Utilization of Recycled Brick Powder as Supplementary Cementitious Materials—A Comprehensive Review

Abstract

:1. Introduction

2. Properties of WBP as SCM in Mortar and Concrete

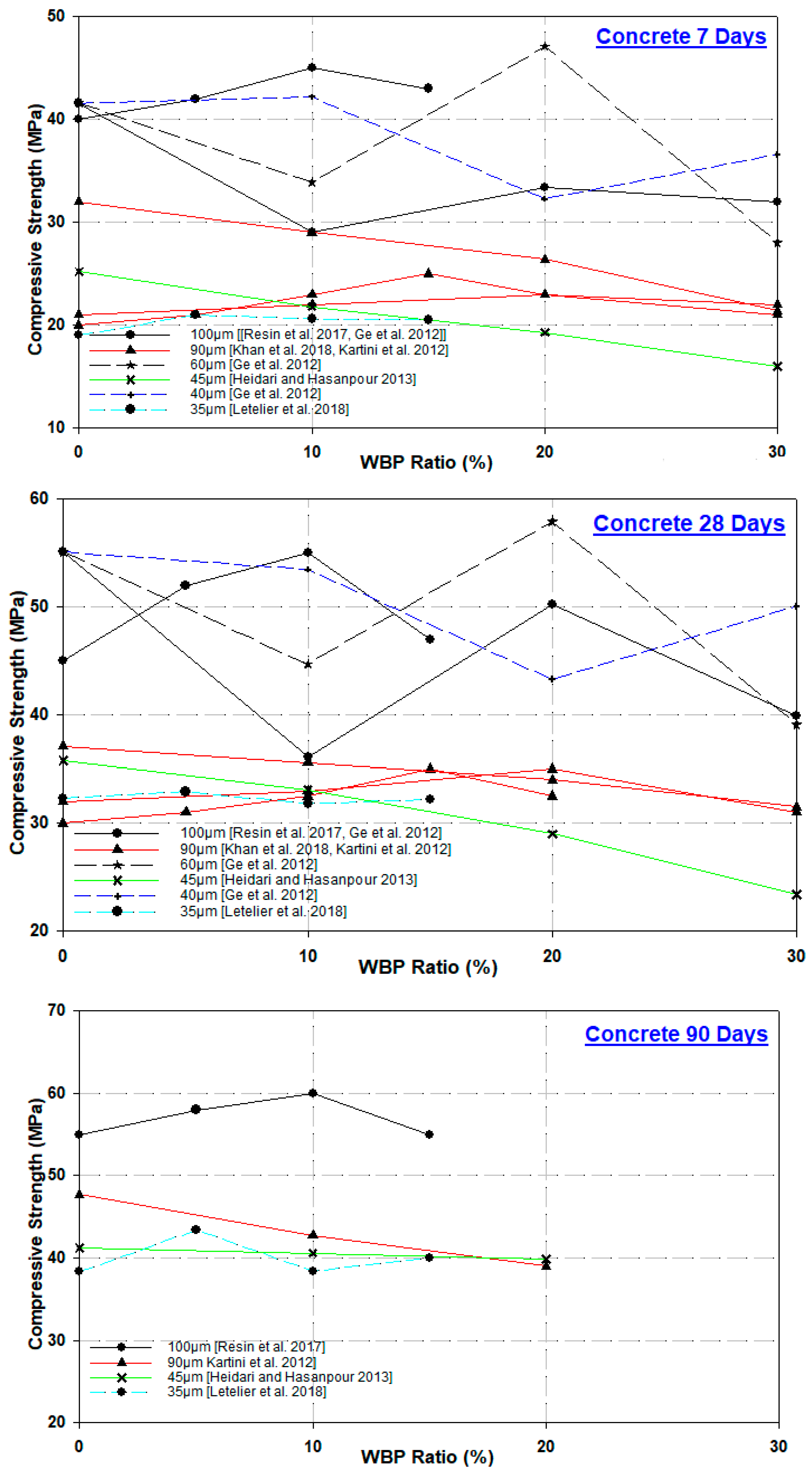

2.1. Effect of WBP Particle Size and Curing Period on Compressive Strength

2.2. Pozzolanic Activity and Mineralogical Structure

3. Durability Properties

3.1. Water Absorption

3.2. Drying Shrinkage

3.3. Resistance to Chloride Attack

3.4. Resistance to Sulfate Attack

4. Life Cycle Assessment (LCA)

5. Conclusions

- -

- The compressive strength of WBP-substituted mortar and concrete specimens decreases as the WBP admixture ratio increases. Notably, particle sizes ranging from 100 µm to 25 µm and substitution rates of up to 10–20% demonstrate a positive contribution to the compressive strength of the produced samples.

