Towards Understanding {10-11}-{10-12} Secondary Twinning Behaviors in AZ31 Magnesium Alloy during Fatigue Deformation

Abstract

1. Introduction

2. Materials and Methods

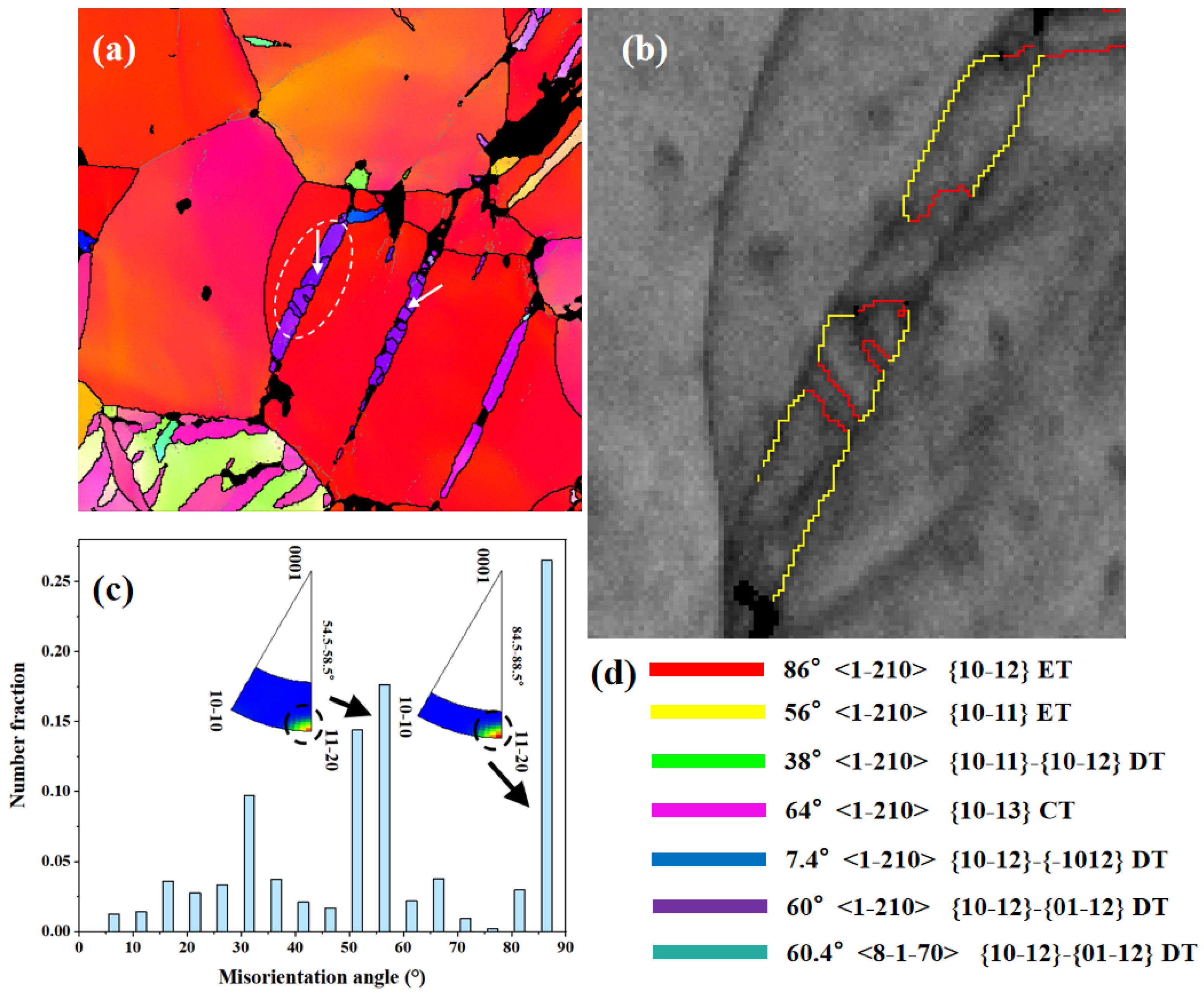

