Composition and Element Distribution Mapping of γ′ and γ″ Phases of Inconel 718 by High-Resolution Scanning Transmission Electron Microscopy and X-ray Energy-Dispersive Spectrometry

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

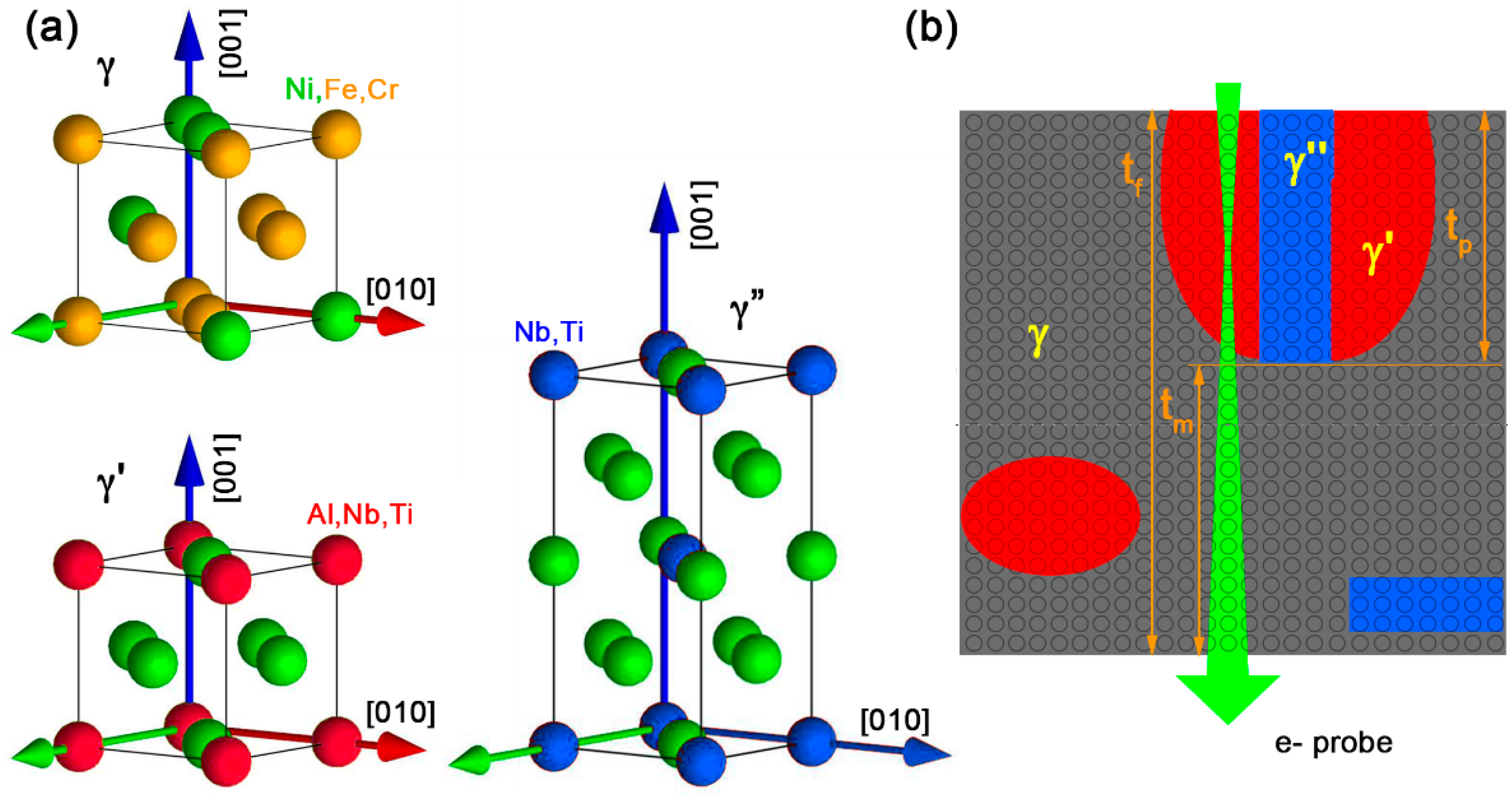

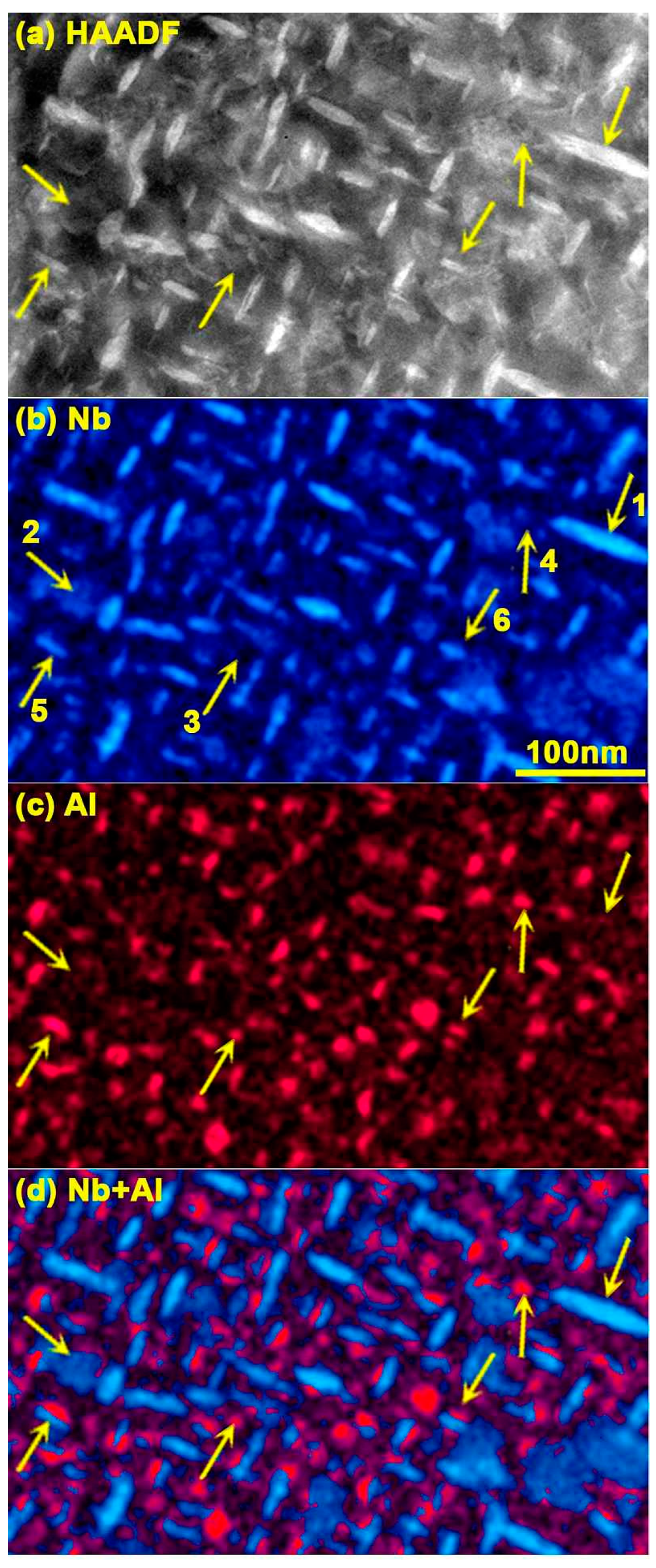

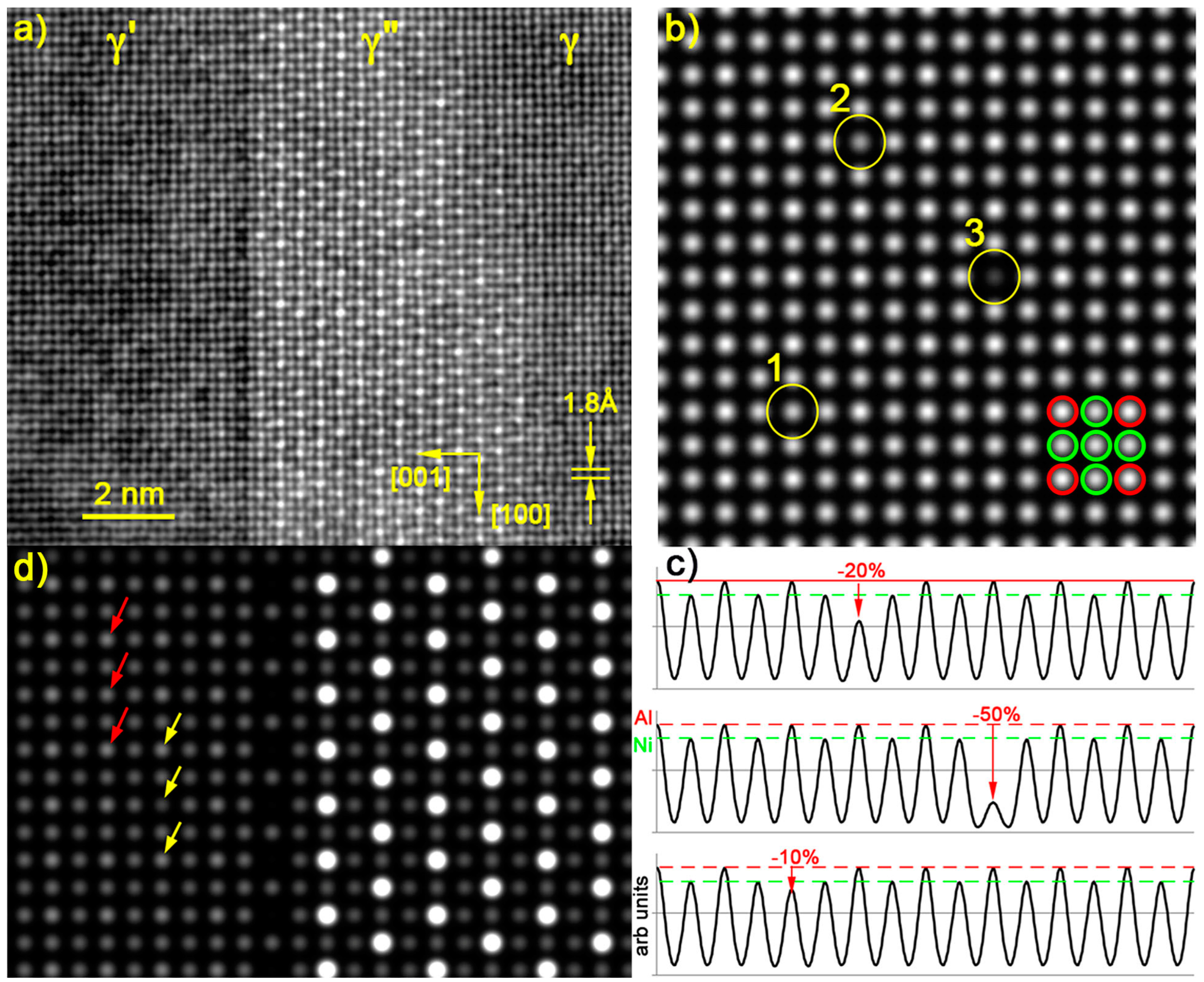

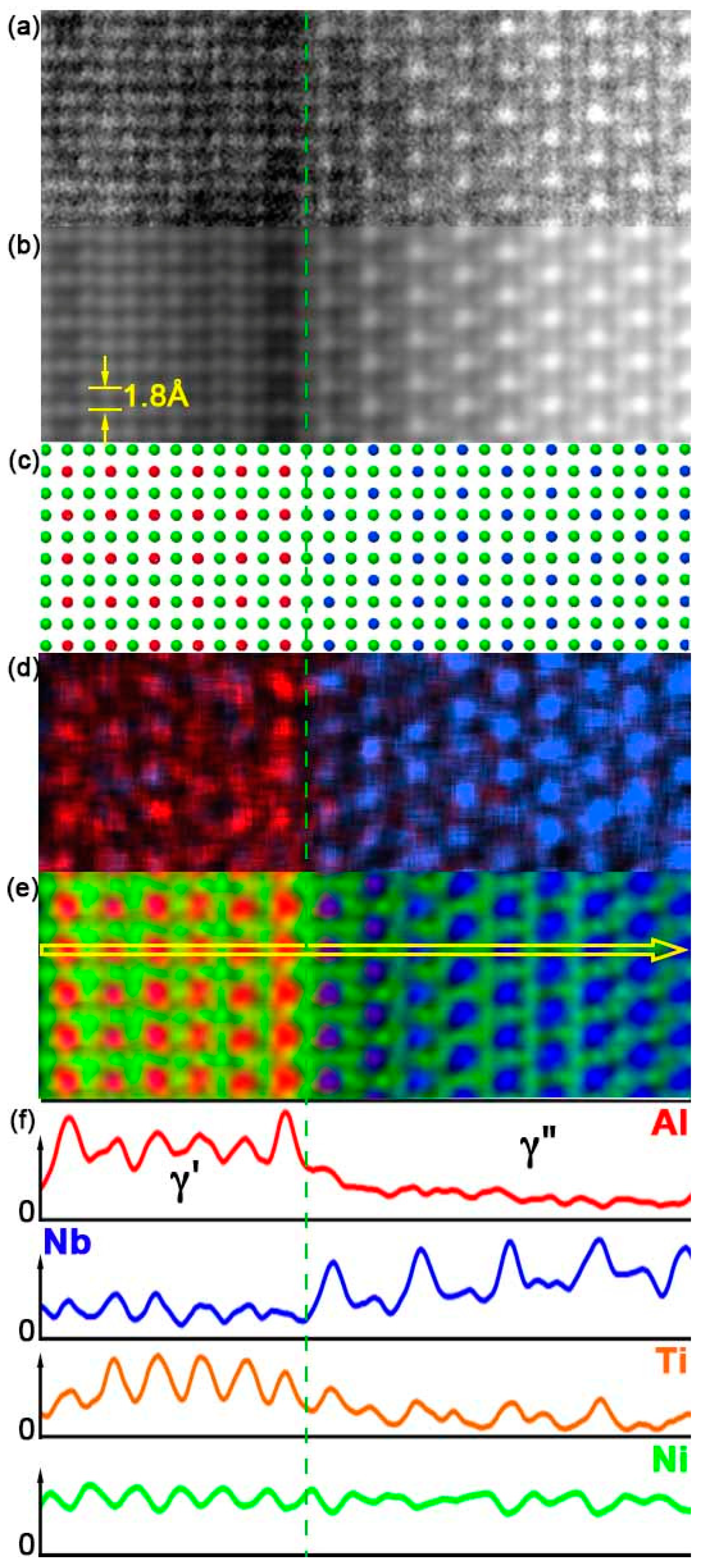

3.1. HAADF-STEM Imaging

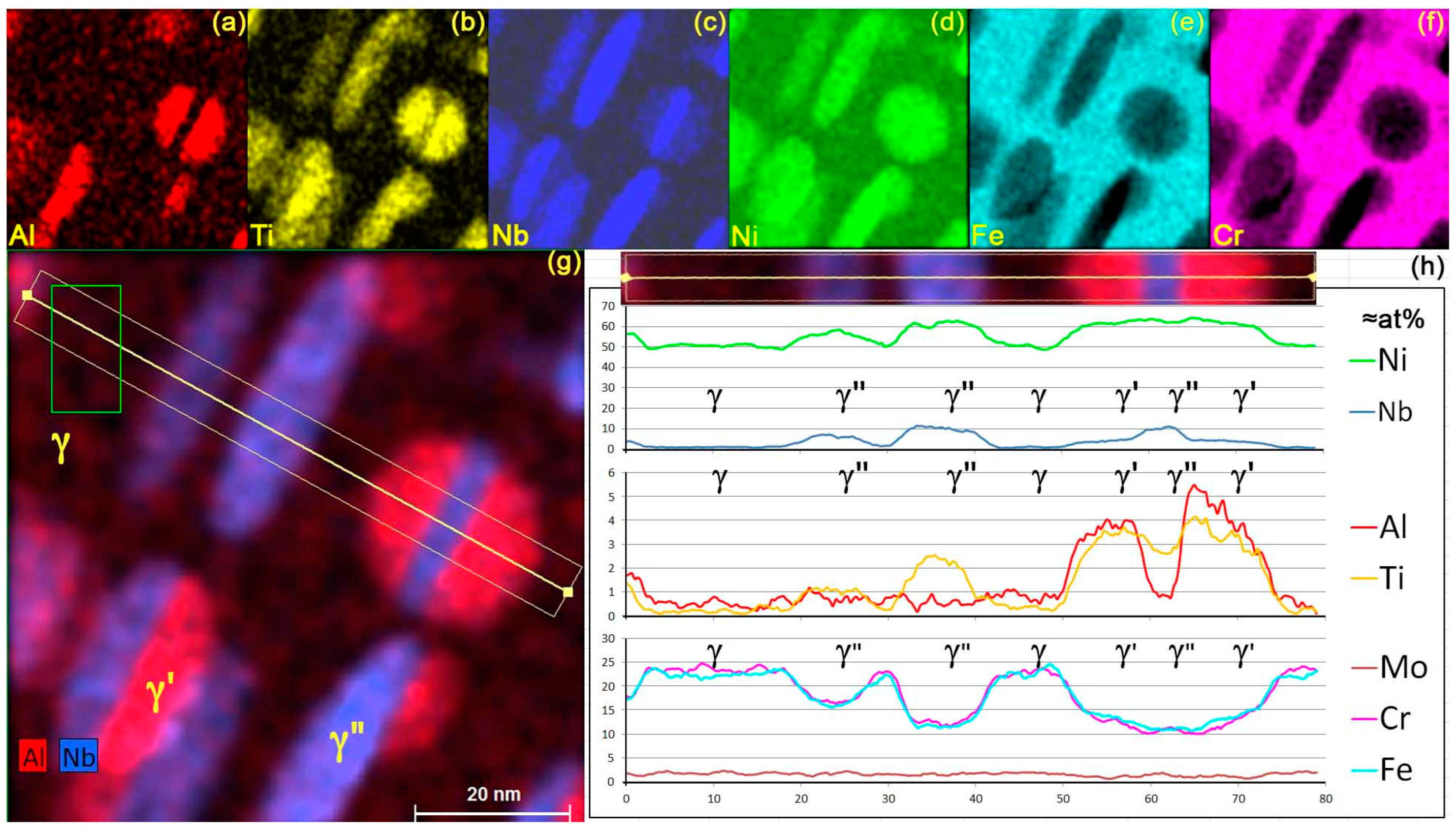

