Evolution of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy under Heat Treatment and Multi-Axial Forging

Abstract

1. Introduction

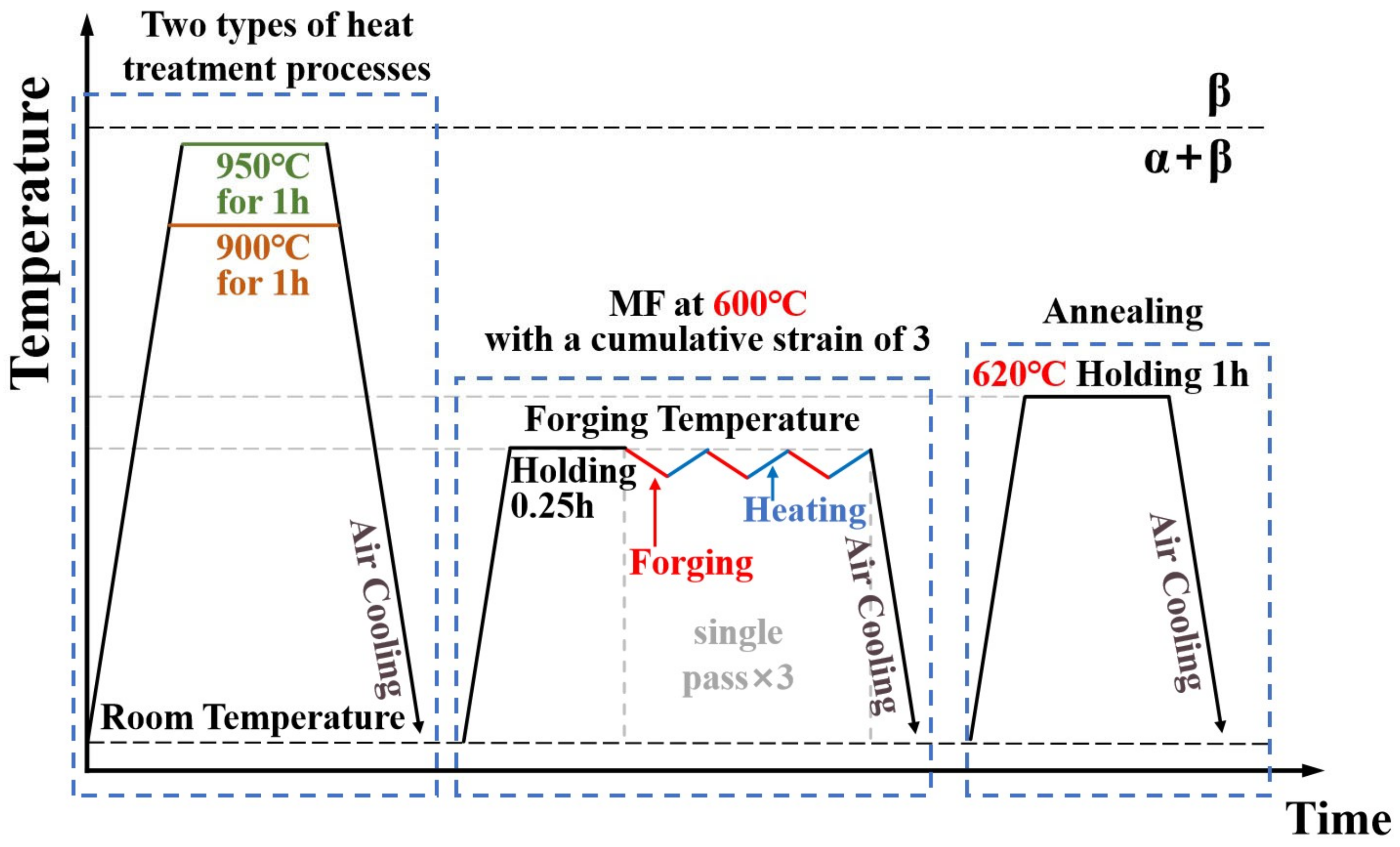

2. Materials and Methods

2.1. Materials

2.2. Characterization of Microstructure

2.3. Performance Testing of Mechanical Properties

3. Results and Discussion

3.1. Evolution of Microstructure during Heat Treatment

3.2. Microstructure Evolution during MF

