Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. XRD Patterns

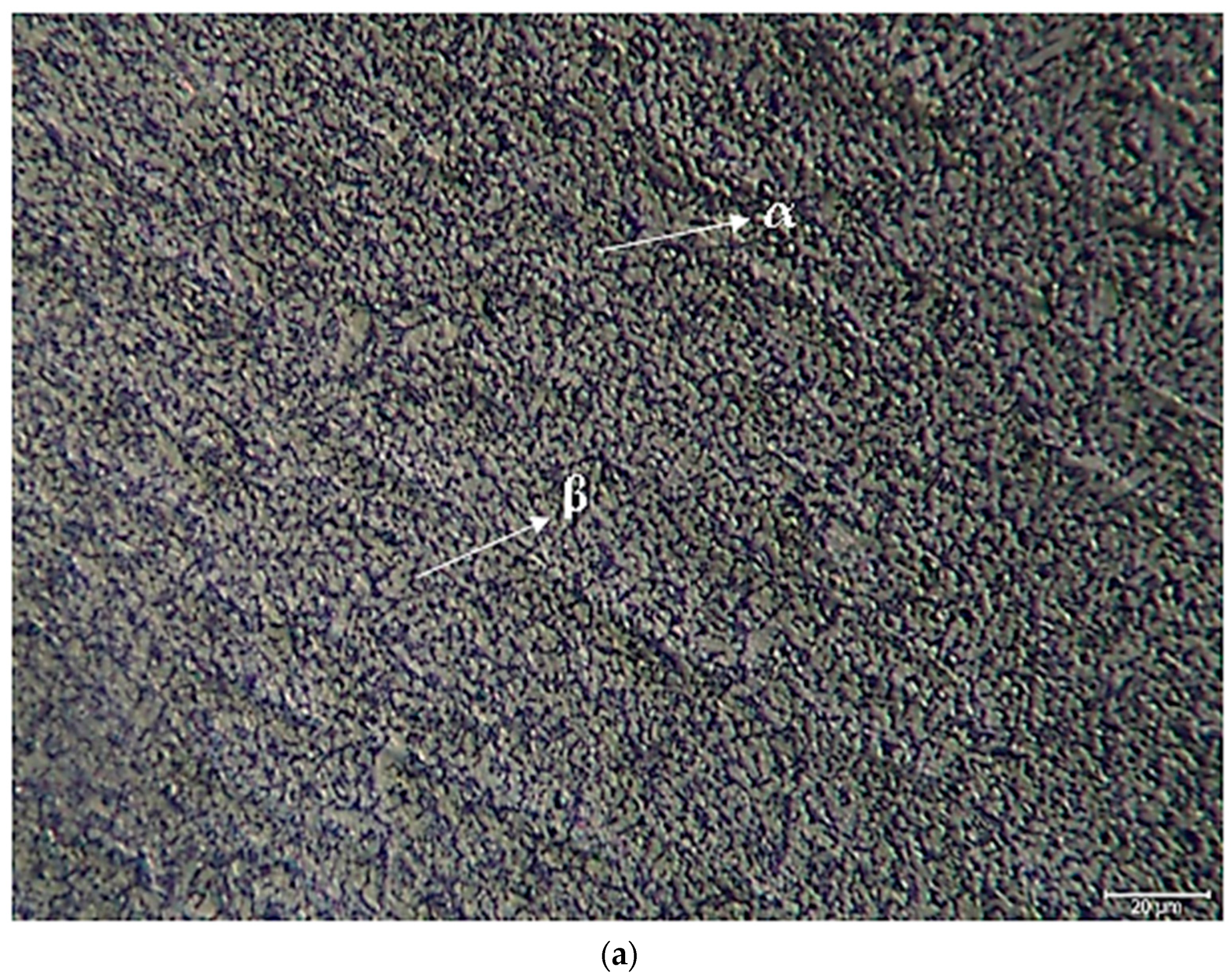

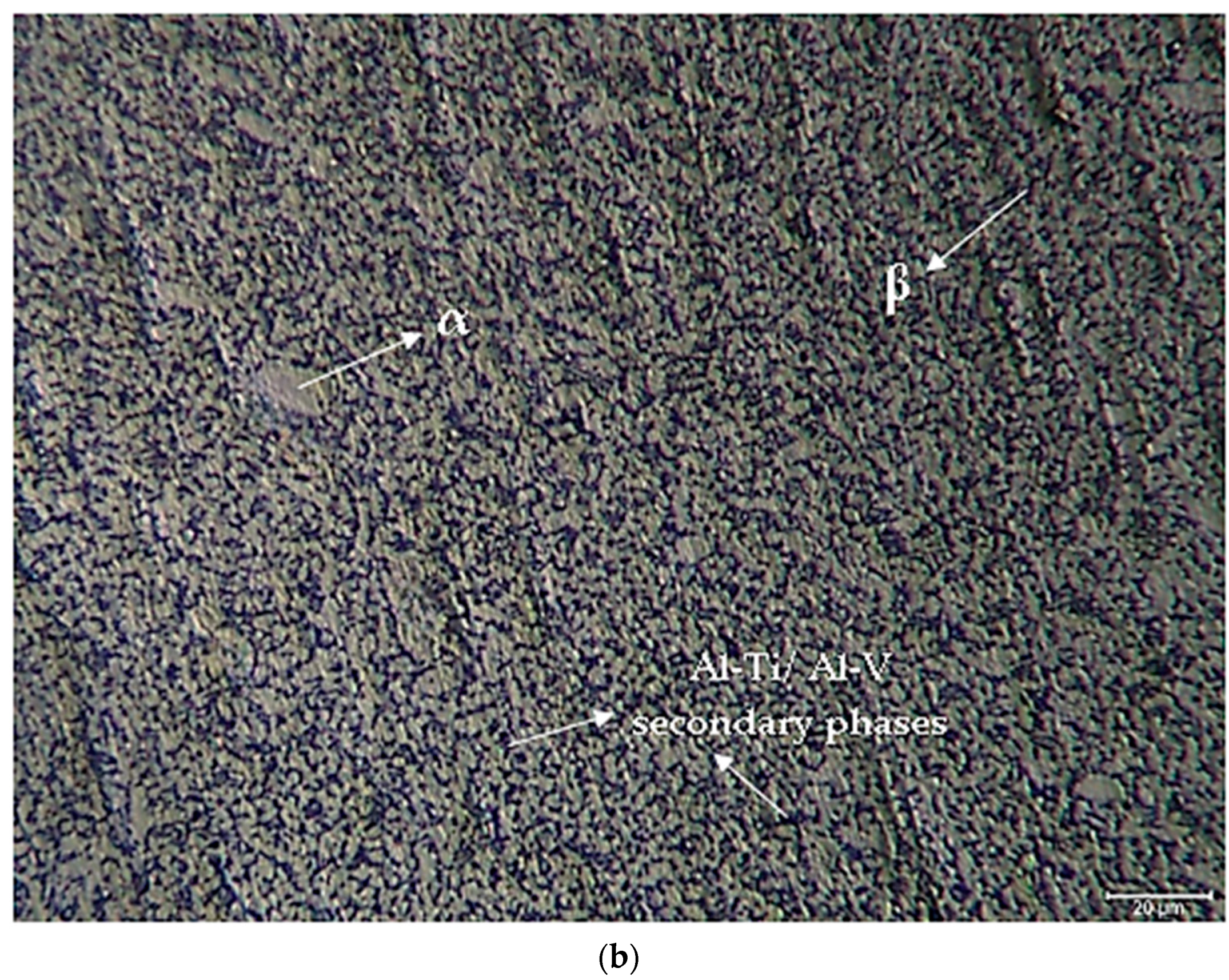

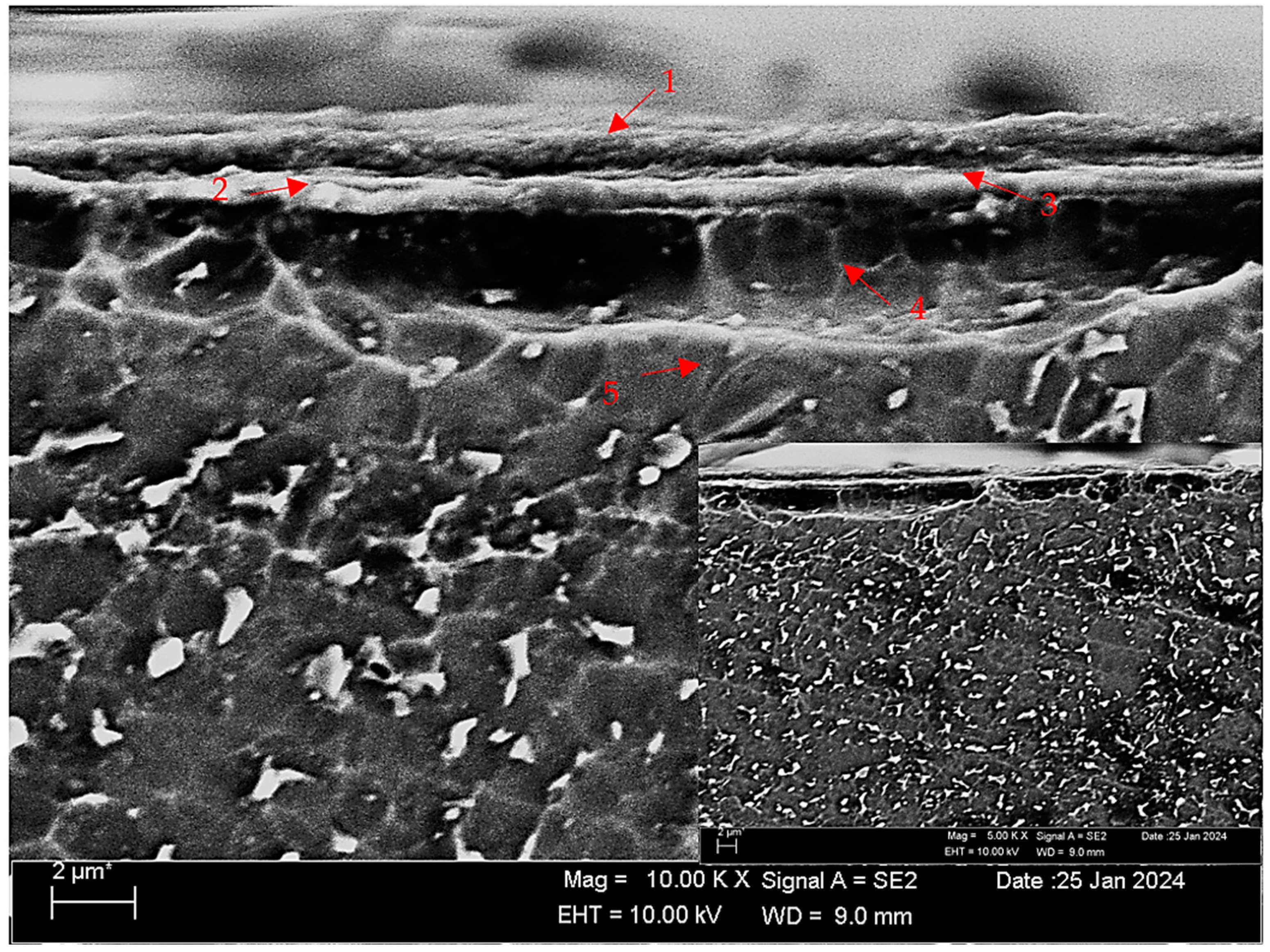