3.2. Energy-Dispersive X-ray Spectrometry

3.2.1. Composition of the γ′ and γ″ Phases

3.2.2. Chemical Information at Interfaces and Defects

- (i)

- The γ′/γ″ phases join together via Ni-rich columns at the interface;

- (ii)

- The γ′ Al-rich columns face the closest γ″ Nb-rich columns, a structure similar to “Geng model Figure 7a [25]” except that Ti comes back in the Al-Nb-rich γ′ columns in a proportion close to 33 at% for each of the three elements;

- (iii)

- The presence of brighter Al-rich columns along the interface confirms the Al enrichment expected from ab initio calculations, Thermo-Calc simulations, and APT observation and that it extends in a single atomic plane only;

- (iv)

- The “defective columns” in the leftmost Al-rich row show a similar tendency to compositional changes caused by the random replacement of Nb atoms by Al.

4. Conclusions

- -

- Al, Ti, and Nb in the γ′ phase occupy the corners of the unit cell cube of the ordered fcc crystal structure and Ni is at the face center;

- -

- Compared with the Geng simulations, Ti is back in the γ′ Al-Nb-rich columns;

- -

- Nb and Ti occupy the corner and center of the γ″ bct tetragonal lattice, with possible traces of Al;

- -

- The γ′ and γ″ phases share a pure Ni atomic layer at the interface in γ′/γ″ co-precipitates and γ′/γ″/γ′ sandwich-like particles;

- -

- The γ′ Al-rich columns face the nearest γ″ Nb-rich ones across the interface with a single Ni column in between, as calculations suggest;

