Efficiency Enhancement in Ocean Thermal Energy Conversion: A Comparative Study of Heat Exchanger Designs for Bi2Te3-Based Thermoelectric Generators

Abstract

:1. Introduction

1.1. Energy Issues

1.2. Application of Thermoelectric Generators (TEGs) in Waste Heat Recovery

1.3. Application of Bi2Te3 TEGs in Ocean Thermal Energy Conversion (OTEC)

1.4. Design of Heat Exchangers

2. Numerical Methods

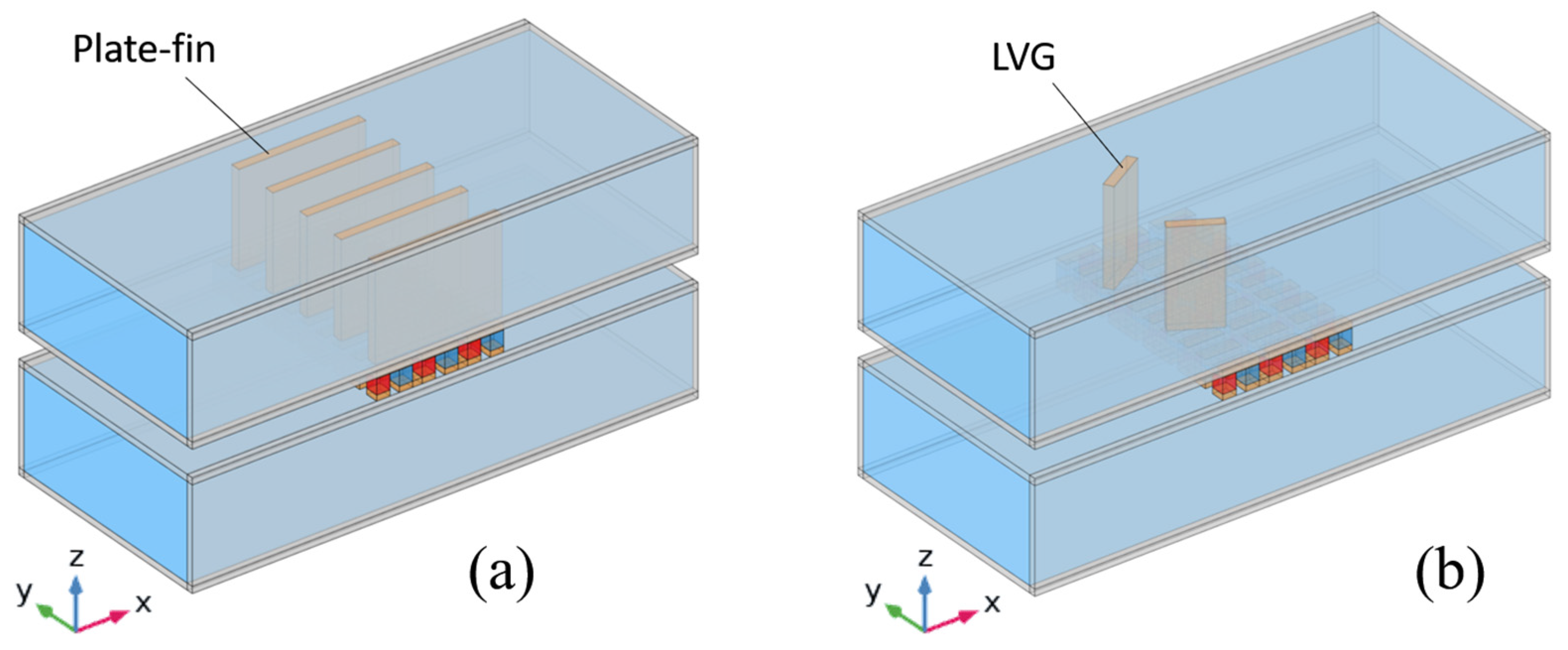

2.1. Structure, Materials, and Dimensional Design

2.2. Governing Equations

2.3. Boundary Conditions

- The inlet of the heat exchanger is set as a fully developed flow with specified average velocity and temperature.

- The outlet of the heat exchanger has a pressure of zero.

- The outer surfaces of the heat exchanger are adiabatic.

- Except for the hot and cold end interfaces, the TEG surfaces are adiabatic.

- All solid walls have no-slip boundaries.

