Abrasive Wear Properties of Wear-Resistant Coating on Bucket Teeth Assessed Using a Dry Sand Rubber Wheel Tester

Abstract

:1. Introduction

2. Materials and Methods

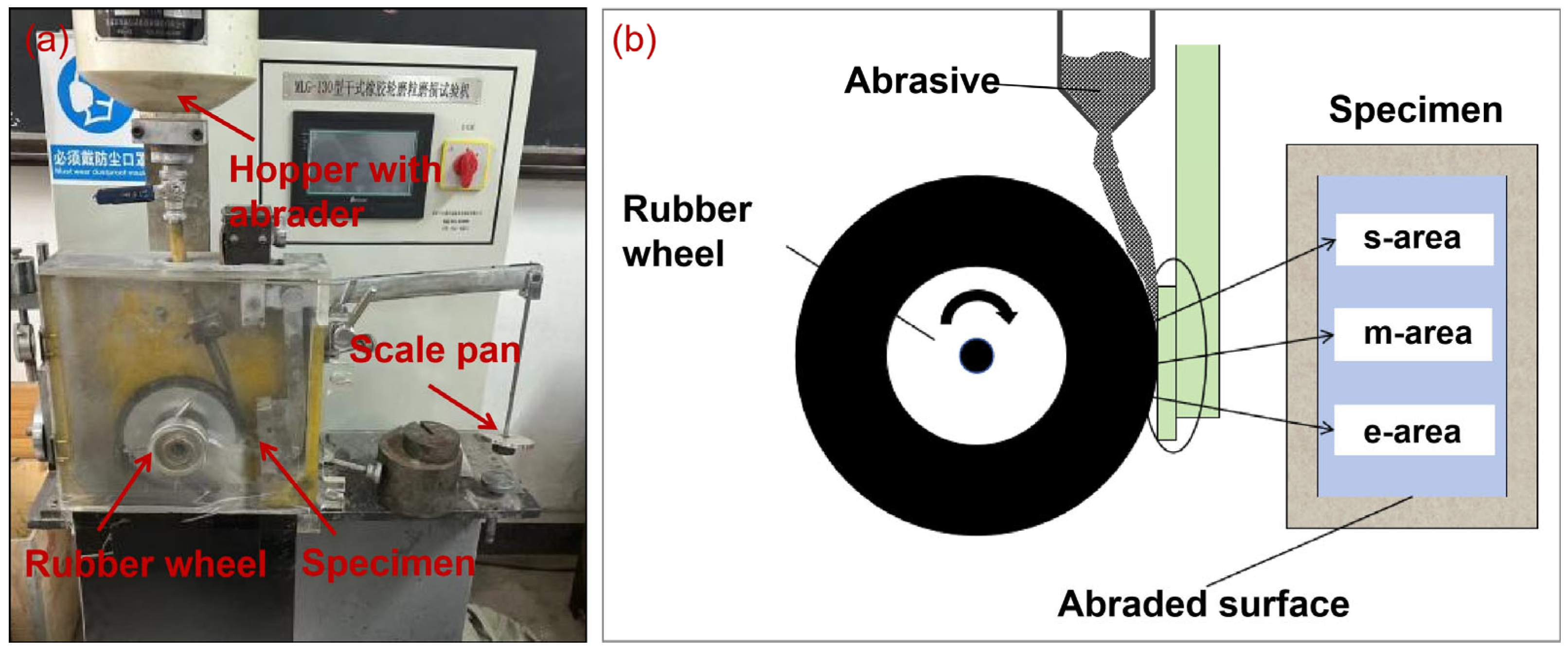

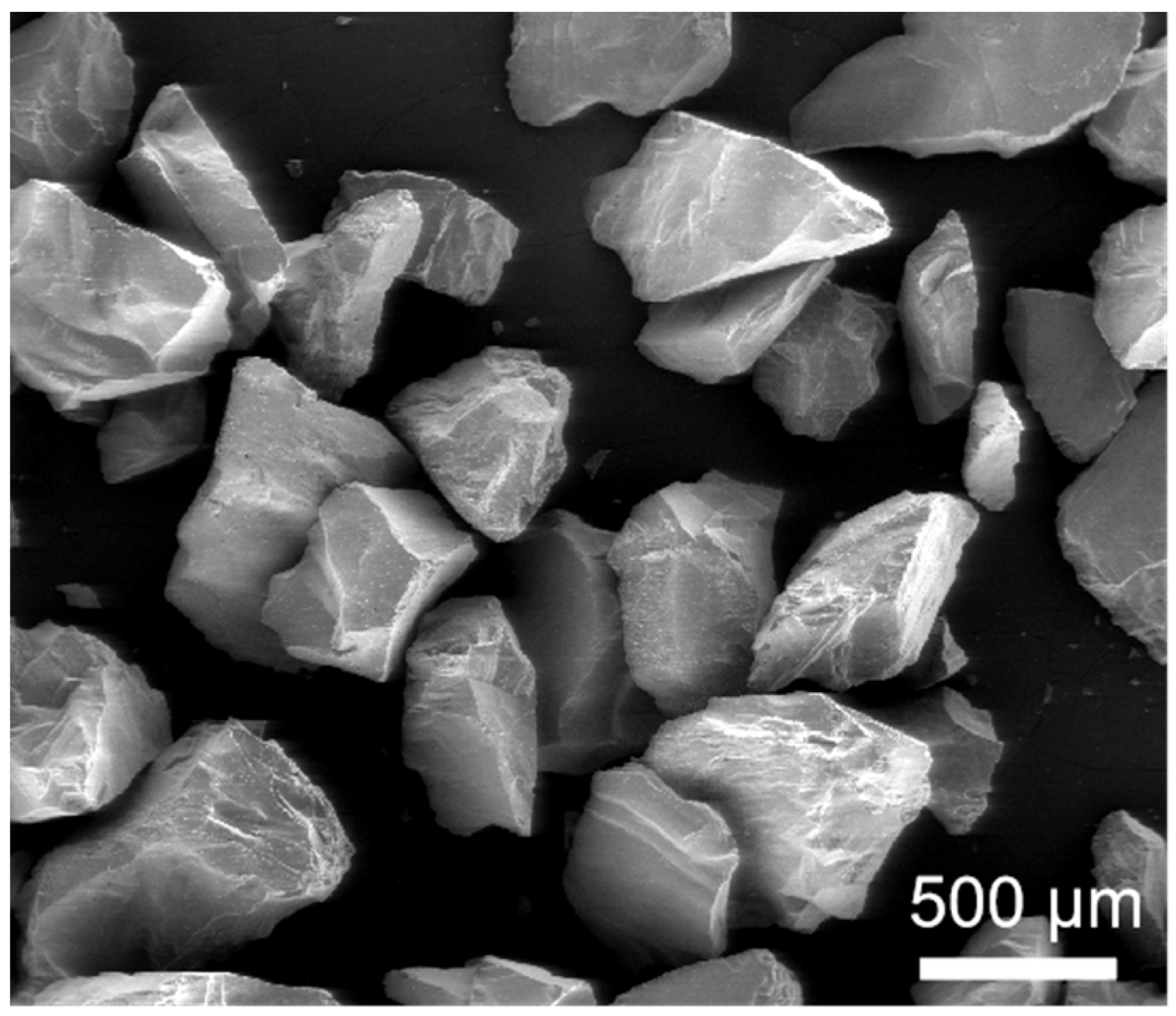

2.1. Test System and Procedures

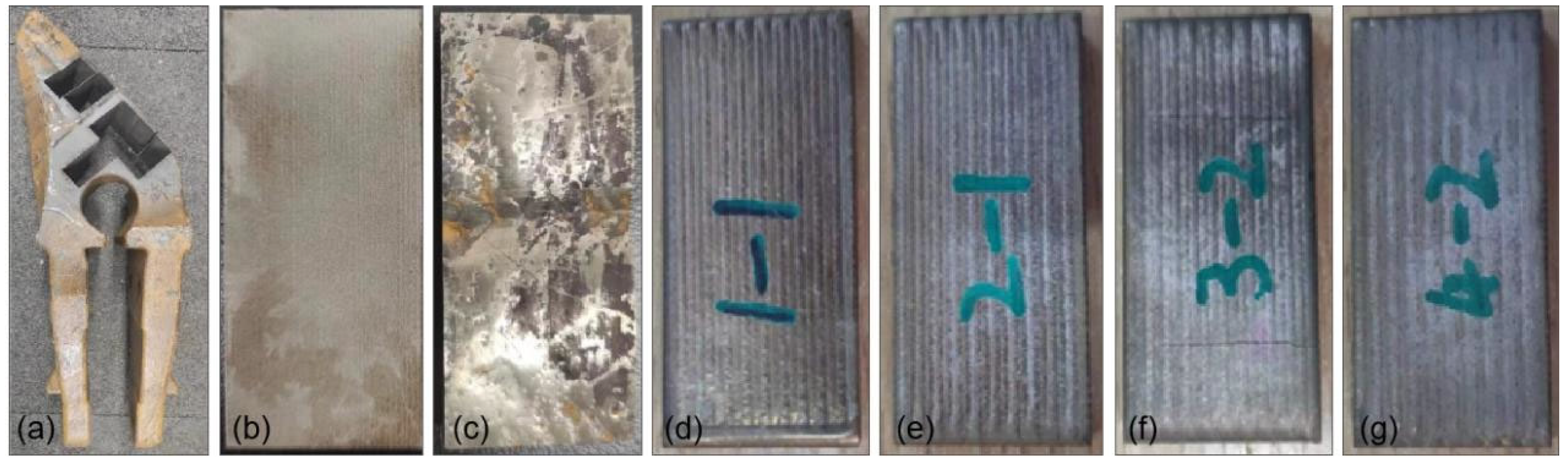

2.2. Materials

2.3. Characterization

