A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions

Abstract

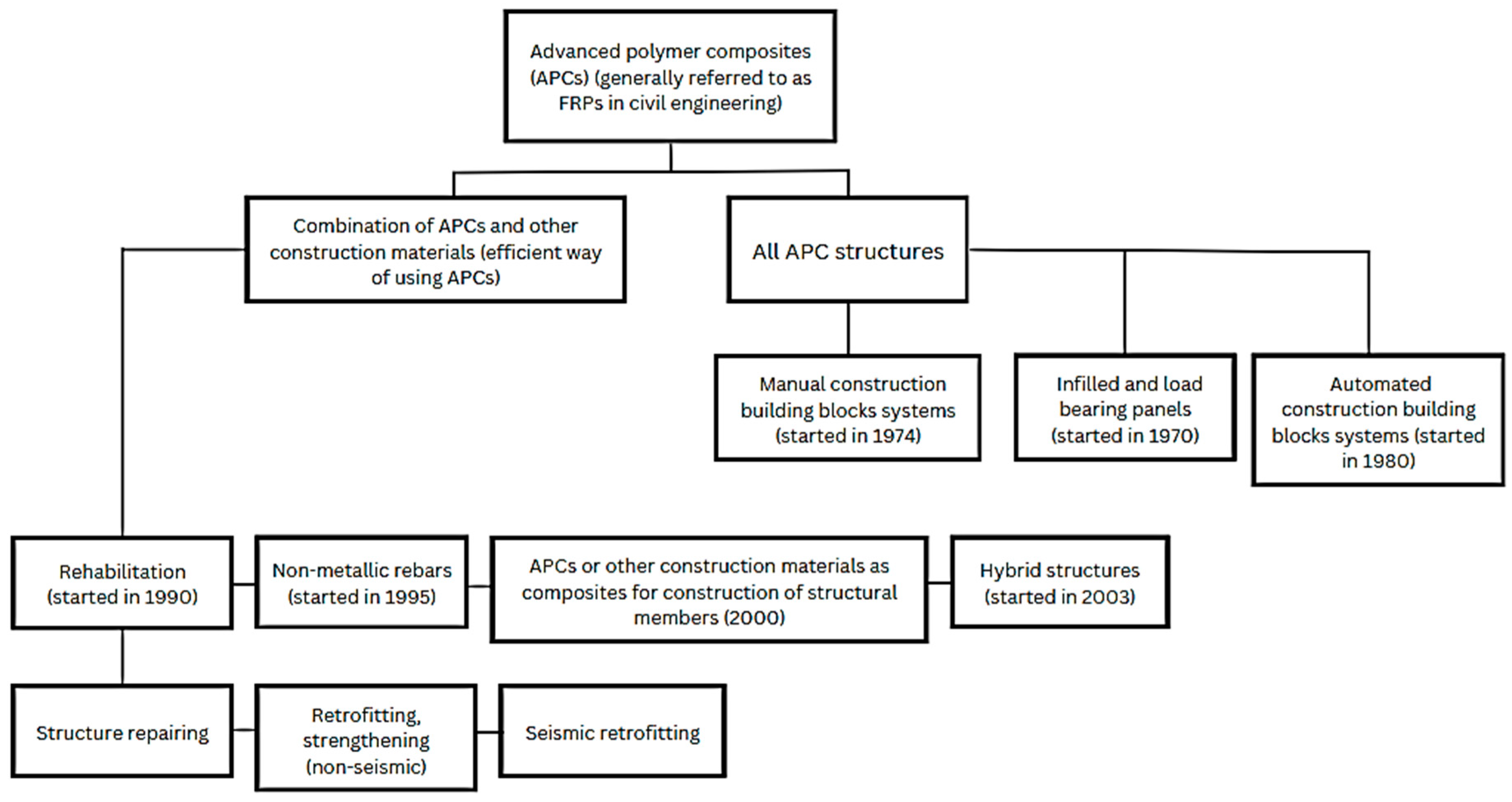

:1. Introduction

2. Various FRP Materials

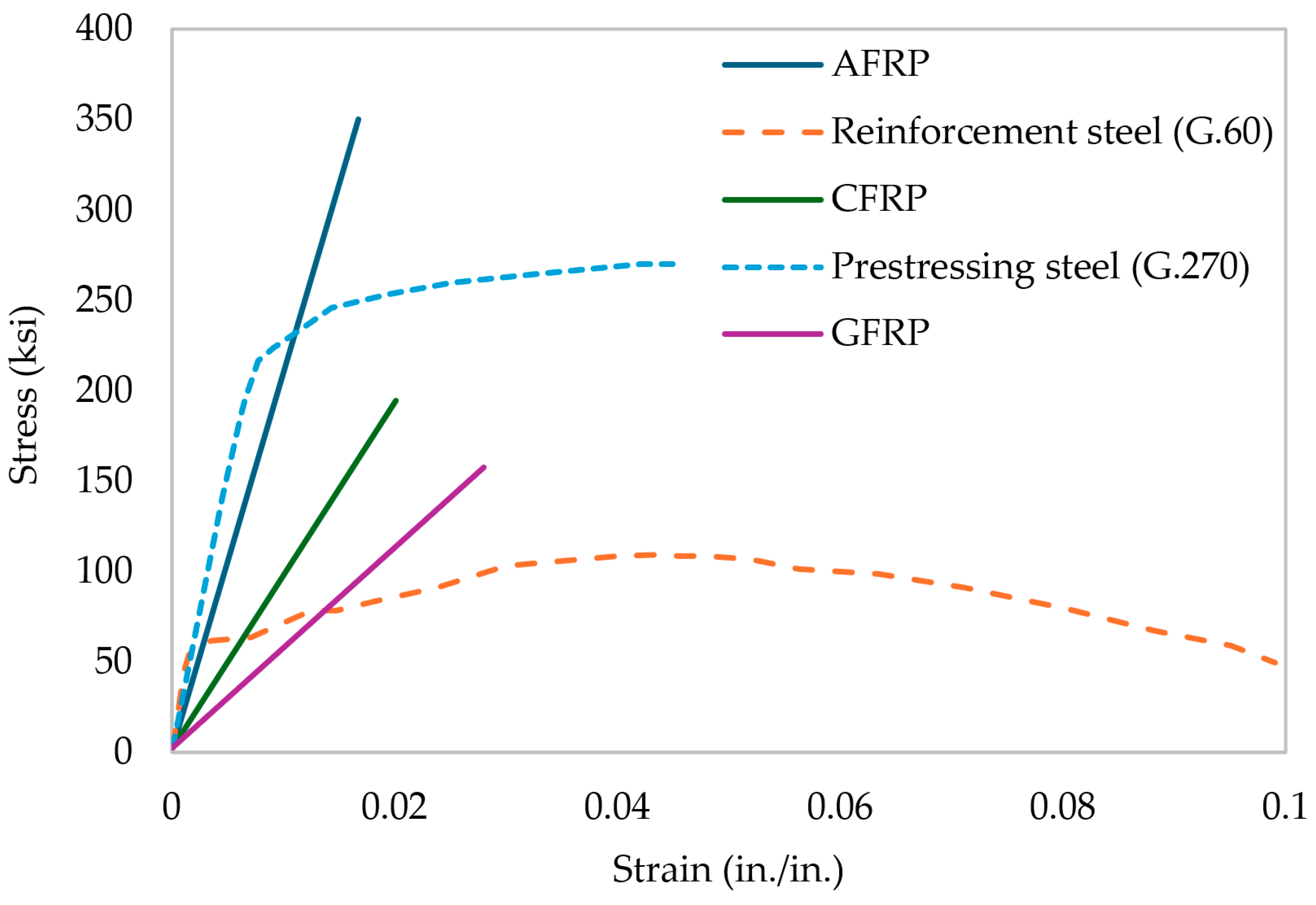

3. Physical Properties

3.1. Strength-to-Weight Ratio

3.2. Density

4. Mechanical Properties

4.1. Shear Strength

4.2. Flexural Strength

| Author | Ref. | Considered Parameters |

|---|---|---|

| Arduini et al. | [143] |

|

| Ritchie et al. | [144] |

|

| ||

| Arduini et al. | [145] |

|

| ||

| He et al. | [146] |

|

| David et al. | [147] |

|

| ||

| Gangarao and Vijay | [148] |

|

| ||

| ||

| Spadea et al. | [149] |

|

| Garden et al. | [8] |

|

| ||

| Ross et al. | [150] |

|

| ||

| Davies et al. | [45] |

|

| ||

| Mastali and Dalvand | [135] |

|

| ||

| Park and Jang | [131] |

|

|

5. Functional Properties

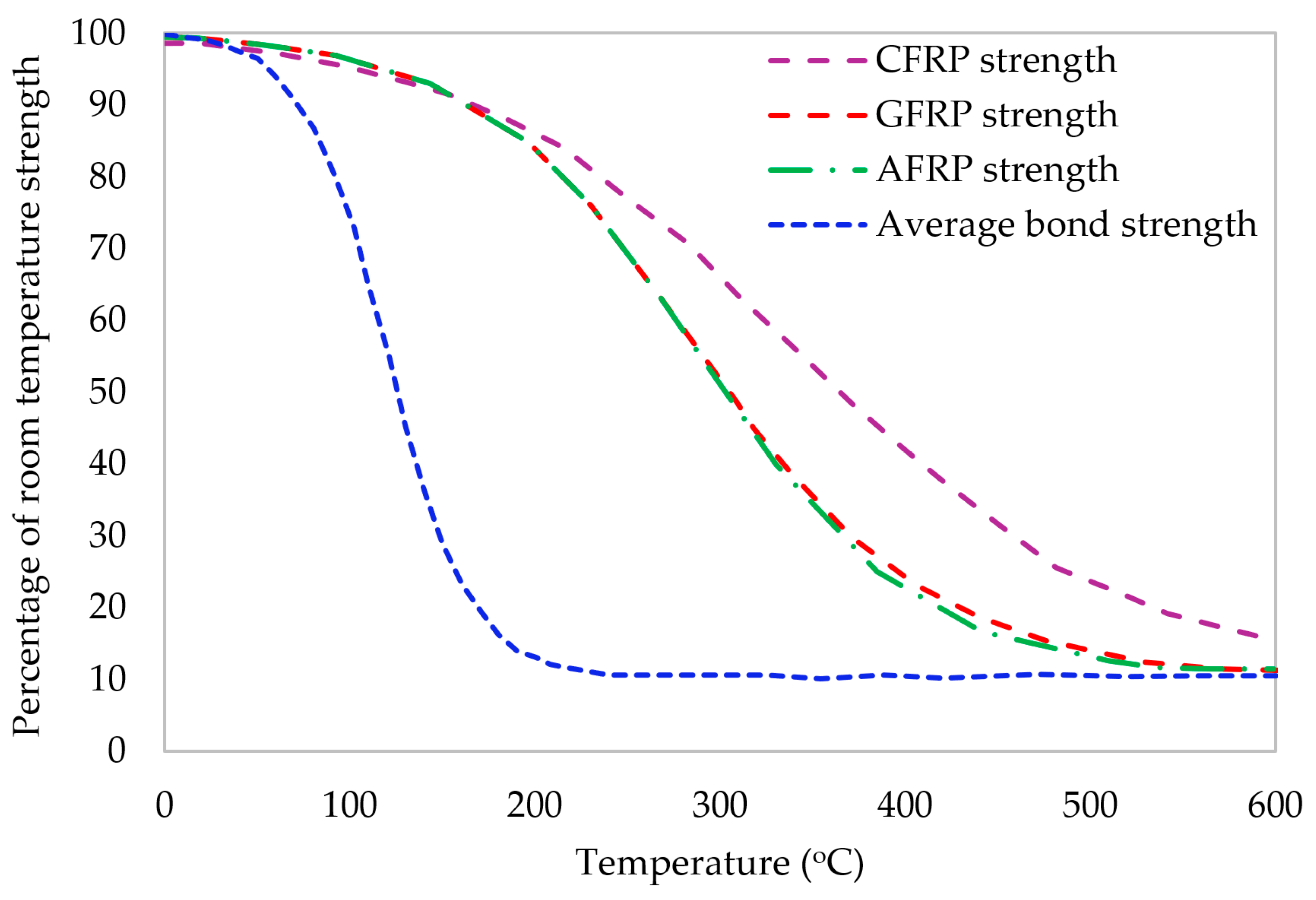

5.1. Temperature Effect

5.2. Fire Resistance

6. Strengthening Techniques

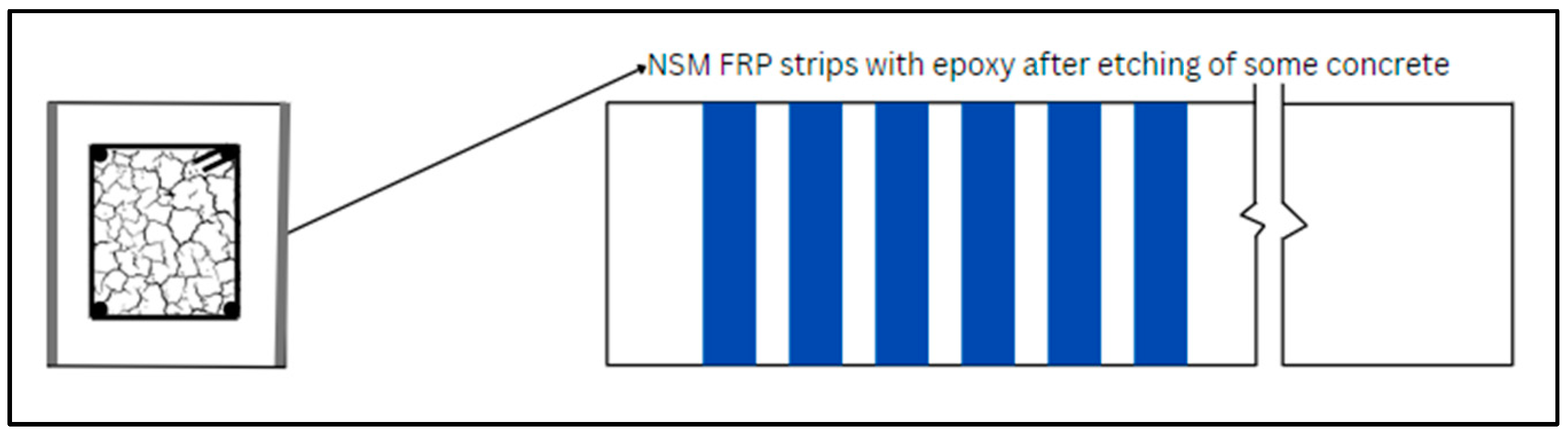

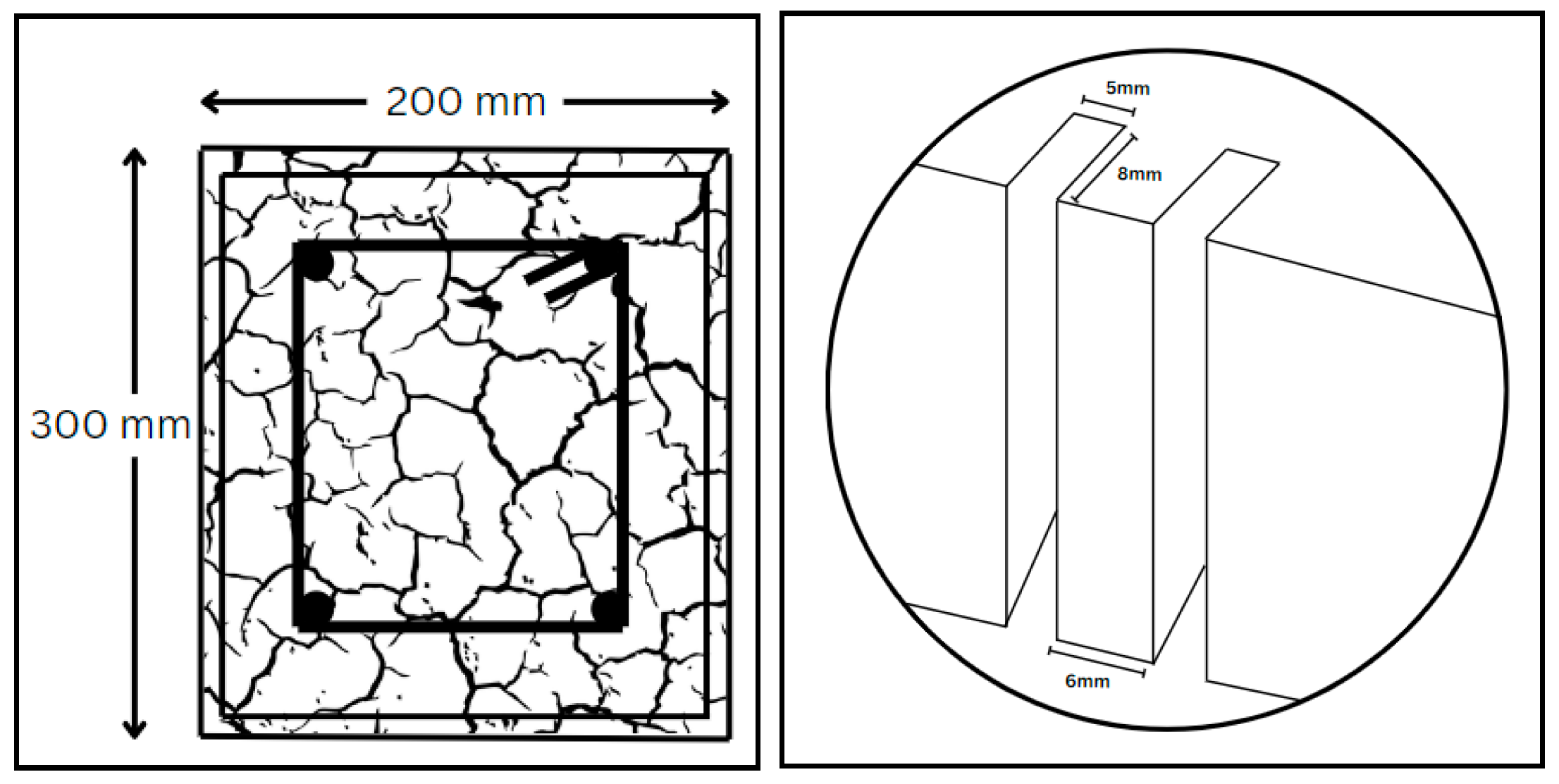

6.1. NSM

| Author | Specimen | FRP | Ref. | FRP Type | Main Finding |

|---|---|---|---|---|---|

| Palmieri et al. | 12 samples | CFRP/GFRP | [30] | Strips/ rebars | Under full-service load, 12 beams that were insulated with different systems and reinforced with NSM FRP bars were exposed to fire. The results showed that well-insulated components maintained some of their initial flexural capacity after fire exposure and that insulated NSM FRP strengthened beams can withstand fire for at least two hours. |

| Wang et al. | 20 samples | BFRP/ CFRP | [187] | Bars | Two anchorage systems, ARs and WML, were used in this study to stop premature debonding during NSM FRP strengthening. Using ARs increased the bond strength by 40.7%, WML by 69.7%, and the combined application of both by 114.3%, according to a pullout test on 20 samples. |

| Zhang et al. | 13 samples | CFRP/GFRP | [188] | Bars | Three control samples and ten RC T-beam samples with NSM FRP bars were examined. Failure mechanism, fracture resistance, yielding, ultimate capacity, flexural stiffness, and ductility were all studied. The flexural stiffness of strengthened samples often increases, according to the results, especially after the yielding stage. The results of experiments are compared to analytical predictions of the flexural strength, and a parameter for the flexural stiffness prediction model is proposed to account for decreases in the FRPs’ effective area when calculating the strength of the section. |

