2021, 199, 109441. [Google Scholar] [CrossRef]

- Sun, Y.S.; Lorimer, G.W.; Ridley, N. Microstructure and its development in Cu–Al–Ni alloys. Metall. Trans. A 1990, 21, 578–588. [Google Scholar] [CrossRef]

- Recarte, V.; Hurtado, I.; Herreros, J.; Nó, M.L.; San Juan, J. Precipitation of the stable phases in Cu–Al–Ni shape memory alloys. Scripta Mater. 1996, 34, 255–260. [Google Scholar] [CrossRef]

- Delaey, L.; Chandrasekaran, M. Comments on “New description of long period stacking order structures of martensites in β-phase alloys” by K. Oksuka, T. Ohba, M. Tokonami and C.M. Wayman. Scripta Metall. Mater. 1994, 30, 1605–1610. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Sáez, R.B.; Nó, M.L.; San Juan, J. Evolution of martensitic transformation in Cu–Al–Ni shape memory alloys during low-temperature aging. J. Mater. Res. 1999, 14, 2806–2813. [Google Scholar] [CrossRef]

- Ibarra, A.; San Juan, J.M.; Bocanegra, E.H.; Caillard, D.; Nó, M.L. “In-situ” and “Post-Mortem” TEM study of the super-elastic effect in Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 787–790. [Google Scholar] [CrossRef]

- Saburi, T.; Wayman, C.M. Crystallographic similarities in Shape Memory Martensites. Acta Metall. 1979, 28, 979–995. [Google Scholar] [CrossRef]

| Materials | Cu (wt.%) | Al (wt.%) | Ni (wt.%) | B (wt.%) | Zr (wt.%) | O ppm | N ppm | C ppm | S ppm |

|---|---|---|---|---|---|---|---|---|---|

| Target | 82.2 | 13.3 | 4.5 | 0.2 | 0.1 | - | - | - | - |

| Obtained | 81.95 | 13.45 | 4.6 | 0.2 | 0.1 | 254 | 1 | 344 | 1 |

| CANBZ | °C | ||||

|---|---|---|---|---|---|

| Ms | Mf | As | Af | ΔT | |

| HIP + HR | 102.3 | 55.0 | 90.9 | 118.4 | 19.3 |

| HIP | 89.5 | 33.5 | 69.1 | 117.5 | 28.0 |

| Powder | 57.2 | 6.6 | 39.0 | 82.6 | 26.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Cerrato, M.; Gómez-Cortés, J.F.; Urionabarrenetxea, E.; Ruiz-Larrea, I.; Carreño, F.; Ayesta, Í.; Nó, M.L.; Burgos, N.; San Juan, J.M. Powder Metallurgy Processing to Enhance Superelasticity and Shape Memory in Polycrystalline Cu–Al–Ni Alloys: Reference Material for Additive Manufacturing. Materials 2024, 17, 6165. https://doi.org/10.3390/ma17246165

Pérez-Cerrato M, Gómez-Cortés JF, Urionabarrenetxea E, Ruiz-Larrea I, Carreño F, Ayesta Í, Nó ML, Burgos N, San Juan JM. Powder Metallurgy Processing to Enhance Superelasticity and Shape Memory in Polycrystalline Cu–Al–Ni Alloys: Reference Material for Additive Manufacturing. Materials. 2024; 17(24):6165. https://doi.org/10.3390/ma17246165

Chicago/Turabian StylePérez-Cerrato, Mikel, Jose F. Gómez-Cortés, Ernesto Urionabarrenetxea, Isabel Ruiz-Larrea, Fernando Carreño, Ízaro Ayesta, María L. Nó, Nerea Burgos, and Jose M. San Juan. 2024. "Powder Metallurgy Processing to Enhance Superelasticity and Shape Memory in Polycrystalline Cu–Al–Ni Alloys: Reference Material for Additive Manufacturing" Materials 17, no. 24: 6165. https://doi.org/10.3390/ma17246165

APA StylePérez-Cerrato, M., Gómez-Cortés, J. F., Urionabarrenetxea, E., Ruiz-Larrea, I., Carreño, F., Ayesta, Í., Nó, M. L., Burgos, N., & San Juan, J. M. (2024). Powder Metallurgy Processing to Enhance Superelasticity and Shape Memory in Polycrystalline Cu–Al–Ni Alloys: Reference Material for Additive Manufacturing. Materials, 17(24), 6165. https://doi.org/10.3390/ma17246165