3. Results and Discussion

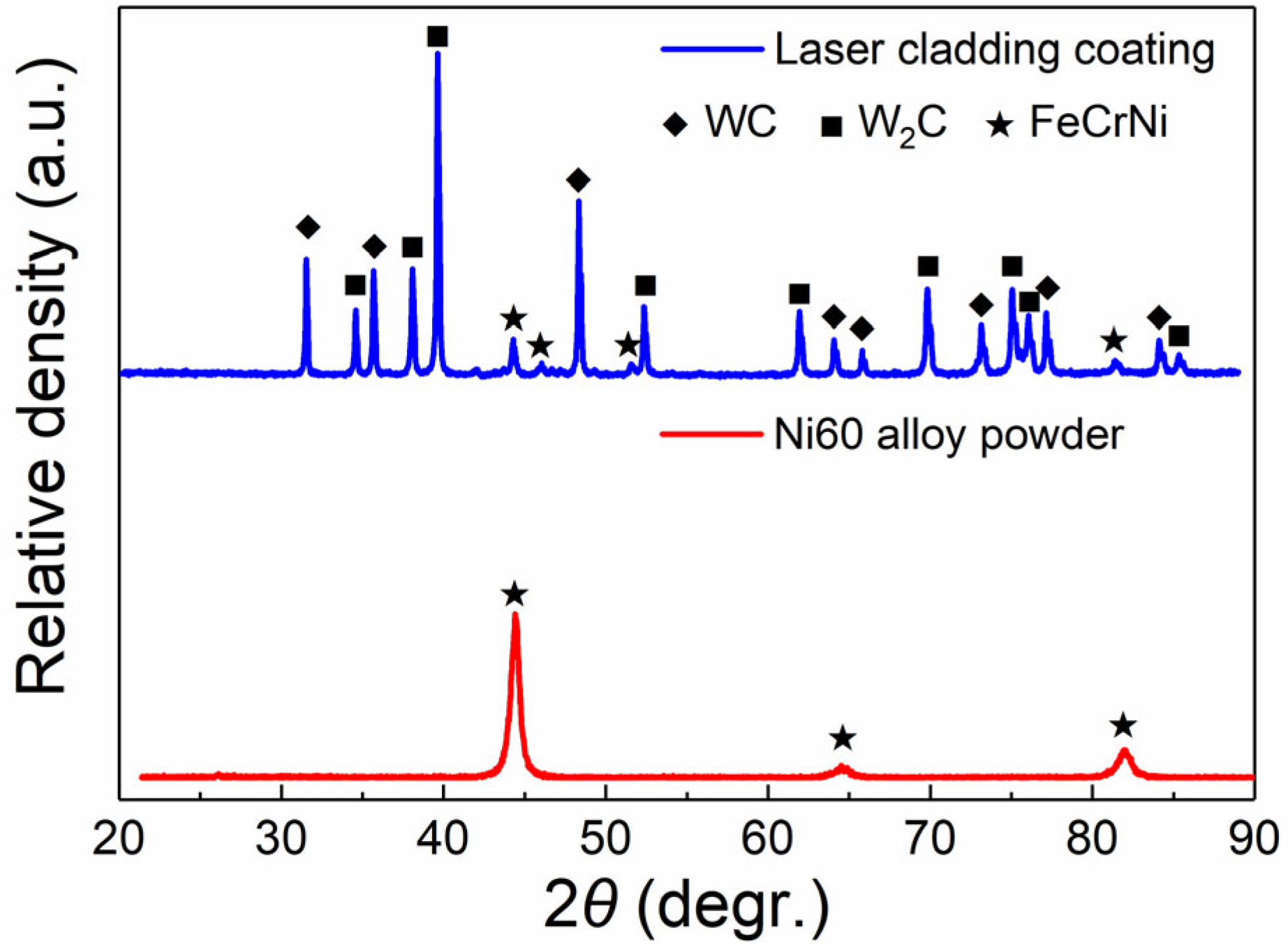

3.1. Microstructure, Phase Composition, and Microhardness

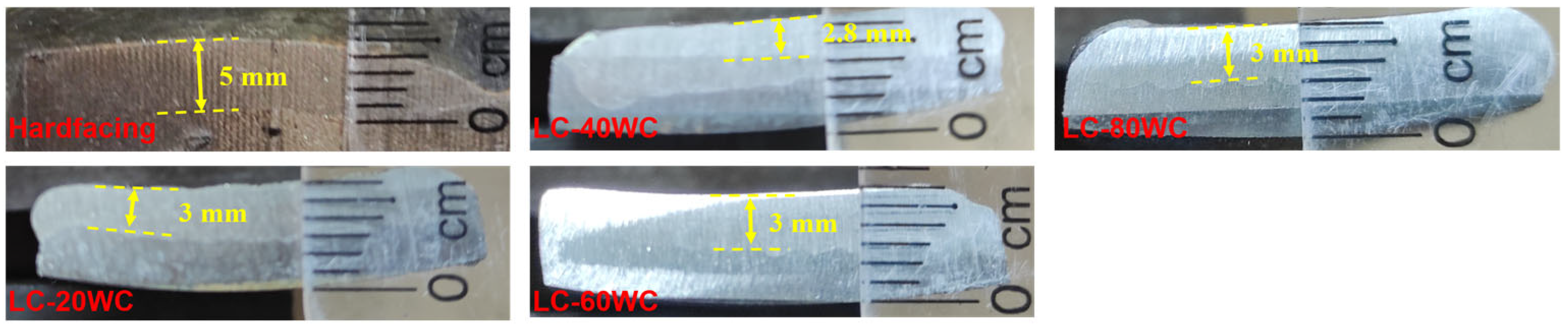