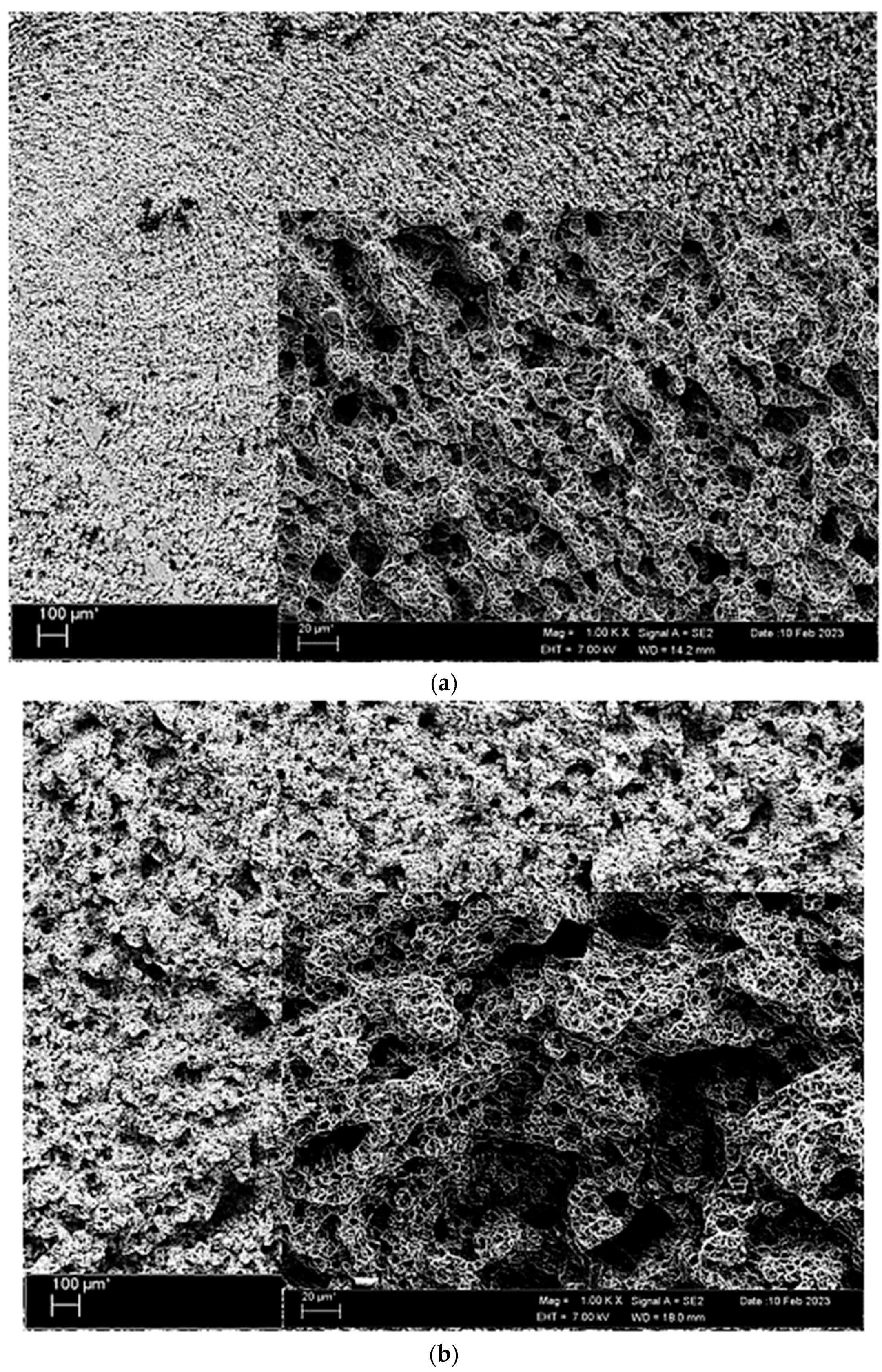

3.2. Microstructure

3.3. Hardness Test Results

3.4. Mechanical Test Results

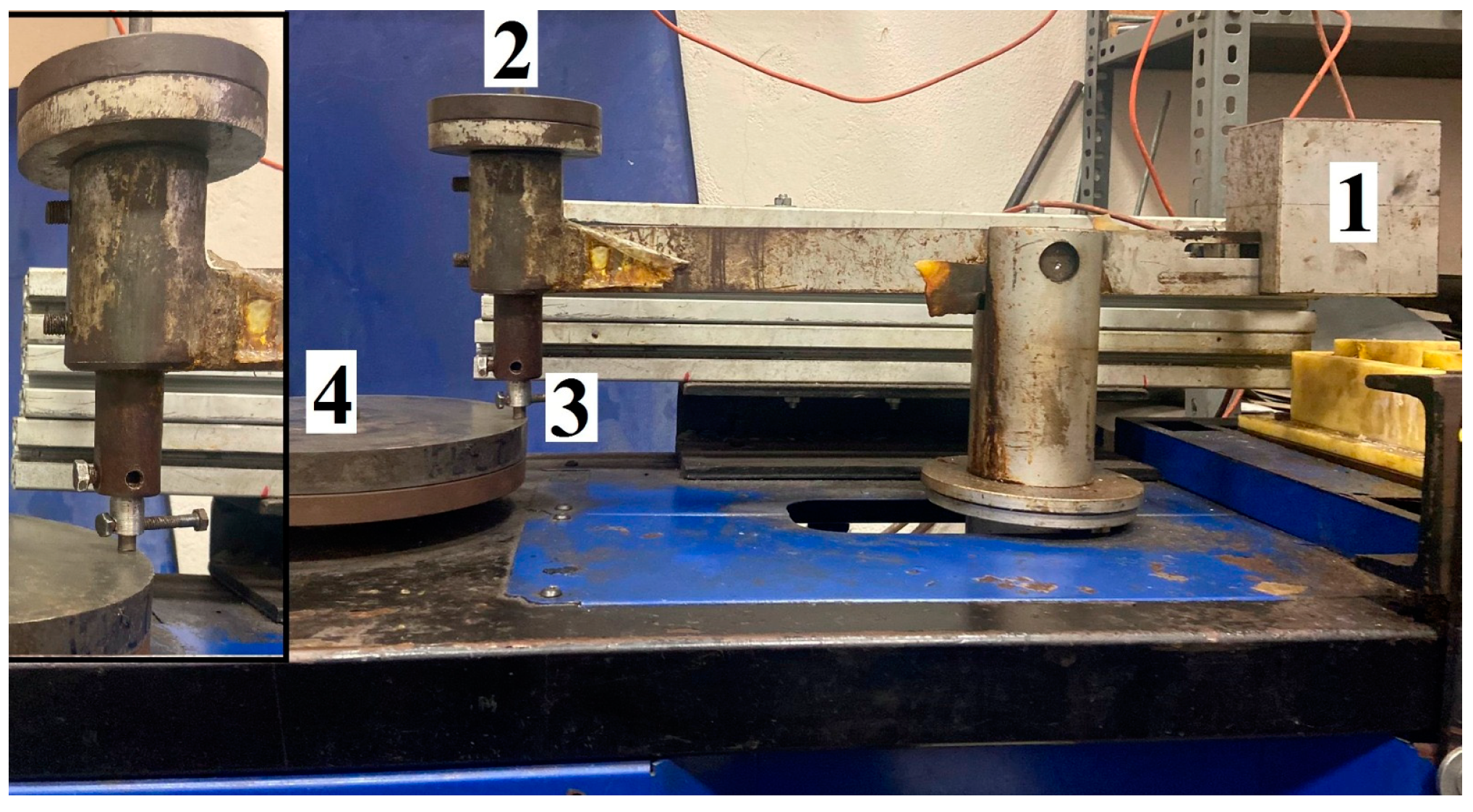

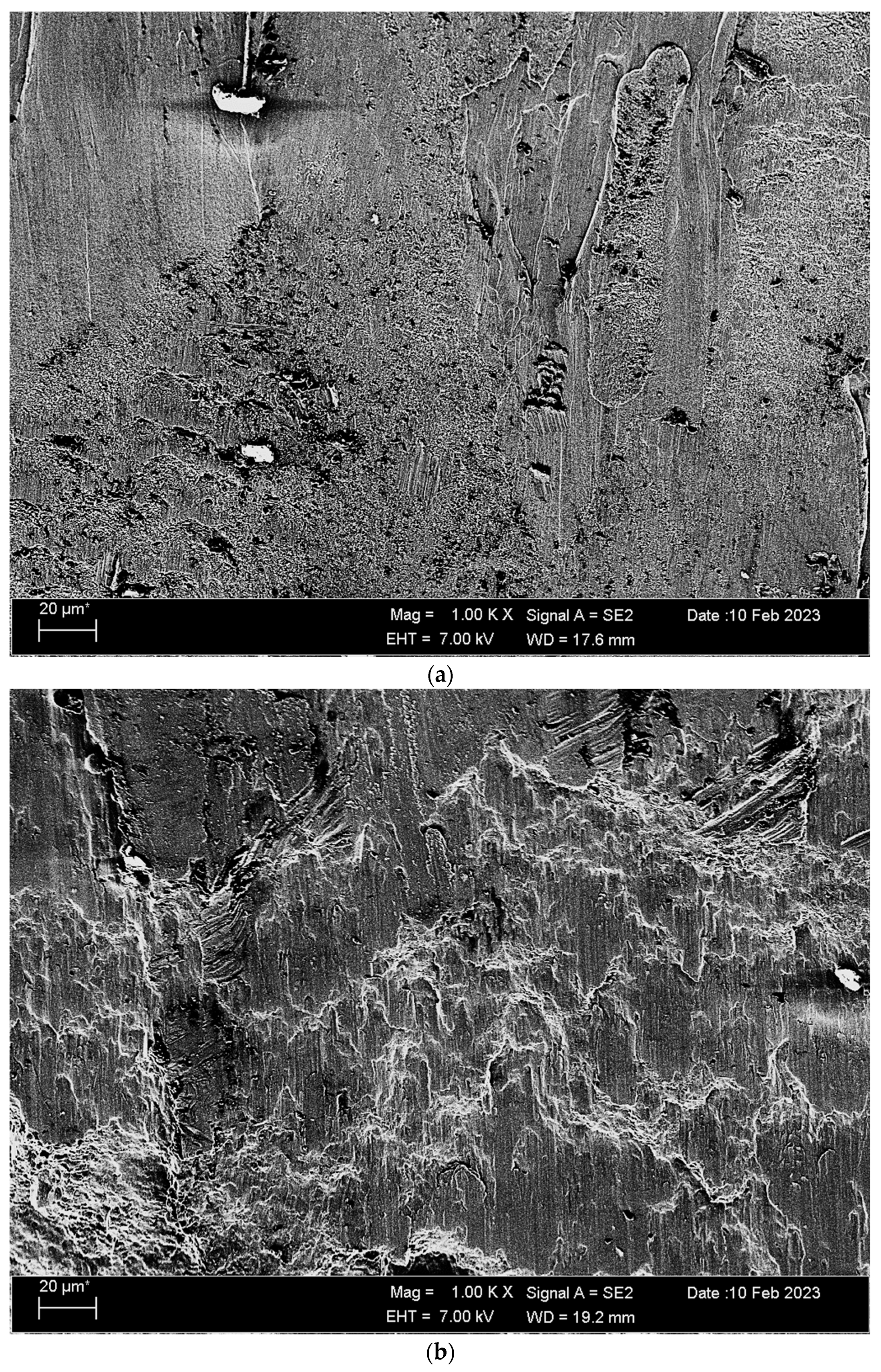

