Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MXene Nanosheets

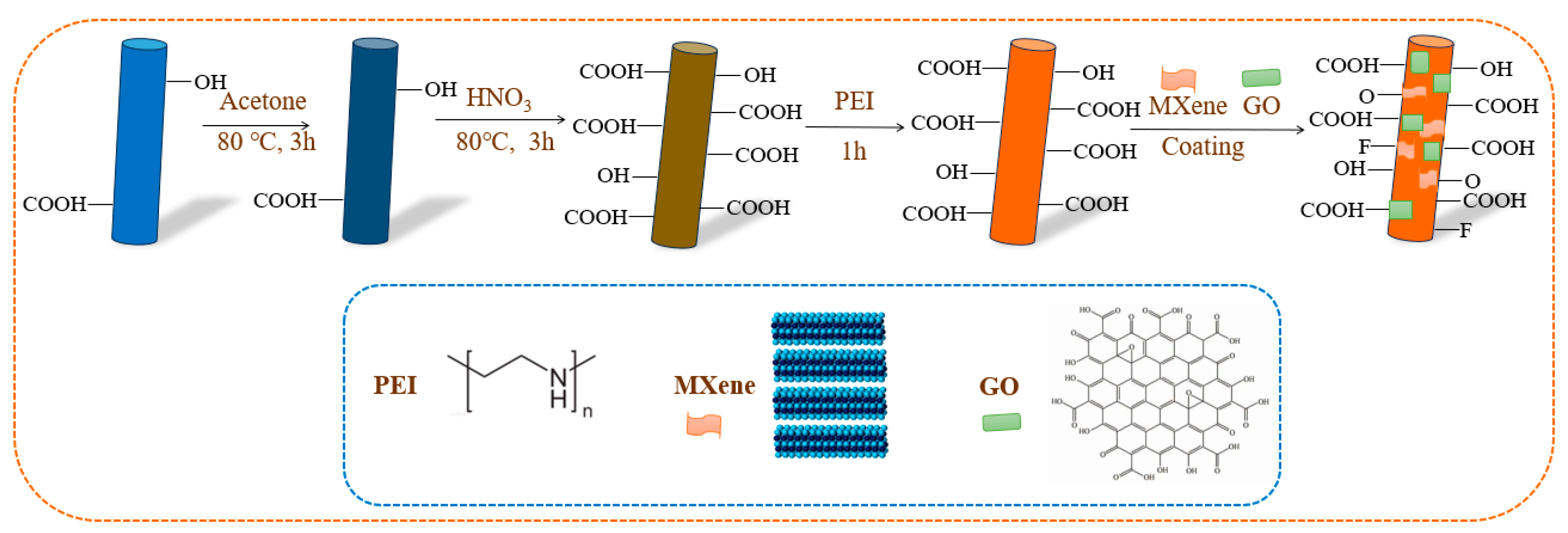

2.3. Preparation of Modified CF

2.4. Preparation of Modified CF/PLA Composite

2.5. Characterizations

3. Results and Discussion

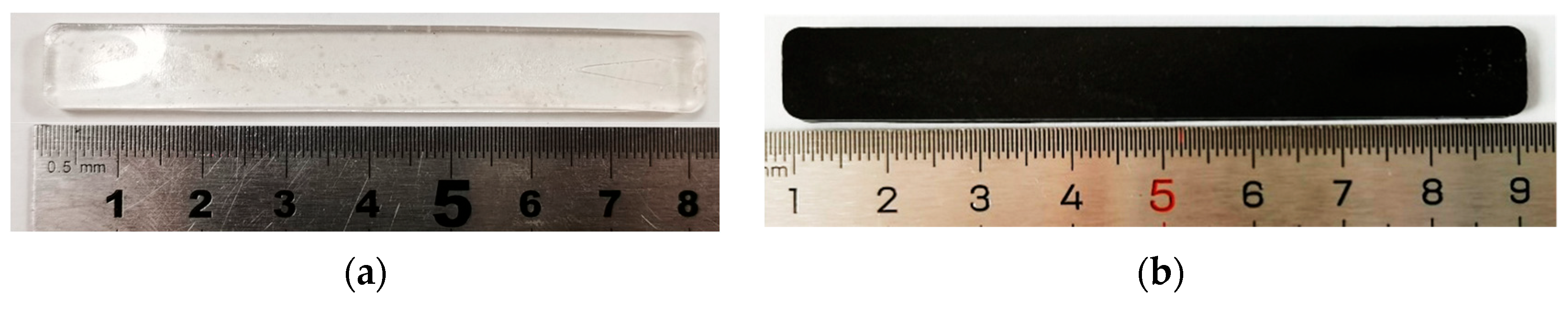

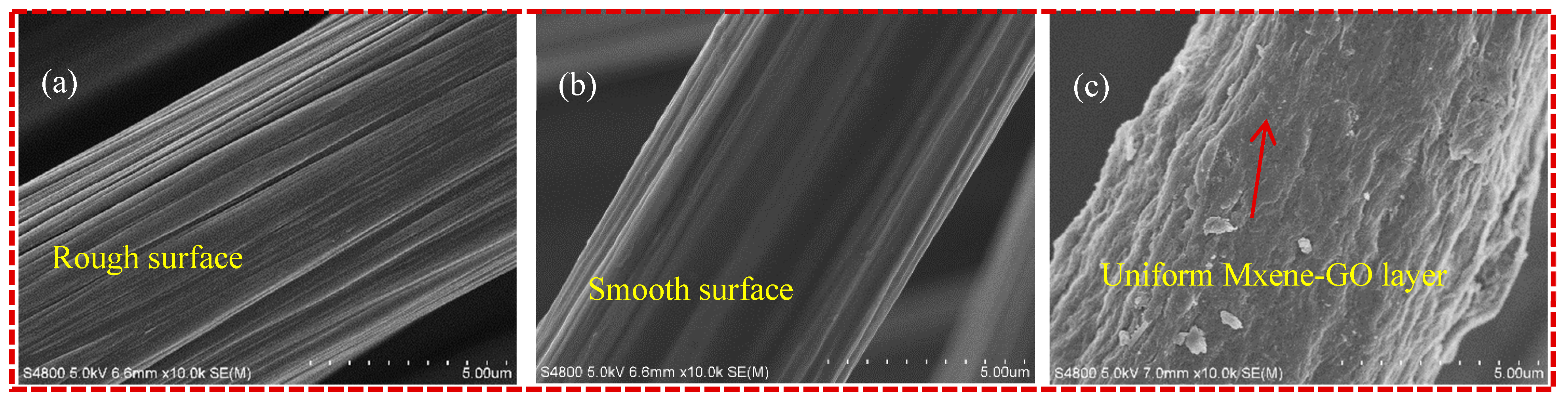

3.1. Surface Morphology of CFs

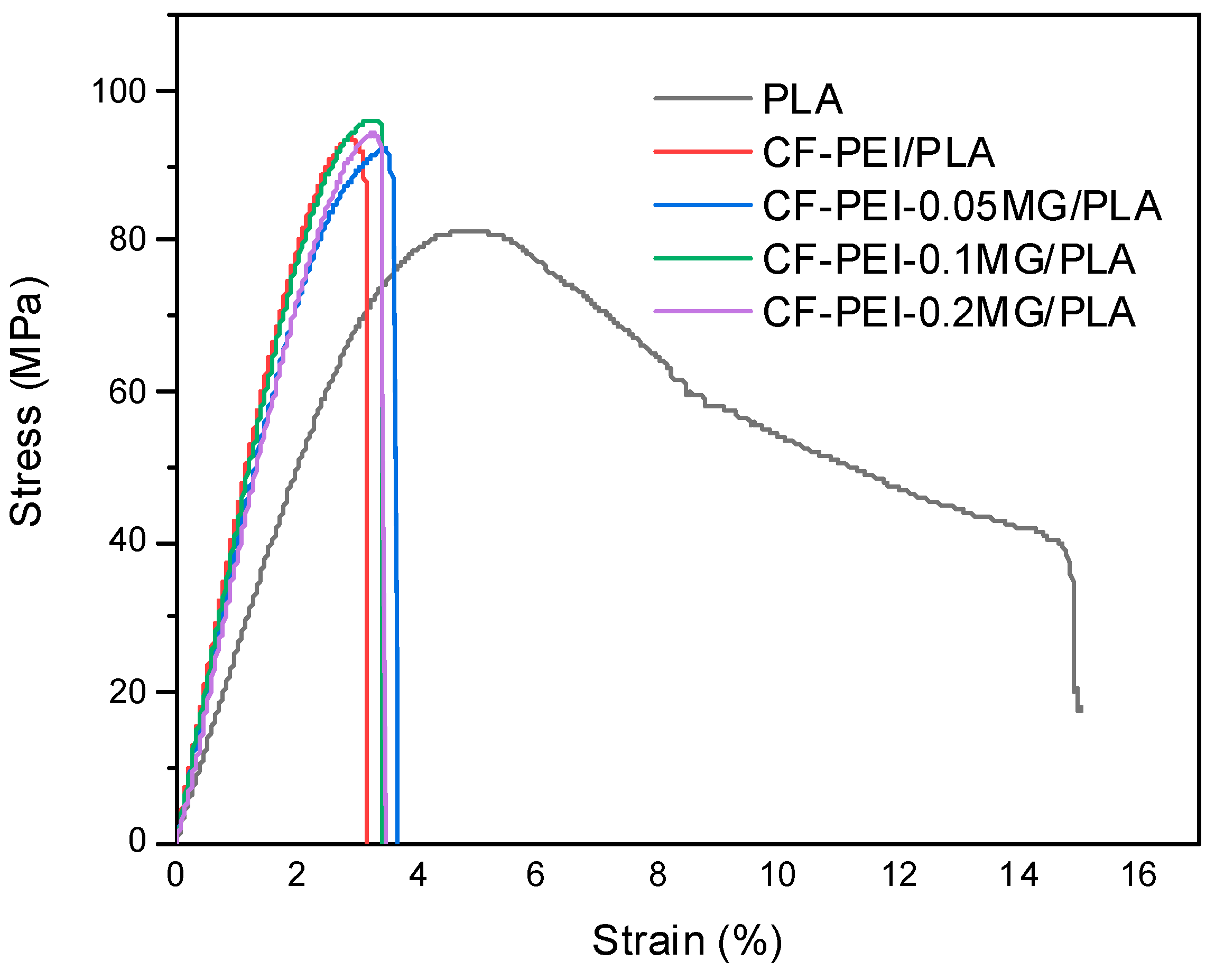

3.2. Flexural Strain–Stress Curves

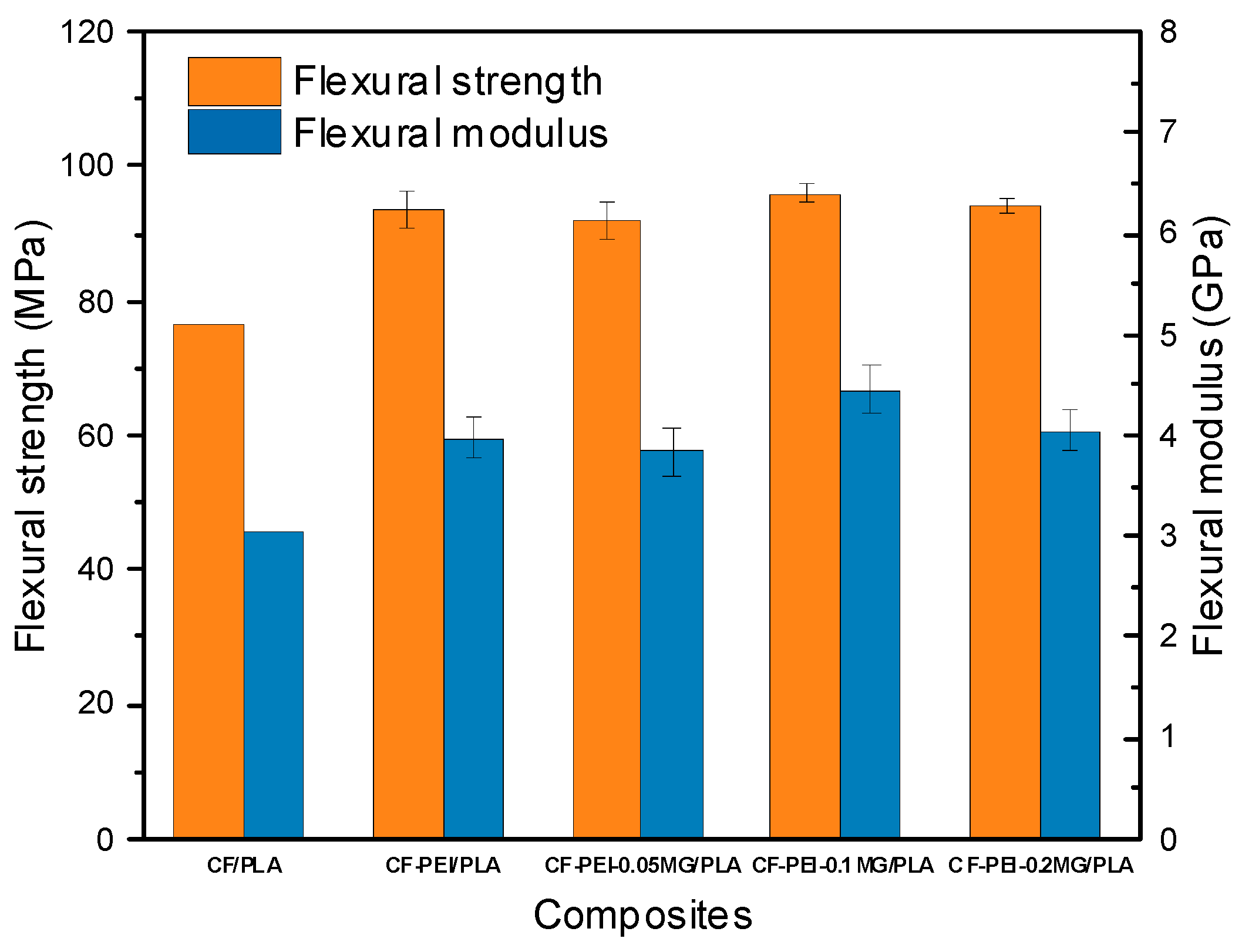

3.3. Flexural Mechanical Properties

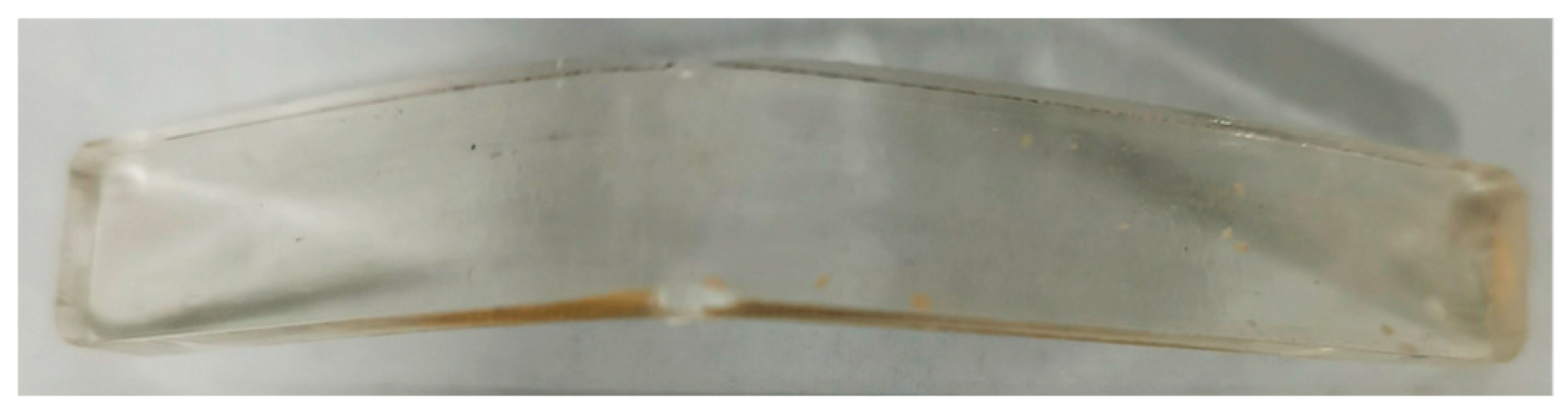

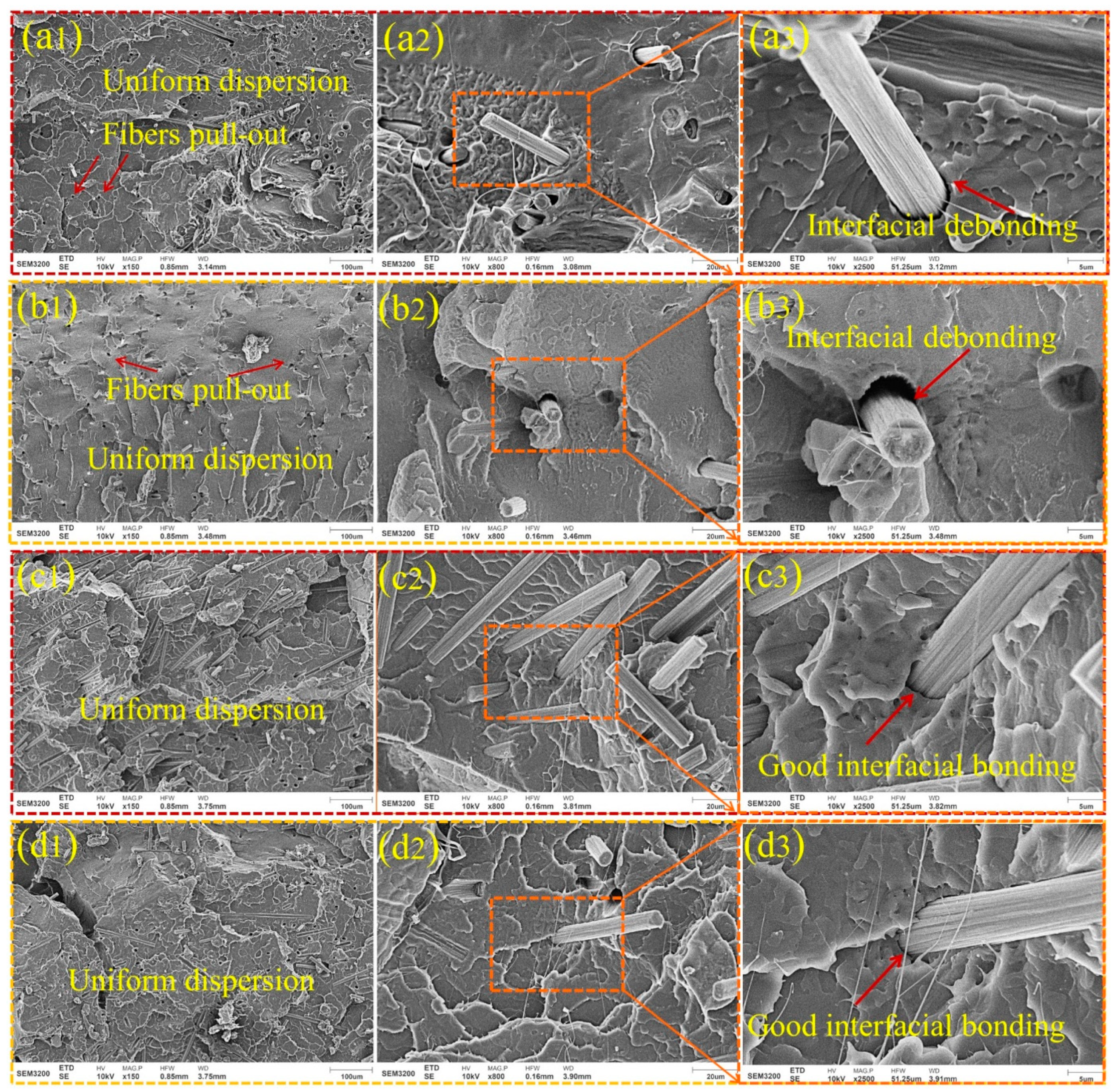

