Microscopic Factors Affecting the Performance of Pervious Concrete

Abstract

:1. Introduction

2. Experimental Process

2.1. Specimen Preparation

2.1.1. Test Materials

- (1)

- Cement: 42.5R ordinary silicate cement produced by the BBMG Corporation (Beijing, China), as shown in Table 1.

- (2)

- Coarse aggregate: Three types of single-size crushed stone with sizes in the ranges of 2.36–4.7, 4.75–9.5, and 9.5–16 mm, as shown in Table 2.

- (3)

- Water: tap water.

- (4)

- Fine sand: mechanism sand.

- (5)

- Mineral powder.

- (6)

- Polypropylene fiber, as shown in Table 3.

2.1.2. Specimen Casting

2.2. Microscopic Parameters

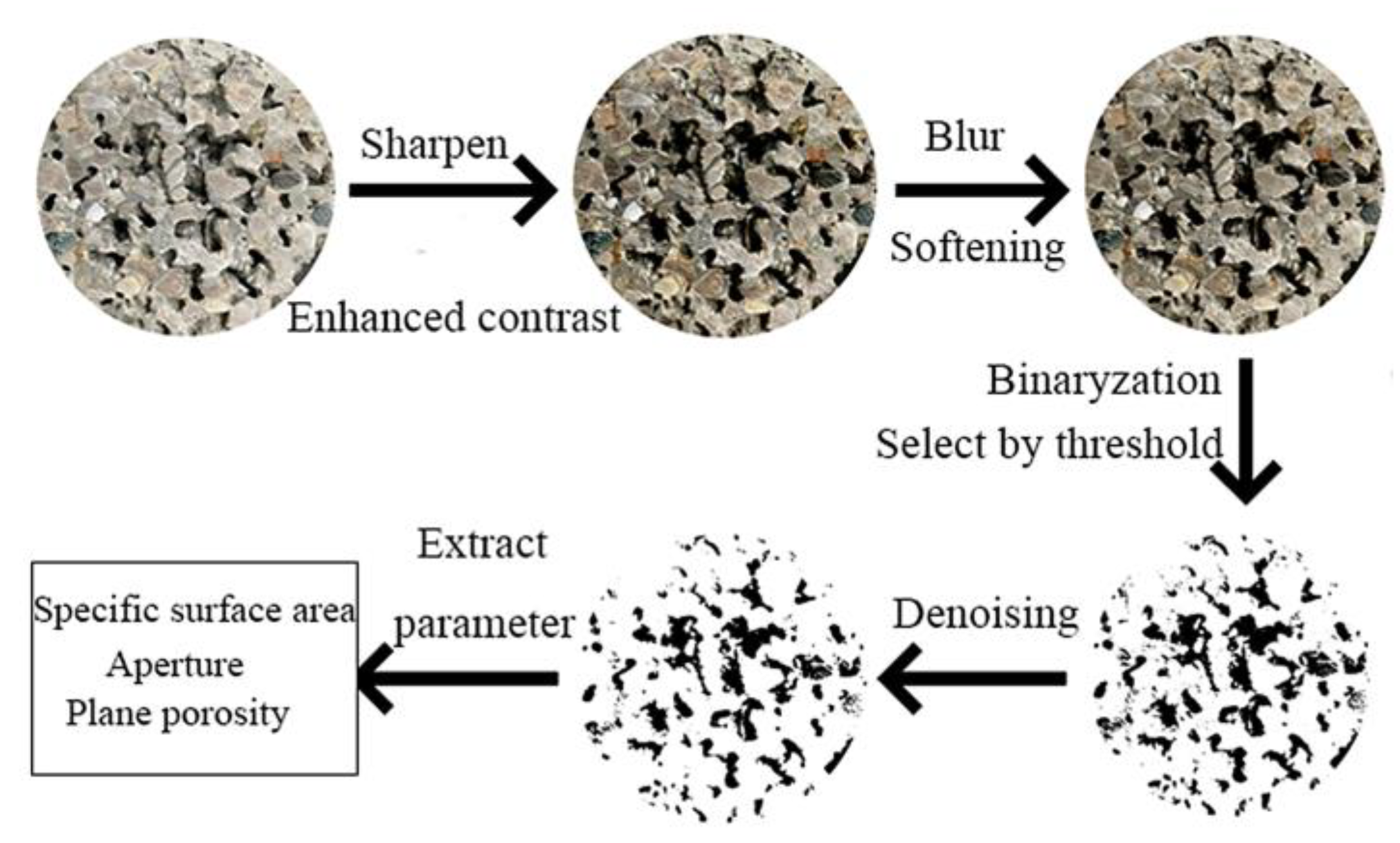

2.2.1. Pore Space Parameter Extraction

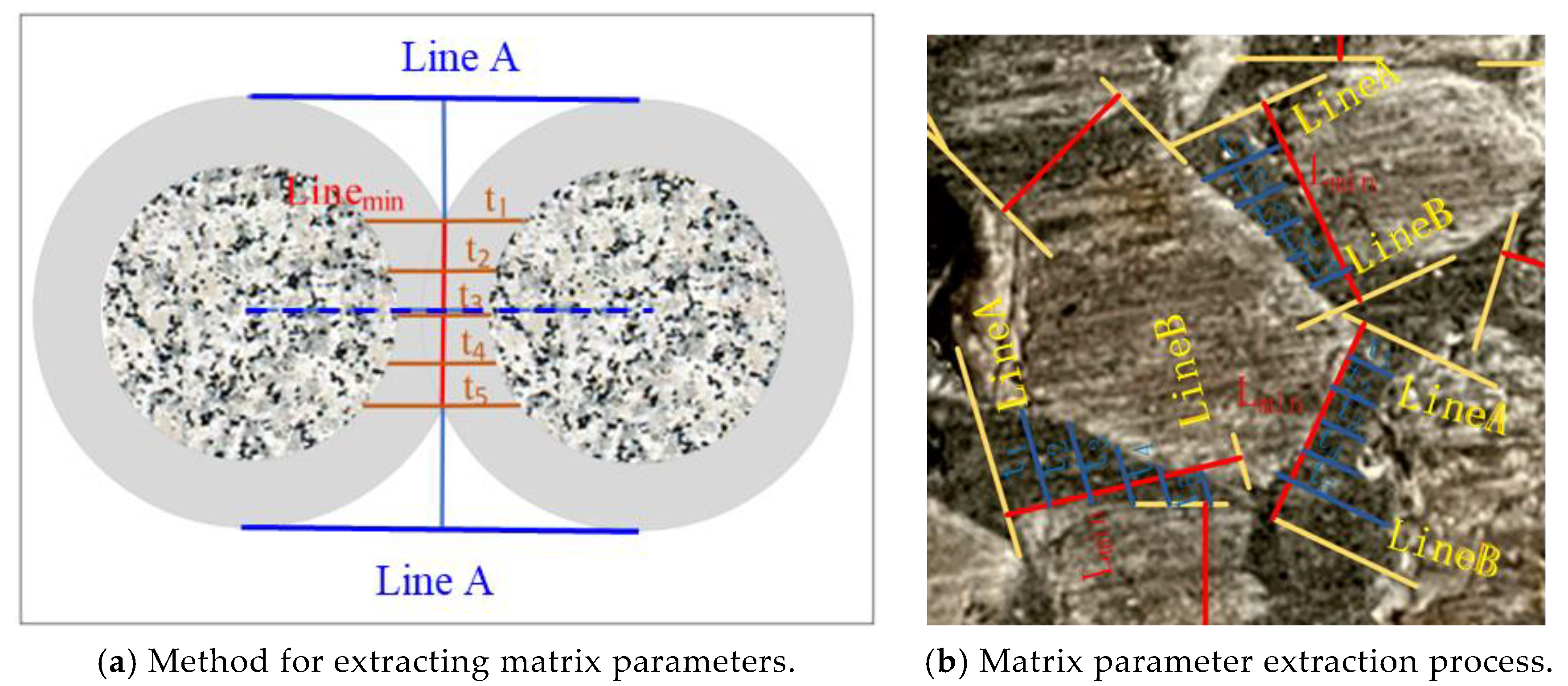

2.2.2. Matrix Parameter Extraction

3. Discussion and Analysis

3.1. Pore Parameters

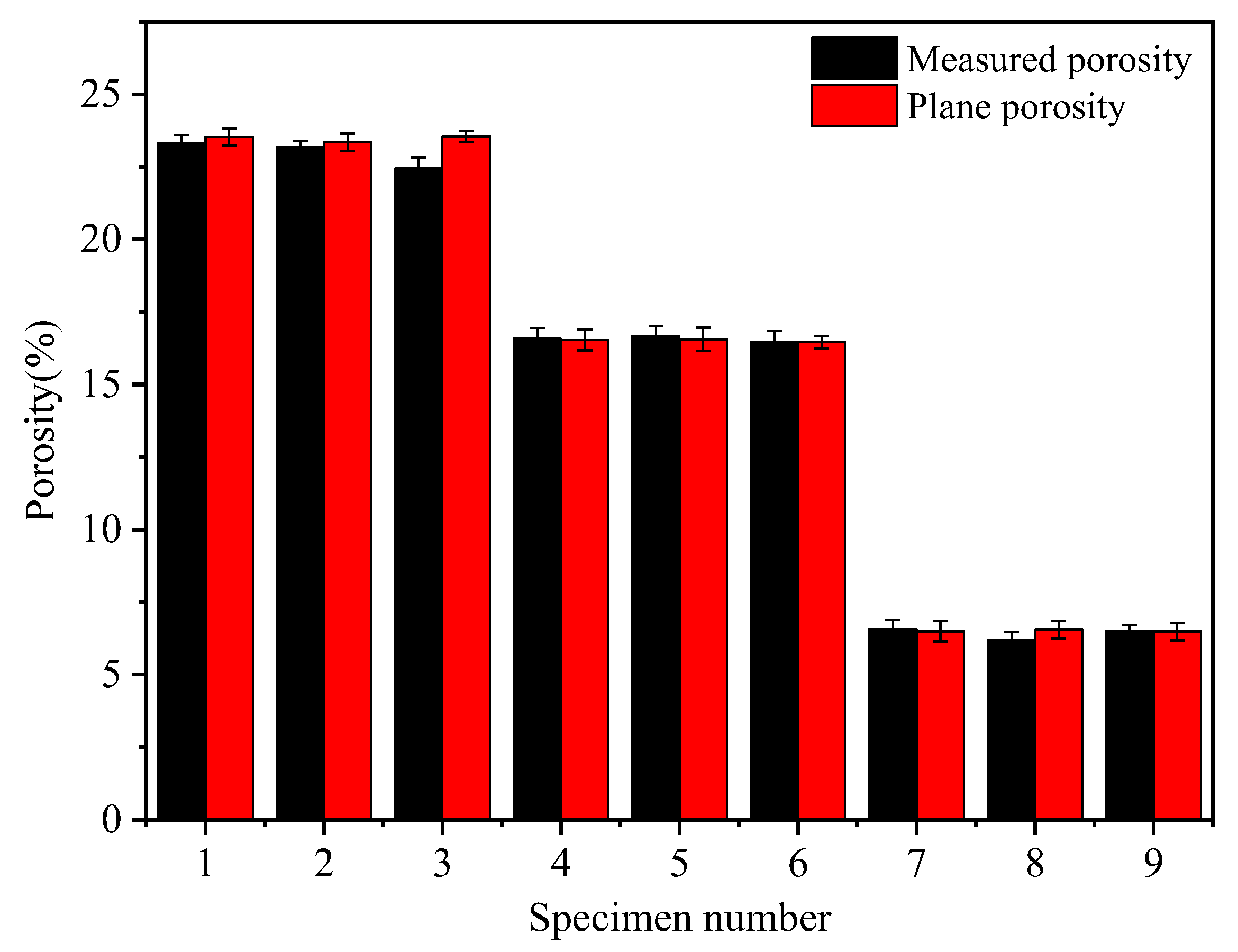

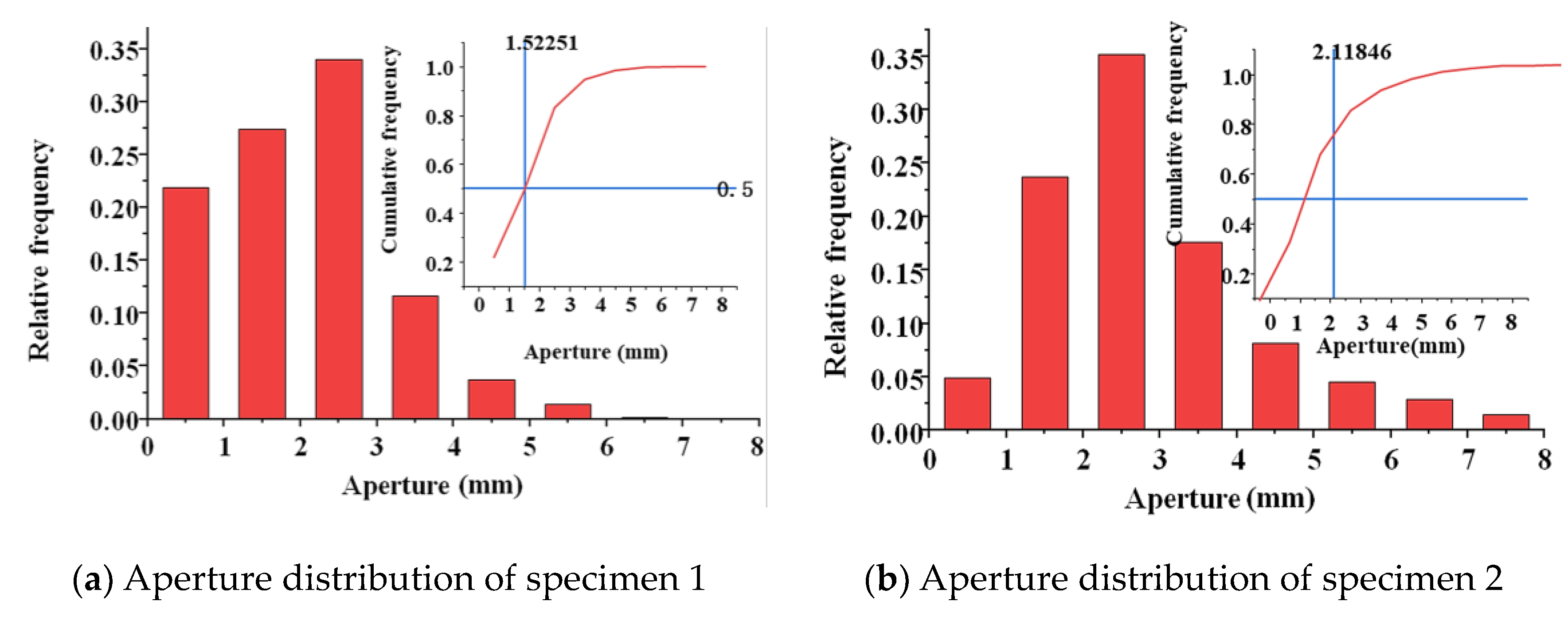

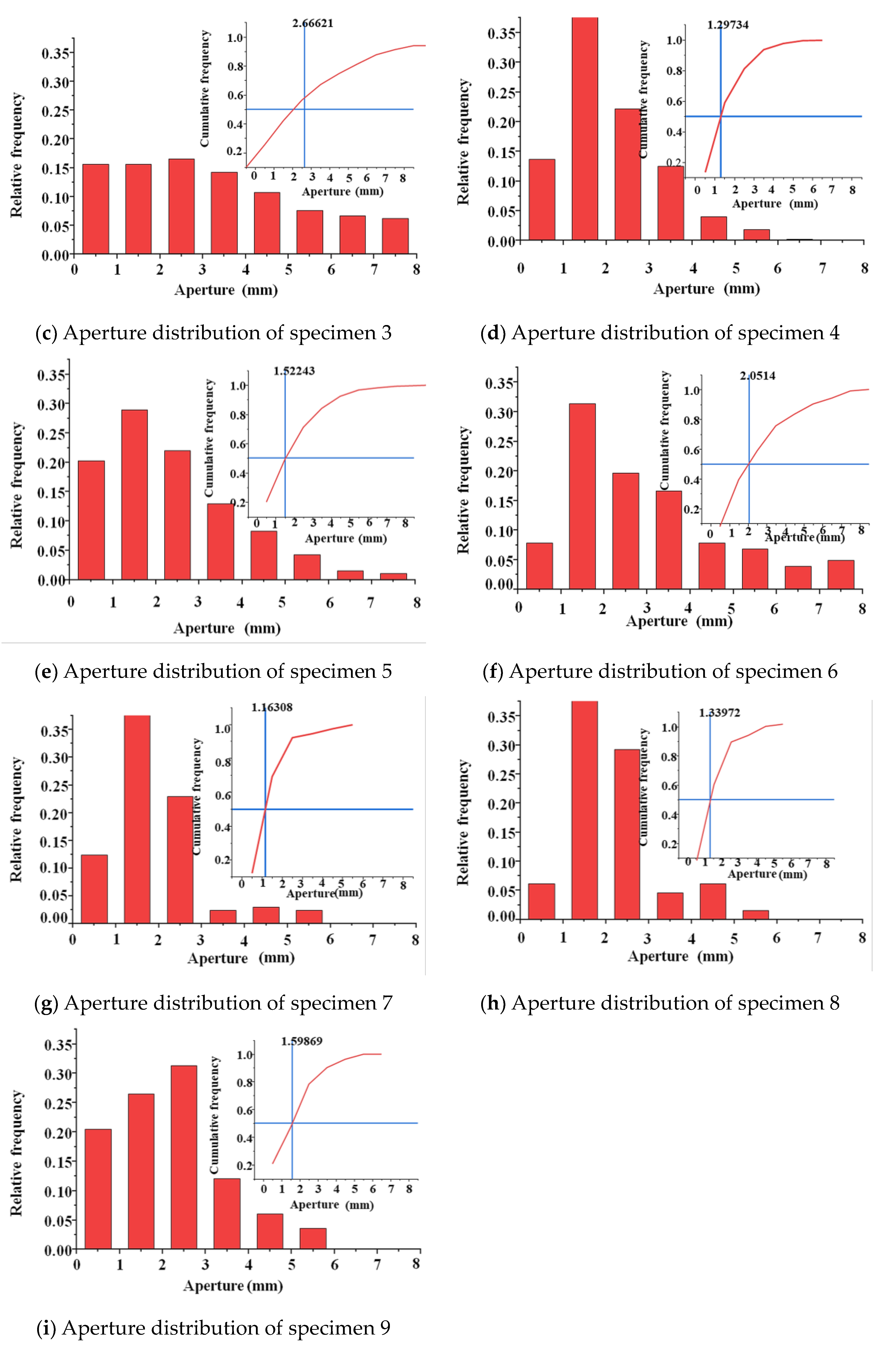

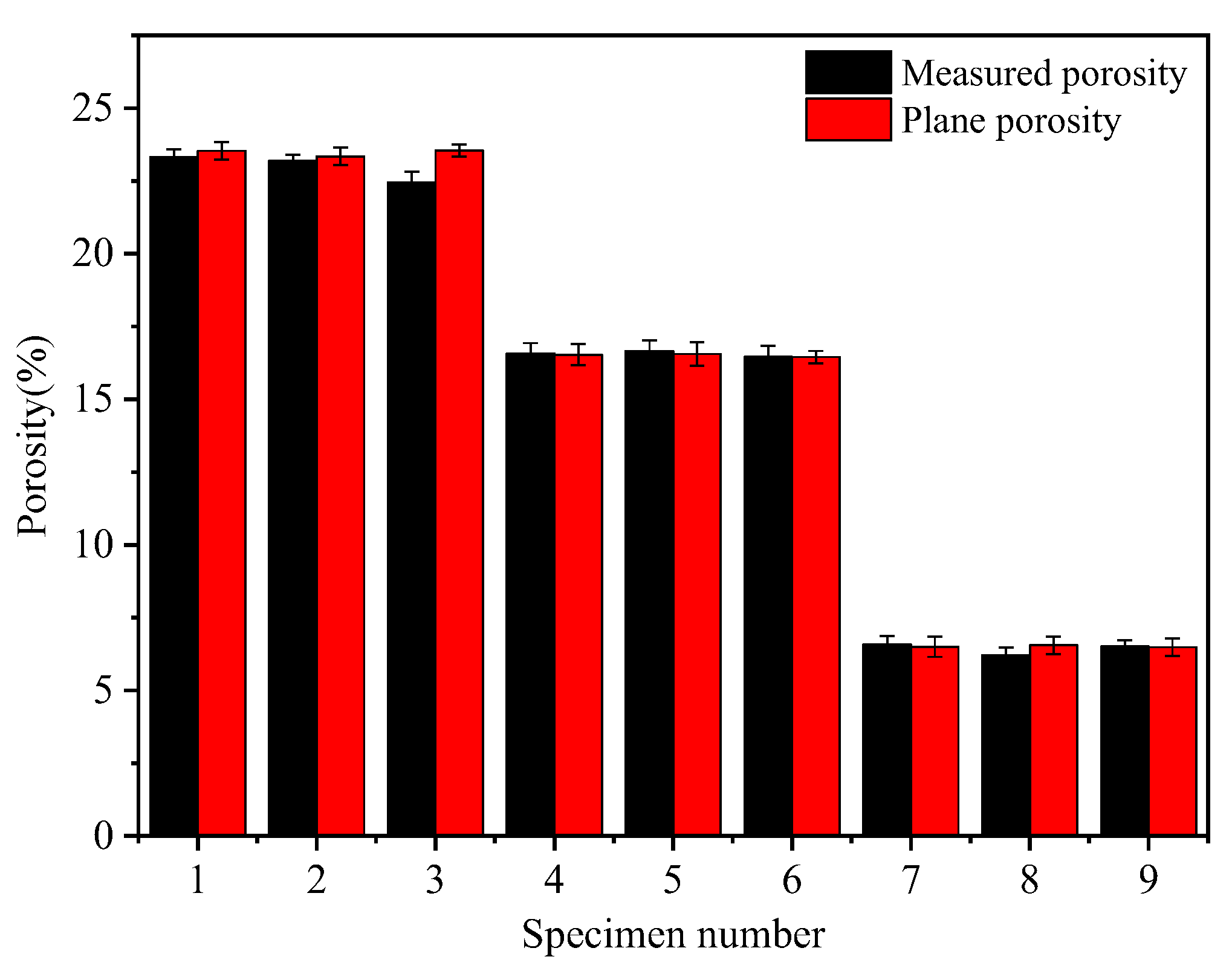

3.1.1. Porosity and Pore Size