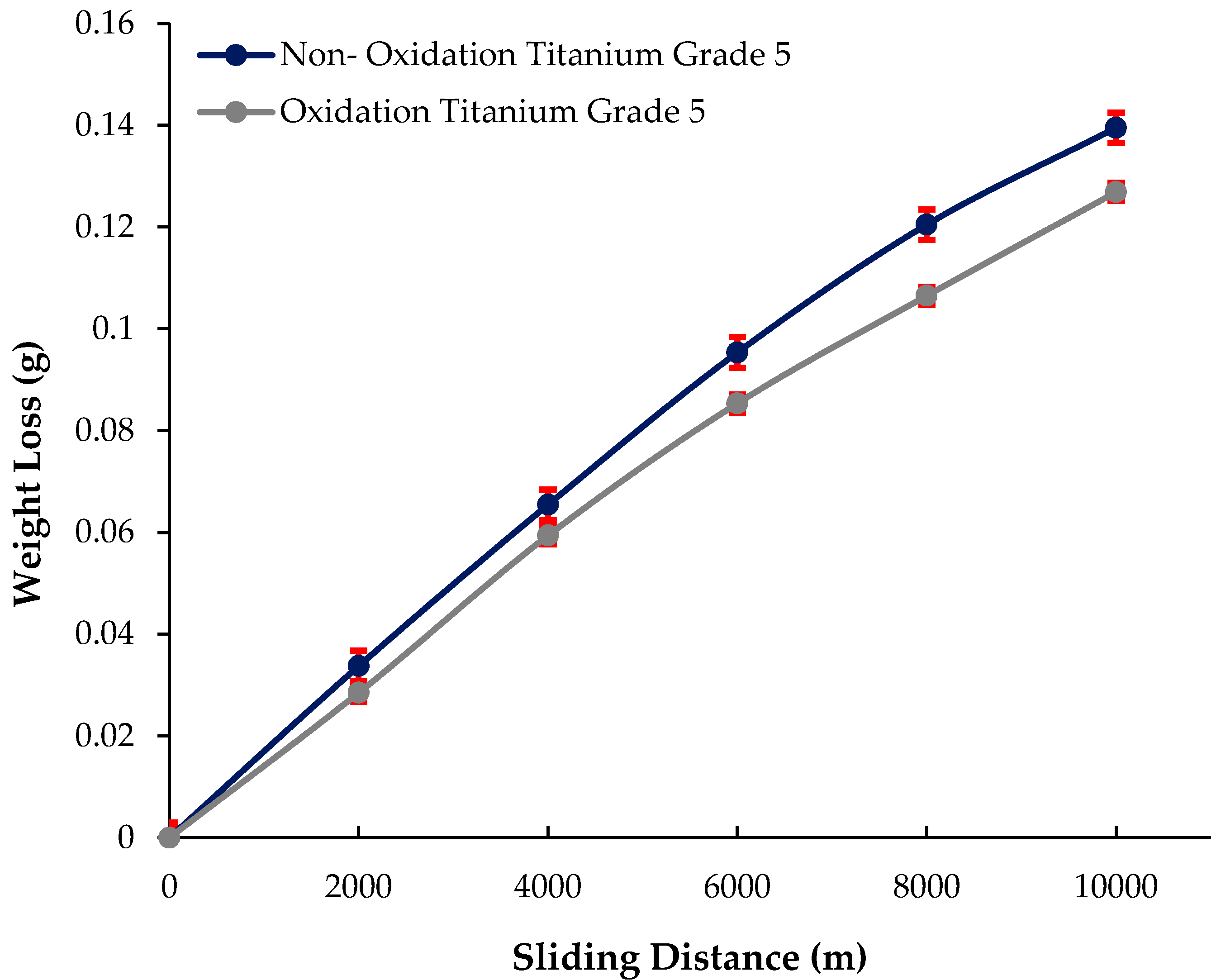

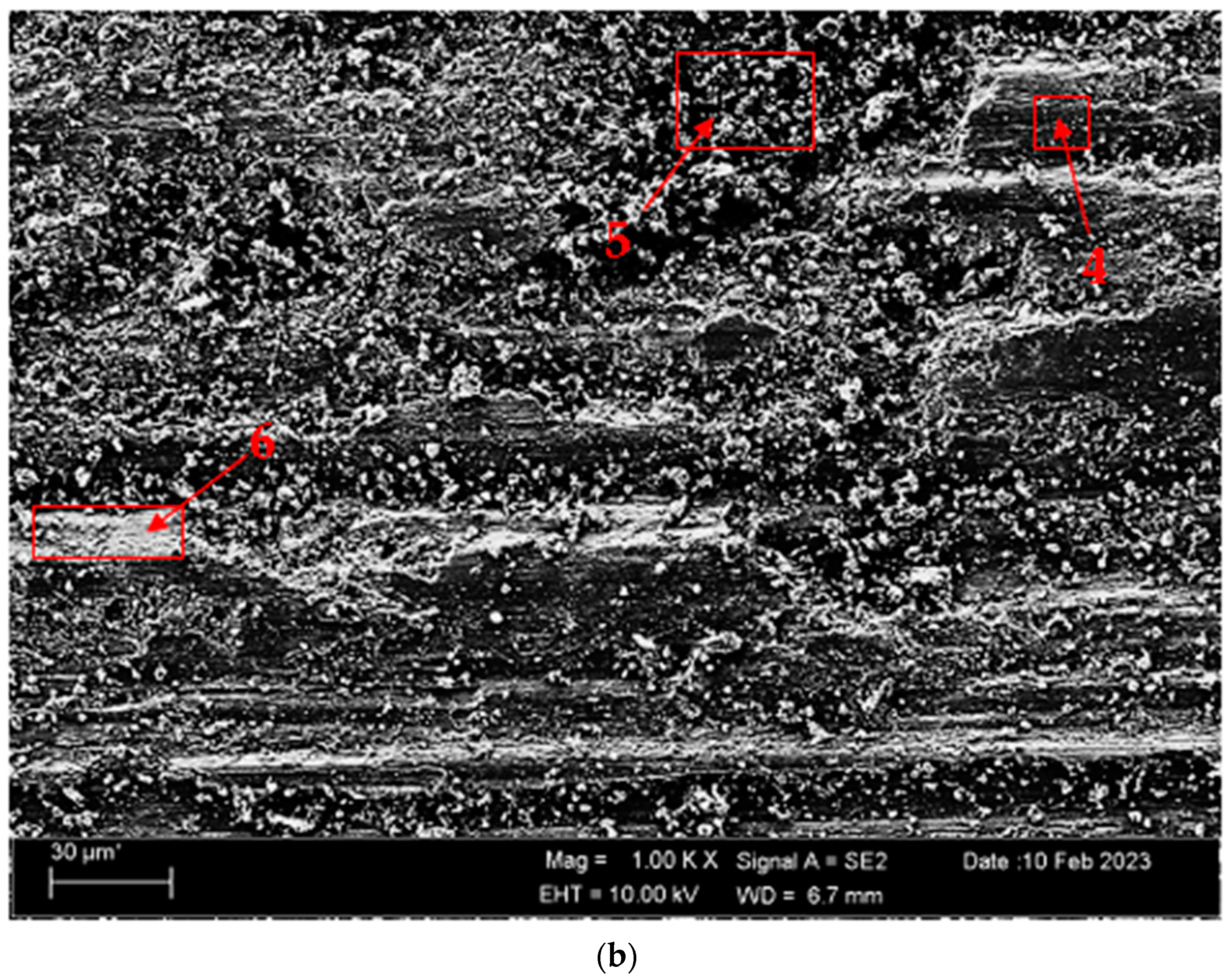

3.5. Tribological (Wear) Test Results

4. Conclusions

- While it is observed that the grey contrast coloured α grains are coaxial in the microstructures, it is seen that there are black contrast coloured β grains at the grain boundaries. However, in oxidised Titanium Grade 5, it is possible to observe that the α structure becomes larger, and the number and density of the structure increases. Small-sized structures can be seen inside the growing α particles and on the β particles. These structures are predicted to be Al-Ti/Al-V secondary phases.

