Advanced Ceramics with Dual Functions of Healing and Decomposition

Abstract

:1. Introduction

1.1. Self-Healing

1.2. Decomposition

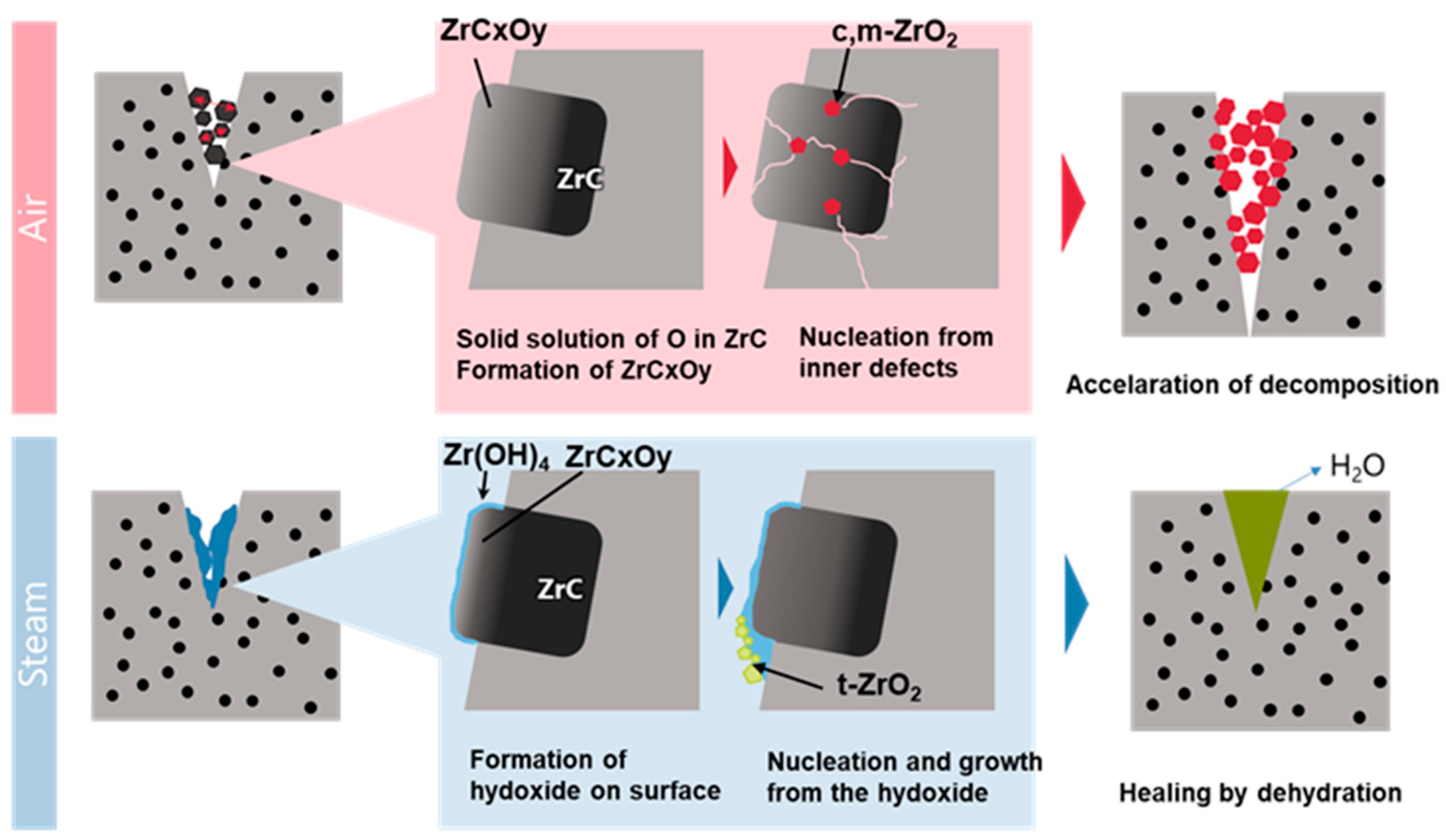

1.3. Steam Oxidation of ZrC

1.4. Air Oxidation of ZrC

2. Methods

2.1. Material

2.2. Indentation, Heat Treatment, Bending Test, and XRD Analysis

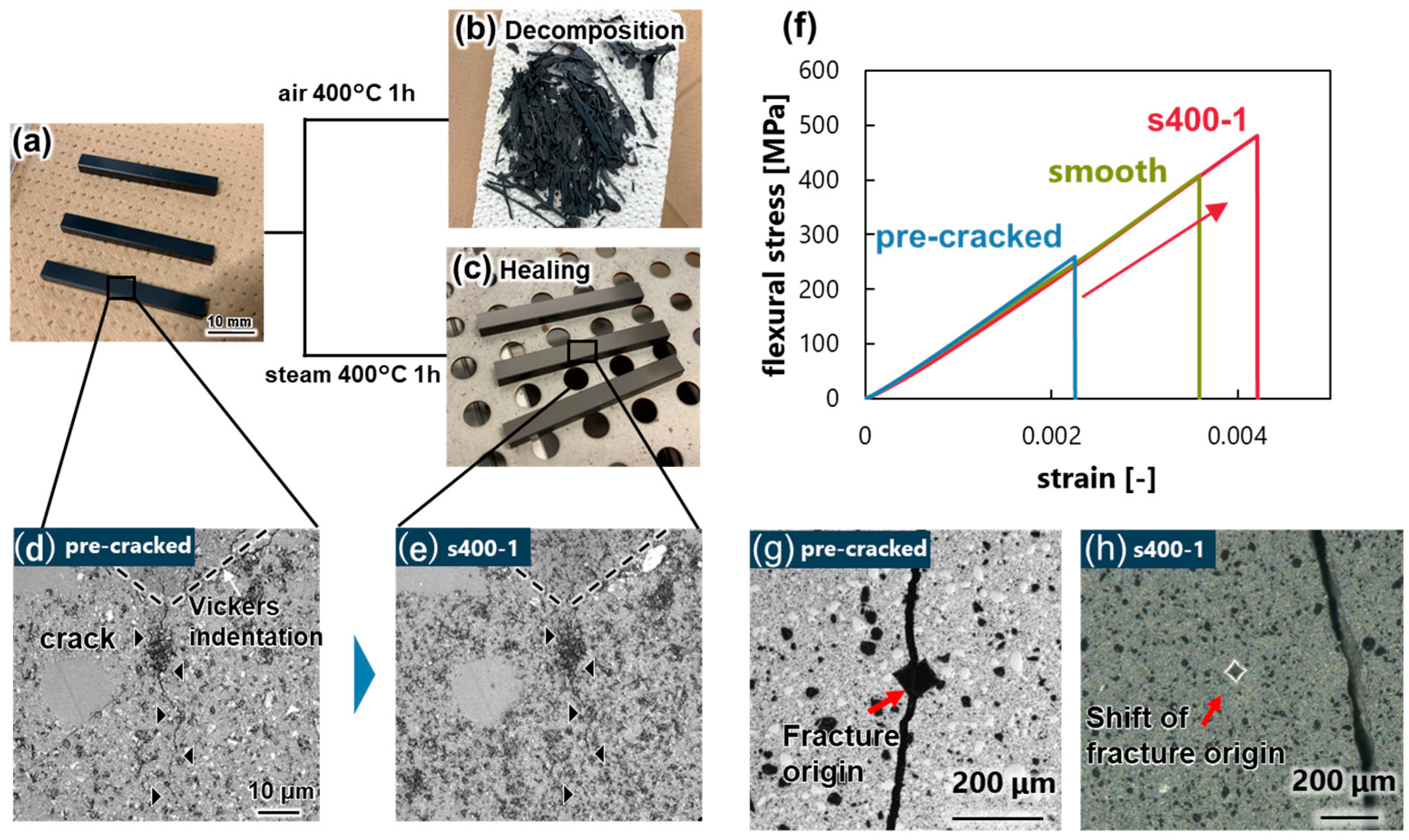

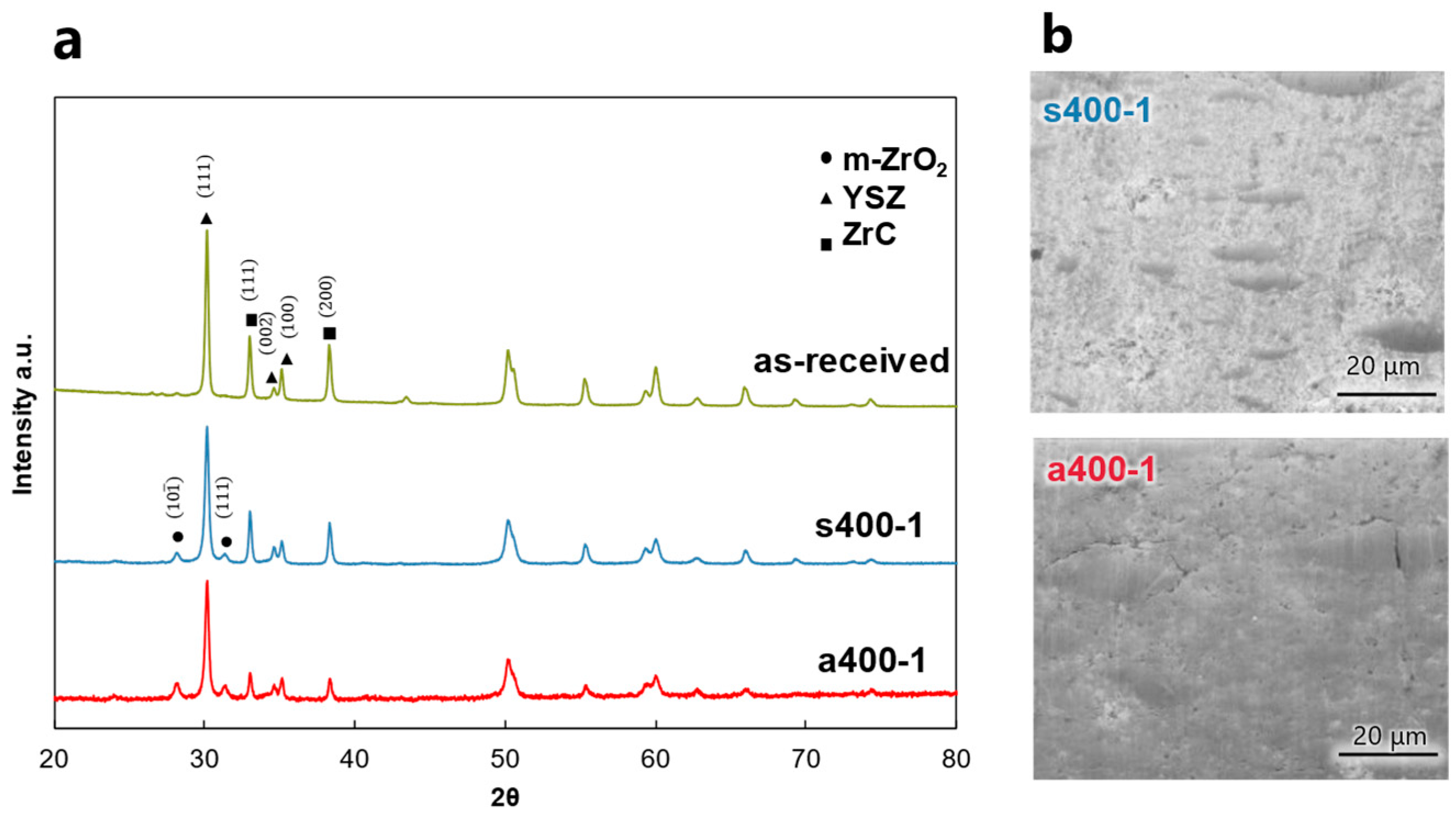

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Umeda, Y.; Kitagawa, K.; Hirose, Y.; Akaho, K.; Sakai, Y.; Ohta, M. Potential Impacts of the European Union’s Circular Economy Policy on Japanese Manufacturers. Int. J. Autom. Technol. 2020, 14, 857–866. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Compretitive Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 8 November 2023).

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 9 November 2023).

- Ellen MacArthur Foundation. Towards the Circular Economy Volume 1: An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- Ministry of Economy Trade and Industry. The Circular Economy Vision 2020 (Summary); Ministry of Economy Trade and Industry: Tokyo, Japan, 2020. (In Japanese)

- OECD. Global Material Resources Outlook to 2060; OECD: Paris, France, 2019; p. 212. [Google Scholar]

- Ramani, K.; Ramanujan, D.; Bernstein, W.Z.; Zhao, F.; Sutherland, J.; Handwerker, C.; Choi, J.-K.; Kim, H.; Thurston, D. Integrated sustainable life cycle design: A review. J. Mech. Des. 2010, 132, 091004. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- European Commission. Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. Available online: http://data.europa.eu/eli/dir/2009/125/oj (accessed on 8 November 2023).

