Analysis of the Rheological Properties of Natural Hydraulic Lime-Based Suspensions for Sustainable Construction and Heritage Conservation

Abstract

1. Introduction

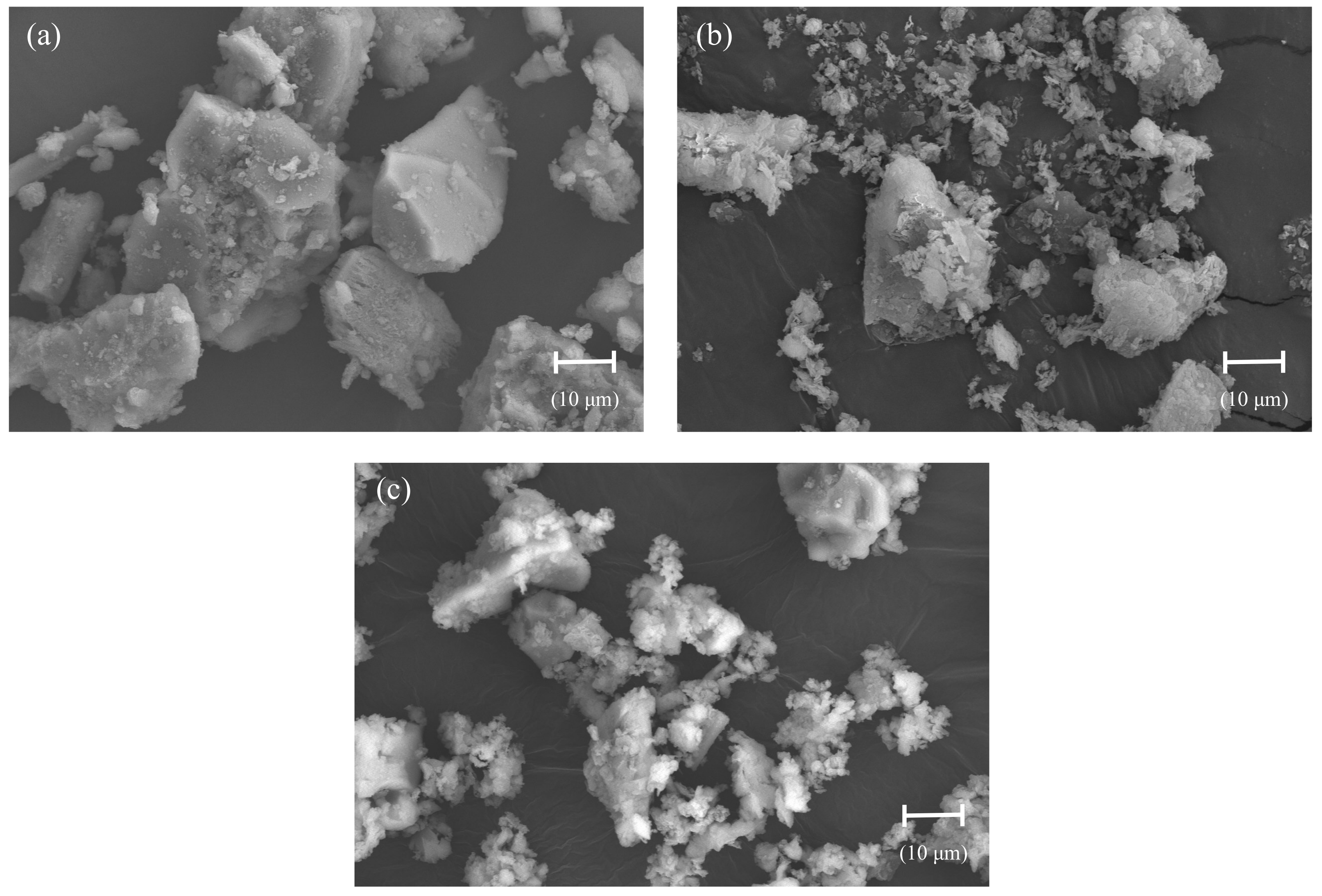

2. Materials and Methods

2.1. Mixing Protocol of the Suspensions

