Investigation of Mechanical and Shrinkage Performance for Large-Size Cement-Stabilized Aggregates

Abstract

:1. Introduction

2. Raw materials and Test Design

2.1. Performance Indicators of Raw Materials

2.1.1. Cement

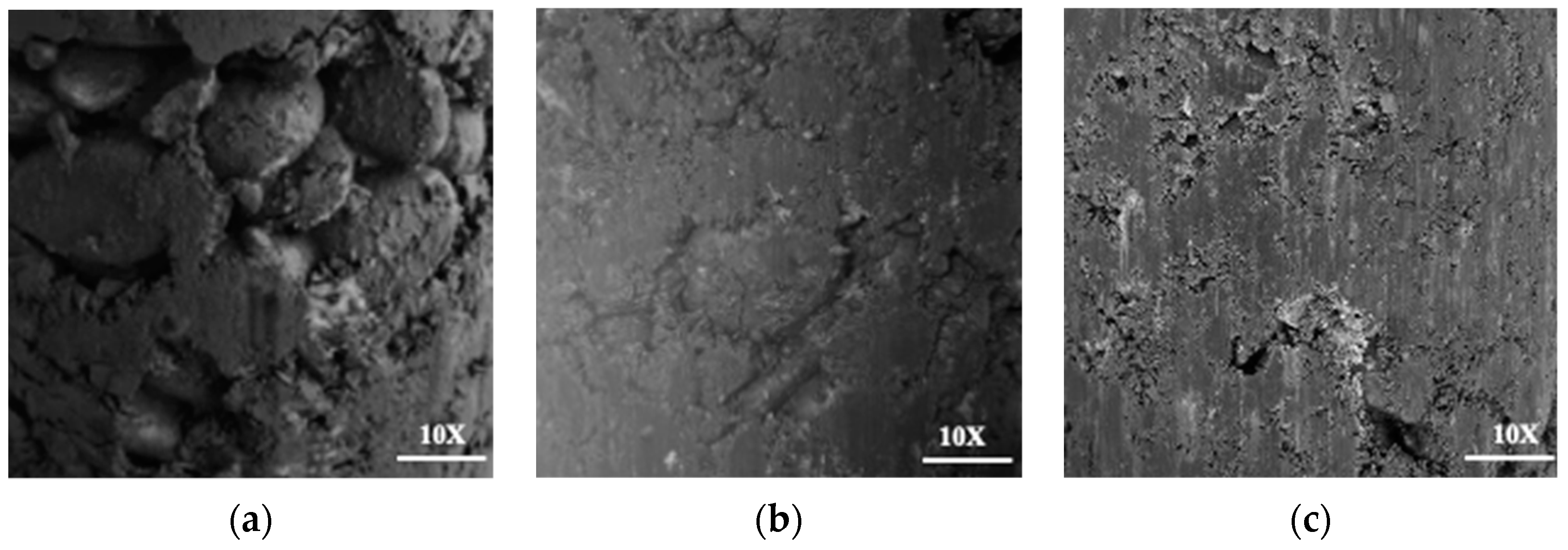

2.1.2. Coarse and Fine Aggregates

2.2. Aggregate Gradation Design

2.3. Test Design

3. Test Methods

3.1. Compressive Strength

3.2. Compressive Rebound Modulus

3.3. Flexural Strength

3.4. Shrinkage Test

3.4.1. Dry Shrinkage Test

3.4.2. Temperature Shrinkage Test

4. Results Analysis

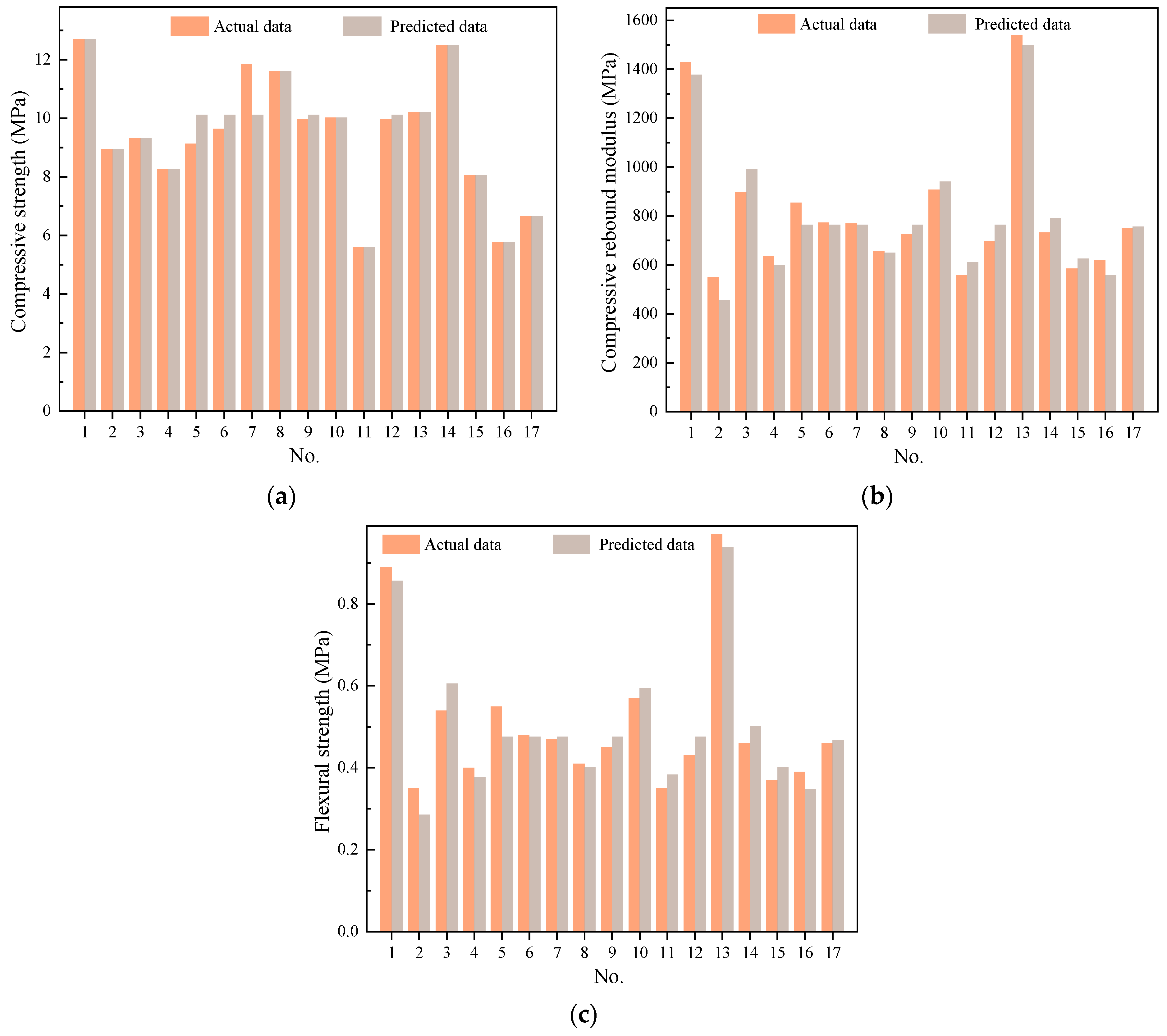

4.1. Statistical Analysis

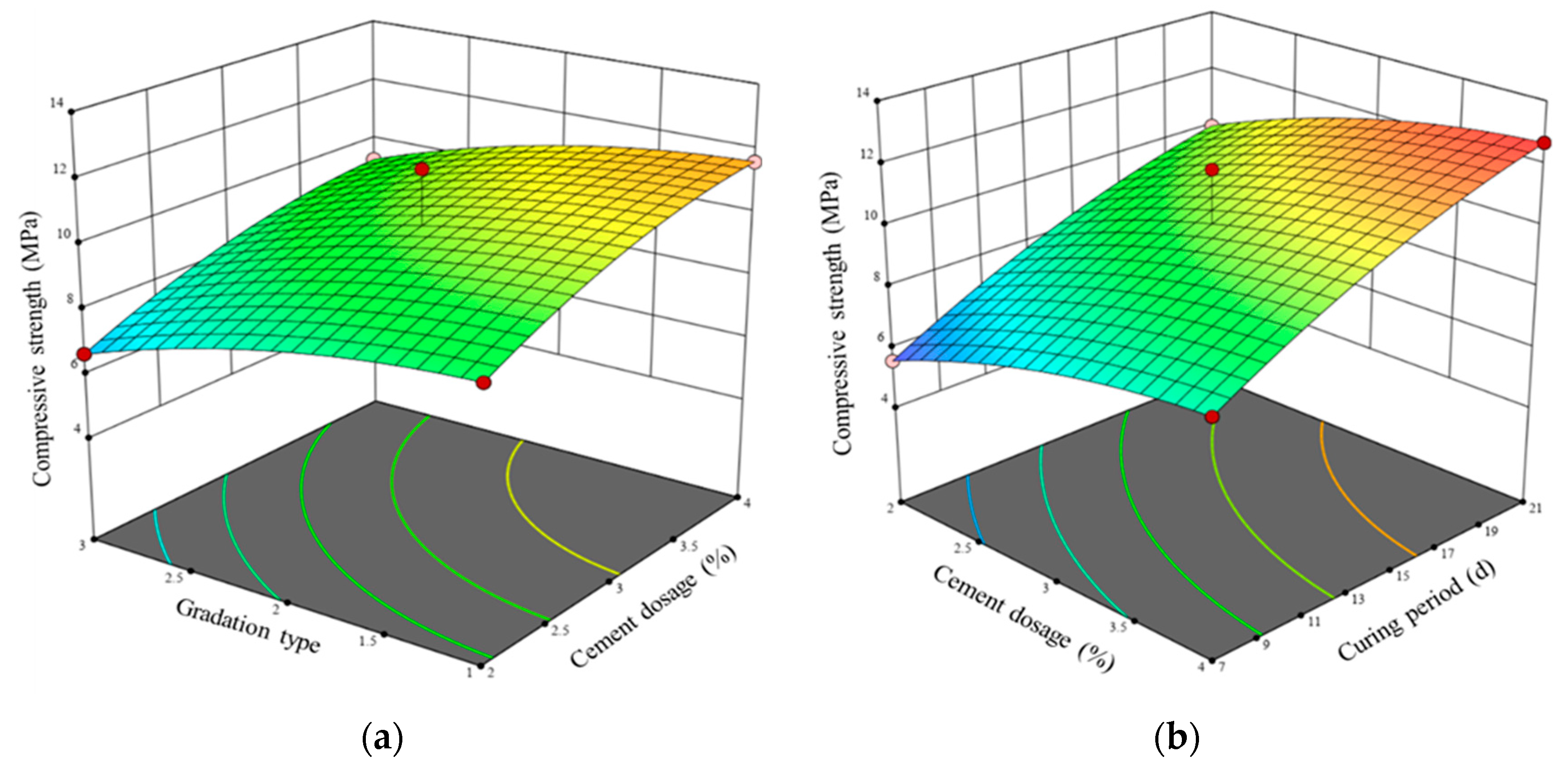