- -

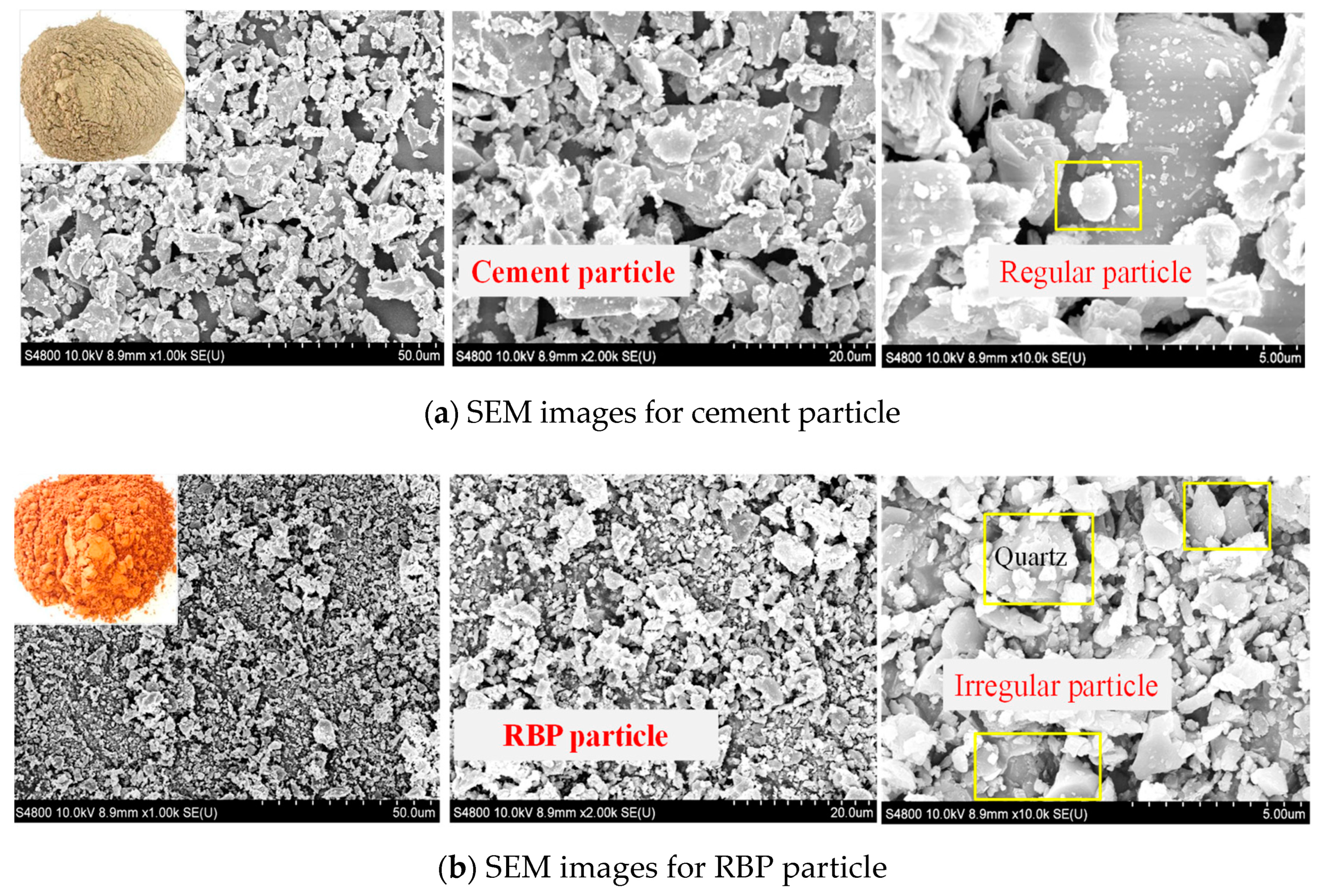

- All WBPs employed in the substitution of cement in mortars and concretes were found to satisfy the criteria supporting pozzolanic activity, specifically with Si2O + Al2O3 + Fe2O3 ≥70. Additionally, the microstructure of WBP is characterized by irregularity, a rough surface, and an angular structure. The pozzolanic reaction results in the formation of additional C-S-H phases in WBP, thereby contributing to the improvement of pore size in the test specimens.

- -

- WBP contributes positively to water absorption resistance by enhancing the compactness of concrete and mortar at a certain substitution ratio and curing period. A WBP replacement ratio of up to 15% of cement in mortars and 10–20% of cement in concrete was observed to be effective in reducing water absorption. However, WBP improves the pore structure of concrete and mortar, resulting in lower drying shrinkage. Furthermore, WBP substitution significantly enhances the sulfate resistance of mortars and concretes, mitigating strength loss.

