Study on Viscoelastic Properties of Various Fiber-Reinforced Asphalt Binders

Abstract

:1. Introduction

2. Materials and Experiment Procedure

2.1. Material

2.1.1. Asphalt Binder

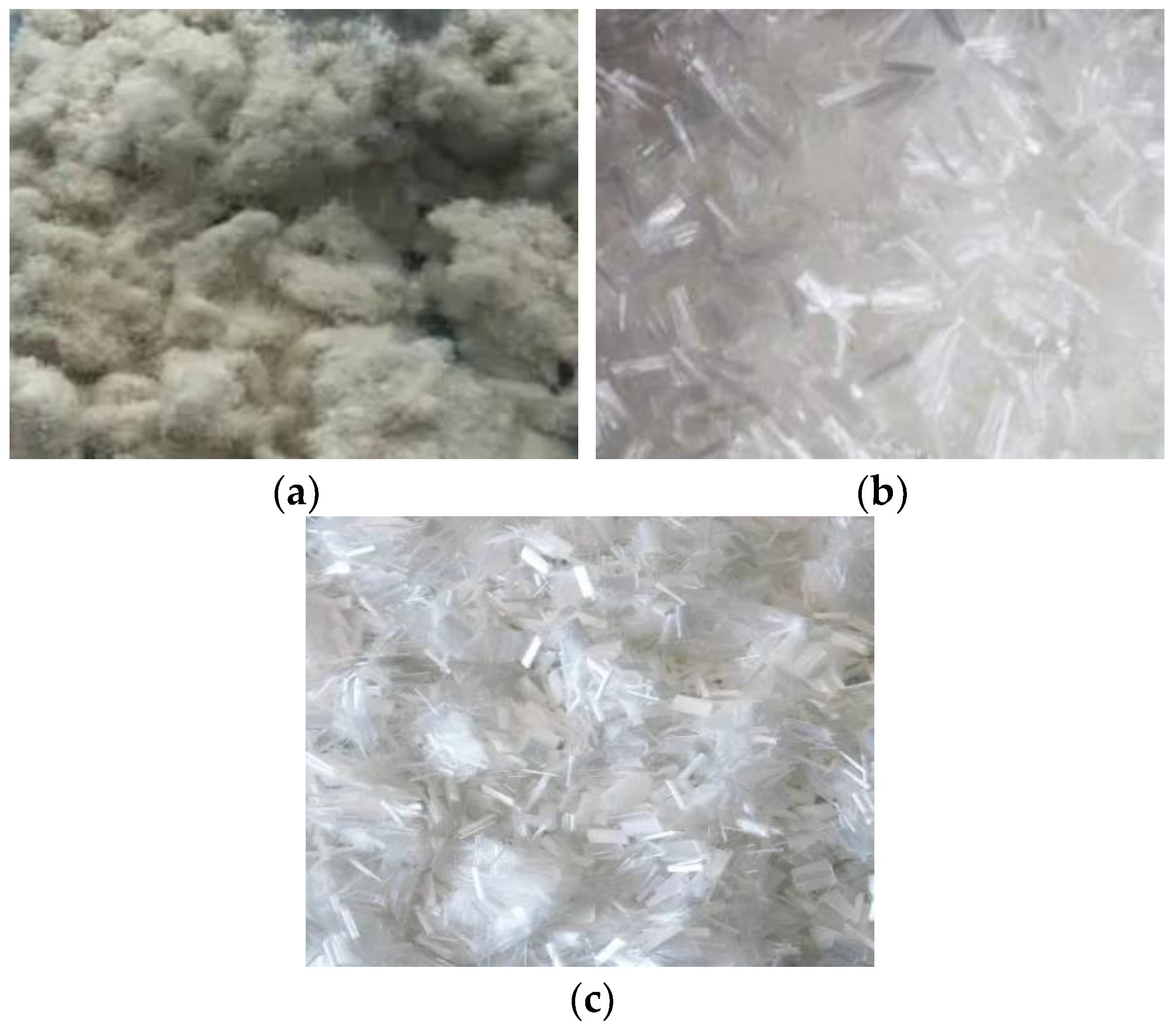