- Wietschel, L.; Halter, F.; Thorenz, A.; Schüppel, D.; Koch, D. Literature Review on the State of the Art of the Circular Economy of Ceramic Matrix Composites. Open Ceramics. 2023, 14, 100357. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Yang, Y.; Urban, M.W. Self-healing polymeric materials. Chem. Soc. Rev. 2013, 42, 7446–7467. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A thermally re-mendable cross-linked polymeric material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef] [PubMed]

- Imato, K.; Nishihara, M.; Kanehara, T.; Amamoto, Y.; Takahara, A.; Otsuka, H. Self-healing of chemical gels cross-linked by diarylbibenzofuranone-based trigger-free dynamic covalent bonds at room temperature. Angew. Chem. 2012, 124, 1164–1168. [Google Scholar] [CrossRef]

- Cordier, P.; Tournilhac, F.; Soulié-Ziakovic, C.; Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Yanagisawa, Y.; Nan, Y.; Okuro, K.; Aida, T. Mechanically robust, readily repairable polymers via tailored noncovalent cross-linking. Science 2018, 359, 72–76. [Google Scholar] [CrossRef]

- Nakahata, M.; Takashima, Y.; Yamaguchi, H.; Harada, A. Redox-responsive self-healing materials formed from host–guest polymers. Nat. Commun. 2011, 2, 511. [Google Scholar] [CrossRef]

- Jonkers, H.M. Self healing concrete: A biological approach. In Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007; pp. 195–204. [Google Scholar]

- Ahn, T.H.; Kishi, T. Crack Self-healing Behavior of Cementitious Composites Incorporating Various Mineral Admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Barr, C.M.; Duong, T.; Bufford, D.C.; Milne, Z.; Molkeri, A.; Heckman, N.M.; Adams, D.P.; Srivastava, A.; Hattar, K.; Demkowicz, M.J. Autonomous healing of fatigue cracks via cold welding. Nature 2023, 620, 552–556. [Google Scholar] [CrossRef]

- Markvicka, E.J.; Bartlett, M.D.; Huang, X.; Majidi, C. An autonomously electrically self-healing liquid metal–elastomer composite for robust soft-matter robotics and electronics. Nat. Mater. 2018, 17, 618–624. [Google Scholar] [CrossRef] [PubMed]

- García, Á. Self-healing of open cracks in asphalt mastic. Fuel 2012, 93, 264–272. [Google Scholar] [CrossRef]

- Ando, K.; Chu, M.-C.; Tsuji, K.; Hirasawa, T.; Kobayashi, Y.; Sato, S. Crack healing behaviour and high-temperature strength of mullite/SiC composite ceramics. J. Eur. Ceram. Soc. 2002, 22, 1313–1319. [Google Scholar] [CrossRef]

- Houjou, K.; Ando, K.; Liu, S.-P.; Sato, S. Crack-healing and oxidation behavior of silicon nitride ceramics. J. Eur. Ceram. Soc. 2004, 24, 2329–2338. [Google Scholar] [CrossRef]

- Ando, K.; Ikeda, T.; Sato, S.; Yao, F.; Kobayasi, Y. A preliminary study on crack healing behaviour of Si3N4/SiC composite ceramics. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 119–122. [Google Scholar] [CrossRef]

- Maruoka, D.; Nanko, M. Recovery of mechanical strength by surface crack disappearance via thermal oxidation for nano-Ni/Al2O3 hybrid materials. Ceram. Int. 2013, 39, 3221–3229. [Google Scholar] [CrossRef]

- Pham, H.V.; Nanko, M.; Nakao, W. High-temperature Bending Strength of Self-Healing Ni/Al2O3 Nanocomposites. Int. J. Appl. Ceram. Technol. 2016, 13, 973–983. [Google Scholar] [CrossRef]

- Yoshioka, S.; Boatemaa, L.; Zwaag, S.V.D.; Nakao, W.; Sloof, W.G. On the use of TiC as high-temperature healing particles in alumina based composites. J. Eur. Ceram. Soc. 2016, 36, 4155–4162. [Google Scholar] [CrossRef]

