Research on the Surface-State Parameterization of a Refill Friction Stir Spot Welding Joint Made of Aluminum Alloy and Its Connection to the Fracture Mode

Abstract

1. Introduction

2. Materials and Methods

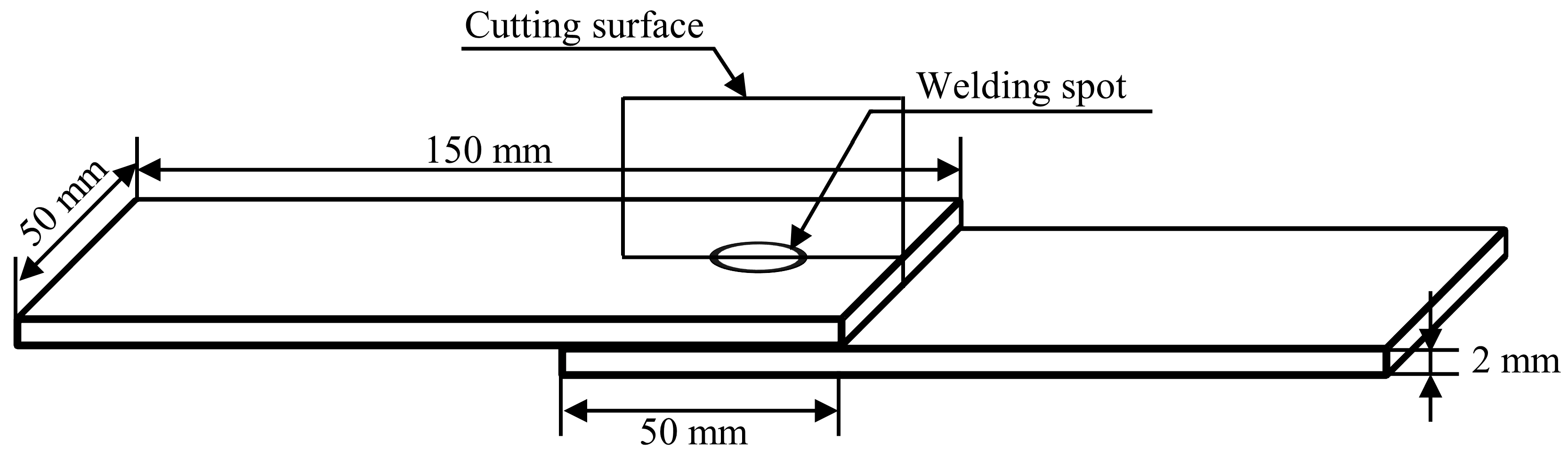

2.1. Welded Material and Preparation of the Specimens

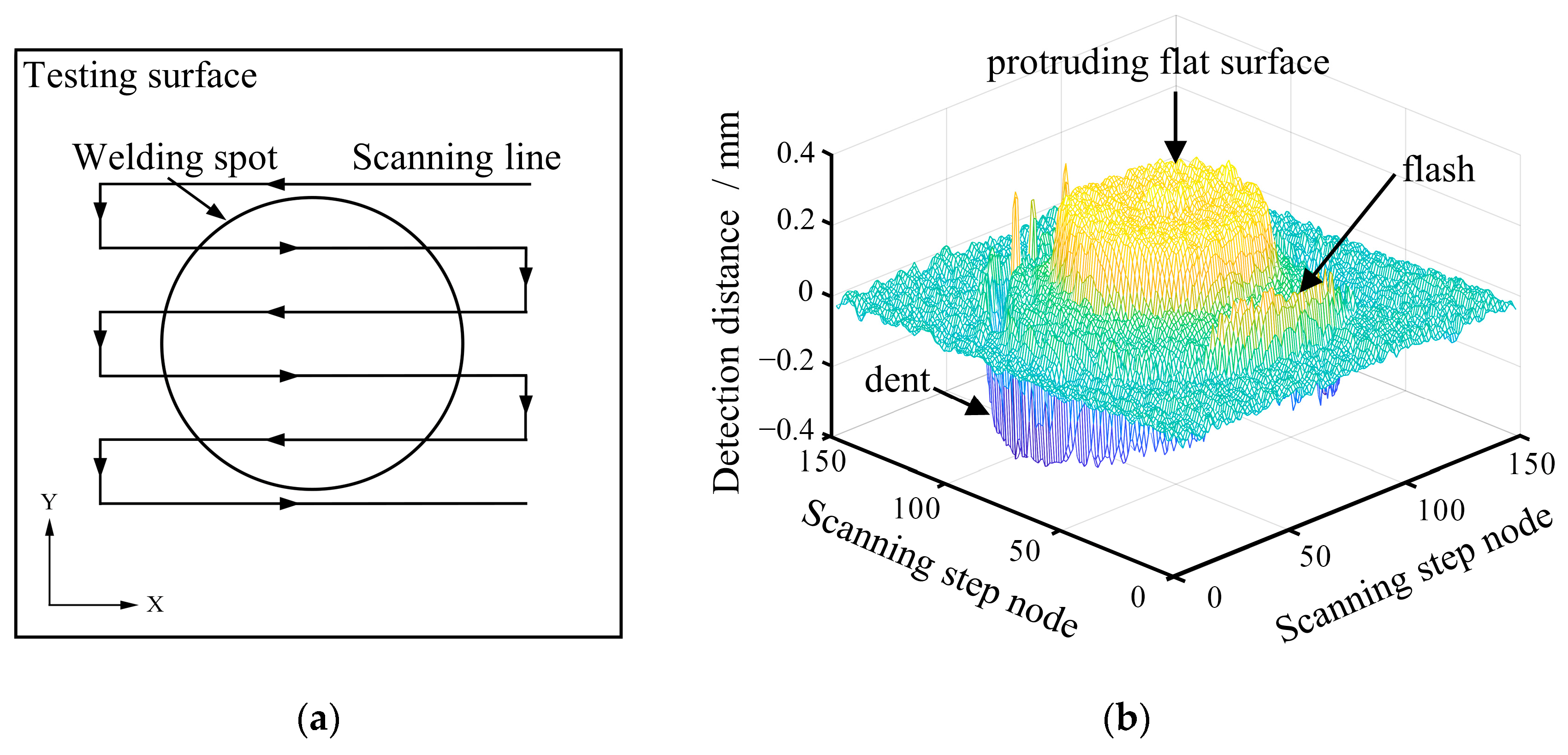

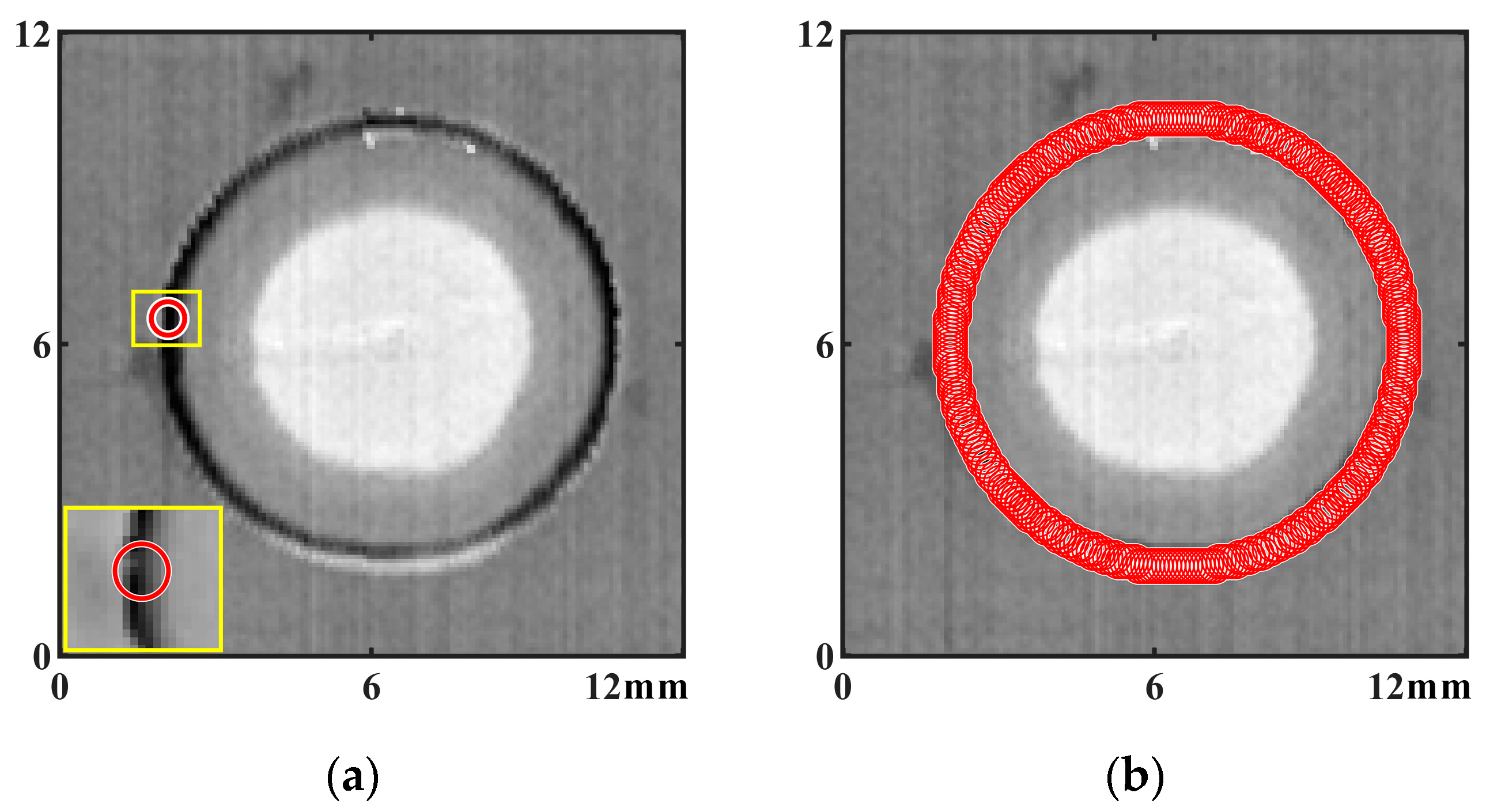

2.2. Surface Testing of the RFSSW Joint Based on the Laser Ranging and Imaging Method

3. Results

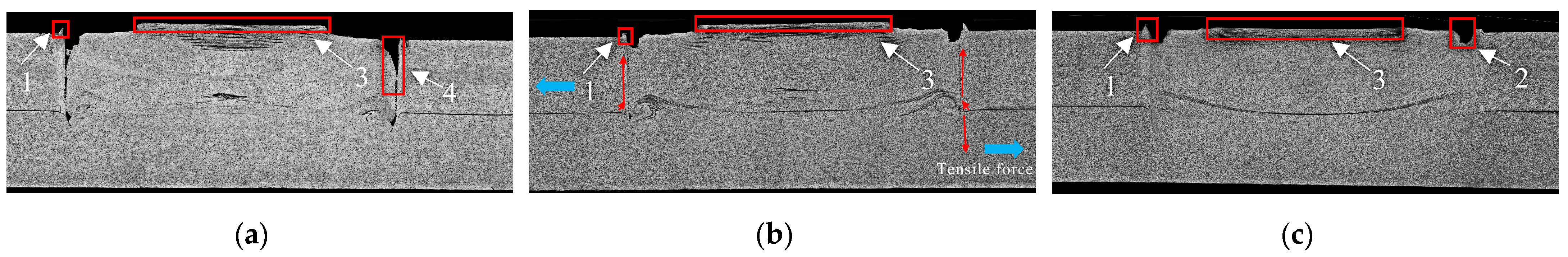