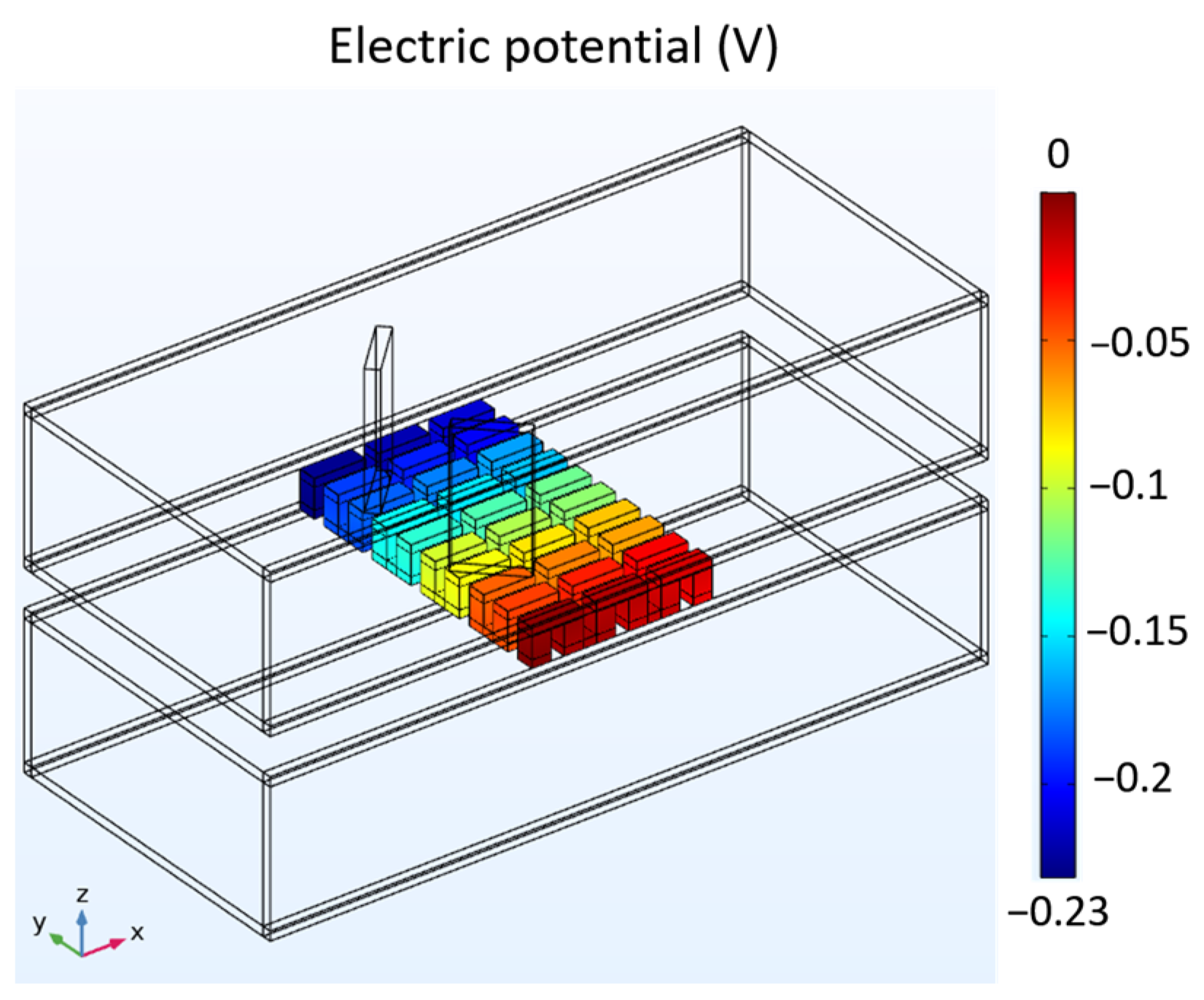

- In the TEG module, the terminal of the first thermocouple on the far right is grounded, and other boundaries of the TEG are electrically insulated.