| Hassan and Rizkalla | 9 samples | CFRP | [190] | Bars/sheet | Half-scale samples of pre-stressed concrete beams fortified with CFRP were tested. The tests revealed a 50% increase in both the stiffness and strength of the beams. The strength increment was affected by the type and layout of CFRP sheets/bars. Moreover, the study compared the economic aspect of several FRP systems, indicating that the overall cost of using CFRP sheets was approximately 25% cheaper than utilizing NSM rebars. |

| Ceroni et al. | 21 samples | CFRP | [22] | Bars/ plates | Flexural tests were conducted on multiple concrete beams strengthened with both NSM bars and CFRP plates. The results demonstrated the effectiveness of FRP when externally bonded as sheets and/or used as NSM rebars. In beams fortified with CFRP sheets, the increment in failure load ranged from 18% to 50%, depending on the steel reinforcement ratio, but this increment was accompanied by a significant decrement in the ductility. Conversely, using an NSM system improved both the ultimate load capacity and ductility (by 45–70%) and suggested that CFRP sheets strengthened beams could achieve sufficient ductility by employing U-sheets. |

| El-Gamal et al. | 10 samples | CFRP/GFRP | [191] | Hybrid (plates/bars) | Ten RC beams were cast and strengthened in flexure using various FRPs. All the beams exhibited an increase in the flexural capacity ranging from 30% to 133%. CFRP-strengthened beams attained the highest ultimate loads compared to those strengthened with GFRP sheets, while GFRP-strengthened beams displayed more ductile behavior. The test results obtained were according to predictions from ACI 440 provisions. |

| Al Bayati et al. | 6 samples | CFRP | [192] | Bars | To evaluate the increase in the torsional strength achieved by various NSM FRP configurations and epoxies, six concrete members underwent testing. Based on the results, the ultimate torsional capacity of the beams increased by roughly 22–31% when the epoxy-based bonding material was utilized, and by 13–16% when the cement-based bonding agent was used. Furthermore, the study showed that while the torsional improvement of fully wrapped (closed) beams was greater than that of open (U)-wrapped concrete beams, in certain situations the adoption of a U-shaped strengthening plan might be more advantageous. |

| Yu and Kodur | 4 samples | CFRP | [193] | Bars | Four concrete T-beams, strengthened with NSM FRP, were subjected to fire exposure and service loading conditions. The results of the fire tests illustrated that NSM CFRP-strengthened beams can achieve a fire resistance of 3 h under fire exposure, even without any fire insulation. |