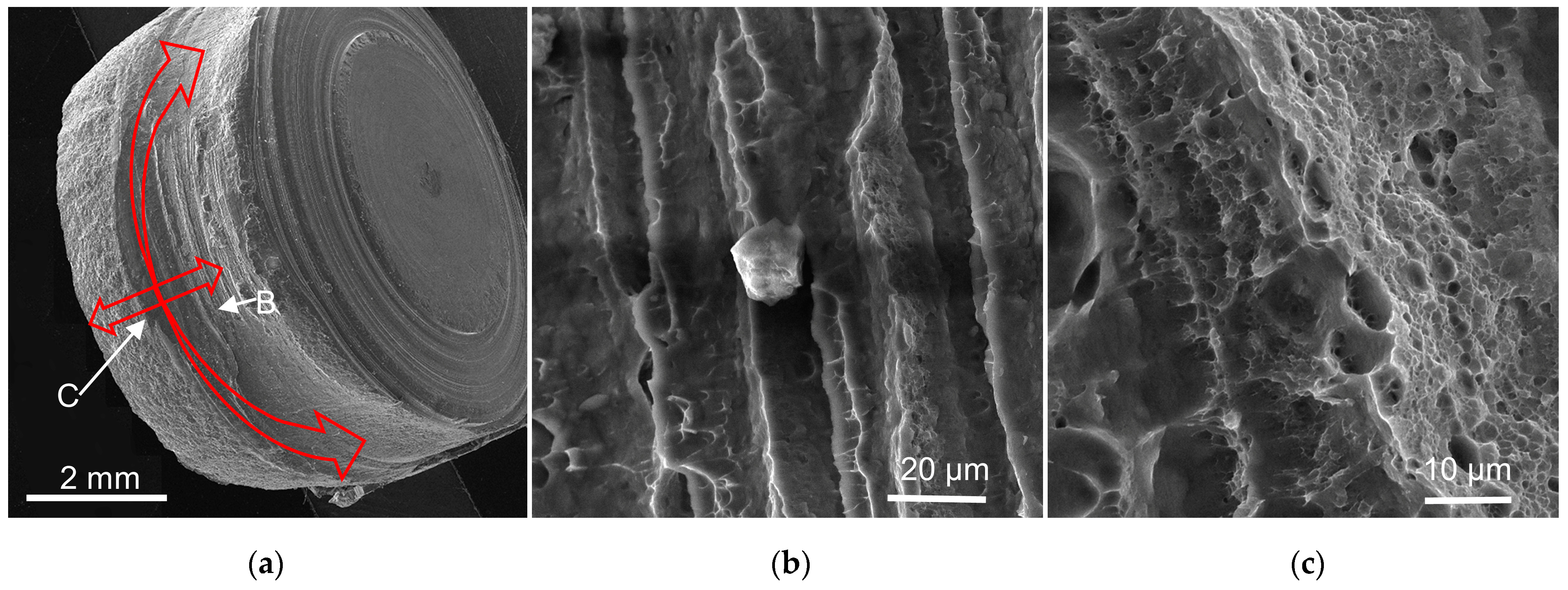

3.1. Analysis of the Relationship between the Surface State and Quality of the RFSSW Joint

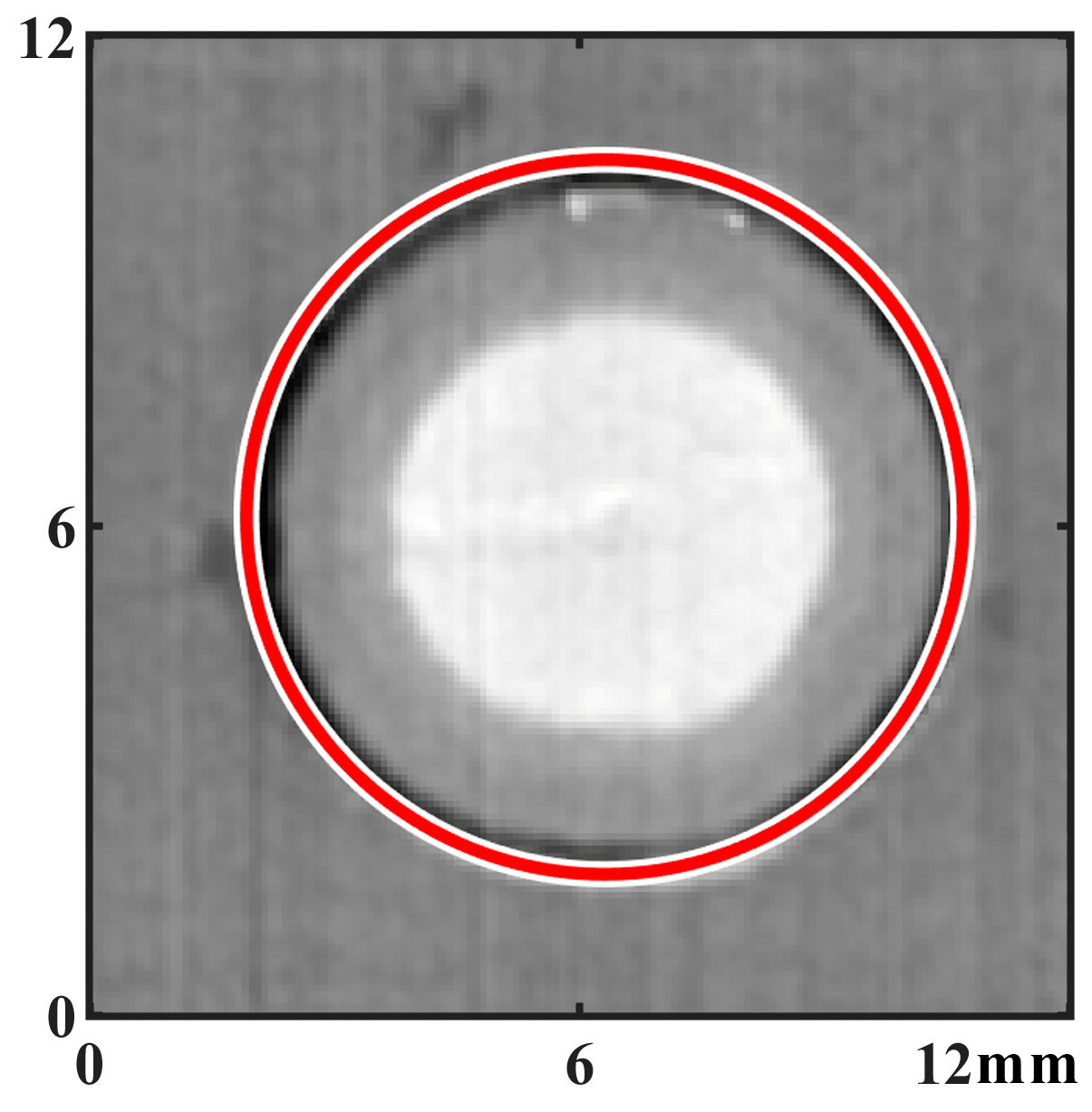

3.2. Calculation of the Surface Characteristic Parameters of the RFSSW Joints

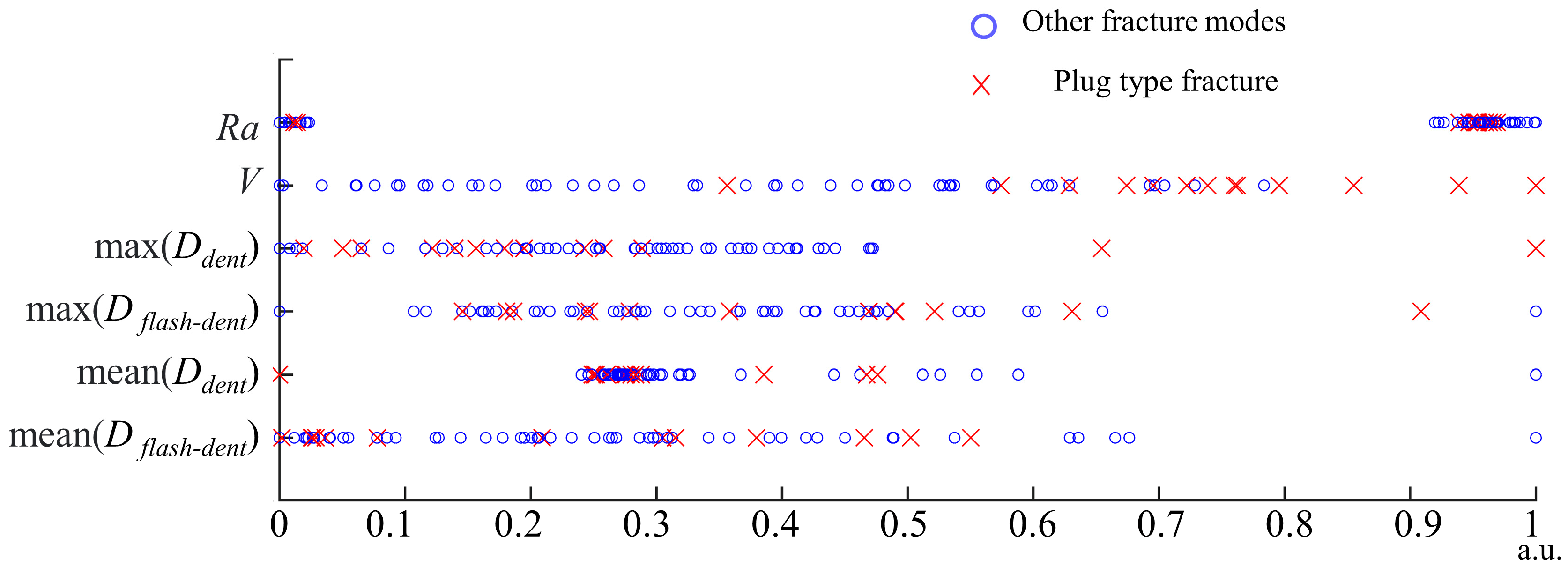

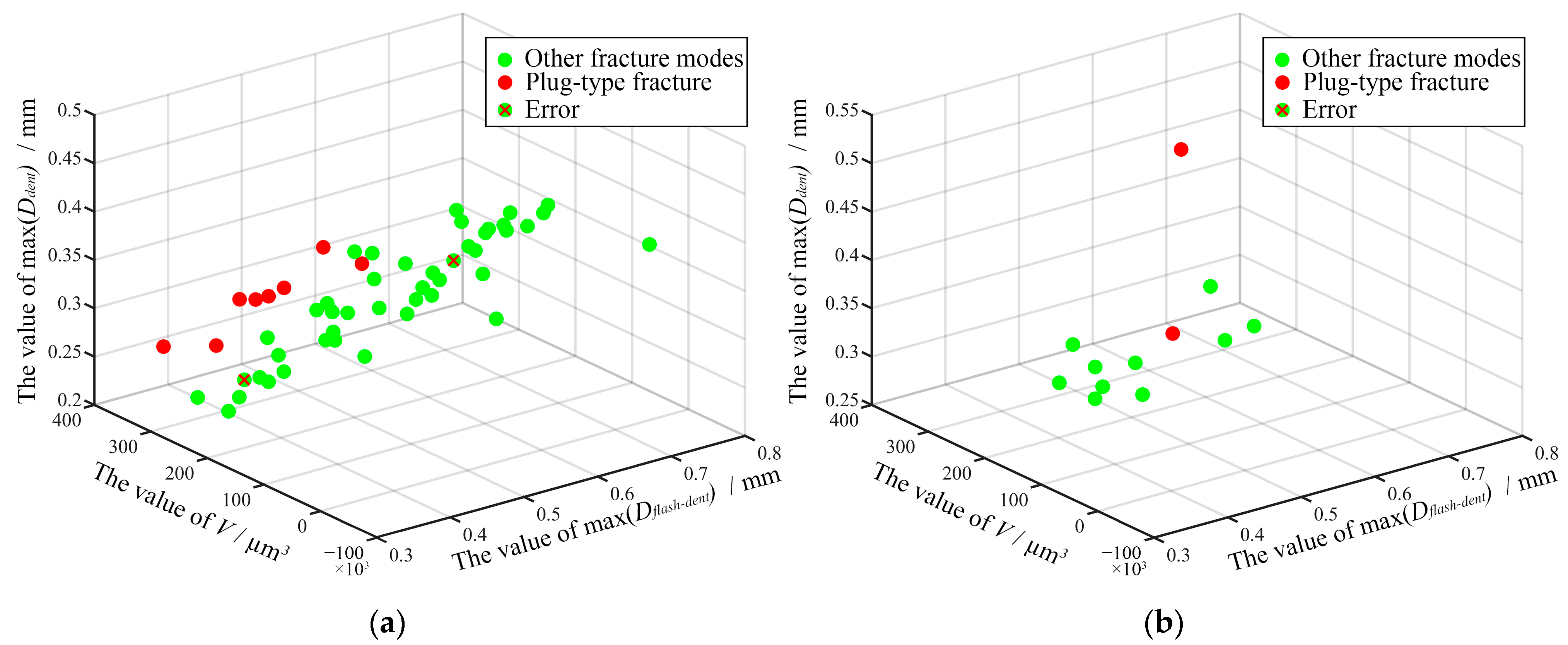

3.3. Study of the Correlation between the Surface Characteristic Parameters and Mechanical Properties of RFSSW Joints

4. Discussion

5. Conclusions