2.4. Performance Evaluation Parameters

2.5. Convergence Test

3. Results and Discussion

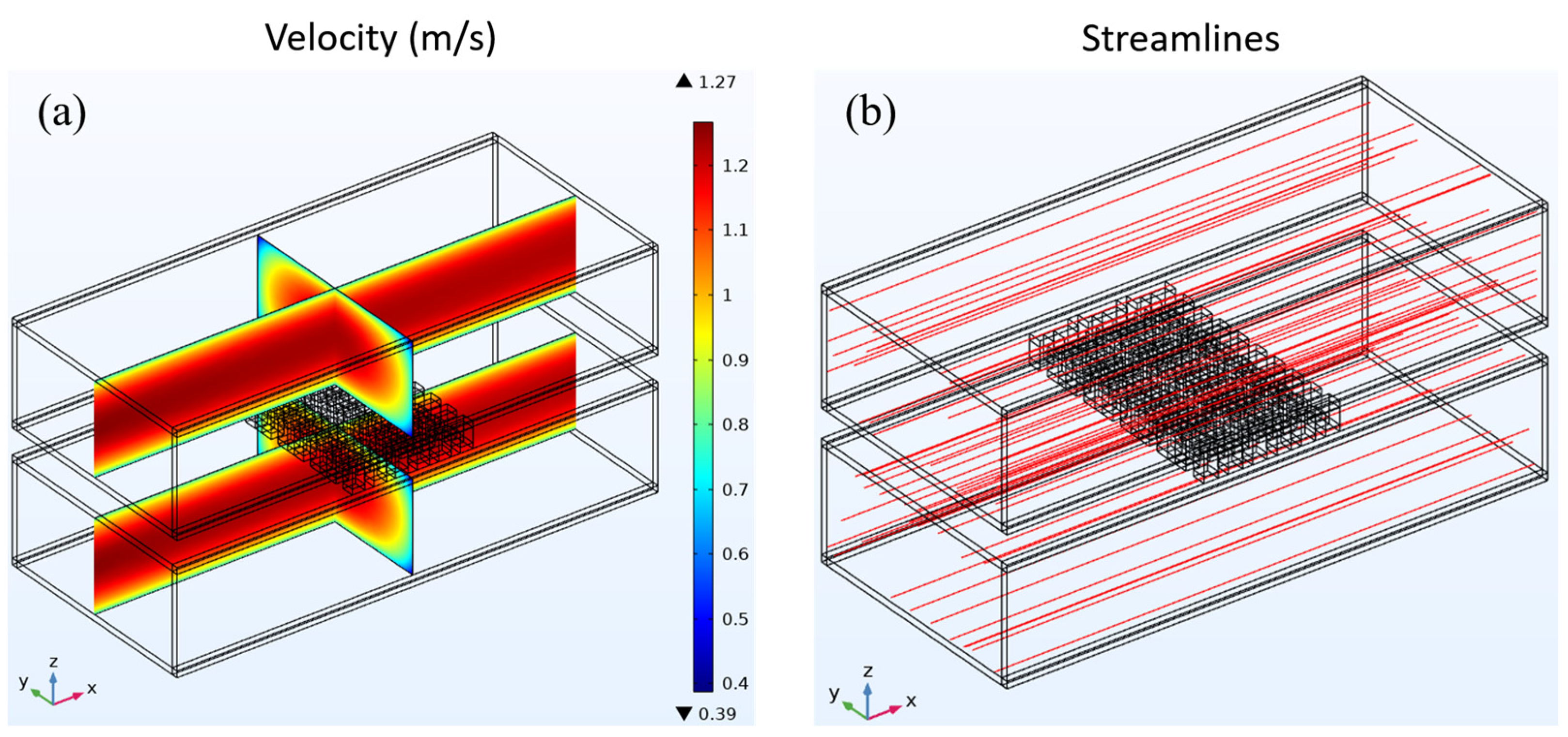

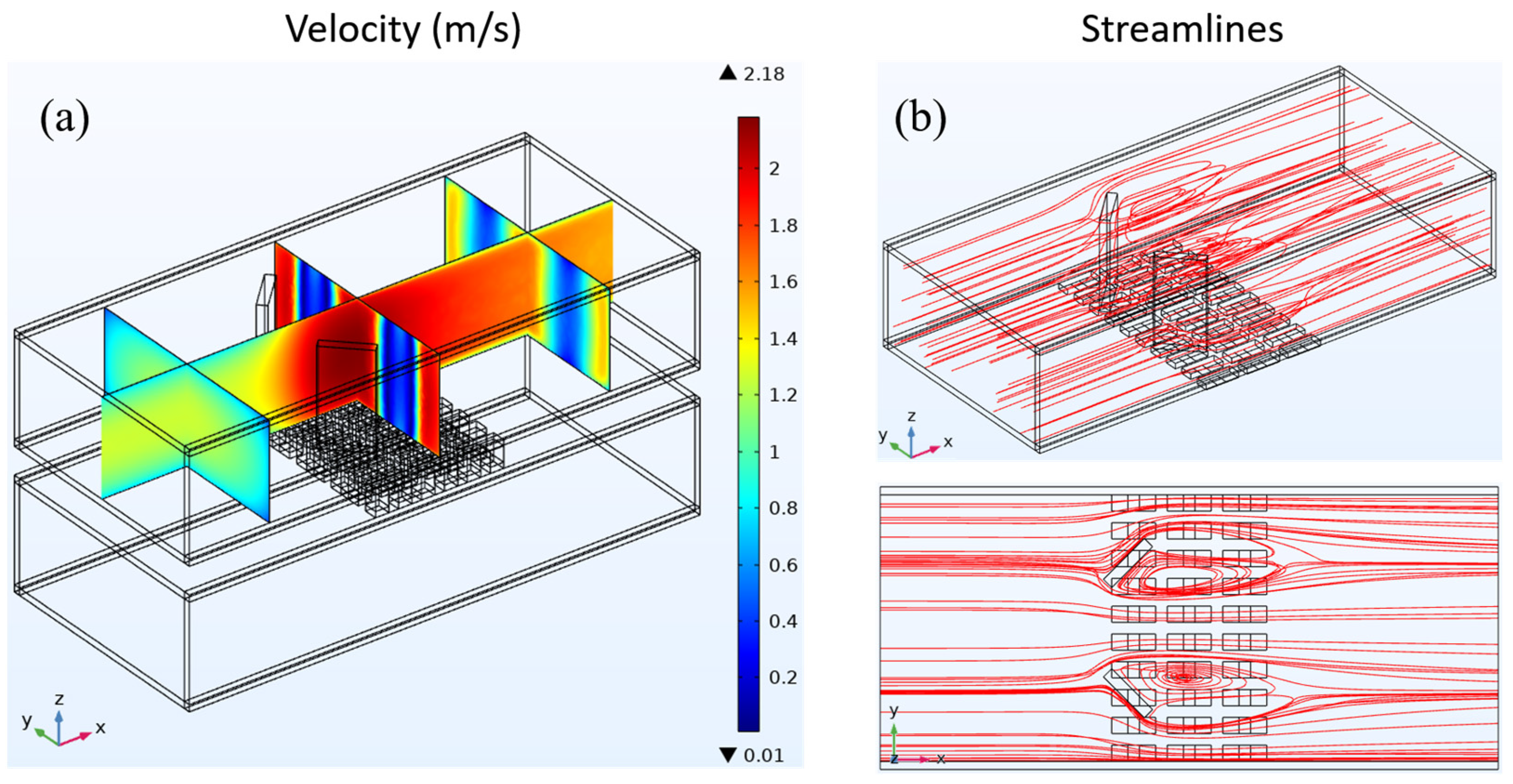

3.1. Thermal Flow Analysis

3.2. TEG Performance Analysis

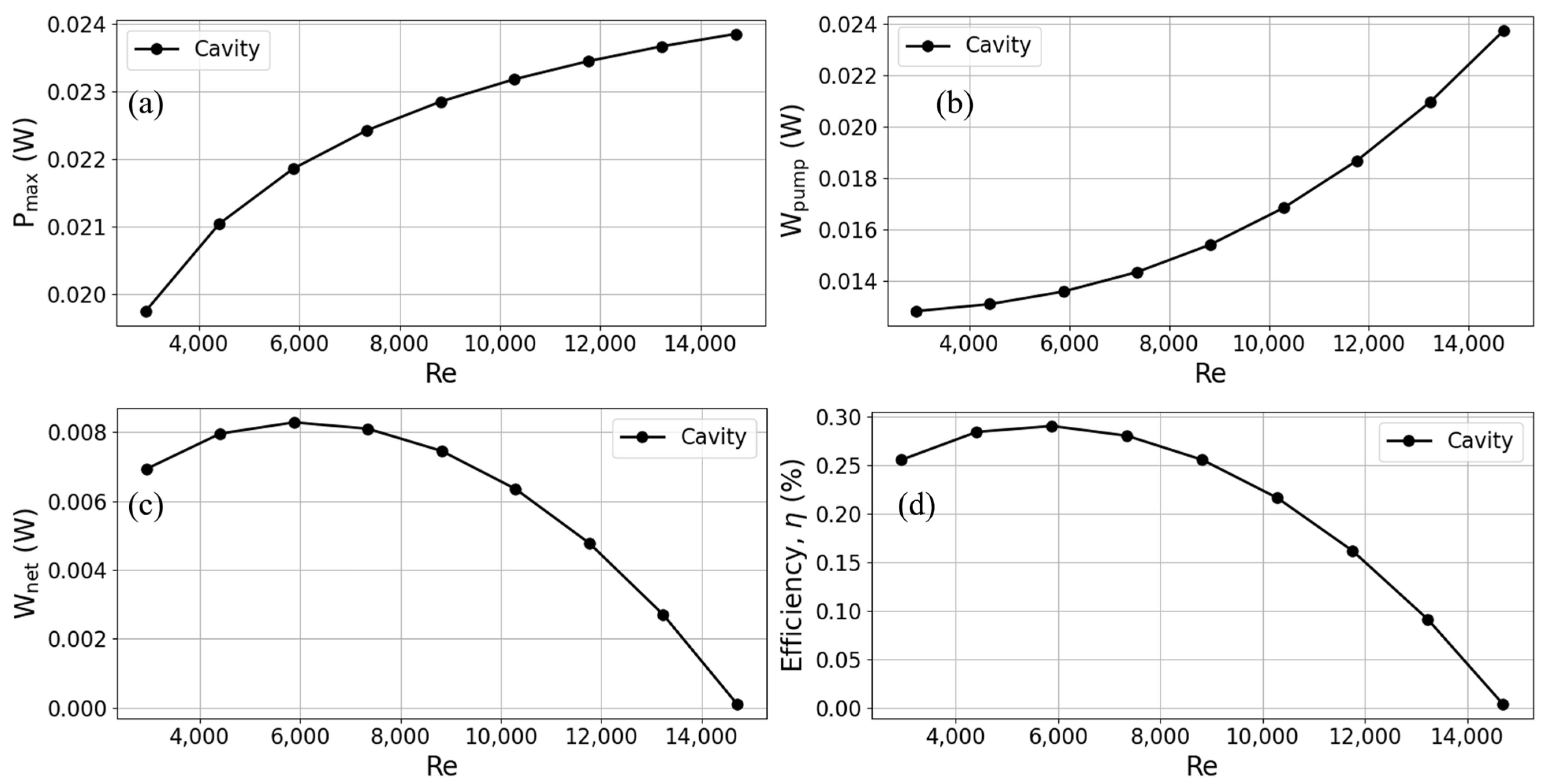

3.2.1. The Impact of Reynolds Number (at the Hot End) on TEG Performance

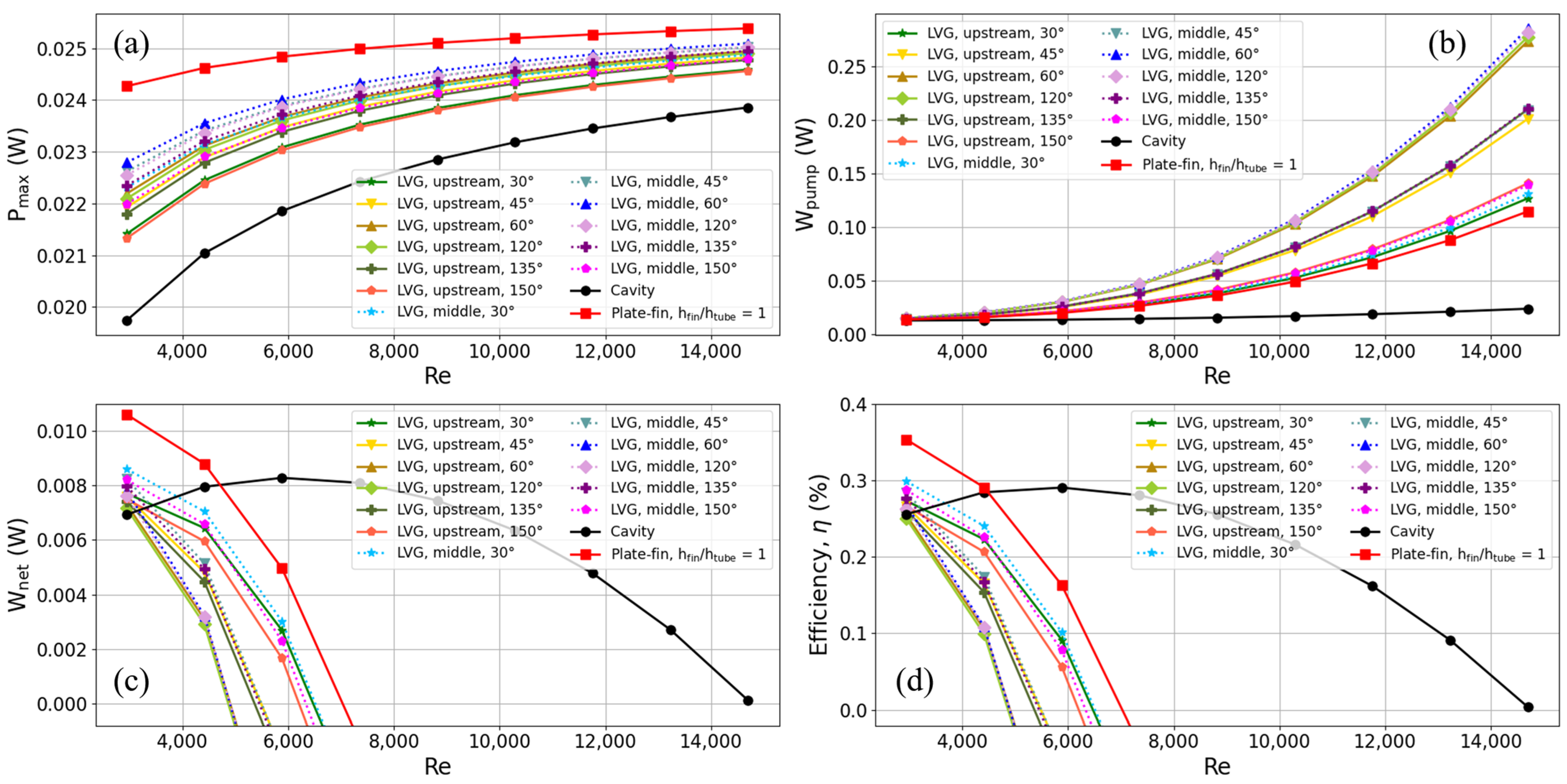

3.2.2. Heat Exchanger with Plate-Fins: The Impact of Fin Height on TEG Performance

3.2.3. Heat Exchanger with LVGs: The Impact of LVG Angle and Position on TEG Performance

4. Conclusions

- It has been seen that when the fluid speed and Reynolds number rise in a cavity heat exchanger, the TEG’s output power also rises. However, it is essential to note that the needed pump power also grows in tandem. Consequently, this relationship gives rise to a downward parabolic trend in thermoelectric conversion efficiency. The optimal efficiency of the TEG is attained close to a flow velocity of 0.4 m/s, corresponding to a Reynolds number of 5880.4. As mentioned above, the findings suggest that a compromise between output power and pumping power must be made to attain optimal thermoelectric conversion efficiency, underscoring the need to select an adequate flow velocity.

