Numerical Investigation and Device Architecture Optimization of Sb2Se3 Thin-Film Solar Cells Using SCAPS-1D

Abstract

1. Introduction

2. Device Structure and Simulation Parameters

2.1. Device Structure

2.2. Numerical Method

3. Results and Discussion

3.1. Comparison of Substrate and Superstrate Configurations

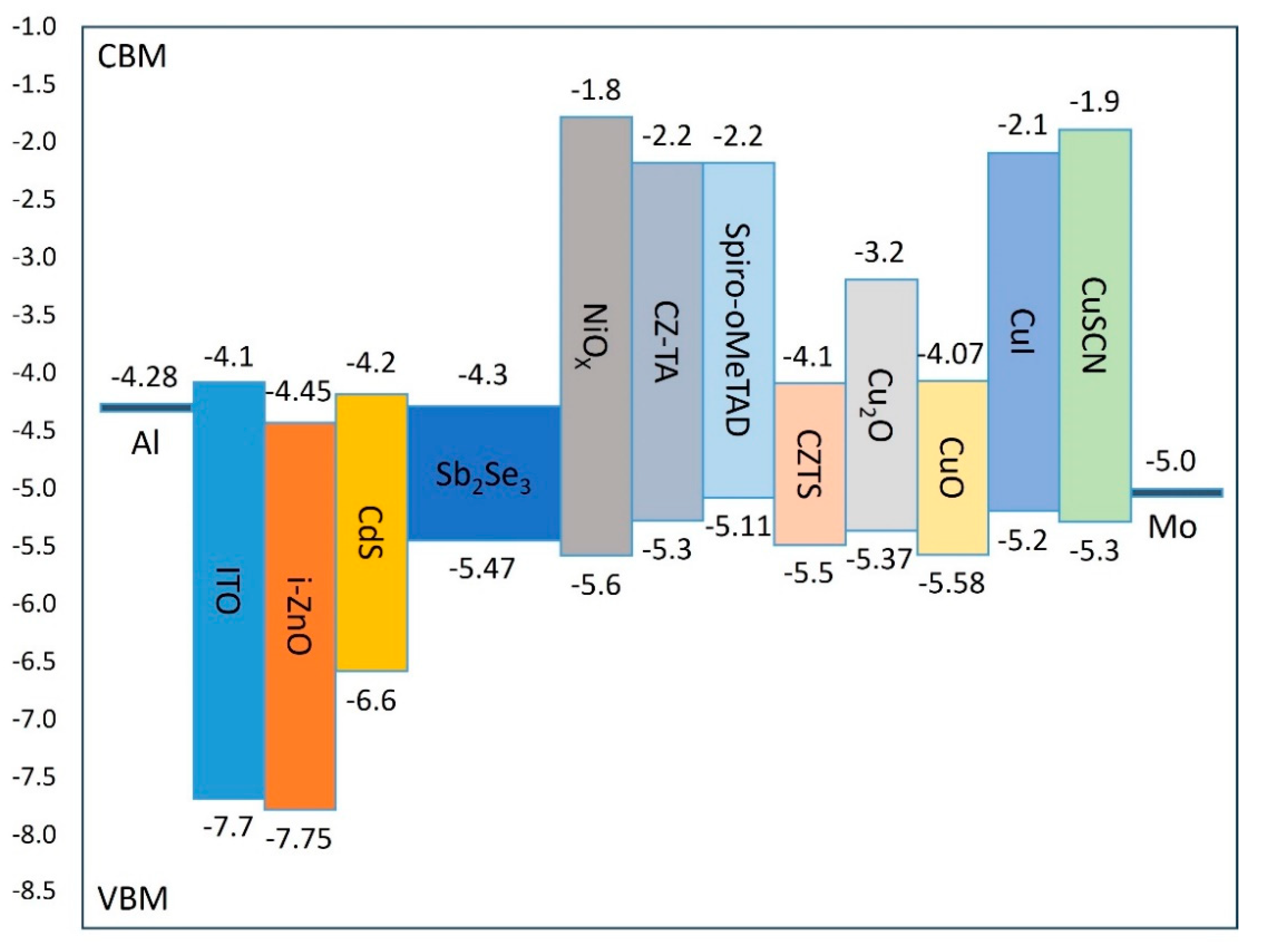

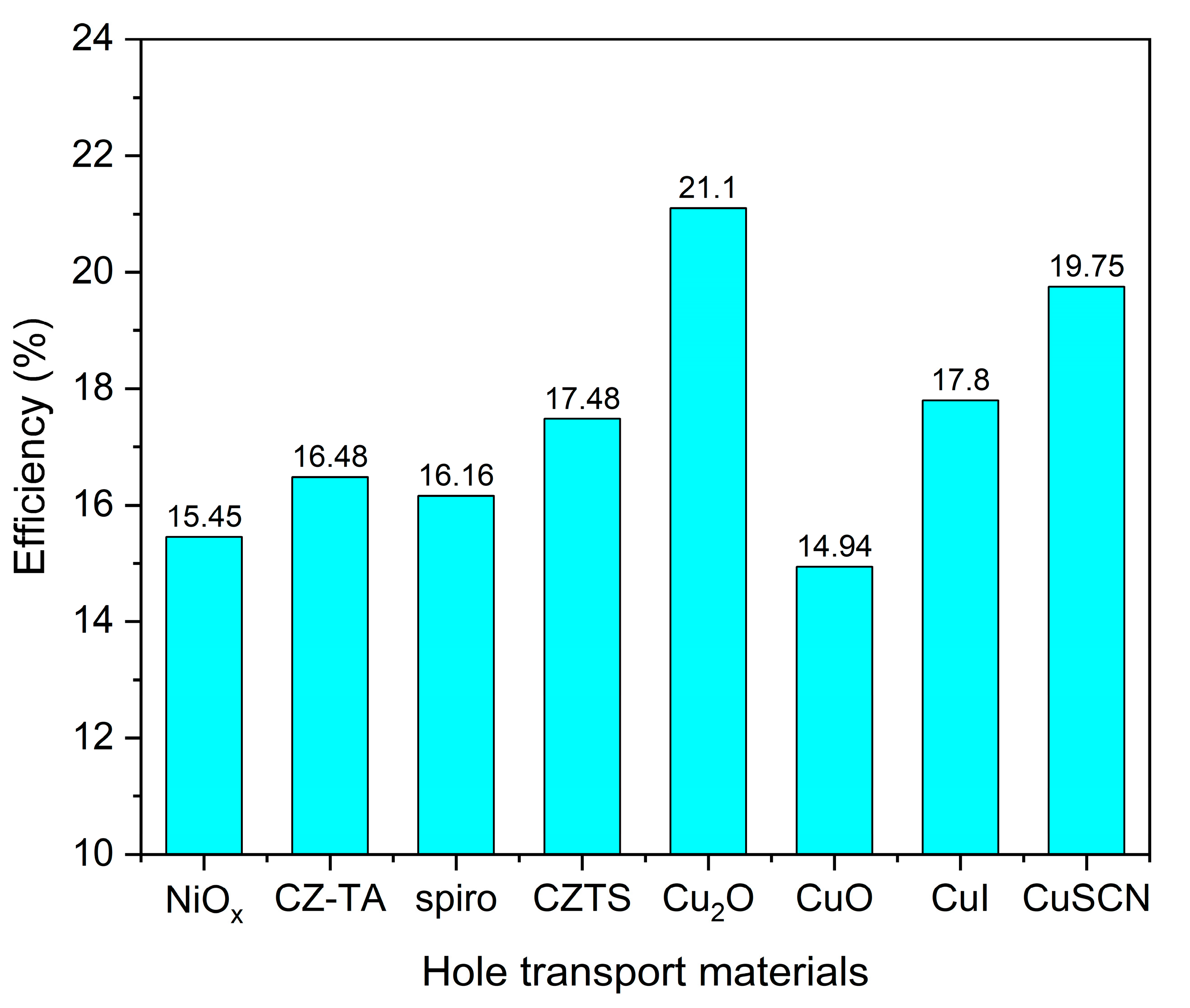

3.2. Comparison of Different HTL Materials

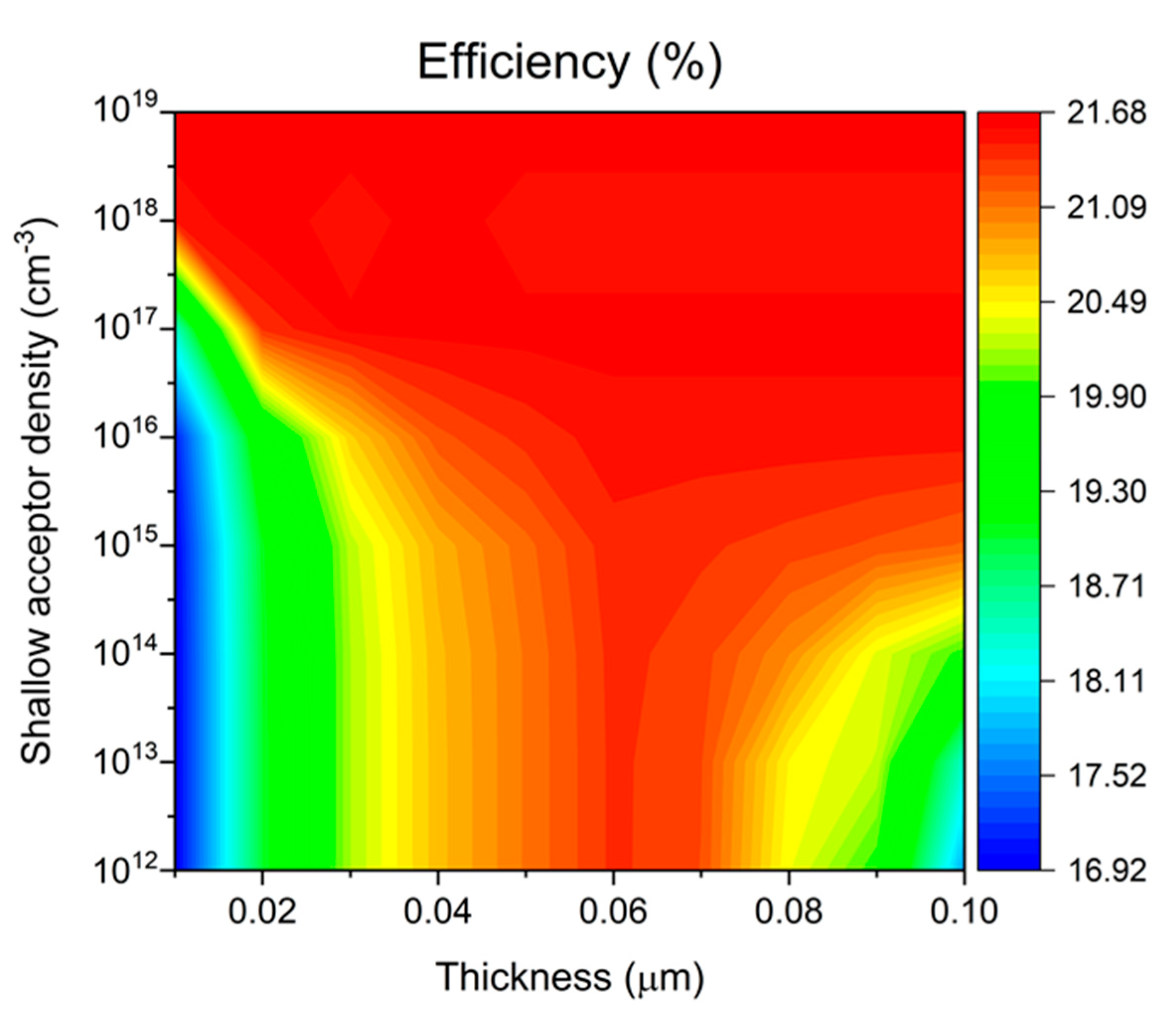

3.3. Effects of Cu2O Thickness and Shallow Acceptor Density on Device Performance

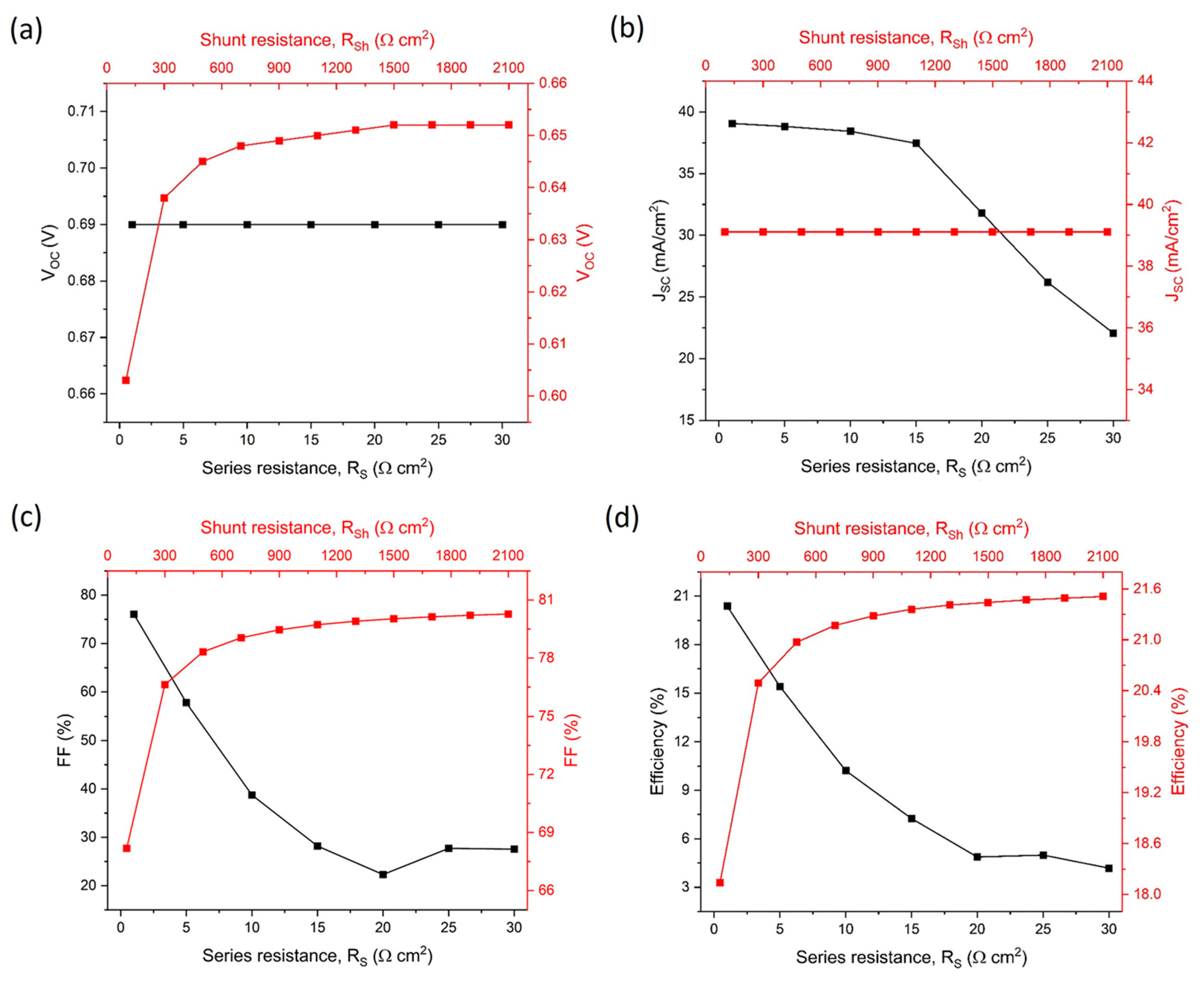

3.4. Effects of Series and Shunt Resistance on Device Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, M.; Zhang, X.; Chen, Y.; Wang, L.; Yang, J.; Liu, F.; Yang, P.; Tang, Z.; Zhou, W.; Chen, S. Sb2Se3 Thin-film solar cells exceeding 10% power conversion efficiency enabled by injection vapor deposition technology. Adv. Mater. 2022, 34, 2202969. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.C.; Wang, L.; Chen, S.; Mahadik, S.K.; Liu, A.; Zhu, C.; Zhang, W.; Yang, H.; Gao, M.; Chen, S. High-efficiency flexible Sb2Se3 solar cells by back interface and absorber bulk deep-level trap engineering. ACS Energy Lett. 2022, 7, 2095–2102. [Google Scholar]