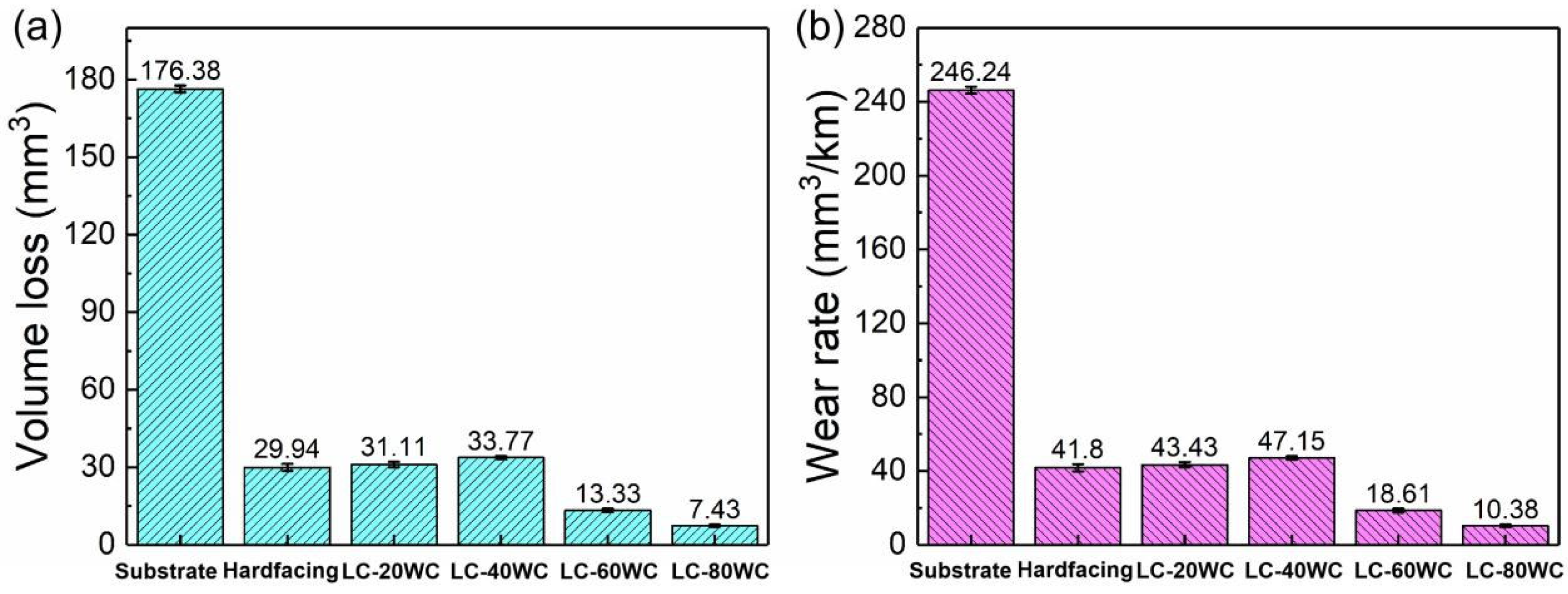

3.2. Dry Sand Rubber Wheel Test

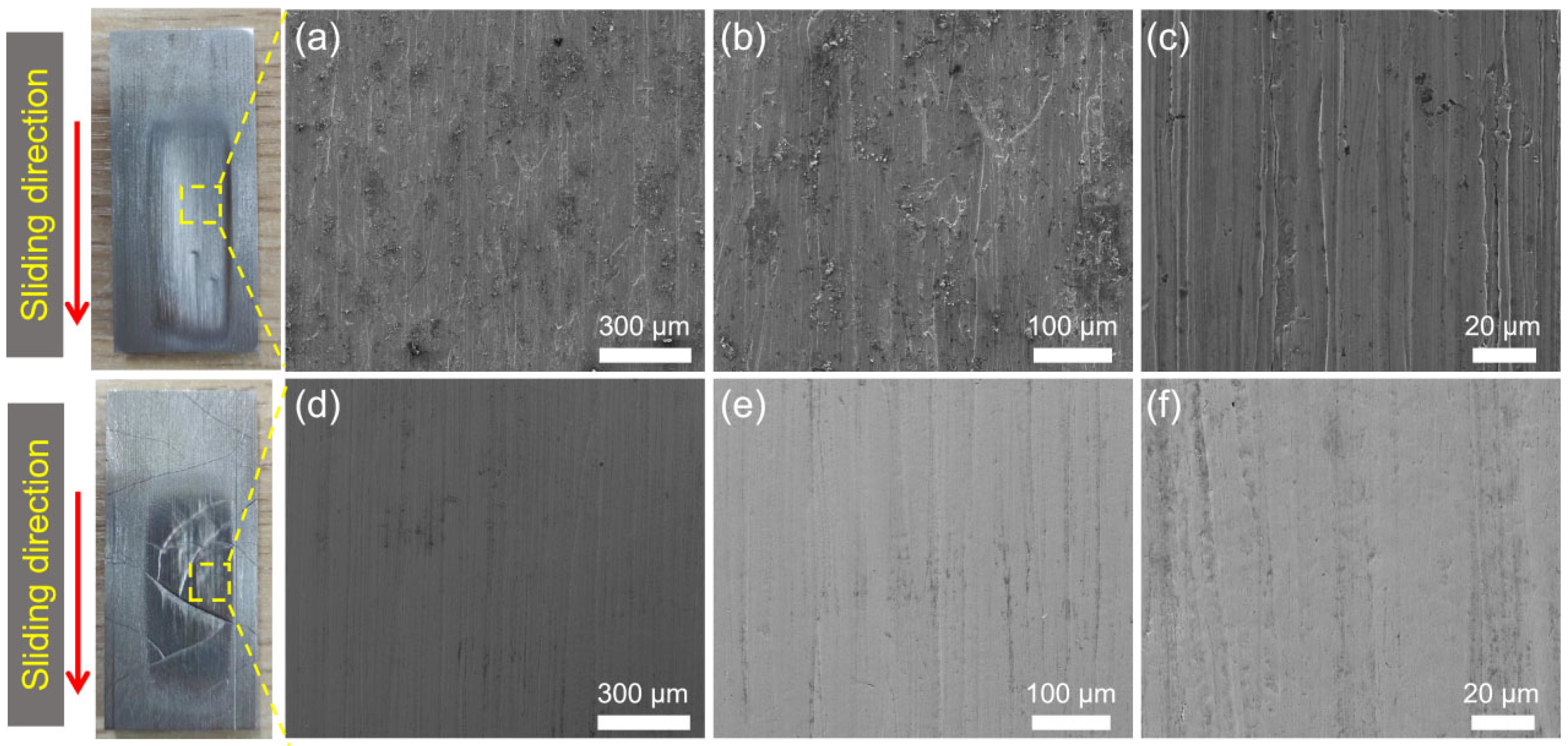

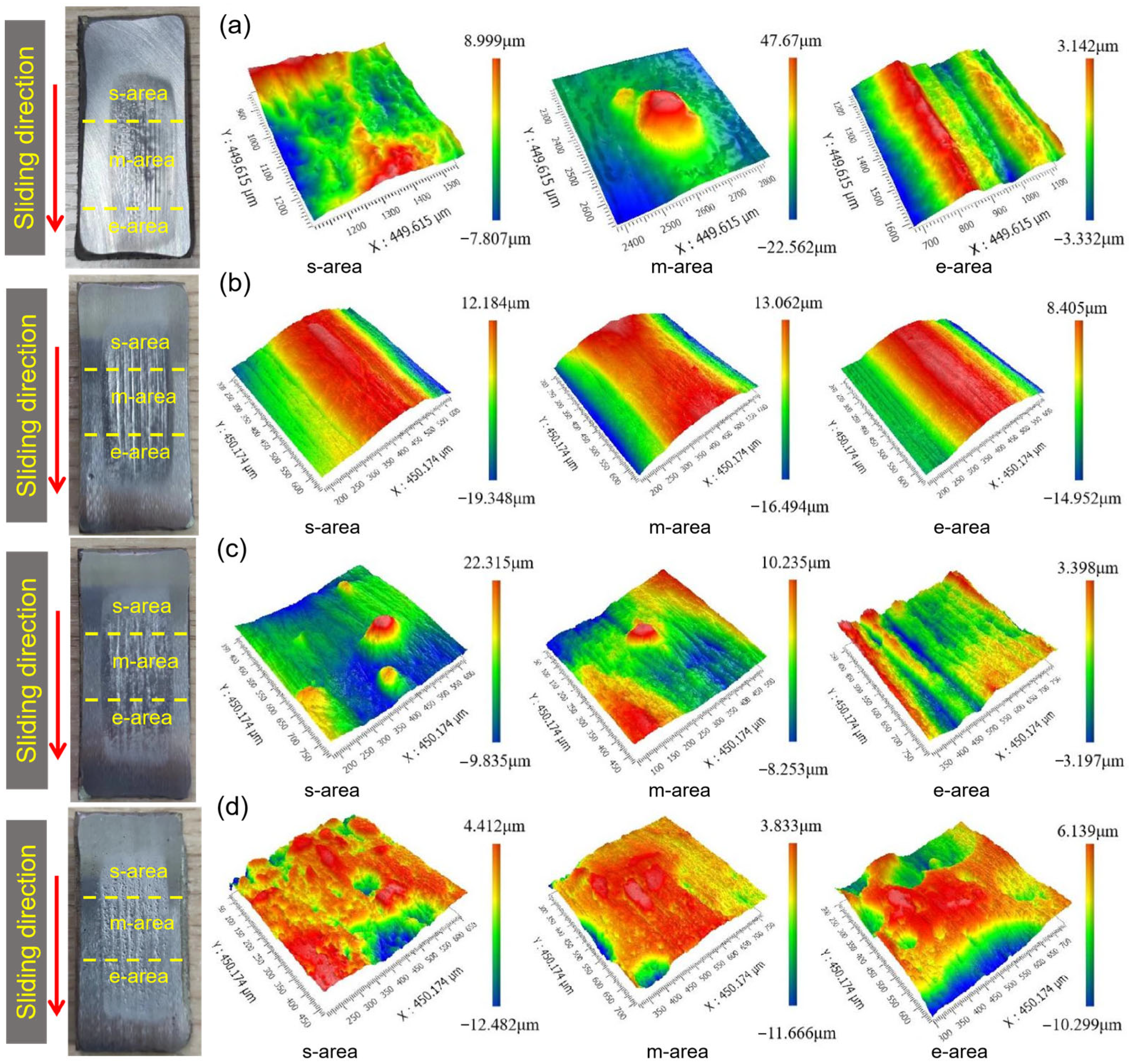

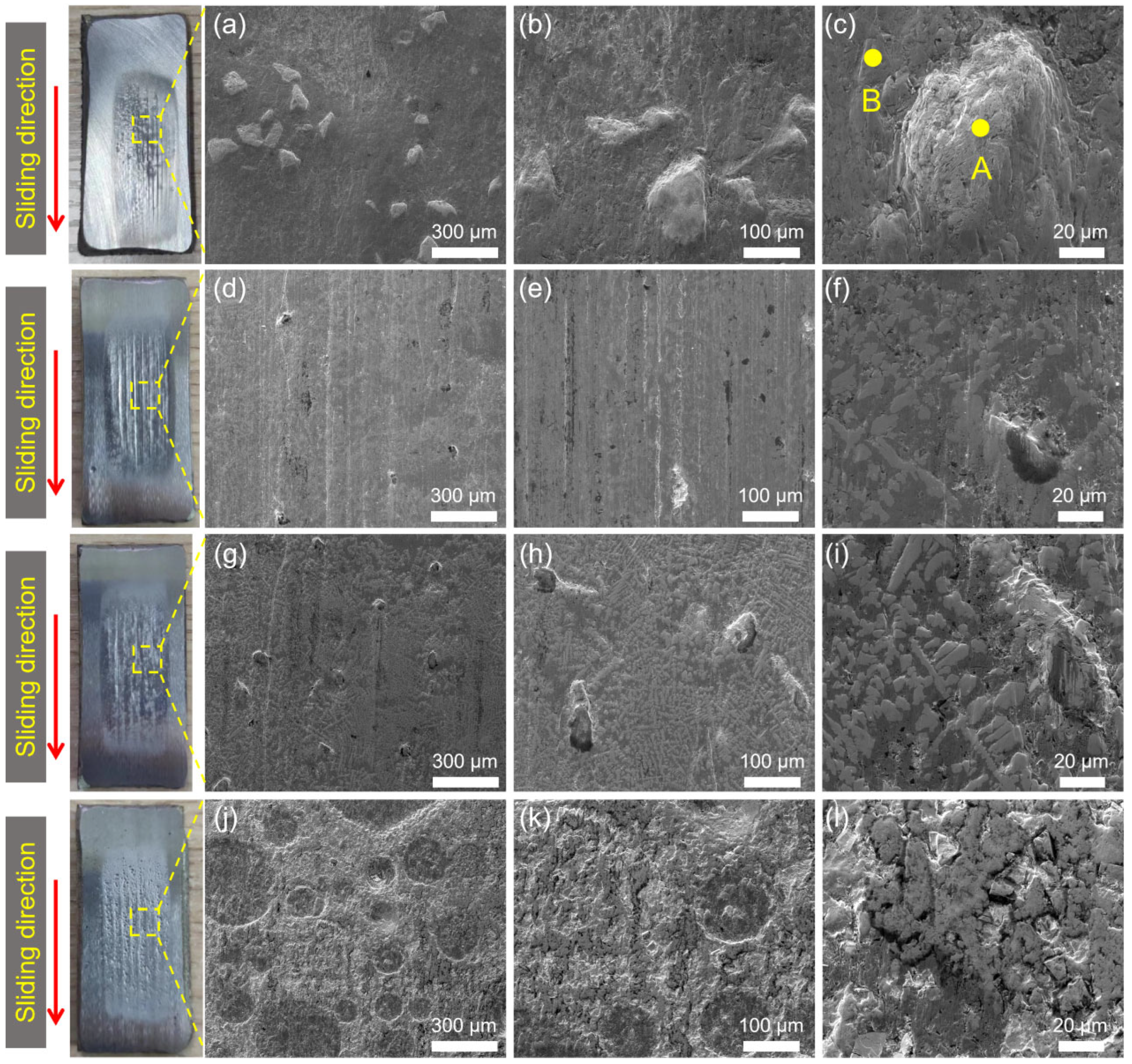