2.2. Rheometric Measurements

3. Results and Discussion

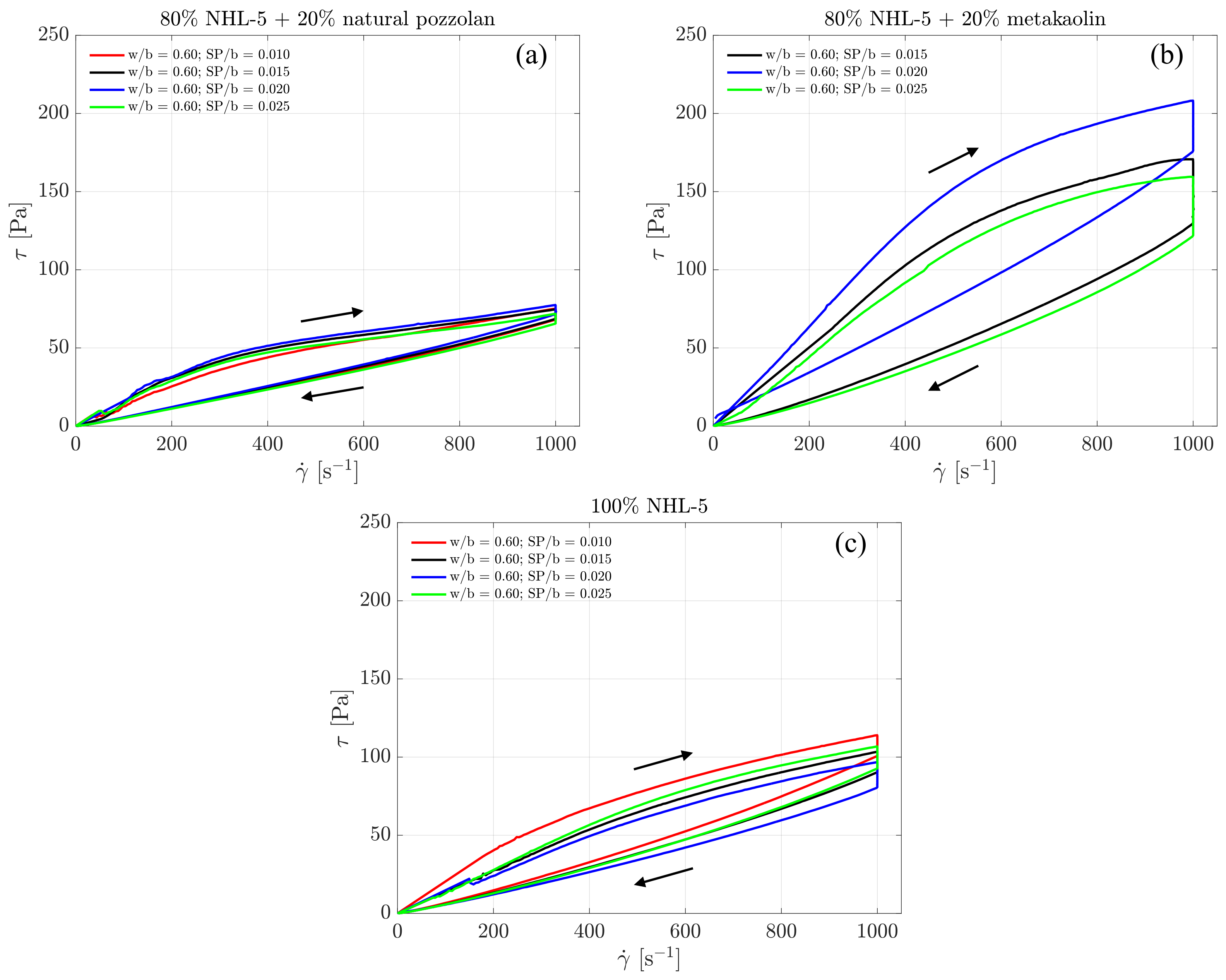

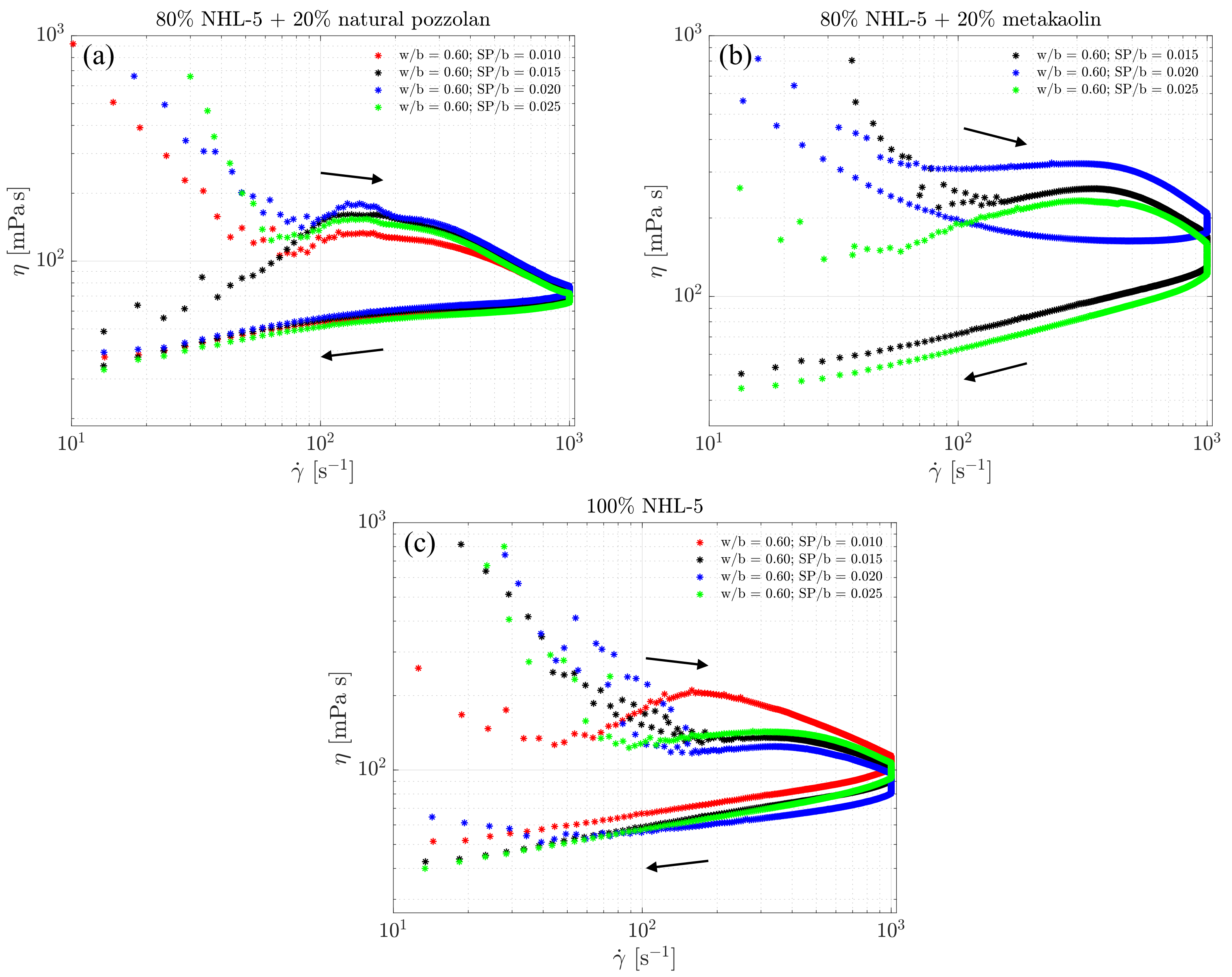

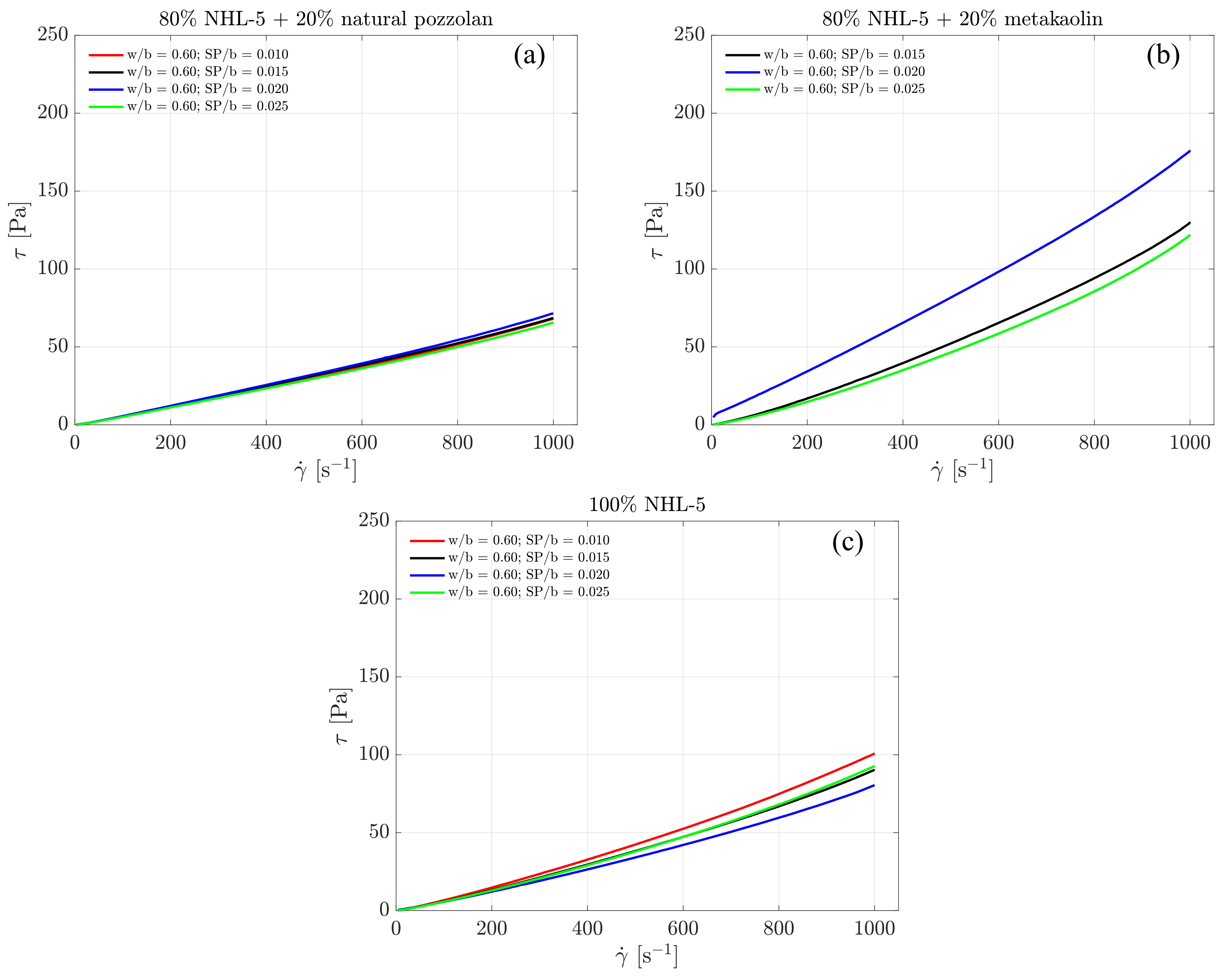

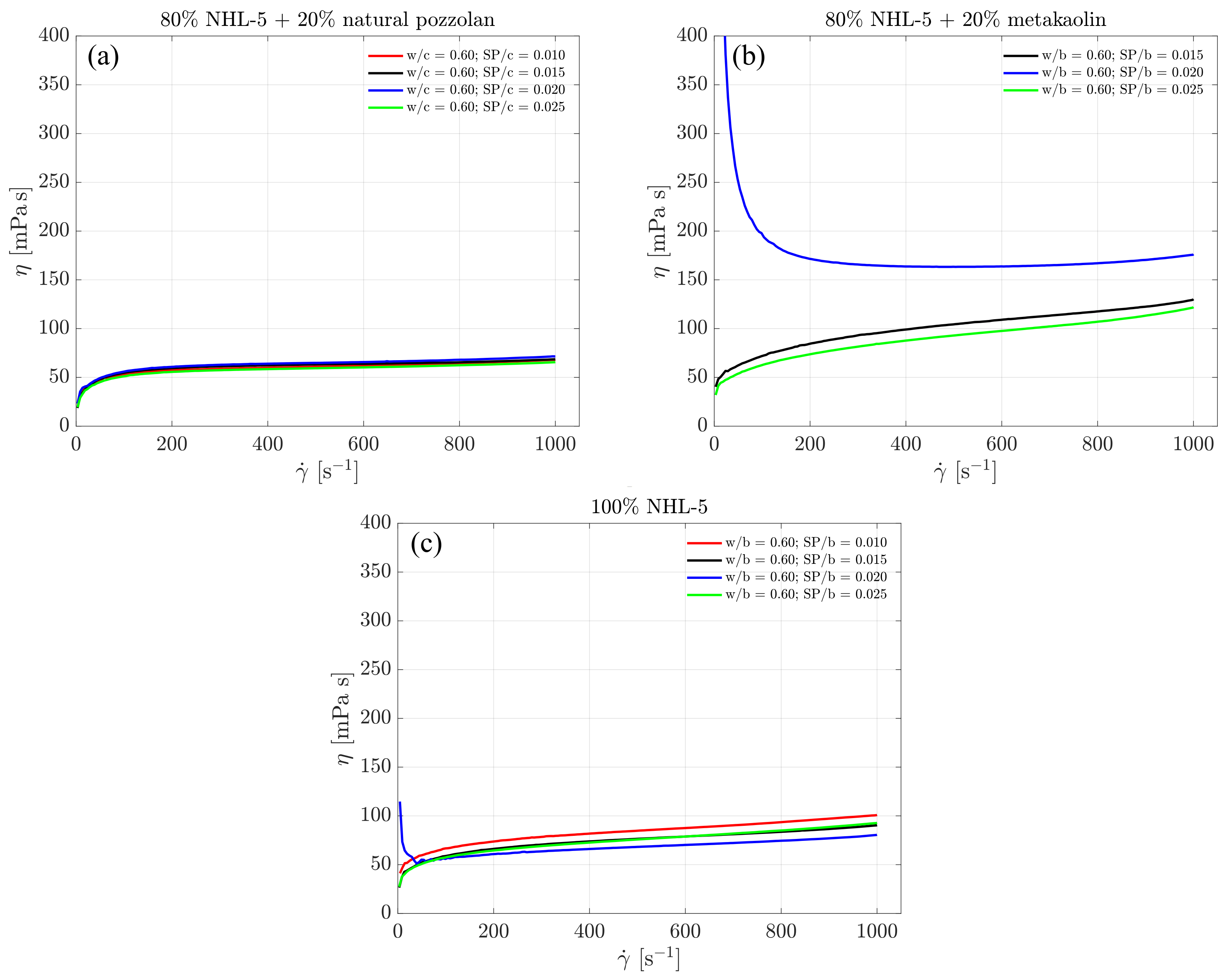

3.1. Rheological Behavior of the Complete Flow Curves

3.2. Rheological Behavior of the Ascending Branches of the Flow Curves

- : Shear stress at which the suspension is subjected;

- : Yield stress of the suspension;

- k: Consistency coefficient of the suspension;

- n: Flow index of the suspension;

- : Shear rate at which the suspension is subjected.

