Low-Temperature Growth of InGaAs Quantum Wells Using Migration-Enhanced Epitaxy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

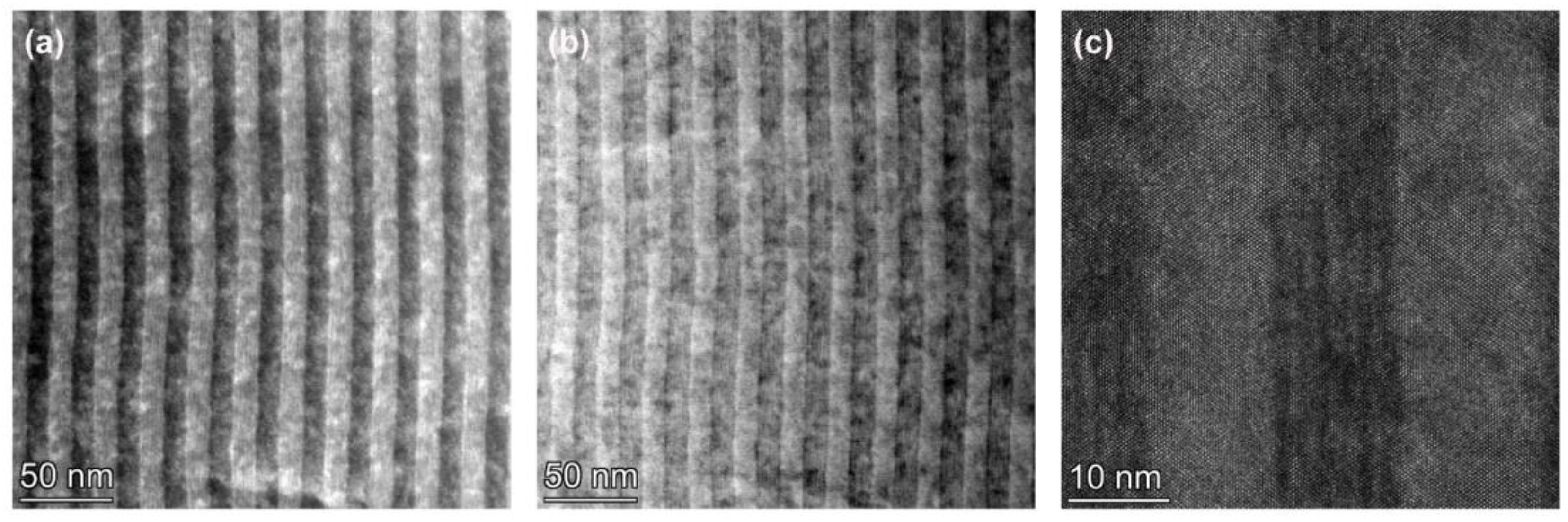

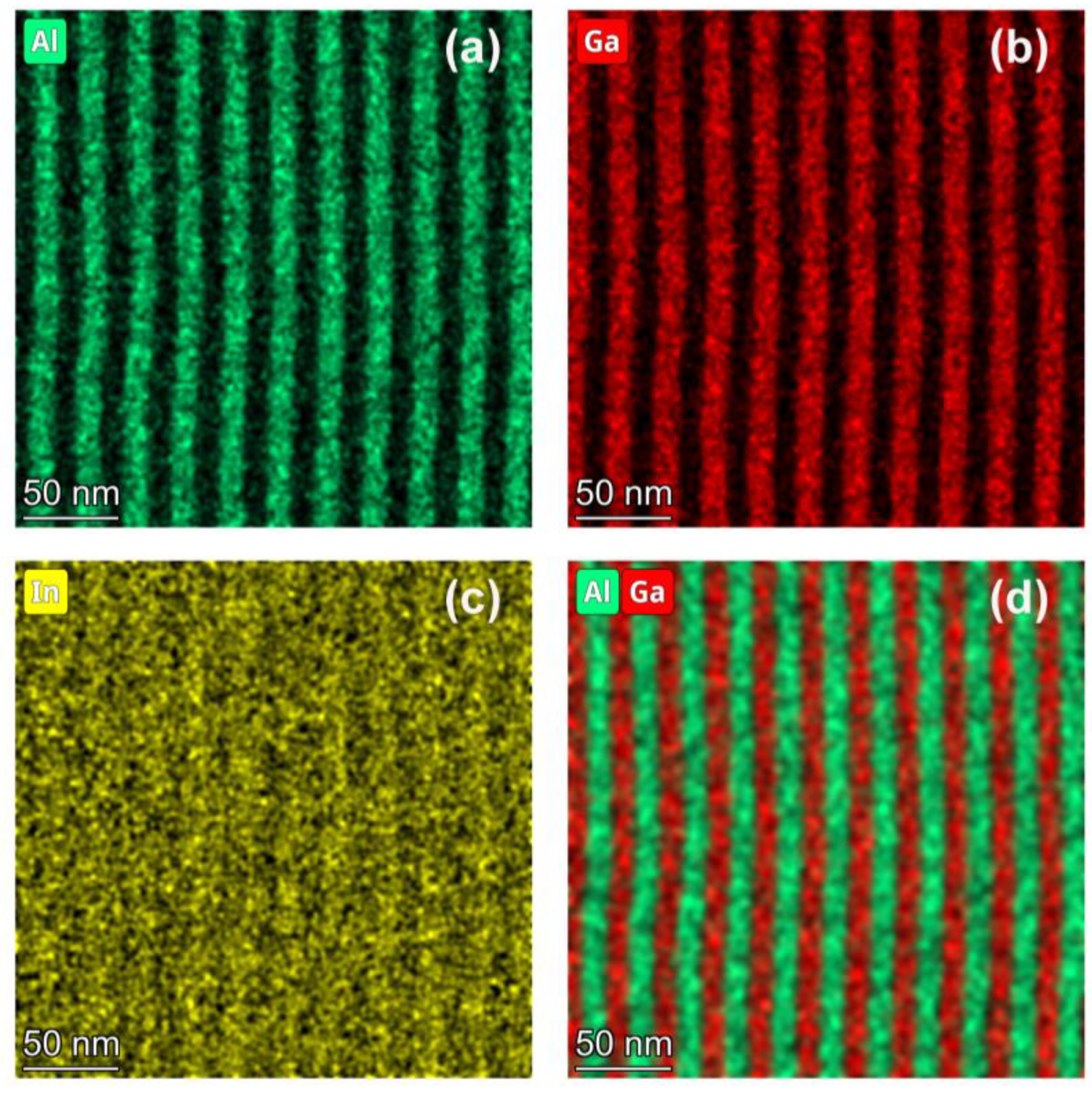

3.1. TEM of Low-Temperature-Grown (InAs)4(GaAs)3/InAlAs Multiple Quantum Wells Using the MEE Growth Mode