3.3. Surface Morphology after Wear Process

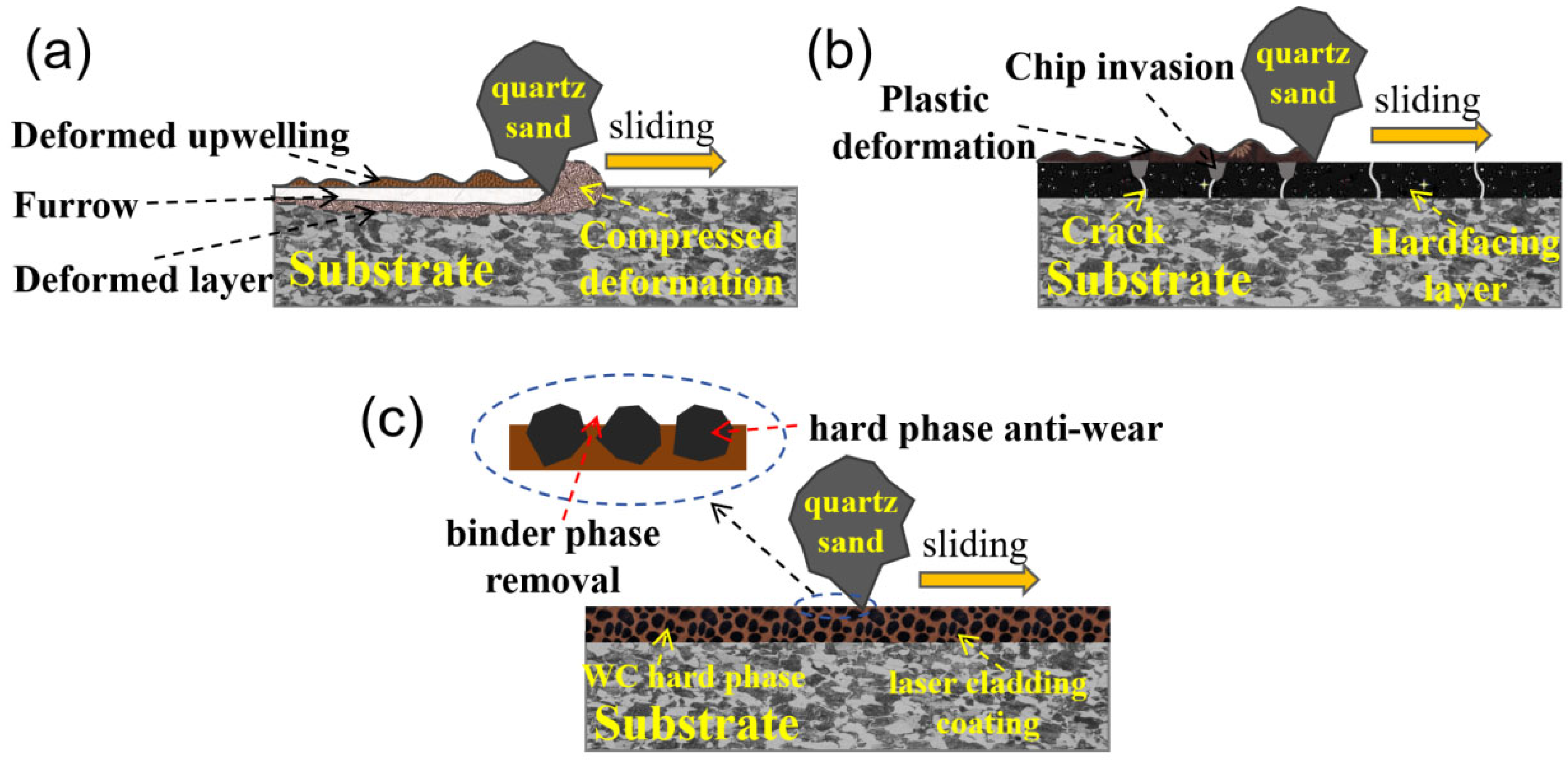

3.4. Wear Mechanism

4. Conclusions

- The Ni60-WC composite coatings were successfully prepared using laser cladding technology, and the coating’s hardness increased with the increase in WC content, reaching the maximum value of 900 HV with an 80 wt.%WC addition.