- Researchers looked at flow speed, streamlines, and temperature inside heat exchangers and found that heat exchangers with plate-fins and LVGs are better at moving heat from warm seawater to the hot end of the TEG than cavity heat exchangers.

- Using a heat exchanger with plate-fins increases the TEG’s output power by making it easier for heat to move through the fins. However, it is essential to note that this configuration also leads to an increase in pump power. Thus, as the Reynolds numbers rise, the TEG’s net power and thermoelectric conversion efficiency slowly drop compared to what can be achieved with a cavity heat exchanger. At Reynolds numbers below 0.5 m/s (specifically, Reynolds number 7350.5), it has been seen that the cavity heat exchanger is less efficient at turning heat into electricity than the heat exchanger with plate-fins. When compared to the cavity heat exchanger, where the heat exchanger has fins that are the same height as the flow channel and a flow velocity of 0.2 m/s (corresponding to a Reynolds number of 2940.2), both output power (22.92% increase) and thermoelectric conversion efficiency (38.20% increase) are much better. Additionally, it is demonstrable that there is a direct relationship between the Reynolds number and the pump power necessary to overcome the flow resistance that the fins impose. For example, lowering the height of the fins to 0.25 times the height of the flow channel can increase thermoelectric conversion efficiency.

- When a heat exchanger with LVGs is used, the TEG’s output power increases because the LVGs create torque waves. However, this approach necessitates a higher pump power, resulting in a notable reduction in net and thermoelectric conversion efficiency as the Reynolds number increases. At Reynolds numbers below a certain threshold, such as 0.2 m/s (corresponding to a Reynolds number of 2940.2), the heat exchanger equipped with LVGs may exhibit a thermoelectric conversion efficiency that surpasses that of the cavity heat exchanger.

- The inclination angle of the LVGs affects the thermoelectric conversion performance of the TEG. The thermoelectric conversion efficiency at various angles, ranked in descending order, is as follows: 30, 45, 150, 135, 60, and 120 degrees. The findings of this study suggest that LVGs operating at both small and large angles have superior thermoelectric conversion efficiency. Specifically, LVGs operating at slight angles, such as 30 and 45 degrees, demonstrate higher performance. As the angle approaches 90 degrees, there is an observed increase in the power demand of the pump, resulting in a decrease in the efficiency of thermoelectric conversion. When comparing the cavity heat exchanger to the heat exchanger with LVGs (with LVGs positioned upstream at an angle of 30 degrees), it was seen that at a flow rate of 0.2 m/s (corresponding