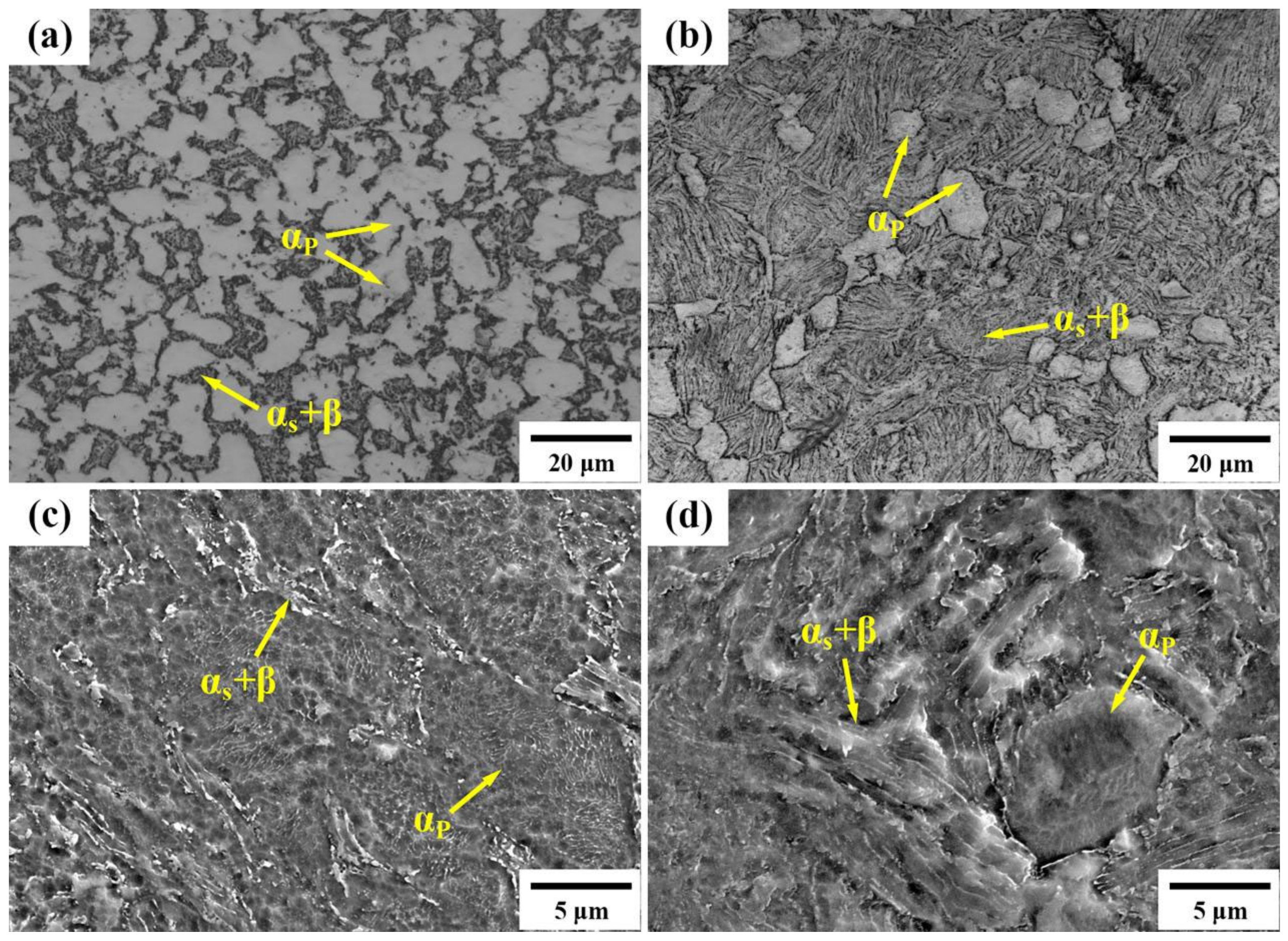

3.2.1. Evolution of αp during MF

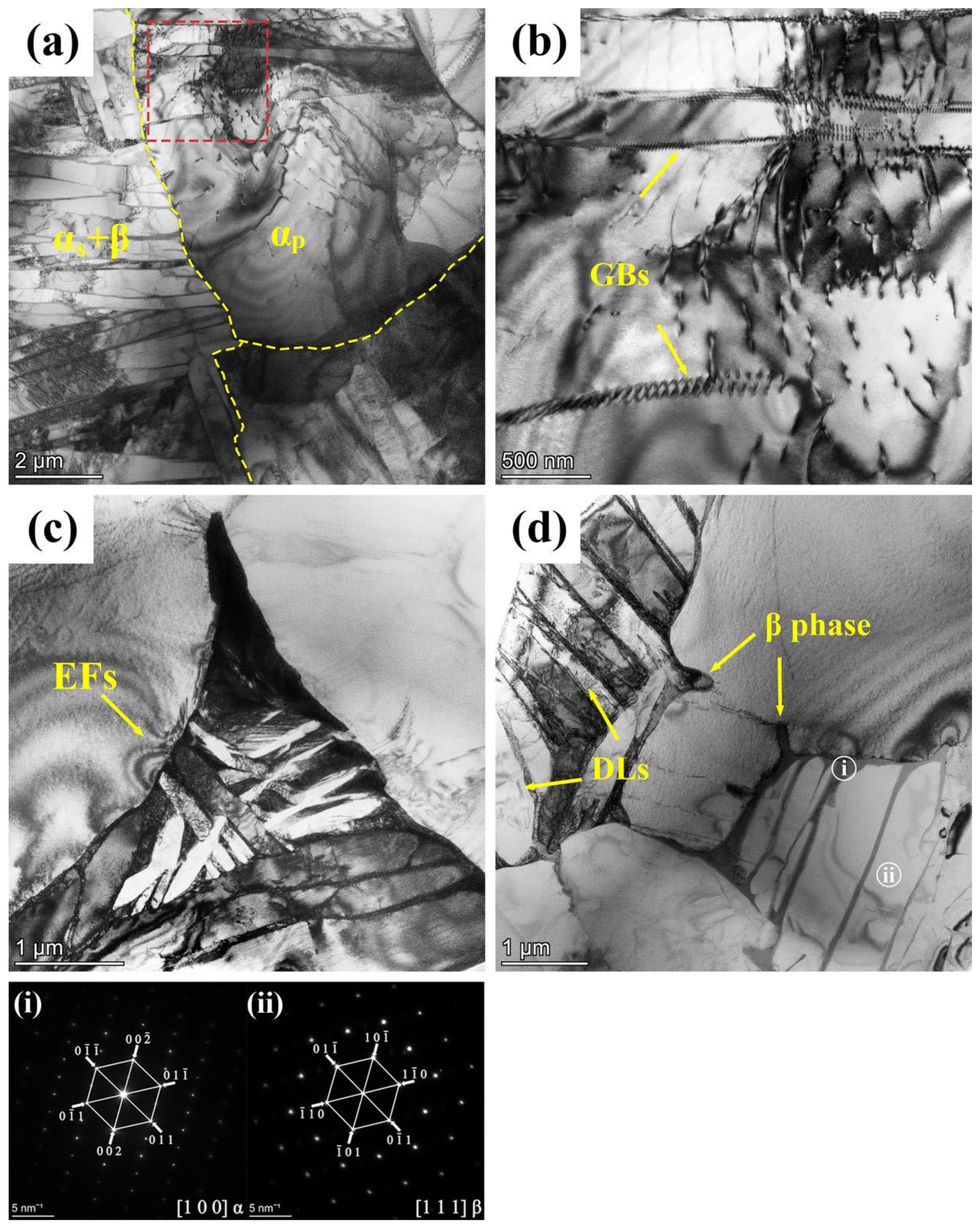

3.2.2. Evolution of αs+β in MF

3.3. Microstructure Evolution during Annealing

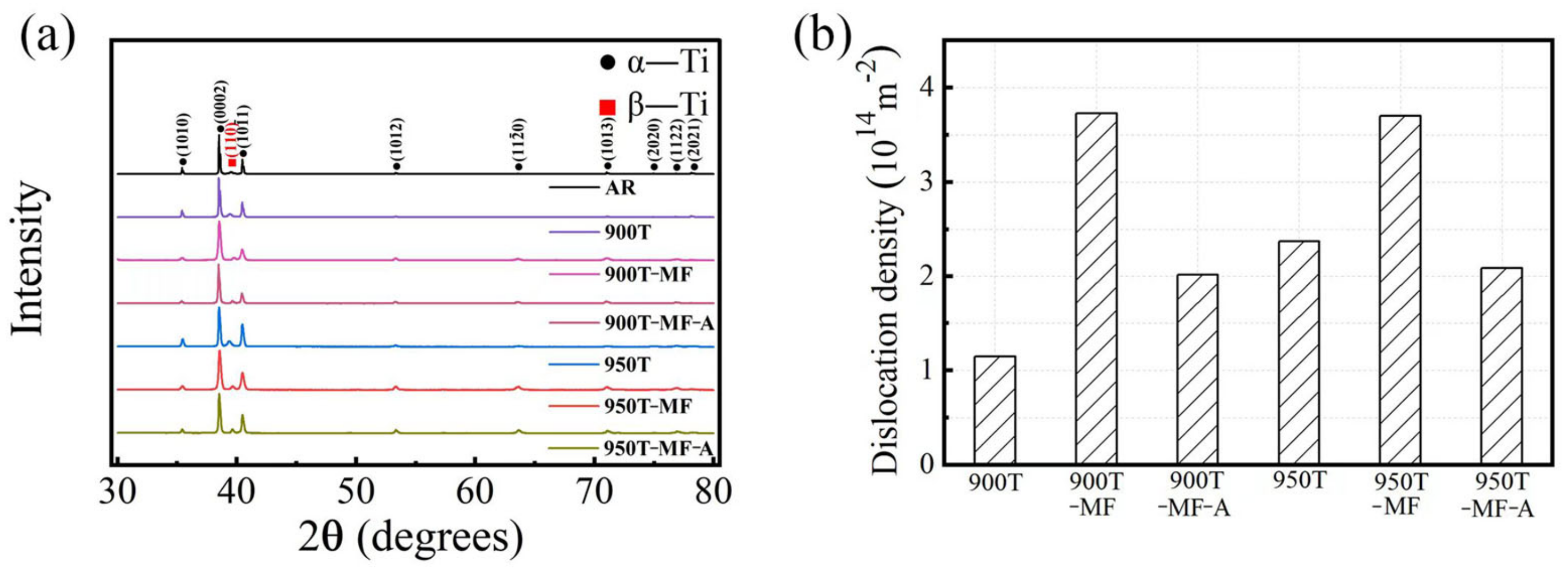

3.4. X-ray Diffraction Analysis

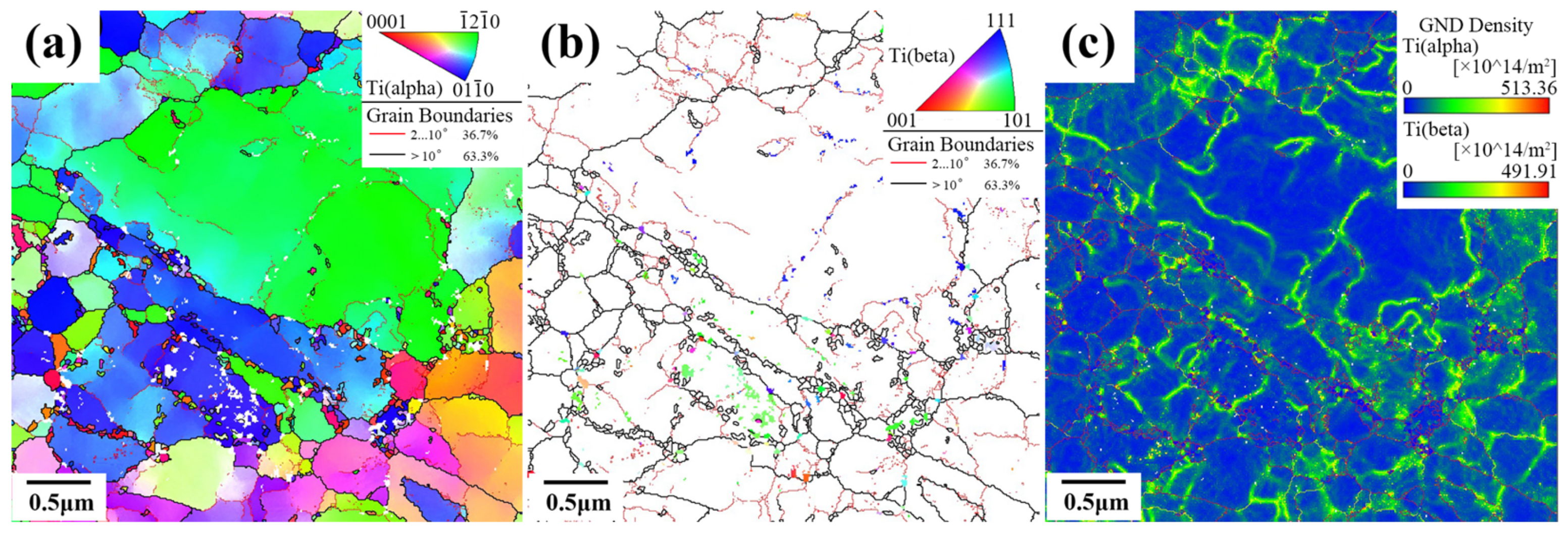

3.5. Deformation Mechanism

3.6. Mechanical Properties

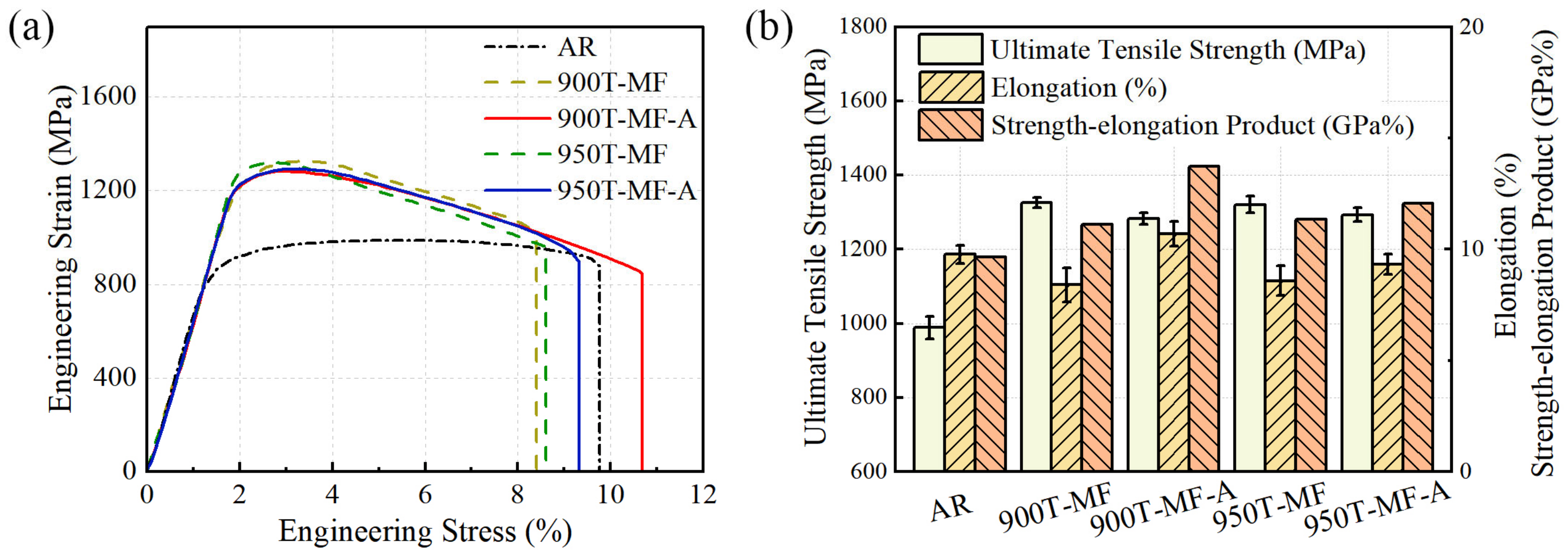

3.6.1. Tensile Testing