3.2. TEM of Low-Temperature-Grown InGaAs/InAlAs Multiple Quantum Wells Using the Conventional MBE Growth Mode

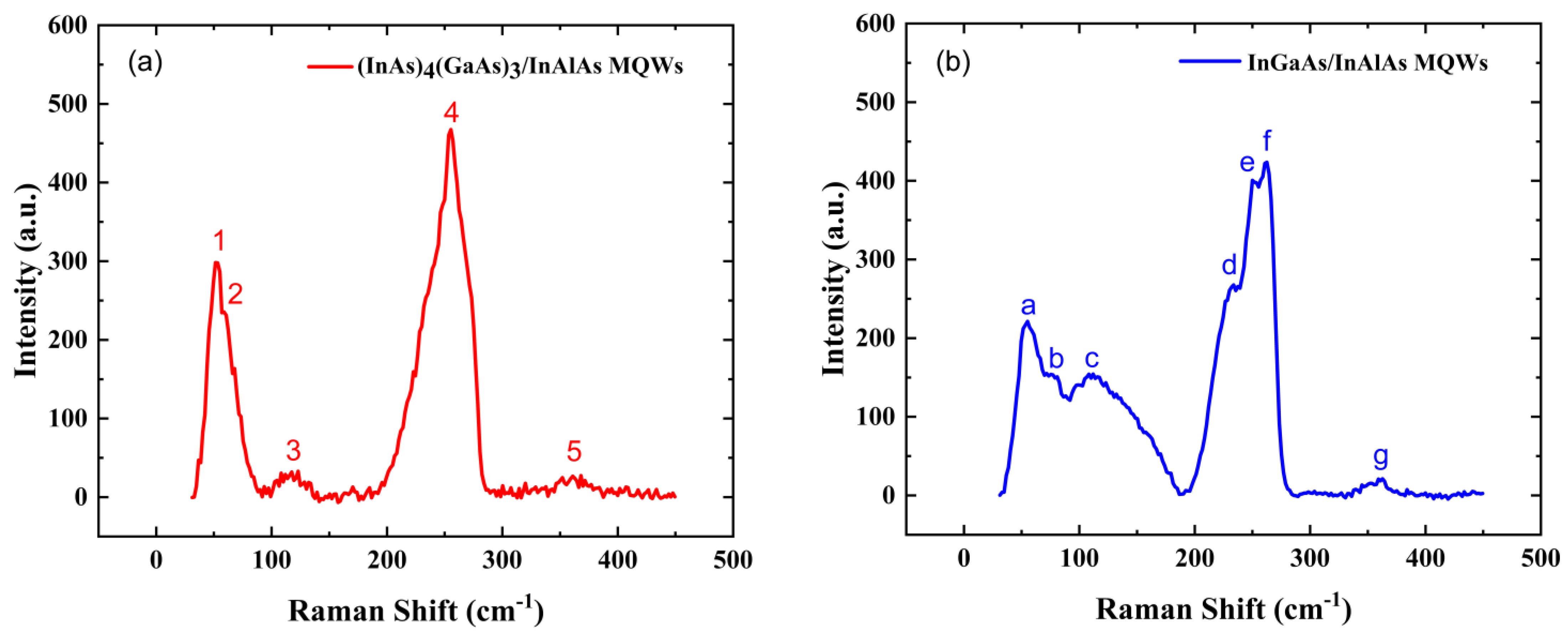

3.3. Raman Measurements of Low-Temperature-Grown (InAs)4(GaAs)3/InAlAs and InGaAs/InAlAs MQWs