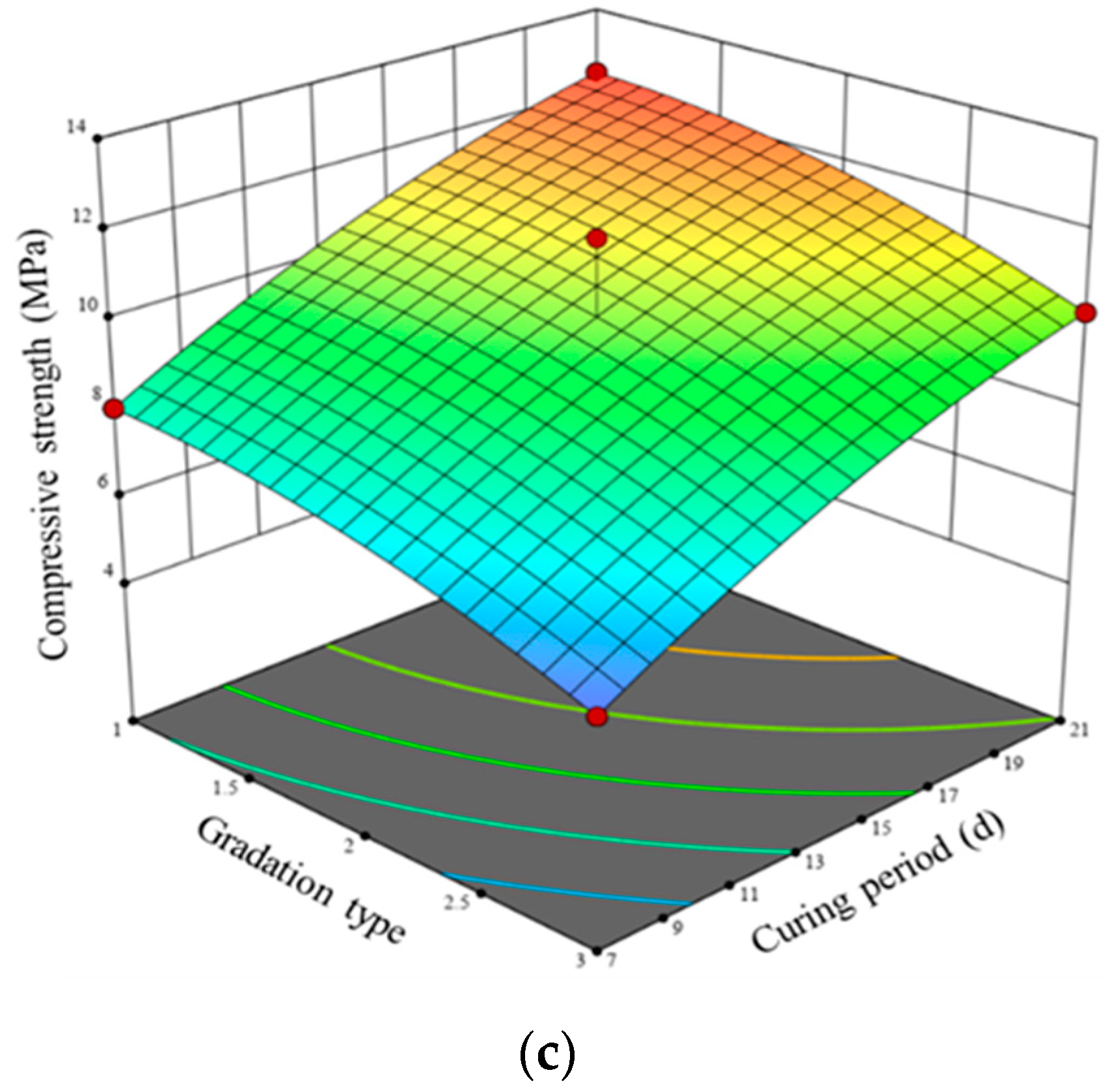

4.2. Performance Responses Based on the Regression Models

4.2.1. Compressive Strength

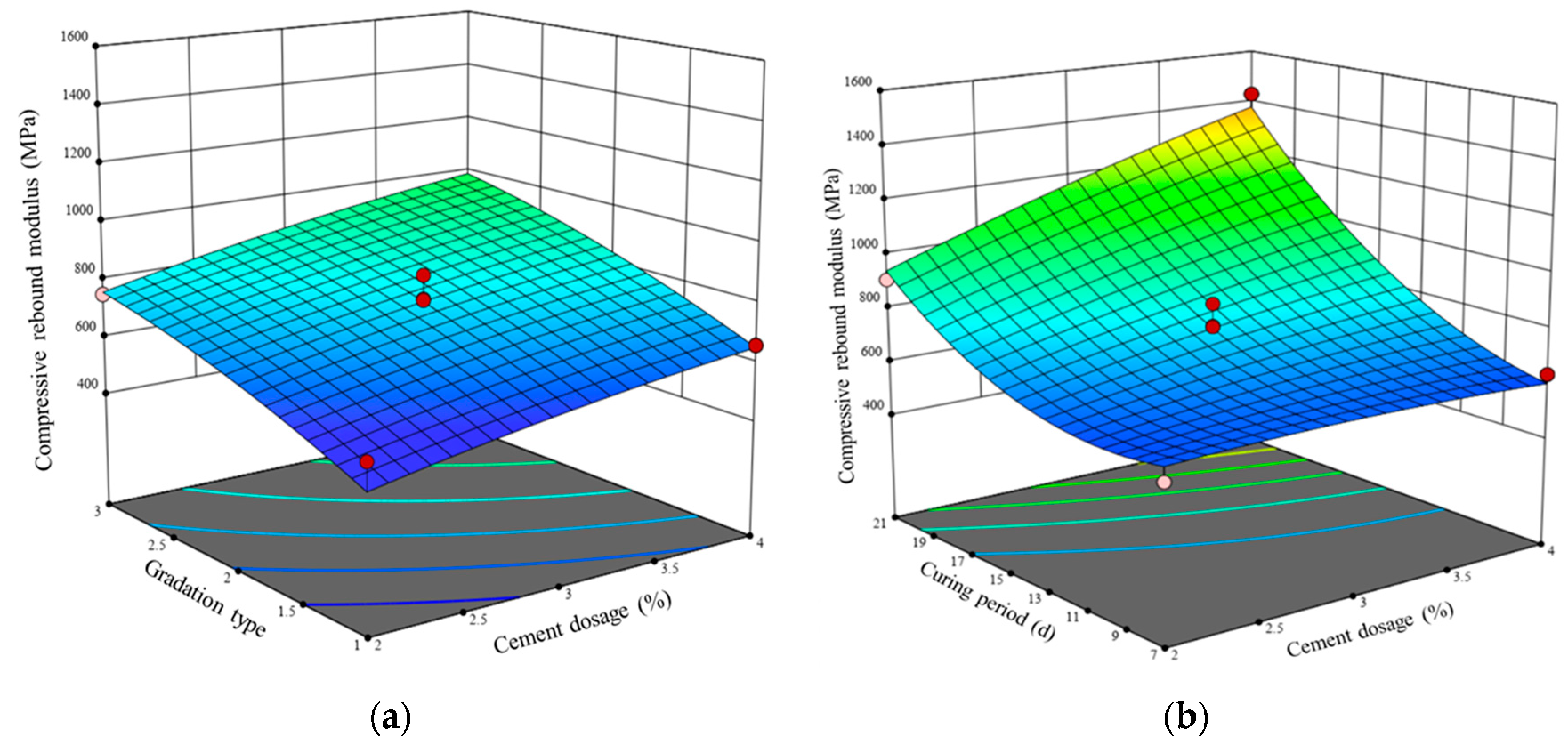

4.2.2. Compressive Rebound Modulus

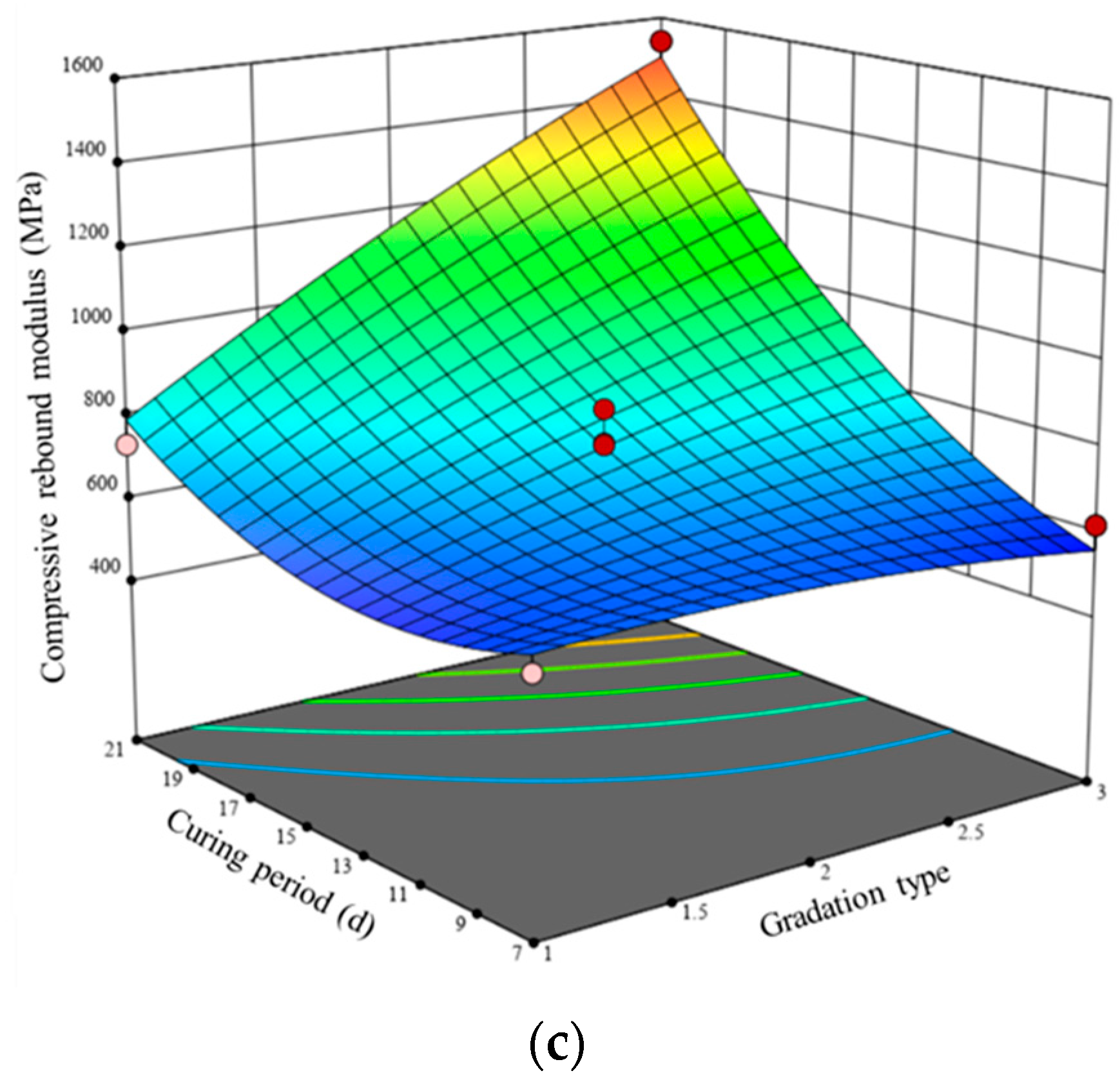

4.2.3. Flexural Strength

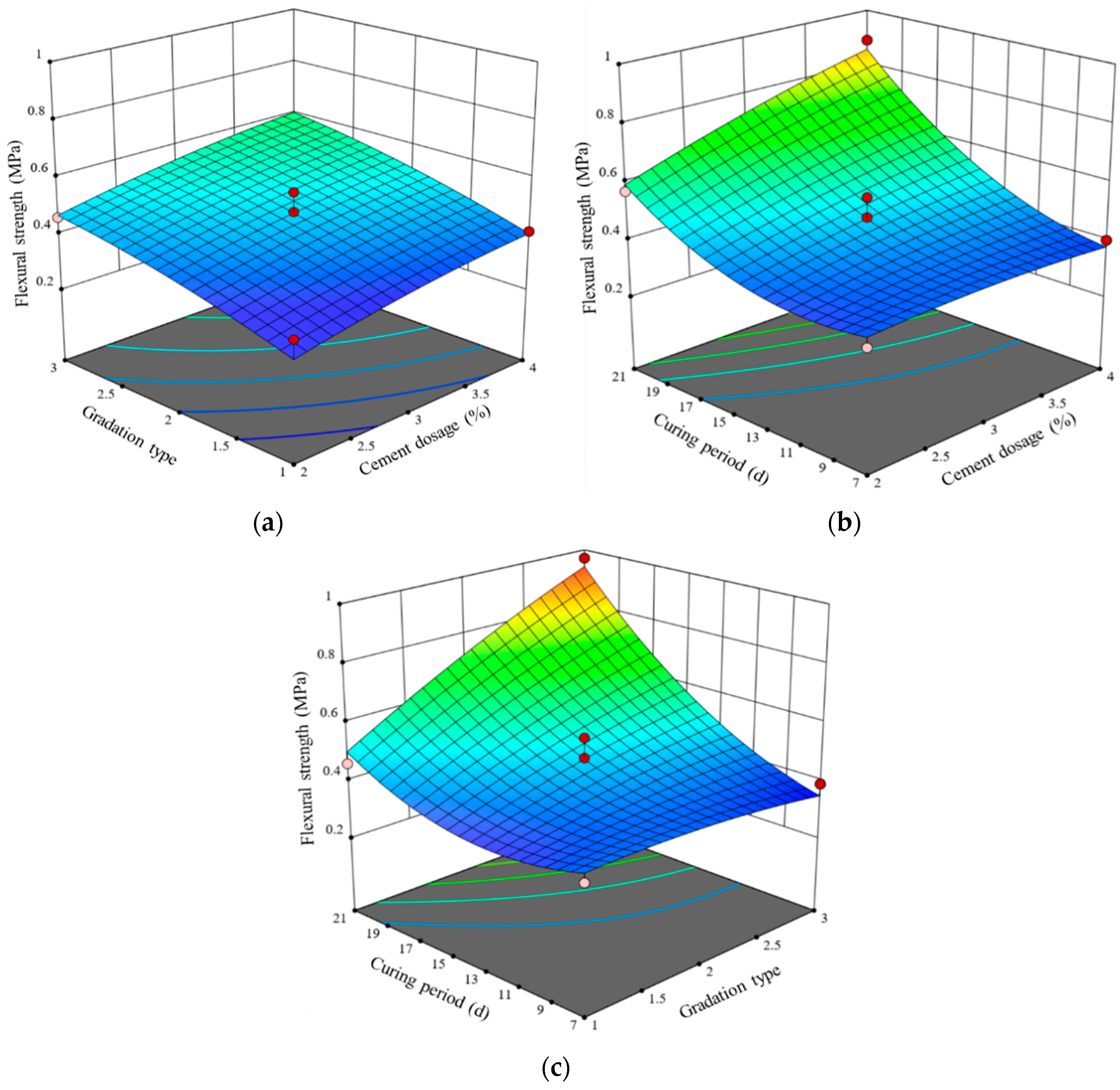

4.3. Optimization and Comparative Analysis of LSCSM

4.3.1. Comparative Analysis of Mechanical Properties

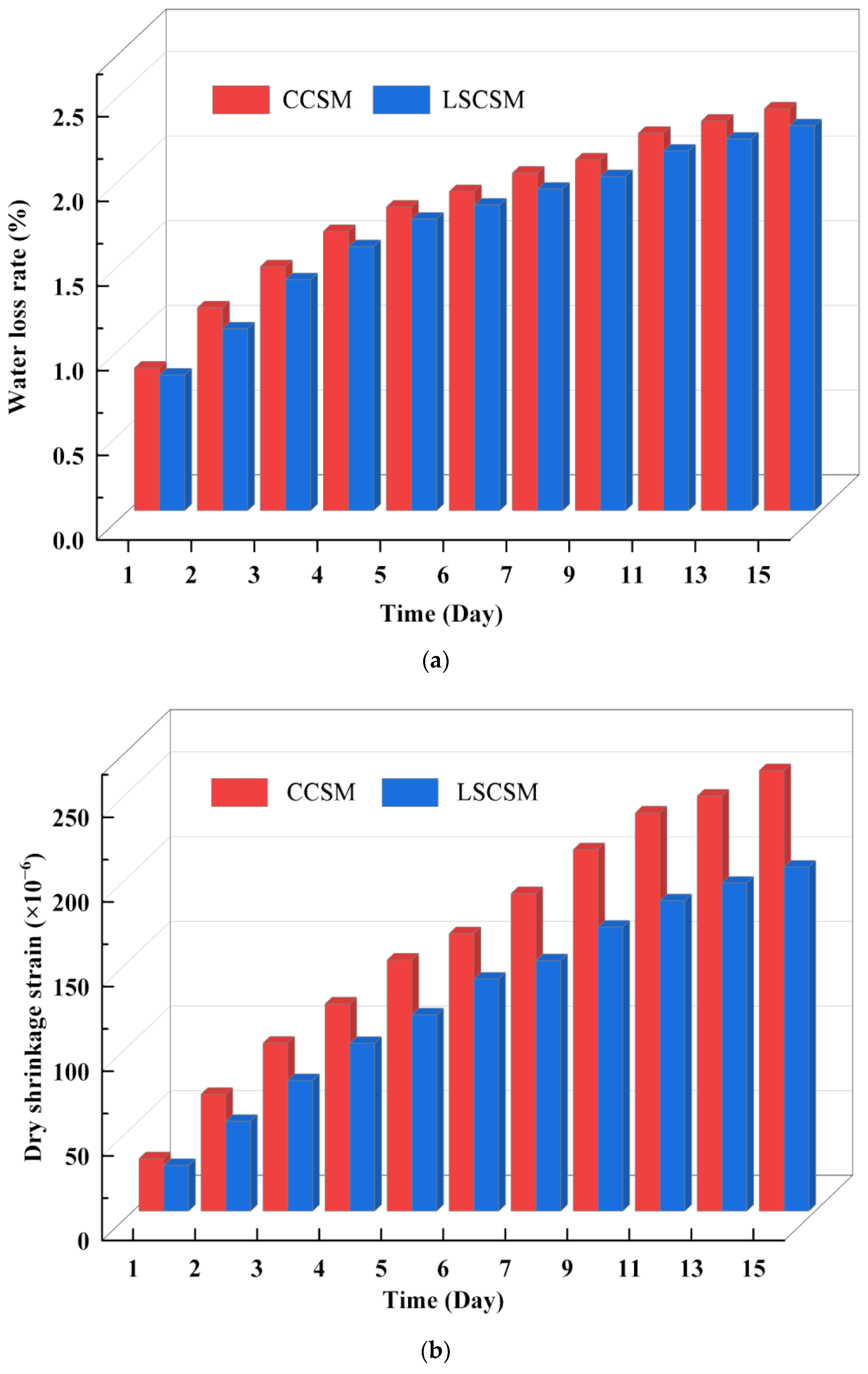

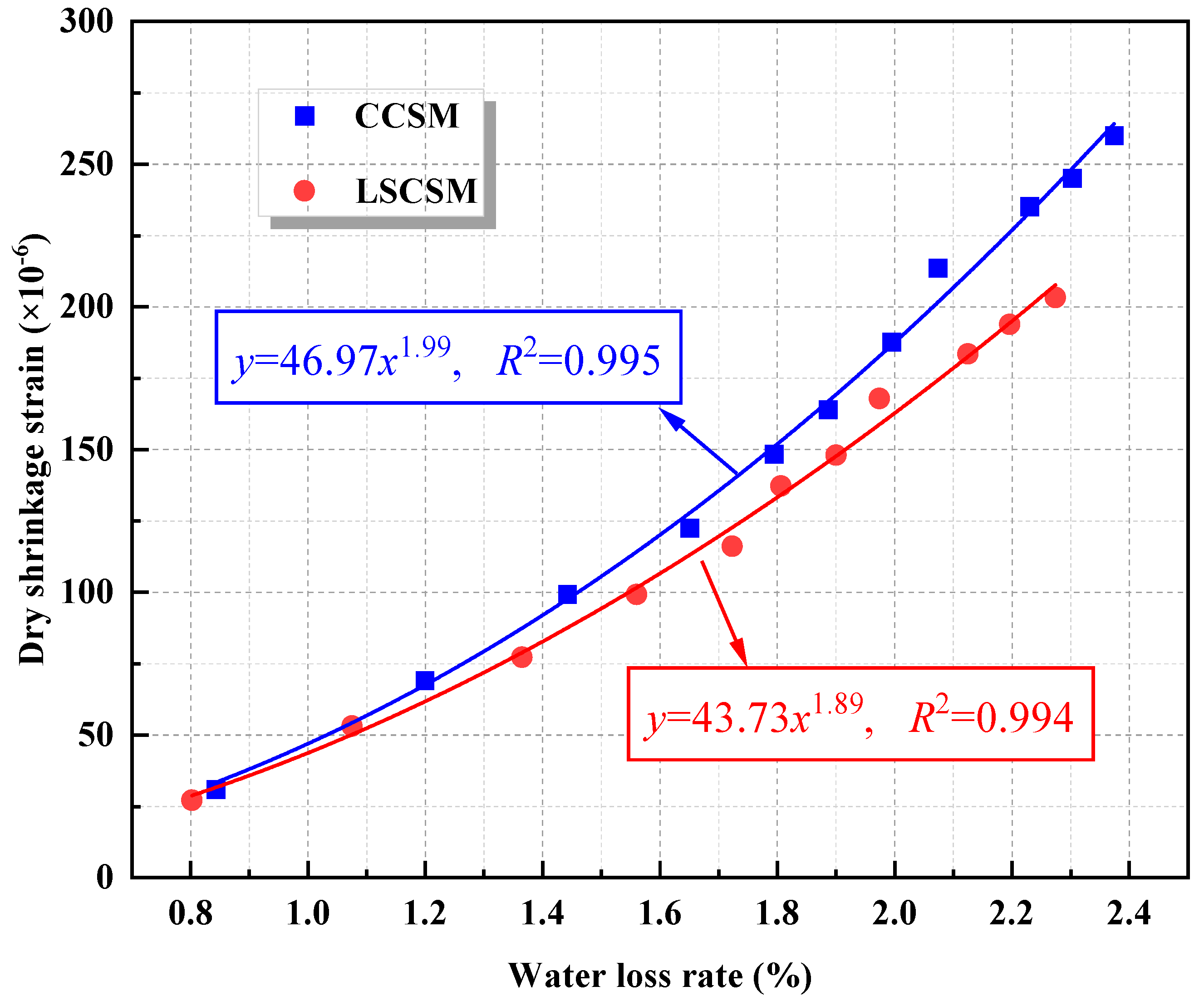

4.3.2. Comparative Analysis of Dry Shrinkage Properties

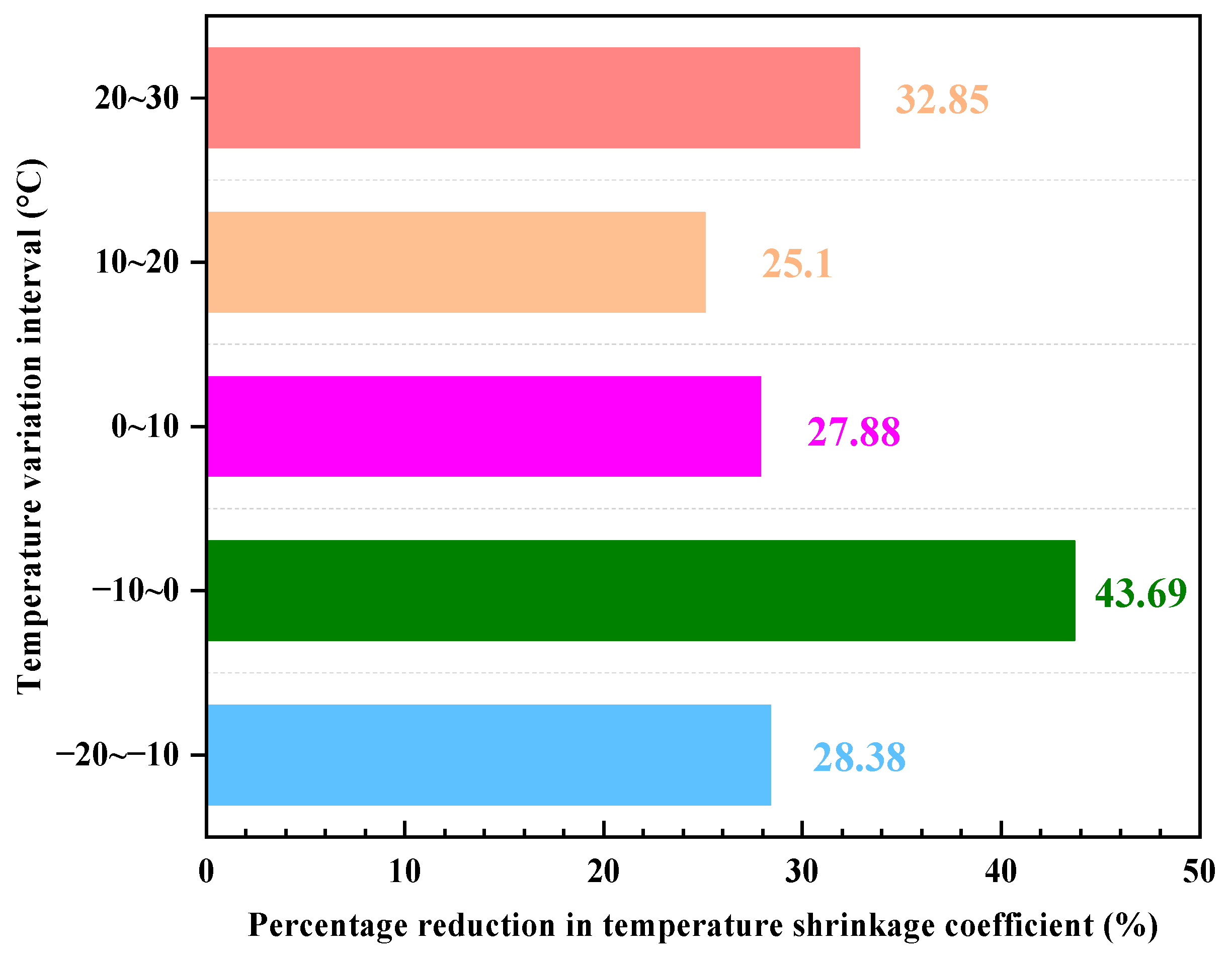

4.3.3. Comparative Analysis of Temperature Shrinkage Properties