- -

- The pozzolanic activity and filling effect of WBP improved the resistance of concrete and mortars to chloride ion penetration. Notably, utilizing 20% WBP substitution in mortar samples and 30% WBP substitution in concrete samples, considering the curing age and substitution ratio, enables the production of concretes with characteristics approaching the threshold for “concrete with low chloride ion permeability” as per the ASTM C1202 standard.

- -

- The utilization of WBP as a substitute for cement in cementitious materials emerges as a promising option by which to mitigate the environmental impact, reducing energy consumption, the emission of CO2, and costs, and addressing the challenges associated with solid waste disposal in the construction industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Cement and Concrete Industry Announces Roadmap to Achieve Groundbreaking ‘Net Zero’ CO2 Emissions by 2050: GCCA. Available online: https://gccassociation.org (accessed on 31 October 2022).

- IEA. Cement; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/cement (accessed on 31 October 2022).

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A Review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in Concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Gartner, E.; Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in Concrete. Cem. Concr. Res. 2015, 78, 126–142. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Justnes, H. How to make concrete more sustainable. J. Adv. Concr. Technol. 2015, 13, 147–154. [Google Scholar] [CrossRef]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef]

- Likes, L.; Markandeya, A.; Haider, M.M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Sivakrishna, A.; Adesina, P.O.; Awoyera, K.; Kumar, R. Green concrete: A review of recent developments. Mater. Today Proc. 2020, 27, 54–58. [Google Scholar] [CrossRef]

- Kumar, M.; Prashant, S.; Kamath, M.V. Enhancing the sustainability of high strength concrete in terms of embodied energy and carbon emission by incorporating sewage sludge and fly ash. Innov. Infrastruct. Solut. 2022, 7, 240. [Google Scholar] [CrossRef]

- Omran, A.; Soliman, N.; Zidol, A.; Tagnit-Hamou, A. Performance of ground-glass pozzolan as a cementitious material—A Review. Adv. Civ. Eng. Mater. 2018, 7, 237–270. [Google Scholar] [CrossRef]

- Wei, J.; Gençtürk, B. Hydration of ternary Portland cement blends containing metakaolin and sodium bentonite. Cem. Concr. Res. 2019, 123, 105772. [Google Scholar] [CrossRef]

- Shah, M.U.; Usman, M.; Hanif, M.U.; Naseem, I.; Farooq, S. Utilization of solid waste from brick industry and hydrated lime in self-compacting cement pastes. Materials 2021, 14, 1109. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; You, Q.; Chen, M.; Zeng, Q. Waste ceramic powder as a pozzolanic supplementary filler of cement for developing sustainable building materials. J. Clean. Prod. 2020, 259, 120853. [Google Scholar] [CrossRef]

- Rao, M.C. Influence of brick dust, stone dust, and recycled fine aggregate on properties of natural and recycled aggregate Concrete. Struct. Concrete 2021, 22 (Suppl. S1), E105–E120. [Google Scholar]

- Schulze, S.E.; Rickert, J. Suitability of natural calcined clays as supplementary cementitious material. Cem. Concr. Compos. 2019, 95, 92–97. [Google Scholar] [CrossRef]

- Liu, B.; Meng, H.; Pan, G.; Zhou, H.; Li, D. Relationship between the fineness and specific surface area of iron tailing powder and its effect on compressive strength and drying shrinkage of cement composites. Constr. Build. Mater. 2022, 357, 129421. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Jain, P.; Gupta, R.; Chaudhary, S. Comprehensive assessment of ceramic ETP sludge waste as a SCM for the production of Concrete. J. Build. Eng. 2022, 57, 104973. [Google Scholar] [CrossRef]

- Thapa, V.B.; Waldmann, D.; Simon, C. Gravel wash mud, a quarry waste material as supplementary cementitious material (SCM). Cem. Concr. Res. 2019, 124, 105833. [Google Scholar] [CrossRef]

- Govedarica, O.; Aškrabić, M.; Hadnađev-Kostić, M.; Vulić, T.; Lekić, B.; Rajaković-Ognjanović, V.; Zakić, D. Evaluation of solidified wastewater treatment sludge as a potential SCM in pervious concrete pavements. Materials 2022, 15, 4919. [Google Scholar] [CrossRef]

- Yang, H.J.; Usman, M.; Hanif, A. Suitability of liquid crystal display (LCD) glass waste as supplementary cementing material (SCM): Assessment based on strength, porosity, and durability. J. Build. Eng. 2021, 42, 102793. [Google Scholar] [CrossRef]

- Tremino, T.R.; Real-Herraiz, T.; Letelier, V.; Ortega, J.M. Four-years influence of waste brick powder addition in the pore structure and several durability-related parameters of cement-based mortar. Constr. Build. Mater. 2021, 306, 124839. [Google Scholar] [CrossRef]