3.4. MicroPL Spectra of Low-Temperature-Grown (InAs)4(GaAs)3/InAlAs and InGaAs/InAlAs MQWs

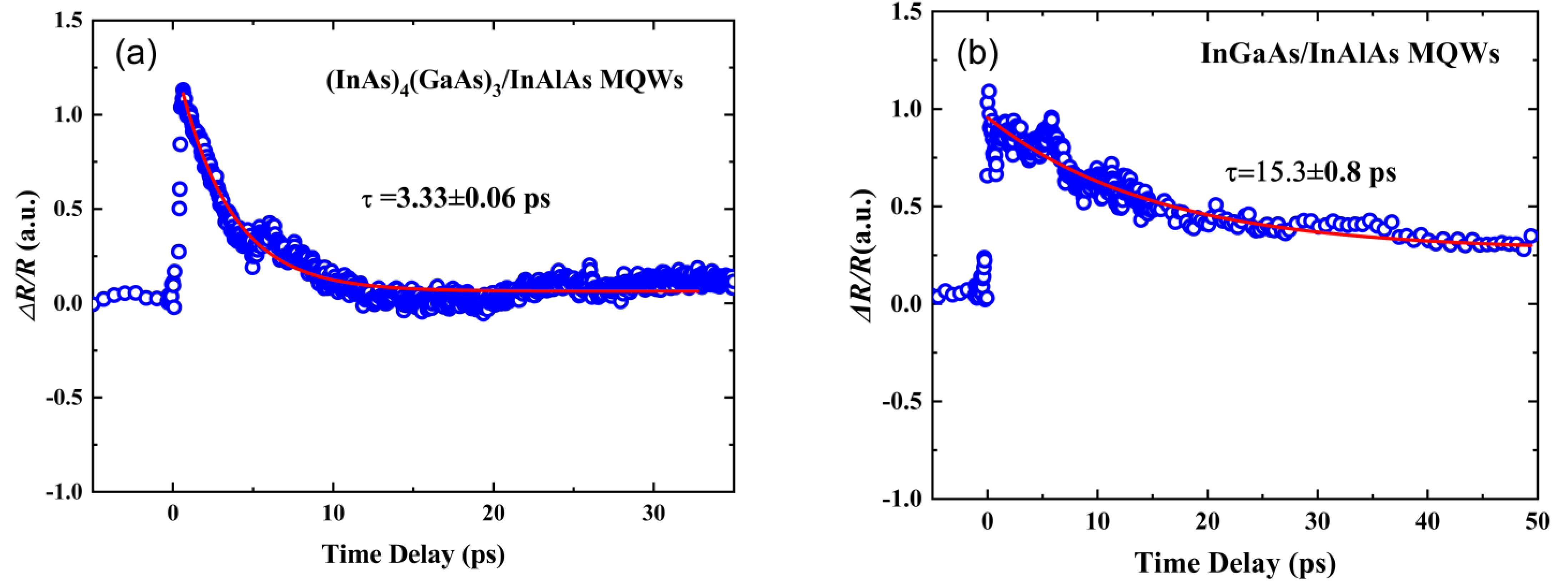

3.5. Hall Effect and Carrier Lifetime Measurements of Low-Temperature-Grown (InAs)4(GaAs)3/InAlAs and InGaAs/InAlAs MQWs

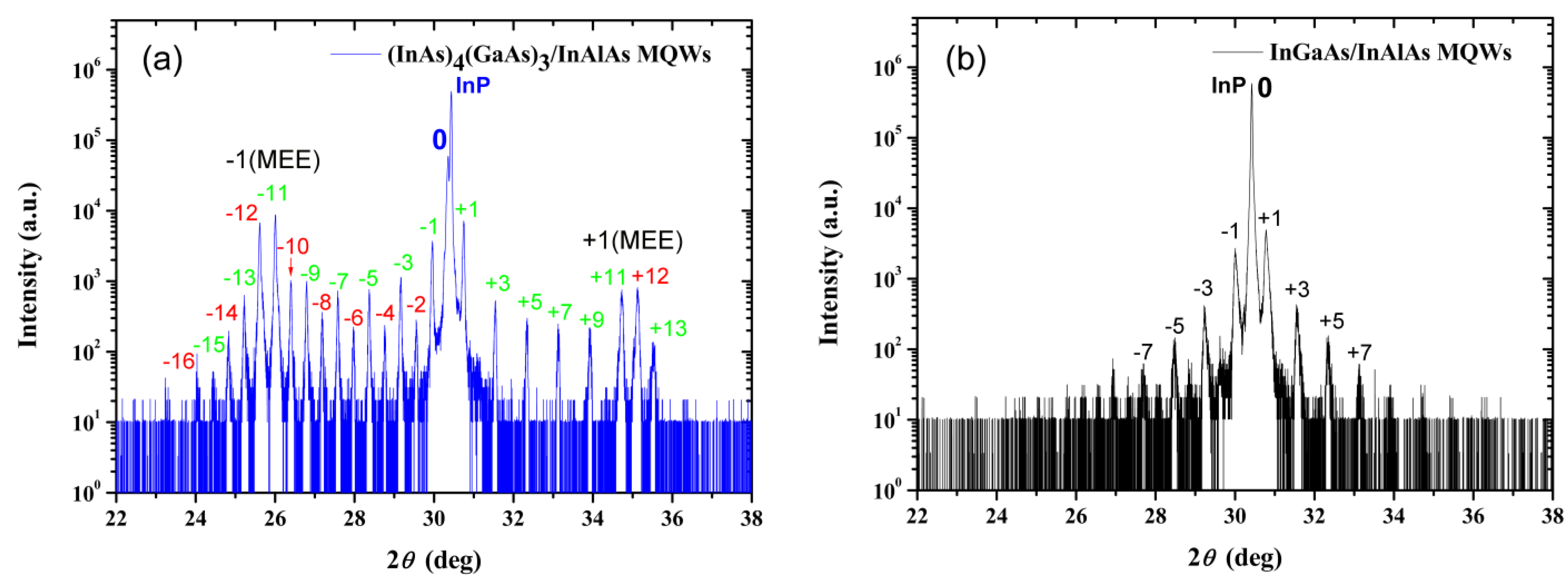

3.6. HRXRD of Low-Temperature-Grown (InAs)4(GaAs)3/InAlAs and InGaAs/InAlAs MQWs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hou, X.; Kang, Y.; Tang, J.; Wang, X.; Wei, Z. InGaAs/InAlAs Quantum Well Structures Grown on GaAs (001) Substrate by Molecular Beam Epitaxy. J. Phys. Conf. Ser. 2021, 1907, 012065. [Google Scholar] [CrossRef]