to a Reynolds number of 2940.2), the latter exhibited a higher TEG output power, showing an increase of 8.46%. Additionally, the heat exchanger with LVGs showed an increase in thermoelectric conversion efficiency of 6.87%.

- The placement of LVGs at various locations inside the heat exchanger, including upstream (L1 = 10 mm) and midstream (L1 = 0 mm), affects the thermoelectric conversion performance of the TEG. The difference in pump power needed for LVGs upstream and midstream is not very big, but the midstream configuration has more output power, which makes thermoelectric conversion more efficient. When the flow rate is 0.2 m/s, equal to a Reynolds number of 2940.2, the heat exchanger with LVGs (with the LVGs placed midstream at an angle of 30 degrees) works better than the cavity heat exchanger. Specifically, the heat exchanger with LVGs exhibits a notable increase in TEG output power of 13.02% and a corresponding improvement in thermoelectric conversion efficiency of 16.83%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hooshmand Zaferani, S.; Jafarian, M.; Vashaee, D.; Ghomashchi, R. Thermal Management Systems and Waste Heat Recycling by Thermoelectric Generators—An Overview. Energies 2021, 14, 5646. [Google Scholar] [CrossRef]

- Energy Flow Charts. Available online: https://flowcharts.llnl.gov/commodities/energy (accessed on 17 October 2023).

