Numerical Study on the Effect of Coarse Aggregate Shape during Concrete Mixing Process

Abstract

1. Introduction

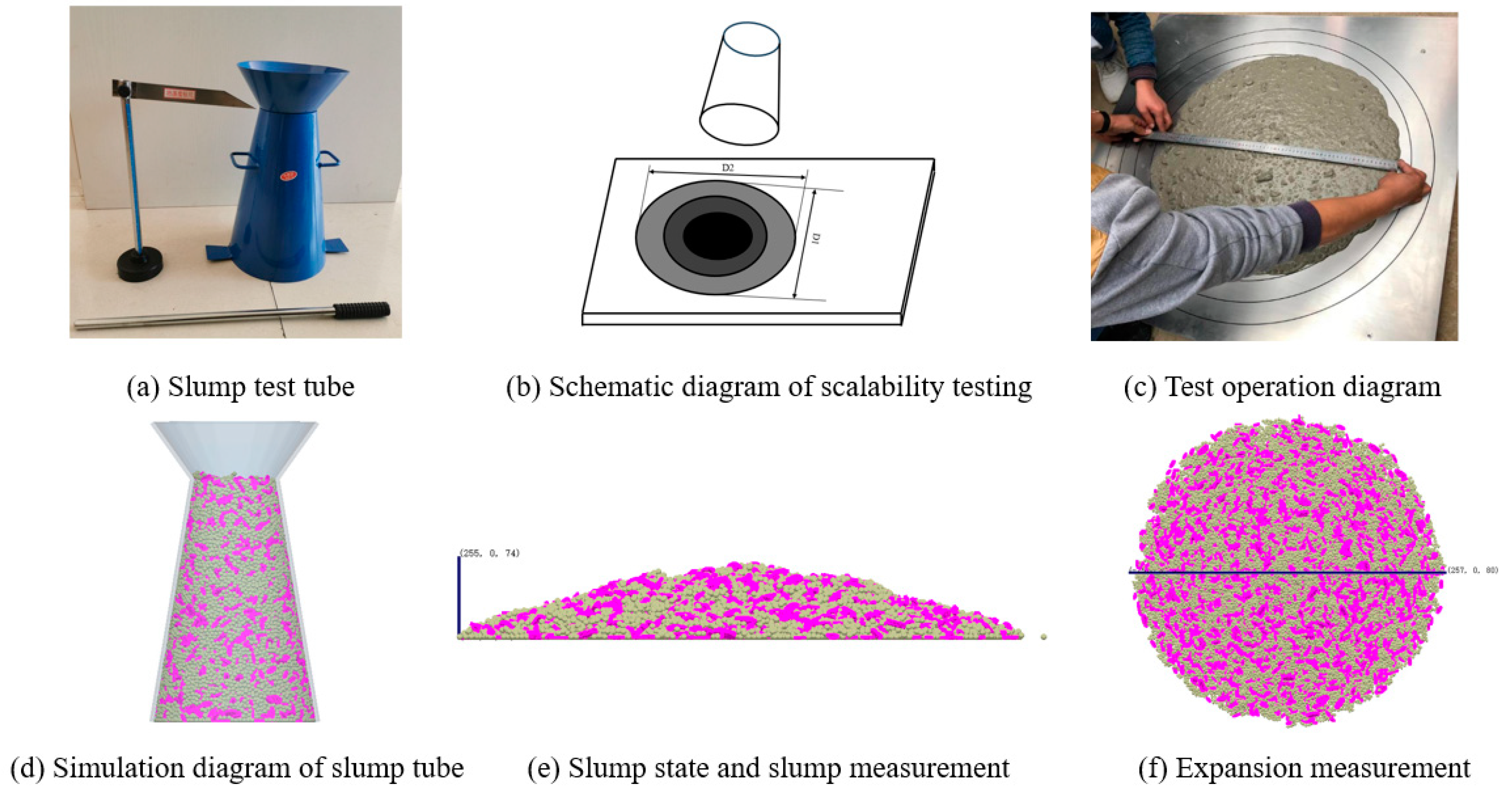

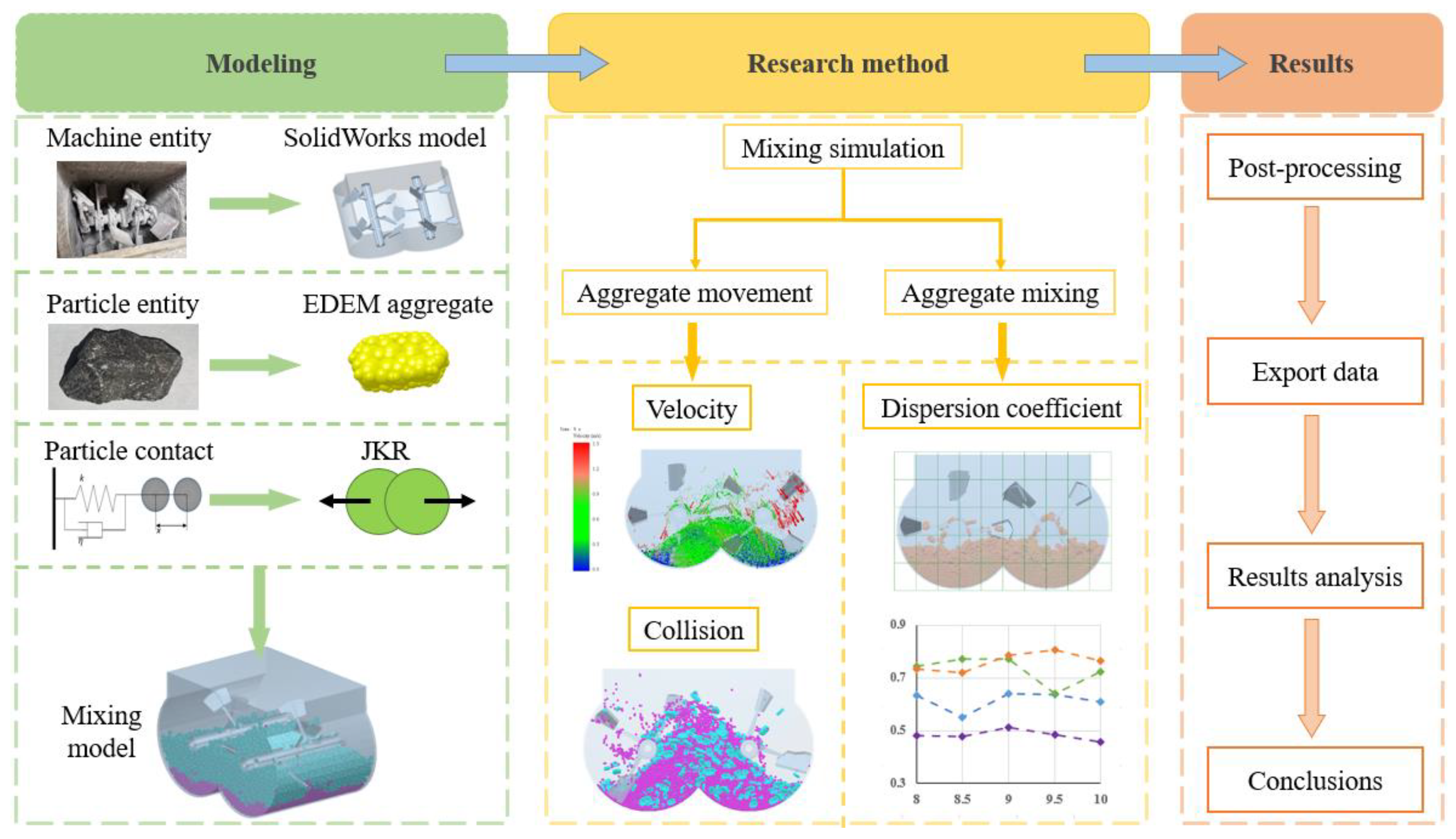

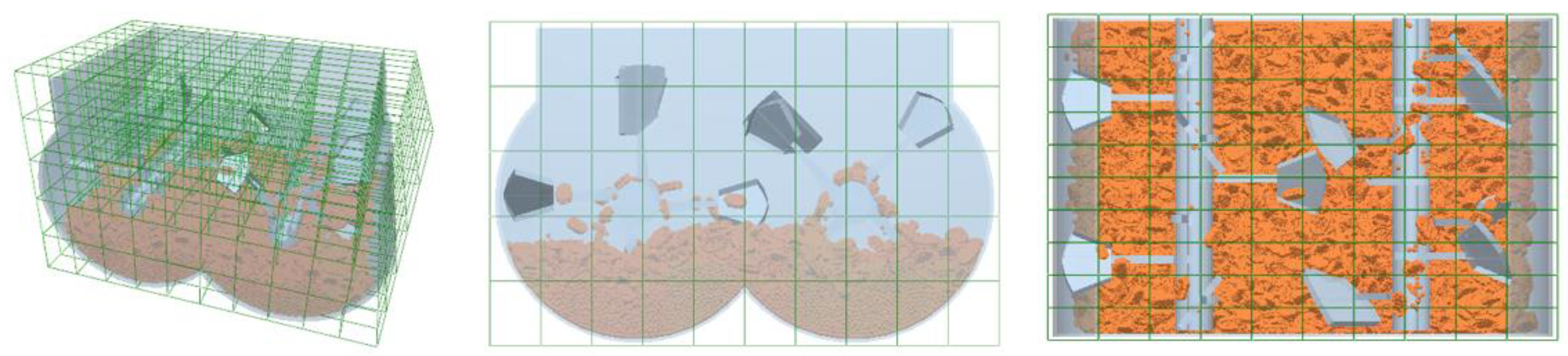

2. Model and Discrete Element Method

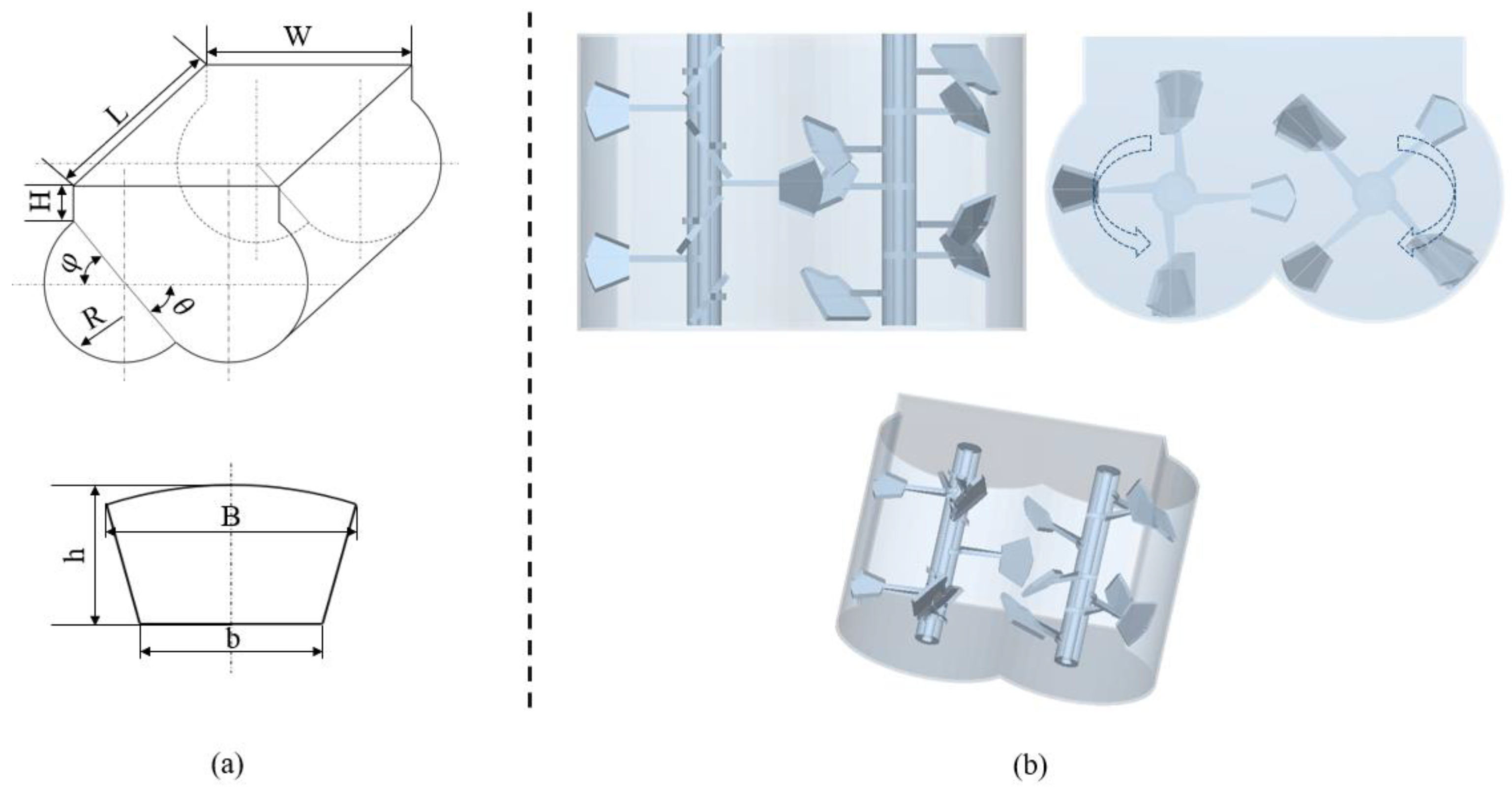

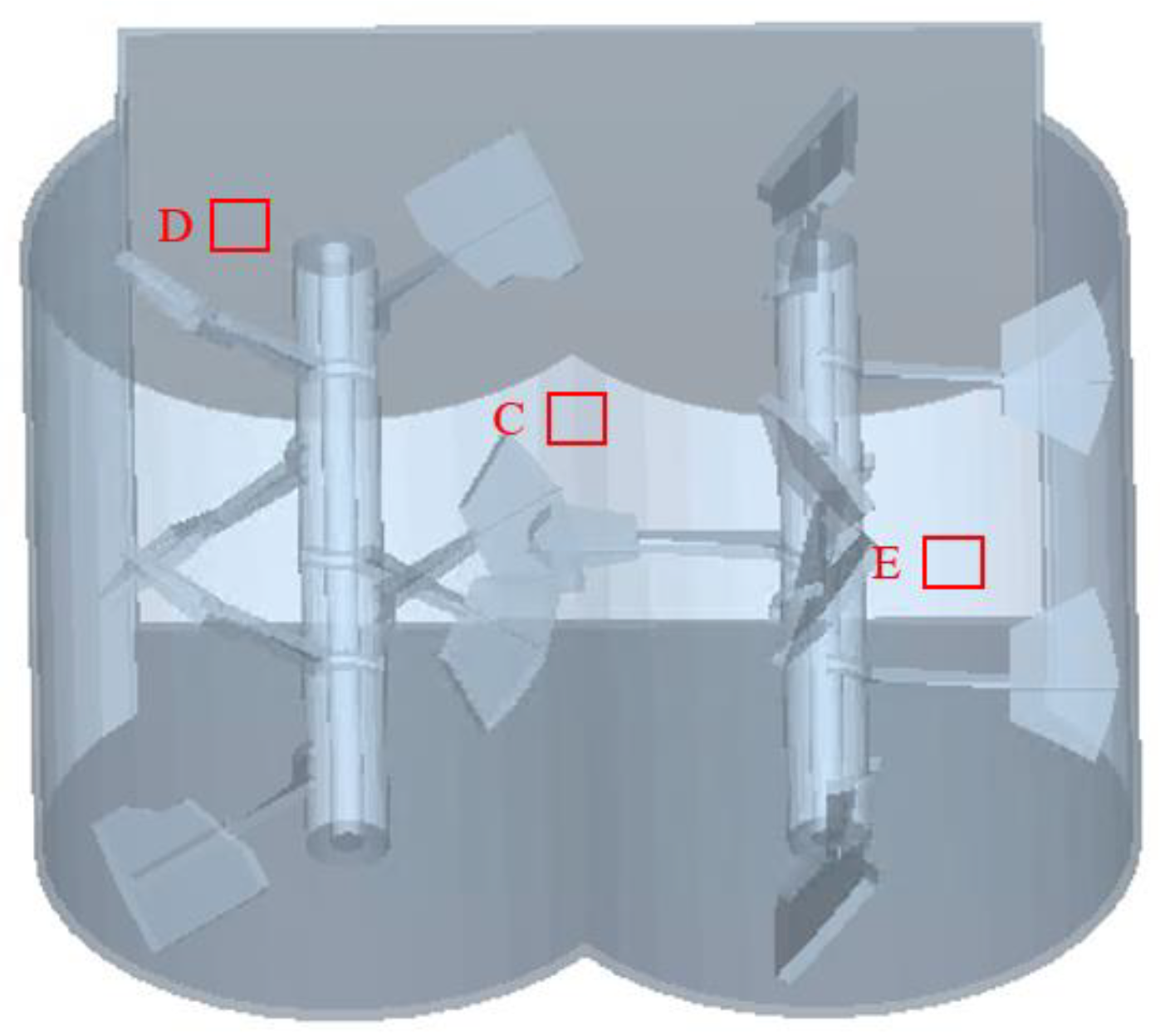

2.1. Model of Mixer

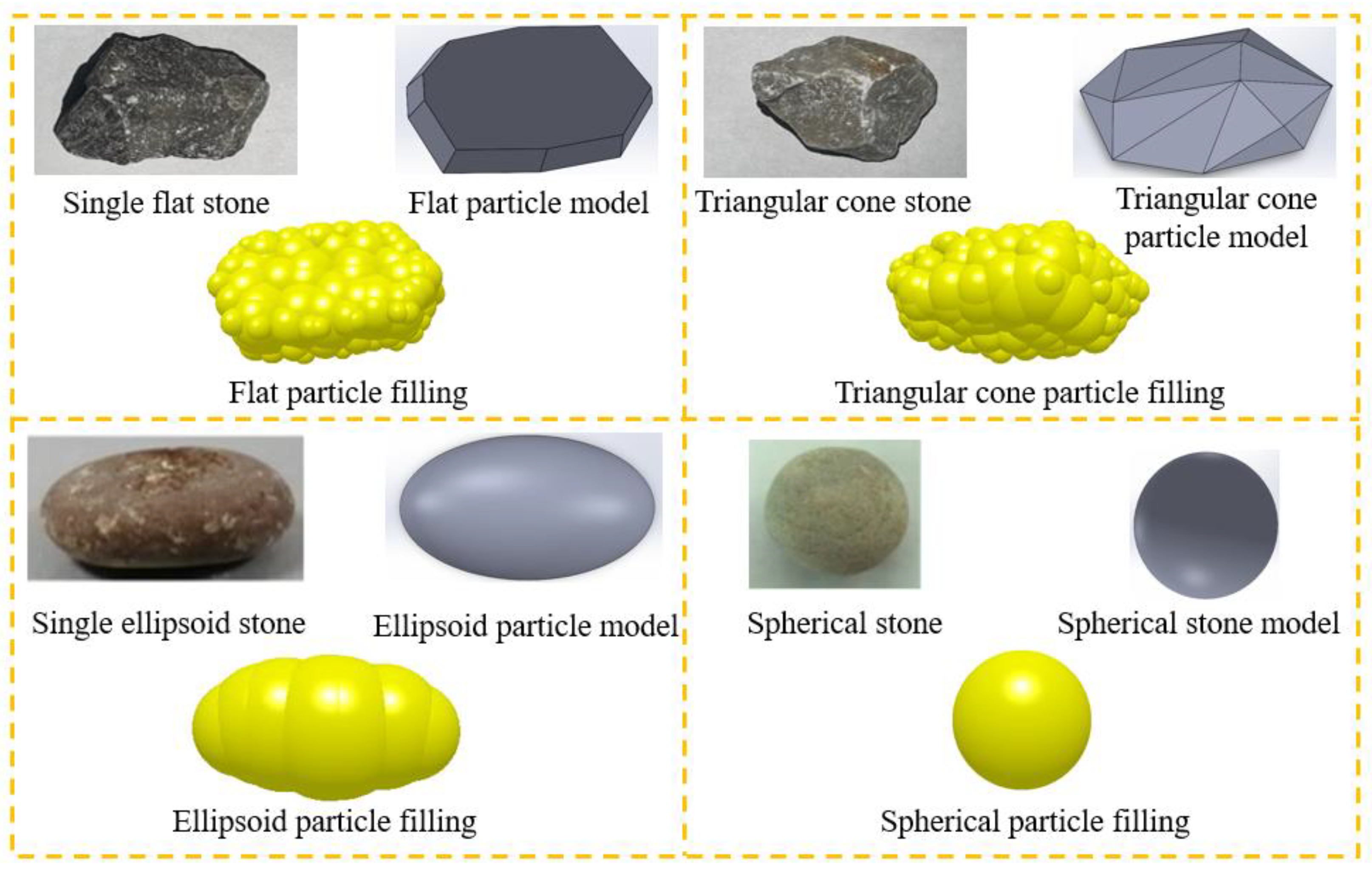

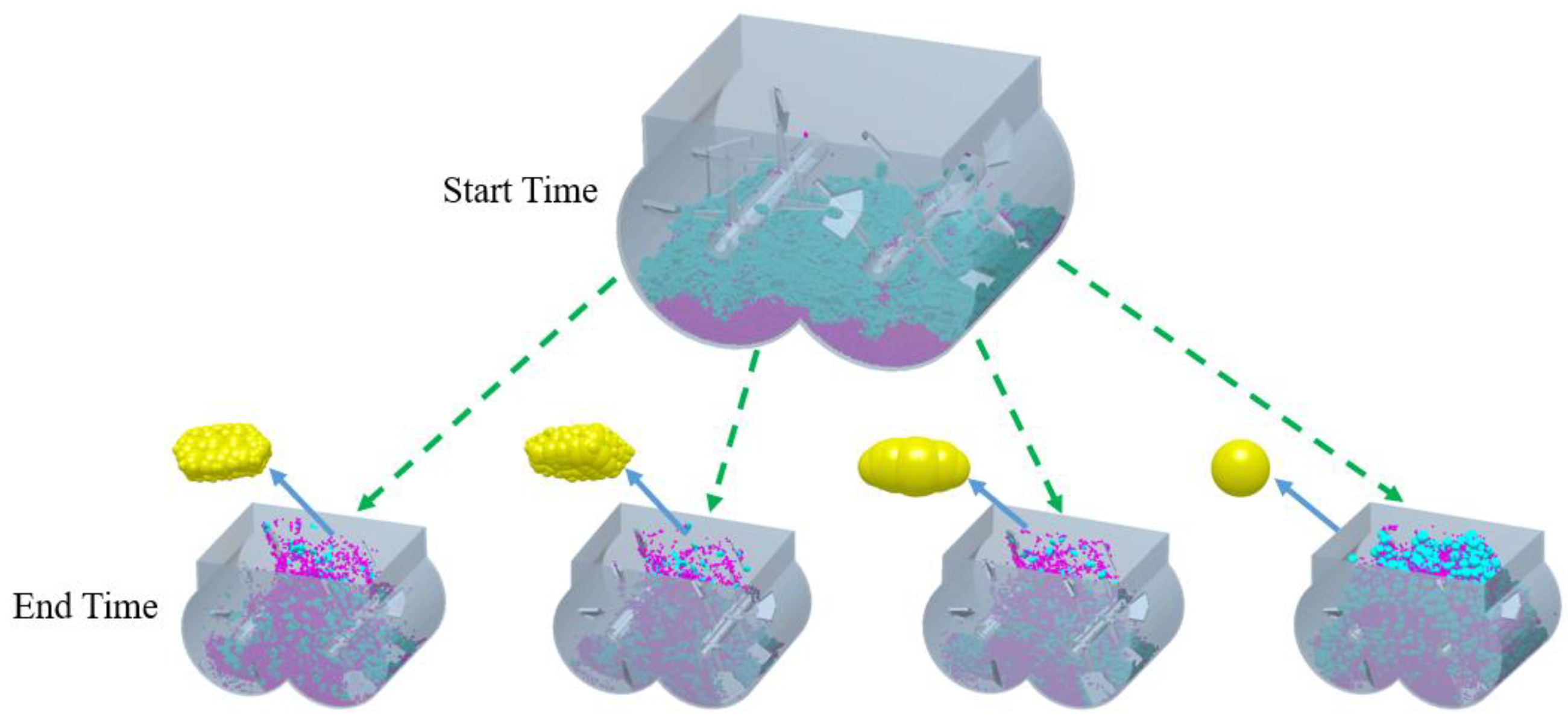

2.2. Model of Coarse Aggregate

2.3. Discrete Element Method Theory and Contact Models

3. Numeric Simulation Results and Analysis

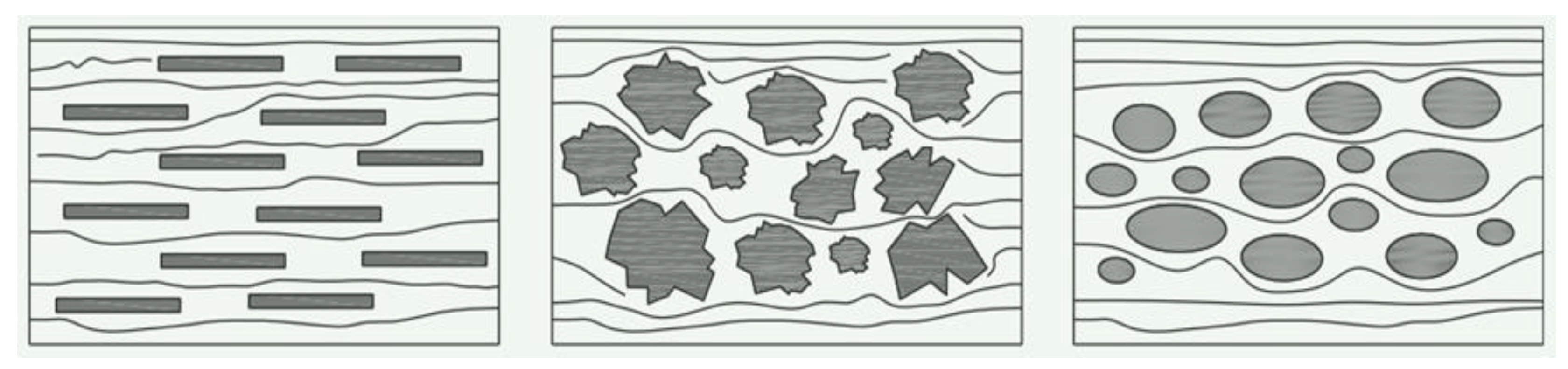

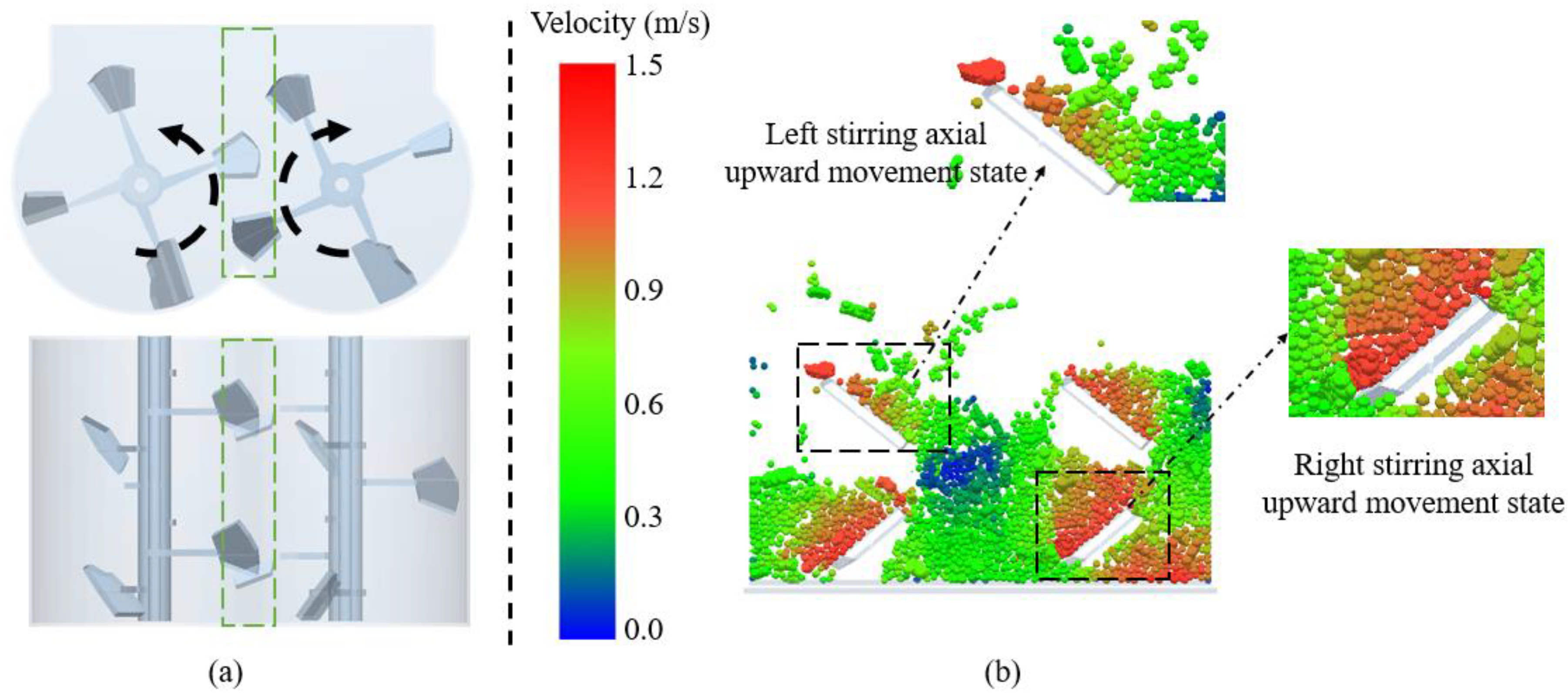

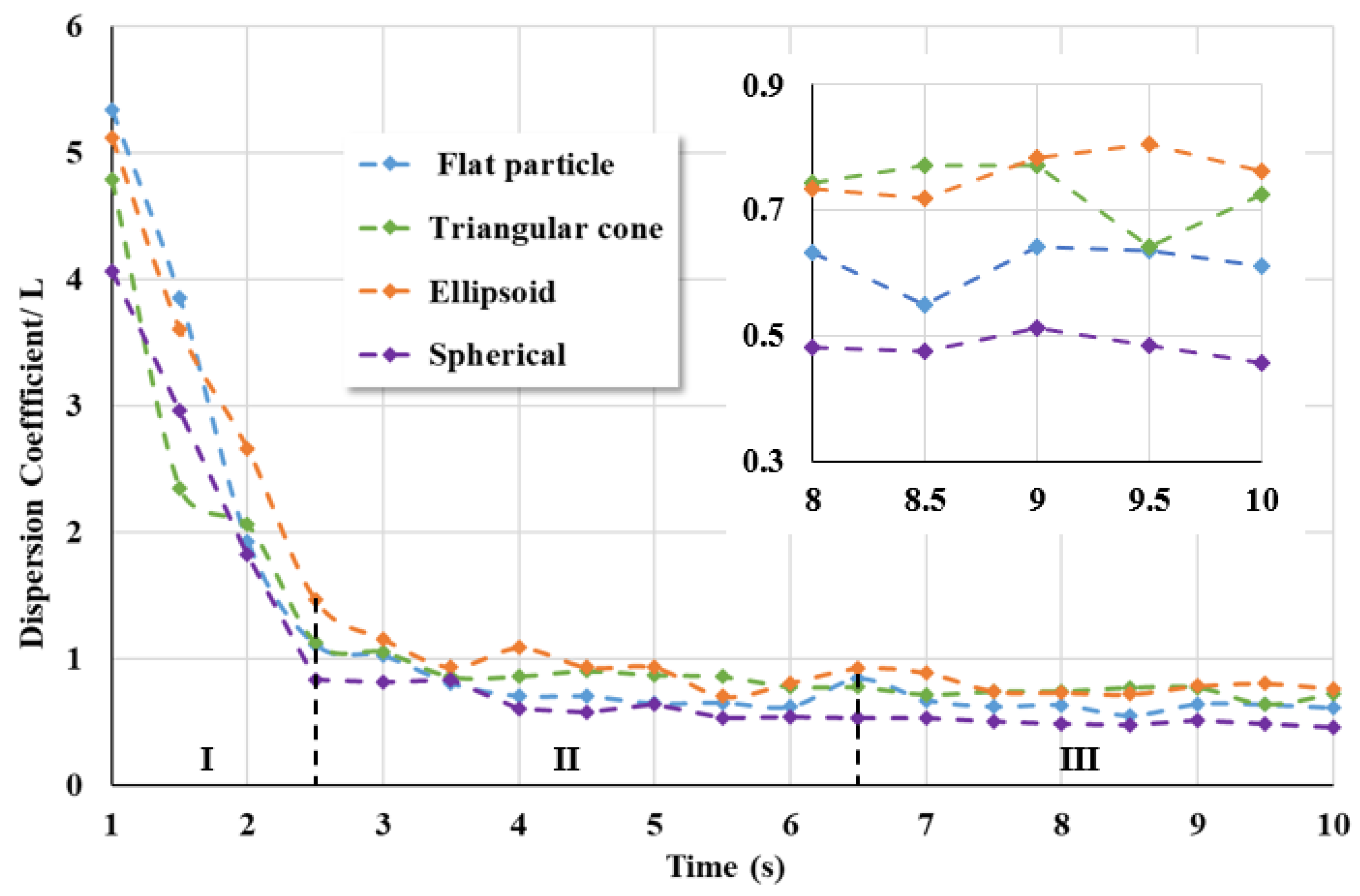

3.1. The Influence of Coarse Aggregate Shape on Concrete Mixing

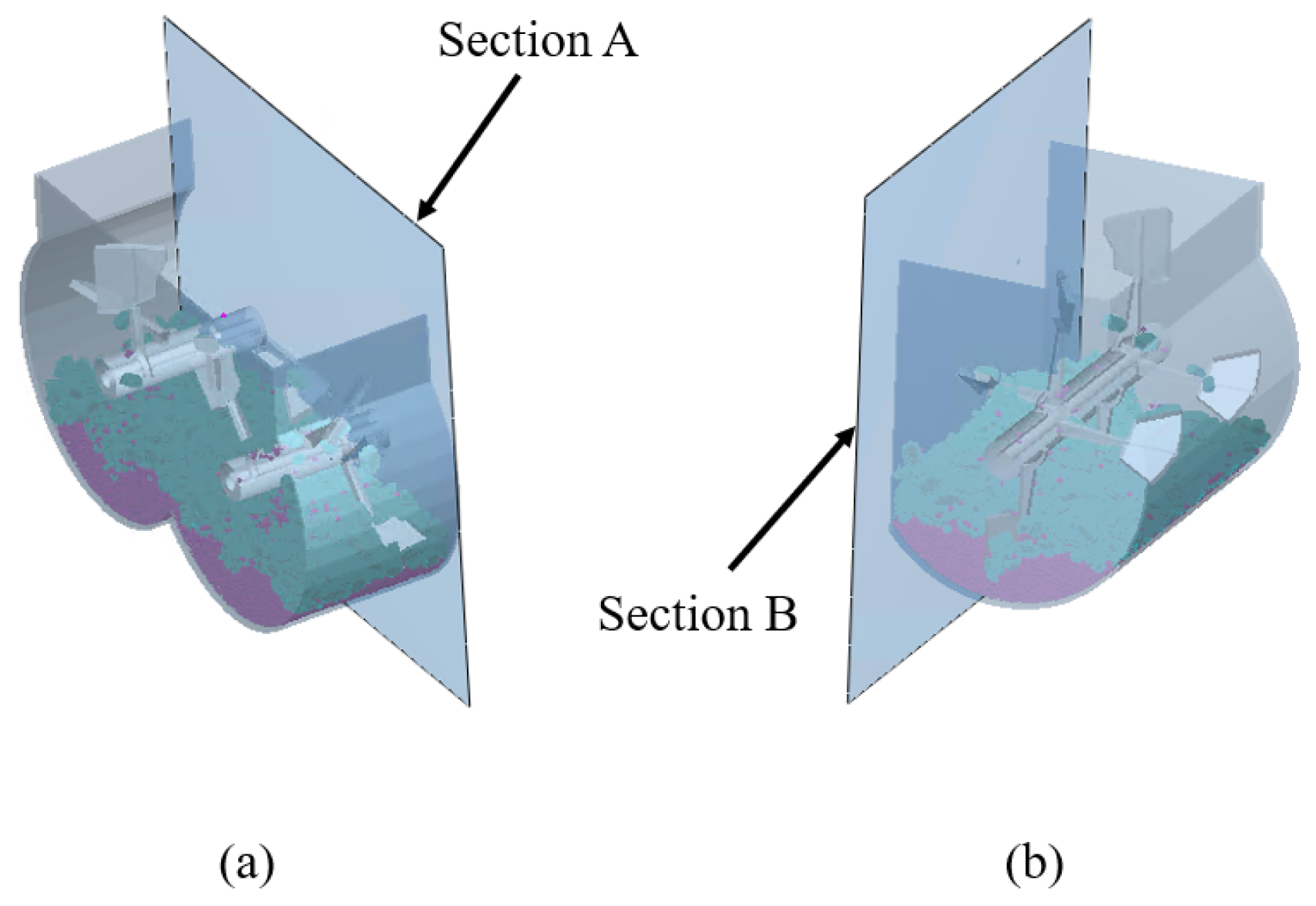

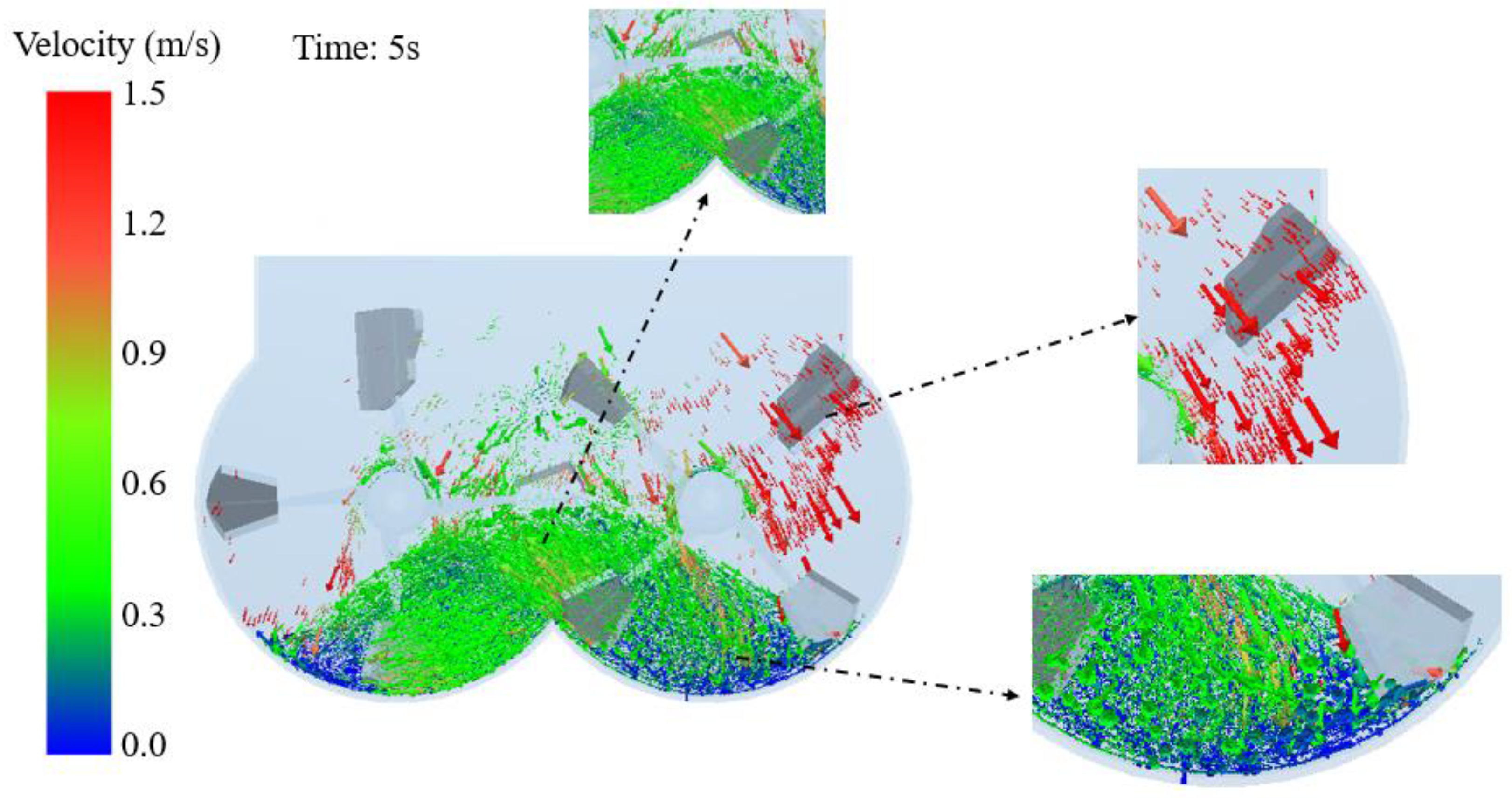