- Peng, Z.; Arakawa, T. Tunable Vernier Series-Coupled Microring Resonator Filters Based on InGaAs/InAlAs Multiple Quantum-Well Waveguide. Photonics 2023, 10, 1256. [Google Scholar] [CrossRef]

- Ganbold, T.; Antonelli, M.; Biasiol, G.; Nichetti, C.; Cautero, G.; Menk, R. Double-Side Pixelated X-ray Detector Based on Metamorphic InGaAs/InAlAs Quantum Well. J. Instrum. 2019, 14, C01014. [Google Scholar] [CrossRef]

- Lin, J.; Antoniadis, D.A.; del Alamo, J.A. Impact of Intrinsic Channel Scaling on InGaAs Quantum-Well MOSFETs. IEEE Trans. Electron Devices 2015, 62, 3470–3476. [Google Scholar] [CrossRef]

- Amthor, M.; Weißenseel, S.; Fischer, J.; Kamp, M.; Schneider, C.; Höfling, S. Electro-Optical Switching between Polariton and Cavity Lasing in an InGaAs Quantum Well Microcavity. Opt. Express 2014, 22, 31146–31153. [Google Scholar] [CrossRef] [PubMed]

- Sizov, F.; Rogalski, A. THz Detectors. Prog. Quantum Electron. 2010, 34, 278–347. [Google Scholar] [CrossRef]

- Balistreri, G.; Tomasino, A.; Dong, J.; Yurtsever, A.; Stivala, S.; Azaña, J.; Morandotti, R. Time-Domain Integration of Broadband Terahertz Pulses in a Tapered Two-Wire Waveguide. Laser Photonics Rev. 2021, 15, 2100051. [Google Scholar] [CrossRef]

- Wang, Y.; Kostakis, I.; Saeedkia, D.; Missous, M. Optimised THz Photoconductive Devices Based on Low-Temperature Grown III–V Compound Semiconductors Incorporating Distributed Bragg Reflectors. IET Optoelectron. 2017, 11, 53–57. [Google Scholar] [CrossRef]

- Lavrukhin, D.V.; Yachmenev, A.E.; Goncharov, Y.G.; Zaytsev, K.I.; Khabibullin, R.A.; Buryakov, A.M.; Mishina, E.D.; Ponomarev, D.S. Strain-Induced InGaAs-Based Photoconductive Terahertz Antenna Detector. IEEE Trans. Terahertz Sci. Technol. 2021, 11, 417–424. [Google Scholar] [CrossRef]

- Richter, P.-H.; Kartal, E.; Kohlhaas, R.B.; Semtsiv, M.P.; Schell, M.; Masselink, W.T.; Globisch, B.; Koch, M. Ultrafast THz Conductivity Dynamics of a Novel Fe-Doped InGaAs Quantum Photoconductor. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 167–175. [Google Scholar] [CrossRef]

- Yachmenev, A.E.; Pushkarev, S.S.; Reznik, R.R.; Khabibullin, R.A.; Ponomarev, D.S. Arsenides-and Related III-V Materials-Based Multilayered Structures for Terahertz Applications: Various Designs and Growth Technology. Prog. Cryst. Growth Charact. Mater. 2020, 66, 100485. [Google Scholar] [CrossRef]

- Dai, D.; Liu, H.; Su, X.; Shang, X.; Li, S.; Ni, H.; Niu, Z. High Resistivity and High Mobility in Localized Beryllium-Doped InAlAs/InGaAs Superlattices Grown at Low Temperature. Crystals 2023, 13, 1417. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, H.; Jiang, C.; Ma, B.; Wang, J.; Ming, R.; Liu, S.; Ge, Q.; Ren, R.; Lin, J.; et al. Improved Performance of InGaAs/AlGaAs Quantum Well Lasers on Silicon Using InAlAs Trapping Layers. Opt. Express 2023, 31, 7900–7906. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.W.; Patil, P.; Marko, I.P.; Clarke, E.; Sweeney, S.J.; Ng, J.S.; David, J.P.R.; Tan, C.H. Electrical and Optical Characterisation of Low Temperature Grown InGaAs for Photodiode Applications. Semicond. Sci. Technol. 2020, 35, 095031. [Google Scholar] [CrossRef]

- Gerard, J.M.; Marzin, J.Y.; d’Anterroches, C.; Soucail, B.; Voisin, P. Optical Investigation of the Band Structure of InAs/GaAs Short-Period Superlattices. Appl. Phys. Lett. 1989, 55, 559–561. [Google Scholar] [CrossRef]