3.3. Rheological Behavior of the Descending Branches of the Flow Curves

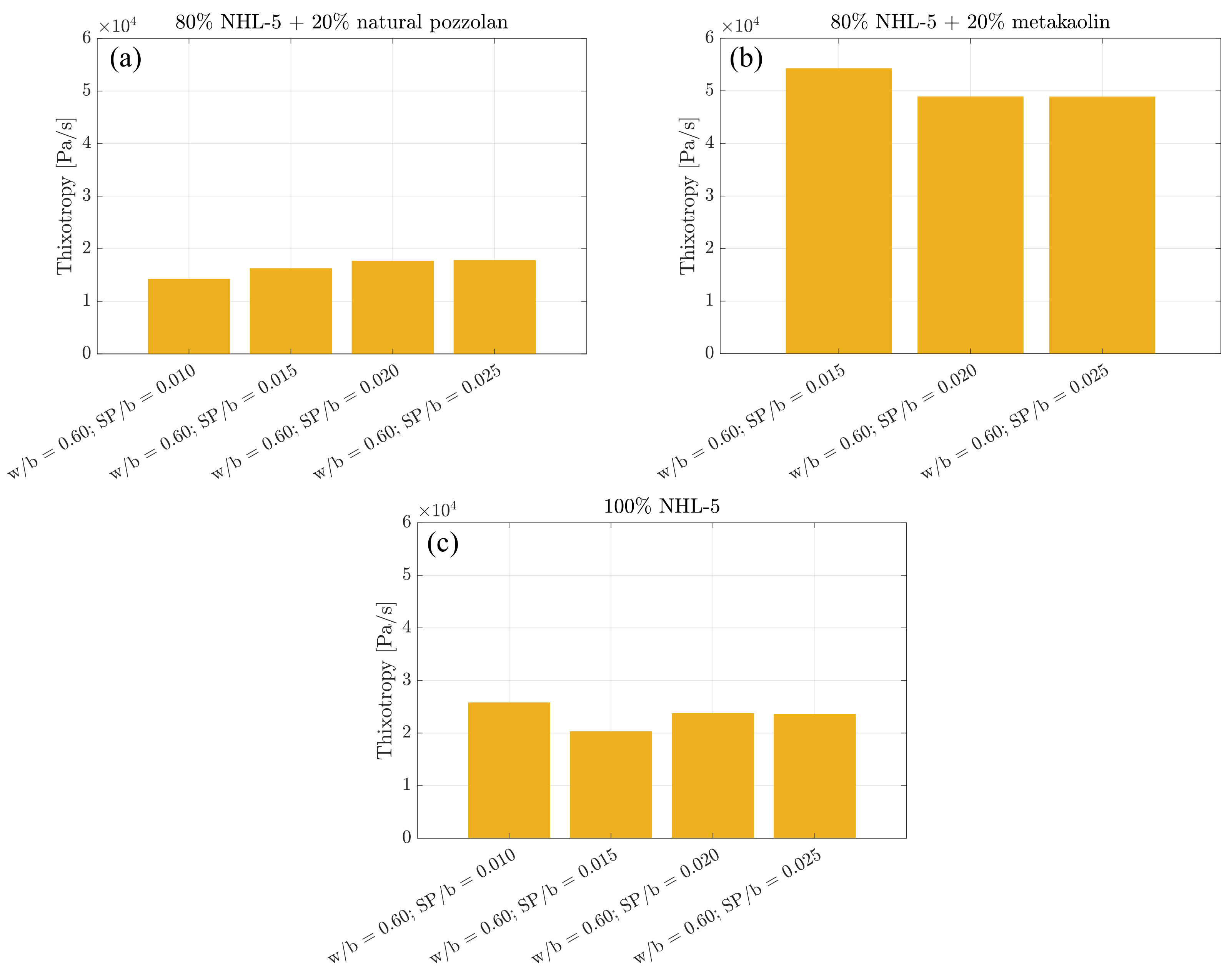

3.4. Thixotropy

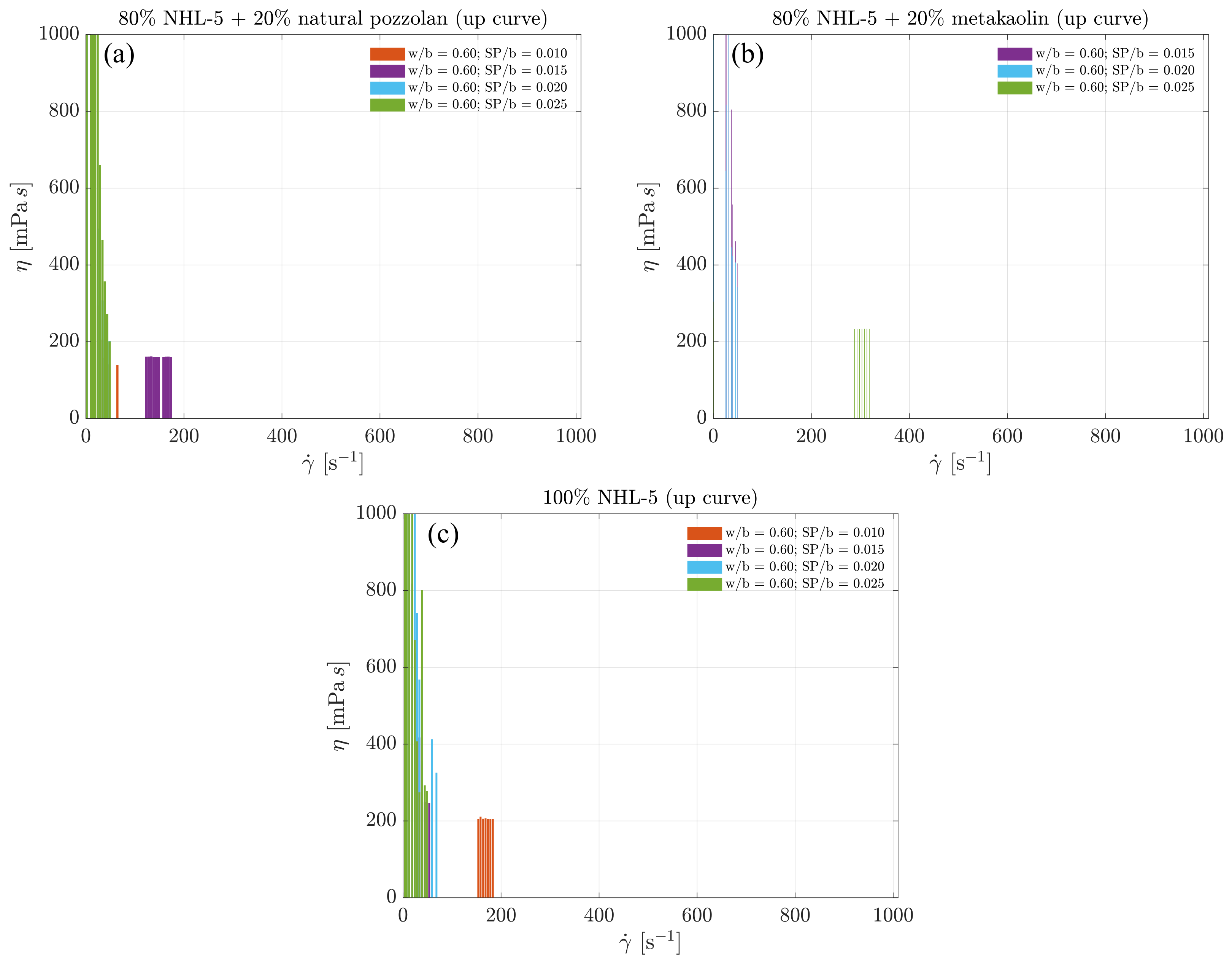

3.5. Maximum Viscosity Ranges along the Flow Curve

3.6. Effects on Lime-Based Systems of the Interaction between Materials

3.7. Implications for Applications: Injectability and Strength Development

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, S.; Ma, Q.; Wang, J.; Wang, L. Grouting performance improvement for natural hydraulic lime-based grout via incorporating silica fume and silicon-acrylic latex. Constr. Build. Mater. 2018, 186, 652–659. [Google Scholar] [CrossRef]

- Vintzileou, E. Grouting of three-leaf stone masonry: Types of grouts, mechanical properties of masonry before and after grouting. Struct. Anal. Hist. Constr. 2006, 1, 41–58. [Google Scholar]

- Toumbakari, E. Lime-Pozzolan-Cement Grouts and Their Structural Effects on Composite Masonry Walls. Ph.D. Thesis, Katholieke Uneversiteit Leuven, Leuven, Belgium, 2002. [Google Scholar]

- Binda, L.; Baronio, G.; Tiraboschi, C.; Tedeschi, C. Experimental research for the choice of adequate materials for the reconstruction of the Cathedral of Noto. Constr. Build. Mater. 2003, 17, 629–639. [Google Scholar] [CrossRef]

- Moropoulou, A.; Cakmak, A.; Biscontin, G.; Bakolas, A.; Zendri, E. Advanced Byzantine cement based composites resisting earthquake stresses: The crushed brick/lime mortars of Justinian’s Hagia Sophia. Constr. Build. Mater. 2002, 16, 543–552. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, C.; Hansen, E.; Ginell, W. Calcium Hydroxide Crystal Evolution upon Aging of Lime Putty. J. Am. Ceram. Soc. 1998, 81, 3032–3034. [Google Scholar] [CrossRef]

- Callaza, O.; Rodriguez-Navarro, C.; Sebastian, E.; Cultrone, G.; De la Torre, M. Aging of Lime Putty: Effects on Traditional Lime Mortar Carbonation. J. Am. Ceram. Soc. 2000, 83, 1070–1076. [Google Scholar] [CrossRef]

- Vavričuk, A.; Bokan-Bosiljkov, V.; Kramar, S. The influence of metakaolin on the properties of natural hydraulic lime-based grouts for historic masonry repair. Constr. Build. Mater. 2018, 172, 706–716. [Google Scholar] [CrossRef]

- Gameiro, A.; Silva, A.; do Rosário Veiga, M.; Velosa, A. Lime-metakaolin hydration products: A microscopy analysis. Mater. Technol. 2012, 46, 145–148. [Google Scholar]