5. Conclusions

- Quadratic regression models were developed for cement dosage, gradation type, curing period, and the corresponding compressive strength, compressive rebound modulus, and flexural strength using the Box–Behnken design. The model correlation coefficients R2 are 0.9409, 0.9601, and 0.9472, respectively. Additionally, the adjusted correlation coefficients are 0.8649, 0.9088, and 0.8794, respectively. The results affirm the high precision and reliability in model fitting.

- A comparison of the mechanical properties between CCSM and LSCSM indicates that the compressive strength of the LSCSM surpasses that of CCSM. Specifically, the 7-day compressive rebound modulus of LSCSM is approximately 49% lower than that of CCSM, and the 7-day flexural strength of LSCSM is only around 60% of that of CCSM.

- In comparison with CCSM, the dry shrinkage strain and dry shrinkage coefficient of LSCSM decreased by 21.86% and 18.49%, respectively, at 15 days. Although the temperature shrinkage pattern of LSCSM generally resembled that of CCSM, a notable reduction in the temperature shrinkage coefficient within the same temperature range was observed. LSCSM exhibits effective capabilities in mitigating the occurrence of shrinkage cracks and preventing the development of reflective cracks in asphalt pavement.

- The shrinkage and the measured properties have direct relation with the void space in designed graded aggregates. Establishing a link between void fraction and the shrinkages and properties of cement-stabilized macadam can help to understand the effect of void ration on properties. In further, it can attempt to establish the relationship between the voids with shrinkages and properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhandapani, B.P.; Mullapudi, R.S. Design and performance characteristics of cement grouted bituminous mixtures—A review. Constr. Build. Mater. 2023, 369, 130586. [Google Scholar] [CrossRef]

- Deng, M.; Xie, X.; Zhuo, J.; He, Y.; Wang, K. Experimental Study on the Strength and Hydration Products of Cement Mortar with Hybrid Recycled Powders Based Industrial-Construction Residue Cement Stabilization of Crushed Aggregate. Materials 2023, 16, 4233. [Google Scholar] [CrossRef] [PubMed]

- Taghipoor, M.; Sirgani, P.B.; Dehaghi, E.A. Improving the resistance of asphalt pavements against cracking with an interlayer: A comprehensive review. Constr. Build. Mater. 2023, 409, 134086. [Google Scholar] [CrossRef]

- Wu, X.; Li, B.; Wei, D.; Guo, F.; Ji, H. Investigation of Preparation and Shrinkage Characteristics of Multi-Source Solid Waste-Based Cementitious Materials. Materials 2023, 16, 7522. [Google Scholar] [CrossRef] [PubMed]