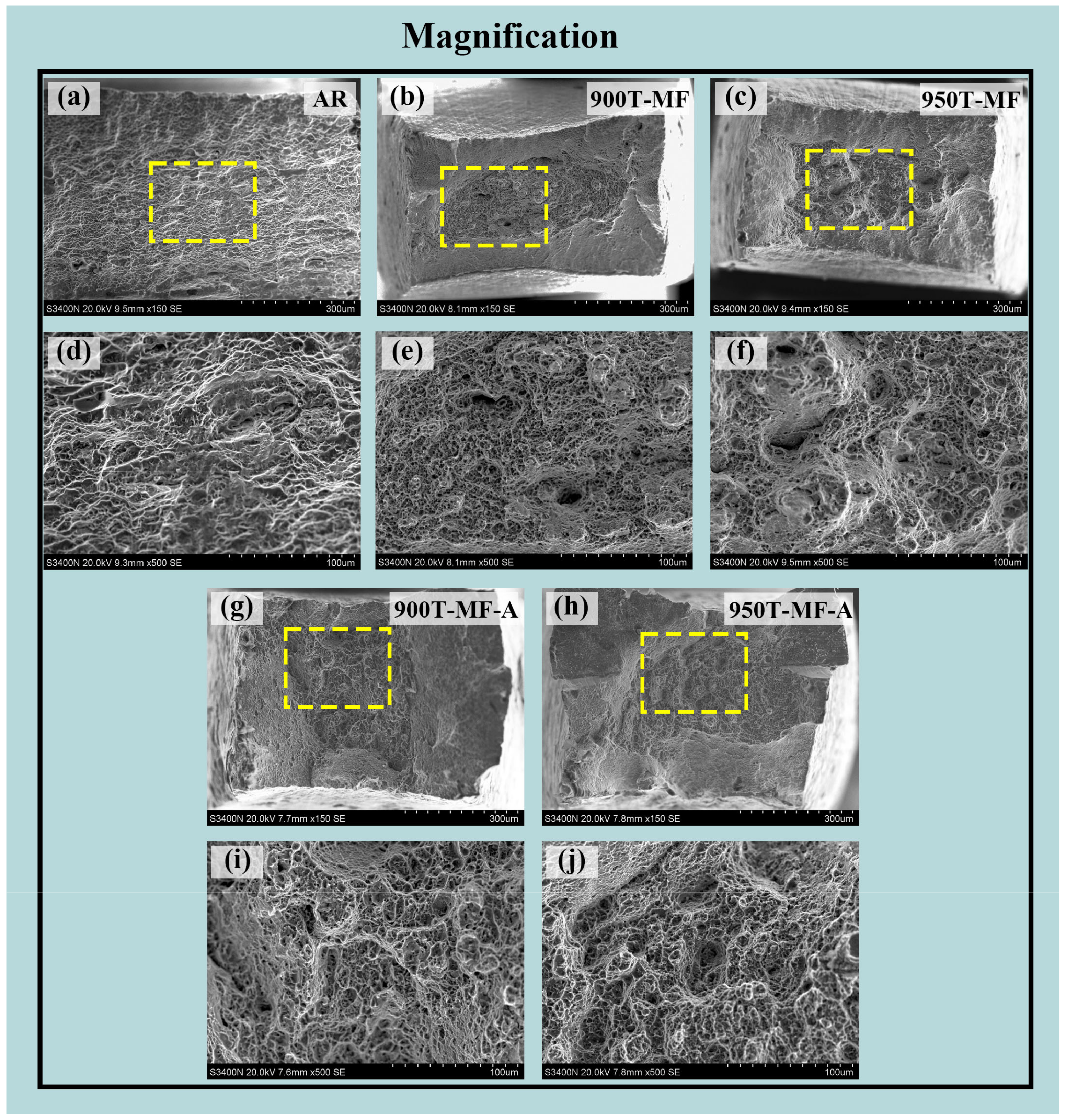

3.6.2. Tensile Fracture Morphology

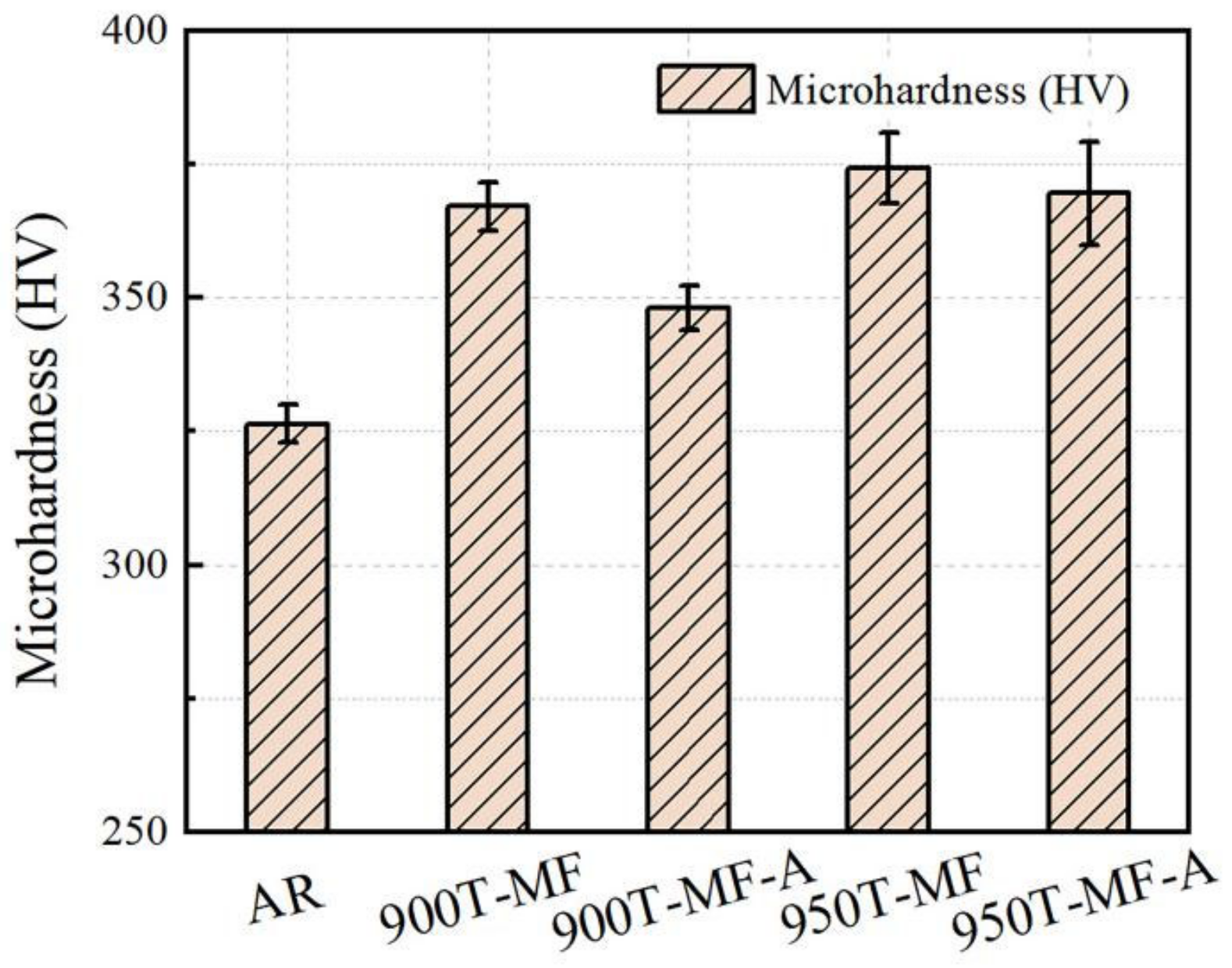

3.6.3. Microhardness

4. Summary and Conclusions

- Holding the material at 900 °C for 1 h, followed by air cooling, results in a microstructure where αp grain constitutes 58.7%, and the average grain size measures 16.7 ± 2 μm. The thickness of the αs lamellar and β lamellar structures is reported as 0.4 ± 0.2 µm and 0.08 ± 0.02 