- Yao, T. A New High-Electron Mobility Monolayer Superlattice. Jpn. J. Appl. Phys. 1983, 22, L680. [Google Scholar] [CrossRef]

- Burford, N.M.; El-Shenawee, M.O. Review of Terahertz Photoconductive Antenna Technology. Opt. Eng. 2017, 56, 010901. [Google Scholar] [CrossRef]

- Bradshaw, J.; Song, X.J.; Shealy, J.R.; Zhu, J.G.; O/stergaard, H. Characterization by Raman Scattering, x-ray Diffraction, and Transmission Electron Microscopy of (AlAs)m(InAs)mShort Period Superlattices Grown by Migration Enhanced Epitaxy. J. Appl. Phys. 1992, 72, 308–310. [Google Scholar] [CrossRef]

- André, J.P.; Deswarte, A.; Lugagne-Delpon, E.; Voisin, P.; Ruterana, P. High Electron Mobility in (InAs)n(GaAs)n Short Period Superlattices Grown by MOVPE for High-Electron Mobility Transistor Structure. J. Electron. Mater. 1994, 23, 141–146. [Google Scholar] [CrossRef]

- Cheng, K.Y.; Hsieh, K.C.; Baillargeon, J.N. Formation of Lateral Quantum Wells in Vertical Short-Period Superlattices by Strain-Induced Lateral-Layer Ordering Process. Appl. Phys. Lett. 1992, 60, 2892–2894. [Google Scholar] [CrossRef]

- Camacho-Reynoso, M.; Hernández-Gutiérrez, C.A.; Yee-Rendón, C.M.; Rivera-Rodríguez, C.; Bahena-Uribe, D.; Gallardo-Hernández, S.; Kudriavtsev, Y.; López-López, M.; Casallas-Moreno, Y.L. Cubic InxGa1−xN/GaN Quantum Wells Grown by Migration Enhanced Epitaxy (MEE) and Conventional Molecular Beam Epitaxy (MBE). J. Alloys Compd. 2022, 921, 165994. [Google Scholar] [CrossRef]

- Mishra, P.; Pandey, R.K.; Kumari, S.; Pandey, A.; Dalal, S.; Sankarasubramanian, R.; Channagiri, S.; Jangir, S.K.; Raman, R.; Srinivasan, T.; et al. Interface Engineered MBE Grown InAs/GaSb Based Type-II Superlattice Heterostructures. J. Alloys Compd. 2021, 889, 161692. [Google Scholar] [CrossRef]

- Cho, I.-W.; Ryu, M.-Y.; Song, J.D. Temperature-Dependent Carrier Dynamics of InP/InGaP Quantum Structures Grown at Various Growth Temperatures Using Migration-Enhanced Epitaxy. J. Lumin. 2020, 223, 117214. [Google Scholar] [CrossRef]

- Woo, H.; Kim, J.; Cho, S.; Jo, Y.; Roh, C.H.; Lee, J.H.; Seo, Y.G.; Kim, H.; Im, H.; Hahn, C.-K. Epitaxial Growth of Low Temperature GaN Using Metal Migration Enhanced Epitaxy for High-Quality InGaN/GaN Heterojunctions. Superlattices Microstruct. 2018, 120, 781–787. [Google Scholar] [CrossRef]

- Gérard, J.M.; Marzin, J.Y.; Jusserand, B.; Glas, F.; Primot, J. Structural and Optical Properties of High Quality InAs/GaAs Short-Period Superlattices Grown by Migration-Enhanced Epitaxy. Appl. Phys. Lett. 1989, 54, 30–32. [Google Scholar] [CrossRef]

- Galiev, G.B.; Vasiliev, A.L.; Vasil’evskii, I.S.; Vinichenko, A.N.; Klimov, E.A.; Klochkov, A.N.; Trunkin, I.N.; Pushkarev, S.S. Structural Characteristics of Epitaxial Low-Temperature Grown {InGaAs/InAlAs} Superlattices on InP(100) and InP(111)A Substrates. Crystallogr. Rep. 2020, 65, 496–501. [Google Scholar] [CrossRef]