- -

- Darker columns of Al-Nb-Ti are observed in the HAADF images in the last γ′ row along the interface, suggesting an increase in Al and a loss of a part of heavier Nb and Ti elements. The EDXS maps at atomic column resolution show that they correspond to an Al enrichment that confirms calculation and APT observation. This corresponds to a loss of Nb and Ti but in an unclear proportion. The Ni columns at the interface remain unaffected;

- -

- In addition, a few dispersed “defective columns” showing darker HAADF contrast and EDXS Al enrichment/Nb+Ti loss are randomly distributed in the γ′ phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Batuk, D.; Batuk, M.; Abakumov, A.M.; Hadermann, J. Synergy between Transmission Electron Microscopy and Powder Diffraction: Application to Modulated Structures. Acta Crystallogr. Sect. B-Struct. Sci. Cryst. Eng. Mater. 2015, 71, 127–143. [Google Scholar] [CrossRef]

- Kwon, J.H.; Lu, P.; Hoffman, J.; Yuan, R.L.; Yoon, A.; Bhattacharya, A.; Zuo, J.M. Elemental and Lattice-Parameter Mapping of Binary Oxide Superlattices of (LaNiO3)(4)/(LaMnO3)(2) at Atomic Resolution. Semicond. Sci. Technol. 2017, 32, 014002. [Google Scholar] [CrossRef]

- Egerton, R.F. Mechanisms of Radiation Damage in Beam-Sensitive Specimens, for TEM Accelerating Voltages between 10 and 300 kV. Microsc. Res. Tech. 2012, 75, 1550–1556. [Google Scholar] [CrossRef] [PubMed]

- Mansfield, J.F.; Okamoto, P.R.; Rehn, L.E.; Zaluzec, N.J. Radiation Effects on X-ray-Microanalysis of a Light-Element Alloy in a Medium-Voltage Electron Microscope. Ultramicroscopy 1987, 21, 13–21. [Google Scholar] [CrossRef]

- Wenner, S.; Jones, L.; Marioara, C.D.; Holmestad, R. Atomic-Resolution Chemical Mapping of Ordered Precipitates in Al Alloys Using Energy-Dispersive X-ray Spectroscopy. Micron 2017, 96, 103–111. [Google Scholar] [CrossRef]

- Schlossmacher, P.; Klenov, D.O.; Freitag, B.; von Harrach, H.S.; Steinbach, A. Nanoscale Chemical Compositional Analysis with an Innovative S/TEM-EDX System. Microsc. Anal. 2010, 24, S5. [Google Scholar]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Guth, S.; Babinský, T.; Antusch, S.; Klein, A.; Kuntz, D.; Šulák, I. Creep–Fatigue Interaction of Inconel 718 Manufactured by Electron Beam Melting. Adv. Eng. Mater. 2023, 25, 2300294. [Google Scholar] [CrossRef]

- Lawitzki, R.; Hassan, S.; Karge, L.; Wagner, J.; Wang, D.; von Kobylinski, J.; Krempaszky, C.; Hofmann, M.; Gilles, R.; Schmitz, G. Differentiation of γ′- and γ″-Precipitates in Inconel 718 by a Complementary Study with Small-Angle Neutron Scattering and Analytical Microscopy. Acta Mater. 2019, 163, 28–39. [Google Scholar] [CrossRef]

- Kulawik, K.; Buffat, P.A.; Kruk, A.; Wusatowska-Sarnek, A.M.; Czyrska-Filemonowicz, A. Imaging and Characterization of γ′ and γ″ Nanoparticles in Inconel 718 by EDX Elemental Mapping and FIB-SEM Tomography. Mater. Charact. 2015, 100, 74–80. [Google Scholar] [CrossRef]

- Phillips, P.J.; McAllister, D.; Gao, Y.; Lv, D.; Williams, R.E.A.; Peterson, B.; Wang, Y.; Mills, M.J. Nano γ′/γ′’ Composite Precipitates in Alloy 718. Appl. Phys. Lett. 2012, 100, 211913. [Google Scholar] [CrossRef]

- Paulonis, D.F.; Oblak, J.M.; Duvall, D.S. Precipitation in Nickel-Base Akkoy 718. ASM (Am. Soc. Met.) Trans. Quart. 1969, 62, 611–622. [Google Scholar]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Some Aspects of the Precipitation of Metastable Intermetallic Phases in Inconel-718. Metall. Trans. A-Phys. Metall. Mater. Sci. 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Ayache, J. Sample Preparation Handbook for Transmission Electron Microscopy, 1st ed.; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Kelly, T.F.; Miller, M.K. Invited Review Article: Atom Probe Tomography. Rev. Sci. Instrum. 2007, 78, 031101. [Google Scholar] [CrossRef]

- Miller, M.K.; Babu, S.S.; Burke, M.G. Comparison of the Phase Compositions in Alloy 718 Measured by Atom Probe Tomography and Predicted by Thermodynamic Calculations. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2002, 327, 84–88. [Google Scholar] [CrossRef]

- Kulawik, K. The Influence of the Precipitates on Strengthening of Inconel 718 Superalloy at High Temperature. Ph.D. Thesis, AGH University of Science and Technology, Krakow, Poland, 2017. [Google Scholar]

- von Harrach, H.; Klenov, D.; Freitag, B.; Schlossmacher, P.; Collins, P.; Fraser, H. Comparison of the Detection Limits of EDS and EELS in S/TEM. Microsc. Microanal. 2010, 16, 1312–1313. [Google Scholar] [CrossRef]

- ImageJ: Image Processing and Analysis in Java. Available online: https://imagej.nih.gov/ij (accessed on 22 October 2017).