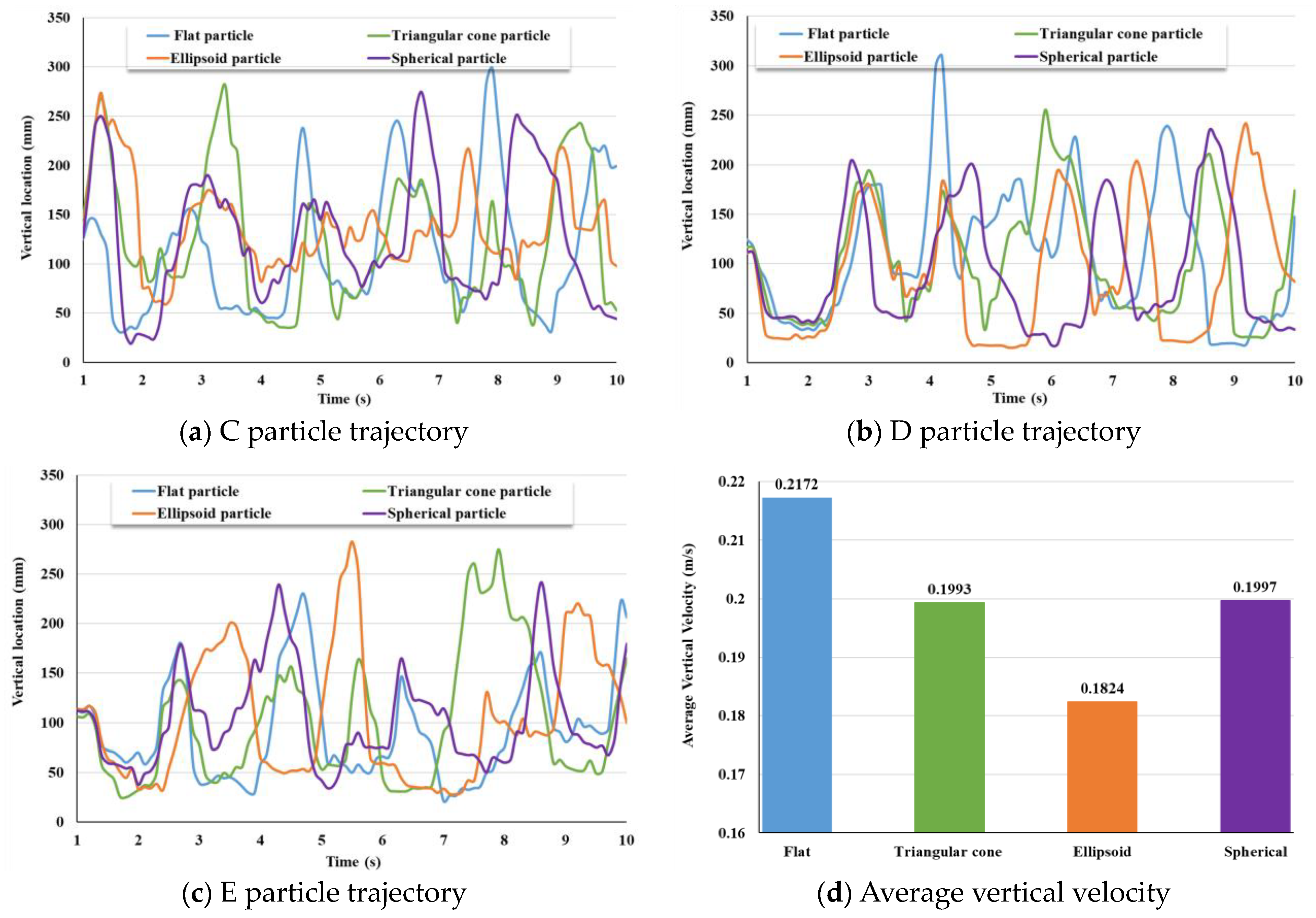

3.1.1. Movement of Coarse Aggregate

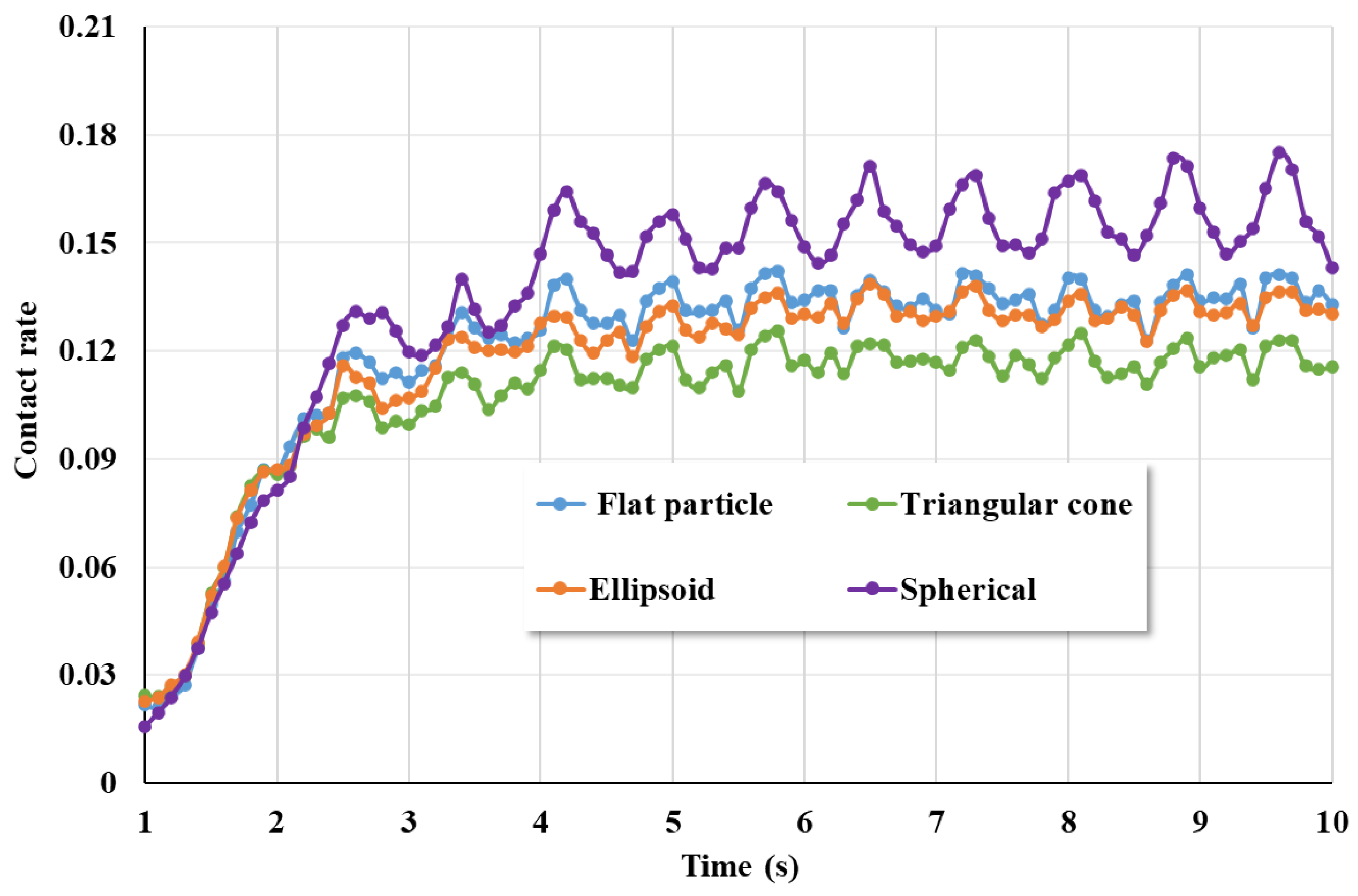

3.1.2. Collision of Coarse Aggregate

3.2. The Influence of Coarse Aggregate Shape on Concrete Mixing

4. Conclusions

- (1)

- The spherical coarse aggregate has the highest average speed, while the ellipsoidal coarse aggregate has the lowest average speed. The movement of the spherical coarse aggregate is the most intense in the mixing process, and it is easier to overcome the mutual impact of this coarse aggregate and its gravity.

- (2)

- The flat coarse aggregate has the fastest speed in the vertical direction, and the triangular cone-shaped and spherical coarse aggregate has a similar speed in the vertical direction. The ellipsoidal coarse aggregate has the smallest speed in the vertical direction, the force is unbalanced, and it is difficult to move in the vertical direction.