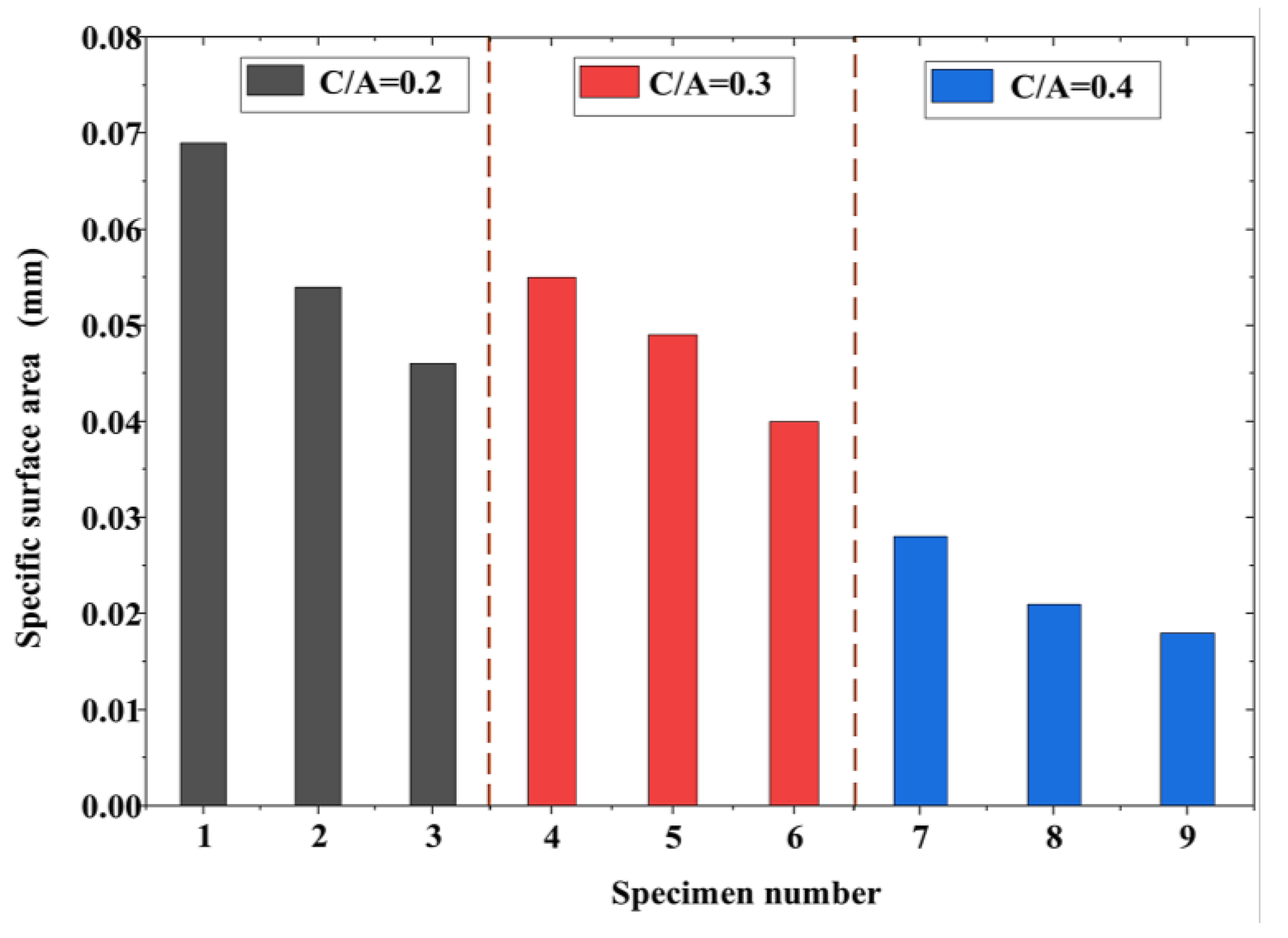

3.1.2. Specific Surface Area

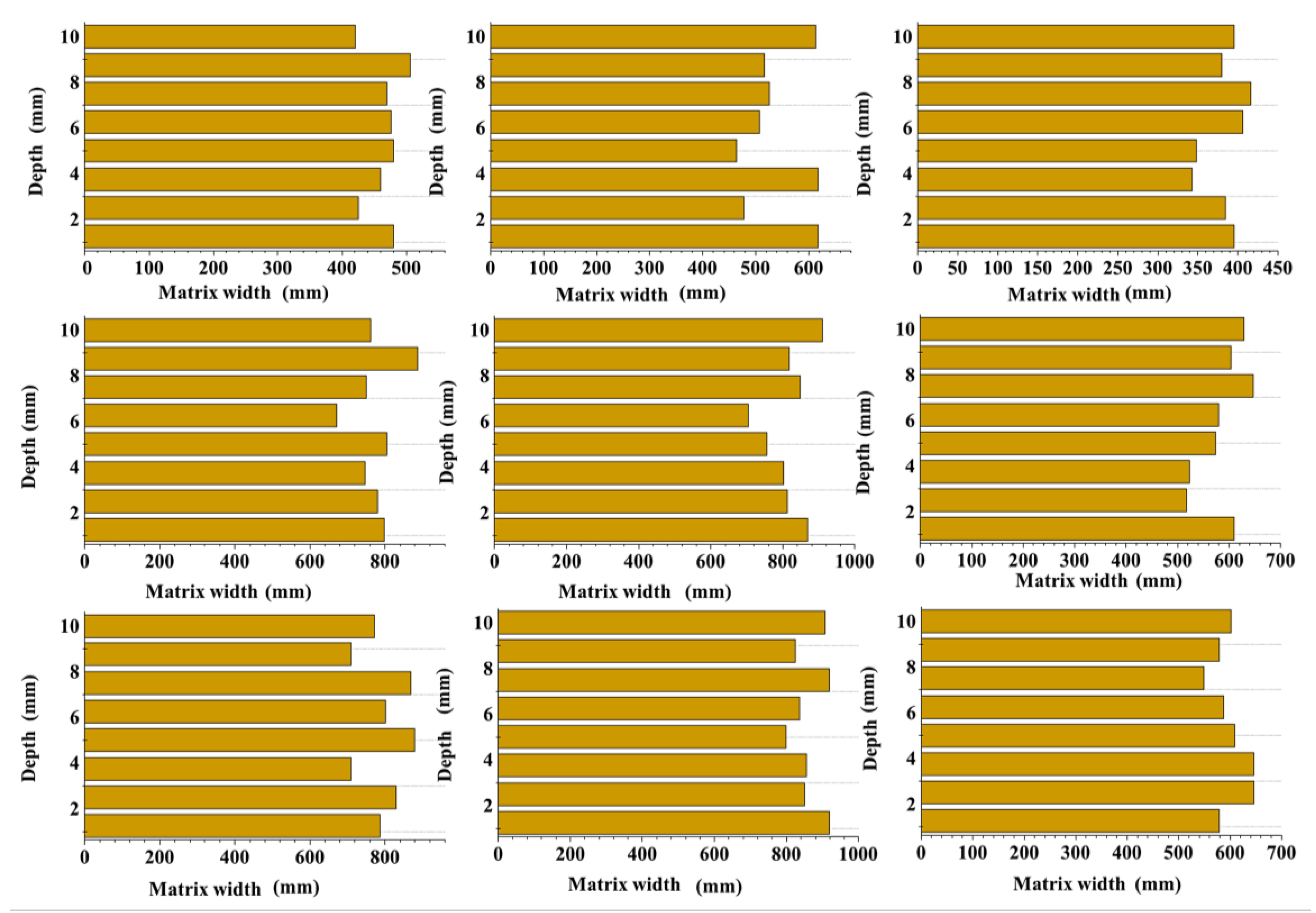

3.2. Substrate Parameters

3.2.1. Number of Effective Matrices

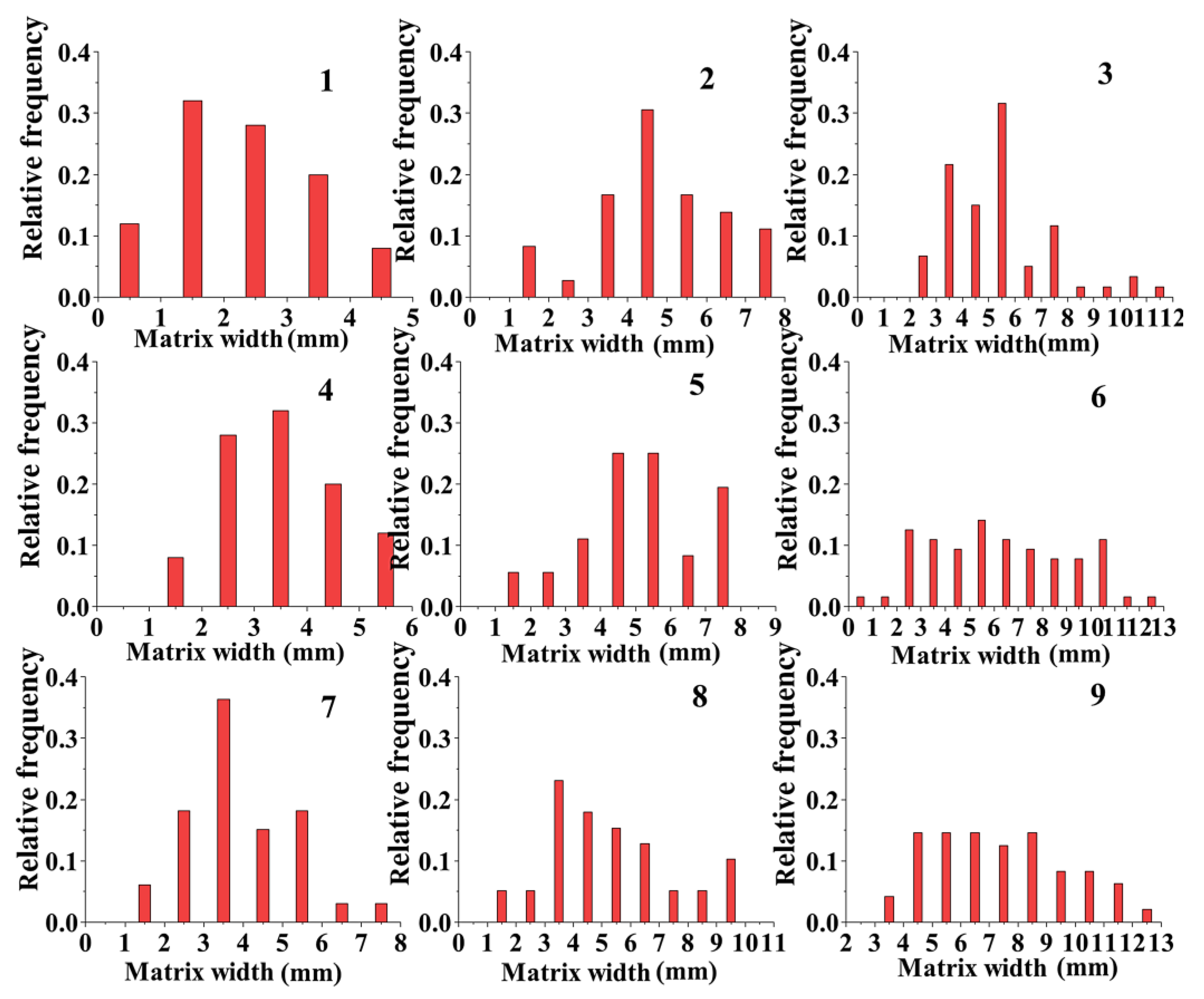

3.2.2. Width of the Effective Matrix

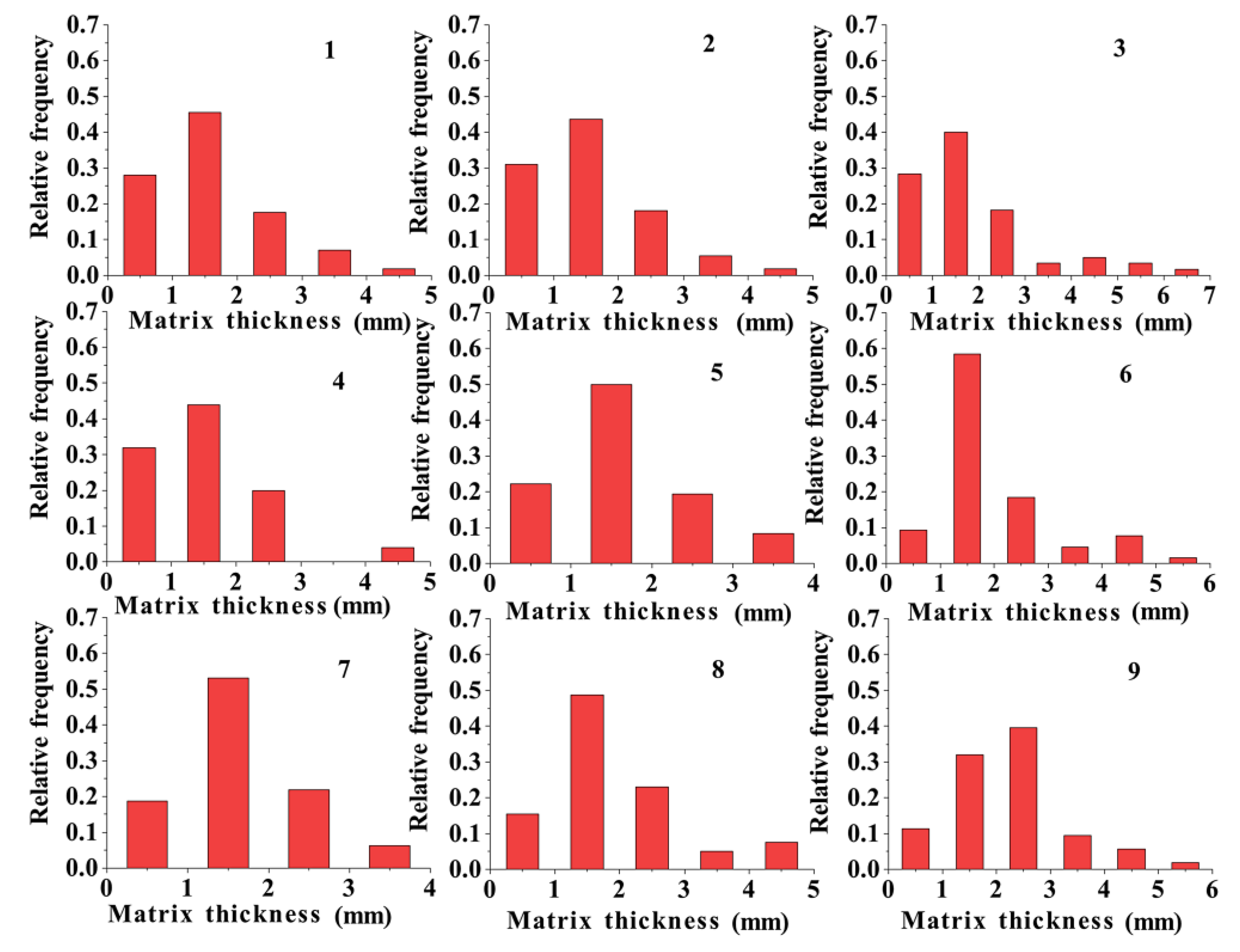

3.2.3. Effective Matrix Thickness

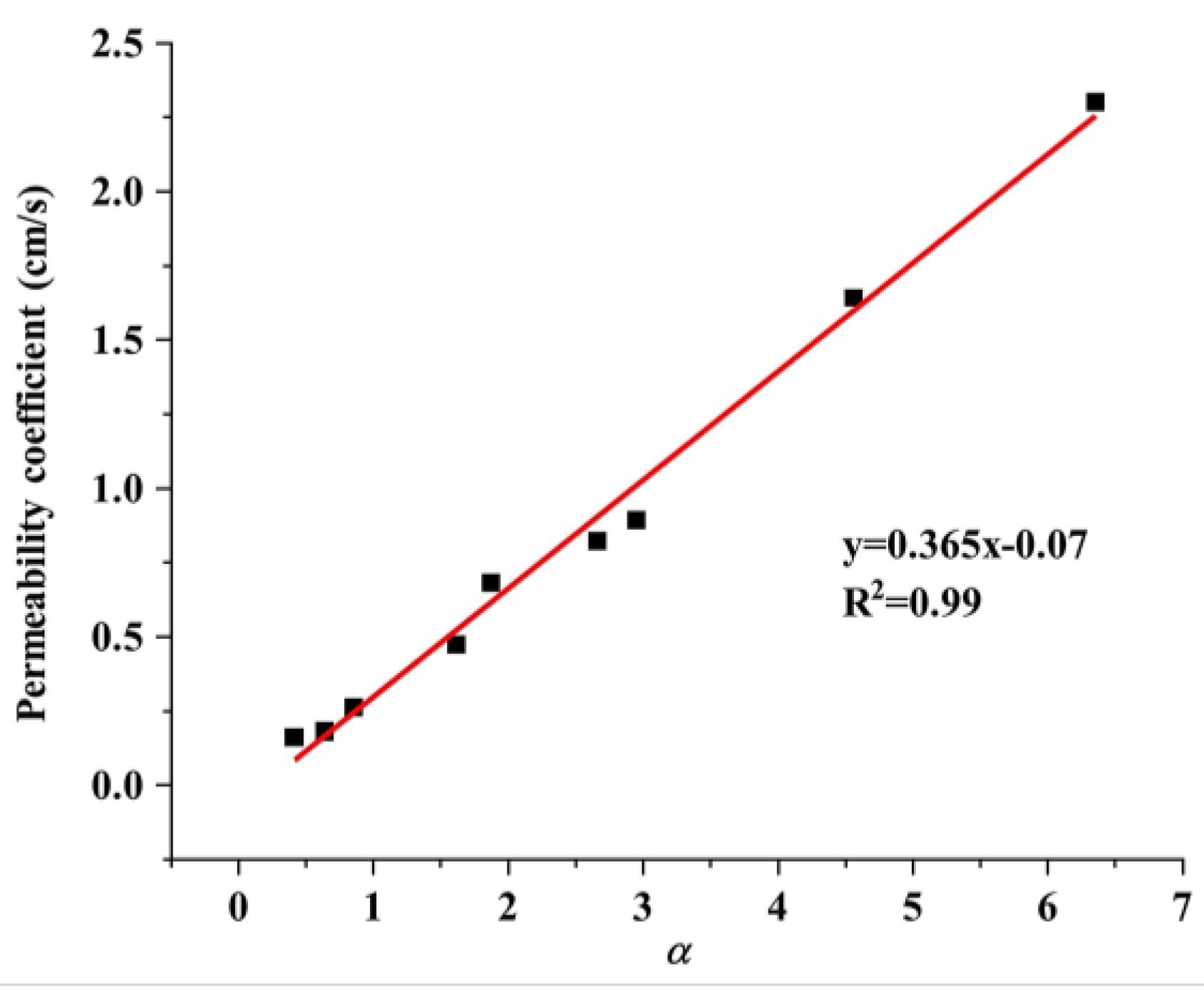

3.3. Coefficient of Permeability

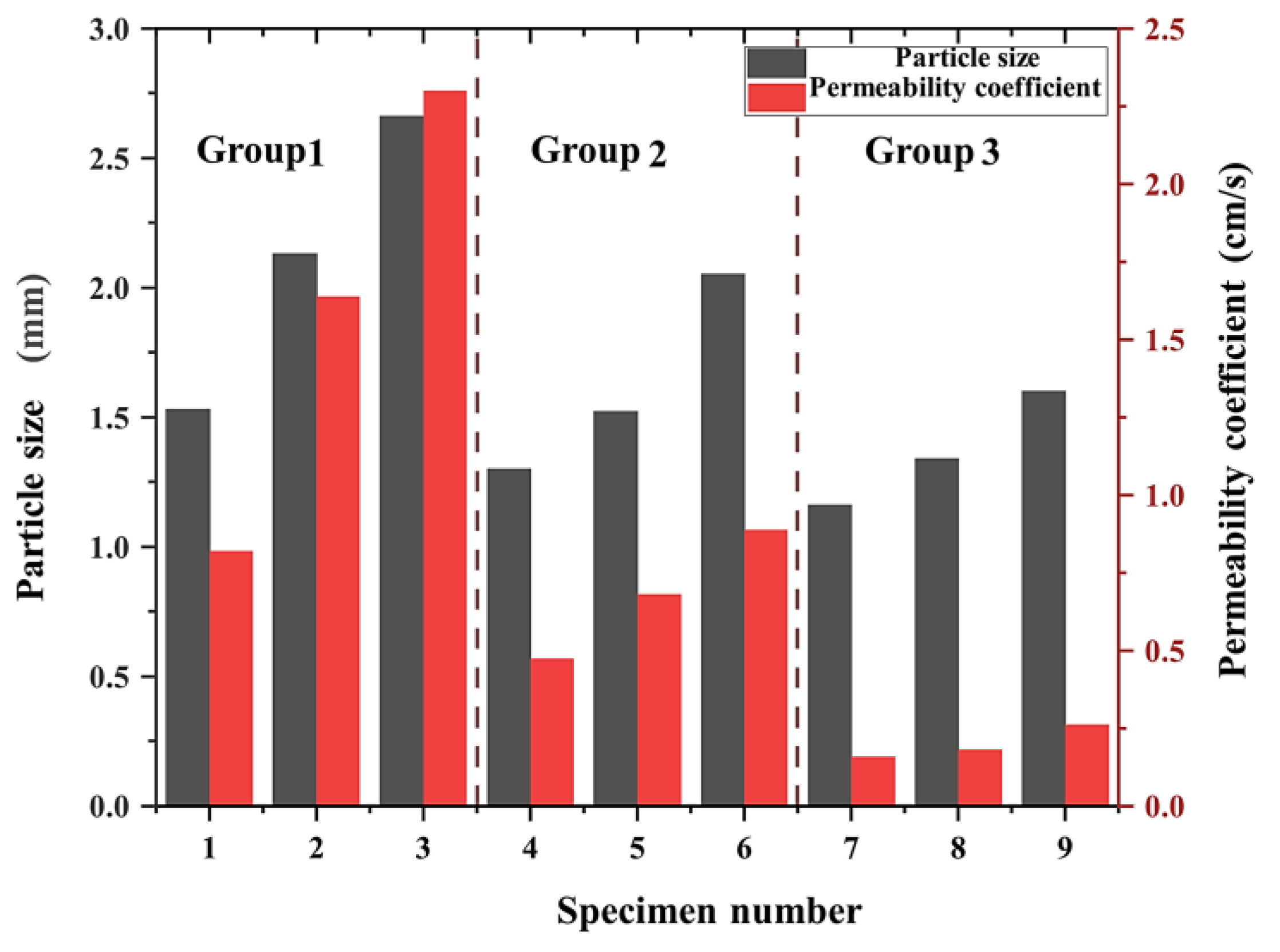

3.3.1. Effect of the Pore Size on the Permeability Coefficient

3.3.2. Effect of the Porosity and Specific Surface Area on the Permeability Coefficient

3.4. Compressive Strength

3.4.1. Matrix Area

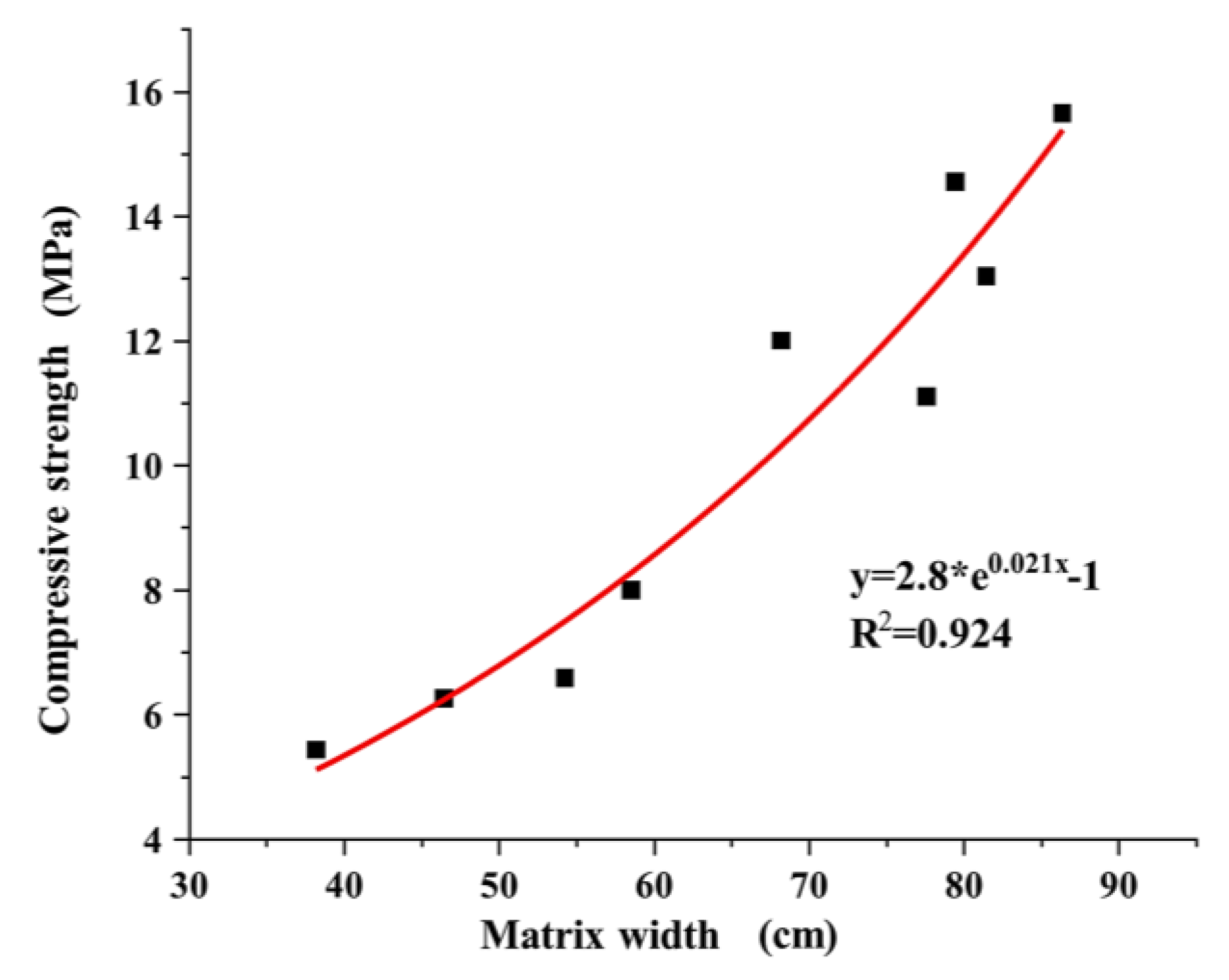

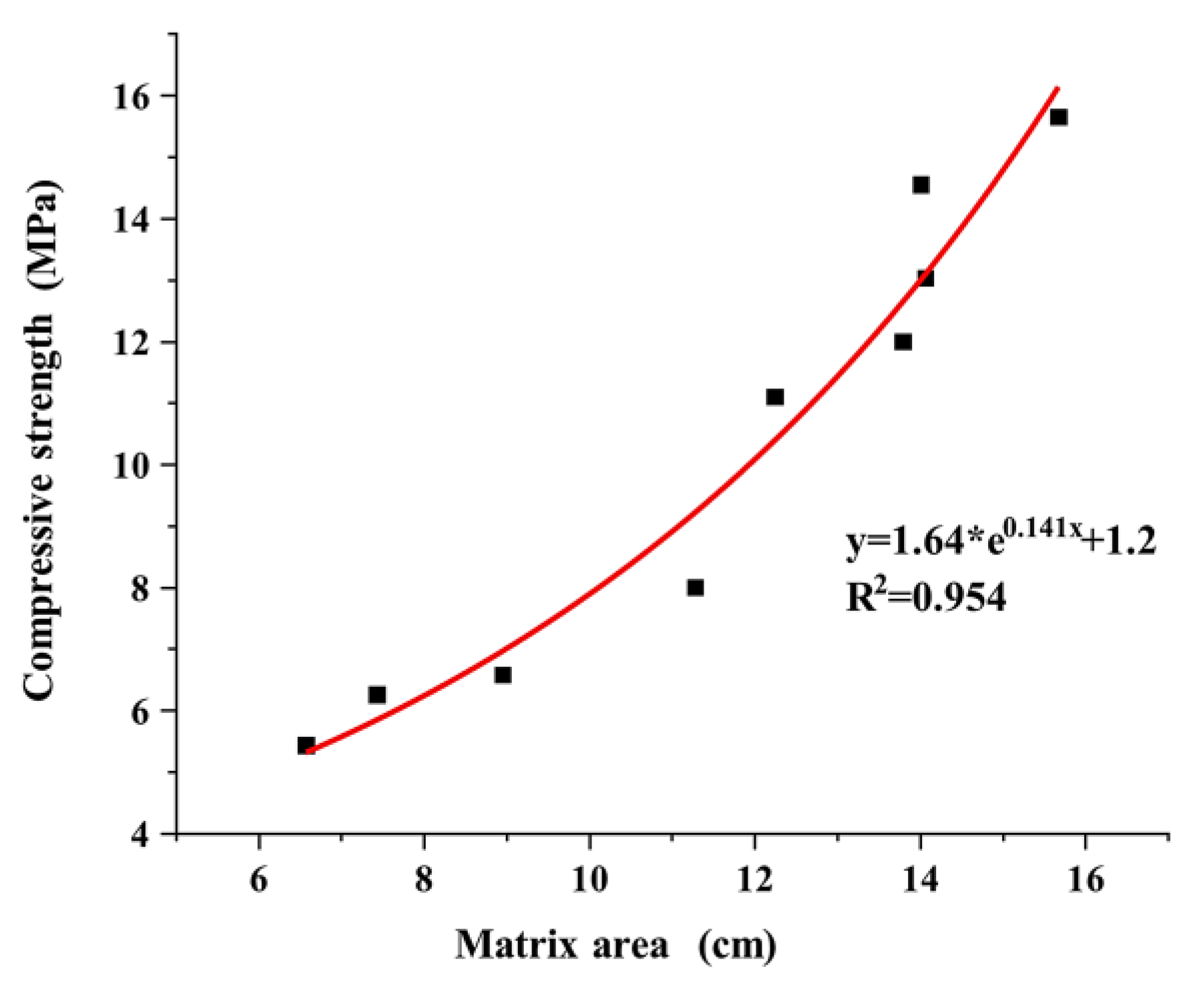

3.4.2. Effect of Matrix Parameters on Compressive Strength

4. Conclusions

- The feasibility of the research method was verified by the high consistency between the planar porosity obtained from the cross-section diagrams and porosity measured in tests. The test block’s internal pore diameter increased