3.4. Flexural Failure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ge, J.; Catalanotti, G.; Falzon, B.G.; McClelland, J.; Higgins, C.; Jin, Y.; Sun, D. Towards understanding the hole making performance and chip formation mechanism of thermoplastic carbon fibre/polyetherketoneketone composite. Compos. Part B: Eng. 2022, 234, 109752. [Google Scholar] [CrossRef]

- Vaidya, U.; Ning, H.; Janney, M.; Mauhar, M.; Graham, K.; Streckel, M. Thermoplastic composite connecting rods. Compos. Part B Eng. 2023, 252, 110518. [Google Scholar] [CrossRef]

- Liu, P.; Zhong, Y.; Pei, Q.-X.; Sorkin, V.; Zhang, Y.-W. Simultaneously enhancing the strength and toughness of short fiber reinforced thermoplastic composites by fiber cross-linking. Compos. Sci. Technol. 2022, 217, 109076. [Google Scholar] [CrossRef]

- Tamboura, S.; Laribi, M.; Fitoussi, J.; Shirinbayan, M.; Bi, R.T.; Tcharkhtchi, A.; Ben Dali, H. Damage and fatigue life prediction of short fiber reinforced composites submitted to variable temperature loading: Application to Sheet Molding Compound composites. Int. J. Fatigue 2020, 138, 105676. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Tandon, S.; Kacker, R.; Singh, S.K. Correlations