- Zeng, Y.; Xie, S.Y.; Chen, C.H.; Fan, J.D.; Yang, R.X. A review of Sb2Se3 photovoltaic absorber materials and thin-film solar cells. Sol. Energy Mater. Sol. Cells 2016, 151, 57–70. [Google Scholar]

- Liu, X.; Chen, J.; Yang, M.; Zhou, Y.; Chen, S.; Liu, Z.; Tang, J. Efficient Sb2Se3 solar cells with Sb and Ge co-doping. J. Mater. Chem. A 2022, 10, 10060–10068. [Google Scholar]

- Zhang, X.; Li, Y.; Sun, J.; Liu, H.; Liu, X.; Zhou, Y. Efficient Sb2Se3 solar cells with defect engineering and surface passivation. ACS Energy Lett. 2023, 8, 47–55. [Google Scholar]

- Chen, X.; Sun, L.; Li, Y.; Zhang, H.; Wang, X.; Tang, J. Solvent-assisted hydrothermal deposition approach for highly-efficient Sb2(S,Se)3 thin-film solar cells. Adv. Energy Mater. 2023, 23, 2300391. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Liu, Z.; Yang, W.; Chen, S. Efficient Sb2Se3 solar cells with a new hole transport layer. Nano Energy 2022, 87, 105803. [Google Scholar]

- Guo, L.; Vijayaraghavan, S.N.; Duan, X.; Menon, H.G.; Wall, J.; Kong, L.; Yan, F. Stable and efficient Sb2Se3 solar cells with solution-processed NiO_x hole-transport layer. Sol. Energy 2021, 218, 525–531. [Google Scholar] [CrossRef]

- Li, P.; Yuan, X.; Feng, M.; Ran, F.; Zhang, D.; Chen, S. Fabrication of TiO_x/Sb2Se3/p-NiO_x photocathode for efficient photoelectrochemical water reduction. Appl. Phys. Lett. 2021, 119, 100445. [Google Scholar]

- Mu, F.; Liu, Z.; Zi, W.; Cao, Y.; Lu, X.; Li, Y.; Cheng, N. CZTS nanoparticles as an effective hole-transport layer for Sb2Se3 thin-film solar cells. Sol. Energy 2021, 226, 154–160. [Google Scholar] [CrossRef]

- Maurya, K.K.; Singh, V.N. Sb2Se3/CZTS dual absorber layer based solar cell with 36.32% efficiency: A numerical simulation. J. Sci. Adv. Mater. Dev. 2022, 7, 100445. [Google Scholar]

- Li, Z.Q.; Ni, M.; Feng, X.D. Simulation of the Sb2Se3 solar cell with a hole transport layer. Mater. Res. Express 2020, 7, 016416. [Google Scholar] [CrossRef]

- Sultana, B.; Islam, A.S.; Haque, M.D.; Kuddus, A. Cu2O-Enhanced Back Surface Field Empowers Selenium-Based TiO2/Sb2Se3 Thin Film Solar Cells to Achieve Efficiency over 32%. Appl. Sol. Energy 2023, 59, 836–850. [Google Scholar] [CrossRef]

- Lee, S.; McInerney, M.F. Optimization of bifacial Ge-incorporated Sb2Se3 thin-film solar cells by modeling Cu2O back buffer layer. Sol. Energy Mater. Sol. Cells 2023, 257, 112399. [Google Scholar] [CrossRef]

- Christians, J.A.; Kamat, P.V. Trap and transfer. Two-step hole injection across the Sb2S3/CuSCN interface in solid-state solar cells. ACS Nano 2013, 7, 7967–7974. [Google Scholar] [CrossRef]

- Li, K.; Wang, S.; Chen, C.; Kondrotas, R.; Hu, M.; Lu, S.; Tang, J. 7.5% n-i-p Sb2Se3 solar cells with CuSCN as a hole-transport layer. J. Mater. Chem. A 2019, 7, 9665–9672. [Google Scholar] [CrossRef]

- Ngoupo, A.T.; Ouédraogo, S.; Zougmoré, F.; Ndjaka, J.M.B. Numerical analysis of ultrathin Sb2Se3-based solar cells by SCAPS-1D numerical simulator device. Chin. J. Phys. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Li, D.B.; Yin, X.; Grice, C.R.; Guan, L.; Song, Z.; Wang, C.; Tang, J. Stable and efficient CdS/Sb2Se3 solar cells prepared by scalable close space sublimation. Nano Energy 2018, 49, 346–353. [Google Scholar] [CrossRef]