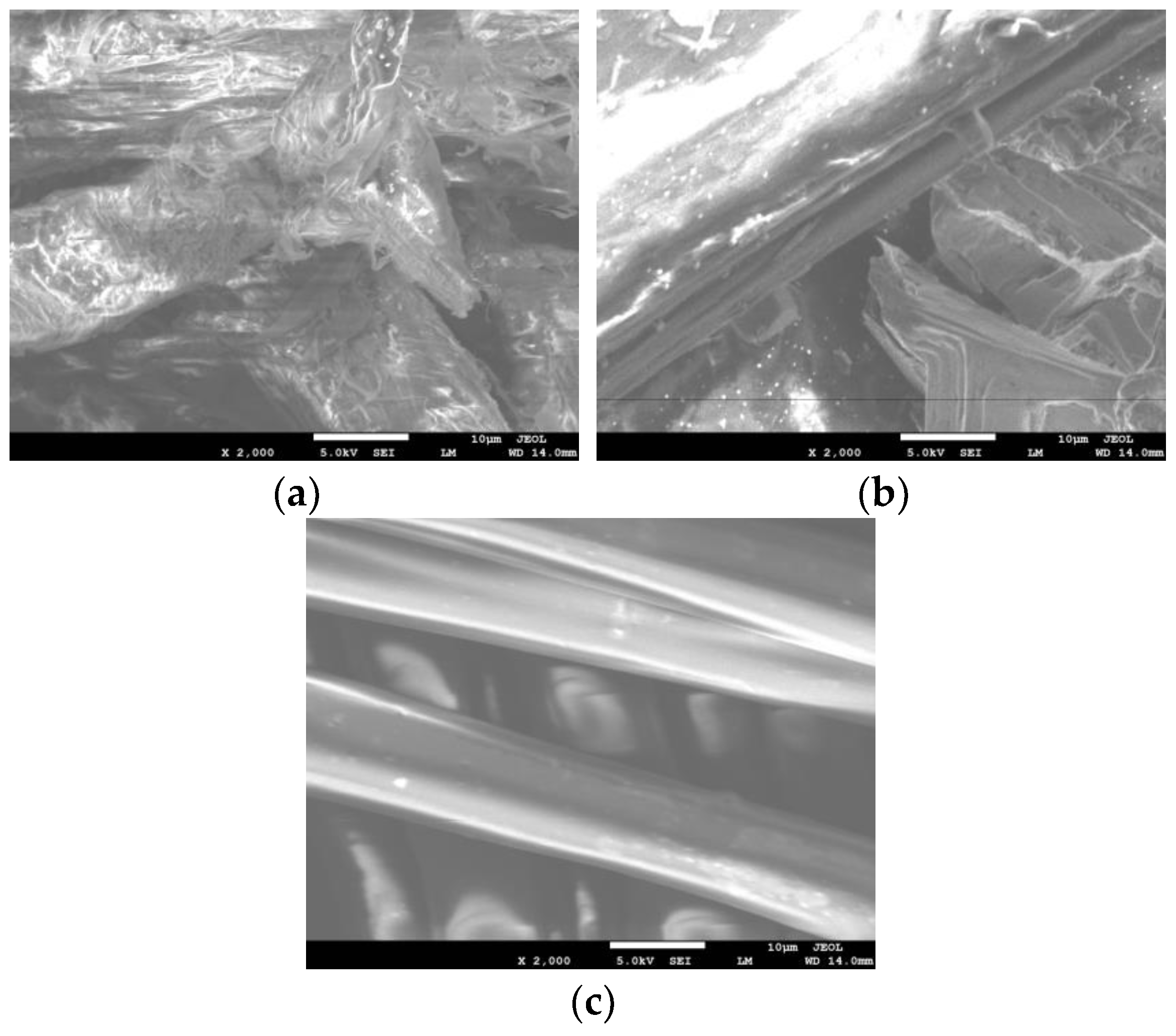

2.1.2. Fibers

2.1.3. Mineral Powder

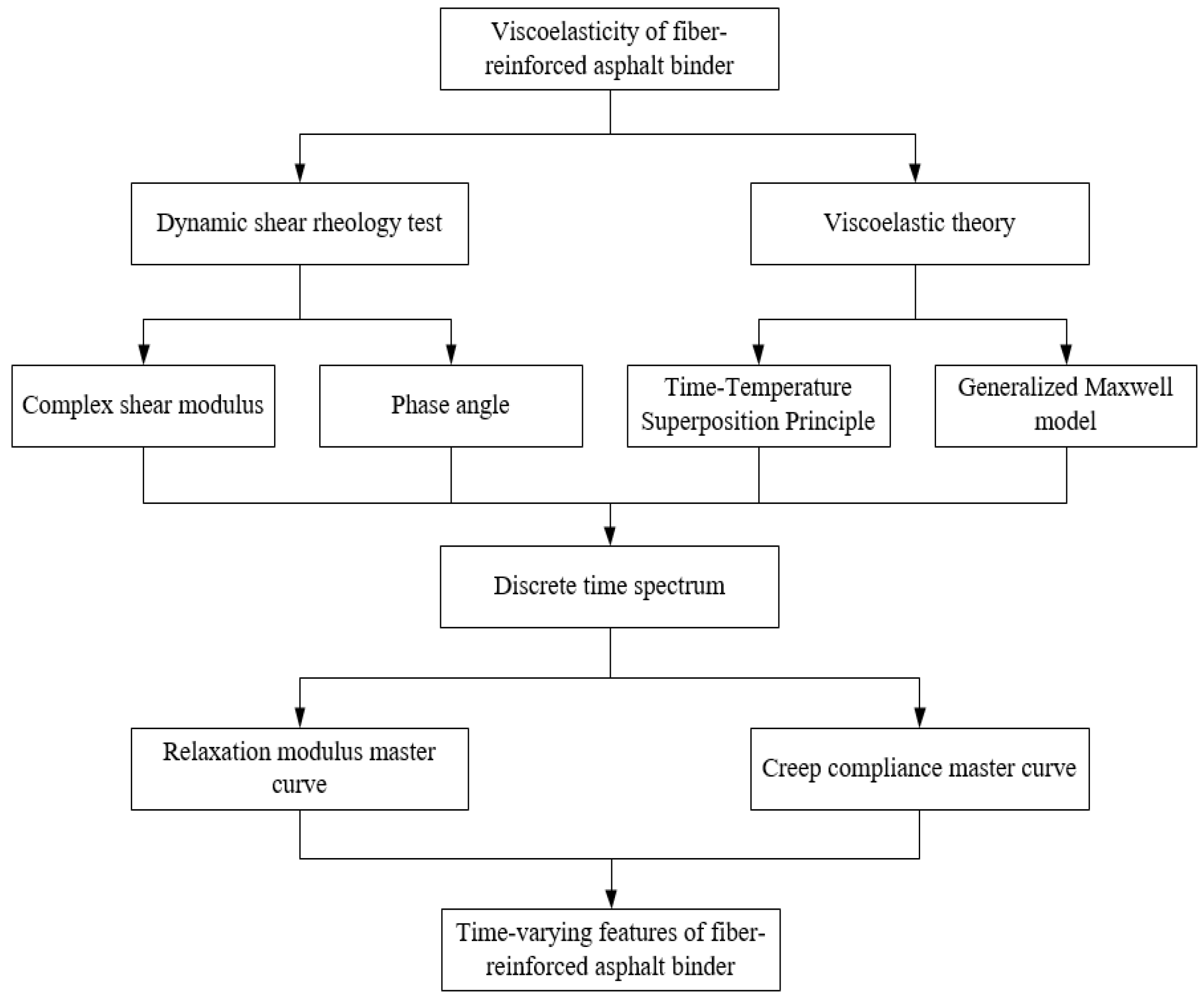

2.2. Methodology

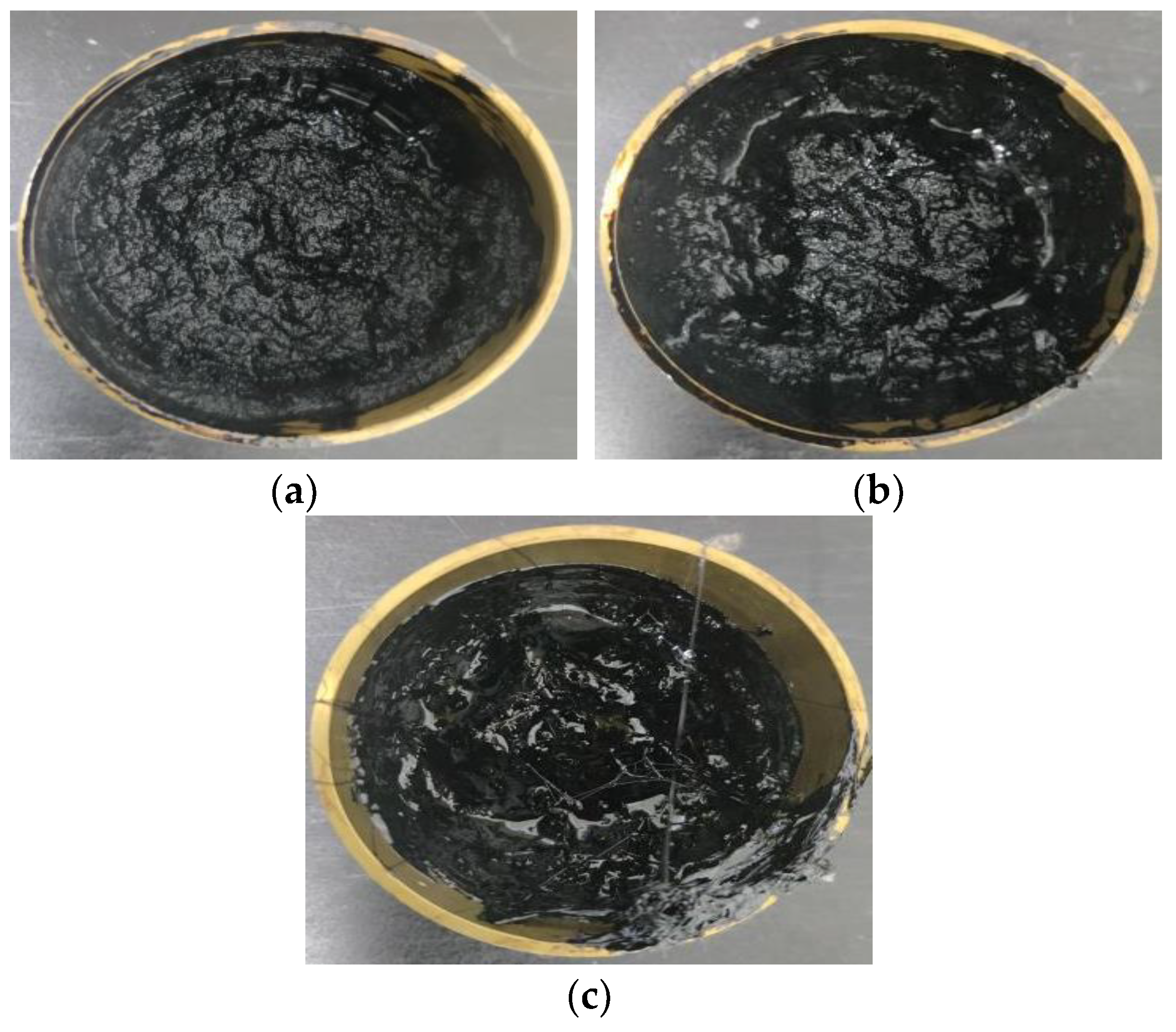

2.2.1. Preparation of Specimens

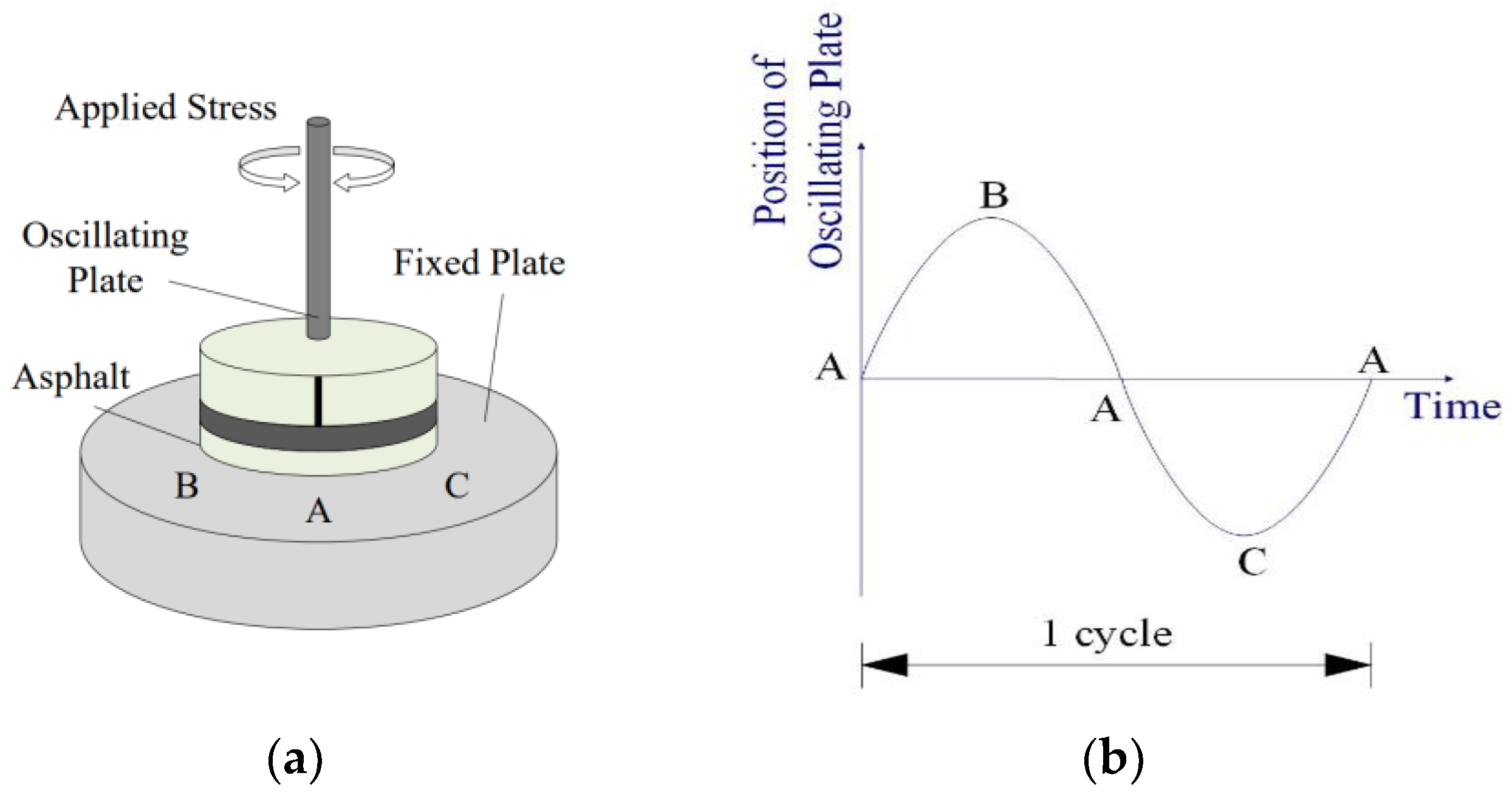