- Ritchie, N.W.M. Using DTSA-II to Simulate and Interpret Energy Dispersive Spectra from Particles. Microsc. Microanal. 2010, 16, 248–258. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, N.W.M. Spectrum Simulation in DTSA-II. Microsc. Microanal. 2009, 15, 454–468. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, N. NIST DTSA-II. 2023. Available online: https://www.nist.gov/services-resources/software/nist-dtsa-II (accessed on 17 January 2024).

- Gauvin, R.; Michaud, P. MC X-ray, a New Monte Carlo Program for Quantitative X-ray Microanalysis of Real Materials. Microsc. Microanal. 2009, 15, 488–489. [Google Scholar] [CrossRef]

- Drouin, D.; Couture, A.R.; Joly, D.; Tastet, X.; Aimez, V.; Gauvin, R. CASINO V2.42-A Fast and Easy-to-Use Modeling Tool for Scanning Electron Microscopy and Microanalysis Users. Scanning 2007, 29, 92–101. [Google Scholar] [CrossRef]

- Geng, W.T.; Ping, D.H.; Gu, Y.F.; Cui, C.Y.; Harada, H. Stability of Nanoscale Co-Precipitates in a Superalloy: A Combined First-Principles and Atom Probe Tomography Study. Phys. Rev. B 2007, 76, 224102. [Google Scholar] [CrossRef]

- Miller, M.K. Contributions of Atom Probe Tomography to the Understanding of Nickel-Based Superalloys. Micron 2001, 32, 757–764. [Google Scholar] [CrossRef]

- Ji, Y.Z.; Lou, Y.C.; Qu, M.; Rowatt, J.D.; Zhang, F.; Simpson, T.W.; Chen, L.Q. Predicting Coherency Loss of Precipitates in IN718 Superalloy. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2016, 47A, 3235–3247. [Google Scholar] [CrossRef]

- Pennycook, S.J. Z-Contrast Stem for Materials Science. Ultramicroscopy 1989, 30, 58–69. [Google Scholar] [CrossRef]

- Pennycook, S.J.; Berger, S.D.; Culbertson, R.J. Elemental Mapping with Elastically Scattered Electrons. J. Microsc. 1986, 144, 229–249. [Google Scholar] [CrossRef]

- Walther, T. A New Experimental Procedure to Quantify Annular Dark Field Images in Scanning Transmission Electron Microscopy. J. Microsc. Oxf. 2006, 221, 137–144. [Google Scholar] [CrossRef]

- Williams, D.B.; Carter, C.B. Transmission Electron Microscopy: A Textbook for Materials Science, 2nd ed.; Plenum Press: New York, NY, USA, 2009; p. 760. [Google Scholar] [CrossRef]

- Lu, P.; Yuan, R.L.; Ihlefeld, J.F.; Spoerke, E.D.; Pan, W.; Zuo, J.M. Fast Atomic-Scale Chemical Imaging of Crystalline Materials and Dynamic Phase Transformations. Nano Lett. 2016, 16, 2728–2733. [Google Scholar] [CrossRef] [PubMed]

- Klenov, D.O.; Stemmer, S. Contributions to the Contrast in Experimental High-Angle Annular Dark-Field Images. Ultramicroscopy 2006, 106, 889–901. [Google Scholar] [CrossRef] [PubMed]

- Stadelmann, P. JEMS: A Program for the Simulation of Images and Diffraction Patterns in Electron Microscopy. 2023. Available online: https://www.jems-swiss.ch (accessed on 17 January 2024).

- Kirkland, E.J. Computation in Electron Microscopy. Acta Crystallogr. A-Found. Adv. 2016, 72, 1–27. [Google Scholar] [CrossRef]

- Barthel, J. Dr. Probe-High-Resolution (S)TEM Image Simulation Software. Available online: http://www.er-c.org/barthel/drprobe/index.html (accessed on 22 October 2017).

- Barthel, J. Dr. Probe: A Software for High-Resolution STEM Image Simulation. Ultramicroscopy 2018, 193, 1–11. [Google Scholar] [CrossRef]

- Lobato, I. MULTEM Simulaton Software, Ivanlh20/Multem. 2022. Available online: http://github.com/Ivanlh20/MULTEM (accessed on 12 December 2023).