- The nonoxidised alloy matrix had a macrolevel hardness of 335 ± 3.21 HB, while the ball trace on the OL layer showed a hardness of 353 ± 1.62 HB. The heat treatment used resulted in a 13% increase in Vickers microhardness from the polished and etched matrix of the nonoxidised and oxidised alloys, from 309 ± 2.08 HV1 to 352 ± 1.43 HV1, respectively. The Vickers microhardness value of the oxidised sample was 528 ± 1.74 HV1, as a 50% increase was noted.

- According to their tensile properties, oxidised alloys showed a better result compared to nonoxidised alloys. While the peak stress in the oxidised alloy was 1028.40 MPa, in the nonoxidised alloy, this value was 1027.20 MPa. It is seen that the peak stresses of both materials are close to each other, and the result of the oxidised alloy is slightly better. When we look at the breaking strain to characterise the deformation behaviour in the materials, it is 0.084 mm/mm in the oxidised alloy; in the nonoxidised alloy, it is 0.066 mm/mm. When we look at the stress at offset yield of the two alloys, it is 694.56 MPa in the oxidised alloy; it was found to be 674.092 MPa in the nonoxidised alloy.

- According to their compressive test properties, the maximum compressive strength is 2164.32 MPa in the oxidised alloy; in the nonoxidised alloy, it is 1531.52 MPa. While the yield strength is 972.50 MPa in oxidised Titanium Grade 5, it is found to be 934.16 MPa in nonoxidised Titanium Grade 5. When the compressive deformation oxidised alloy is 100.01%, in the nonoxidised alloy, it is 68.50%.

- According to their tribological properties, the oxidised alloy provides the least weight loss after 10,000 m and has the best wear resistance. The oxidised alloy experiences a weight loss of 0.127 ± 0.0002 g after sliding a distance of 10,000 m. Additionally, its wear coefficient is (63.45 ± 0.15) × 10−8 g/Nm. The unoxidised alloy exhibits the highest degree of weight reduction and the lowest level of wear resistance. The weight loss and wear coefficient, measured after a sliding distance of 10,000 m, is determined as 0.140 ± 0.0003 g and (69.75 ± 0.09) × 10−8 g/Nm, respectively. The oxidation process is shown to improve the tribological properties of Titanium Grade 5 alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El Khalloufi, M.; Drevelle, O.; Soucy, G. Titanium: An Overview of Resources and Production Methods. Minerals 2021, 11, 1425. [Google Scholar] [CrossRef]

- Çelïk, Y.H.; Kiliçkap, E. Titanyum Alaşımlarından Ti-6Al-4V’nın İşlenmesinde Karşılaşılan Zorluklar: Derleme. Gazi Üniv. Fen Bilim. Derg. Part C Tasarım Teknol. 2018, 6, 163–175. [Google Scholar]

- Bloyce, A.; Qi, P.-Y.; Dong, H.; Bell, T. Surface modification of titanium alloys for combined improvements in corrosion and wear resistance. Surf. Coat. Technol. 1998, 107, 125–132. [Google Scholar] [CrossRef]

- Habazaki, H.; Onodera, T.; Fushimi, K.; Konno, H.; Toyotake, K. Spark anodizing of β-Ti alloy for wear-resistant coating. Surf. Coat. Technol. 2007, 201, 8730–8737. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, G.; Liu, Y. Dry Sliding Tribological Behavior of TC11 Titanium Alloy Subjected to the Ultrasonic Impacting and Rolling Process. Metals 2018, 8, 13. [Google Scholar] [CrossRef]

- Pohrelyuk, I.; Sheykin, S.; Padgurskas, J.; Lavrys, S. Wear resistance of two-phase titanium alloy after deformation-diffusion treatment. Tribol. Int. 2018, 127, 404–411. [Google Scholar] [CrossRef]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M. Mechanical, tribological and adhesive properties of oxide layers obtained on the surface of the Ti–6Al–7Nb alloy in the thermal oxidation process. Wear 2019, 432–433, 202929. [Google Scholar] [CrossRef]

- Ayday, A. Coatings of Bioactive TiO2 Films on TI6AL4V Alloy by Micro Arc Oxidation. Acta Phys. Pol. A 2018, 134, 412–414. [Google Scholar] [CrossRef]

- Astinchap, B.; Moradian, R.; Gholami, K. Effect of sputtering power on optical properties of prepared TiO2 thin films by thermal oxidation of sputtered Ti layers. Mater. Sci. Semicond. Process. 2017, 63, 169–175. [Google Scholar] [CrossRef]

- Sartale, S.; Ansari, A.; Rezvani, S.-J. Influence of Ti film thickness and oxidation temperature on TiO2 thin film formation via thermal oxidation of sputtered Ti film. Mater. Sci. Semicond. Process. 2013, 16, 2005–2012. [Google Scholar] [CrossRef]

- Mïndïvan, H.; Özkan, O. An Electrodeposition Method of Nickel–Graphene Composite Coatings on Ti–6Al–4V alloy. Bilge Int. J. Sci. Technol. Res. 2018, 2, 47–52. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Yetik, O.; Koçoğlu, H.; Avcu, E.; Sınmazçelik, T. Dry Sliding Wear Behaviour of Shot Peened TI6AL4V Alloys at Different Peening Times. Acta Phys. Pol. A 2018, 134, 349–353. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, Z.; He, W.; Pang, Z.; Ning, Z.; Chen, R.; Zheng, C.; Yan, C.; Guo, L. Improved Tribocorrosion Properties of Ti6Al4V Alloy by Anodic Plasma Electrolytic Oxidation. Adv. Eng. Mater. 2023, 25, 2300228. [Google Scholar] [CrossRef]