2.2.2. Dynamic Shear Rheology Test

3. Theoretical Background

3.1. The Time–Temperature Superposition Principle

3.2. Viscoelastic Constitutive Model

4. Results and Discussion

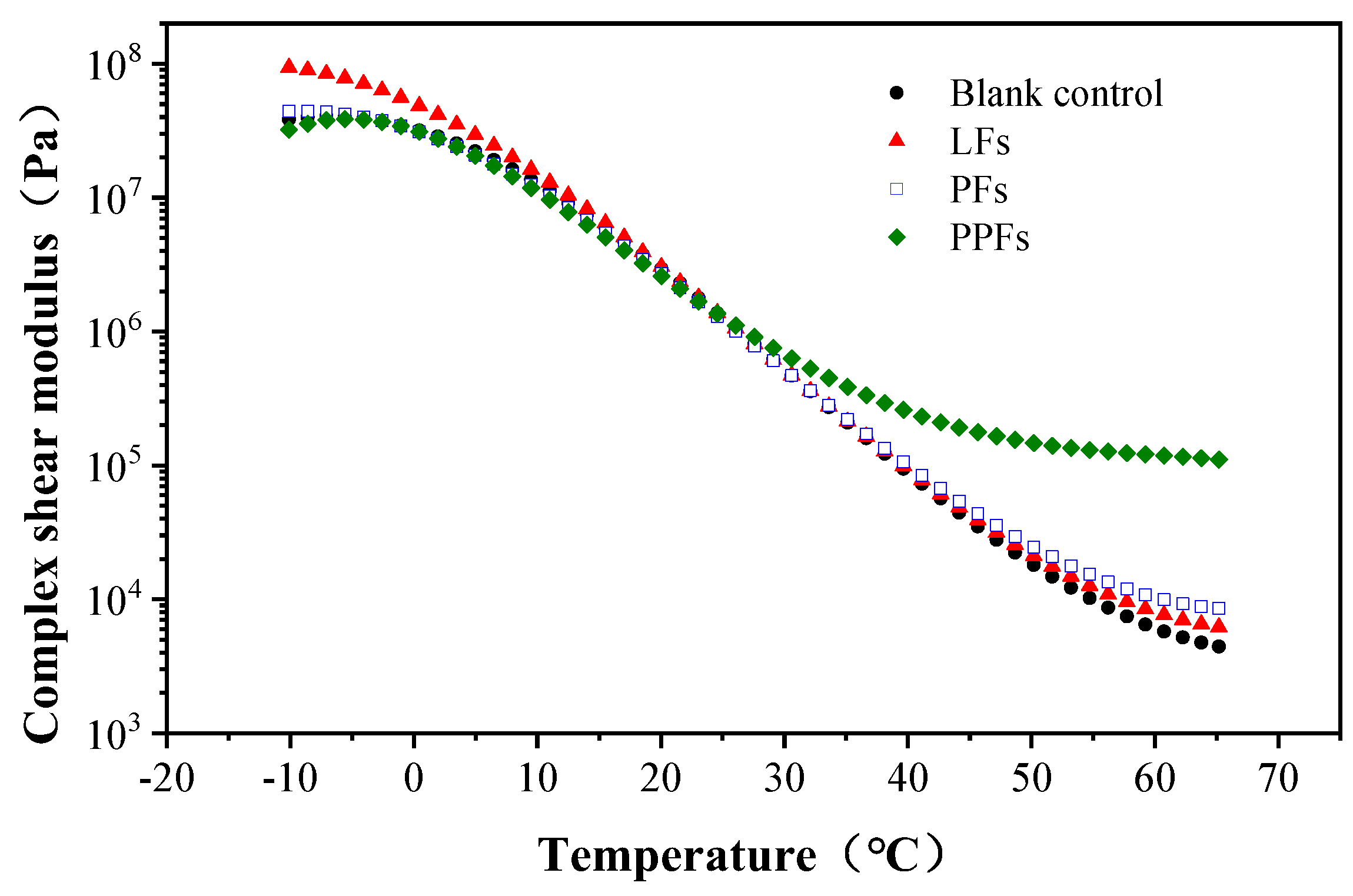