- Lobato, I.; Van Aert, S.; Verbeeck, J. Progress and New Advances in Simulating Electron Microscopy Datasets Using MULTEM. Ultramicroscopy 2016, 168, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Saito, G.; Yamaki, F.; Kunisada, Y.; Sakaguchi, N.; Akiyama, T. Three-Dimensional Analysis of Eu Dopant Atoms in Ca-Alpha-SiAlON via through-Focus HAADF-STEM Imaging. Ultramicroscopy 2017, 175, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Forbes, B.D.; D’Alfonso, A.J.; Williams, R.E.A.; Srinivasan, R.; Fraser, H.L.; McComb, D.W.; Freitag, B.; Klenov, D.O.; Allen, L.J. Contribution of Thermally Scattered Electrons to Atomic Resolution Elemental Maps. Phys. Rev. B 2012, 86, 024108. [Google Scholar] [CrossRef]

- Allen, L.J.; D’Alfonso, A.J.; Freitag, B.; Klenov, D.O. Chemical Mapping at Atomic Resolution Using Energy-Dispersive x-Ray Spectroscopy. MRS Bull. 2012, 37, 47–52. [Google Scholar] [CrossRef]

- Xu, W.; Dycus, J.H.; Sang, X.; LeBeau, J.M. A Numerical Model for Multiple Detector Energy Dispersive X-ray Spectroscopy in the Transmission Electron Microscope. Ultramicroscopy 2016, 164, 51–61. [Google Scholar] [CrossRef]

- Lu, P.; Romero, E.; Lee, S.; MacManus-Driscoll, J.L.; Jia, Q.X. Chemical Quantification of Atomic-Scale EDS Maps under Thin Specimen Conditions. Microsc. Microanal. 2014, 20, 1782–1790. [Google Scholar] [CrossRef] [PubMed]

- Spence, J.C.H.; Taftø, J. ALCHEMI: A New Technique for Locating Atoms in Small Crystals. J. Microsc. 1983, 130, 147–154. [Google Scholar] [CrossRef]

- Jeong, J.S.; Odlyzko, M.L.; Xu, P.; Jalan, B.; Mkhoyan, K.A. Probing Core-Electron Orbitals by Scanning Transmission Electron Microscopy and Measuring the Delocalization of Core-Level Excitations. Phys. Rev. B 2016, 93, 165140. [Google Scholar] [CrossRef]

- Oxley, M.P.; Allen, L.J. Impact Parameters for Ionization by High-Energy Electrons. Ultramicroscopy 1999, 80, 125–131. [Google Scholar] [CrossRef]

- Pennycook, S.J. Delocalization Corrections for Electron Channeling Analysis. Ultramicroscopy 1988, 26, 239–248. [Google Scholar] [CrossRef]

- Allen, L.J. Simulation in Elemental Mapping Using Aberration-Corrected Electron Microscopy. Ultramicroscopy 2017, 180, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Taplin, D.J.; Weyland, M.; Allen, L.J.; Findlay, S.D. Composition Measurement in Substitutionally Disordered Materials by Atomic Resolution Energy Dispersive X-ray Spectroscopy in Scanning Transmission Electron Microscopy. Ultramicroscopy 2017, 176, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Kothleitner, G.; Neish, M.J.; Lugg, N.R.; Findlay, S.D.; Grogger, W.; Hofer, F.; Allen, L.J. Quantitative Elemental Mapping at Atomic Resolution Using X-ray Spectroscopy. Phys. Rev. Lett. 2014, 112, 085501. [Google Scholar] [CrossRef]

- Lugg, N.R.; Kothleitner, G.; Shibata, N.; Ikuhara, Y. On the Quantitativeness of EDS STEM. Ultramicroscopy 2015, 151, 150–159. [Google Scholar] [CrossRef]

- Chen, Z.; Weyland, M.; Sang, X.; Xu, W.; Dycus, J.H.; LeBeau, J.M.; D’Alfonso, A.J.; Allen, L.J.; Findlay, S.D. Quantitative Atomic Resolution Elemental Mapping via Absolute-Scale Energy Dispersive X-ray Spectroscopy. Ultramicroscopy 2016, 168, 7–16. [Google Scholar] [CrossRef]

- Buffat, P. Identification of Nano-Phases: Relative Merit of Local Analysis Techniques (HRTEM, Nanodiffraction, EDS/EELS); European Microscopy Society Yearbook. France, 2004; pp. 78–90. Available online: https://infoscience.epfl.ch/record/227203/files/Buffat_Yearbook_EMS2004.pdf (accessed on 17 January 2024).

- Dycus, J.H.; Xu, W.; Sang, X.; D’Alfonso, A.J.; Chen, Z.; Weyland, M.; Allen, L.J.; Findlay, S.D.; LeBeau, J.M. Influence of Experimental Conditions on Atom Column Visibility in Energy Dispersive X-ray Spectroscopy. Ultramicroscopy 2016, 171, 1–7. [Google Scholar] [CrossRef]

| Phase: Columns | Lattice | a | b | c | |

|---|---|---|---|---|---|

| γ: 53Ni 24Cr 23Fe | Cubic | F m 3 m | 0.365 | 0.365 | 0.365 |

| γ′: 8Al 9Nb 8Ti/Ni | Cubic FCC | P m −3 m | 0.365 | 0.365 | 0.365 |

| γ″: 3Al 39 Nb 8Ti/Ni | Tetragonal BC | I 4/m m m | 0.365116-117 | 0.365 | 0.73 |

| Contrast in 80 nm Thick Foil | Phase | ||||

|---|---|---|---|---|---|

| γ′ 20 nm diameter sphere, in the middle of the foil | γ | 3.0% | 1.8% | 709 | 706 |