- Nuthalapati, S.; Kee, K.; Pedapati, S.R.; Jumbri, K. A review of chloride induced stress corrosion cracking characterization in austenitic stainless steels using acoustic emission technique. Nucl. Eng. Technol. 2024, 56, 688–706. [Google Scholar] [CrossRef]

- Sofri, L.A.; Abdullah, M.M.A.B.; Sandu, A.V.; Imjai, T.; Vizureanu, P.; Hasan, M.R.M.; Almadani, M.; Ab Aziz, I.H.; Rahman, F.A. Mechanical Performance of Fly Ash Based Geopolymer (FAG) as Road Base Stabilizer. Materials 2022, 15, 7242. [Google Scholar] [CrossRef] [PubMed]

- Mounes, S.M.; Karim, M.R.; Mahrez, A.; Khodaii, A. An overview on the use of geosynthetics in pavement structures. Sci. Res. Essays 2011, 6, 2234–2241. [Google Scholar]

- Coviello, C.G.; Lassandro, P.; Sabbà, M.F.; Foti, D. Mechanical and Thermal Effects of Using Fine Recycled PET Aggregates in Common Screeds. Sustainability 2023, 15, 16692. [Google Scholar] [CrossRef]

- Foti, D.; Lerna, M. New Mortar Mixes with Chemically Depolymerized Waste PET Aggregates. Adv. Mater. Sci. Eng. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Bilodeau, J.-P.; Plamondon, C.O.; Doré, G. Estimation of resilient modulus of unbound granular materials used as pavement base: Combined effect of grain-size distribution and aggregate source frictional properties. Mater. Struct. 2016, 49, 4363–4373. [Google Scholar] [CrossRef]

- George, K. Minimizing Cracking in Cement-Treated Materials for Improved Performance; No. R&D Bulletin RD123; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- Litzka, J.; Haslehner, W. Cold in-place recycling on low-volume roads in Austria. In Proceedings of the Sixth International Conference on Low-Volume Roads, Minneapolis, MN, USA, 25–29 June 1995. [Google Scholar]

- Brandl, H. Mixed-in-place stabilization of pavement structures with cement and additives. In Proceedings of the Twelfth European Conference on Soil Mechanics and Geotechnical Engineering (Proceedings) The Netherlands Society of Soil Mechanics and Geotechnical Engineering, Amsterdam, The Netherlands, 7–10 June 1999. [Google Scholar]

- Sebesta, S.; Scullion, T. Effectiveness of Minimizing Reflective Cracking in Cement-Treated Bases by Microcracking; Texas Transportation Institute: College Station, TX, USA, 2004. [Google Scholar]

- Yuan, J.; Lv, S.; Peng, X.; Liu, K. Comprehensive Properties Evaluation of Modified Bio-Asphalt Mixture Based on Comparison Matrix. J. Mater. Civ. Eng. 2024, 36, 16740. [Google Scholar] [CrossRef]

- Giroud, J.P.; Han, J.; Tutumluer, E.; Dobie, M.J.D. The use of geosynthetics in roads. Geosynth. Int. 2023, 30, 47–80. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Xia, X.; Han, D.; Ma, Y.; Zhao, Y.; Tang, D.; Chen, Y. Experiment investigation on mix proportion optimization design of an-ti-cracking stone filled with cement stabilized macadam. Constr. Build. Mater. 2023, 393, 132136. [Google Scholar] [CrossRef]

- JTG E42; Test Methods of Aggregate for Highway Engineering. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2005.

- Yilmaz, E.; Belem, T.; Bussière, B.; Mbonimpa, M.; Benzaazoua, M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents. Constr. Build. Mater. 2015, 75, 99–111. [Google Scholar] [CrossRef]

- Krajnik, P.; Kopac, J.; Sluga, A. Design of grinding factors based on response surface methodology. J. Am. Acad. Dermatol. 2005, 162–163, 629–636. [Google Scholar] [CrossRef]

- Fariz, F.; Patel, B.; Chiu, H.-C.; Pan, S.-J.; Chen, C.-L.; Lee, H.-Y.; Lin, P.T. Optimization of Autoclave Reactors to Improve Bearing Life Using the Taguchi Method and the Response Surface Methodology. Inventions 2023, 8, 144. [Google Scholar] [CrossRef]

- JTG E51; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport of the People’s Republic of China; China Communications Press: Beijing, China, 2009.

| Technical Indicators | Test Results | |

|---|---|---|

| Specific surface area (m2/kg) | 338 | |

| Fineness (%) | 4.1 | |

| Setting time (min) | Initial time | 308 |

| Final time | 402 | |

| Soundness | 1.6 | |

| Compressive strength (MPa) | 3 d | 22.5 |

| 28 d | 45.3 | |

| Flexural strength (MPa) | 3 d | 5.2 |

| 28 d | 8.4 | |

| Aggregate Sizes | Accumulated Density (g/cm3) | Solidification Density (g/cm3) | Bulk Density (g/cm3) | Apparent Density (g/cm3) | Percentage of Voids in Aggregate (%) |

|---|---|---|---|---|---|

| 30~50 mm | 1.653 | 1.705 | 2.669 | 2.675 | 38.06 |

| 5~10 mm | 1.648 | 1.688 | 2.629 | 2.638 | 37.31 |

| 0~5 mm | 1.605 | 1.674 | 2.613 | 2.616 | - |

| Aggregate Size | Gradation 1 (G1) | Gradation 2 (G2) | Gradation 3 (G3) |

|---|---|---|---|

| 0~5 mm | 14 | 15 | 30 |

| 5~10 mm | 20 | 29 | 14 |

| 30~50 mm | 66 | 56 | 56 |

| Factors | Number | Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Cement dosage | A | 2 | 3 | 4 |

| Gradation type | B | 1 | 2 | 3 |

| Curing period | C | 7 | 14 | 21 |

| No. | Factor | Test Conditions | Responses | |||||

|---|---|---|---|---|---|---|---|---|

| Cement Dosage (%) | Gradation Type | Curing Period (d) | Optimal Moisture Content (%) | Maximum Dry Density (g/cm3) | Compressive Strength (MPa) | Compressive Rebound Modulus (MPa) | Flexural Strength (MPa) | |