µm, respectively. Following a heat treatment holding at 950 °C for 1 h and subsequent air cooling, the resulting sample exhibits an αp grain proportion of 12.8%, accompanied by an average grain size of 5.1 ± 0.8 μm. The thickness of the αs lamellar and β lamellar structures is slightly thicker.

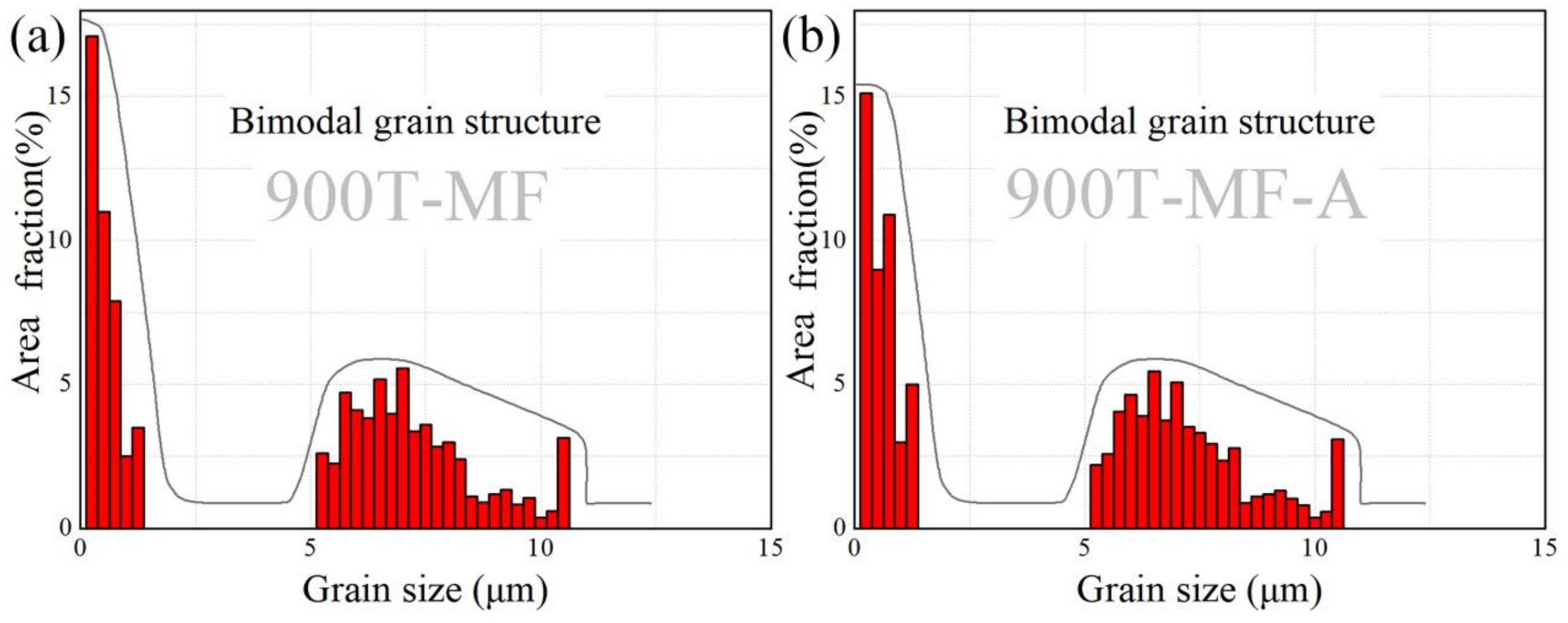

- The αp grain undergoes significant deformation during the MF process, and its morphology remains equal. A substantial amount of DTs and LABs are generated inside the αp grains, and some αp grains are broken into smaller grains. During the MF process, the αs+β lamellar structure of the 900T-MF sample undergoes complete globularization, forming a UFG region with an average grain size of 146.9 nm. The average grain size of αp grains decreases to 7.3 ± 0.6 μm. In contrast, the 950T-MF sample initially breaks down the β lamellar structure, while the αs lamellar undergoes distortion but does not completely globularize. The average grain size of the αp grain remains unchanged at 4.7 ± 1.2 μm.

- Following annealing, the grains in the fine-grained region of the sample increased to a certain extent, and the overall dislocation density decreased. Some GNDs were retained in the αp grains, and the average grain size in the UFG region of the 900T-MF-A sample increased to 177.4 nm.