- (3)

- The spherical coarse aggregate with mortar has the fastest change in the curve of the coefficient of dispersion, the smallest value of the coefficient of dispersion, and the best mixing effect with mortar. The ellipsoidal coarse aggregate has the worst mixing effect with mortar. The discrete coefficient curves of the lamellar and triangular cone coarse aggregates are different in the early stages and similar in the middle and late stages, and the mixing of these two kinds of coarse aggregates with mortar is similar.

- (4)

- In the process of concrete mixing, the spherical coarse aggregate is the easiest to mix evenly, but for the ellipsoidal coarse aggregate the mixing time should be prolonged and the mixing intensity increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarde, B.; Patil, Y.D. Recent research status on polymer composite used in concrete-an overview. Mater. Today Proc. 2019, 18, 3780–3790. [Google Scholar] [CrossRef]

- Gonnon, P.; Lootens, D. Toward net zero carbon for concrete and mortar: Clinker substitution with ground calcium carbonate. Cem. Concr. Compos. 2023, 142, 105190. [Google Scholar] [CrossRef]

- Li, L.G.; Feng, J.J.; Lu, Z.C.; Xie, H.Z.; Xiao, B.F.; Kwan, A.K.H. Effects of aggregate bulking and film thicknesses on water permeability and strength of pervious concrete. Powder Technol. 2022, 396, 743–753. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, C.; Yin, H. Virtual Experiments of Particle Mixing Process with the SPH-DEM Model. Materials 2021, 14, 2199. [Google Scholar] [CrossRef] [PubMed]

- Longarini, N.; Crespi, P.; Zucca, M.; Giordano, N.; Silvestro, G. The advantages of fly ash use in concrete structures. Inżynieria Miner. 2014, 15, 141–145. [Google Scholar]