- Joy, A.; Abir, A.T.; Mondal, B.K.; Hossain, J. Numerical studies on a ternary AgInTe2 chalcopyrite thin film solar cell. Heliyon 2023, 9, e15876. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, S.L.; Wu, J.Y.; Wang, W.H.; Liu, W.; Wu, L.; Zhang, Y. Current improvement in substrate structured Sb2S3 solar cells with MoSe2 interlayer. Chin. Phys. B 2020, 29, 058801. [Google Scholar] [CrossRef]

- Ngoupo, A.T.; Ndjaka, J.M.B. Performance enhancement of Sb2Se3-based solar cell with hybrid buffer layer and MoSe2 as a hole transport material using simulator device. Discov. Mech. Eng. 2022, 1, 5. [Google Scholar] [CrossRef]

- Guijarro, N.; Lutz, T.; Lana-Villarreal, T.; O’Mahony, F.; Gómez, R.; Haque, S.A. Toward antimony selenide sensitized solar cells: Efficient charge photogeneration at spiro-OMeTAD/Sb2Se3/metal oxide heterojunctions. J. Phys. Chem. Lett. 2012, 3, 1351–1356. [Google Scholar] [CrossRef] [PubMed]

- Du, Q.; Shen, Z.; Chen, C.; Li, F.; Jin, M.; Li, H.; Wang, M. Spiro-OMeTAD: Sb2S3 Hole Transport Layer with Triple Functions of Overcoming Lithium Salt Aggregation, Long-Term High Conductivity, and Defect Passivation for Perovskite Solar Cells. Sol. RRL 2021, 5, 2100622. [Google Scholar] [CrossRef]

- Bera, A.; Mahapatra, A.D.; Mondal, S.; Basak, D. Sb2S3/Spiro-OMeTAD inorganic-organic hybrid p-n junction diode for high performance self-powered photodetector. ACS Appl. Mater. Interfaces 2016, 8, 34506–34512. [Google Scholar] [CrossRef]

- Hernandez-Como, N.; Morales-Acevedo, A. Simulation of hetero-junction silicon solar cells with AMPS-1D. Sol. Energy Mater. Sol. Cells 2010, 94, 62–67. [Google Scholar] [CrossRef]

- Hadjab, M.; Wagner, J.M.; Bouzid, F.; Boudour, S.; Larbi, A.H.; Bennacer, H.; Berrah, S. A numerical optimization study of CdS and Mg0.125Zn0.875O buffer layers in CIGS-based solar cells using wxAMPS-1D package. Int. J. Model. Simul. 2022, 42, 179–191. [Google Scholar] [CrossRef]

- Smucker, J.; Gong, J. A comparative study on the band diagrams and efficiencies of silicon and perovskite solar cells using wxAMPS and AMPS-1D. Sol. Energy 2021, 228, 187–199. [Google Scholar] [CrossRef]

- Al-Hattab, M.; Khenfouch, M.; Bajjou, O.; Chrafih, Y.; Rahmani, K. Numerical simulation of a new heterostructure CIGS/GaSe solar cell system using SCAPS-1D software. Sol. Energy 2021, 227, 13–22. [Google Scholar] [CrossRef]

- Basak, A.; Singh, U.P. Numerical modelling and analysis of earth abundant Sb2S3 and Sb2Se3 based solar cells using SCAPS-1D. Sol. Energy Mater. Sol. Cells 2021, 230, 111184. [Google Scholar] [CrossRef]

- Islam, M.S.; Sobayel, K.; Al-Kahtani, A.; Islam, M.A.; Muhammad, G.; Amin, N.; Akhtaruzzaman, M. Defect study and modelling of SnX3-based perovskite solar cells with SCAPS-1D. Nanomaterials 2021, 11, 1218. [Google Scholar] [CrossRef]

- Lovergine, N.; Cingolani, R.; Mancini, A.M.; Ferrara, M. Photoluminescence of CVD grown CdS epilayers on CdTe substrates. J. Cryst. Growth 1992, 118, 304–308. [Google Scholar] [CrossRef]