- Monteverde, F.; Saraga, F.; Reimer, T.; Sciti, D. Thermally stimulated self-healing capabilities of ZrB2-SiC ceramics. J. Eur. Ceram. Soc. 2021, 41, 7423–7433. [Google Scholar] [CrossRef]

- Nguyen, S.T.; Okawa, A.; Iwasawa, H.; Nakayama, T.; Hashimoto, H.; Sekino, T.; Suematsu, H.; Niihara, K. Titanium Nitride and Yttrium Titanate Nanocomposites, Endowed with Renewable Self-Healing Ability. Adv. Mater. Interfaces 2021, 8, 2100979. [Google Scholar] [CrossRef]

- Farle, A.-S.; Kwakernaak, C.; van der Zwaag, S.; Sloof, W.G. A conceptual study into the potential of Mn+1AXn-phase ceramics for self-healing of crack damage. J. Eur. Ceram. Soc. 2015, 35, 37–45. [Google Scholar] [CrossRef]

- Cui, X.; Huang, C.; Shi, Z.; Liu, H.; Li, S.; Han, Y.; Ji, L.; Wang, Z.; Xu, L.; Huang, S. The crack-healing and strength recovery mechanisms for the new developed Ti (C, N)-TiSi2-WC composite ceramic tool materials with crack-healing ability. Ceram. Int. 2023, 49, 35382–35391. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Huang, C.; Ji, L.; Wang, L.; Yuan, Y.; Liu, Q.; Han, Q. Study on crack healing performance of Al2O3/SiCw/TiSi2 new ceramic tool material. Ceram. Int. 2023, 49, 13790–13798. [Google Scholar] [CrossRef]

- Lee, S.-K.; Ishida, W.; Lee, S.-Y.; Nam, K.-W.; Ando, K. Crack-healing behavior and resultant strength properties of silicon carbide ceramic. J. Eur. Ceram. Soc. 2005, 25, 569–576. [Google Scholar] [CrossRef]

- Osada, T.; Nakao, W.; Takahashi, K.; Ando, K.; Saito, S. Strength recovery behavior of machined Al2O3/SiC nano-composite ceramics by crack-healing. J. Eur. Ceram. Soc. 2007, 27, 3261–3267. [Google Scholar] [CrossRef]

- Shi, S.; Goto, T.; Cho, S.; Sekino, T. Electrochemically assisted room-temperature crack healing of ceramic-based composites. J. Am. Ceram. Soc. 2019, 102, 4236–4246. [Google Scholar] [CrossRef]

- Li, S.; Song, G.; Kwakernaak, K.; van der Zwaag, S.; Sloof, W.G. Multiple crack healing of a Ti2AlC ceramic. J. Eur. Ceram. Soc. 2012, 32, 1813–1820. [Google Scholar] [CrossRef]

- Osada, T.; Kamoda, K.; Mitome, M.; Hara, T.; Abe, T.; Tamagawa, Y.; Nakao, W.; Ohmura, T. A Novel Design Approach for Self-Crack-Healing Structural Ceramics with 3D Networks of Healing Activator. Sci. Rep. 2017, 7, 17853. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Hu, W.H.; Nakamura, Y.; Fujisawa, N.; Herlyng, A.E.; Ebara, M.; Naito, M. Bio-Inspired Adhesive with Reset-On Demand, Reuse-Many (RORM) Modes. Adv. Funct. Mater. 2023, 33, 2215064. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Shao, G.; Tsakiropoulos, P. On the oxidation behaviour of MoSi2. Intermetallics 2001, 9, 125–136. [Google Scholar] [CrossRef]

- Westbrook, J.; Wood, D. “PEST” degradation in beryllides, silicides, aluminides, and related compounds. J. Nucl. Mater. 1964, 12, 208–215. [Google Scholar] [CrossRef]

- Sooby Wood, E.; Parker, S.S.; Nelson, A.T.; Maloy, S.A. MoSi2 Oxidation in 670–1498 K Water Vapor. J. Am. Ceram. Soc. 2016, 99, 1412–1419. [Google Scholar] [CrossRef]

- Shimada, S.; Mochidsuki, K. The oxidation of TiC in dry oxygen, wet oxygen, and water vapor. J. Mater. Sci. 2004, 39, 581–586. [Google Scholar] [CrossRef]

- Aghazadeh, M.; Barmi, A.A.M.; Hosseinifard, M. Nanoparticulates Zr(OH)4 and ZrO2 prepared by low-temperature cathodic electrodeposition. Mater. Lett. 2012, 73, 28–31. [Google Scholar] [CrossRef]