- Muzzio, F.J.; Llusa, M.; Goodridge, C.L.; Duong, N.H. Evaluating the mixing performance of a ribbon blender. Powder Technol. 2008, 186, 247–254. [Google Scholar] [CrossRef]

- Chen, J.J.; Guan, G.X.; Ng, P.L.; Kwan, A.K.H.; Chu, S.H. Packing optimization of paste and aggregate phases for sustainability and performance improvement of concrete. Adv. Powder Technol. 2021, 32, 987–997. [Google Scholar] [CrossRef]

- Yuan, Q.C.; Xu, L.M.; Ma, S.; Niu, C.; Yan, C.G.; Zhao, S.J. The effect of paddle configurations on particle mixing in a soil-fertilizer continuous mixing device. Powder Technol. 2021, 391, 292–300. [Google Scholar] [CrossRef]

- Zerbino, R.; Barragán, B.; Garcia, T.; Agulló, L. Workability tests and rheological parameters in self-compacting concrete. Mater. Struct. 2009, 42, 947–960. [Google Scholar] [CrossRef]

- Yang, S.; Cui, H.; Poon, C.S. Comparison of the mechanically compacted dry-mix and ordinary vibrated wet-mix glass concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2020, 114, 103720. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, H.; Hua, J. DEM study on effects of particle size and grinding media properties on energy transitions in a horizontal agitator. Adv. Powder Technol. 2022, 33, 103604. [Google Scholar] [CrossRef]

- Herman, A.P.; Gan, J.Q.; Yu, A.B. The effect of rotation speed and mixer size on granular flow and mixing in bladed mixers, EPJ Web of Conferences. EDP Sci. 2021, 249, 03036. [Google Scholar]

- Alian, M.; Ein-Mozaffari, F.; Upreti, S.R. Analysis of the mixing of solid particles in a plowshare mixer via discrete element method (DEM). Powder Technol. 2015, 274, 77–87. [Google Scholar] [CrossRef]

- Gao, W.; Liu, L.; Liao, Z.C.; Chen, S.H.; Zang, M.Y.; Tan, Y.Q. Discrete element analysis of the particle mixing performance in a ribbon mixer with a double U-shaped vessel. Granul. Matter 2019, 21, 12. [Google Scholar] [CrossRef]

- Wang, X.; Nie, Z.; Gong, J.; Liang, Z. Random generation of convex aggregates for DEM study of particle shape effect. Constr. Build. Mater. 2021, 268, 121468. [Google Scholar] [CrossRef]

- Bridgwater, J. Fundamental powder mixing mechanisms. Powder Technol. 1976, 15, 215–236. [Google Scholar] [CrossRef]

- Sobolev, K.; Amirjanov, A. The simulation of particulate materials packing using a particle suspension model. Adv. Powder Technol. 2007, 18, 261–271. [Google Scholar] [CrossRef]

- Zhu, A.; Chang, Q.; Xu, J.; Ge, W. A dynamic load balancing algorithm for CFD–DEM simulation with CPU–GPU heterogeneous computing. Powder Technol. 2023, 428, 118782. [Google Scholar] [CrossRef]