with the aggregate particle size; however, it decreased with the ash set ratio. Furthermore, a high porosity value corresponded to a large specific surface area. Conversely, when the porosity was the same, a large pore diameter resulted in a small specific surface area.

- When the ash set ratio was increased, the large pores were divided into smaller pores, increasing the number of cement matrices. Additionally, the smaller the aggregate particle size, the greater the number of matrices within the pervious concrete specimen. The effective matrix width was influenced by both the cement content and the aggregate particle size, and an increase in both factors resulted in a wider matrix. The matrix thickness was affected by the particle size; large particles resulted in a thicker matrix. Notably, the variations in cement content had minimal influence on the thickness of the cement matrix.

- The permeability coefficient of the pervious concrete was directly proportional to the product of the third power of porosity and the square of the specific surface area. Additionally, the permeability coefficient increased with the pore diameter. In contrast, the compressive strength of the pervious concrete was exponential relative to the matrix parameters. Specifically, the larger the total thickness and total area of the effective matrix, the greater the pervious concrete’s compressive strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mostafa, A.; Yamani, A.; Tabarestani, M.K.; Rooholamini, H. A comprehensive review on pervious concrete. Constr. Build. Mater. 2023, 407, 133308. [Google Scholar] [CrossRef]

- Emiko, L.; Tan, K.H.; Fwa, T.F. Effect of mix proportion on strength and permeability of pervious concrete for use in pavement. J. East. Asia Soc. Transp. Stud. 2013, 10, 1565–1575. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.T. Investigating the effect of mixture design parameters on pervious concrete by statistical modelling. Constr. Build. Mater. 2013, 38, 147–154. [Google Scholar] [CrossRef]