on Average Tensile Strength of 3D-Printed Acrylonitrile Butadiene Styrene, Polylactic Acid, and Polylactic Acid + Carbon Fiber Specimens. Adv. Eng. Mater. 2023, 25, 2201413. [Google Scholar] [CrossRef]

- Li, Y.; Huang, L.; Wang, X.; Wang, Y.; Lu, X.; Wei, Z.; Mo, Q.; Sheng, Y.; Zhang, S.; Huang, C.; et al. Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling. Rev. Adv. Mater. Sci. 2023, 62, 20230140. [Google Scholar] [CrossRef]

- Li, Y.; Venkateshan, K.; Sun, X.S. Mechanical and thermal properties, morphology and relaxation characteristics of poly(lactic acid) and soy flour/wood flour blends. Polym. Int. 2010, 59, 1099–1109. [Google Scholar] [CrossRef]

- Nadondu, B.; Surin, P.; Deeying, J. Mechanical Property Evaluation of Glass-carbon-durian Skin Fiber Reinforced Polylactic Acid Composites. J. Wuhan Univ. Technol. Sci. Ed. 2023, 38, 244–247. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E. Mechanical and electrical properties of polylactic acid/carbon nanotube composites by rolling process. Sci. Eng. Compos. Mater. 2018, 25, 891–901. [Google Scholar] [CrossRef]

- Dehnou, K.H.; Norouzi, G.S.; Majidipour, M. A review: Studying the effect of graphene nanoparticles on mechanical, physical and thermal properties of polylactic acid polymer. RSC Adv. 2023, 13, 3976–4006. [Google Scholar] [CrossRef]

- Chen, R.; Misra, M.; Mohanty, A.K. Injection-moulded biocomposites from polylactic acid (PLA) and recycled carbon fibre. J. Thermoplast. Compos. Mater. 2013, 27, 1286–1300. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Lian, H.-Y.; Shih, Y.-F.; Chen-Wei, S.-M. Chemically Functionalized Plant Fibers and Carbon Nanotubes for High Compatibility and Reinforcement in Polylactic Acid (PLA) Composite. J. Polym. Environ. 2017, 26, 1962–1968. [Google Scholar] [CrossRef]