- The 900T-MF-A sample demonstrated the highest strength–elongation product, achieving a UTS of 1280 MPa, TE of 10.7%, and a 6.7% increase in microhardness. The fracture surfaces of both MF and annealed samples exhibit characteristics dominated by ductile fracture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power. Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Lu, X.; Tan, H.; Lin, X.; Huang, W. Formation mechanism of the α variant and its influence on the tensile properties of laser solid formed Ti-6Al-4V titanium alloy. Mater. Sci. Eng. A 2017, 691, 16–24. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants–A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Salishchev, G.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Mironov, S.Y.; Semiatin, S.L. Production of submicrocrystalline structure in large-scale Ti–6Al–4V billet by warm severe deformation processing. Scr. Mater. 2004, 51, 1147–1151. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Yapici, G.G.; Karaman, I.; Luo, Z.-P. Mechanical twinning and texture evolution in severely deformed Ti–6Al–4V at high temperatures. Acta Mater. 2006, 54, 3755–3771. [Google Scholar] [CrossRef]

- Gupta, A.K.; Maddukuri, T.S.; Singh, S.K. Constrained groove pressing for sheet metal processing. Prog. Mater. Sci. 2016, 84, 403–462. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Mudaliar, V.; Gohil, N.; Gupta, A.K.; Kumar, S.S.S. Evolution of microstructure and mechanical properties of Ti6Al4V alloy by multiple passes of constrained groove pressing at elevated temperature. J. Mater. Process. Tech. 2021, 288, 116891. [Google Scholar] [CrossRef]

- Kwan, C.; Wang, Z.; Kang, S.-B. Mechanical behavior and microstructural evolution upon annealing of the accumulative roll-bonding (ARB) processed Al alloy 1100. Mater. Sci. Eng. A 2008, 480, 148–159. [Google Scholar] [CrossRef]

- Dixit, S.; Dash, B.B.; Kumar, D.; Bhattacharjee, A.; Sankaran, S. Influence of phase morphology, static recrystallization, and crystallographic texture on room temperature tensile properties of Ti–6Al–4V alloy: Comparison between post-tested equiaxed, bimodal, and lamellar microstructures. Mater. Sci. Eng. A 2023, 873, 144990. [Google Scholar] [CrossRef]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten structure: Effects of grain size and cooling rate on the Widmanstätten morphologies and on the mechanical properties in Ti6Al4V alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Lin, Y.C.; Jiang, X.-Y.; Shuai, C.-j.; Zhao, C.-Y.; He, D.-G.; Chen, M.-S.; Chen, C. Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2018, 711, 293–302. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, T.; Han, J.; Ren, Z.; Wu, R.; Sun, J. Achieving ultrafine grained structure in Ti-6Al-4V alloy by high strain rate deformation with a martensitic microstructure. Mater. Lett. 2019, 250, 46–50. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, T.; Lin, P. Effect of forging steps on microstructure evolution and mechanical properties of Ti-6Al-4V alloy during multidirectional isothermal forging. Proce. Manuf. 2020, 50, 817–821. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Gohil, N.; Gupta, A.K.; Kumar, S.S.S. An experimental investigation on the influence of elevated-temperature constrained groove pressing on the microstructure, mechanical properties and hardening behaviour of Ti6Al4V alloy. Mater. Sci. Eng. A 2021, 802, 140651. [Google Scholar] [CrossRef]

- Chao, Q.; Cizek, P.; Wang, J.; Hodgson, P.D.; Beladi, H. Enhanced mechanical response of an ultrafine grained Ti–6Al–4V alloy produced through warm symmetric and asymmetric rolling. Mater. Sci. Eng. A 2016, 650, 404–413. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Kudryavtsev, E.; Kostjuchenko, S.; Malysheva, S.; Salishchev, G. Strength and ductility-related properties of ultrafine grained two-phase titanium alloy produced by warm multiaxial forging. Mater. Sci. Eng. A 2012, 536, 190–196. [Google Scholar] [CrossRef]

- Ding, X.; Sun, L.; Huang, X.; Zhao, Z. Research on Three-Roll Screw Rolling Process for Ti6Al4V Titanium Alloy Bar. High Temp. Mater. Process. 2019, 38, 178–182. [Google Scholar] [CrossRef]

- Hu, Z.-Y.; Cheng, X.-W.; Zhang, Z.-H.; Wang, H.; Li, S.-L.; Korznikova, G.F.; Gunderov, D.V.; Wang, F.-C. The influence of defect structures on the mechanical properties of Ti-6Al-4V alloys deformed by high-pressure torsion at ambient temperature. Mater. Sci. Eng. A 2017, 684, 1–13. [Google Scholar] [CrossRef]

- Samal, S.; Cho, S.; Kim, H. Bimodal distribution of filler on viscosity and thermal expansion of glass composites. Ceram. Int. 2013, 39, 1659–1666. [Google Scholar] [CrossRef]

- Samal, S.; Blanco, I. Investigation of Dispersion, Interfacial Adhesion of Isotropic and Anisotropic Filler in Polymer Composite. Appl. Sci. 2021, 11, 8561. [Google Scholar] [CrossRef]

- Liu, Y.G.; Li, M.Q. Structure response characteristics and surface nanocrystallization mechanism of alpha phase in Ti-6Al-4V subjected to high energy shot peening. J. Alloys Compd. 2019, 773, 860–871. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef]

- Xu, T.; Wang, S.; Wang, W.; Liang, P.; Li, X.; Mitsuzaki, N.; Chen, Z. Multimodal grain structure and tensile properties of cold-rolled titanium after short-duration annealing. Mater. Charact. 2020, 160, 110095. [Google Scholar] [CrossRef]

- Vlasov, I.V.; Gomorova, Y.F.; Yakovlev, A.V.; Naidenkin, E.V. The Influence of Cooling Conditions of Titanium Alloy After High-Temperature Helical Rolling on The Structure and Impact Toughness. Russ. Phys. J. 2021, 64, 1408–1414. [Google Scholar] [CrossRef]

- E28.04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–30.