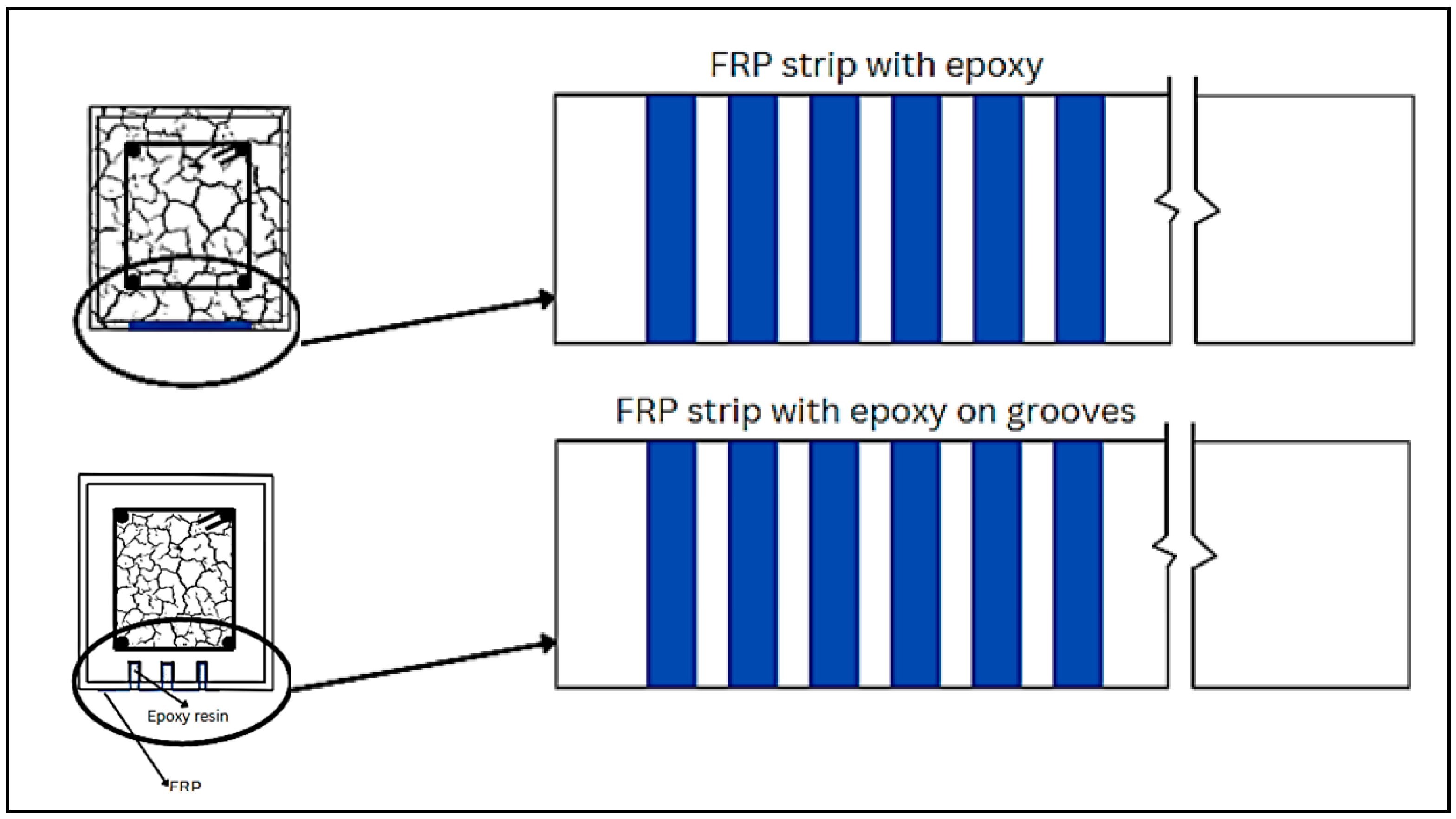

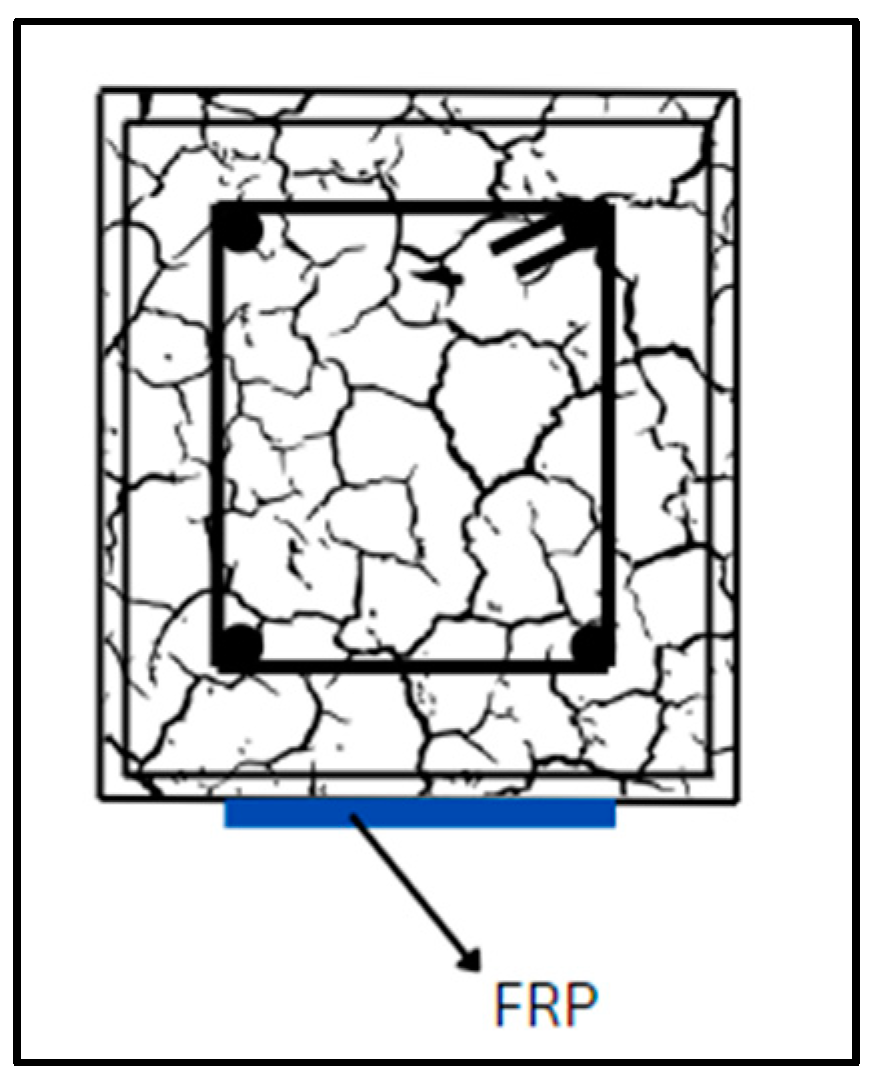

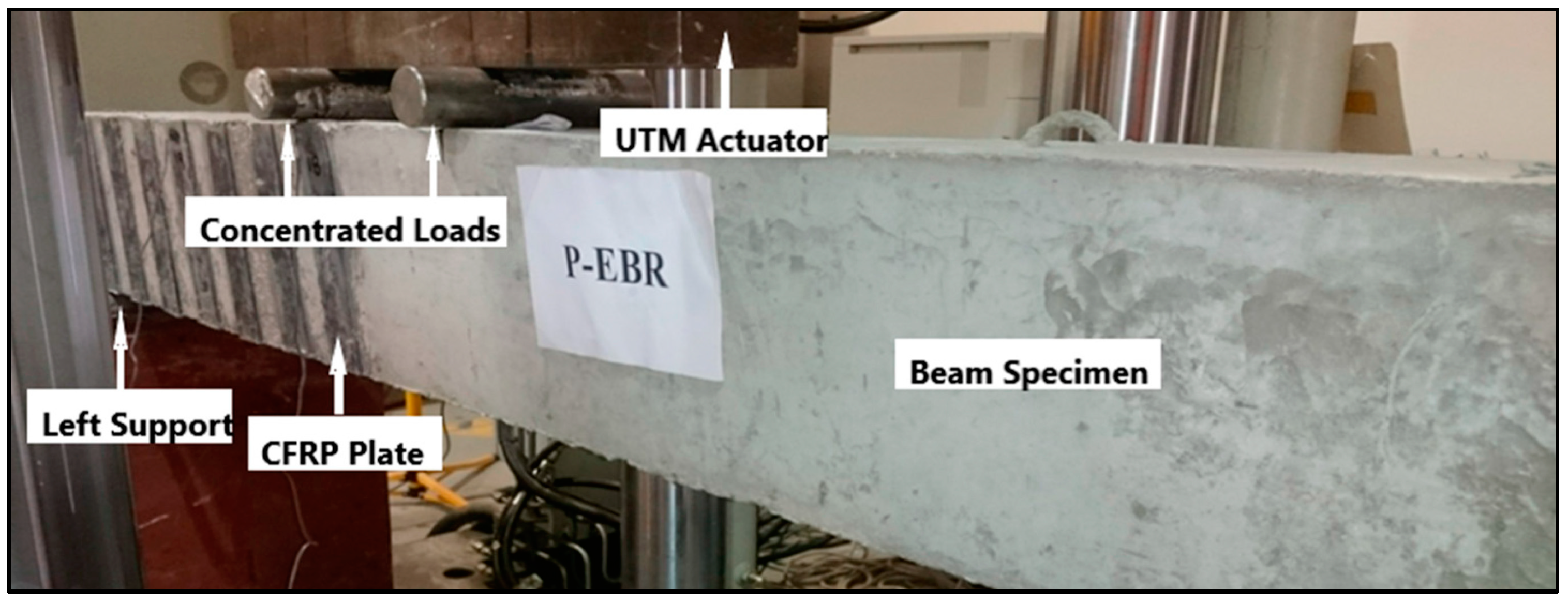

6.2. EBR and EBROG

| Author | Sample | FRP | Ref. | FRP Type | Main Finding |

|---|---|---|---|---|---|

| Gamage et al. | 10 | CFRP | [204] | Sheets | This study evaluated issues related to the bond performance at elevated temperatures using a shear test method. The experimental program measured the bond strength at increasing epoxy temperatures, revealing a rapid loss of the strength beyond 60 °C. |

| Sabzi et al. | 8 | CFRP | [38] | Sheets/bars | This investigation assessed the influence of reinforcement arrangement and concrete strength. The findings demonstrated that conventional concrete beams strengthened with the EBR and EBROG methods exhibit FRP debonding and concrete spalling failure modes, respectively. Conversely, in HSC beams, both the EBR and EBROG methods resulted in FRP debonding failure mode. Moreover, HSC specimens treated with the EBROG method displayed a noticeable increase in the ultimate load-carrying capacity and mid-span deflection compared to the EBR method. |

| Torabian et al. | 5 | CFRP | [205] | Sheets | The EBROG technique effectively delays debonding. Compared to EBR, EBROG increases the load capacity by 35% when FRP sheets are attached to the joint and by 15% when bonded away from the joint. Debonding strains are substantially higher in EBROG. |

| Moghaddas and Mostofinejad | 154 | GFRP | [201] | Sheets | Debonding failure is observed in all specimens, illustrating the excellence of EBROG over EBR. An average enhancement of 30% in the bond strength and postponed debonding is achieved with the EBROG method. |

| Mostofinejad and Kashani | 32 | CFRP | [207] | Sheets | The results revealed that while surface preparation does not entirely prevent debonding, it can delay it, leading to an increase in beam-carrying loads of up to 12%. Additionally, the grooving method outperforms surface preparation, as none of the beam specimens strengthened using this method experienced FRP strip detachment. This resulted in the disappearance of shear weaknesses, making the flexural failure the dominant mode. |

| Mostofinejad et al. | 20 | CFRP | [208] | Sheets | The effectiveness of the EBR, EBROG, and EBRIG methods in flexural strengthening of RC beams was comparable with a single layer of FRP sheet. However, with two FRP layers, beams strengthened utilizing the grooving method in the form of both the EBROG and EBRIG techniques exhibited up to 25% higher peak loads compared to the EBR method. In addition, with three FRP layers, the increase was 20% and 25% for the EBROG and EBRIG strengthening techniques, respectively, compared to the EBR method. |