- Mohan, M.; Apurva, A.; Kumar, N.; Ojha, A. A review on use of crushed brick powder as a supplementary cementitious material. In Proceedings of the International Conference on Materials, Mechanics and Structures 2020 (ICMMS2020), Kerala, India, 14–15 July 2020; IOP Publishing: Bristol, UK, 2020; Volume 936. [Google Scholar]

- Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J.; Olubanwo, A.O. Consistency and mechanical properties of sustainable concrete blended with brick dust waste cementitious materials. SN Appl. Sci. 2021, 3, 420. [Google Scholar] [CrossRef]

- Huxiao, W.; Xiao, J.; Liang, C.; Ma, Z. Properties of cementitious materials with recycled aggregate and powder both from clay brick waste. Buildings 2021, 11, 119. [Google Scholar]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate Concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Hu, W.; Du, Z.; Gao, D. Properties of mortar with waste clay bricks as fine aggregate. Constr. Build. Mater. 2018, 166, 898–907. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J. Influence of waste clay bricks as fine aggregate on the mechanical and microstructural properties of concrete. Constr. Build. Mater. 2019, 228, 116757. [Google Scholar] [CrossRef]

- Uddin, M.T.; Mahmood, A.H.; Kamal, M.D.R.I.; Yashin, S.M.; Zihan, Z.U.A. Effects of maximum size of brick aggregate on properties of concrete. Constr. Build. Mater. 2017, 134, 713–726. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Heidari, A.; Hasanpour, B. Effects of waste bricks powder of Gachsaran Company as a pozzolanic material in concrete. Asian J. Civ. Eng. (BHRC) 2013, 14, 755–763. [Google Scholar]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Bamigboye, G.O. Structural Properties of Concrete Containing Ground Waste Clay Brick Powder as Partial Substitute for Cement. In Material Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2016; Volume 866, pp. 63–67. [Google Scholar]

- Resin, R.; Alwared, A.; Al-Hubboubi, S. Utilization of brick waste as pozzolanic material in concrete mix. In Proceedings of the 3rd International Conference on Buildings, Construction and Environmental Engineering, BCEE3-2017, Sharm El Sheikh, Egypt, 23–25 October 2017; Volume 162, p. 02006. [Google Scholar] [CrossRef]

- Cong, L.; Jialin, L.; Jing, C.; Hailun, W.; Dong, L. Study on the Application of Recycled Fine Powder in Ready-Mixed Concrete. In Proceedings of the MATEC Web of Conferences, Lisbon, Portugal, 26–28 September 2019; EDP Sciences; Volume 278, p. 01010. [Google Scholar]

- Zheng, L.; Ge, Z.; Yao, Z.; Gao, Z. Mechanical Properties of Mortar with Recycled Clay-Brick-Powder. In Proceedings of the ICCTP 2011: Towards Sustainable Transportation Systems, Nanjing, China, 14–17 August 2011; pp. 3379–3388. [Google Scholar] [CrossRef]

- Abbas, Z.K.; Abbood, A.A. The influence of incorporating recycled brick on concrete properties. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012010. [Google Scholar] [CrossRef]

- Luo, X.; Gao, J.; Liu, X.; Li, S.; Zhao, Y. Hydration and microstructure evolution of recycled clay brick powder-cement composite cementitious materials. J. Therm. Anal. Calorim. 2022, 147, 10977–10989. [Google Scholar] [CrossRef]

- Wu, H.; Liang, C.; Wang, C.; Ma, Z. Properties of green mortar blended with waste concrete-brick powder at various components, replacement ratios and particle sizes. Constr. Build. Mater. 2022, 342, 128050. [Google Scholar] [CrossRef]

- Siline, M. Processing, effect and reactivity assessment of artificial pozzolans obtained from clays and clay wastes: A Review. Constr. Build. Mater. 2017, 140, 10–19. [Google Scholar]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Xu, Z.; Luo, X.; Gao, J. Particle-size effect of recycled clay brick powder on the pore structure of blended cement paste. Constr. Build. Mater. 2022, 344, 128288. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Lam, N.T.; Nguyen, D.T.; Nguyen, D.L. Potential use of clay brick waste powder and ceramic waste aggregate in mortar. Constr. Build. Mater. 2021, 313, 125516. [Google Scholar] [CrossRef]

- Ge, Z.; Gao, Z.; Sun, R.; Zheng, L. Mix design of concrete with recycled clay-brick-powder using the orthogonal design method. Constr. Build. Mater. 2012, 31, 289–293. [Google Scholar] [CrossRef]

- Kartini, K.; Rohaidah, M.N.; Zuraini, Z.A. Performance of ground clay bricks as partial cement replacement in grade 30 concrete. World Academy of Science, Engineering and Technology, Open Science Index 68. Int. J. Civ. Environ. Eng. 2012, 6, 569–572. [Google Scholar]