- Shimada, S.; Ishil, T. Oxidation Kinetics of Zirconium Carbide at Relatively Low Temperatures. J. Am. Ceram. Soc. 1990, 73, 2804–2808. [Google Scholar] [CrossRef]

- Rama Rao, G.A.; Venugopal, V. Kinetics and mechanism of the oxidation of ZrC. J. Alloys Compd. 1994, 206, 237–242. [Google Scholar] [CrossRef]

- Shimada, S.; Inagaki, M.; Suzuki, M. Microstructural observation of the ZrCZrO2 interface formed by oxidation of ZrC. J. Mater. Res. 1996, 11, 2594–2597. [Google Scholar] [CrossRef]

- Gasparrini, C.; Chater, R.J.; Horlait, D.; Vandeperre, L.; Lee, W.E. Zirconium carbide oxidation: Kinetics and oxygen diffusion through the intermediate layer. J. Am. Ceram. Soc. 2018, 101, 2638–2652. [Google Scholar] [CrossRef]

- Mori, S.; Kobayashi, R.; Tanaka, M.; Okuyama, K. Rapid Generation Process of Superheated Steam Using a Water-Containing Porous Material. In Proceedings of the ASME 2012 10th International Conference on Nanochannels, Microchannels, and Minichannels Collocated with the ASME 2012 Heat Transfer Summer Conf. and the ASME 2012 Fluids Engineering Division Sum, ICNMM 2012, Rio Grande, PR, USA, 8–12 July 2012; Published Online 22 July 2013. pp. 709–716. [Google Scholar]

- McKamey, C.G.; Tortorelli, P.F.; DeVan, J.H.; Carmichael, C.A. A study of pest oxidation in polycrystalline MoSi2. J. Mater. Res. 1992, 7, 2747–2755. [Google Scholar] [CrossRef]

- Chou, T.C.; Nieh, T.G. Nucleation and Growth of MoSi2 Pest During Low Temperature Oxidation. MRS Online Proc. Libr. (OPL) 1992, 288, 965. [Google Scholar] [CrossRef]

- Osei-Agyemang, E.; Paul, J.-F.; Lucas, R.; Foucaud, S.; Cristol, S. Stability, equilibrium morphology and hydration of ZrC (111) and (110) surfaces with H2O: A combined periodic DFT and atomistic thermodynamic study. Phys. Chem. Chem. Phys. 2015, 17, 21401–21413. [Google Scholar] [CrossRef]

- Guo, X. On the degradation of zirconia ceramics during low-temperature annealing in water or water vapor. J. Phys. Chem. Solids 1999, 60, 539–546. [Google Scholar] [CrossRef]

- Sekine, N.; Nakao, W. Advanced Self-Healing Ceramics with Controlled Degradation and Repair by Chemical Reaction. Materials 2023, 16, 6368. [Google Scholar] [CrossRef]

| ZrC | Zr + Hf | C | Fe | Y2O3 | |||

| wt% | 87.83 | 12.0 | <0.01 | 0.16 | |||

| YSZ | ZrO2 | Y2O3 | Al2O3 | Fe2O3 | TiO2 | SiO2 | |

| wt% | 94.28 | 5.72 | 0.24 | 0.001 | 0.001 | 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sekine, N.; Nakajima, Y.; Kamo, T.; Ito, M.; Nakao, W. Advanced Ceramics with Dual Functions of Healing and Decomposition. Materials 2024, 17, 647. https://doi.org/10.3390/ma17030647

Sekine N, Nakajima Y, Kamo T, Ito M, Nakao W. Advanced Ceramics with Dual Functions of Healing and Decomposition. Materials. 2024; 17(3):647. https://doi.org/10.3390/ma17030647

Chicago/Turabian StyleSekine, Nobuhide, Yasushi Nakajima, Takahiro Kamo, Masahiro Ito, and Wataru Nakao. 2024. "Advanced Ceramics with Dual Functions of Healing and Decomposition" Materials 17, no. 3: 647. https://doi.org/10.3390/ma17030647

APA StyleSekine, N., Nakajima, Y., Kamo, T., Ito, M., & Nakao, W. (2024). Advanced Ceramics with Dual Functions of Healing and Decomposition. Materials, 17(3), 647. https://doi.org/10.3390/ma17030647