- Hsiao, Y.Y.; Chang, W.C.; Chen, S.L. A mathematic model of thermoelectric module with applications on waste heat recovery from automobile engine. Energy 2010, 35, 1447–1454. [Google Scholar] [CrossRef]

- Suarez, F.; Nozariasbmarz, A.; Vashaee, D.; Öztürk, M.C. Designing thermoelectric generators for self-powered wearable electronics. Energy Environ. Sci. 2016, 9, 2099–2113. [Google Scholar] [CrossRef]

- Mirhosseini, M.; Rezania, A.; Rosendahl, L. Harvesting waste heat from cement kiln shell by thermoelectric system. Energy 2019, 168, 358–369. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Zhang, Q.-H.; Bai, S.-Q.; Chen, L.-D. Technologies and Applications of Thermoelectric Devices: Current Status, Challenges and Prospects. J. Inorg. Mater. 2019, 34, 279–293. [Google Scholar] [CrossRef]

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A comprehensive review of Thermoelectric Generators: Technologies and common applications. Energy Rep. 2020, 6, 264–287. [Google Scholar] [CrossRef]

- Khan, N.; Kalair, A.; Abas, N.; Haider, A. Review of ocean tidal, wave and thermal energy technologies. Renew. Sustain. Energy Rev. 2017, 72, 590–604. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Baseri, M.M.; Ahmadi, P.; Al-Rashed, A.A.; Afrand, M. Proposal of a novel integrated ocean thermal energy conversion system with flat plate solar collectors and thermoelectric generators: Energy, exergy and environmental analyses. J. Clean. Prod. 2020, 256, 120600. [Google Scholar] [CrossRef]

- Kim, A.S.; Kim, H.-J.; Lee, H.-S.; Cha, S. Dual-use open cycle ocean thermal energy conversion (OC-OTEC) using multiple condensers for adjustable power generation and seawater desalination. Renew. Energy 2016, 85, 344–358. [Google Scholar] [CrossRef]

- Bohn, M.S.; Benson, D.K.; Jayadev, T.S. Thermoelectric ocean thermal energy conversion. J. Sol. Energy Eng. 1980, 102, 119–127. [Google Scholar] [CrossRef]

- Yan, S.-R.; Moria, H.; Asaadi, S.; Sadighi Dizaji, H.; Khalilarya, S.; Jermsittiparsert, K. Performance and profit analysis of thermoelectric power generators mounted on channels with different cross-sectional shapes. Appl. Therm. Eng. 2020, 176, 115455. [Google Scholar] [CrossRef]

- Kumar, R.; Sonthalia, A.; Goel, R. Experimental study on waste heat recovery from an IC engine using thermoelectric technology. Therm. Sci. 2011, 15, 1011–1022. [Google Scholar] [CrossRef]

- Weng, C.-C.; Huang, M.-J. A simulation study of automotive waste heat recovery using a thermoelectric power generator. Int. J. Therm. Sci. 2013, 71, 302–309. [Google Scholar] [CrossRef]

- Jang, J.-Y.; Tsai, Y.-C.; Wu, C.-W. A study of 3-D numerical simulation and comparison with experimental results on turbulent flow of venting flue gas using thermoelectric generator modules and plate fin heat sink. Energy 2013, 53, 270–281. [Google Scholar] [CrossRef]

- Bai, S.; Lu, H.; Wu, T.; Yin, X.; Shi, X.; Chen, L. Numerical and experimental analysis for exhaust heat exchangers in automobile thermoelectric generators. Case Stud. Therm. Eng. 2014, 4, 99–112. [Google Scholar] [CrossRef]

- Liu, S.; Sakr, M. A comprehensive review on passive heat transfer enhancements in pipe exchangers. Renew. Sustain. Energy Rev. 2013, 19, 64–81. [Google Scholar] [CrossRef]

- Liu, C.; Teng, J.-T.; Chu, J.-C.; Chiu, Y.-L.; Huang, S.; Jin, S.; Dang, T.; Greif, R.; Pan, H.-H. Experimental investigations on liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Int. J. Heat Mass Transfer 2011, 54, 3069–3080. [Google Scholar] [CrossRef]

- Ma, T.; Lu, X.; Pandit, J.; Ekkad, S.V.; Huxtable, S.T.; Deshpande, S.; Wang, Q.-W. Numerical study on thermoelectric–hydraulic performance of a thermoelectric power generator with a plate-fin heat exchanger with longitudinal vortex generators. Appl. Energy 2017, 185, 1343–1354. [Google Scholar] [CrossRef]