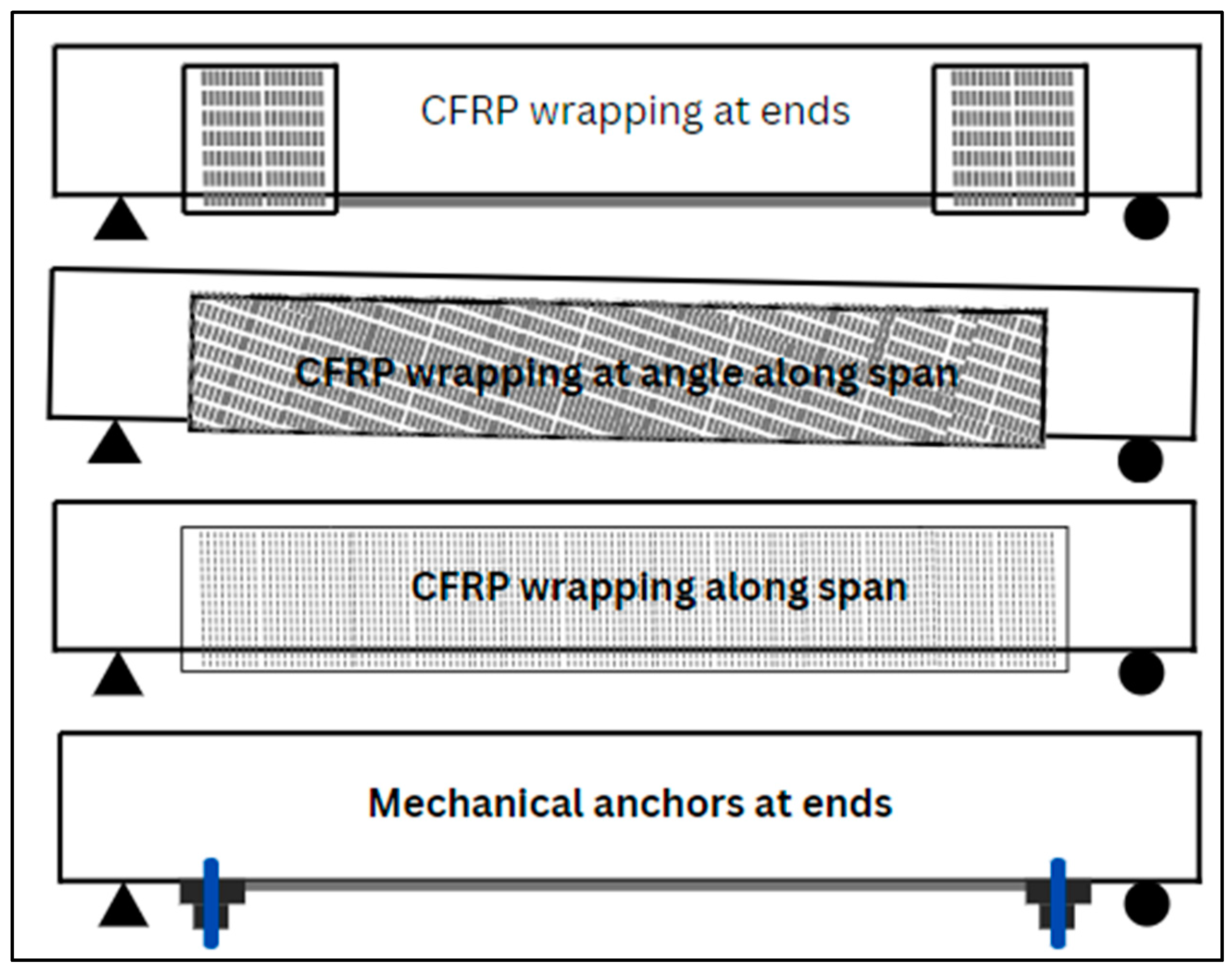

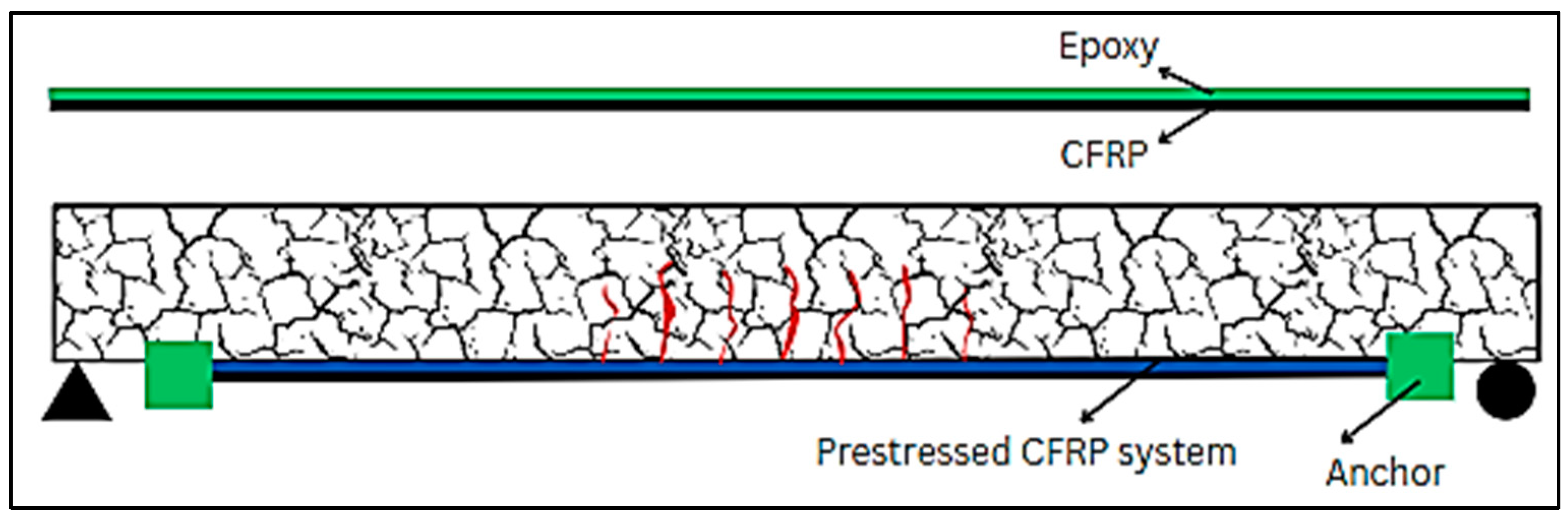

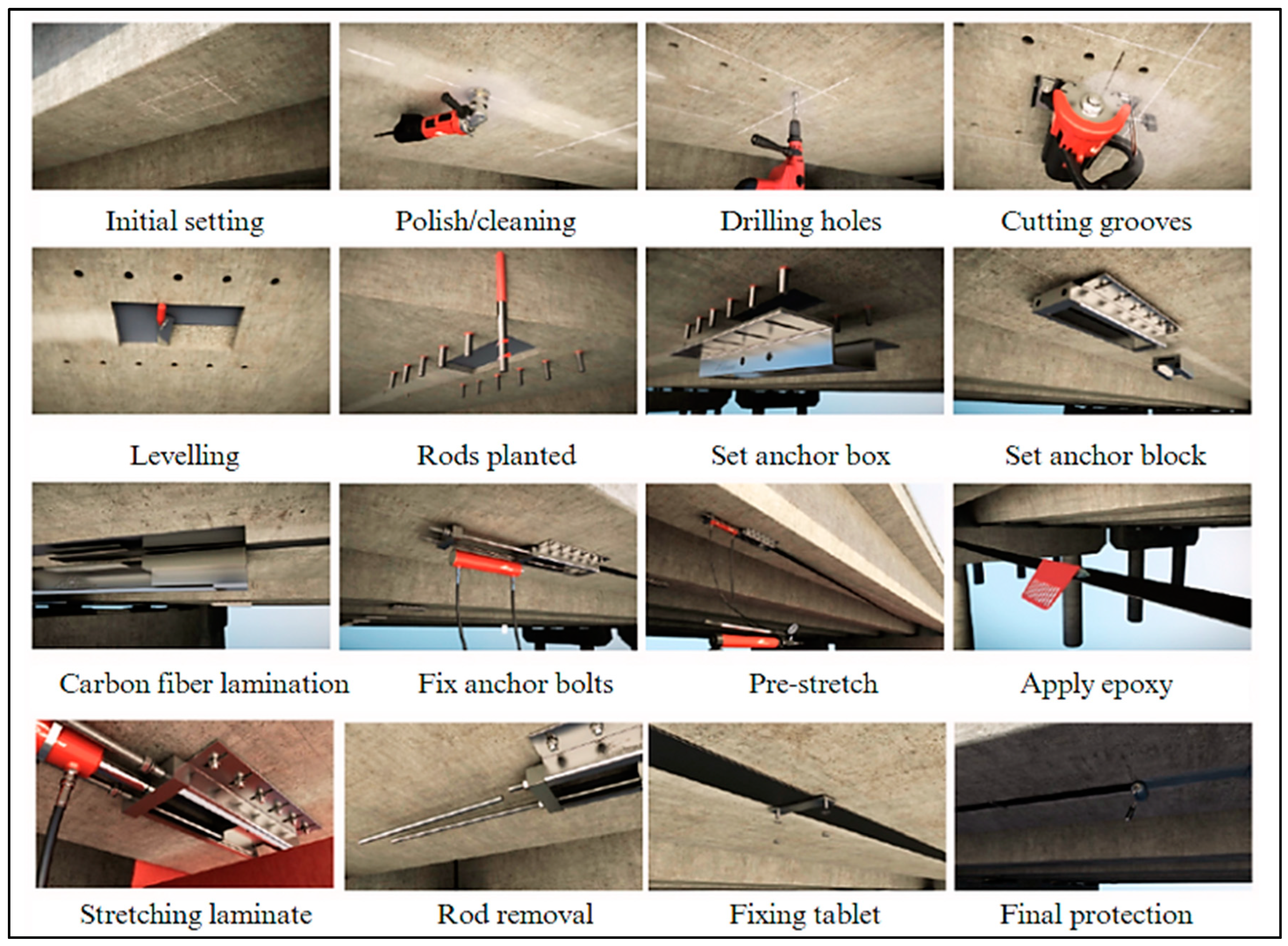

6.3. EP

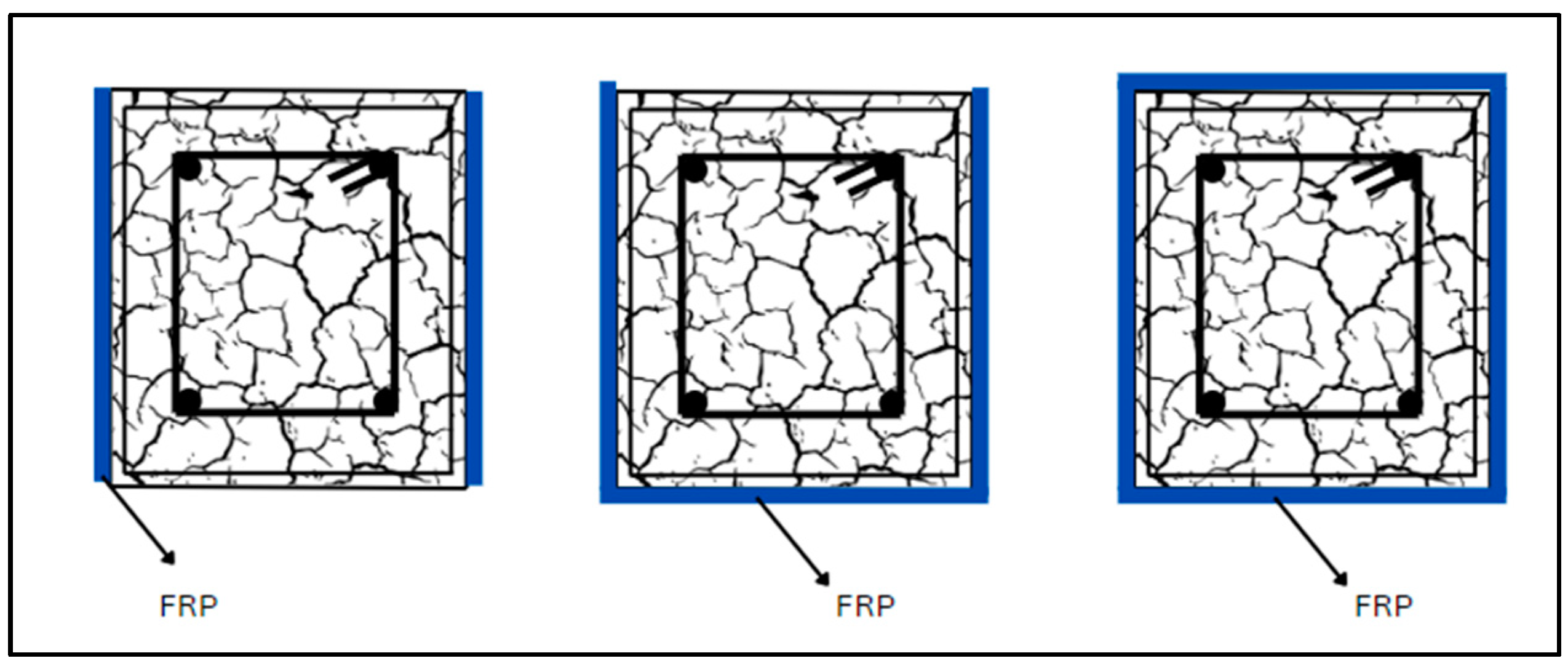

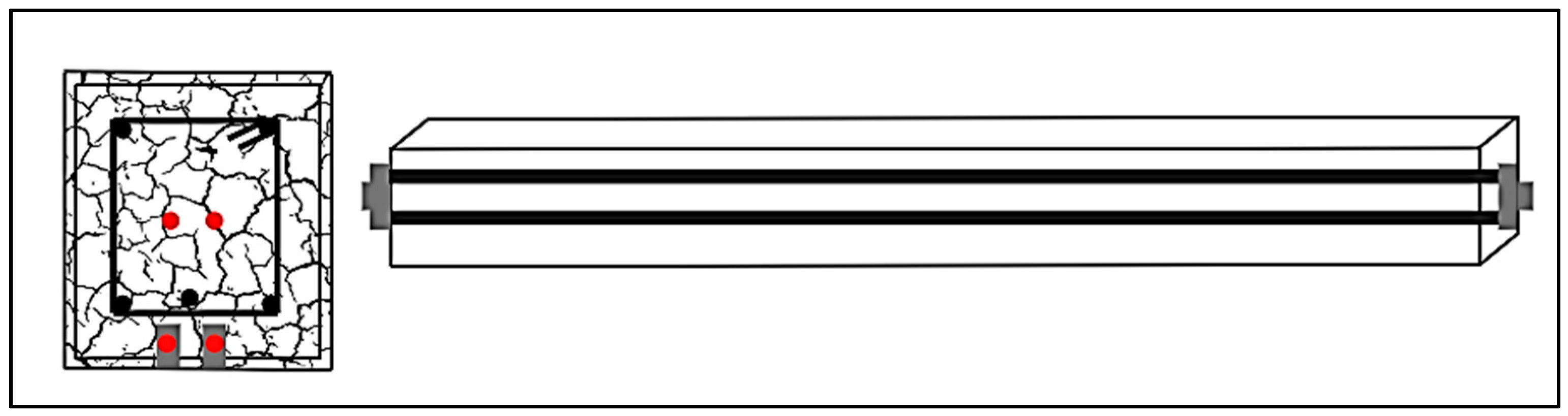

6.4. SC

7. Future Research Directions

- Numerical/Analytical Study

- As discussed earlier, there is a huge gap in the research on the enhancement of stress–strain models for FRP-confined concrete such as confined concrete in CSC. The existing design-oriented stress–strain models available can underestimate the ultimate strength of confined concrete in CSCs. Furthermore, predictive machine learning models can be trained to make the work easier.

- Detailed numerical analysis is required for the validation of all the structural strengthening techniques discussed above for better applicability and acceptance of the methods.

- Long-Term Behavior of FRP

- Although many studies that evaluate the short-term performance of FRP-strengthened concrete under different conditions are available, the long-term behavior and performance of FRP-strengthened concrete are still to be studied. Advanced structural health monitoring techniques (sensing devices) should be applied to the FRP-strengthened members to assess their long-term behavior.

- Environmental Aspects

- Various studies [87,88,98] have explored the durability of FRPs, yet the combined impact of particularly harsh environmental conditions in wastewater treatment plants, chemical plants, and nuclear plants has not been thoroughly investigated. These conditions can be direct exposure to UV rays, temperature fluctuations, freeze–thaw cycles, and exposure to acidic–alkaline environments. Therefore, there is a need to assess the durability of FRP-strengthened RC structures under the simultaneous influence of these challenging conditions.

- Additional research into the life cycle assessment of different strengthening techniques using various FRPs is necessary for evaluating environmental performance and enhancing future strengthening methods.

- To keep the environment clean, research on green alternatives to traditional polymer matrices like epoxy and polyester is crucial. These alternatives can remarkably reduce the environmental effects related to significant energy inputs in the manufacturing process and the potential toxicity of conventional polymers.

- Structural Testing and Design

- There are several research limitations and challenges in every strengthening technique when subjected to combined loadings such as fatigue, cyclic loading, seismic events, and impacts. Conducting research that considers these coupled loading conditions would be valuable for the practical application of FRP strengthening techniques in real-world scenarios.

- A very limited number of studies with other types of FRPs such as BFRP and AFRP are available. A comparative study of structural strengthening methods utilizing various types of FRP material can result in a more economical, sustainable, and safer structure. Additionally, there is a research gap in the torsional behavior of FRP-strengthened members which must be filled to properly examine their performance under different conditions.

- For some new strengthening methods, the accurate design procedures have not been clearly defined. Some common challenges are anchorages, member and material interface differences, step differences between the member and anchorage, and variations in material properties among different manufacturers. Future research must collect and use more precise data from design and building sites to address these concerns.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramezanianpour, A.; Jovein, H.B. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Singh, N.B. Fly ash-based geopolymer binder: A future construction material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef]

- Hussain, F.; Rehman, F.; Khushnood, R.A.; Khan, S.A.; Hamza, A. Study of physical and mechanical behavior of artificial lightweight aggregate made of Pakistani clays. Constr. Build. Mater. 2023, 378, 131103. [Google Scholar] [CrossRef]

- Khan, S.A.; Ghazi, S.M.U.; Amjad, H.; Imran, M.; Khushnood, R.A. Emerging horizons in 3D printed cement-based materials with nanomaterial integration: A review. Constr. Build. Mater. 2024, 411, 134815. [Google Scholar] [CrossRef]

- Malik, U.J.; Khokhar, S.A.; Hammad, M.; Khushnood, R.A.; Najam, F.A.; Ali, F.; Shahid, M. ANN-based predictive mimicker for the constitutive model of engineered cementitious composites (ECC). Constr. Build. Mater. 2024, 420, 135530. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Garden, H.; Hollaway, L. An experimental study of the influence of plate end anchorage of carbon fibre composite plates used to strengthen reinforced concrete beams. Compos. Struct. 1998, 42, 175–188. [Google Scholar] [CrossRef]

- Jameel, M.T.; Sheikh, M.N.; Hadi, M.N. Behaviour of circularized and FRP wrapped hollow concrete specimens under axial compressive load. Compos. Struct. 2017, 171, 538–548. [Google Scholar] [CrossRef]

- Lu, X.; Chen, J.; Ye, L.; Teng, J.; Rotter, J. RC beams shear-strengthened with FRP: Stress distributions in the FRP reinforcement. Constr. Build. Mater. 2009, 23, 1544–1554. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; Kang, L.; Sun, G.; Li, Q. An experimental study on fatigue characteristics of CFRP-steel hybrid laminates. Mater. Des. 2015, 88, 643–650. [Google Scholar] [CrossRef]

- Attari, N.; Amziane, S.; Chemrouk, M. Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Constr. Build. Mater. 2012, 37, 746–757. [Google Scholar] [CrossRef]

- Gdoutos, E.E.; Pilakoutas, K.; Rodopoulos, C.A. Failure Analysis of Industrial Composite Materials; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Ortiz, J.D.; Dolati, S.S.K.; Malla, P.; Nanni, A.; Mehrabi, A. FRP-reinforced/strengthened concrete: State-of-the-art review on durability and mechanical effects. Materials 2023, 16, 1990. [Google Scholar] [CrossRef]

- Hollaway, L.C. Key issues in the use of fibre reinforced polymer (FRP) composites in the rehabilitation and retrofitting of concrete structures. In Service Life Estimation and Extension of Civil Engineering Structures; Woodhead Publishing: Sawston, UK, 2011; pp. 3–74. [Google Scholar] [CrossRef]

- Van Den Einde, L.; Zhao, L.; Seible, F. Use of FRP composites in civil structural applications. Constr. Build. Mater. 2003, 17, 389–403. [Google Scholar] [CrossRef]

- Ali, M.S.; Mirza, M.S.; Lessard, L. Durability assessment of hybrid FRP composite shell and its application to prestressed concrete girders. Constr. Build. Mater. 2017, 150, 114–122. [Google Scholar] [CrossRef]

- Taerwe, L. Non-Metallic (FRP) Reinforcement for Concrete Structures; Taylor & Francis Ltd.: London, UK, 2004; ISBN 9780203627273. [Google Scholar]

- Bank, L.C. Application of FRP Composites to Bridges in the USA. In Proceedings of the International Colloquium on Application of FRP to Bridges, Tokyo, Japan, 20 January 2006. [Google Scholar]