- Tominaga, Y.; Hirose, S.; Hirayama, K.; Morioka, H.; Ikenaga, N.; Ueda, O. Crystalline Quality of Low-Temperature-Grown InxGa1−xAs Coherently Grown on InP(0 0 1) Substrate. J. Cryst. Growth 2020, 544, 125703. [Google Scholar] [CrossRef]

- Kuznetsov, K.; Klochkov, A.; Leontyev, A.; Klimov, E.; Pushkarev, S.; Galiev, G.; Kitaeva, G. Improved InGaAs and InGaAs/InAlAs Photoconductive Antennas Based on (111)-Oriented Substrates. Electronics 2020, 9, 495. [Google Scholar] [CrossRef]

- Ueda, O.; Ikenaga, N.; Hirose, S.; Hirayama, K.; Tsurisaki, S.; Horita, Y.; Tominaga, Y. Structural Evaluation of Low-Temperature-Grown InGaAs Crystals on (0 0 1) InP Substrates. J. Cryst. Growth 2020, 548, 125852. [Google Scholar] [CrossRef]

- Tominaga, Y.; Tomiyasu, Y.; Kadoya, Y. Crystal Structure of Low-Temperature-Grown In0.45Ga0.55As on an InP Substrate. J. Cryst. Growth 2015, 425, 99–101. [Google Scholar] [CrossRef]

- Grandidier, B.; Chen, H.; Feenstra, R.M.; McInturff, D.T.; Juodawlkis, P.W.; Ralph, S.E. Scanning Tunneling Microscopy and Spectroscopy of Arsenic Antisites in Low Temperature Grown InGaAs. Appl. Phys. Lett. 1999, 74, 1439–1441. [Google Scholar] [CrossRef]

- Juodawlkis, P.W.; McInturff, D.T.; Ralph, S.E. Ultrafast Carrier Dynamics and Optical Nonlinearities of Low-temperature-grown InGaAs/InAlAs Multiple Quantum Wells. Appl. Phys. Lett. 1996, 69, 4062–4064. [Google Scholar] [CrossRef]

- Iwai, Y.; Yano, M.; Hagiwara, R.; Inoue, M. Structural Analysis of InAsIGaAs Strained- Layer Superlattices Grown by Migration Enhanced Epitaxy. Semicond. Sci. Technol. 1991, 6, 1048. [Google Scholar] [CrossRef]

- Gérard, J.M.; Marzin, J.Y.; Jusserand, B. Modulated Molecular Beam Epitaxy: A Successful Route toward High Quality Highly Strained Heterostructures. J. Cryst. Growth 1991, 111, 205–209. [Google Scholar] [CrossRef]

- Colvard, C.; Gant, T.A.; Klein, M.V.; Merlin, R.; Fischer, R.; Morkoc, H.; Gossard, A.C. Folded Acoustic and Quantized Optic Phonons in (GaAl)As Superlattices. Phys. Rev. B 1985, 31, 2080–2091. [Google Scholar] [CrossRef]

- Scamarcio, G.; Brandt, O.; Tapfer, L.; Mowbray, D.J.; Cardona, M.; Ploog, K. Structural and Vibrational Properties of (InAs)m(GaAs)nStrained Superlattices Grown by Molecular Beam Epitaxy. J. Appl. Phys. 1991, 69, 786–792. [Google Scholar] [CrossRef]

- Ben Arbia, M.; Demir, I.; Kaur, N.; Saidi, F.; Zappa, D.; Comini, E.; Altuntaş, I.; Maaref, H. Experimental Insights toward Carrier Localization in In-Rich InGaAs/InP as Candidate for SWIR Detection: Microstructural Analysis Combined with Optical Investigation. Mater. Sci. Semicond. Process. 2023, 153, 107149. [Google Scholar] [CrossRef]

- Smiri, B.; Saidi, F.; Mlayah, A.; Maaref, H. Comparative Optical Studies of InAlAs/InP Quantum Wells Grown by MOCVD on (311)A and (311)B InP Planes. J. Mater. Sci. Mater. Electron. 2020, 31, 10750–10759. [Google Scholar] [CrossRef]

- Emura, S.; Soni, R.K.; Gonda, S.-I. Interfacial Stress in Strained-Ultrathin-Layer (InAs)2/(GaAs)1 Superlattice. Phys. Rev. B 1992, 46, 1463–1467. [Google Scholar] [CrossRef]