- Chen, W.-H.; Wang, C.-M.; Huat Saw, L.; Hoang, A.T.; Bandala, A.A. Performance evaluation and improvement of thermoelectric generators (TEG): Fin installation and compromise optimization. Energy Convers. Manag. 2021, 250, 114858. [Google Scholar] [CrossRef]

- Hassan, M.A.; Samanta, R. Heat Exchanger Assisted Exhaust Heat Recovery with Thermoelectric Generator in Heavy Vehicles. Energy Technol. 2021, 9, 2100037. [Google Scholar] [CrossRef]

- Prasad, A.; Thiagarajan, R.C. Multiphysics Modeling and Multilevel Optimization of Thermoelectric Generator for Waste Heat Recovery. In Proceedings of the COMSOL Conference, Bangalore, India, 9–10 August 2018; pp. 1–7. [Google Scholar]

- Prasad, A.; Thiagarajan, R.C. Multiphysics Modeling and Development of Thermoelectric Generator for Waste Heat Recovery. Available online: https://www.comsol.com/paper/multiphysics-modeling-and-development-of-thermoelectric-generator-for-waste-heat-61281 (accessed on 17 October 2023).

- The Engineering ToolBox. Seawater—Properties. Available online: https://www.engineeringtoolbox.com/sea-water-properties-d_840.html (accessed on 17 October 2023).

- Chen, W.-H.; Lin, Y.-X.; Wang, X.-D.; Lin, Y.-L. A comprehensive analysis of the performance of thermoelectric generators with constant and variable properties. Appl. Energy 2019, 241, 11–24. [Google Scholar] [CrossRef]

- Sandoz-Rosado, E.J. Investigation and Development of Advanced Models of Thermoelectric Generators for Power Generation Applications; Rochester Institute of Technology: Rochester, NY, USA, 2009. [Google Scholar]

- Tian, H.; Sun, X.; Jia, Q.; Liang, X.; Shu, G.; Wang, X. Comparison and parameter optimization of a segmented thermoelectric generator by using the high temperature exhaust of a diesel engine. Energy 2015, 84, 121–130. [Google Scholar] [CrossRef]

- Kumar, S.; Heister, S.D.; Xu, X.; Salvador, J.R.; Meisner, G.P. Thermoelectric Generators for Automotive Waste Heat Recovery Systems Part I: Numerical Modeling and Baseline Model Analysis. J. Electron. Mater. 2013, 42, 665–674. [Google Scholar] [CrossRef]

- COMSOL Multiphysics. Available online: https://www.comsol.com/ (accessed on 17 October 2023).

| Channel Type | Number of Elements | Relative Errors | |||

|---|---|---|---|---|---|

| Pmax (W) | Qh (W) | ∆p (Pa) | Wnet (W) | ||

| Cavity | 161,902 | −0.16% | −0.06% | 8.23% | −7.94% |

| 388,308 | 0.03% | 0.01% | 3.58% | −3.25% | |

| 575,438 | — | — | — | — | |

| Plate-fin | 417,119 | −0.36% | −0.15% | −12.60% | −16.63% |

| 1,047,071 | −0.20% | −0.09% | 0.49% | 0.72% | |

| 1,571,362 | — | — | — | — | |

| LVG | 239,673 | −0.29% | −0.12% | −0.54% | −0.58% |

| 555,767 | −0.32% | −0.14% | −0.21% | −0.20% | |

| 1,634,565 | — | — | — | — | |

| Channel Type (vin,warm = 0.2 m/s) | Pmax (W) | Qtotal (W) | η (%) | |

|---|---|---|---|---|

| Cavity | 1.97 × 10−2 | 2.71 | 0.26 | |

| Plate-fin (hfin/htube = 1) | 2.43 × 10−2 | 3.00 | 0.35 | |

| LVG (θ1 = 30°) | Upstream | 2.14 × 10−2 | 2.82 | 0.27 |

| Midstream | 2.23 × 10−2 | 2.88 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, Y.-C.; Wu, C.-I. Efficiency Enhancement in Ocean Thermal Energy Conversion: A Comparative Study of Heat Exchanger Designs for Bi2Te3-Based Thermoelectric Generators. Materials 2024, 17, 714. https://doi.org/10.3390/ma17030714

Chung Y-C, Wu C-I. Efficiency Enhancement in Ocean Thermal Energy Conversion: A Comparative Study of Heat Exchanger Designs for Bi2Te3-Based Thermoelectric Generators. Materials. 2024; 17(3):714. https://doi.org/10.3390/ma17030714

Chicago/Turabian StyleChung, Yi-Cheng, and Chun-I Wu. 2024. "Efficiency Enhancement in Ocean Thermal Energy Conversion: A Comparative Study of Heat Exchanger Designs for Bi2Te3-Based Thermoelectric Generators" Materials 17, no. 3: 714. https://doi.org/10.3390/ma17030714