- Cho, B.-G.; Lee, J.-E.; Hwang, S.-H.; Han, J.H.; Chae, H.G.; Park, Y.-B. Enhancement in mechanical properties of polyamide 66-carbon fiber composites containing graphene oxide-carbon nanotube hybrid nanofillers synthesized through in situ interfacial polymerization. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105938. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Choi, E.-J.; Lee, S.-J.; Bin Kim, H.; Oh, S.-H.; Jeong, Y.G. Roles of modified polyethylene addition and electron beam treatment on the interfacial, thermal, mechanical, and electrical properties of polyethylene/short carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107350. [Google Scholar] [CrossRef]

- Mamolo, S.U.; Sodano, H.A. Interfacial reinforcement of carbon fiber composites through a chlorinated aramid nanofiber interphase. Compos. Sci. Technol. 2024, 245, 110351. [Google Scholar] [CrossRef]

- Xu, N.; Chen, S.; Li, Y.; Jiang, N.; Zheng, T.; Goossens, N.; Vleugels, J.; Zhang, D.; Seveno, D. A hybrid 1D/2D coating strategy with MXene and CNT towards the interfacial reinforcement of carbon fiber/poly(ether ether ketone) composite. Compos. Part B Eng. 2022, 246, 110278. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, F.-L.; Li, Y.-Q.; Hu, J.-M.; Liu, Q.-X.; Mo, X.-L.; Huang, P.; Fu, S.-Y. Effects of carbon nanotube-polydopamine hybridization on the mechanical properties of short carbon fiber/polyetherimide composites. Compos. Part B: Eng. 2022, 236, 109848. [Google Scholar] [CrossRef]

- Kang, H.M.; Yoon, T.H.; Bump, M.; Riffle, J.S. Effect of solubility and miscibility on the adhesion behavior of polymer-coated carbon fibers with vinyl ester resins. J. Appl. Polym. Sci. 2001, 79, 1042–1053. [Google Scholar] [CrossRef]

- Zhu, P.; Shi, J.; Bao, L. Effect of polyetherimide nanoparticle coating on the interfacial shear strength between carbon fiber and thermoplastic resins. Appl. Surf. Sci. 2020, 509, 145395. [Google Scholar] [CrossRef]

- Bianchi, I.; Mancia, T.; Mignanelli, C.; Simoncini, M. Effect of nozzle wear on mechanical properties of 3D printed carbon fiber-reinforced polymer parts by material extrusion. Int. J. Adv. Manuf. Technol. 2024, 130, 4699–4712. [Google Scholar] [CrossRef]

- Bright, B.M.; Binoj, J.S.; Abu Hassan, S.; Wong, W.L.E.; Suryanto, H.; Liu, S.; Goh, K.L. Feasibility study on thermo-mechanical performance of 3D printed and annealed coir fiber powder/polylactic acid eco-friendly biocomposites. Polym. Compos. 2024, 1–13. [Google Scholar] [CrossRef]

- Jain, R.; Goomer, S. Understanding extrusion technology for cereal–pulse blends: A review. Cogent Food Agric. 2023, 9, 2253714. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Herrera-Carmona, V.S.; Gonzalez-García, Y.; del Campo, A.S.M.; González-López, M.E.; Ramírez-Arreola, D.E.; Robledo-Ortíz, J.R. Influence of the blending method over the thermal and mechanical properties of biodegradable polylactic acid/polyhydroxybutyrate blends and their wood biocomposites. Polym. Adv. Technol. 2021, 32, 3483–3494. [Google Scholar] [CrossRef]

- Czepiel, M.; Bańkosz, M.; Sobczak-Kupiec, A. Advanced Injection Molding Methods: Review. Materials 2023, 16, 5802. [Google Scholar] [CrossRef]