- Srinivas, B.; Babujani, S.; Chandra, G.H.; Subbaiah, Y.P.V.; Gupta, M. Synthesis and characterization of Cu-sandwiched Sb2Se3 thin films and numerical simulation of p-Sb2Se3/n-ZnSe heterojunction solar cell. Opt. Mater. 2023, 135, 113289. [Google Scholar] [CrossRef]

- Moujoud, S.; Hartiti, B.; Touhtouh, S.; Belhora, F.; Hajjaji, A. Optimizing Sb2Se3 thin-film solar cells: A comprehensive simulation study of multiple influential factors. Optik 2024, 303, 171723. [Google Scholar] [CrossRef]

- Cao, Y.; Zhu, X.; Chen, H.; Zhang, X.; Zhou, J.; Hu, Z.; Pang, J. Towards high efficiency inverted Sb2Se3 thin film solar cells. Sol. Energy Mater. Sol. Cells 2019, 200, 109945. [Google Scholar] [CrossRef]

- Ranjan, R.; Anand, N.; Tripathi, M.N.; Srivastava, N.; Sharma, A.K.; Yoshimura, M.; Chang, L.; Tiwari, R.N. SCAPS study on the effect of various hole transport layer on highly efficient 31.86% eco-friendly CZTS based solar cell. Sci. Rep. 2023, 13, 18411. [Google Scholar] [CrossRef]

- Abdur, R.; Choudhury, S.; Bashar, M.S.; Mossain, M.R.; Quddus, M.S.; Akhtar, U.S.; Shaikh, M.A.A.; Hossain, M.; Jamal, M.S. Enhancing perovskite solar cell performance: Investigating the impact of post-annealing on the optoelectrical and structural properties of RF-sputtered NiO films via SCAPS-1D device modeling. Sol. Energy 2024, 271, 112443. [Google Scholar] [CrossRef]

- Karade, V.C.; Jang, J.S.; Kumbhar, D.; Rao, M.; Pawar, P.S.; Kim, S.; Gour, K.S.; Park, J.; Heo, J.; Dongale, T.D.; et al. Combating open circuit voltage loss in Sb2Se3 solar cell with an application of SnS as a back surface field layer. Sol. Energy 2022, 233, 435–445. [Google Scholar] [CrossRef]

- Mamta Maurya, K.K.; Singh, V.N. Sb2Se3 as an HTL for Mo/Sb2Se3/Cs2TiF6/TiO2 solar structure: Performance evaluation with SCAPS-1D. Heliyon 2022, 8, e10925. [Google Scholar] [CrossRef]

- Azhakanantham, D.; Selvamani, M.; Kim, T.G.; Contreras, D.; Kesavan, A.V. Exploring novel HTL suitable for Eco-friendly and high performance FASnI3 photovoltaics. Mater. Sci. Eng. B 2022, 284, 115789. [Google Scholar] [CrossRef]