- Roussel, N.; Geiker, M.R.; Dufour, F.; Thrane, L.N.; Szabo, P. Computational modeling of concrete flow: General overview. Cem. Concr. Res. 2007, 37, 1298–1307. [Google Scholar] [CrossRef]

- Santos, D.A.; Barrozo, M.A.S.; Duarte, C.R.; Weigler, F.; Mellman, J. Investigation of particle dynamics in a rotary drum by means of experiments and numerical simulations using DEM. Adv. Powder Technol. 2016, 27, 692–703. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Shyshko, S. Simulating the behavior of fresh concrete with the Distinct Element Method–Deriving model parameters related to the yield stress. Cem. Concr. Compos. 2015, 55, 81–90. [Google Scholar] [CrossRef]

- Cao, G.; Liu, L.; Long, S.; Jiang, S.; Tan, Y.; Li, Z. Numerical flow simulation of fresh concrete in mixing truck. Powder Technol. 2022, 409, 117781. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Gram, A.; Krenzer, K.; Schwabe, J.H. Simulation of fresh concrete flow using Discrete Element Method (DEM): Theory and applications. Mater. Struct. 2014, 47, 615–630. [Google Scholar] [CrossRef]

- Stroeven, P.; He, H.; Stroeven, M. Discrete element modeling approach to assessment of granular properties in concrete. J. Zhejiang Univ.-Sci. A 2011, 12, 335–344. [Google Scholar] [CrossRef]

- Yan, W.; Cui, W.; Qi, L. DEM study on the response of fresh concrete under vibration. Granul. Matter 2022, 24, 37. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, Y.; Zhu, L.; Wang, Y.; Jin, Z. Characterization of coarse aggregate morphology and its effect on rheological and mechanical properties of fresh concrete. Constr. Build. Mater. 2021, 286, 122940. [Google Scholar] [CrossRef]

- Koch, J.A.; Castaneda, D.I.; Ewoldt, R.H.; Lange, D.A. Vibration of fresh concrete understood through the paradigm of granular physics. Cem. Concr. Res. 2019, 115, 31–42. [Google Scholar] [CrossRef]

- Krenzer, K.; Mechtcherine, V.; Palzer, U. Simulating mixing processes of fresh concrete using the discrete element method (DEM) under consideration of water addition and changes in moisture distribution. Cem. Concr. Res. 2019, 115, 274–282. [Google Scholar] [CrossRef]

- Cui, W.; Ji, T.; Li, M.; Wu, X. Simulating the workability of fresh self-compacting concrete with random polyhedron aggregate based on DEM. Mater. Struct. 2017, 50, 92. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, C.; Hao, X.; Li, W.; Zhang, X. Quantitative evaluation for shape characteristics of aggregate particles based on 3D point cloud data. Constr. Build. Mater. 2020, 263, 120156. [Google Scholar] [CrossRef]

- Cabaret, F.; Rivera, C.; Fradette, L.; Heniche, M.; Tanguy, P.A. Hydrodynamics performance of a dual shaft mixer with viscous Newtonian liquids. Chem. Eng. Res. Des. 2007, 85, 583–590. [Google Scholar] [CrossRef]

- Ostroukh, A.V.; Aysarina, A.A. Development of Automated Control Systems for Concrete Mixing Plants Based Twin-Shaft Mixer. Autom. Control Tech. Syst. 2015, 1, 51–59. [Google Scholar] [CrossRef]

- Guo, L.; Zhao, W.; Wang, J.; Shen, W.W. Simulation analysis and experimental research on installation angle of mixing blade of double vertical shaft vibration mixer based on edem. Mod. Manuf. Technol. Equip. 2018, 11, 3–6. [Google Scholar]

- Wen, W.X.; Zhang, B.; Liu, G.B. Research on the influence of pebbles and crushed stones on the performance of concrete. Creat. Living 2019, 3, 1–2. [Google Scholar]

- Cao, G.; Liu, Y.; Long, S.; Deng, D.; Jiang, S.; Su, H.; Tan, T. Influence of aggregate shape on the flow properties of fresh concrete. Powder Technol. 2023, 415, 118186. [Google Scholar] [CrossRef]

- National Standards of the People’s Republic of China. GB/T 14685-2022; Pebble and Crushed Stone for Construction. National Standardization Management Committee: Beijing, China, 2022.

- Chen, W.; Wu, W.; Lu, G.; Tian, G. Simulation Analysis of Concrete Pumping Based on Smooth Particle Hydrodynamics and Discrete Elements Method Coupling. Materials 2022, 15, 4294. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Cao, G.; Guo, K. Numerical method for thixotropic behavior of fresh concrete. Constr. Build. Mater. 2018, 187, 931–941. [Google Scholar] [CrossRef]

- Zhou, X.; Xie, Y.; Long, G.; Li, J. Effect of surface characteristics of aggregates on the compressive damage of high-strength concrete based on 3D discrete element method. Constr. Build. Mater. 2021, 301, 124101. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Xiao, X.; Li, Y.; Peng, R.; Gao, J.; Hu, C. Parameter calibration and mixing uniformity of irregular gravel materials in a rotating drum. Powder Technol. 2023, 414, 118074. [Google Scholar] [CrossRef]

- Zhu, X.; Jiang, Z. Reuse of waste rubber in pervious concrete: Experiment and DEM simulation. J. Build. Eng. 2023, 71, 106452. [Google Scholar] [CrossRef]

- Mu, J.; Li, Y.; Hao, J.; Liu, Y.; Shen, J. Research on discrete element simulation of slump test for fresh self-compacting concrete. J. Build. Eng. 2023, 70, 106464. [Google Scholar] [CrossRef]

- Zhang, H. Analysis and research on working performance of double horizontal shaft mixer based on discrete element method. J. Chongqing Univ. Technol. 2019, 33, 68–73. (In Chinese) [Google Scholar]

| Parameter (Unit) | Value |

|---|---|

| Cylinder radius, R (mm) | 186 |

| Cylinder length, L (mm) | 433 |

| Cylinder width, W (mm) | 548 |

| Difference between overall height and cylinder radius, H (mm) | 93 |

| Angle 1, () | 40 |

| Angle 2, () | 45 |

| Height of blade, h (mm) | 65 |

| The long axis of the blade, B (mm) | 92 |

| Short shaft of the blade, b (mm) | 54 |

| Contact Pairs | Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Rolling Friction | Surface Energy |

|---|---|---|---|---|

| Aggregates–Aggregates | 0.15 | 0.07 | 0.05 | 1.2 |

| Aggregate–Mortar | 0.05 | 0.08 | 0.06 | 3 |

| Aggregates–Steel | 0.2 | 0.05 | 0.03 | 0.8 |

| Mortar–Mortar | 0.01 | 0.16 | 0.12 | 8 |

| Mortar–Steel | 0.03 | 0.11 | 0.09 | 1 |

| Category | Density (kg/m3) | Shear Modulus /(GPa) | Poisson’s Ratio |

|---|---|---|---|

| Aggregate | 2600 | 20 | 0.35 |

| Mortar | 2100 | 2 | 0.25 |

| Steel | 7800 | 70 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Wang, B.; Hou, J.; Yao, P. Numerical Study on the Effect of Coarse Aggregate Shape during Concrete Mixing Process. Materials 2024, 17, 1515. https://doi.org/10.3390/ma17071515

Shen J, Wang B, Hou J, Yao P. Numerical Study on the Effect of Coarse Aggregate Shape during Concrete Mixing Process. Materials. 2024; 17(7):1515. https://doi.org/10.3390/ma17071515

Chicago/Turabian StyleShen, Jianjun, Binqiang Wang, Jingru Hou, and Pengchao Yao. 2024. "Numerical Study on the Effect of Coarse Aggregate Shape during Concrete Mixing Process" Materials 17, no. 7: 1515. https://doi.org/10.3390/ma17071515

APA StyleShen, J., Wang, B., Hou, J., & Yao, P. (2024). Numerical Study on the Effect of Coarse Aggregate Shape during Concrete Mixing Process. Materials, 17(7), 1515. https://doi.org/10.3390/ma17071515