- Kumar, S.; Dang, R.; Manna, A.; Dhiman, N.K.; Sharma, S.; Dwivedi, S.P.; Kumar, A.; Li, C.; Tag-Eldin, E.M.; Abbas, M. Optimization of chemical treatment process parameters for enhancement of mechanical properties of Kenaf fiber-reinforced polylactic acid composites: A comparative study of mechanical, morphological and microstructural analysis. J. Mater. Res. Technol. 2023, 26, 8366–8387. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Meng, W.; Jiang, L.; Fang, D. Scalable, superelastic, and superhydrophobic MXene/silver nanowire/melamine hybrid sponges for high-performance electromagnetic interference shielding. J. Mater. Chem. C 2022, 10, 5336–5344. [Google Scholar] [CrossRef]

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Hong, H.; Mingxing, Z.; Fangueiro, R.; De Araujo, M. Mechanical Properties of Composite Materials Made of 3D Stitched Woven-knitted Preforms. J. Compos. Mater. 2010, 44, 1753–1767. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Srikanth, N.; Liu, T.; Chai, G.B. Quantification of flexural fatigue life and 3D damage in carbon fibre reinforced polymer laminates. Compos. Part A Appl. Sci. Manuf. 2016, 90, 778–785. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Delamination observation occurred during the flexural bending in additively manufactured PLA-short carbon fiber filament reinforced with continuous carbon fiber composite. Results Eng. 2021, 11, 100246. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of carbon fiber reinforced PLA composites manufactured by fused deposition modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Feng, P.; Ma, L.; Zhou, X.; Li, M.; Zhang, Q.; Zhang, M.; Liu, X.; Jian, X.; Xu, J. Constructing a gradient modulus interface layer on the surface of carbon fibers to enhance the mechanical properties of carbon fiber/epoxy composites at different temperatures. Compos. Part B Eng. 2024, 271, 111190. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Li, C. Polyamide 6 composite with highly improved mechanical properties by PEI-CNT grafted glass fibers through interface wetting, infiltration and crystallization. Polymer 2019, 172, 253–264. [Google Scholar] [CrossRef]

- Pu, Y.; Ma, Z.; Liu, L.; Bai, Y.; Huang, Y. Improvement on strength and toughness for CFRPs by construction of novel “soft-rigid” interface layer. Compos. Part B Eng. 2022, 236, 109846. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Li, C. The combined effect of impregnated rollers configuration and glass fibers surface modification on the properties of continuous glass fibers reinforced polypropylene prepreg composites. Compos. Sci. Technol. 2020, 197, 108259. [Google Scholar] [CrossRef]

| Composites | Flexural Strength (MPa) | Flexural Modulus (GPa) | Fracture Strain (%) | References |

|---|---|---|---|---|

| CF/PLA | 76.33 | 3.06 | - | [33] |

| CF-PEI/PLA | 93.67 | 3.98 | 3.01 | In this work |

| CF-PEI-0.05MG/PLA | 92.12 | 3.85 | 3.48 | In this work |

| CF-PEI-0.1MG/PLA | 96.12 | 4.45 | 3.41 | In this work |

| CF-PEI-0.2MG/PLA | 94.28 | 4.05 | 3.31 | In this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, S.-C.; Xiang, D.-W.; Gao, M.; Zuo, H.-M.; Li, D.-S. Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO. Materials 2024, 17, 1389. https://doi.org/10.3390/ma17061389

Wang X, Li S-C, Xiang D-W, Gao M, Zuo H-M, Li D-S. Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO. Materials. 2024; 17(6):1389. https://doi.org/10.3390/ma17061389

Chicago/Turabian StyleWang, Xu, Shao-Cong Li, Duo-Wen Xiang, Min Gao, Hong-Mei Zuo, and Dian-Sen Li. 2024. "Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO" Materials 17, no. 6: 1389. https://doi.org/10.3390/ma17061389

APA StyleWang, X., Li, S.-C., Xiang, D.-W., Gao, M., Zuo, H.-M., & Li, D.-S. (2024). Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO. Materials, 17(6), 1389. https://doi.org/10.3390/ma17061389