- Khajouei, M.; Khamani, S.; Adavi, K. Hybrid pipes for high performance and reliability. In Polymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental Impacts; Gulf Professional Publishing: Houston, TX, USA, 2023; pp. 71–92. [Google Scholar] [CrossRef]

- Galati, N.; Nanni, A.; Dharani, L.R.; Focacci, F.; Aiello, M.A. Thermal effects on bond between FRP rebars and concrete. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1223–1230. [Google Scholar] [CrossRef]

- Ceroni, F. Experimental performances of RC beams strengthened with FRP materials. Constr. Build. Mater. 2010, 24, 1547–1559. [Google Scholar] [CrossRef]

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. FRP: Strengthened RC Structures; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Burgoyne, C.J.; Byars, E.; Guadagnini, M.; Manfredi, G.; Neocleous, K.; Pilakoutas, K.; Taerwe, L.; Taranu, N.; Tepfers, R.; Weber, A.; et al. fib Bulletin 40. FRP Reinforcement in RC Structures; The International Federation for Structural Concrete: Lausanne, Switzerland, 2007; ISBN 2883940428. [Google Scholar]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Response to fire of concrete structures that incorporate FRP. Prog. Struct. Eng. Mater. 2005, 7, 136–149. [Google Scholar] [CrossRef]

- Kodur, V.; Yu, B.; Dwaikat, M. A simplified approach for predicting temperature in reinforced concrete members exposed to standard fire. Fire Saf. J. 2013, 56, 39–51. [Google Scholar] [CrossRef]

- Berardi, U.; Meacham, B.J.; Dembsey, N.A.; You, Y.-G. Fire performance assessment of a fiber reinforced polymer wall panel used in a single family dwelling. Fire Technol. 2014, 50, 1607–1617. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Yu, B. Rational approach for evaluating fire resistance of FRP-strengthened concrete beams. J. Compos. Constr. 2016, 20, 04016041. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Experimental investigation on fire endurance of insulated concrete beams strengthened with near surface mounted FRP bar reinforcement. Compos. Part B Eng. 2012, 43, 885–895. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, G.; Zhang, L.; Zhang, J.; Hui, D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos. Part B Eng. 2014, 60, 680–687. [Google Scholar] [CrossRef]

- Wu, C.; Zhao, X.L.; Chiu, W.K.; Al-Mahaidi, R.; Duan, W.H. Effect of fatigue loading on the bond behaviour between UHM CFRP plates and steel plates. Compos. Part B Eng. 2013, 50, 344–353. [Google Scholar] [CrossRef]

- Zhao, X.-L.; Bai, Y.; Al-Mahaidi, R.; Rizkalla, S. Effect of dynamic loading and environmental conditions on the bond between CFRP and steel: State-of-the-art review. J. Compos. Constr. 2014, 18, A4013005. [Google Scholar] [CrossRef]

- British Standards. Eurocode 2: Design of Concrete Structures; British Standards: London, UK, 2004; p. 230. [Google Scholar]

- Singh, S.; Sivasubramanian, M.V.; Reddy, A.L.; Prakash, K.C.; Nagarjuna, K.; Kiran, A.H. Performance of NSM-FRP RC beams in flexure and shear using locally developed CFRP rebars. Int. J. Sustain. Mater. Struct. Syst. 2012, 1, 42. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Wu, G.; Yang, L.; Wu, Z. Effectiveness of basalt FRP tendons for strengthening of RC beams through the external prestressing technique. Eng. Struct. 2015, 101, 34–44. [Google Scholar] [CrossRef]

- Aules, W.A.; Raoof, S.M. Effect of shape modification on the confinement effectiveness of CFRP strengthened square concrete compression members: Experimental study. Case Stud. Constr. Mater. 2021, 15, e00679. [Google Scholar] [CrossRef]

- Sabzi, J.; Esfahani, M.R.; Ozbakkaloglu, T.; Farahi, B. Effect of concrete strength and longitudinal reinforcement arrangement on the performance of reinforced concrete beams strengthened using EBR and EBROG methods. Eng. Struct. 2020, 205, 110072. [Google Scholar] [CrossRef]

- Azevedo, A.; Firmo, J.; Correia, J.; Chastre, C.; Biscaia, H.; Franco, N. Fire behaviour of CFRP-strengthened RC slabs using different techniques—EBR, NSM and CREatE. Compos. Part B Eng. 2022, 230, 109471. [Google Scholar] [CrossRef]

- Ghaleh, R.Z.; Mostofinejad, D. Behaviour of EBRIG CFRP sheet-concrete joint: Comparative assessment with EBR and EBROG methods. Constr. Build. Mater. 2022, 346, 128374. [Google Scholar] [CrossRef]

- Wysmulski, P. The effect of load eccentricity on the compressed CFRP Z-shaped columns in the weak post-critical state. Compos. Struct. 2022, 301, 116184. [Google Scholar] [CrossRef]

- Rozylo, P. Comparison of failure for thin-walled composite columns. Materials 2021, 15, 167. [Google Scholar] [CrossRef] [PubMed]

- Abbood, I.S.; Odaa, S.A.; Hasan, K.F.; Jasim, M.A. Properties evaluation of fiber reinforced polymers and their constituent materials used in structures—A review. Mater. Today Proc. 2020, 43, 1003–1008. [Google Scholar] [CrossRef]

- Sahu, N.P.; Khande, D.K.; Patel, G.C.; Sen, P. Study on aramid fibre and comparison with other composite materials. Int. J. Innov. Res. Sci. Technol. 2015, 1, 303–306. [Google Scholar]

- Davies, P.; Reaud, Y.; Dussud, L.; Woerther, P. Mechanical behaviour of HMPE and aramid fibre ropes for deep sea handling operations. Ocean Eng. 2011, 38, 2208–2214. [Google Scholar] [CrossRef]

- Zhou, J.; Bi, F.; Wang, Z.; Zhang, J. Experimental investigation of size effect on mechanical properties of carbon fiber reinforced polymer (CFRP) confined concrete circular specimens. Constr. Build. Mater. 2016, 127, 643–652. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhao, X.L.; Al-Mahaidi, R. Effect of fatigue loading on bond strength between CFRP sheets and steel plates. Int. J. Struct. Stab. Dyn. 2010, 10, 1–20. [Google Scholar] [CrossRef]

- Abdelrahman, K.; El-Hacha, R. Cost and ductility effectiveness of concrete columns strengthened with CFRP and SFRP sheets. Polymers 2014, 6, 1381–1402. [Google Scholar] [CrossRef]

- Delgado, P.; Arêde, A.; Pouca, N.V.; Rocha, P.; Costa, A.; Delgado, R. Retrofit of RC hollow piers with CFRP sheets. Compos. Struct. 2012, 94, 1280–1287. [Google Scholar] [CrossRef]

- Saeed, Y.M. Behavior of Prestressed Concrete Beams with CFRP Behavior of Prestressed Concrete Beams with CFRP Strands Strands. Ph.D. Dissertation, Portland State University, Portland, OR, USA, 2016. [Google Scholar] [CrossRef]

- Callister, W.D. Materials Science and Engineering: An Introduction, 7th ed.; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures and Processing. 1986. Available online: http://materialstandard.com/wp-content/uploads/2019/06/AshbyEngineering-Materials-2.pdf (accessed on 20 January 2024).

- Lubin, G.; Klerer, J. Handbook of Fiberglass and Advanced Plastics Composites. J. Electrochem. Soc. 1970, 117, 219C. [Google Scholar] [CrossRef]

- Cabral-Fonseca, S.; Correia, J.R.; Rodrigues, M.P.; Branco, F.A. Artificial accelerated ageing of GFRP pultruded profiles made of polyester and vinylester resins: Characterisation of physical–chemical and mechanical damage. Strain 2011, 48, 162–173. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I. Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests. J. Compos. Constr. 2006, 10, 279–286. [Google Scholar] [CrossRef]

- Cousin, P.; Hassan, M.; Vijay, P.; Robert, M.; Benmokrane, B. Chemical resistance of carbon, basalt, and glass fibers used in FRP reinforcing bars. J. Compos. Mater. 2019, 53, 3651–3670. [Google Scholar] [CrossRef]

- Rafi, M.; Nadjai, A.; Ali, F.; O’Hare, P. Evaluation of thermal resistance of FRP reinforced concrete beams in fire. J. Struct. Fire Eng. 2011, 2, 91–107. [Google Scholar] [CrossRef]

- Javier Malvar, L. Tensile and bond properties of GFRP reinforcing bars. ACI Mater. J. 1995, 92, 276–285. [Google Scholar] [CrossRef]

- Önal, M.M. Strengthening reinforced concrete beams with CFRP and GFRP. Adv. Mater. Sci. Eng. 2014, 2014, 967964. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Ehsani, M.R. RC Beams strengthened with GFRP plates. I: Experimental study. J. Struct. Eng. 1991, 117, 3417–3433. [Google Scholar] [CrossRef]

- Hosen, M.A.; Alengaram, U.J.; Jumaat, M.Z.; Sulong, N.H.R.; Darain, K.M.U. Glass fiber reinforced polymer (GFRP) bars for enhancing the flexural performance of RC beams using Side-NSM technique. Polymers 2017, 9, 180. [Google Scholar] [CrossRef]

- Wang, L.; Yi, J.; Zhang, J.; Chen, W.; Fu, F. Short-term flexural stiffness prediction of CFRP bars reinforced coral concrete beams. Materials 2021, 14, 467. [Google Scholar] [CrossRef] [PubMed]

- Rolland, A.; Chataigner, S.; Benzarti, K.; Quiertant, M.; Argoul, P.; Paul, J.M. Mechanical behaviour of aramid fiber reinforced polymer (AFRP) rebar/concrete interfaces. TRA 2014, 2014, 10. [Google Scholar]

- Jiang, J.; Luo, J.; Yu, J.; Wang, Z. Performance improvement of a fiber-reinforced polymer bar for a reinforced sea sand and seawater concrete beam in the serviceability limit state. Sensors 2019, 19, 654. [Google Scholar] [CrossRef] [PubMed]

- Ning, H.; Li, Y.; Hu, N.; Arai, M.; Takizawa, N.; Liu, Y.; Wu, L.; Li, J.; Mo, F. Experimental and numerical study on the improvement of interlaminar mechanical properties of Al/CFRP laminates. J. Am. Acad. Dermatol. 2014, 216, 79–88. [Google Scholar] [CrossRef]

- Banibayat, P.; Patnaik, A. Creep rupture performance of basalt fiber-reinforced polymer bars. J. Aerosp. Eng. 2015, 28, 4014074. [Google Scholar] [CrossRef]

- Meier, U. Carbon fiber reinforced polymer cables: Why? why not? what if? Arab. J. Sci. Eng. 2012, 37, 399–411. [Google Scholar] [CrossRef]

- ACI. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars. 2015. Available online: www.concrete.org (accessed on 29 November 2023).

- Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement. Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/19891 (accessed on 29 November 2023).

- Gore, P.M.; Kandasubramanian, B. Functionalized aramid fibers and composites for protective applications: A review. Ind. Eng. Chem. Res. 2018, 57, 16537–16563. [Google Scholar] [CrossRef]

- Cheon, J.; Lee, M.; Kim, M. Study on the stab resistance mechanism and performance of the carbon, glass and aramid fiber reinforced polymer and hybrid composites. Compos. Struct. 2019, 234, 111690. [Google Scholar] [CrossRef]

- Springer, H.; Abu Obaid, A.; Prabawa, A.; Hinrichsen, G. Influence of hydrolytic and chemical treatment on the mechanical properties of aramid and copolyaramid fibers. Text. Res. J. 1998, 68, 588–594. [Google Scholar] [CrossRef]

- Wilfong, R.E.; Zimmerman, J. Strength and Durability Characteristics of Kevlar Aramid Fiber. 1977. Available online: http://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=PASCAL7860334814 (accessed on 3 March 2024).

- Nakayama, Y.; Nakai, H.; Kanakubo, T. Bond behavior between deformed aramid fiber-reinforced plastic reinforcement and concrete. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Andrews, M.; Lu, D.; Young, R. Compressive properties of aramid fibres. Polymer 1997, 38, 2379–2388. [Google Scholar] [CrossRef]

- Li, H.; Xian, G.; Xiao, B.; Wu, J. Comprehensive characterization of BFRP applied in civil engineering. In Advances in FRP composites in civil engineering: Proceedings of the 5th international conference on FRP Composites in civil engineering, CICE 2010, Beijing, China, 27–29 September 2010; Springer: Berlin/Heidelberg, Germany, 2011; pp. 65–68. [Google Scholar] [CrossRef]

- Ceroni, F.; Cosenza, E.; Gaetano, M.; Pecce, M. Durability issues of FRP rebars in reinforced concrete members. Cem. Concr. Compos. 2006, 28, 857–868. [Google Scholar] [CrossRef]

- Dawood, M.; Rizkalla, S. Environmental durability of a CFRP system for strengthening steel structures. Constr. Build. Mater. 2010, 24, 1682–1689. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Jiao, H.; Zhao, X.-L. CFRP strengthened butt-welded very high strength (VHS) circular steel tubes. Thin-Walled Struct. 2004, 42, 963–978. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L.; Gaudenzi, P.; Cioffi, S.; Iannace, S.; Sorrentino, L. Drop-weight impact behavior of woven hybrid basalt–carbon/epoxy composites. Compos. Part B Eng. 2013, 59, 204–220. [Google Scholar] [CrossRef]

- Issa, M.S.; Ismail, E.S. Long-term deflections of FRP reinforced concrete beams. HBRC J. 2020, 16, 269–282. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Khanam, P.N.; Khalil, H.P.S.A.; Jawaid, M.; Reddy, G.R.; Narayana, C.S.; Naidu, S.V. Sisal/carbon fibre reinforced hybrid composites: Tensile, flexural and chemical resistance properties. J. Polym. Environ. 2010, 18, 727–733. [Google Scholar] [CrossRef]

- Prian, L.; Barkatt, A. Chemical, thermochemical, and mechanical studies of FRP degradation in corrosive environments. In Proceedings of the CORROSION 98, San Diego, CA, USA, 22–27 March 1998. [Google Scholar]

- Li, G.; Wu, J.; Ge, W. Effect of loading rate and chemical corrosion on the mechanical properties of large diameter glass/basalt-glass FRP bars. Constr. Build. Mater. 2015, 93, 1059–1066. [Google Scholar] [CrossRef]

- Gleditsch, C. Corrosion barrier compositions of FRP chemical process equipment. In NACE CORROSION; NACE: Bethlehem, PA, USA, 2003; p. NACE-03619. [Google Scholar]

- Park, C.-G.; Won, J.-P.; Yoo, J.-K. Long-term effect of chemical environments on FRP reinforcing bar for concrete reinforcement. J. Korea Concr. Inst. 2003, 15, 811–819. [Google Scholar] [CrossRef]

- Gangarao, H.V.S.; Vijay, P.E.P.V. BAA Topic NO. CHL-2: Inland Hydraulic Structures Feasibility Review of FRP Materials for Structural Applications. 2010. Available online: https://cee.statler.wvu.edu/files/d/fa47c84b-27fa-44c0-b828-1032d324ae69/feasibility-review-of-frp-materials-for-structural-applications.pdf (accessed on 30 November 2023).