- Ibrahim, H.A.; Goh, Y.; Ng, Z.A.; Yap, S.P.; Moa, K.H.; Yuen, C.W.; Abutaha, F. Hydraulic and strength characteristics of pervious concrete containing a high volume of construction and demolition waste as aggregates. Constr. Build. Mater. 2020, 253, 119251. [Google Scholar] [CrossRef]

- Dai, Z.; Li, H.; Zhao, W.; Wang, X.; Wang, H.; Zhou, H.; Yang, B. Multi-modified effects of varying admixtures on the mechanical properties of pervious concrete based on optimum design of gradation and cement-aggregate ratio. Constr. Build. Mater. 2020, 233, 117178. [Google Scholar] [CrossRef]

- Makoto, Y.; Tomiku, R.; Okamoto, N. Influence of particle size of fine aggregate and void ratio on sound absorption property of porous mortar. Cem. Sci. Concr. Technol. 2015, 69, 718–724. [Google Scholar] [CrossRef]

- Elikten, S.; Canbaz, M. The influence of aggregate particle size and binder type on the properties of pervious concrete (agrega tane boyutunun ve balayici trnn germl beton zelklerne etks). Eskişehir Tek. Üniversitesi Bilim Teknol. Derg. B-Teor. Bilim. 2020, 8, 171–181. [Google Scholar] [CrossRef]