- The experimental analysis revealed that due to the particularity of the RFSSW process, the surface characteristics of RFSSW joints reflect the internal defects and connection states of the joints to a certain extent, and thus, are correlated with the mechanical properties of the joints.

- The surface-state image characterization method of RFSSW joints based on the surface detection of laser ranging was studied, and methods for the parametric characterization of the surface-state features of RFSSW joints are proposed, laying a foundation for the prediction of the mechanical performance of an RFSSW joint based on the surface characteristics of the joint.

- Based on the surface characteristic parameters of RFSSW joints, an SVM was adopted to classify and analyze the fracture modes of the RFSSW joints, with an accuracy of 95.8%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schilling, C.; Santos, J.D. Method and Device for Joining at Least Two Adjoining Work Pieces by Friction Welding. U.S. Patent 10172816, 20 April 2004. [Google Scholar]

- Ahmed, M.M.Z.; Seleman, M.; Ahmed, E.; Reyad, H.A.; Alsaleh, N.A.; Albaijan, I. A Novel Friction Stir Deposition Technique to Refill Keyhole of Friction Stir Spot Welded AA6082-T6 Dissimilar Joints of Different Sheet Thicknesses. Materials 2022, 15, 6799. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Wu, C.B.; Kim, J.W. Numerical Optimization of the Welding Sequence for Mitigating Welding Deformation in Aluminum Pipe Structures by Using a Genetic Algorithm. Int. J. Precis. Eng. Manuf. 2020, 21, 2323–2333. [Google Scholar]

- Kim, G.C.; Hwang, I.; Kang, M.; Kim, D.; Park, H.; Kim, Y.M. Effect of Welding Time on Resistance Spot Weldability of Aluminum 5052 Alloy. Met. Mater. Int. 2019, 25, 207–218. [Google Scholar] [CrossRef]

- Kubit, A.; Bucior, M.; Wydrzynski, D.; Trzepiecinski, T.; Pytel, M. Failure mechanisms of refill friction stir spot welded 7075-T6 aluminium alloy single-lap joints. Int. J. Adv. Manuf. Technol. 2018, 94, 4479–4491. [Google Scholar] [CrossRef]