| Parameter | ITO [32] | i-ZnO [33] | CdS [33] | Sb2Se3 [33] |

|---|---|---|---|---|

| Thickness (µm) | 0.3 | 0.05 | 0.07 | 1.5 |

| Eg (eV) | 3.6 | 3.3 | 2.4 | 1.17 |

| χ (eV) | 4.1 | 4.45 | 4.2 | 4.3 |

| εr | 10 | 9 | 10 | 19 |

| NC (1 cm−3) | 2.2 × 1018 | 2.2 × 1018 | 2.2 × 1018 | 2.2 × 1018 |

| NV (1 cm−3) | 1.8 × 1019 | 1.8 × 1019 | 1.8 × 1019 | 1.8 × 1019 |

| υth,e (cm/s) | 107 | 107 | 107 | 107 |

| υth,h (cm/s) | 107 | 107 | 107 | 107 |

| μe (cm2 (V S)−1) | 75 | 100 | 100 | 15 |

| μh (cm2 (V S)−1) | 50 | 25 | 25 | 42 |

| Donor density, ND (1/cm3) | 1019 | 1018 | 1017 | 0 |

| Acceptor density, NA (1 cm−3) | 0 | 1018 | 102 | 1016 |

| Defect type | Acceptor | Donor | Neutral | |

| Reference | Above EV | Above EV | Above EV | |

| Et (eV) | 0.6 | 0.6 | 0.6 | |

| Nt (1 cm−3) | 1010 | 1015 | 1012 |

| Interface | i-ZnO/CdS [33] | CdS/Sb2Se3 [33] | Sb2Se3/HTL [34] |

|---|---|---|---|

| Defect type | Neutral | Neutral | Neutral |

| σe (cm2) | 4 × 10−18 | 1 × 10−19 | 1 × 10−19 |

| σh (cm2) | 4 × 10−18 | 1 × 10−19 | 1 × 10−19 |

| Nt (1 cm−2) | 1010 | 2.8 × 1010 | 1012 |

| Parameter | CZ-TA [17] | Spiro [17] | CZTS [11] | Cu2O [35] | CuO [35] | CuI [35] | CuSCN [36] | NiOx [36] |

|---|---|---|---|---|---|---|---|---|

| Thickness (µm) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Eg (eV) | 3.10 | 2.91 | 1.4 | 2.17 | 1.51 | 3.1 | 3.4 | 3.8 |

| χ (eV) | 2.2 | 2.2 | 4.1 | 3.2 | 4.07 | 2.1 | 1.9 | 1.8 |

| εr | 3 | 3 | 9 | 7.11 | 18.1 | 6.5 | 10.0 | 11.75 |

| NC (cm−3) | 8 × 1017 | 8 × 1017 | 2.2 ×1018 | 2.02 × 1017 | 2.2 × 1019 | 2.8 × 1019 | 2.2 × 1018 | 2 × 1018 |

| NV (cm−3) | 1.8 × 1019 | 1.8 × 1019 | 1.8 × 1018 | 1.1 × 1019 | 5.5 × 1020 | 1.0 × 1019 | 1.8 × 1018 | 2 × 1018 |

| μe (cm2 (VS)−1) | 1.65 × 10−4 | 6.17 × 10−5 | 100 | 200 | 10 | 100 | 100 | 8 |

| μh (cm2 (VS) −1) | 1.65 × 10−4 | 6.17 × 10−5 | 12.5 | 80 | 0.1 | 43.9 | 25 | 81.10 |

| ND (1 cm−3) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| NA (1 cm−3) | 1019 | 1019 | 1019 | 1019 | 1019 | 1019 | 1019 | 1019 |

| Contacts | Al [37] | Mo [38] | FTO [39] |

|---|---|---|---|

| Wf | 4.28 | 5.0 | 4.4 |

| Se | 107 | 105 | 107 |

| Sh | 105 | 107 | 105 |

| Reflection | No | No | No |

| VOC (V) | FF (%) | PCE (%) | ||

|---|---|---|---|---|

| Substrate | 0.52 | 38.42 | 71.88 | 14.23 |

| Superstrate | 0.38 | 35.34 | 74.62 | 10.09 |

| Superstrate with Au (Wf = 5.1) | 0.52 | 35.66 | 75.21 | 13.83 |

| HTL | NiOX | CZ-TA | Spiro | CZTS | Cu2O | CuO | CuI | CuSCN |

|---|---|---|---|---|---|---|---|---|

| VBO | −0.13 | 0.17 | 0.36 | −0.03 | 0.1 | −0.11 | 0.27 | 0.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, C.-K.; Lin, Y.-C. Numerical Investigation and Device Architecture Optimization of Sb2Se3 Thin-Film Solar Cells Using SCAPS-1D. Materials 2024, 17, 6203. https://doi.org/10.3390/ma17246203

Lai C-K, Lin Y-C. Numerical Investigation and Device Architecture Optimization of Sb2Se3 Thin-Film Solar Cells Using SCAPS-1D. Materials. 2024; 17(24):6203. https://doi.org/10.3390/ma17246203

Chicago/Turabian StyleLai, Chung-Kuan, and Yi-Cheng Lin. 2024. "Numerical Investigation and Device Architecture Optimization of Sb2Se3 Thin-Film Solar Cells Using SCAPS-1D" Materials 17, no. 24: 6203. https://doi.org/10.3390/ma17246203

APA StyleLai, C.-K., & Lin, Y.-C. (2024). Numerical Investigation and Device Architecture Optimization of Sb2Se3 Thin-Film Solar Cells Using SCAPS-1D. Materials, 17(24), 6203. https://doi.org/10.3390/ma17246203