- Navarro-Mendoza, E.G.; Alonso-Guzman, E.M.; Sanchez-Calvillo, A.; Bedolla-Arroyo, J.A.; Becerra-Santacruz, H.; Navarro-Ezquerra, A.; Gonzalez-Sanchez, B.; Martinez-Molina, W. Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration. Heritage 2023, 6, 2582–2600. [Google Scholar] [CrossRef]

- Vitruvius. The Ten Books on Architecture; Alianza Forma: Madrid, Spain, 2000. [Google Scholar]

- Kalagri, A.; Miltiadou-Fezans, A.; Vintzileou, E. Design and evaluation of hydraulic lime grouts for the strengthening of stone masonry historic structures. Mater. Struct. 2010, 43, 1135–1146. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.; Cidade, M.T. Rheology of Natural Hydraulic Lime Grouts for Conservation of Stone Masonry—Influence of Compositional and Processing Parameters. Fluids 2019, 4, 13. [Google Scholar] [CrossRef]

- Toumbakari, E.E.; Van Gemert, D.; Tenoutasse, N. Injection Grouts for Ancient Masonry: Strength Properties and Microstructural Evidence; Technical Chamber of Commerce: Athens, Greece, 1998. [Google Scholar]

- Bayram, M.; Oktay, D.; Yuzer, N. Evaluation of Fresh Properties and Rheological Behavior of lime-based Grouts with Cappadocia Waste Earth. Int. J. Archit. Herit. 2023, 17, 1984–2000. [Google Scholar] [CrossRef]

- Bras, A. Grout Optimization for Masonry Consolidation. Ph.D. Thesis, Universidade Nova de Lisboa, Lisbon, Portugal, 2011. [Google Scholar]

- Jorne, F.; Henriques, F.; Baltazar, L.G. Influence of superplasticizer, temperature, resting time and injection pressure on hydraulic lime grout injectability. Correlation analysis between fresh grout parameters and grout injectability. J. Build. Eng. 2015, 4, 140–151. [Google Scholar] [CrossRef]

- Nikolopoulou, V.; Adami, C.; Karagiannaki, D.; Vintzileou, E.; Miltiadou-Fezans, A. Grouts for strengthening two- and three-leaf stone masonry, made with earthen mortars. Int. J. Archit. Herit. 2019, 13, 663–678. [Google Scholar] [CrossRef]

- Papayianni, I.; Pachta, V. Experimental study on the performance of lime-based grouts used in consolidating historic masonries. Mater. Struct. 2015, 48, 2111–2121. [Google Scholar] [CrossRef]

- Jorne, F.; Henriques, F.; Baltazar, L. Evaluation of consolidation of different porous media with hydraulic lime grout injection. J. Cult. Herit. 2015, 16, 438–451. [Google Scholar] [CrossRef]