- Chen, X.; Gu, Y.; Zhang, Y.; Ma, Y.; Xi, S.; Du, B.; Di, Z.; Ji, W.; Shi, Y. Optical Characterization of Si-Doped Metamorphic InGaAs with High Indium Content. Phys. Status Solidi B 2017, 254, 1700094. [Google Scholar] [CrossRef]

- Pearsall, T.P.; Carles, R.; Portal, J.C. Single Longitudinal-Mode Optical Phonon Scattering in Ga0.47In0.53As. Appl. Phys. Lett. 1983, 42, 436–438. [Google Scholar] [CrossRef]

- Min, K.-I.; Rho, H.; Song, J.D.; Choi, W.J.; Lee, Y.T. Raman Studies of InGaAlAs Digital Alloys. J. Korean Phys. Soc. 2011, 59, 2801–2805. [Google Scholar] [CrossRef]

- Li, E.H. Material Parameters of InGaAsP and InAlGaAs Systems for Use in Quantum Well Structures at Low and Room Temperatures. Phys. E Low-Dimens. Syst. Nanostruct. 2000, 5, 215–273. [Google Scholar] [CrossRef]

- Jain, S.C.; McGregor, J.M.; Roulston, D.J. Band-Gap Narrowing in Novel III-V Semiconductors. J. Appl. Phys. 1990, 68, 3747–3749. [Google Scholar] [CrossRef]

- Gerard, J.M.; Marzin, J.Y.; d’Anterroches, C.; Soucail, B.; Voisin, P. Optical Study of the Band Structure of InAs/GaAs Ordered Alloys. Surf. Sci. 1990, 229, 456–458. [Google Scholar] [CrossRef]

- Tadayon, B.; Tadayon, S.; Spencer, M.G.; Harris, G.L.; Griffin, J.; Eastman, L.F. Increase of Electrical Activation and Mobility of Si-Doped GaAs, Grown at Low Substrate Temperatures, by the Migration-Enhanced Epitaxy Method. J. Appl. Phys. 1990, 67, 589–591. [Google Scholar] [CrossRef]

- Kim, N.; Han, S.-P.; Ko, H.; Leem, Y.A.; Ryu, H.-C.; Lee, C.W.; Lee, D.; Jeon, M.Y.; Noh, S.K.; Park, K.H. Tunable Continuous-Wave Terahertz Generation/Detection with Compact 1.55 μm Detuned Dual-Mode Laser Diode and InGaAs Based Photomixer. Opt. Express 2011, 19, 15397–15403. [Google Scholar] [CrossRef]

- Toyoshima, H.; Anan, T.; Nishi, K.; Ichihashi, T.; Okamoto, A. Growth by Molecular-beam Epitaxy and Characterization of (InAs)m(GaAs)m Short Period Superlattices on InP Substrates. J. Appl. Phys. 1990, 68, 1282–1286. [Google Scholar] [CrossRef]

- Liu, Q.; Lindner, A.; Scheffer, F.; Prost, W.; Tegude, F.J. X-ray Diffraction Characterization of Highly Strained InAs and GaAs Layers on InP Grown by Metalorganic Vapor-Phase Epitaxy. J. Appl. Phys. 1994, 75, 2426–2433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Chen, R.; Kong, C.; Deng, Z.; Liu, G.; Yan, J.; Qin, L.; Du, H.; Song, S.; Zhang, X.; et al. Low-Temperature Growth of InGaAs Quantum Wells Using Migration-Enhanced Epitaxy. Materials 2024, 17, 845. https://doi.org/10.3390/ma17040845

Liu L, Chen R, Kong C, Deng Z, Liu G, Yan J, Qin L, Du H, Song S, Zhang X, et al. Low-Temperature Growth of InGaAs Quantum Wells Using Migration-Enhanced Epitaxy. Materials. 2024; 17(4):845. https://doi.org/10.3390/ma17040845

Chicago/Turabian StyleLiu, Linsheng, Ruolin Chen, Chongtao Kong, Zhen Deng, Guipeng Liu, Jianfeng Yan, Le Qin, Hao Du, Shuxiang Song, Xinhui Zhang, and et al. 2024. "Low-Temperature Growth of InGaAs Quantum Wells Using Migration-Enhanced Epitaxy" Materials 17, no. 4: 845. https://doi.org/10.3390/ma17040845