| γ″ disc, edge-on view, extending through the whole foil thickness | γ′ | 32% | 28% | 794 | 757 |

| γ″ disc in plane view, 5 nm thick | γ″ | 2.0% | 1.8% | 937 | 904 |

| Matrix γ | γ′ | γ′ and γ″ | γ″ | |

|---|---|---|---|---|

| [0,1,0] column composition | Ni0.53Cr0.24Fe0.23 | Al0.33Ti0.30Nb0.37 | Pure Ni | Nb0.83Ti0.17 |

| 〈Z〉//Zeff | 26.6//26.6 | 26.1//28.7 | 28.0//28 | 37.8//38.4 |

| Intensity ≈ 〈Z〉2// | 706//709 | 679//823 | 784//784 | 1426//1477 |

| Al | Cr | Fe | Mo | Nb | Ni | Ti | Co | Al/Ti | Al/Nb | Ti/Nb | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal investigated alloy | 1.1 | 20.1 | 19.8 | 1.8 | 3.1 | 52.9 | 1.2 | - | |||

| EDXS Esprit matrix only γ ± 2σ | 0.5 ± 0.08 | 23.4 ± 0.52 | 22.4 ± 0.50 | 1.9 ± 0.07 | 1.0 ± 0.07 | 50.7 ± 1.06 | 0.1 ± 0.04 | - | |||

| EDXS ImageJ deconv. γ | 0.6 ± 0.01 | 23.1 ± 0.18 | 22.3 ± 0.07 | 2.2 ± 0.01 | 1.00 ± 0.04 | 50.5 ± 0.10 | 0.3 ± 0.01 | - | 2.29 | 0.6 | 0.26 |

| EDXS ImageJ deconv. γ′ | 7.2 ± 0.18 | - | - | 1.0 ± 0.12 | 7.9 ± 0.23 | 77.6 ± 0.53 | 6.4 ± 0.16 | - | 1.12 | 0.91 | 0.81 |

| EDXS ImageJ deconv. γ″ | 1.5± 0.16 | - | - | 1.4 ± 0.07 | 19.6 ± 0.49 | 75.6 ± 0.28 | 4.0 ± 0.09 | - | 0.36 | 0.07 | 0.21 |

| Nominal Miller’s alloy | 1.27 | 19.6 | 21.5 | 1.76 | 3.24 | 51.15 | 1.18 | 0.31 | |||

| APT γ | 0.58 | 23.48 | 25.54 | 2.13 | 1.59 | 45.83 | 0.47 | 0.38 | 1.23 | 0.36 | 0.3 |

| APT γ′ | 9.11 | 0.79 | 2 | 0.53 | 7.22 | 72.88 | 7.38 | 0.09 | 1.23 | 1.26 | 1.02 |

| APT γ″ | 0.35 | 2.16 | 2.11 | 1.3 | 20.07 | 68.37 | 5.59 | 0.05 | 0.06 | 0.02 | 0.28 |

| Thermo-Calc γ | 0.38 | 23.75 | 26.45 | 1.82 | 0.46 | 46.66 | 0.14 | 0.34 | 2.71 | 0.83 | 0.3 |

| Thermo-Calc γ′ | 8.43 | 0.8 | 3.64 | 0.18 | 7.52 | 71.67 | 7.59 | 0.17 | 1.11 | 1.12 | 1.01 |

| Thermo-Calc γ″ | 0.2 | 0.56 | 1.09 | 0.5 | 20.41 | 73.14 | 3.89 | 0.21 | 0.05 | 0.01 | 0.19 |

| Column | Al | Nb | Ti |

|---|---|---|---|

| Interface | 0.38 | 0.36 | 0.26 |

| Last before interface | 0.32 | 0.36 | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buffat, P.A.; Alexandrou, I.; Czyrska-Filemonowicz, A. Composition and Element Distribution Mapping of γ′ and γ″ Phases of Inconel 718 by High-Resolution Scanning Transmission Electron Microscopy and X-ray Energy-Dispersive Spectrometry. Materials 2024, 17, 594. https://doi.org/10.3390/ma17030594

Buffat PA, Alexandrou I, Czyrska-Filemonowicz A. Composition and Element Distribution Mapping of γ′ and γ″ Phases of Inconel 718 by High-Resolution Scanning Transmission Electron Microscopy and X-ray Energy-Dispersive Spectrometry. Materials. 2024; 17(3):594. https://doi.org/10.3390/ma17030594

Chicago/Turabian StyleBuffat, Philippe A., Ioannis Alexandrou, and Aleksandra Czyrska-Filemonowicz. 2024. "Composition and Element Distribution Mapping of γ′ and γ″ Phases of Inconel 718 by High-Resolution Scanning Transmission Electron Microscopy and X-ray Energy-Dispersive Spectrometry" Materials 17, no. 3: 594. https://doi.org/10.3390/ma17030594

APA StyleBuffat, P. A., Alexandrou, I., & Czyrska-Filemonowicz, A. (2024). Composition and Element Distribution Mapping of γ′ and γ″ Phases of Inconel 718 by High-Resolution Scanning Transmission Electron Microscopy and X-ray Energy-Dispersive Spectrometry. Materials, 17(3), 594. https://doi.org/10.3390/ma17030594