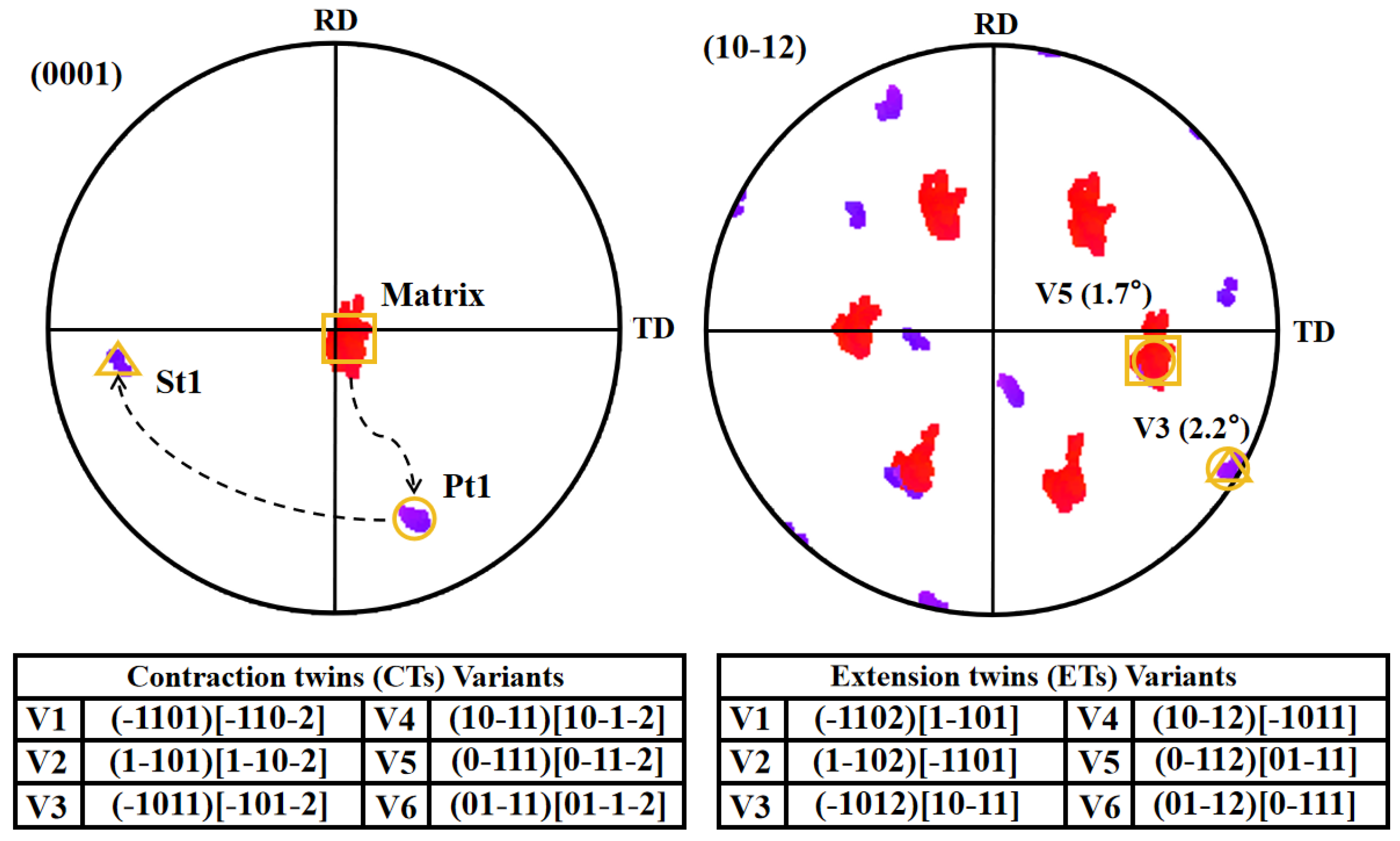

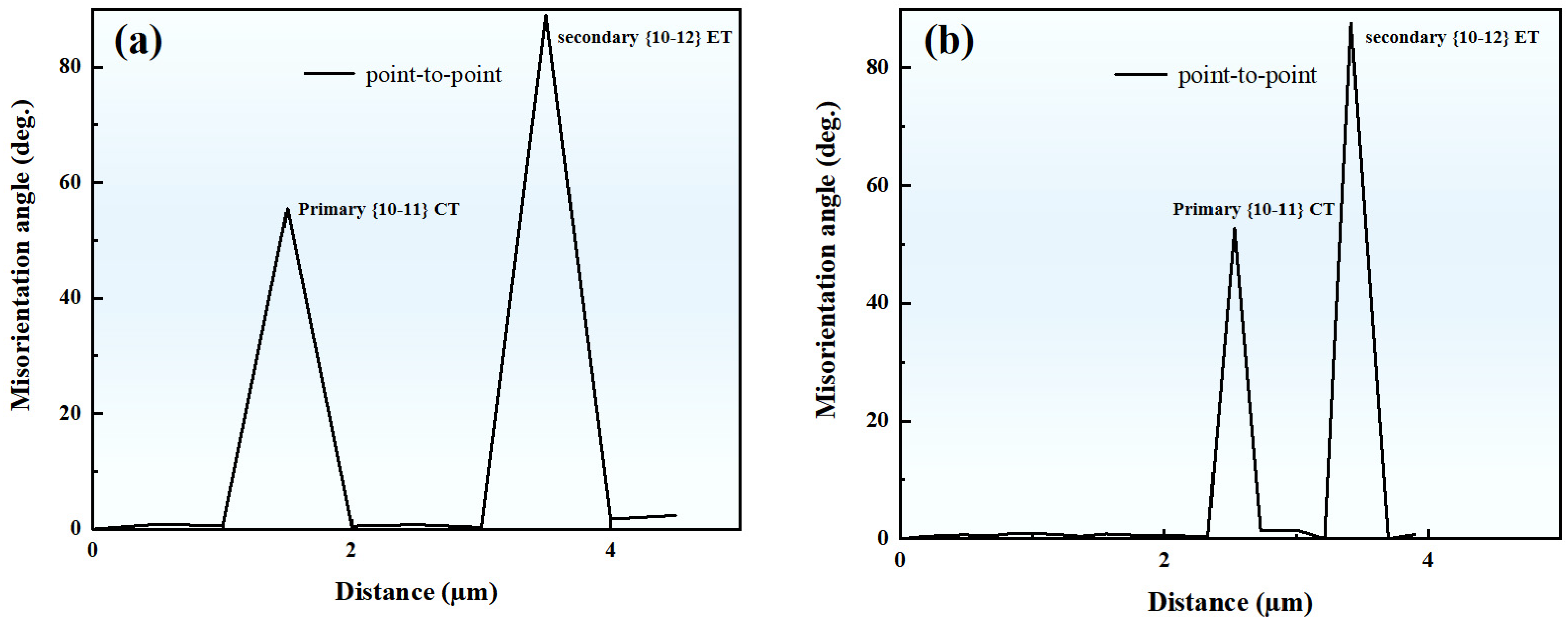

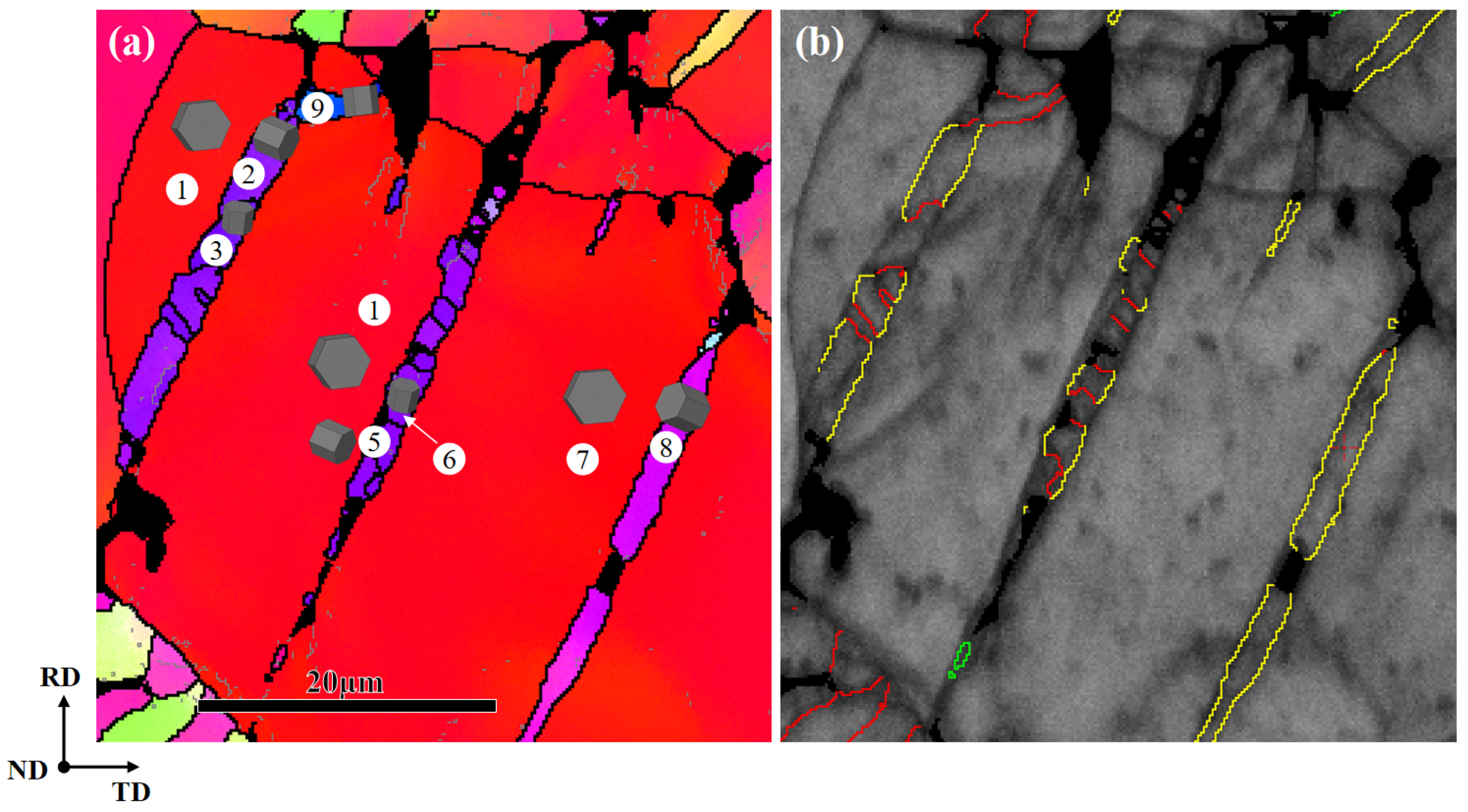