- Hiroshi, H.; Shimizu, J.; Mizukoshi, M. Influence of particle size and volume of fine aggregate on bending performace of ductile fiber reinforced cementitious composites. Cem. Sci. Concr. Technol. 2009, 63, 500–506. [Google Scholar] [CrossRef]

- Agar-Ozbek, A.S.; Weerheijm, J.; Schlangen, E.; van Breugel, K. Investigating porous concrete with improved strength: Testing at different scales. Constr. Build. Mater. 2013, 41, 480–490. [Google Scholar] [CrossRef]

- Elango, K.S.; Revathi, V. Fal-G binder pervious concrete. Constr. Build. Mater. 2017, 140, 91–99. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Z.; Khan, M.B.E. Impact of aggregate type and size and mineral admixtures on the properties of pervious concrete: An experimental investigation. Constr. Build. Mater. 2020, 265, 120759. [Google Scholar] [CrossRef]

- Cosic, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Ahmet, A.; Çağatay, I.K. Investigation of the density, porosity, and permeability properties of pervious concrete with different methods. Constr. Build. Mater. 2021, 294, 123539. [Google Scholar] [CrossRef]

- Neithalath, N.; Bentz, D.P.; Sumanasoorlya, M.S. Predicting the permeability of pervious concrete: Advances in characterization of pore structure and transport properties. Concr. Int. 2010, 32, 35–40. [Google Scholar]

- Emiko, L.; Tan, K.H.; Fwa, T.F. High-strength high-porosity pervious concrete pavement. Adv. Mater. Res. 2013, 723, 361–367. [Google Scholar] [CrossRef]

- Endawati, J. Permeability and porosity of pervious concrete containing blast furnace slag as a part of binder materials and aggregate. Solid State Phenom. 2017, 266, 272–277. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y. Optimum mix design of enhanced permeable concrete—An experimental investigation. Constr. Build. Mater. 2010, 24, 2664–2671. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Hatanaka, S.; Chareerat, T.; Mishima, N.; Yuasa, Y. Cement paste characteristics and porous concrete properties. Constr. Build. Mater. 2008, 22, 894–901. [Google Scholar] [CrossRef]