- Khan, M.N.A.; Liaqat, N.; Ahmed, I.; Basit, A.; Umar, M.; Khan, M.A. Effect of brick dust on strength and workability of concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 1st International Conference on Advances in Engineering and Technology (ICAET-2018), Quetta, Pakistan, 2–3 April 2018; Volume 414. [Google Scholar]

- Rani, M.U.; Jenifer, J.M. Mechanical properties of concrete with partial replacement of Portland cement by clay brick powder. Int. J. Eng. Res. Technol. (IJERT) 2016, 5, 63–67. [Google Scholar]

- Ouyang, X.; Wang, L.; Fu, J.; Xu, S.; Ma, Y. Surface properties of clay brick powder and its influence on hydration and strength development of cement paste. Constr. Build. Mater. 2021, 300, 123958. [Google Scholar] [CrossRef]

- Nwankwo, E.; John, A.T. Strength and workability assessment of concrete produced by partial replacement of cement with waste clay bricks. Niger. J. Environ. Sci. Technol. 2019, 3, 352–360. [Google Scholar] [CrossRef]

- Khan, M.D.N.N.; Saha, A.K.; Sarker, P.K. Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: A Review. J. Build. Eng. 2020, 28, 101052. [Google Scholar] [CrossRef]

- Bediako, M. Pozzolanic potentials and hydration behavior of ground waste clay brick obtained from clamp-firing technology. Case Stud. Constr. Mater. 2018, 8, 1–7. [Google Scholar] [CrossRef]

- Lin, K.-L.; Wu, H.-H.; Shie, J.-L.; Hwang, C.-L.; Cheng, A. Recycling waste brick from construction and demolition of buildings as pozzolanic materials. Waste Manag. Res. 2010, 28, 653–659. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened Concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Luo, X.; Shujun, L.; Guo, Z.; Chen, G.; Gao, J. Effect of brick powder on the pore solution and microstructure of Portland cement. J. Build. Eng. 2023, 63, 105497. [Google Scholar] [CrossRef]

- Luo, X.; Li, S.; Guo, Z.; Liu, C.; Gao, J. Effect of curing temperature on the hydration property and microstructure of Portland cement blended with recycled brick powder. J. Build. Eng. 2022, 61, 105327. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.-C. Potential use of brick waste as alternate concrete-making materials: A Review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Navrátilová, E.; Rovnaníková, P. Pozzolanic properties of brick powders and their effect on the properties of modified lime mortars. Constr. Build. Mater. 2016, 120, 530–539. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2003.

- Aliabdo, A.A.; Abd-Elmoaty, M.; Hassan, H.H. Utilization of crushed clay brick in concrete industry. Alex. Eng. J. 2014, 53, 151–168. [Google Scholar] [CrossRef]

- ASTM C311; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2022.

- Pitarch, A.M.; Reig, L.; Tomás, A.E.; Forcada, G.; Soriano, L.; Borrachero, M.V.; Payá, J.; Monzó, J.M. Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Clean. Prod. 2021, 279, 123713. [Google Scholar] [CrossRef]

- O’Farrell, M.; Wild, S.; Sabir, B.B. Pore size distribution and compressive strength of waste clay brick mortar. Cem. Concr. Compos. 2001, 23, 81–91. [Google Scholar] [CrossRef]

- Reig, L.; Tashima, M.M.; Borrachero, M.V.; Monzó, J.; Cheeseman, C.R.; Payá, J. Properties and microstructure of alkali-activated red clay brick waste. Constr. Build. Mater. 2013, 43, 98–106. [Google Scholar] [CrossRef]

- Rovnaník, P.; Řezník, B.; Rovnaníková, P. Blended alkali-activated fly ash/brick powder materials. Procedia Eng. 2016, 151, 108–113. [Google Scholar] [CrossRef]

- Harbi, R.; Derabla, R.; Nafa, Z. Improvement of the properties of a mortar with 5% of kaolin fillers in sand combined with metakaolin, brick waste and glass powder in cement. Constr. Build. Mater. 2017, 152, 632–641. [Google Scholar] [CrossRef]

- Simut, B.J.; Vyšvařil, M.; Bayer, P.; Keppert, M.; Rovnaníková, P. Effect of particle size of waste brick powder on the properties of alkaline activated materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference Building Materials, Products and Technologies, Blansko-Češkovice, Czech Republic, 29–31 May 2018; Volume 379. [Google Scholar]

- Fort, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Rovnaníková, P.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.A.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Changwei, X.; Xutong, Y. Study on activation of waste clay brick powder. In Proceedings of the 3rd International Conference on Mechanical Engineering and Applied Composite Materials (MEACM 2019), Singapore, 22–23 November 2019; Volume 744. [Google Scholar]