- Moon, C.-R.; Bang, B.-R.; Choi, W.-J.; Kang, G.-H.; Park, S.-Y. A technique for determining fiber content in FRP by thermogravimetric analyzer. Polym. Test. 2005, 24, 376–380. [Google Scholar] [CrossRef]

- Idicula, M.; Boudenne, A.; Umadevi, L.; Ibos, L.; Candau, Y.; Thomas, S. Thermophysical properties of natural fibre reinforced polyester composites. Compos. Sci. Technol. 2006, 66, 2719–2725. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Haeger, A.; Schoen, G.; Lissek, F.; Meinhard, D.; Kaufeld, M.; Schneider, G.; Schuhmacher, S.; Knoblauch, V. Non-destructive detection of drilling-induced delamination in CFRP and its effect on mechanical properties. Procedia Eng. 2016, 149, 130–142. [Google Scholar] [CrossRef]

- Quadrino, A.; Penna, R.; Feo, L.; Nisticò, N. Mechanical characterization of pultruded elements: Fiber orientation influence vs web-flange junction local problem. Experimental and numerical tests. Compos. Part B Eng. 2018, 142, 68–84. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Piscitelli, F.; Prota, A.; Lavorgna, M.; Mensitieri, G.; Manfredi, G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr. Build. Mater. 2012, 31, 273–283. [Google Scholar] [CrossRef]

- Cheng, C.-T.; Mo, Y.L.; Yeh, Y.-K. Evaluation of as-built, retrofitted, and repaired shear-critical hollow bridge columns under earthquake-type loading. J. Bridg. Eng. 2005, 10, 520–529. [Google Scholar] [CrossRef]

- Bousselham, A.; Chaallal, O. Effect of transverse steel and shear span on the performance of RC beams strengthened in shear with CFRP. Compos. Part B Eng. 2006, 37, 37–46. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Influence of water up-take on interlaminar fracture properties of carbon fibre-reinforced polymer composites. J. Mater. Sci. 1995, 30, 334–338. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part A Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- Darby, A.; Clarke, J.; Shave, J.D.; Ibell, T. Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials: Report of a Concrete Society Working Party, 3rd ed.; The Concrete Society: Berkshire, UK, 2012; Volume 55, Available online: https://researchportal.bath.ac.uk/en/publications/design-guidance-for-strengthening-concrete-structures-using-fibre (accessed on 30 November 2023).

- Vuddandam, R.; Toutanji, H.; Ueno, S. Review of design code provisions on externally strengthened concrete structures with FRP laminates. In Proceedings of the 11th International Symposium on Fiber Reinforced Polymer Reinforcement for Concrete Structures (FRPRCS-11), Guimarães, Portugal, 26–28 June 2013. [Google Scholar]

- Mistretta, F.; Puppio, M.L.; Camata, G.; Nanni, A. Analytical and experimental shear evaluation of GFRP-reinforced concrete beams. Mater. Struct. 2023, 56, 173. [Google Scholar] [CrossRef]

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- D’Antino, T.; Triantafillou, T.C. Accuracy of design-oriented formulations for evaluating the flexural and shear capacities of FRP-strengthened RC beams. Struct. Concr. 2016, 17, 425–442. [Google Scholar] [CrossRef]

- Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. Incorporating Corrigendum March 2010. Available online: https://www.phd.eng.br/wp-content/uploads/2014/07/en.1998.3.2005.pdf (accessed on 22 February 2024).

- ACI 440.2R-08; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2008; p. 80.

- Arya, C.; Clarke, J.; Kay, E.; O’regan, P. TR 55: Design guidance for strengthening concrete structures using fibre composite materials: A review. Eng. Struct. 2002, 24, 889–900. [Google Scholar] [CrossRef]

- Finckh, W.; Ignatiadis, A.; Niedermeier, R.; Wiens, U.; Zilch, K. Explanations and examples of the DAfStb guideline ‘Reinforcing concrete components with bonded reinforcement’-2013-07-Beuth.de. Beton-Und Stahlbetonbau 2012, 107, 711–715. [Google Scholar] [CrossRef]

- Aiello, M.A. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures. 2014. Available online: https://www.cnr.it/en/node/2636 (accessed on 22 December 2023).

- Lee, J.-H.; Choi, J.-H.; Hwang, D.-K.; Kwahk, I.-J. Seismic performance of circular hollow RC bridge columns. KSCE J. Civ. Eng. 2014, 19, 1456–1467. [Google Scholar] [CrossRef]

- Fawzia, S.; Al-Mahaidi, R.; Zhao, X.; Rizkalla, S. Strengthening of circular hollow steel tubular sections using high modulus CFRP sheets. Constr. Build. Mater. 2007, 21, 839–845. [Google Scholar] [CrossRef]

- Yu, T.; Fernando, D.; Teng, J.; Zhao, X. Experimental study on CFRP-to-steel bonded interfaces. Compos. Part B Eng. 2012, 43, 2279–2289. [Google Scholar] [CrossRef]

- Fawzia, S.; Al-Mahaidi, R.; Zhao, X.-L. Experimental and finite element analysis of a double strap joint between steel plates and normal modulus CFRP. Compos. Struct. 2006, 75, 156–162. [Google Scholar] [CrossRef]

- Akbar, I.; Oehlers, D.J.; Ali, M.M. Derivation of the bond–slip characteristics for FRP plated steel members. J. Constr. Steel Res. 2010, 66, 1047–1056. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, L.; Wu, L.; Xiong, J. A novel strengthening method for carbon fiber composite lattice truss structures. Compos. Struct. 2016, 153, 585–592. [Google Scholar] [CrossRef]

- Harries, K.A.; Webb, P. Experimental assessment of bonded FRP-to-steel interfaces. Proc. Inst. Civ. Eng.-Struct. Build. 2009, 162, 233–240. [Google Scholar] [CrossRef]

- Al-Zubaidy, H.; Al-Mahaidi, R.; Zhao, X.-L. Experimental investigation of bond characteristics between CFRP fabrics and steel plate joints under impact tensile loads. Compos. Struct. 2012, 94, 510–518. [Google Scholar] [CrossRef]

- Al-Zubaidy, H.; Zhao, X.-L.; Al-Mahaidi, R. Mechanical characterization of the dynamic tensile properties of CFRP sheet and adhesive at medium strain rates. Compos. Struct. 2012, 96, 153–164. [Google Scholar] [CrossRef]

- Al-Zubaidy, H.A.; Zhao, X.-L.; Al-Mahaidi, R. Experimental evaluation of the dynamic bond strength between CFRP sheets and steel under direct tensile loads. Int. J. Adhes. Adhes. 2013, 40, 89–102. [Google Scholar] [CrossRef]

- Al-Zubaidy, H.; Al-Mahaidi, R.; Zhao, X.-L. Finite element modelling of CFRP/steel double strap joints subjected to dynamic tensile loadings. Compos. Struct. 2013, 99, 48–61. [Google Scholar] [CrossRef]

- El-Sayed, A.K. Effect of longitudinal CFRP strengthening on the shear resistance of reinforced concrete beams. Compos. Part B Eng. 2014, 58, 422–429. [Google Scholar] [CrossRef]

- Li, W.; Tang, S.; Huang, Z.; Yang, X.; Shi, T.; Xing, F. Shear behavior of concrete beam reinforced in shear with carbon fiber-reinforced polymer mesh fabric (CFRP-MF) configuration. Eng. Struct. 2020, 218, 110828. [Google Scholar] [CrossRef]

- Faramarzi, A.; Sogut, K.; Dirar, S.; Theofanous, M. Effect of shear span-to-effective depth ratio on the behaviour of RC T-beams shear-strengthened with embedded CFRP bars. In Proceedings of the 3rd International Civil Engineering and Architecture Congress (ICEARC’23), Trabzon, Turkey, 12–14 October 2023. [Google Scholar] [CrossRef]

- Murad, Y. The influence of CFRP orientation angle on the shear strength of RC beams. Open Constr. Build. Technol. J. 2018, 12, 269–281. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. AASHTO LRFD Bridge Design Guide Specifications for GFRP-Reinforced Concrete Bridge Decks and Traffic Railings; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Matthys, S. International fed Beration for Structural Concrete Task Group Monitoring and Safety Evaluation of Existing Concrete Structures. Externally Applied FRP Reinforcement for Concrete Structures; Technical Report; International Federation for Structural Concrete: Lausanne, Switzerland, 2019. [Google Scholar]

- Campione, G.; Mangiavillano, M.L. Fibrous reinforced concrete beams in flexure: Experimental investigation, analytical modelling and design considerations. Eng. Struct. 2008, 30, 2970–2980. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, T.; Chen, G. Reinforced concrete beams strengthened in flexure with near-surface mounted (NSM) CFRP strips: Current status and research needs. Compos. Part B Eng. 2017, 131, 30–42. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Kianoush, M.; Tajari, A. Flexural behaviour of reinforced concrete beams strengthened by CFRP sheets. Eng. Struct. 2007, 29, 2428–2444. [Google Scholar] [CrossRef]

- Sharafeddin, F.; Alavi, A.A.; Talei, Z. Flexural strength of glass and polyethylene fiber combined with three different composites. J. Dent. 2013, 14, 13–19. [Google Scholar]

- Grace, N.F.; Ragheb, W.F.; Abdel-Sayed, G. Flexural and shear strengthening of concrete beams using new triaxially braided ductile fabric. ACI Struct. J. 2003, 100, 804–814. [Google Scholar] [CrossRef]

- Lim, J.I.; Rhee, K.Y.; Kim, H.J.; Jung, D.H. Effect of stacking sequence on the flexural and fracture properties of carbon/basalt/epoxy hybrid composites. Carbon Lett. 2014, 15, 125–128. [Google Scholar] [CrossRef]

- Andrews, R.; Grulke, E.; Kimber, G. Mechanical Properties of Carbon Fiber Composites for Environmental Applications. 1996. Available online: https://www.osti.gov/biblio/370373 (accessed on 23 February 2024).

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Compos. Part B Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Park, R.; Jang, J. Performance improvement of carbon fiber/polyethylene fiber hybrid composites. J. Mater. Sci. 1999, 34, 2903–2910. [Google Scholar] [CrossRef]

- Inge, W.; Audrey; Nugroho, S.; Njo, H. Strengthening method of concrete structure. IOP Conf. Series Earth Environ. Sci. 2018, 126, 012051. [Google Scholar] [CrossRef]

- Kamalakannan, S.M.; Murali, S.A.A.; Malik, M.A.R.A.; Saravanan, N.A.; Kumar, B.V.; Vijayaragavan, R.; Umarani, C. Retrofitting of an existing structure design and techniques. IOP Conf. Series Mater. Sci. Eng. 2021, 1197, 012059. [Google Scholar] [CrossRef]

- Dhawan, V.; Singh, S.; Singh, I. Effect of natural fillers on mechanical properties of GFRP composites. J. Compos. 2013, 2013, 792620. [Google Scholar] [CrossRef]

- Schué, F. FRP: Strengthened RC structures. JG Teng, JF Chen, ST Smith and L Lam. John Wiley & Sons, Ltd.: Chichester, UK, 2001. pp 245, ISBN 0-471-48706-6. Polym. Int. 2004, 53, 232–233. [Google Scholar] [CrossRef]

- Orton, S.L.; Jirsa, J.O.; Bayrak, O. Design considerations of carbon fiber anchors. J. Compos. Constr. 2008, 12, 608–616. [Google Scholar] [CrossRef]

- Arduini, M.; Di Tommaso, A.; Antonio, N. Brittle failure in FRP plate and sheet bonded beams. ACI Struct. J. 1997, 94, 363–370. [Google Scholar] [CrossRef]

- Ritchie, P.A.; Thomas, D.A.; Lu, L.-W.; Conelly, G.M. External reinforcement of concrete beams using fiber-reinforced plastics. ACI Struct. J. 1991, 88, 490–500. [Google Scholar] [CrossRef]

- Arduini, M.; Nanni, A. Parametric study of beams with externally bonded FRP reinforcement. ACI Struct. J. 1997, 94, 493–501. [Google Scholar] [CrossRef]

- He, J.; Pilakoutas, K.; Waldron, P. CFRP Plate Strengthening of RC Beams. 1997. Available online: https://trid.trb.org/View/710067 (accessed on 23 February 2024).

- David, E.; Djelal, C.; Buyle-Bodin, F. Repair and Strengthening of Reinforced Concrete Beams USING Composite Materials. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=75a59acaa458d04819232f7320ce234562bdb61c (accessed on 22 February 2024).