4.1. Complex Shear Modulus

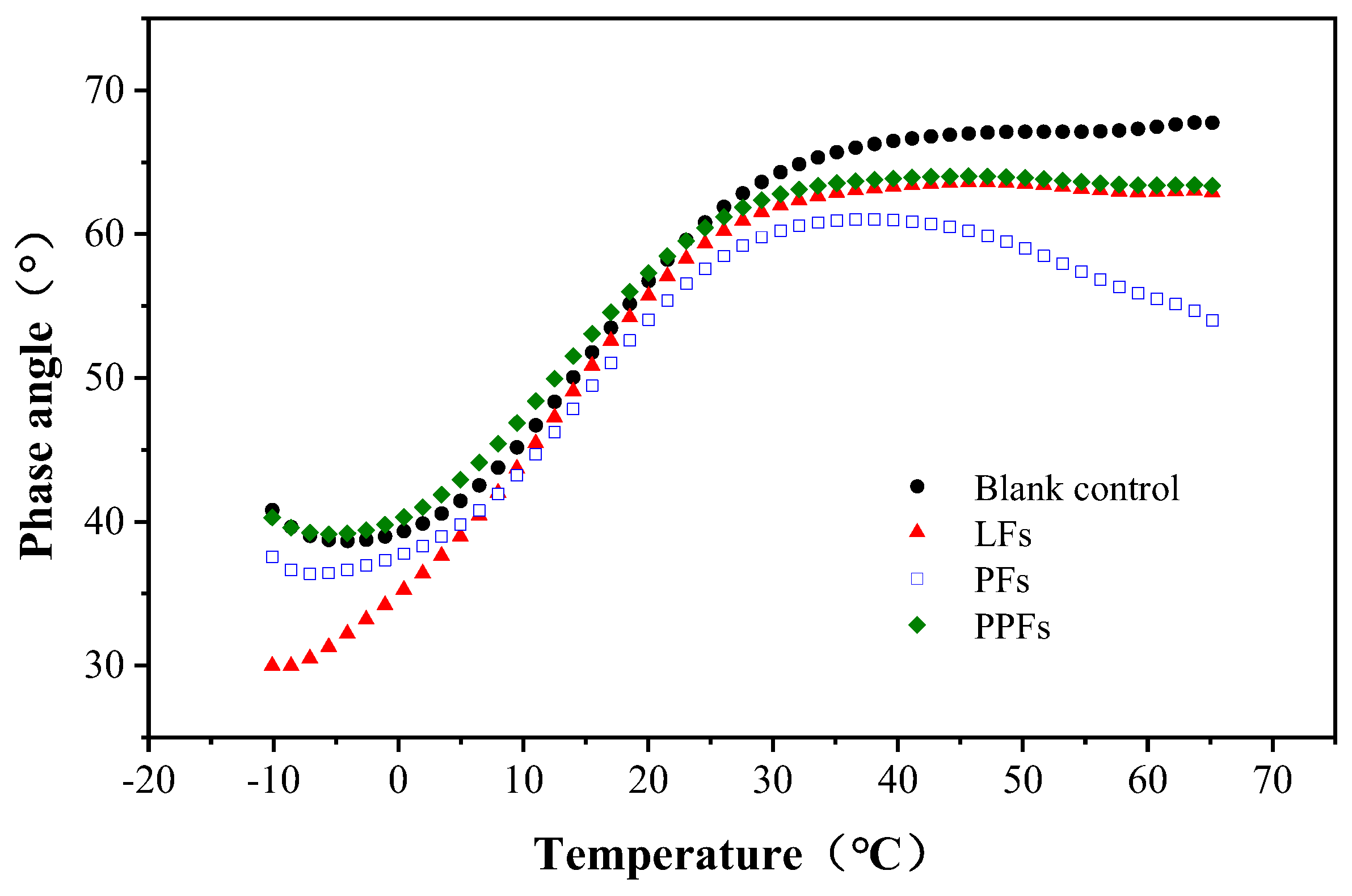

4.2. Phase Angle

5. Creep Master Curve Development

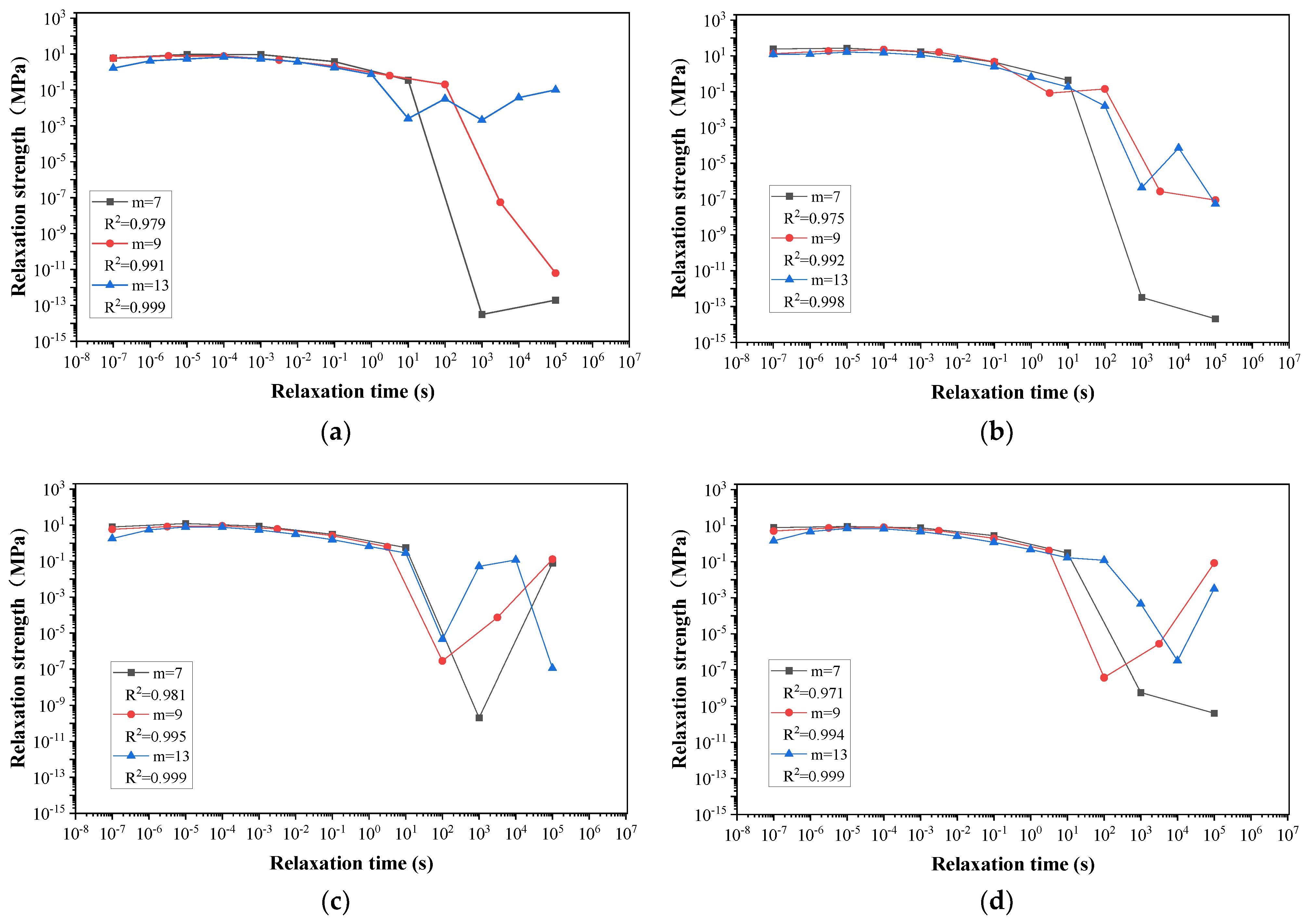

5.1. The Discrete Relaxation Time Spectrum and GM Model Analysis