- Bras, A.; Henriques, F. Natural hydraulic lime based grouts—The selection of grout injection parameters for masonry consolidation. Constr. Build. Mater. 2012, 26, 135–144. [Google Scholar] [CrossRef]

- Miltiadou-Fezans, A.; Tassios, T. Penetrability of hydraulic grouts. Mater. Struct. 2013, 46, 1653–1671. [Google Scholar] [CrossRef]

- Sepulcre-Aguilar, A.; Hernández-Olivares, F. Assessment of phase formation in lime-based mortars with added metakaolin, Portland cement and sepiolite, for grouting of historic masonry. Cem. Concr. Res. 2010, 40, 66–76. [Google Scholar] [CrossRef]

- Pachta, V.; Papadopoulos, T.; Stefanidou, M. Development and testing of grouts based on perlite by-products and lime. Constr. Build. Mater. 2019, 207, 338–344. [Google Scholar] [CrossRef]

- Baltazar, L.; Henriques, F.; Jorne, F.; Cidade, M. Combined effect of superplasticizer, silica fume and temperature in the performance of natural hydraulic lime grouts. Constr. Build. Mater. 2014, 50, 584–597. [Google Scholar] [CrossRef]

- Vasiliki, P.; Goulas, D. Fresh and hardened state properties of fiber reinforced lime-based grouts. Constr. Build. Mater. 2020, 261, 119818. [Google Scholar] [CrossRef]

- Azeiteiro, L.; Velosa, A.; Paiva, H.; Mantas, P.; Ferreira, V.; Veiga, R. Development of grouts for consolidation of old renders. Constr. Build. Mater. 2014, 50, 352–360. [Google Scholar] [CrossRef]

- Pachta, V.; Papayianni, I.; Spyriliotis, T. Assessment of Laboratory and Field Testing Methods in Lime-based Grouts for the Consolidation of Architectural Surfaces. Int. J. Archit. Herit. 2020, 14, 1098–1105. [Google Scholar] [CrossRef]

- Pasian, C.; Secco, M.; Piqué, F.; Artioli, G.; Rickerby, S.; Cather, S. Lime-based injection grouts with reduced water content: An assessment of the effects of the water-reducing agents ovalbumin and ethanol on the mineralogical evolution and properties of grouts. J. Cult. Herit. 2018, 30, 70–80. [Google Scholar] [CrossRef]

- Zhu, J.; Hui, J.; Luo, H.; Zhang, B.; Wei, X.; Wang, F.; Li, Y. Effects of polycarboxylate superplasticizer on rheological properties and early hydration of natural hydraulic lime. Cem. Concr. Compos. 2021, 122, 104052. [Google Scholar] [CrossRef]

- Malathy, R.; Shanmugam, R.; Dhamotharan, D.; Kamaraj, D.; Prabakaran, M.; Kim, J. Lime based concrete and mortar enhanced with pozzolanic materials—State of art. Constr. Build. Mater. 2023, 390, 131415. [Google Scholar] [CrossRef]

- Master Builders Solutions. MasterEase 5025 Technical Data Sheet. 2023. Available online: https://assets.master-builders-solutions.com/es-es/masterease-5025.pdf (accessed on 31 January 2024).

- Alonso, M. Comportamiento y compatibilidad de cementos y aditivos superplastificantes basados en policarboxilatos. Efectos de la naturaleza de los cementos y estructura de los aditivos. Ph.D. Thesis, Instituto de Ciencias de la Construcción Eduardo Torroja, CSIC, Madrid, Spain, 2011. [Google Scholar]

- Ley-Hernández, A.; Feys, D.; Kumar, A. How do different testing procedures affect the rheological properties of cement paste? Cem. Concr. Res. 2020, 137, 106189. [Google Scholar] [CrossRef]

- De La Rosa, A.; Garijo, G.; Ruiz, G.; Moreno, R. Non-linear rheological behavior of superplasticized cementitious suspensions at high shear rates. Constr. Build. Mater. 2021, 306, 124825. [Google Scholar] [CrossRef]

- Feys, D.; Cepuritis, R.; Jacobsen, S.; Lesage, K.; Secrieru, E.; Yahia, A. Measuring rheological properties of cement pastes: Most common techniques, procedures and challenges. RILEM Tech. Lett. 2017, 2, 129–135. [Google Scholar] [CrossRef]

- Ferrara, L.; Cremonesi, M.; Tregger, N.; Frangi, A.; Shah, S. On the identification of rheological properties of cement suspensions: Rheometry, Computational Fluid Dynamics modeling and field test measurements. Cem. Concr. Res. 2012, 42, 1134–1146. [Google Scholar] [CrossRef]

- Burgos-Montes, O.; Alonso, M.; Puertas, F. Viscosity and water demand of limestone-and fly ash-blended cement pastes in the presence of superplasticisers. Constr. Build. Mater. 2013, 48, 417–423. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q. Time–dependent rheological behavior of cementitious paste under continuous shear mixing. Constr. Build. Mater. 2019, 226, 591–600. [Google Scholar] [CrossRef]

- D’Aloia Schwartzentruber, L.; Le Roy, R.; Cordin, J. Rheological behaviour of fresh cement pastes formulated from a Self Compacting Concrete (SCC). Cem. Concr. Res. 2006, 36, 1203–1213. [Google Scholar] [CrossRef]

- Moorthi, P.V.P.; Pra Mio, F.; Nanthagopalan, P.; Ferrara, L. Onset and intensity of shear thickening in cementitious suspensions—A parametrical study. Constr. Build. Mater. 2020, 244, 118292. [Google Scholar] [CrossRef]

- Ferron, R.; Gregori, A.; Sun, Z.; Shah, S. Rheological Method to Evaluate Structural Buildup in Self–Consolidating Concrete Cement Pastes. ACI Mater. J. 2007, 104, 242–250. [Google Scholar]

- Moreno, R. Reología de Suspensiones Ceramicas; Consejo Superior de Investigaciones Científicas: Madrid, Spain, 2005. [Google Scholar]

- Jaafri, R.; Aboulayt, A.; Alam, S.; Roziere, E.; Loukili, A. Natural hydraulic lime for blended cement mortars: Behavior from fresh to hardened states. Cem. Concr. Res. 2019, 120, 52–65. [Google Scholar] [CrossRef]

- Sales, L.P.; de Queiroz, M.G.; da Nóbrega, A.F.; da Nóbrega, A.C.; de Souza, J.J.; Carneiro, A.M. Study of rheological properties of lime–metakaolin slurries. Appl. Clay Sci. 2021, 215, 106309. [Google Scholar] [CrossRef]