- GangaRao, H.V.S.; Vijay, P.V. Bending behavior of concrete beams wrapped with carbon fabric. J. Struct. Eng. 1998, 124, 3–10. [Google Scholar] [CrossRef]

- Spadea, G.; Bencardino, F.; Swamy, R.N. Structural behavior of composite RC beams with externally bonded CFRP. J. Compos. Constr. 1998, 2, 132–137. [Google Scholar] [CrossRef]

- Allen Ross, C.; Jerome, D.M.; Tedesco Joseph, W.; Hughes Mary, L. Strengthening of reinforced concrete beams with externally bonded composite laminates. ACI Struct. J. 1999, 96, 212–220. [Google Scholar] [CrossRef]

- Jiang, X.; Kolstein, H.; Bijlaard, F.; Qiang, X. Effects of hygrothermal aging on glass-fibre reinforced polymer laminates and adhesive of FRP composite bridge: Moisture diffusion characteristics. Compos. Part A Appl. Sci. Manuf. 2014, 57, 49–58. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Behavior of GFRP reinforcing bars subjected to extreme temperatures. J. Compos. Constr. 2010, 14, 353–360. [Google Scholar] [CrossRef]

- Wu, C.; Li, V.C. Thermal-mechanical behaviors of CFRP-ECC hybrid under elevated temperatures. Compos. Part B Eng. 2017, 110, 255–266. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Huang, L.; Yao, Y.; Li, G.; Mobasher, B. Mechanical characterization of the tensile properties of glass fiber and its reinforced polymer (GFRP) composite under varying strain rates and temperatures. Polymers 2016, 8, 196. [Google Scholar] [CrossRef]

- Adams, R.; Singh, M. Low temperature transitions in fibre reinforced polymers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 797–814. [Google Scholar] [CrossRef]

- Katz, A.; Berman, N.; Bank, L.C. Effect of high temperature on bond strength of FRP rebars. J. Compos. Constr. 1999, 3, 73–81. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Abu-Obeidah, A.; Abdalla, J.A.; Al-Tamimi, A. Temperature effect on the mechanical properties of carbon, glass and carbon–glass FRP laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Durability of steel/CFRP double strap joints exposed to sea water, cyclic temperature and humidity. Compos. Struct. 2012, 94, 1834–1845. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Saiedi, R.; Fam, A.; Green, M.F. Behavior of CFRP-Prestressed concrete beams under high-cycle fatigue at low temperature. J. Compos. Constr. 2011, 15, 482–489. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Al-Mahaidi, R.; Zhao, X. Effect of elevated temperature on bond behaviour of high modulus CFRP/steel double-strap joints. Aust. J. Struct. Eng. 2009, 10, 63–74. [Google Scholar] [CrossRef]

- Katz, A.; Berman, N. Modeling the effect of high temperature on the bond of FRP reinforcing bars to concrete. Cem. Concr. Compos. 2000, 22, 433–443. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Effects of ultraviolet radiation and associated elevated temperature on mechanical performance of steel/CFRP double strap joints. Compos. Struct. 2012, 94, 3563–3573. [Google Scholar] [CrossRef]

- Han, Q.; Wang, L.; Xu, J. Experimental research on mechanical properties of transverse enhanced and high-temperature-resistant CFRP tendons for prestressed structure. Constr. Build. Mater. 2015, 98, 864–874. [Google Scholar] [CrossRef]

- Gawil, B.; Wu, H.-C.; Elarbi, A. Modeling the behavior of CFRP strengthened concrete beams and columns at different temperatures. Fibers 2020, 8, 10. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Rivera, J.; Dutta, P.K. Effect of short-term freeze-thaw cyclingon composite confined concrete. J. Compos. Constr. 2000, 4, 191–197. [Google Scholar] [CrossRef]

- Zhao, J.; Li, G.; Wang, Z.; Zhao, X.-L. Fatigue behavior of concrete beams reinforced with glass- and carbon-fiber reinforced polymer (GFRP/CFRP) bars after exposure to elevated temperatures. Compos. Struct. 2019, 229, 111427. [Google Scholar] [CrossRef]

- Davalos, J.F.; Chen, Y.; Ray, I. Effect of FRP bar degradation on interface bond with high strength concrete. Cem. Concr. Compos. 2008, 30, 722–730. [Google Scholar] [CrossRef]

- Abdalla, H. Concrete cover requirements for FRP reinforced members in hot climates. Compos. Struct. 2006, 73, 61–69. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Zhao, X.-L. Adhesive rheology impact on wet lay-up CFRP/steel joints’ behaviour under infrastructural subzero exposures. Compos. Part B Eng. 2013, 47, 207–219. [Google Scholar] [CrossRef]

- Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Fire behaviour of reinforced concrete columns confined with fibre-reinforced polymers. In Advanced Polymer Composites for Structural Applications in Construction; Woodhead Publishing: Shaston, UK, 2004; pp. 465–472. [Google Scholar] [CrossRef]

- El-Salakawy, E.; Benmokrane, B. Serviceability of concrete bridge deck slabs reinforced with fiber-reinforced polymer composite bars. ACI Struct. J. 2004, 101, 727–736. [Google Scholar] [CrossRef]

- Dai, J.-G.; Gao, W.Y.; Teng, J.G. Bond-slip model for FRP laminates externally bonded to concrete at elevated temperature. J. Compos. Constr. 2013, 17, 217–228. [Google Scholar] [CrossRef]

- Protchenko, K. Residual fire resistance testing of basalt- and hybrid-FRP reinforced concrete beams. Materials 2022, 15, 1509. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, M.-R.; Dai, J.-G.; Dong, B.-Q.; Zhang, M.-J.; Hong, S.-X.; Xing, F. Strengthening concrete using phosphate cement-based fiber-reinforced inorganic composites for improved fire resistance. Constr. Build. Mater. 2019, 212, 755–764. [Google Scholar] [CrossRef]

- Protchenko, K.; Szmigiera, E. Post-fire characteristics of concrete beams reinforced with hybrid FRP bars. Materials 2020, 13, 1248. [Google Scholar] [CrossRef]

- Duarte, A.P.C.; Rosa, I.C.; Arruda, M.R.T.; Firmo, J.P.; Correia, J.R. Fire behaviour of GFRP-reinforced concrete slab strips: Fire resistance tests and numerical simulation. Lect. Notes Civ. Eng. 2022, 198, 788–800. [Google Scholar] [CrossRef]

- Rosa, I.C.; Santos, P.; Firmo, J.P.; Correia, J.R. Fire behaviour of concrete slab strips reinforced with sand-coated GFRP bars. Compos. Struct. 2020, 244, 112270. [Google Scholar] [CrossRef]

- Kumar, M.R.; Anbuchezhiyan, G. Comparative study of flexural strength and fire resistance of novel eggshell powder blended GFRP and jute fibre blended GFRP with GFRP. Mater. Today Proc. 2022, 69, 1055–1060. [Google Scholar] [CrossRef]

- Hajiloo, H.; Green, M.F.; Noël, M.; Bénichou, N.; Sultan, M. GFRP-reinforced concrete slabs: Fire resistance and design efficiency. J. Compos. Constr. 2019, 23, 04019009. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tran, P.; Ngo, T.D.; Tran, P.A.; Mendis, P. Experimental and computational investigations on fire resistance of GFRP composite for building façade. Compos. Part B Eng. 2014, 62, 218–229. [Google Scholar] [CrossRef]

- GangaRao, H.V.S.; Vijay, P.V. Feasibility Review of FRP Materials for Structural Applications; Report; West Virginia University: Morgantown, WV, USA, 2010. [Google Scholar]

- Zhang, R.; Xue, X. A predictive model for the bond strength of near-surface-mounted FRP bonded to concrete. Compos. Struct. 2021, 262, 113618. [Google Scholar] [CrossRef]

- Su, M.; Gong, S.; Liu, Y.; Peng, H. Flexural behavior of RC beams strengthened with fully or partially prestressed near-surface mounted FRP strips: An experimental investigation. Eng. Struct. 2022, 262, 114345. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- Barris, C.; Sala, P.; Gómez, J.; Torres, L. Flexural behaviour of FRP reinforced concrete beams strengthened with NSM CFRP strips. Compos. Struct. 2020, 241, 112059. [Google Scholar] [CrossRef]

- Wang, Q.; Li, T.; Zhu, H.; Su, W.; Hu, X. Bond enhancement for NSM FRP bars in concrete using different anchorage systems. Constr. Build. Mater. 2020, 246, 118316. [Google Scholar] [CrossRef]

- Zhang, Y.; Elsayed, M.; Zhang, L.; Nehdi, M. Flexural behavior of reinforced concrete T-section beams strengthened by NSM FRP bars. Eng. Struct. 2021, 233, 111922. [Google Scholar] [CrossRef]

- Barris, C.; Baena, M.; Jahani, Y.; Codina, A.; Torres, L. Experimental study on flexural cracking and deformation of reinforced-concrete beams strengthened with NSM FRP reinforcement. J. Compos. Constr. 2023, 27, 04023006. [Google Scholar] [CrossRef]

- Hassan, T.; Rizkalla, S. Flexural strengthening of prestressed bridge slabs with FRP systems. PCI J. 2002, 47, 76–93. [Google Scholar] [CrossRef]

- El-Gamal, S.; Al-Nuaimi, A.; Al-Saidy, A.; Al-Lawati, A. Efficiency of near surface mounted technique using fiber reinforced polymers for the flexural strengthening of RC beams. Constr. Build. Mater. 2016, 118, 52–62. [Google Scholar] [CrossRef]

- Al-Bayati, G.; Al-Mahaidi, R.; Kalfat, R. Torsional strengthening of reinforced concrete beams using different configurations of NSM FRP with epoxy resins and cement-based adhesives. Compos. Struct. 2017, 168, 569–581. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Fire behavior of concrete T-beams strengthened with near-surface mounted FRP reinforcement. Eng. Struct. 2014, 80, 350–361. [Google Scholar] [CrossRef]

- Askandar, N.H.; Mahmood, A.D. Torsional strengthening of RC beams with continuous spiral near-surface mounted steel wire rope. Int. J. Concr. Struct. Mater. 2020, 14, 7. [Google Scholar] [CrossRef]

- Codina, A.; Barris, C.; Jahani, Y.; Baena, M.; Torres, L. Experimental and theoretical study on the flexural behaviour of RC beams strengthened with externally bonded reinforcement on grooves CFRP laminates. Eng. Struct. 2024, 299. [Google Scholar] [CrossRef]

- Moshiri, N.; Martinelli, E.; Breveglieri, M.; Czaderski, C. Experimental tests and numerical simulations on the mechanical response of RC slabs externally strengthened by passive and prestressed FRP strips. Eng. Struct. 2023, 292, 117091. [Google Scholar] [CrossRef]

- Shabani, E.; Mostofinejad, D.; Saljoughian, A. Bond behavior of prestressed FRP sheet-concrete joints: Comparison of EBROG and EBR methods. Constr. Build. Mater. 2023, 400, 132752. [Google Scholar] [CrossRef]

- Sanginabadi, K.; Yazdani, A.; Mostofinejad, D.; Czaderski, C. Bond behavior of FRP composites attached to concrete using EBROG method: A state-of-the-art review. Compos. Struct. 2022, 299, 116060. [Google Scholar] [CrossRef]

- Sanginabadi, K.; Yazdani, A.; Mostofinejad, D.; Czaderski, C. RC members externally strengthened with FRP composites by grooving methods including EBROG and EBRIG: A state-of-the-art review. Constr. Build. Mater. 2022, 324, 126662. [Google Scholar] [CrossRef]

- Huang, H.-B.; Zhang, W.; Sun, Z.-G.; Wang, D.-S. Development of probabilistic FRP-to-concrete bond strength models for externally-bonded reinforcement on grooves: Bayesian approach. Constr. Build. Mater. 2022, 350, 128857. [Google Scholar] [CrossRef]

- Moghaddas, A.; Mostofinejad, D.; Ilia, E. Empirical FRP-concrete effective bond length model for externally bonded reinforcement on the grooves. Compos. Part B Eng. 2019, 172, 323–338. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Mostofinejad, D.; Fantuzzi, N.; Luciano, R.; Fabbrocino, F. Experimental evaluation of FRP-concrete bond using externally-bonded reinforcement on grooves (EBROG) method. Compos. Struct. 2023, 310, 116693. [Google Scholar] [CrossRef]

- Wu, Z.; Iwashita, K.; Yagashiro, S.; Ishikawa, T.; Hamaguchi, Y. Effect of temperature on adhesive interface of FRP sheet. J. Soc. Mater. Sci. Jpn. 2005, 54, 474–480. [Google Scholar] [CrossRef]

- Gamage, J.; Wong, M.; Al-Mahaidi, R. Performance of CFRP strengthened concrete members under elevated temperatures. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005); International Institute for FRP in Construction Hong Kong: Hong Kong, China, 2005; pp. 113–118. [Google Scholar]

- Torabian, A.; Isufi, B.; Mostofinejad, D.; Ramos, A.P. Flexural strengthening of flat slabs with FRP composites using EBR and EBROG methods. Eng. Struct. 2020, 211, 110483. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Mohammadi, M. Effect of Freeze–Thaw Cycles on FRP-Concrete Bond Strength in EBR and EBROG Systems. J. Compos. Constr. 2020, 24, 04020009. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Kashani, A.T. Experimental study on effect of EBR and EBROG methods on debonding of FRP sheets used for shear strengthening of RC beams. Compos. Part B Eng. 2013, 45, 1704–1713. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Shameli, S.M.; Hosseini, A. EBROG and EBRIG methods for strengthening of RC beams by FRP sheets. Eur. J. Environ. Civ. Eng. 2014, 18, 652–668. [Google Scholar] [CrossRef]

- Mohamed, K.; Abdalla, J.A.; Hawileh, R.A. Experimental and analytical investigations of the use of groove-epoxy anchorage system for shear strengthening of RC beams using CFRP laminates. Materials 2020, 13, 4350. [Google Scholar] [CrossRef] [PubMed]

- Havez, A.A.; Al-Mayah, A. Flexural strengthening of concrete structures using externally bonded and unbonded prestressed CFRP laminates: A Literature review. J. Compos. Constr. 2023, 27, 03123001. [Google Scholar] [CrossRef]

- Gao, D.; Fang, D.; You, P.; Chen, G.; Tang, J. Flexural behavior of reinforced concrete one-way slabs strengthened via external post-tensioned FRP tendons. Eng. Struct. 2020, 216, 110718. [Google Scholar] [CrossRef]

- Structural Strengthening System & Concrete Repair System-Horse Construction. Available online: https://www.horseen.com/product/six-structural-strengthening-system (accessed on 29 February 2024).