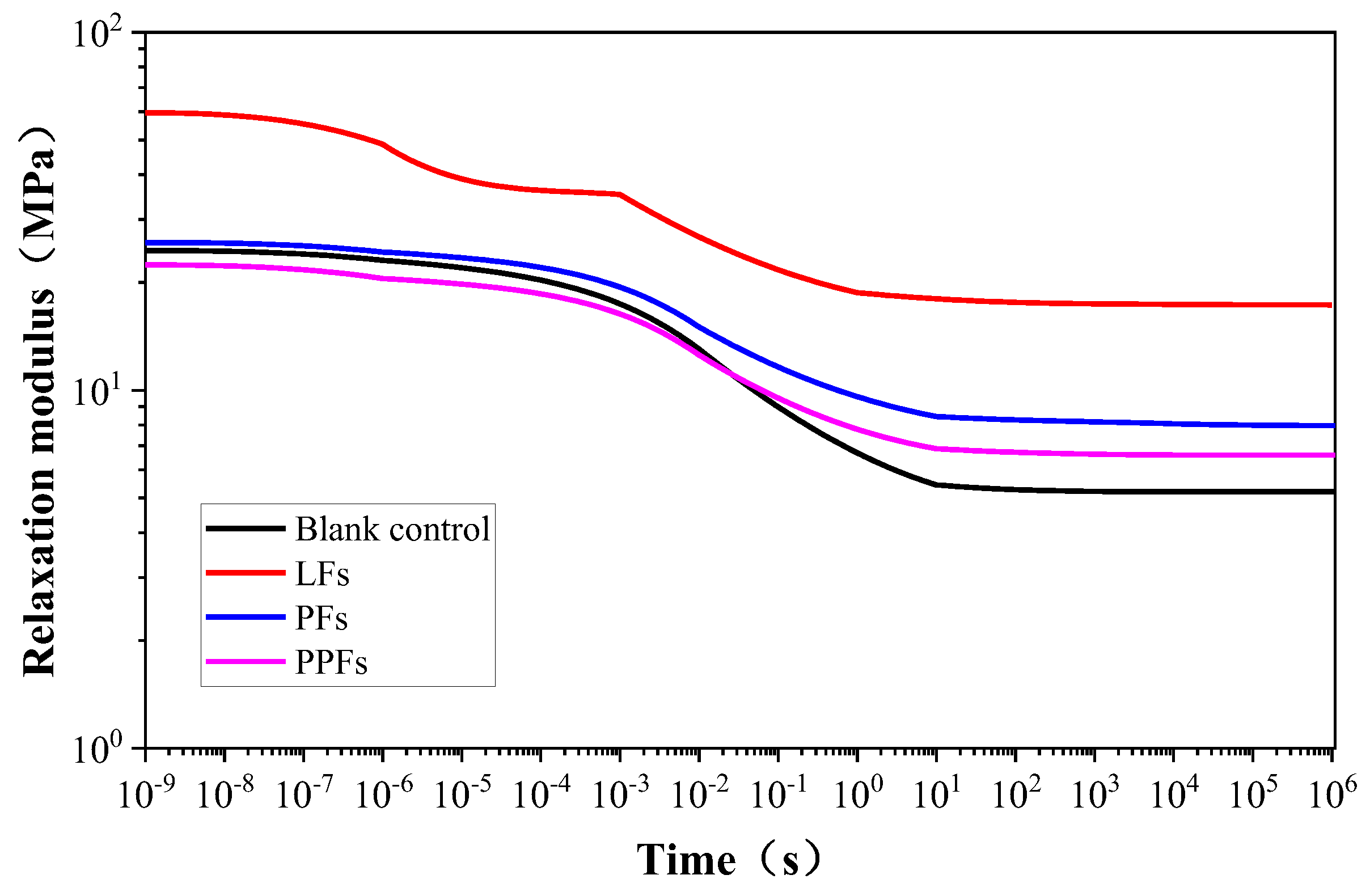

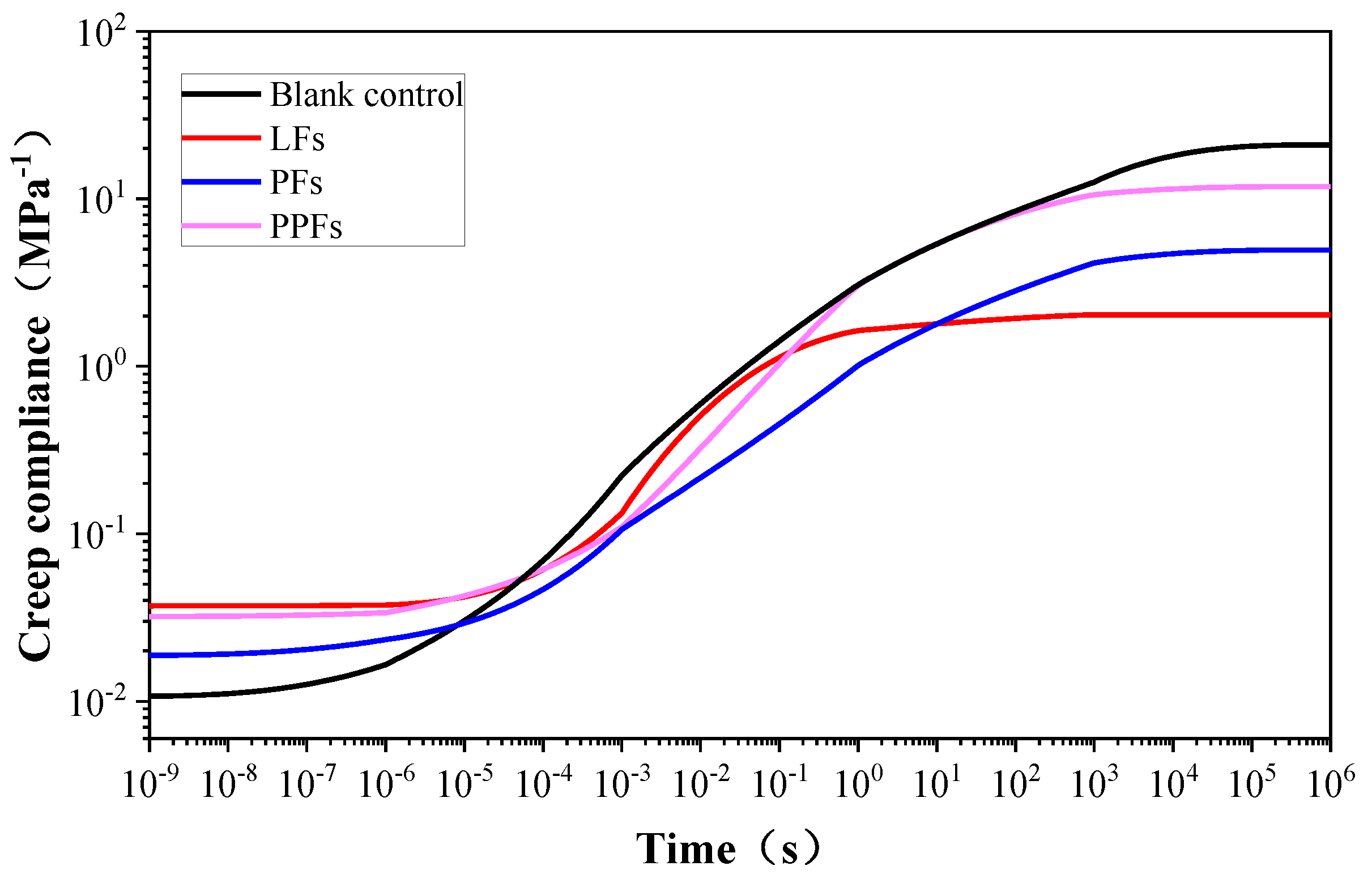

5.2. Establishment of the Master Curves Relaxation Modulus and Creep Compliance

6. Conclusions

- (1)

- For all binders, the dynamic modulus decreases as the temperature increases, while the phase angle increases. This suggests that the resistance to deformation of the binders decreases as the temperature increases, and the viscous properties become more prominent.