- Using hardfacing, the wear resistance of bucket teeth can be greatly improved, and the wear rate can be reduced to 1/6 of the tooth substrate. The wear resistance of the bucket teeth can also be greatly improved using laser cladding Ni60-WC coatings. The wear rate of the coatings with 20–40 wt.% WC was similar to that of hardfacing layer. The wear resistance of the coatings with 60–80 wt.%WC was 4 times higher than that of the hardfacing layer and 24 times higher than that of the bucket tooth substrate.

- The abrasive wear mechanism of the bucket tooth substrate was mainly micro-cutting with surface plastic deformation, forming narrow and deep furrows. The wear mechanism of hardfacing layer was mainly plastic deformation, forming a wide groove. At the same time, the cracks on the hardfacing layer promoted the removal of the material. The main wear mechanism of the laser cladding coating was the removal binder phase caused by micro-cutting. However, the hard phase of WC hindered micro-cutting and plastic deformation, which improved the wear resistance of the coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, Z.; Jiang, F.; Tan, Y.; Wang, F.; Ma, R.; Liu, J. Review of the Modeling Methods of Bucket Tooth Wear for Construction Machinery. Lubricants 2023, 11, 253. [Google Scholar] [CrossRef]

- Singla, S.; Kang, A.S.; Grewal, J.S.; Cheema, G.S. Wear Behavior of Weld Overlays on Excavator Bucket Teeth. Procedia Mater. Sci. 2014, 5, 256–266. [Google Scholar] [CrossRef]

- Filip, M.; Predrag, J.; Djenadića, S. Behavior Determining of Bucket Wheel Drive Depending on the Wear Impact of the Cutting Elements. Procedia Struct. Integr. 2018, 13, 1644–1650. [Google Scholar]

- Rusiński, E.; Cegiel, L.; Michalczyk, A.; Moczko, P.; Olejarz, J.; Pietrusiak, D. Investigation and modernization of buckets of surface mining machines. Eng. Struct. 2015, 90, 29–37. [Google Scholar] [CrossRef]

- Lu, P.; Jia, L.; Zhang, C.; Heng, X.; Xi, X.; Duan, M.; Lu, Z.; Zhou, Y. Optimization on laser cladding parameters for preparing Ni60 coating along with its friction and wear properties. Mater. Today Commun. 2023, 37, 107162. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Y.; Wang, R.; Wei, D.; Cai, M.; Fu, Y. Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys. J. Alloys Compd. 2018, 740, 1099–1107. [Google Scholar] [CrossRef]

- Keleş, A.; Yildirim, M. Improvement of mechanical properties by means of titanium alloying to steel teeth used in the excavator. Eng. Sci. Technol. Int. J. 2020, 23, 1208–1213. [Google Scholar] [CrossRef]

- ASTM G65-04; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM G105-02; Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM B611-85; Standard Test Method for Abrasive Wear Resistance of Cemented Carbides. ASTM International: West Conshohocken, PA, USA, 2005.

- Ren, X.; Peng, Z.; Hu, Y.; Rong, H.; Wang, C.; Fu, Z.; Qi, L.; Miao, H. Three-body abrasion behavior of ultrafine WC-Co hardmetal RX8UF with carborundum, corundum and silica sands in water-based slurries. Tribol. Int. 2014, 80, 179–190. [Google Scholar] [CrossRef]

- Yue, C.; Cai, H.; Kong, L.; Liang, C.; Peng, Z.; Wang, Y. Wear Behaviors of AISI 4145H Drilling Tool Steel under Drilling Fluid Environment Conditions. Materials 2022, 15, 1221. [Google Scholar] [CrossRef]

- Sanna, A.K.; Päivi, K.R.; Jari, L.; Jussi, H.; Simo-Pekka, H. Abrasive wear properties of tool steel matrix composites in rubber wheel abrasion test and laboratory cone crusher experiments. Wear 2007, 263, 180–187. [Google Scholar]

- Bialobrzeska, B.; Jasinski, R. Resistance to Abrasive Wear with Regards to Mechanical Properties Using Low-Alloy Cast Steels Examined with the Use of a Dry Sand/Rubber Wheel Tester. Materials 2023, 16, 3052. [Google Scholar] [CrossRef] [PubMed]

- Yousif, B.F. Design of newly fabricated tribological machine for wear and frictional experiments under dry/wet condition. Mater. Des. 2013, 48, 2–13. [Google Scholar] [CrossRef]

- Elalem, K.; Li, D.Y. Variations in wear loss with respect to load and sliding speed under dry sand/rubber-wheel abrasion condition: A modeling study. Wear 2001, 250, 59–65. [Google Scholar] [CrossRef]

- Rajendhran, N.; Pondicherry, K.; Huang, S.; Vleugels, J.; Sukumaran, J.; De Baets, P. Influence of grit particles characteristics on the abrasive wear micro-mechanisms of NbC-Ni and WC-Co hard materials. Int. J. Refract. Met. Hard Mater. 2024, 118, 106422. [Google Scholar] [CrossRef]

- Katinas, E.; Chotěborský, R.; Linda, M.; Kuře, J. Sensitivity analysis of the influence of particle dynamic friction, rolling resistance and volume/shear work ratio on wear loss and friction force using DEM model of dry sand rubber wheel test. Tribol. Int. 2021, 156, 106853. [Google Scholar] [CrossRef]

- Yakovlev, A.; Bertrand, P.; Smurov, I. Wear-resistant coatings with engineered structure by laser cladding. Tribol. Lett. 2004, 17, 705–708. [Google Scholar] [CrossRef]