| 1 | 4 | 2 | 21 | 5.2 | 2.32 | 12.69 | 1430 | 0.89 |

| 2 | 2 | 1 | 14 | 4.5 | 2.24 | 8.95 | 549 | 0.35 |

| 3 | 4 | 3 | 14 | 5.5 | 2.36 | 9.32 | 897 | 0.54 |

| 4 | 4 | 2 | 7 | 5.2 | 2.32 | 8.25 | 634 | 0.4 |

| 5 | 3 | 2 | 14 | 4.8 | 2.29 | 9.13 | 855 | 0.55 |

| 6 | 3 | 2 | 14 | 4.8 | 2.29 | 9.64 | 773 | 0.48 |

| 7 | 3 | 2 | 14 | 4.8 | 2.29 | 11.85 | 769 | 0.47 |

| 8 | 4 | 1 | 14 | 4.8 | 2.28 | 11.61 | 657 | 0.41 |

| 9 | 3 | 2 | 14 | 4.8 | 2.29 | 9.98 | 726 | 0.45 |

| 10 | 2 | 2 | 21 | 4.7 | 2.27 | 10.02 | 908 | 0.57 |

| 11 | 2 | 2 | 7 | 4.7 | 2.27 | 5.58 | 559 | 0.35 |

| 12 | 3 | 2 | 14 | 4.8 | 2.29 | 9.98 | 698 | 0.43 |

| 13 | 3 | 3 | 21 | 5.2 | 2.34 | 10.21 | 1540 | 0.97 |

| 14 | 3 | 1 | 21 | 4.6 | 2.26 | 12.5 | 732 | 0.46 |

| 15 | 3 | 1 | 7 | 4.6 | 2.26 | 8.06 | 585 | 0.37 |

| 16 | 3 | 3 | 7 | 5.2 | 2.34 | 5.77 | 618 | 0.39 |

| 17 | 2 | 3 | 14 | 5.0 | 2.30 | 6.66 | 749 | 0.46 |

| Factor | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Compressive strength (MPa) | ||||||

| Quadratic model | 67.52 | 9 | 7.5 | 12.38 | 0.0016 | Significant |

| A-Cement dosage | 14.2 | 1 | 14.2 | 23.44 | 0.0019 | |

| B-Gradation type (Void ratio) | 10.49 | 1 | 10.49 | 17.3 | 0.0042 | |

| C-Curing period | 39.43 | 1 | 39.43 | 65.05 | <0.0001 | |

| AB | 0 | 1 | 0 | 0 | 1 | |

| AC | 0 | 1 | 0 | 0 | 1 | |

| BC | 0 | 1 | 0 | 0 | 1 | |

| A2 | 1.01 | 1 | 1.01 | 1.67 | 0.2371 | |

| B2 | 1.01 | 1 | 1.01 | 1.67 | 0.2371 | |

| C2 | 1.01 | 1 | 1.01 | 1.67 | 0.2371 | |

| Compressive rebound modulus (MPa) | ||||||

| Quadratic model | 1.192 × 106 | 9 | 132400 | 18.71 | 0.0004 | Significant |

| A-Cement dosage | 90,951.13 | 1 | 90,951.13 | 12.85 | 0.0089 | |

| B-Gradation type (Void ratio) | 2.051 × 105 | 1 | 205,100 | 28.98 | 0.001 | |

| C-Curing period | 6.127 × 105 | 1 | 612,700 | 86.57 | <0.0001 | |

| AB | 400 | 1 | 400 | 0.0565 | 0.8189 | |

| AC | 49,952.25 | 1 | 49,952.25 | 7.06 | 0.0326 | |

| BC | 1.502 × 105 | 1 | 150,200 | 21.22 | 0.0025 | |

| A2 | 1456.67 | 1 | 1456.67 | 0.2058 | 0.6638 | |

| B2 | 4474.78 | 1 | 4474.78 | 0.6322 | 0.4526 | |

| C2 | 79,200.52 | 1 | 79,200.52 | 11.19 | 0.0123 | |

| Flexural strength (MPa) | ||||||

| Quadratic model | 0.4603 | 9 | 0.0511 | 13.96 | 0.0011 | Significant |

| A-Cement dosage | 0.0325 | 1 | 0.0325 | 8.87 | 0.0205 | |

| B-Gradation type (Void ratio) | 0.0741 | 1 | 0.0741 | 20.23 | 0.0028 | |

| C-Curing period | 0.238 | 1 | 0.238 | 64.98 | <0.0001 | |

| AB | 0.0001 | 1 | 0.0001 | 0.0273 | 0.8734 | |

| AC | 0.0182 | 1 | 0.0182 | 4.97 | 0.0609 | |

| BC | 0.06 | 1 | 0.06 | 16.38 | 0.0049 | |

| A2 | 0.001 | 1 | 0.001 | 0.2761 | 0.6155 | |

| B2 | 0.0018 | 1 | 0.0018 | 0.483 | 0.5095 | |

| C2 | 0.0356 | 1 | 0.0356 | 9.73 | 0.0169 | |

| Responses | Compressive Strength (MPa) | Compressive Rebound Modulus (MPa) | Flexural Strength (MPa) |

|---|---|---|---|

| Standard deviation | 0.7885 | 84.13 | 0.0605 |

| Mean | 9.42 | 804.65 | 0.5024 |

| R2 | 0.9409 | 0.9601 | 0.9472 |

| Adjusted R2 | 0.8649 | 0.9088 | 0.8794 |

| Adequate precision | 11.8993 | 16.1664 | 14.0826 |

| Model type | Quadratic model | Quadratic model | Quadratic model |

| Model | Significant | Significant | Significant |

| Lack of fit | Insignificant | Insignificant | Insignificant |

| F-value | 12.38 | 18.71 | 13.96 |

| p-value | 0.0016 | 0.0004 | 0.0011 |

| Mesh Size (mm) | 63 | 53 | 37.5 | 31.5 | 26.5 | 19 | 9.5 | 4.75 | 2.36 | 0.6 | 0.075 |

| LSCSM Passing Rate (%) | 100 | 100 | 70.94 | 48.82 | 44.34 | 44.34 | 44.08 | 19.46 | 12.66 | 9.01 | 3.28 |

| CCSM Passing Rate (%) | - | - | - | 100 | 95.4 | 87.9 | 65.9 | 38.2 | 24.5 | 13.6 | 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Huang, T.; Gao, X.; Li, Y.; Lu, L. Investigation of Mechanical and Shrinkage Performance for Large-Size Cement-Stabilized Aggregates. Materials 2024, 17, 1027. https://doi.org/10.3390/ma17051027

Zhao C, Huang T, Gao X, Li Y, Lu L. Investigation of Mechanical and Shrinkage Performance for Large-Size Cement-Stabilized Aggregates. Materials. 2024; 17(5):1027. https://doi.org/10.3390/ma17051027

Chicago/Turabian StyleZhao, Chengwei, Tuo Huang, Xinglong Gao, Yahui Li, and Li Lu. 2024. "Investigation of Mechanical and Shrinkage Performance for Large-Size Cement-Stabilized Aggregates" Materials 17, no. 5: 1027. https://doi.org/10.3390/ma17051027

APA StyleZhao, C., Huang, T., Gao, X., Li, Y., & Lu, L. (2024). Investigation of Mechanical and Shrinkage Performance for Large-Size Cement-Stabilized Aggregates. Materials, 17(5), 1027. https://doi.org/10.3390/ma17051027