- Zhao, Z.; Grellier, A.; Bouarroudj, M.E.K.; Michel, F.; Bulteel, D.; Courard, L. Substitution of limestone filler by waste brick powder in self-compacting mortars: Properties and durability. J. Build. Eng. 2021, 43, 102898. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, X.; Xiong, G.; Wang, C.; Liu, D.; Zhao, L. Recycling of crushed waste clay brick as aggregates in cement mortars: An approach from macro- and micro-scale investigation. Constr. Build. Mater. 2021, 274, 122068. [Google Scholar] [CrossRef]

- Dang, J.; Xiao, J.; Duan, Z. Effect of pore structure and morphological characteristics of recycled fine aggregates from clay bricks on mechanical properties of concrete. Constr. Build. Mater. 2022, 358, 129455. [Google Scholar] [CrossRef]

- Yuan, C.; Fu, W.; Raza, A.; Li, H. Study on mechanical properties and mechanism of recycled brick powder UHPC. Buildings 2022, 12, 1622. [Google Scholar] [CrossRef]

- Ruminski, P.; Szeląg, M.; de Matos, P. Evaluating the feasibility of using brick powder and clay powder in cement replacement. Materials 2022, 15, 8127. [Google Scholar] [CrossRef] [PubMed]

- Sinkhonde, D.; Mashava, D. Analysis of milling treatments of waste clay bricks effect on density and compressive strength of cement paste. Results Mater. 2022, 16, 100346. [Google Scholar] [CrossRef]

- Lin, K.L.; Chen, B.Y.; Chiou, C.S.; Cheng, A. Waste brick’s potential for use as a pozzolan in blended Portland cement. Waste Manag. Res. 2010, 28, 647–652. [Google Scholar] [CrossRef]

- Pavlík, Z.; Trník, A.; Kulovaná, T.; Scheinherrová, L.; Rahhal, V.; Irassar, E.; Černý, R. DSC and TG Analysis of a blended binder based on waste ceramic powder and Portland cement. Int. J. Thermophys. 2016, 37, 32. [Google Scholar] [CrossRef]

- Rahhal, V.F.; Trezza, M.A.; Tironi, A.; Castellano, C.C.; Pavlíková, M.; Pokorný, J.; Irassar, E.F.; Jankovský, O.; Pavlík, Z. Complex Characterization and Behavior of Waste Fired Brick Powder-Portland Cement System. Materials 2019, 12, 1650. [Google Scholar] [CrossRef]

- Wu, J.D.; Guo, L.P.; Qin, Y.Y. Preparation and characterization of ultra-high-strength and ultra-high-ductility cementitious composites incorporating waste clay brick powder. J. Clean. Prod. 2021, 312, 127813. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A Review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of clay brick waste in mortar and concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6326178. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, J.; Duan, Z.; Hubert, J.; Grigoletto, S.; Courard, L. Performance and durability of self-compacting mortar with recycled sand from crushed brick. J. Build. Eng. 2022, 57, 104867. [Google Scholar] [CrossRef]

- Mansoor, S.S.; Hama, S.M.; Hamdullah, D.N. Effectiveness of replacing cement partially with waste brick powder in mortar. J. King Saud Univ.-Eng. Sci. 2022. [Google Scholar] [CrossRef]

- Schackow, A.; Stringari, D.; Senff, L.; Correia, S.L.; Segadães, A.M. Influence of fired clay brick waste additions on the durability of mortars. Cem. Concr. Compos. 2015, 62, 82–89. [Google Scholar] [CrossRef]

- Silva, Y.F.; Delvasto, S. Durability of self-compacting concrete with addition of residue of masonry when exposed to carbonation and chlorides mediums. Constr. Build. Mater. 2021, 297, 123817. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Gonçalves, J.P.; Americano, B.B.; Fairbairn, E.M.R. Potential for use of crushed waste calcined-clay brick as a supplementary cementitious material in Brazil. Cem. Concr. Res. 2007, 37, 1357–1365. [Google Scholar] [CrossRef]

- Silva, Y.F.; Lange, D.A.; Delvasto, S. Effects of the incorporation of residue of masonry on the properties of cementitious mortars. Rev. Construcción 2020, 19, 407–421. [Google Scholar] [CrossRef]

- Sinkhonde, D.; Onchiri, R.O.; Oyawa, W.O.; Mwero, J.N. Durability and water absorption behaviour of rubberised concrete incorporating burnt clay brick powder. Clean. Mater. 2022, 4, 100084. [Google Scholar] [CrossRef]

- Aghabaglou, A.M.; Özen, S.; Bayqra, S.H.; Ouedraogo, H.A. Comparison of different pozzolans from strength and permeability performance of mortar mixtures containing plain, binary and ternary cementitious systems view point. J. BAUN Inst. Sci. Technol. 2018, 20, 612–625. [Google Scholar] [CrossRef]