- (2)

- Incorporating fibers into an asphalt binder can enhance its deformation resistance, as indicated by the data for dynamic modulus and phase angles. PPFs are the most effective additive for improving high-temperature deformation resistance, while LFs are superior for low-temperature crack resistance in asphalt binders. Additionally, incorporating fibers can decrease the material’s susceptibility to temperature and a more significant elastic characterization, particularly for LFs.

- (3)

- Based on the tested and calculated data, it is clear that the GM model with 13 units serves as an efficient representation of the viscoelastic characteristics of the binders under consideration. This is attributed to the model’s exceptional precision and effectiveness during calculations.

- (4)

- Incorporating fibers improves the long-term deformation resistance of asphalt binders, as demonstrated by data from the relaxation modulus and creep compliance master curves. Incorporation of lignin fibers is the most efficient approach to improve long-term properties, followed by polyester fibers and then polypropylene fibers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the effect of fiber type, length, and content on asphalt properties and asphalt mixture performance. Materials 2020, 13, 1556. [Google Scholar] [CrossRef]

- Sulyman, M.; Sienkiewicz, M.; Haponiuk, J. Asphalt pavement material improvement: A review. Int. J. Environ. Sci. Dev. 2014, 5, 444. [Google Scholar] [CrossRef]

- Liu, Y.; Su, P.; Li, M.; You, Z.; Zhao, M. Review on evolution and evaluation of asphalt pavement structures and materials. J. Traffic Transp. Eng. 2020, 7, 573–599. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A review of nanomaterials’ effect on mechanical performance and aging of asphalt mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef]

- Han, D.; Wei, L.; Zhang, J. Experimental study on performance of asphalt mixture designed by different method. Procedia Eng. 2016, 137, 407–414. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, Q.; Wang, Y.; Zhang, H. Influence of service time of recycled coarse aggregate on the mechanical properties of recycled aggregate concrete. Mater. Struct. 2019, 52, 1–16. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the art study on aging of asphalt mixtures and use of antioxidant additives. Adv. Civ. Eng. 2018, 2018, 1–18. [Google Scholar] [CrossRef]

- Kaloush, K.E. Simple performance test for permanent deformation of asphalt mixtures. In Proceedings of the Sixth International RILEM Symposium on Performance Testing and Evaluation of Bituminous Materials, Zurich, Switzerland, 14–16 April 2003. [Google Scholar]

- Elkashef, M.; Williams, R.C.; Cochran, E. Investigation of fatigue and thermal cracking behavior of rejuvenated reclaimed asphalt pavement binders and mixtures. Int. J. Fatigue 2018, 108, 90–95. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Tashman, L.; Pearson, B. Characterisation of stone matrix asphalt mixtures. Int. J. Pavement Eng. 2012, 13, 297–309. [Google Scholar] [CrossRef]

- da Rocha Segundo, I.G.; Margalho, É.M.; Lima, O.D.S., Jr.; Pinheiro, C.G.D.S.; de Freitas, E.F.; Carneiro, J.A.S.O. Smart asphalt mixtures: A bibliometric analysis of the research trends. Coatings 2023, 13, 1396. [Google Scholar] [CrossRef]

- Crispino, M.; Mariani, E.; Toraldo, E. Assessment of fiber-reinforced bituminous mixtures’ compaction temperatures through mastics viscosity tests. Constr. Build. Mater. 2013, 38, 1031–1039. [Google Scholar] [CrossRef]

- Vale, A.C.; Casagrande MD, T.; Soares, J.B. Behavior of natural fiber in stone matrix asphalt mixtures using two design methods. J. Mater. Civ. Eng. 2014, 26, 457–465. [Google Scholar] [CrossRef]

- Wang, D.; Wang, L.; Gu, X.; Zhou, G. Effect of basalt fiber on the asphalt binder and mastic at low temperature. J. Mater. Civ. Eng. 2013, 25, 355–364. [Google Scholar] [CrossRef]

- Rui, X.; Shuanfa, C.; Bowen, G.; Yanping, S.; Lu, W. Laboratory investigation of brucite fiber in stabilizing and reinforcing asphalt binder. Int. J. Pavement Res. Technol. 2014, 7, 256. [Google Scholar]

- Chen, Z.; Yi, J.; Chen, Z.; Feng, D. Properties of asphalt binder modified by corn stalk fiber. Constr. Build. Mater. 2019, 212, 225–235. [Google Scholar] [CrossRef]

- Khater, A.; Luo, D.; Abdelsalam, M.; Yue, Y.; Hou, Y.; Ghazy, M. Laboratory evaluation of asphalt mixture performance using composite admixtures of lignin and glass fibers. Appl. Sci. 2021, 11, 364. [Google Scholar] [CrossRef]

- Wu, J.; Li, F.; Ma, Q. Effect of polyester fiber on air voids and low-temperature crack resistance of permeable asphalt mixture. Adv. Civ. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Tapkın, S. The effect of polypropylene fibers on asphalt performance. Build. Environ. 2008, 43, 1065–1071. [Google Scholar] [CrossRef]

- Bayat, R.; Talatahari, S. Influence of polypropylene length on stability and flow of fiber-reinforced asphalt mixtures. Civ. Eng. J. 2016, 2, 538–545. [Google Scholar] [CrossRef]

- Lagos-Varas, M.; Movilla-Quesada, D.; Arenas, J.; Raposeiras, A.; Castro-Fresno, D.; Calzada-Pérez, M.; Vega-Zamanillo, A.; Maturana, J. Study of the mechanical behavior of asphalt mixtures using fractional rheology to model their viscoelasticity. Constr. Build. Mater. 2019, 200, 124–134. [Google Scholar] [CrossRef]

- Loizos, A.; Gkyrtis, K.; Plati, C. Modelling asphalt pavement responses based on field and laboratory data. In Accelerated Pavement Testing to Transport Infrastructure Innovation: Proceedings of 6th APT Conference; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 438–447. [Google Scholar]