- Coussot, P. Rheophysics—The Matter in All Its States; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Fourmentin, M.; Ovarlez, G.; Faure, P. Rheology of lime paste—A comparison with cement paste. Rheol. Acta 2015, 54, 647–656. [Google Scholar] [CrossRef]

- Roussel, N. A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cem. Concr. Res. 2006, 36, 1797–1806. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The origins of thixotropy of fresh cement pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Roussel, N. Steady and transient flow behaviour of fresh cement pastes. Cem. Concr. Res. 2005, 35, 1656–1664. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Bos, F.; Perrot, A.; Leal da Silva, W.; Nerella, V.; Fataei, S.; Wolfs, R.; Sonebi, M.; Roussel, N. Extrusion-based additive manufacturing with cement-based materials—Production steps, processes, and their underlying physics: A review. Cem. Concr. Res. 2020, 132, 106037. [Google Scholar] [CrossRef]

- Carnicer, V.; Alcázar, C.; Orts, M.; Sánchez, E.; Moreno, R. Microfluidic rheology: A new approach to measure viscosity of ceramic suspensions at extremely high shear rates. Open Ceram. 2021, 5, 100052. [Google Scholar] [CrossRef]

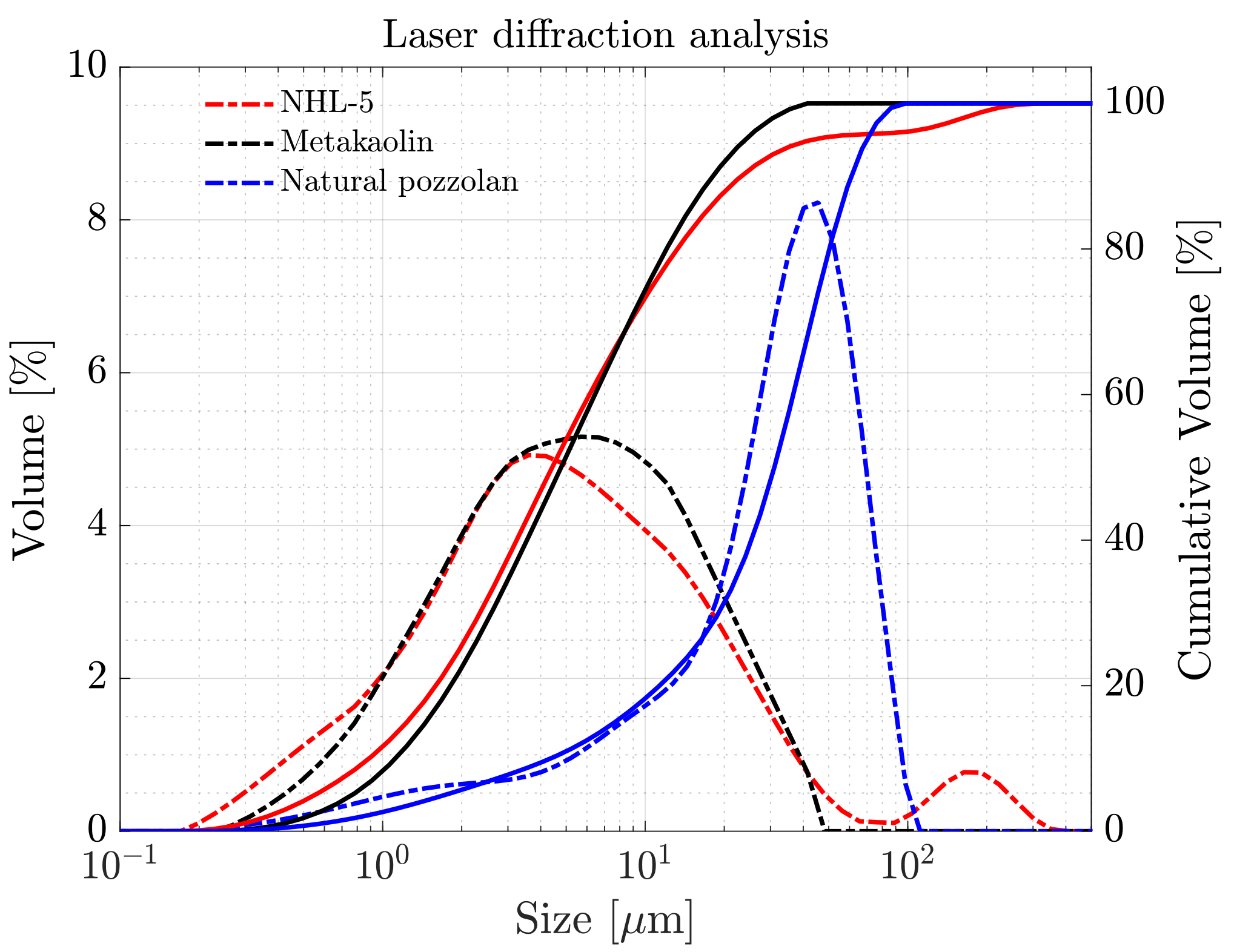

| NHL-5 | NVP | MK | |

|---|---|---|---|

| Specific gravity | 2.80 | 3.15 | 2.66 |

| Surface area (BET) [m/g] | 5.4 | 19.1 | 17.2 |

| D [ ] | 22.5 | 60.1 | 18.0 |

| D [ ] | 4.5 | 31.1 | 4.8 |

| D [ ] | 0.9 | 4.1 | 1.1 |

| Chemical Composition (%) | |||

|---|---|---|---|

| NHL-5 | NVP | MK | |

| NaO | 0.348 | 3.932 | 0.100 |

| MgO | 8.346 | 10.982 | 0.230 |

| AlO | 4.053 | 13.850 | 41.439 |

| SiO | 13.650 | 43.349 | 52.848 |

| PO | 0.060 | 0.591 | 0.142 |

| SO | 1.524 | 0.022 | 0.031 |

| Cl | 0.020 | 0.027 | – |

| KO | 1.090 | 1.469 | 1.328 |

| CaO | 53.897 | 9.145 | 0.035 |

| TiO | 0.227 | 2.886 | 0.563 |

| VO | 0.041 | – | 0.008 |

| CrO | 0.014 | 0.053 | 0.009 |

| MnO | 0.040 | 0.144 | 0.006 |

| FeO | 1.864 | 9.496 | 1.425 |

| CoO | – | 0.014 | – |

| NiO | 0.017 | 0.029 | 0.012 |

| CuO | – | 0.008 | 0.003 |

| ZnO | 0.004 | 0.012 | 0.006 |

| GaO | – | – | 0.004 |

| RbO | 0.005 | 0.005 | 0.013 |

| SrO | 0.219 | 0.089 | 0.016 |

| YO | – | 0.003 | 0.003 |

| ZrO | – | 0.048 | 0.026 |

| NbO | – | 0.006 | 0.002 |

| BaO | – | 0.041 | 0.013 |

| CeO | – | 0.053 | 0.044 |

| PrO | – | – | 0.009 |

| PbO | – | – | 0.015 |

| CO | 14.580 | 3.747 | 1.669 |

| Raw Materials [kg/m] | ||||||

|---|---|---|---|---|---|---|

| Denomination | NHL-5 | NVP | MK | Water | Superplasticizer | |

| 100 NHL-5 | 0.010 | 1034.7 | 0 | 0 | 620.8 | 10.4 |

| 0.015 | 1029.7 | 0 | 0 | 617.8 | 15.5 | |

| 0.020 | 1024.7 | 0 | 0 | 614.8 | 20.5 | |

| 0.025 | 1019.8 | 0 | 0 | 611.9 | 25.5 | |

| 80 NHL-5 + 20 NVP | 0.010 | 834.6 | 208.7 | 0 | 626.0 | 10.4 |

| 0.015 | 830.5 | 207.6 | 0 | 622.9 | 15.8 | |

| 0.020 | 826.5 | 206.6 | 0 | 619.9 | 20.7 | |

| 0.025 | 822.5 | 205.6 | 0 | 616.8 | 25.7 | |

| 80 NHL-5 + 20 MK | 0.015 | 820.5 | 0 | 205.1 | 615.4 | 15.4 |

| 0.020 | 816.5 | 0 | 204.1 | 612.4 | 20.4 | |

| 0.025 | 812.6 | 0 | 203.2 | 609.4 | 25.4 | |