- Zuo, J.H.; Wang, Z.G.; Han, E.H. Effect of microstructure on ultra-high cycle fatigue behavior of Ti–6Al–4V. Mater. Sci. Eng. A 2008, 473, 147–152. [Google Scholar] [CrossRef]

- Seal, J.R.; Crimp, M.A.; Bieler, T.R.; Boehlert, C.J. Analysis of slip transfer and deformation behavior across the α/β interface in Ti–5Al–2.5Sn (wt.%) with an equiaxed microstructure. Mater. Sci. Eng. A 2012, 552, 61–68. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Y.; Han, Z.; Liu, Z.; Liu, K.; Tu, Y.; Fang, F.; Jiang, J. Unusual stress-induced martensite transformation in Ti-6Al-4V alloy enabled by solution treatment in the lower α+β regime. J. Alloys Compd. 2023, 956, 170330. [Google Scholar] [CrossRef]

- Garbacz, H.; Lewandowska, M.; Pachla, W.; KurzydŁOwski, K.J. Structural and mechanical properties of nanocrystalline titanium and 316LVM steel processed by hydrostatic extrusion. J. Microsc-Oxford 2006, 223, 272–274. [Google Scholar] [CrossRef]

- Nath, P.; Marandi, L.; Sen, I. Processing-microstructure-property correlation in thermo-mechanically processed Ti-6Al-4V alloys: A comparative study between conventional and novel approaches. J. Alloys Compd. 2022, 927, 167039. [Google Scholar] [CrossRef]

- Wang, L.; Fan, X.G.; Zhan, M.; Chen, Q. Experimental characterization and physical modeling of strain path dependent microstructure evolution: A case study of primary hot working of titanium alloy. Int. J. Plasticity 2022, 158, 103450. [Google Scholar] [CrossRef]

- Froes, F.H. Titanium: Physical Metallurgy, Processing, and Applications, 1st ed.; Froes, F.H., Ed.; ASM International: New York, NY, USA, 2015. [Google Scholar]

- Song, J.-H.; Hong, K.-J.; Ha, T.K.; Jeong, H.T. The effect of hot rolling condition on the anisotropy of mechanical properties in Ti–6Al–4V alloy. Mater. Sci. Eng. A 2007, 449–451, 144–148. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Microstructure and Texture Evolution During Sub-Transus Thermomechanical Processing of Ti-6Al-4V-0.1B Alloy: Part I. Hot Rolling in (α+β) Phase Field. Metall. Mater. Trans. A 2013, 44, 3303–3321. [Google Scholar] [CrossRef]

- Liu, Y.G.; Li, M.Q.; Liu, H.J. Deformation induced face-centered cubic titanium and its twinning behavior in Ti–6Al–4V. Scr. Mater. 2016, 119, 5–8. [Google Scholar] [CrossRef]

- Youssef, K.M.; Scattergood, R.O.; Murty, K.L.; Koch, C.C. Nanocrystalline Al–Mg alloy with ultrahigh strength and good ductility. Scr. Mater. 2006, 54, 251–256. [Google Scholar] [CrossRef]

- Li, H.; Chen, P.; Wang, Z.; Zhu, F.; Song, R.; Zheng, Z. Tensile properties, microstructures and fracture behaviors of an Al-Zn-Mg-Cu alloy during ageing after solution treating and cold-rolling. Mater. Sci. Eng. A 2019, 742, 798–812. [Google Scholar] [CrossRef]

- Xiao, Y.; Qian, G.; Sun, J.; Berto, F.; Correia, J.A.F.; Hong, Y. Effects of temperature on tensile and fracture performance of Ti6Al4V alloy fabricated by laser powder bed fusion. Theor. Appl. Fract. Mec. 2023, 125, 103931. [Google Scholar] [CrossRef]

| Element | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| % wt. | 5.9 | 4.2 | 0.2 | 0.15 | 0.05 | 0.015 | 0.15 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, S.; Song, Y.; He, Y.; Wei, C.; Chen, R.; Guo, S.; Liang, W.; Lei, S.; Liu, X. Evolution of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy under Heat Treatment and Multi-Axial Forging. Materials 2024, 17, 1060. https://doi.org/10.3390/ma17051060

Du S, Song Y, He Y, Wei C, Chen R, Guo S, Liang W, Lei S, Liu X. Evolution of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy under Heat Treatment and Multi-Axial Forging. Materials. 2024; 17(5):1060. https://doi.org/10.3390/ma17051060

Chicago/Turabian StyleDu, Sijie, Yang Song, Yiting He, Chunhua Wei, Rongyou Chen, Shubo Guo, Wei Liang, Shengyuan Lei, and Xiaohong Liu. 2024. "Evolution of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy under Heat Treatment and Multi-Axial Forging" Materials 17, no. 5: 1060. https://doi.org/10.3390/ma17051060

APA StyleDu, S., Song, Y., He, Y., Wei, C., Chen, R., Guo, S., Liang, W., Lei, S., & Liu, X. (2024). Evolution of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy under Heat Treatment and Multi-Axial Forging. Materials, 17(5), 1060. https://doi.org/10.3390/ma17051060