- Bai, T.; Huang, X.; Zheng, X.; Wang, H.; Cheng, Y.; Cui, B.; Xu, F.; Mao, B.; Li, Y. Viscoelastic parametric conversions and mechanical response analysis of asphalt mixtures. Constr. Build. Mater. 2023, 390, 131777. [Google Scholar] [CrossRef]

- Lagos-Varas, M.; Movilla-Quesada, D.; Raposeiras, A.C.; Castro-Fresno, D.; Muñoz-Cáceres, O.; Andrés-Valeri, V.C.; Rodríguez-Esteban, M.A. Viscoelasticity modelling of asphalt mastics under permanent deformation through the use of fractional calculus. Constr. Build. Mater. 2022, 329, 127102. [Google Scholar] [CrossRef]

- You, Q.; Ma, J.; Liu, X. An experimentally-based viscoelastic behavior of asphalt mastic at high temperatures. Constr. Build. Mater. 2018, 177, 358–365. [Google Scholar] [CrossRef]

- Zhang, W.; Cui, B.; Gu, X.; Dong, Q. Comparison of relaxation modulus converted from frequency-and time-dependent viscoelastic functions through numerical methods. Appl. Sci. 2018, 8, 2447. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, H.; Li, L.; Zhang, Y.; Wang, H.; Bai, Y. Viscoelastic properties of asphalt mixtures with different modifiers at different temperatures based on static creep tests. Appl. Sci. 2019, 9, 4246. [Google Scholar] [CrossRef]

- Behzadfar, E.; Hatzikiriakos, S.G. Viscoelastic properties and constitutive modelling of bitumen. Fuel 2013, 108, 391–399. [Google Scholar] [CrossRef]

- Lv, H.; Zhang, C.; Liu, H.; Luo, R.; Chen, H. A new method for conversion of creep compliance to relaxation modulus of asphalt mixtures. J. Highw. Transp. Res. Dev. 2017, 34, 1–7. [Google Scholar]

- Walubita, L.F.; Alvarez, A.E.; Simate, G.S. Evaluating and comparing different methods and models for generating relaxation modulus master-curves for asphalt mixes. Constr. Build. Mater. 2011, 25, 2619–2626. [Google Scholar] [CrossRef]

- JTG E20-2011; Highway Engineering Asphalt and Asphalt Mixture Test Regulations. People’s Communications Press: Beijing, China, 2011.

- JTT 533-2020; Fiber for Asphalt Pavements. China Communication Press: Beijing, China, 2020.

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. China Communications Press: Beijing, China, 2005.

- Nakano, T. Applicability condition of time–temperature superposition principle (TTSP) to a multi-phase system. Mech. Time-Depend. Mater. 2013, 17, 439–447. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Di Benedetto, H.; Sauzéat, C.; Tapsoba, N. Time temperature superposition principle validation for bituminous mixes in the linear and nonlinear domains. J. Mater. Civ. Eng. 2013, 25, 1181–1188. [Google Scholar] [CrossRef]

- Naderi, K.; Moghadas Nejad, F.; Khodaii, A. Time-temperature-age superposition validation for linear viscoelastic properties of bituminous materials. J. Mater. Civ. Eng. 2018, 30, 04017292. [Google Scholar] [CrossRef]

- Godenzoni, C.; Bocci, M.; Graziani, A. Rheological characterization of cold bituminous mastics produced with different mineral additions. In Transport Infrastructure and Systems: Proceedings of the AIIT International Congress on Transport Infrastructure and Systems, Rome, Italy, 10–12 April 2017; CRC Press: Boca Raton, FL, USA, 2017; p. 185. [Google Scholar]

- Schapery, R.A. A Simple Collocation Method for Fitting Viscoelastic Models to Experimental Data; GALCIT SM61-23; California Institute of Technology: Pasadena, CA, USA, 1961. [Google Scholar]

- Park, S.W.; Schapery, R.A. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- Kim, J.; Sholar, G.A.; Kim, S. Determination of accurate creep compliance and relaxation modulus at a single temperature for viscoelastic solids. J. Mater. Civ. Eng. 2008, 20, 147–156. [Google Scholar] [CrossRef]

| Parameter | Test Result | Requirement |

|---|---|---|

| Penetration at 25 °C/0.1 mm | 58.6 | 50–60 |

| Ductility at 5 °C/cm | 23.8 | ≥20 |

| Softening point/°C | 79.1 | ≥60 |

| Flash point (COC)/°C | 365 | ≥230 |

| Kinematic viscosity at 135 °C/m2/s | 2.2 | ≤3 |

| Solubility (trichloroethylene)/% | 99.6 | ≥99 |

| Fibers | Length (mm) | Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Melting Point (°C) | Moisture Content (%) | Oil Absorption (Times) |

|---|---|---|---|---|---|---|---|

| Lignin | 5 | - | 1.10 | - | - | - | 6.2 |

| Polypropylene | 6 | 35.0 | 0.91 | 450 | 220 | 0.8 | - |

| Polyester | 8 | 24.0 | 1.38 | 508 | 260 | 1.0 | - |

| Standard | 6–12 (LFs < 6) | 15–35 | - | >270 | >220 | ≤1.0 | 5–9 |

| Projects | Unit | Measurement Value | Specification Requirements |

|---|---|---|---|

| Apparent density | t/m3 | 2.694 | 1 |

| Hydrophilic coefficient | — | 0.76 | <1 |

| Size range < 0.6 mm | % | 100 | 100 |

| <0.15 mm | % | 95.8 | 90~100 |

| <0.075 mm | % | 85.7 | 75~100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xu, F.; Wang, Y.; Liu, H.; Peng, L.; Xiao, Y.; Liang, Q.; Li, X. Study on Viscoelastic Properties of Various Fiber-Reinforced Asphalt Binders. Materials 2024, 17, 1085. https://doi.org/10.3390/ma17051085

Li Y, Xu F, Wang Y, Liu H, Peng L, Xiao Y, Liang Q, Li X. Study on Viscoelastic Properties of Various Fiber-Reinforced Asphalt Binders. Materials. 2024; 17(5):1085. https://doi.org/10.3390/ma17051085

Chicago/Turabian StyleLi, Yunyu, Fan Xu, Yongsheng Wang, Hao Liu, Longfan Peng, Yue Xiao, Qian Liang, and Xuquan Li. 2024. "Study on Viscoelastic Properties of Various Fiber-Reinforced Asphalt Binders" Materials 17, no. 5: 1085. https://doi.org/10.3390/ma17051085