| Denomination | [s] | [Pa] | k [Pa s] | n | ||

|---|---|---|---|---|---|---|

| 100% NHL-5 | 0.010 | 100–1000 | – | 19.6 (18.7, 20.5) | 0.323 (0.318, 0.328) | 0.999 |

| 0.015 | – | 3.0 (2.4, 3.6) | 0.546 (0.520, 0.573) | 0.998 | ||

| 0.020 | – | 1.7 (1.2, 2.3) | 0.610 (0.569, 0.650) | 0.994 | ||

| 0.025 | – | 8.5 (6.7, 10.3) | 0.425 (0.400, 0.450) | 0.998 | ||

| 80% NHL-5 + 20% NVP | 0.010 | 100–1000 | – | 9.4 (7.7, 11.1) | 0.355 (0.335, 0.376) | 0.998 |

| 0.015 | – | 155.8 (104.0, 207.5) | 0.094 (0.074, 0.114) | 0.998 | ||

| 0.020 | – | 171.3 (95.0, 247.7) | 0.089 (0.063, 0.115) | 0.997 | ||

| 0.025 | – | 177.7 (93.9, 261.5) | 0.084 (0.057, 0.110) | 0.997 | ||

| 80% NHL-5 + 20% MK | 0.010 | 100–1000 | – | 115.3 (63.2, 167.5) | 0.198 (0.157, 0.239) | 0.993 |

| 0.020 | – | 204.7 (100.3, 309.1) | 0.164 (0.121, 0.206) | 0.993 | ||

| 0.025 | – | 68.0 (38.9, 97.2) | 0.245 (0.202, 0.287) | 0.993 |

| Denomination | [s] | [Pa] | k [Pa s] | n | ||

|---|---|---|---|---|---|---|

| 100% NHL-5 | 0.010 | 0–1000 | 1.305 (1.054, 1.557) | 0.017 (0.016, 0.018) | 1.256 (1.247, 1.265) | 0.999 |

| 0.015 | 0.897 (0.675, 1.119) | 0.017 (0.016, 0.018) | 1.236 (1.227, 1.245) | 0.999 | ||

| 0.020 | 1.297 (1.088, 1.505) | 0.015 (0.014, 0.015) | 1.243 (1.233, 1.253) | 0.999 | ||

| 0.025 | 1.277 (1.044, 1.509) | 0.012 (0.011, 0.012) | 1.296 (1.286, 1.306) | 0.999 | ||

| 80% NHL-5 + 20% NVP | 0.010 | 0–1000 | 0.714 (0.528, 0.900) | 0.023 (0.021, 0.024) | 1.155 (1.146, 1.164) | 0.999 |

| 0.015 | 0.228 (0.059, 0.397) | 0.034 (0.032, 0.035) | 1.101 (1.093, 1.108) | 0.999 | ||

| 0.020 | 0.501 (0.304, 0.698) | 0.029 (0.027, 0.030) | 1.129 (1.120, 1.138) | 0.999 | ||

| 0.025 | 0.454 (0.291, 0.617) | 0.026 (0.024, 0.027) | 1.131 (1.124, 1.139) | 0.999 | ||

| 80% NHL-5 + 20% MK | 0.010 | 0–1000 | 1.164 (0.851, 1.476) | 0.015 (0.014, 0.016) | 1.304 (1.295, 1.314) | 0.999 |

| 0.020 | 8.298 (7.779, 8.816) | 0.053 (0.050, 0.057) | 1.162 (1.152, 1.173) | 0.999 | ||

| 0.025 | 1.850 (1.429, 2.270) | 0.008 (0.007, 0.009) | 1.392 (1.377, 1.407) | 0.999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De La Rosa, Á.; Ruiz, G.; Moreno, R. Analysis of the Rheological Properties of Natural Hydraulic Lime-Based Suspensions for Sustainable Construction and Heritage Conservation. Materials 2024, 17, 825. https://doi.org/10.3390/ma17040825

De La Rosa Á, Ruiz G, Moreno R. Analysis of the Rheological Properties of Natural Hydraulic Lime-Based Suspensions for Sustainable Construction and Heritage Conservation. Materials. 2024; 17(4):825. https://doi.org/10.3390/ma17040825

Chicago/Turabian StyleDe La Rosa, Ángel, Gonzalo Ruiz, and Rodrigo Moreno. 2024. "Analysis of the Rheological Properties of Natural Hydraulic Lime-Based Suspensions for Sustainable Construction and Heritage Conservation" Materials 17, no. 4: 825. https://doi.org/10.3390/ma17040825

APA StyleDe La Rosa, Á., Ruiz, G., & Moreno, R. (2024). Analysis of the Rheological Properties of Natural Hydraulic Lime-Based Suspensions for Sustainable Construction and Heritage Conservation. Materials, 17(4), 825. https://doi.org/10.3390/ma17040825