- Care, F.R.A.M. Fatigue life analysis of rigid pavement structure with pervious concrete base layer using 2d finite element method. Int. J. GEOMATE 2019, 17, 263–270. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Effect of pore structure on fatigue of pervious concrete. Road Mater. Pavement Des. 2019, 20, 1525–1547. [Google Scholar] [CrossRef]

- Zaman, A.B.K. Lateral infiltration capacity of pervious concrete and its performance as pavement curb. J. Mater. Civ. Eng. 2022, 34, 04021468. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P.P. Prediction and model development for fatigue performance of pervious concrete made with over burnt brick aggregate. Mater. Struct. 2020, 53, 86. [Google Scholar] [CrossRef]

- Brisard, S. Mesoscale pore structure of a high-performance concrete by coupling focused ion beam/scanning electron microscopy and small angle X-ray scattering. J. Am. Ceram. Soc. 2019, 102, 2905–2923. [Google Scholar] [CrossRef]

- Islam, M.D.S.; Islam, R. A critical survey on developed reconstruction algorithms for computed tomography imaging from a limited number of projections. Int. J. Image Graph. 2023, 23, 2350026. [Google Scholar] [CrossRef]

- Das, B.B.; Kondraivendhan, B. Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Constr. Build. Mater. 2012, 28, 382–386. [Google Scholar] [CrossRef]

- Ong, G.P.; Jagadeesh, A.; Su, Y.-M. Effect of pore network characteristics on non-darcy permeability of pervious concrete mixture. Constr. Build. Mater. 2020, 259, 119859. [Google Scholar] [CrossRef]

- Lu, J.-X.; Yan, X.; He, P.; Poon, C.S. Sustainable design of pervious concrete using waste glass and recycled concrete aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Lima, G.T.d.S.; Rocha, J.C.; Cheriaf, M. Investigation of the properties of pervious concrete with a recycled aggregate designed with a new combination of admixture. Constr. Build. Mater. 2022, 340, 127710. [Google Scholar] [CrossRef]

- Calonne, N.; Geindreau, C.; Flin, F.; Morin, S.; Lesaffre, B.; Rolland, R.; Charrier, P. 3-D image-based numerical computations of snow permeability: Links to specific surface area, density, and microstructural anisotropy. Cryosphere 2012, 6, 939–951. [Google Scholar] [CrossRef]

- Shishir, G.; Das, S.; Dutta, R. Peltier and Seebeck effects on a nonlocal couple stress double porous thermoelastic diffusive material under memory-dependent Moore-Gibson-Thompson theory. Mech. Adv. Mater. Struct. 2023, 30, 449–472. [Google Scholar] [CrossRef]

- Powers, T.C. The specific surface area of hydrated cement obtained from permeability data. Matériaux Constr. 1979, 12, 159–168. [Google Scholar] [CrossRef]

- Li, Y.; Sheng, J.; Li, W.; Yu, M.; Zheng, X.; Wang, F. Effect of a novel spherical tailings aggregate on the macro- and mesoscopic properties of pervious concrete. Cem. Concr. Compos. 2023, 144, 105311. [Google Scholar] [CrossRef]

- Brasileiro, K.P.T.V.; Nahime, B.d.O.; Lima, E.C.; Alves, M.M.; Ferreira, W.P.; Santos, I.S.d.; Filho, C.P.B.; Reis, I.C.d. Influence of recycled aggregates and silica fume on the performance of pervious concrete. J. Build. Eng. 2024, 82, 108347. [Google Scholar] [CrossRef]

- Zhao, H.; Geng, Q.; Liu, X. Influence of freeze–thaw cycles on mechanical properties of pervious concrete: From experimental studies to discrete element simulations. Constr. Build. Mater. 2023, 409, 133988. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Y.; Zhang, H.; Du, X.; Chen, L.; Zhao, Q.; Li, B. Brick-concrete recycled aggregate/powder synergistic preparation of pervious concrete. Constr. Build. Mater. 2023, 407, 133517. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | SiO3 | Fe2O3 | Al2O3 | CaO | MgO | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|

| Content/% | 21.45 | 2.75 | 2.40 | 5.15 | 63.40 | 1.5 | 0.19 | 1.50 |

| Particle Size Range/(mm) | Sludge Content/% | Apparent Density/(kg/m3) | Compact Bulk Density/(kg/m3) | Porosity/% |

|---|---|---|---|---|

| 2.36–4.7 | 0.5 | 2802 | 1471 | 48.8 |

| 4.75–9.5 | 0.5 | 2788 | 1452 | 47.3 |

| 9.5–16 | 0.5 | 2709 | 1429 | 45.6 |

| Density/(g/cm3) | Diameter/(μm) | Length/(μm) | E/MPa | Elongation/% | Tensile Strength/MPa | Water Absorption/% |

|---|---|---|---|---|---|---|

| 0.94 | 3~4.5 | 120 | 4.2 × 103 | 9.3 | 3950 | <0.1 |

| No. | Aggregate Particle Size | Water–Cement Ratio | Ash Set Ratio | Fine Aggregate |

|---|---|---|---|---|

| 1 | 2.36–4.75 mm | 0.36 | 0.2 | 10% |

| 2 | 4.75–9.5 mm | 0.36 | 0.2 | 10% |

| 3 | 9.5–16 mm | 0.36 | 0.2 | 10% |

| 4 | 2.36–4.75 mm | 0.36 | 0.3 | 10% |

| 5 | 4.75–9.5 mm | 0.36 | 0.3 | 10% |

| 6 | 9.5–16 mm | 0.36 | 0.3 | 10% |

| 7 | 2.36–4.75 mm | 0.36 | 0.4 | 10% |

| 8 | 4.75–9.5 mm | 0.36 | 0.4 | 10% |

| 9 | 9.5–16 mm | 0.36 | 0.4 | 10% |

| No. | Measured Porosity (%) | Calculated Porosity (%) | Average Pore Size (mm) | Specific Surface Area (mm2/mm3) | Width of Matrix (mm) | Matrix Quantity | Matrix Thickness (mm) | Permeability Coefficient (cm/s) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 23.62 | 23.31 | 1.53 | 0.069 | 2.29 | 201 | 1.60 | 0.82 | 6.26 |

| 2 | 23.47 | 23.70 | 2.13 | 0.054 | 4.79 | 112 | 1.65 | 1.64 | 6.58 |

| 3 | 22.94 | 23.79 | 2.66 | 0.046 | 5.27 | 73 | 1.72 | 2.30 | 5.43 |

| 4 | 16.50 | 16.98 | 1.30 | 0.055 | 3.59 | 216 | 1.57 | 0.47 | 11.1 |

| 5 | 16.71 | 16.52 | 1.52 | 0.049 | 5.13 | 158 | 1.71 | 0.68 | 13.03 |

| 6 | 16.29 | 16.78 | 2.05 | 0.04 | 6.16 | 95 | 1.92 | 0.89 | 8 |

| 7 | 6.51 | 6.88 | 1.16 | 0.028 | 3.87 | 205 | 1.68 | 0.16 | 14.55 |

| 8 | 6.49 | 6.56 | 1.34 | 0.021 | 5.29 | 137 | 1.91 | 0.18 | 15.65 |

| 9 | 6.58 | 6.52 | 1.60 | 0.018 | 7.50 | 80 | 2.12 | 0.26 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Li, H.; Cao, Q.; Ke, D.; Yin, S.; Li, Q. Microscopic Factors Affecting the Performance of Pervious Concrete. Materials 2024, 17, 1479. https://doi.org/10.3390/ma17071479

Liu Q, Li H, Cao Q, Ke D, Yin S, Li Q. Microscopic Factors Affecting the Performance of Pervious Concrete. Materials. 2024; 17(7):1479. https://doi.org/10.3390/ma17071479

Chicago/Turabian StyleLiu, Qin, Hu Li, Qianli Cao, Di Ke, Shiyang Yin, and Qinpeng Li. 2024. "Microscopic Factors Affecting the Performance of Pervious Concrete" Materials 17, no. 7: 1479. https://doi.org/10.3390/ma17071479

APA StyleLiu, Q., Li, H., Cao, Q., Ke, D., Yin, S., & Li, Q. (2024). Microscopic Factors Affecting the Performance of Pervious Concrete. Materials, 17(7), 1479. https://doi.org/10.3390/ma17071479