- Erinosho, M.F.; Akinlabi, E.T.; Pityana, S.; Owolabi, G. Laser Surface Modification of Ti6Al4V-Cu for Improved Microhardness and Wear Resistance Properties. Mater. Res. 2017, 20, 1143–1152. [Google Scholar] [CrossRef]

- Silva, G.; Ueda, M.; Otani, C.; Mello, C.; Lepienski, C. Improvements of the surface properties of Ti6Al4V by plasma based ion implantation at high temperatures. Surf. Coat. Technol. 2010, 204, 3018–3021. [Google Scholar] [CrossRef]

- Jing, P.; Zhang, M.; Chan, C.H.H.; Jing, F.; Pauls, J.P.; Dargusch, M.S.; Fraser, J.F.; Leng, Y. Diamond-like carbon films prepared by a low temperature periodic process for application in ventricular assist devices. J. Biomed. Mater. Res. Part B Appl. Biomater. 2022, 111, 1048–1058. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Wu, M.; Cui, C.; Wang, H. Effect of Graphene Oxide on the Performance of Co-Based Coatings on Ti6Al4V Alloys by Laser Cladding. Coatings 2020, 10, 1048. [Google Scholar] [CrossRef]

- György, E.; del Pino, A.P.; Sauthier, G.; Figueras, A.; Alsina, F.; Pascual, J. Structural, morphological and local electric properties of TiO2thin films grown by pulsed laser deposition. J. Phys. D Appl. Phys. 2007, 40, 5246–5251. [Google Scholar] [CrossRef]

- Byun, J.M.; Choi, H.R.; Kim, S.H.; Suk, M.-J.; Kim, Y.D. Formation of nanostructured rutile TiO2 synthesized on Ti powder via thermal oxidation. Appl. Surf. Sci. 2017, 415, 43–48. [Google Scholar] [CrossRef]

- Yang, W.; Xu, D.; Guo, Q.; Chen, T.; Chen, J. Influence of electrolyte composition on microstructure and properties of coatings formed on pure Ti substrate by micro arc oxidation. Surf. Coat. Technol. 2018, 349, 522–528. [Google Scholar] [CrossRef]

- Boettcher, C.; Bell, T.; Dong, H. Surface engineering of timet 550 with oxygen to form a rutile-based, wear-resistant coating. Met. Mater. Trans. A 2002, 33, 1201–1211. [Google Scholar] [CrossRef]

- Mishra, A.; Davidson, J.A.; Poggie, R.; Kovacs, P.; FitzGerald, T.J. Mechanical and tribological properties and biocompatibility of diffusion hardened Ti-13Nb-13Zr—A new titanium alloy for surgical implants. ASTM Spec. Tech. Publ. 1996, 1272, 96–112. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Boyer, R.R. Titanium and Its Alloys: Metallurgy, Heat Treatment and Alloy Characteristics. Encycl. Aerosp. Eng. 2010, 1–12. [Google Scholar] [CrossRef]

- Miyoshi, K. Aerospace mechanisms and tribology technology. Tribol. Int. 1999, 32, 673–685. [Google Scholar] [CrossRef]

- Roberts, E.W. Space tribology: Its role in spacecraft mechanisms. J. Phys. D Appl. Phys. 2012, 45, 503001. [Google Scholar] [CrossRef]

- Güleryüz, H.; Çimenoğlu, H. Effect of thermal oxidation on corrosion and corrosion–wear behaviour of a Ti–6Al–4V alloy. Biomaterials 2004, 25, 3325–3333. [Google Scholar] [CrossRef] [PubMed]

- Biswas, A.; Srikant, P.V.S.; Manna, I.; Chatterjee, U.K.; Majumdar, J.D. Chemical oxidation of Ti–6Al–4V for improved wear and corrosion resistance. Surf. Eng. 2008, 24, 442–446. [Google Scholar] [CrossRef]

- García-Rueda, A.; Guzmán-Castillo, D.; García-González, L.; Zamora-Peredo, L.; Hernández-Torres, J. Surface modification of a Ti6Al4V alloy by thermal oxidation to improve its tribological properties. Mater. Lett. 2022, 317, 132082. [Google Scholar] [CrossRef]

- Cevik, E.; Sun, Y.; Turen, Y.; Ahlatci, H. An investigation on dry sliding wear behaviour of pressure infiltrated AA1050-XMg/B4C composites. Sci. Eng. Compos. Mater. 2018, 25, 67–73. [Google Scholar] [CrossRef]

- Soltan, A.A.M.; Esen, I.; Kara, S.A.; Ahlatçı, H. Examination of the Corrosion Behavior of Shape Memory NiTi Material for Biomedical Applications. Materials 2023, 16, 3951. [Google Scholar] [CrossRef]

- Sager, A.; Esen, I.; Ahlatçi, H.; Turen, Y. Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites. Materials 2022, 15, 8582. [Google Scholar] [CrossRef]

- Sun, Y.; Cevik, E.; Turen, Y.; Ahlatci, H.; Turan, M.E.; Aydin, F.; Zengin, H. Influence of GNPs and B4C reinforcements on mechanical, thermal and wear properties of magnesium matrix composite produced by powder metallurgy. J. Compos. Mater. 2021, 55, 3881–3891. [Google Scholar] [CrossRef]

- Palta, A.; Sun, Y.; Ahlatci, H. Effect of copper addition on wear and corrosion behaviours of Mg2Si particle reinforced composites. Mater. Des. 2012, 36, 451–458. [Google Scholar] [CrossRef]

- Cug, H.; Ahlatci, H. Effect of Zn and Mn Additions on the Wear Resistance of Cast Alloy Mg–5% Al–1% Si. Met. Sci. Heat Treat. 2017, 59, 161–167. [Google Scholar] [CrossRef]

- Su, Y.; Luo, S.-C.; Meng, L.; Gao, P.; Wang, Z.-M. Selective Laser Melting of In Situ TiB/Ti6Al4V Composites: Formability, Microstructure Evolution and Mechanical Performance. Acta Met. Sin. 2020, 33, 774–788. [Google Scholar] [CrossRef]