- Kim, T.-K.; Kim, S.-H.; Park, J.-S.; Park, H.-B. Experimental evaluation of PSC structures from FRP with a prestressing strengthening method. Materials 2021, 14, 1265. [Google Scholar] [CrossRef]

- Kim, T.-K.; Park, J.-S.; Kim, S.-H.; Jung, W.-T. Structural behavior evaluation of reinforced concrete using the fiber-reinforced polymer strengthening method. Polymers 2021, 13, 780. [Google Scholar] [CrossRef]

- Tran, D.T.; Pham, T.M.; Hao, H.; Chen, W. Numerical study on bending response of precast segmental concrete beams externally prestressed with FRP tendons. Eng. Struct. 2021, 241, 112423. [Google Scholar] [CrossRef]

- Al-Tameemi, H.; Akın, E. Improving the efficiency of FRP-Confined square concrete column by rounding the sharp edges and circularizing the flat sides. Structures 2022, 45, 1762–1773. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Liang, Q.-J.; Cai, W.-J.; Liao, J.; Zhou, J.-K.; Zhu, J.-Y.; Zhang, L. Strengthening RC square columns with UHP-ECC section curvilinearization and FRP confinement: Concept and axial compression tests. Eng. Struct. 2023, 280, 115666. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Lin, G.; Teng, J.-G.; Chan, T.-M.; Zeng, J.-J.; Li, L.-J. FRP-Confined square concrete columns with section curvilinearization under axial compression. J. Compos. Constr. 2020, 24, 04020004. [Google Scholar] [CrossRef]

- Zeng, J.J.; Teng, J.G.; Lin, G.; Li, L.J. Large-Scale FRP-confined rectangular RC columns with section curvilinearization under axial compression. J. Compos. Constr. 2021, 25, 04021020. [Google Scholar] [CrossRef]

- Pan, J.; Xu, T.; Hu, Z. Experimental investigation of load carrying capacity of the slender reinforced concrete columns wrapped with FRP. Constr. Build. Mater. 2007, 21, 1991–1996. [Google Scholar] [CrossRef]

- Teng, J.G.; Lam, L. Compressive behavior of carbon fiber reinforced polymer-confined concrete in elliptical columns. J. Struct. Eng. 2002, 128, 1535–1543. [Google Scholar] [CrossRef]

- Zhao, W. Experimental Behaviour of Curvilinearized Square Columns Confined with Fiber-Reinforced Polymer. 2012. Available online: https://theses.lib.polyu.edu.hk/handle/200/6862 (accessed on 1 December 2023).

- Yan, Z.; Pantelides, C.P.; Reaveley, L.D. Fiber-reinforced polymer jacketed and shape-modified compression members: I-experimental behavior. ACI Struct. J. 2006, 103, 885. [Google Scholar]

- Parvin, A.; Schroeder, J.M. Investigation of eccentrically loaded CFRP-confined elliptical concrete columns. J. Compos. Constr. 2008, 12, 93–101. [Google Scholar] [CrossRef]

| Trade | Tensile Strength (MPa) | Young’s Modulus (GPa) | Ultimate Tensile Strain |

|---|---|---|---|

| Aslan | 690 | 40.8 | 0.017 |

| Nefmac | 600 | 30 | 0.020 |

| Trade | Tensile Strength (MPa) | Young’s Modulus (GPa) | Ultimate Tensile Strain |

|---|---|---|---|

| Aslan | 2068 | 124 | 0.017 |

| Nefmac | 1200 | 100 | 0.012 |

| Trade | Tensile Strength (MPa) | Young’s Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|

| Kevlar | 2.3–3.4 | 70–43 | 1.44–1.47 |

| Heracron | 2.8 | 123 | 1.44 |

| Trade | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation (%) |

|---|---|---|---|

| Rockbar | 1000 | 50 | 2.24 |

| BCR | 1100 | 70 | 2.2 |

| Material | Strength of Fiber (MPa) | Strength of Laminate (MPa) | Density of Laminate (g/cc) | Strength to Weight Ratio | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| GFRP | 3450 | 1500 | 2.3–2.5 | 565 | 30–40 |

| CFRP | 4128 | 1600 | 1.8–2.1 | 1013 | 125–180 |

| AFRP | 2757 | 1430 | 1.44 | 993 | 70.5–112.4 |

| BFRP | 3792 | 1100 | 2.6–2.8 | 1000 | 70–90 |

| Reinforcement | Yield Strength (MPa) | Density (g/cm3) | Tensile Strength (MPa) | Specific Gravity | Elastic Modulus (GPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|

| Steel | 500–500 | 7.8–8.1 | - | 7.8 | 200 | - |

| GFRP | 600–1400 | 2.12–2.75 | 480–1600 | 1.5–2.5 | 35–51 | 1.2–3.1 |

| BFRP | 1000–1600 | 2.15–2.70 | 1035–1650 | 2.7–2.89 | 45–59 | 1.6–3.0 |

| AFRP | 1700–2500 | 1.28–2.6 1.39–1.45 | 1720–2540 | 1.38–1.39 | 41–125 | 1.9–4.4 |

| CFRP | 1755–3600 | 1.55–1.76 | 1720–3690 | 1.0–1.1 | 120–580 | 0.5–1.9 |

| Author | Ref. | Sample | FRP Type | Cross Section (mm) | No. of Layers | Thickness of Layers (mm) | Midspan Deflection at Maximum Load (mm) | Failure Mode | Experimental Shear Strength (kN) |

|---|---|---|---|---|---|---|---|---|---|

| El-Sayed | [121] | C-1.0 (control) | - | 150 × 300 | - | - | 2.8 | Shear | 46.5 |

| PL-1.0-0.43 | Low modulus plates | 150 × 300 | 1 | 1.4 | 2.48 | Shear | 59 | ||

| PL-1.0-0.85 | Low modulus plates | 150 × 300 | 2 | 1.4 | 2.57 | Shear | 61.5 | ||

| PL-1.0-0.36 | Low modulus plates | 150 × 300 | 1 | 1.4 | 2.27 | Shear | 58.5 | ||

| S-1.0-0.27 | Carbon sheets | 150 × 300 | 3 | 0.3 | 2.59 | Shear | 50 | ||

| C-1.5 (control) | - | 150 × 300 | - | - | 2.17 | Shear | 44.5 | ||

| PL-1.5-0.85 | Low modulus plates | 150 × 300 | 2 | 1.4 | 1.94 | Shear | 60 | ||

| Li et al. | [122] | AC (control) | - | 150 × 300 | - | - | 3.13 | Deep beam | 253 |

| AS (control) | - | 150 × 300 | - | - | 3.41 | Deep beam | 258 | ||

| A150 | CFRP-MF | 150 × 300 | - | 0.167 | 3.74 | Deep beam | 260 | ||

| A80 | CFRP-MF | 150 × 300 | - | 0.167 | 3.94 | Deep beam | 272 | ||

| A55 | CFRP-MF | 150 × 300 | - | 0.167 | 4.6 | Deep beam | 282 | ||

| BC (control) | - | 150 × 300 | - | - | 3.94 | SC | 74 | ||

| BS (control) | - | 150 × 300 | - | - | 4.63 | SC | 108 | ||

| B150 | CFRP-MF | 150 × 300 | - | 0.167 | 4.91 | SC | 112 | ||

| B80 | CFRP-MF | 150 × 300 | - | 0.167 | 5.23 | SC | 124 | ||

| B55 | CFRP-MF | 150 × 300 | - | 0.167 | 5.94 | SC | 129 | ||

| CC (control) | - | 150 × 300 | - | - | 4.56 | Flexural shear | 58 | ||

| CS (control) | - | 150 × 300 | - | - | 6.14 | Flexural shear | 94 | ||

| C150 | CFRP-MF | 150 × 300 | - | 0.167 | 6.27 | Flexural shear | 97 | ||

| C80 | CFRP-MF | 150 × 300 | - | 0.167 | 6.51 | Flexural shear | 109 | ||

| C55 | CFRP-MF | 150 × 300 | - | 0.167 | 7.51 | Flexural shear | 118 | ||

| Faramarzi et al. | [123] | U/3 (control) | - | 75–200 × 325 | - | - | 10 | Diagonal tension | 75.5 |

| S/3 | CFRP bars | 75–200 × 325 | - | - | 11.3 | Diagonal tension | 103.6 | ||

| U/1.9 (control) | - | 75–200 × 325 | - | - | 6 | SC | 103.9 | ||

| S/1.9 | CFRP bars | 75–200 × 325 | - | - | 10 | SC | 134.7 | ||

| Murad | [124] | SC (control) | - | 150 × 200 | - | 18 | Shear | 88 | |

| S0 | CFRP sheets at 0° | 150 × 200 | N/A | 0.166 | 16 | Shear | 93 | ||

| S90 | CFRP sheets at 90° | 150 × 200 | N/A | 0.166 | 20 | Shear | 100 | ||

| S45 | CFRP sheets at 45° | 150 × 200 | N/A | 0.166 | 20 | Shear | 103 | ||

| S60 | CFRP sheets at 60° | 150 × 200 | N/A | 0.166 | 25 | Shear | 91 |

| Properties | Benefit Rating | Scale | |

| FRP | Steel | 5 = Very high 4 = High 3 = Medium 2 = Low | |

| Weight | 5 | 2 | |

| Strength/stiffness | 4–5 | 4 | |

| Corrosion resilience | 4–5 | 3 | |

| Ease of construction work | 5 | 3–4 | |

| Ease of repair | 4–5 | 3–5 | |

| Fire behavior | 3–5 | 4 | |

| Ease of mobility | 5 | 3 | |

| Toughness | 4 | 4 | |

| Maintenance | 5 | 3 | |

| Author | Sample | FRP | Ref. | FRP Type | Main Finding |

|---|---|---|---|---|---|

| Gao et al. | 6 | GFRP | [211] | Tendon | Slabs were tested until the point of failure and their flexural behaviors and failure modes were examined in detail. The tests indicated that the proposed anchoring methodology is reliable and efficient. In the end, a method for stress calculation in the tendons was also proposed. |

| Kim et al. | 12 | CFRP | [213] | Sheets | All NSM fabricated samples and those utilizing the EP method exhibited the stiffness increase of 50–60% compared to the control PSC specimen. The EP method, when combined with prestressing, displayed the most effective strengthening results. |

| Wang et al. | 4 | BFRP | [36] | Tendon | All strengthened RC beams indicated failure due to concrete crushing, featuring satisfactory crack patterns and superior ductility compared to the control beam. This underscores the concurrent action of internal steel reinforcements and external BFRP tendons during loading. |

| Tran et al. | 32 | CFRP/HM-CFRP, AFRP, BFRP, GFRP | [215] | Tendon | CFRP tendons with an elastic modulus (E) of 145 GPa were determined as the optimal option for replacing steel in PSCBs with external tendons. This is attributed to their ability to provide similar strength and ductility to steel tendons in PSCBs. On the other hand, the utilization of high-modulus CFRP tendons, for instance, Ep = 200 GPa, resulted in the enhanced stiffness and strength for PSCBs but came at the expense of significantly reduced ductility in the beams. |

| Author | Ref. | Main Finding |

|---|---|---|

| Zeng et al. | [217] | The stress–strain curve for FRP-enclosed concrete within a CRC had a substantially steeper linear second section than the other rectangular column. Furthermore, when the rise to span ratio (r/s) increased, so did the ultimate axial tension. When compared to a corresponding rectangular column, CRCs with the r/s ratios of 0.05, 0.066, and 0.1 showed improvements in the ultimate axial stresses of 20%, 40%, and 70%, respectively. The corner radius ratio of 0.2 and the r/s value of 0.066 seem to be the best choices for a discernible increase in the final axial stress and effectiveness of the FRP encasement. |

| Zhu et al. | [218] | The impact of size variation is restricted in these FRP-confined CSCs, and the compressive strength can be noticeably improved through the SC method, except for the ultimate axial strain which was not considerably affected. |

| Pan et al. | [220] | With the increment in the slenderness ratio, the effect of strengthening decreased. The load-carrying capacity of FRP-covered columns was 20% more than the ordinary reinforced RC column when the slenderness ratio was limited under 18. |

| Teng and Lam. | [221] | The efficacy of confinement decreased as the major to minor axis length ratio reduced, and the stress-strain curve descended when the effective confinement ratio was 0.11 or less. Also, a strength model was established for FRP-confined concrete in elliptical columns. |

| Zhao et al. | [222] | The highest and lowest increments in the compressive strength were 125% and 88% for the samples with the r/s ratios of 0.1 and 0.05, respectively. |

| Yan et al. | [223] | The FRP-confined CSC and CRC’s post-peak hardening behavior was caused by SC/section ellipticalization. When compared to FRP jacket-confined elements, SM square/rectangular columns with post-tensioned FRP shells demonstrated a greater axial compressive strength and energy absorption. |

| Parvin and Shroeder. | [224] | The efficacy of CFRP covering was significantly decreased when loaded eccentrically compared to when loaded concentrically, and CFRP covering was more efficacious in the axial direction than the hoop direction for columns loaded eccentrically. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammad, M.; Bahrami, A.; Khokhar, S.A.; Khushnood, R.A. A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions. Materials 2024, 17, 1408. https://doi.org/10.3390/ma17061408

Hammad M, Bahrami A, Khokhar SA, Khushnood RA. A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions. Materials. 2024; 17(6):1408. https://doi.org/10.3390/ma17061408

Chicago/Turabian StyleHammad, Muhammad, Alireza Bahrami, Sikandar Ali Khokhar, and Rao Arsalan Khushnood. 2024. "A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions" Materials 17, no. 6: 1408. https://doi.org/10.3390/ma17061408

APA StyleHammad, M., Bahrami, A., Khokhar, S. A., & Khushnood, R. A. (2024). A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions. Materials, 17(6), 1408. https://doi.org/10.3390/ma17061408