- Ding, Y.; Li, H.; Zhang, H.; Li, S.; Zhang, X.; Hua, S.; Zhao, J.; Tong, Y. Shrinkage and durability of waste brick and recycled concrete aggregate stabilized by cement and fly ash. Materials 2022, 15, 3684. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. A critical review on drying shrinkage mitigation strategies in cement-based materials. J. Build. Eng. 2021, 38, 102210. [Google Scholar] [CrossRef]

- Zhu, P.; Mao, X.; Qu, W.; Li, Z.; John Ma, Z. Investigation of using recycled powder from waste of clay bricks and cement solids in reactive powder Concrete. Constr. Build. Mater. 2016, 113, 246–254. [Google Scholar] [CrossRef]

- Erdoğdu, K.; Tokyay, M.; Türker, P. Traslar ve traslı Çimentolar. Araştırmaların Gözden Geçirilmesi ve Durum Değerlendirmesi Raporu, 9. Baskı TÇMB/AR-GE/Y 99.2; TÇMB/AR-GE ENSTİTÜSÜ: Ankara, Türkiye, 2011; ISBN 975-8136-13-5. (In Turkish) [Google Scholar]

- Gonçalves, J.P.; Tavares, L.M.; Filho, R.D.; Fairbairn, E.M.R. Performance evaluation of cement mortars modified with metakaolin or ground brick. Constr. Build. Mater. 2009, 23, 1971–1979. [Google Scholar] [CrossRef]

- ASTM C1202-97; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 1997.

- Tuyan, M. Effect of Use of Waste Clay Brick Powder as Mineral Admixture on Fresh, Mechanical and Durability Properties of Self-Consolidating Concrete, Süleyman Demirel University. J. Nat. Appl. Sci. 2019, 23, 540–548. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar]

- O’Farrell, M.; Wild, S.; Sabir, B.B. Resistance to chemical attack of ground brick-PC mortar: Part I. Sodium sulphate solution. Cem. Concr. Res. 1999, 29, 1781–1790. [Google Scholar] [CrossRef]

- Alcharchafche, M.A.S.; Al-mashhadani, M.M.; Aygörmez, Y. Investigation of mechanical and durability properties of brick powder-added White Cement composites with three different fibers. Constr. Build. Mater. 2022, 347, 128548. [Google Scholar] [CrossRef]

- Binici, H.; Kapur, S.; Arocena, J.; Kaplan, H. The sulphate resistance of cements containing red brick dust and ground basaltic pumice with sub-microscopic evidence of intra-pore gypsum and ettringite as strengtheners. Cem. Concr. Compos. 2012, 34, 279–287. [Google Scholar] [CrossRef]

- O’Farrell, M.; Sabir, B.B.; Wild, S. Strength and chemical resistance of mortars containing brick manufacturing clays subjected to different treatments. Cem. Concr. Compos. 2006, 28, 790–799. [Google Scholar] [CrossRef]

- Li, L.G.; Lin, Z.H.; Chen, G.M.; Kwan, A.K.H. Reutilizing clay brick dust as paste substitution to produce environment-friendly durable mortar. J. Clean. Prod. 2020, 274, 122787. [Google Scholar] [CrossRef]

- Wild, S.; Khatib, J.M.; O’Farrell, M. Sulphate resistance of mortar, containing ground brick clay calcined at different temperatures. Cem. Concr. Res. 1997, 27, 697–709. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organisation for Standards: Geneva, Switzerland, 2006.

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental performance analysis of insulated composite facade panels using life cycle assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.B.H.; Christiansen, K.; Klüppel, H.-J. Thenew international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Curran, M.A. Life cycle assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elemam, W.E.; Alanazi, H.; Tahwia, A.M. Production and optimization of sustainable cement brick incorporating clay brick wastes using response surface method. Ceram. Int. 2023, 49, 9395–9411. [Google Scholar] [CrossRef]

- Nasr, M.S.; Salman, A.J.; Ghayyib, R.J.; Shubbar, A.; Al-Mamoori, S.; Al-khafaji, Z.; Hashim, T.M.; Hasan, Z.A.; Sadique, M. Effect of clay brick waste powder on the fresh and hardened properties of self-compacting concrete: State-of-the-art and life cycle assessment. Energies 2023, 16, 4587. [Google Scholar] [CrossRef]