- Harachai, K.; Prasomthong, S. Investigation of the optimal parameters for butt joints in a friction stir welding (FSW) process with dissimilar aluminium alloys. Mater. Res. Express 2023, 10, 026514. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Singh, G.; Kumar, A. Optimizing submerged arc welding using response surface methodology, regression analysis, and genetic algorithm. Def. Technol. 2018, 14, 204–212. [Google Scholar] [CrossRef]

- Anandan, B.; Manikandan, M. Machine learning approach for predicting the peak temperature of dissimilar AA7050-AA2014A friction stir welding butt joint using various regression models. Mater. Lett. 2022, 325, 132879. [Google Scholar] [CrossRef]

- de Castro, C.C.; Plaine, A.H.; de Alcantara, N.G.; dos Santos, J.F. Taguchi approach for the optimization of refill friction stir spot welding parameters for AA2198-T8 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 99, 1927–1936. [Google Scholar] [CrossRef]

- Santana, L.M.; Suhuddin, U.F.H.; Oelscher, M.H.; Strohaecker, T.R.; dos Santos, J.F. Process optimization and microstructure analysis in refill friction stir spot welding of 3-mm-thick Al-Mg-Si aluminum alloy. Int. J. Adv. Manuf. Technol. 2017, 92, 4213–4220. [Google Scholar] [CrossRef]

- Birsan, D.C.; Paunoiu, V.; Teodor, V.G. Neural Networks Applied for Predictive Parameters Analysis of the Refill Friction Stir Spot Welding Process of 6061-T6 Aluminum Alloy Plates. Materials 2023, 16, 4519. [Google Scholar] [CrossRef] [PubMed]

- Himawan, R.; Haryanto, M.; Subekti, M.; Sunaryo, G.R. Ultrasonic Non-destructive Prediction of Spot Welding Shear Strength. J. Phys. Conf. Ser. 2018, 962, 012047. [Google Scholar] [CrossRef]

- Amiri, N.; Farrahi, G.H.; Kashyzadeh, K.R.; Chizari, M. Applications of ultrasonic testing and machine learning methods to predict the static & fatigue behavior of spot-welded joints. J. Manuf. Process. 2020, 52, 26–34. [Google Scholar]

- Schmal, C.; Meschut, G.; Buhl, N. Joining of high strength aluminum alloys by refill friction stir spot welding (III-1854-18). Weld. World 2019, 63, 541–550. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Yi, H.; Wang, Z.; Li, M. Welding quality evaluation for refill friction stir spot welding based on three-dimensional feature of ultrasonic image. Weld. World 2022, 66, 935–950. [Google Scholar] [CrossRef]

- Ahmed, G.M.S.; Algahtani, A.; Mahmoud, E.R.I.; Badruddin, I.A. Experimental Evaluation of Interfacial Surface Cracks in Friction Welded Dissimilar Metals through Image Segmentation Technique (IST). Materials 2018, 11, 2460. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.C.; Jahanshahi, M.R.; Wu, R.T.; Joffe, C. A texture-Based Video Processing Methodology Using Bayesian Data Fusion for Autonomous Crack Detection on Metallic Surfaces. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 271–287. [Google Scholar] [CrossRef]

- Sudhagar, S.; Sakthivel, M.; Ganeshkumar, P. Monitoring of friction stir welding based on vision system coupled with Machine learning algorithm. Measurement 2019, 144, 135–143. [Google Scholar] [CrossRef]

- Penttila, S.; Lund, H.; Skriko, T. Possibilities of Artificial Intelligence-Enabled Feedback Control System in Robotized Gas Metal Arc Welding. J. Manuf. Mater. Process. 2023, 7, 102. [Google Scholar] [CrossRef]

- Chu, H.H.; Wang, Z.Y. A vision-based system for post-welding quality measurement and defect detection. Int. J. Adv. Manuf. Technol. 2016, 86, 3007–3014. [Google Scholar] [CrossRef]

- Huang, W.; Kovacevic, R. A Laser-Based Vision System for Weld Quality Inspection. Sensors 2011, 11, 506–521. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.F.; Hu, W.Y. The study on defects in aluminum 2219-T6 thick butt friction stir welds with the application of multiple non-destructive testing methods. Mater. Des. 2011, 32, 2073–2084. [Google Scholar] [CrossRef]

- Bogue, R.W. Machine Vision Theory, Algorithms, Practicalities. Assem. Autom. 2005, 25, 144–5154. [Google Scholar] [CrossRef]