- Liu, W.; Gao, D. Microstructure and wear of Ni-WC hardfacing used for steel-body PDC bits. Int. J. Refract. Met. Hard Mater. 2021, 101, 105683. [Google Scholar] [CrossRef]

- Kumar, S.; Mondal, D.P.; Jha, A.K. Effect of Microstructure and Chemical Composition of Hardfacing Alloy on Abrasive Wear Behavior. J. Mater. Eng. Perform. 2000, 9, 649–655. [Google Scholar] [CrossRef]

- Brezinová, J.; Draganovská, D.; Guzanová, A.; Balog, P.; Viňáš, J. Influence of the Hardfacing Welds Structure on Their Wear Resistance. Metals 2016, 6, 36. [Google Scholar] [CrossRef]

- Tuominen, J.; Kiviö, J.; Balusson, C.; Raami, L.; Vihinen, J.; Peura, P. High-speed laser cladding of chromium carbide reinforced Ni-based coatings. Weld. World 2023, 67, 2175–2186. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Y.; Gu, C.; Sai, Q.; Lei, T.; Williams, J. Antifouling Coatings Fabricated by Laser Cladding. Coatings 2023, 13, 397. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Y.; Zeng, Z.; Fu, Y. Effect of rare-earth on friction and wear properties of laser cladding Ni-based coatings on 6063Al. J. Alloys Compd. 2017, 727, 278–285. [Google Scholar] [CrossRef]

- Nurminen, J.; Näkki, J.; Vuoristo, P. Microstructure and properties of hard and wear resistant MMC coatings deposited by laser cladding. Int. J. Refract. Met. Hard Mater. 2009, 27, 472–478. [Google Scholar] [CrossRef]

- Gu, Z.; Xi, S.; Sun, C. Microstructure and properties of laser cladding and CoCr2.5FeNi2Tix high-entropy alloy composite coatings. J. Alloys Compd. 2020, 819, 152986. [Google Scholar] [CrossRef]

- Li, J.; Ju, J.; Chang, W.; Yang, C.; Wang, J. Investigation on the Microstructure and Wear Behavior of Laser-Cladded High Aluminum and Chromium Fe-B-C Coating. Materials 2020, 13, 2443. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Zhou, J.; Wei, H.; Zeng, R.; Li, W. Effect of Cu addition on the microstructure and tribological performance of Ni60 directional structure coating. Int. J. Miner. Metall. Mater. 2023, 30, 715–723. [Google Scholar] [CrossRef]

- Sahu, M.M.R. Structure and properties of Ni1–XTiXN thin films processed by reactive magnetron co-sputtering. Mater. Charact. 2020, 169, 110604. [Google Scholar] [CrossRef]

- Yang, X.; Li, X.; Yang, Q.; Wei, H.; Fu, X.; Li, W. Effects of WC on microstructure and corrosion resistance of directional structure Ni60 coatings. Surf. Coat. Technol. 2020, 385, 125359. [Google Scholar] [CrossRef]

- Liao, H.; Normand, B.; Coddet, C. Influence of coating microstructure on the abrasive wear resistance of WC/Co cermet coatings. Surf. Coat. Technol. 2000, 124, 235–242. [Google Scholar] [CrossRef]

- Szala, M.; Szafran, M.; Matijošius, J.; Drozd, K. Abrasive Wear Mechanisms of S235JR, S355J2, C45, AISI 304, and Hardox 500 Steels Tested Using Garnet, Corundum and Carborundum Abrasives. Adv. Sci. Technol. Res. J. 2023, 17, 147–160. [Google Scholar] [CrossRef]

| Samples No. | Compositions (wt.%) |

|---|---|

| Substrate | C: 0.26; Mn: 0.93; Si: 1.39; Mo: 0.28; Ni: 0.36; Cr: 1.68; Fe: Bal. |

| Hardfacing | C: 0.13; Mn: 1.11; Si: 0.76; Ti: 0.1; Ni: 0.092; Cr: 10.52; Fe: Bal. |

| LC-20WC | 80 wt.% Ni60 + 20 wt.% WC |

| LC-40WC | 60 wt.% Ni60 + 40 wt.% WC |

| LC-60WC | 40 wt.% Ni60 + 60 wt.% WC |

| LC-80WC | 20 wt.% Ni60 + 80 wt.% WC |

| Elements | C | O | W | Si | Cr | Fe | Ni | Total |

|---|---|---|---|---|---|---|---|---|

| Point A (at.%) | 45.6 | 10.7 | 43.7 | - | - | - | - | 100 |

| Point B (at.%) | 18.7 | 3.2 | 2.0 | 3.9 | 33.2 | 12.2 | 26.8 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Sun, L.; Wang, D.; Song, B.; Liu, C.; Su, Z.; Ma, C.; Ren, X. Abrasive Wear Properties of Wear-Resistant Coating on Bucket Teeth Assessed Using a Dry Sand Rubber Wheel Tester. Materials 2024, 17, 1495. https://doi.org/10.3390/ma17071495

Wang Z, Sun L, Wang D, Song B, Liu C, Su Z, Ma C, Ren X. Abrasive Wear Properties of Wear-Resistant Coating on Bucket Teeth Assessed Using a Dry Sand Rubber Wheel Tester. Materials. 2024; 17(7):1495. https://doi.org/10.3390/ma17071495

Chicago/Turabian StyleWang, Zhongxin, Long Sun, Dong Wang, Bo Song, Chang Liu, Zhenning Su, Chaobin Ma, and Xiaoyong Ren. 2024. "Abrasive Wear Properties of Wear-Resistant Coating on Bucket Teeth Assessed Using a Dry Sand Rubber Wheel Tester" Materials 17, no. 7: 1495. https://doi.org/10.3390/ma17071495