- Liang, G.; Luo, L.; Yao, W. Reusing waste red brick powder as partial mineral precursor in eco-friendly binders: Reaction kinetics, microstructure and life-cycle assessment. Resour. Conserv. Recycl. 2022, 185, 106523. [Google Scholar] [CrossRef]

| Compound | SiO2 | Al2O3 | Fe2O3 | Si2O + Al2O3 + Fe2O3 ≥ 70 | CaO | K2O | Na2O | MgO | Loss on Ignition | References |

|---|---|---|---|---|---|---|---|---|---|---|

| (% by mass) | 41.47 | 39.05 | 12.73 | 93.25 | 0.63 | 2.81 | ---- | ---- | ---- | [24] |

| 41.47 | 39.05 | 12.73 | 93.25 | 0.63 | 2.81 | ---- | ---- | ---- | [26] | |

| 76.10 | 11.80 | 4.80 | 92.70 | 1.30 | ---- | ---- | 1.70 | ---- | [28] | |

| 59.07 | 13.99 | 5.90 | 78.96 | 12.50 | 2.72 | ---- | 2.14 | ---- | [30] | |

| 64.50 | 18.40 | 8.00 | 90.90 | 1.90 | 2.70 | 1.10 | 1.50 | 0.20 | [43] | |

| 63.40 | 25.60 | 5.45 | 94.45 | 0.44 | 2.78 | ---- | 0.36 | 0.70 | [48] | |

| 66.74 | 18.81 | 6.03 | 91.58 | 1.31 | 2.66 | ---- | 1.69 | ---- | [57] | |

| 54.20 | 15.40 | 7.60 | 77.20 | 6.80 | ---- | ---- | 2.50 | 6.20 | [62] | |

| 69.99 | 10.62 | 4.02 | 84.63 | 8.86 | 2.61 | 1.02 | 1.39 | ---- | [65] | |

| 49.90 | 16.60 | 6.50 | 73.00 | 9.70 | 4.40 | 0.50 | 5.50 | 2.40 | [66] | |

| 57.67 | 14.91 | 5.02 | 77.60 | 9.81 | 3.20 | 1.45 | 3.74 | 0.00 | [67] | |

| 69.05 | 23.02 | 1.52 | 93.59 | 2.31 | 2.59 | 1.28 | 1.05 | ---- | [68] | |

| 55.50 | 17.00 | 5.80 | 78.30 | 10.50 | 2.80 | 0.70 | 2.40 | ---- | [69] | |

| 58.80 | 19.60 | 5.70 | 84.10 | 6.90 | 2.90 | 1.50 | 2.80 | ---- | [70] | |

| 41.47 | 39.05 | 12.73 | 93.25 | 0.63 | 2.81 | ---- | ---- | ---- | [71] | |

| 62.01 | 21.11 | 7.00 | 90.12 | 1.45 | 3.37 | 1.60 | 2.00 | ---- | [72] | |

| 62.80 | 10.40 | 16.30 | 89.50 | 1.70 | 2.10 | 0.60 | 2.20 | 0.50 | [73] | |

| 71.34 | 16.21 | 5.68 | 93.23 | 1.51 | 1.22 | 0.58 | 0.73 | 0.47 | [74] | |

| 67.09 | 17.32 | 4.75 | 89.16 | 4.32 | 2.91 | ---- | ---- | ---- | [75] | |

| 68.15 | 16.51 | 7.20 | 91.86 | 1.80 | ---- | 0.65 | 0.94 | ---- | [76] | |

| 59.30 | 14.10 | 7.60 | 81.00 | 2.00 | 3.40 | ---- | 2.30 | 10.1 | [77] | |

| 64.36 | 8.71 | 12.86 | 85.93 | 2.00 | 3.05 | 1.82 | ---- | 0.97 | [78] | |

| 63.21 | 16.41 | 6.05 | 85.67 | --- | 2.83 | 1.19 | 1.11 | --- | [79] | |

| 51.30 | 19.30 | 6.00 | 76.60 | 11.50 | 3.20 | 1.30 | 4.50 | 1.10 | [80] | |

| 51.30 | 20.00 | 6.00 | 77.30 | 11.50 | 3.20 | 1.30 | 4.50 | 1.10 | [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sallı Bideci, Ö.; Bideci, A.; Ashour, A. Utilization of Recycled Brick Powder as Supplementary Cementitious Materials—A Comprehensive Review. Materials 2024, 17, 637. https://doi.org/10.3390/ma17030637

Sallı Bideci Ö, Bideci A, Ashour A. Utilization of Recycled Brick Powder as Supplementary Cementitious Materials—A Comprehensive Review. Materials. 2024; 17(3):637. https://doi.org/10.3390/ma17030637

Chicago/Turabian StyleSallı Bideci, Özlem, Alper Bideci, and Ashraf Ashour. 2024. "Utilization of Recycled Brick Powder as Supplementary Cementitious Materials—A Comprehensive Review" Materials 17, no. 3: 637. https://doi.org/10.3390/ma17030637

APA StyleSallı Bideci, Ö., Bideci, A., & Ashour, A. (2024). Utilization of Recycled Brick Powder as Supplementary Cementitious Materials—A Comprehensive Review. Materials, 17(3), 637. https://doi.org/10.3390/ma17030637