- Zou, Y.F.; Li, W.Y.; Yang, X.W.; Su, Y.; Chu, Q.; Shen, Z.K. Microstructure and mechanical properties of refill friction stir spot welded joints: Effects of tool size and welding parameters. J. Mater. Res. Technol.-JMRT 2022, 21, 5066–5080. [Google Scholar] [CrossRef]

- Shen, Z.K.; Yang, X.Q.; Zhang, Z.H.; Cui, L.; Li, T.L. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater. Des. 2013, 44, 476–486. [Google Scholar] [CrossRef]

- Zou, Y.F.; Li, W.Y.; Chu, Q.; Wu, D.; Su, Y.; Shen, Z.K.; Wang, F.F.; Tang, H.W. Formability and mechanical property of refill friction stir spot-welded joints. Weld. World 2021, 65, 899–907. [Google Scholar] [CrossRef]

- Sun, G.D.; Zhou, L.; Zhang, R.X.; Luo, L.Y.; Xu, H.; Zhao, H.Y.; Guo, N.; Zhang, D. Effect of Sleeve Plunge Depth on Interface/Mechanical Characteristics in Refill Friction Stir Spot Welded Joint. Acta Metall. Sin.-Engl. Lett. 2020, 33, 551–560. [Google Scholar] [CrossRef]

- Wang, W.; Cai, Y.; Wang, H.-P.; Carlson, B.E.; Poss, M. Quality inspection scheme for automotive laser braze joints. Int. J. Adv. Manuf. Technol. 2020, 106, 1553–1566. [Google Scholar] [CrossRef]

| Cu | Si | Fe | Mn | Mg | Zn | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.4 | 0.4 | 0.4–1.0 | 4.0–4.9 | 0.25 | 0.05–0.25 | 0.15 | Bal. |

| Group | Stirring Time (s) | Depth (mm) | Rotational Speed (rpm) | Refilling Time (s) |

|---|---|---|---|---|

| 1 | 2.5 | 2.4 | 1000 | 1.5 |

| 2 | 2.5 | 2.4 | 1000 | 2 |

| 3 | 2.5 | 2.4 | 1000 | 2.5 |

| 4 | 2.5 | 2.4 | 1000 | 3 |

| 5 | 2.5 | 2.4 | 1400 | 1.5 |

| 6 | 2.5 | 2.4 | 1400 | 2 |

| 7 | 2.5 | 2.4 | 1400 | 2.5 |

| 8 | 2.5 | 2.4 | 1400 | 3 |

| 9 | 2.5 | 2.4 | 1800 | 1.5 |

| 10 | 2.5 | 2.4 | 1800 | 2 |

| 11 | 2.5 | 2.4 | 1800 | 2.5 |

| 12 | 2.5 | 2.4 | 1800 | 3 |

| 13 | 2.5 | 2.4 | 2200 | 1.5 |

| 14 | 2.5 | 2.4 | 2200 | 2 |

| 15 | 2.5 | 2.4 | 2200 | 2.5 |

| 16 | 2.5 | 2.4 | 2200 | 3 |

| Kernel Function | Accuracy |

|---|---|

| Linear | 85.9% |

| Quadratic | 73.4% |

| Polynomial | 78.1% |

| SVM with Bayesian optimization | 95.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, H.; Xu, G.; Dong, J.; Gu, X.; Fan, Q. Research on the Surface-State Parameterization of a Refill Friction Stir Spot Welding Joint Made of Aluminum Alloy and Its Connection to the Fracture Mode. Materials 2024, 17, 762. https://doi.org/10.3390/ma17030762

Zhong H, Xu G, Dong J, Gu X, Fan Q. Research on the Surface-State Parameterization of a Refill Friction Stir Spot Welding Joint Made of Aluminum Alloy and Its Connection to the Fracture Mode. Materials. 2024; 17(3):762. https://doi.org/10.3390/ma17030762

Chicago/Turabian StyleZhong, Hua, Guocheng Xu, Juan Dong, Xiaopeng Gu, and Qiuyue Fan. 2024. "Research on the Surface-State Parameterization of a Refill Friction Stir Spot Welding Joint Made of Aluminum Alloy and Its Connection to the Fracture Mode" Materials 17, no. 3: 762. https://doi.org/10.3390/ma17030762

APA StyleZhong, H., Xu, G., Dong, J., Gu, X., & Fan, Q. (2024). Research on the Surface-State Parameterization of a Refill Friction Stir Spot Welding Joint Made of Aluminum Alloy and Its Connection to the Fracture Mode. Materials, 17(3), 762. https://doi.org/10.3390/ma17030762