- Li, Z.; Yang, F.; Wang, H.; Li, Y.; Chen, C.; Guo, Z. Direct Ink Writing of Porous Ti6Al4V Alloys via UV Light Curing. Adv. Eng. Mater. 2022, 24, 176. [Google Scholar] [CrossRef]

- Peirs, J.; Tirry, W.; Amin-Ahmadi, B.; Coghe, F.; Verleysen, P.; Rabet, L.; Schryvers, D.; Degrieck, J. Microstructure of adiabatic shear bands in Ti6Al4V. Mater. Charact. 2013, 75, 79–92. [Google Scholar] [CrossRef]

- Urban, P.; Ternero, F.; Caballero, E.S.; Nandyala, S.; Montes, J.M.; Cuevas, F.G. Amorphous Al-Ti Powders Prepared by Mechanical Alloying and Consolidated by Electrical Resistance Sintering. Metals 2019, 9, 1140. [Google Scholar] [CrossRef]

- Ti (Titanium) Binary Alloy Phase Diagrams. In Alloy Phase Diagrams; ASM International: Almere, The Netherlands, 2016; pp. 615–618. [CrossRef]

- Lazurenko, D.V.; Stark, A.; Esikov, M.A.; Paul, J.; Bataev, I.A.; Kashimbetova, A.A.; Mali, V.I.; Lorenz, U.; Pyczak, F. Ceramic-Reinforced γ-TiAl-Based Composites: Synthesis, Structure, and Properties. Materials 2019, 12, 629. [Google Scholar] [CrossRef]

- Yürektürk, Y. Sıcak daldırma alüminyumlama (SDA) ve difüzyon tavlaması ile yüzeyi modifiye edilmiş Ti-6Al-4V alaşımının karakterizasyonu. Gazi Üniv. Mühendis. Mimar. Fak. Derg. 2022, 38, 309–318. [Google Scholar] [CrossRef]

- Sujata, M.; Bhargava, S.; Sangal, S. On the formation of TiAl3 during reaction between solid Ti and liquid Al. J. Mater. Sci. Lett. 1997, 16, 1175–1178. [Google Scholar] [CrossRef]

- Rastkar, A.R.; Parseh, P.; Darvishnia, N.; Hadavi, S.M.M. Microstructural evolution and hardness of TiAl3 and TiAl2 phases on Ti–45Al–2Nb–2Mn–1B by plasma pack aluminizing. Appl. Surf. Sci. 2013, 276, 112–119. [Google Scholar] [CrossRef]

- Velten, D.; Biehl, V.; Aubertin, F.; Valeske, B.; Possart, W.; Breme, J. Preparation of TiO2 layers on cp-Ti and Ti6Al4V by thermal and anodic oxidation and by sol-gel coating techniques and their characterization. J. Biomed. Mater. Res. 2002, 59, 18–28. [Google Scholar] [CrossRef]

- Dickes, D.; Öztürk, B.; Völkl, R.; Galetz, M.C.; Glatzel, U. Improving the Adhesion of a Hard Oxide Layer on Ti6Al4V by a Three-Step Thermal Oxidation Process. Adv. Eng. Mater. 2022, 24, 2100864. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M.; Barylski, A.; Mieszczak, L. Characteristic of Oxide Layers Obtained on Titanium in the Process of Thermal Oxidation. Arch. Met. Mater. 2016, 61, 853–856. [Google Scholar] [CrossRef]

| Chemical Composition (wt.%) | |||

|---|---|---|---|

| Alloy | Al | V | Ti |

| Titanium Grade 5 | 7.07 | 3.51 | Bal. |

| Points | Al | Ti | V |

|---|---|---|---|

| 1 | 7.69 | 92.02 | 0.29 |

| 2 | 8.10 | 91.91 | - |

| 3 | 8.64 | 91.36 | - |

| 4 | 7.53 | 90.45 | 2.03 |

| 5 | 7.59 | 92.41 | - |

| 6 | 8.66 | 91.35 | - |

| Points | Al | Ti | V | O |

|---|---|---|---|---|

| 1 | 2.16 | 41.69 | - | 56.16 |

| 2 | 0.20 | 98.27 | - | 1.53 |

| 3 | 0.31 | 98.37 | - | 1.31 |

| 4 | 0.51 | 97.82 | - | 1.67 |

| 5 | 7.65 | 91.38 | 0.49 | 0.47 |

| Alloy | Hardness Test (Macro and Micro) | ||

|---|---|---|---|

| Titanium Grade 5 | Nonoxidised | Oxidised | |

| Polished and Etched Matrix | Polished and Etched Matrix | OL | |

| Macro (HB/2.5/187.5) | 335 ± 3.21 | - | 353 ± 1.62 |

| Micro (HV1) | 309 ± 2.08 | 352 ± 1.43 | 528 ± 1.74 |

| Points | Al | Ti | V | Fe | O |

|---|---|---|---|---|---|

| 1 | 4.14 | 53.22 | 0.18 | 10.12 | 32.34 |

| 2 | 3.97 | 64.40 | - | 8.23 | 23.41 |

| 3 | 4.34 | 77.46 | 0.10 | 5.73 | 12.44 |

| 4 | 4.33 | 61.50 | 0.11 | 9.16 | 24.89 |

| 5 | 3.50 | 70.87 | 1.66 | 4.53 | 19.44 |

| 6 | 4.32 | 61.59 | 0.44 | 10.50 | 23.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saier, A.; Esen, I.; Ahlatci, H.; Keskin, E. Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy. Materials 2024, 17, 776. https://doi.org/10.3390/ma17040776

Saier A, Esen I, Ahlatci H, Keskin E. Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy. Materials. 2024; 17(4):776. https://doi.org/10.3390/ma17040776

Chicago/Turabian StyleSaier, Abdulsalam, Ismail Esen, Hayrettin Ahlatci, and Esma Keskin. 2024. "Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy" Materials 17, no. 4: 776. https://doi.org/10.3390/ma17040776

APA StyleSaier, A., Esen, I., Ahlatci, H., & Keskin, E. (2024). Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy. Materials, 17(4), 776. https://doi.org/10.3390/ma17040776