3. Results

4. Discussion

4.1. Analyses of Schmid Factors

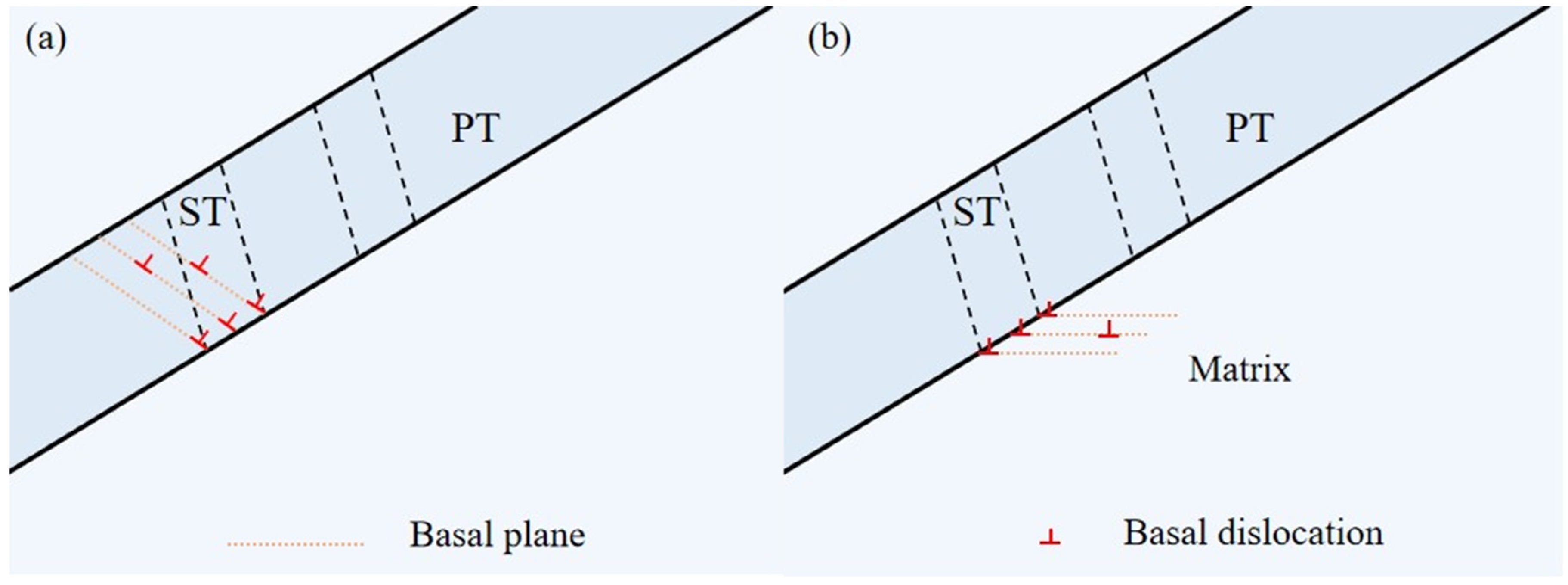

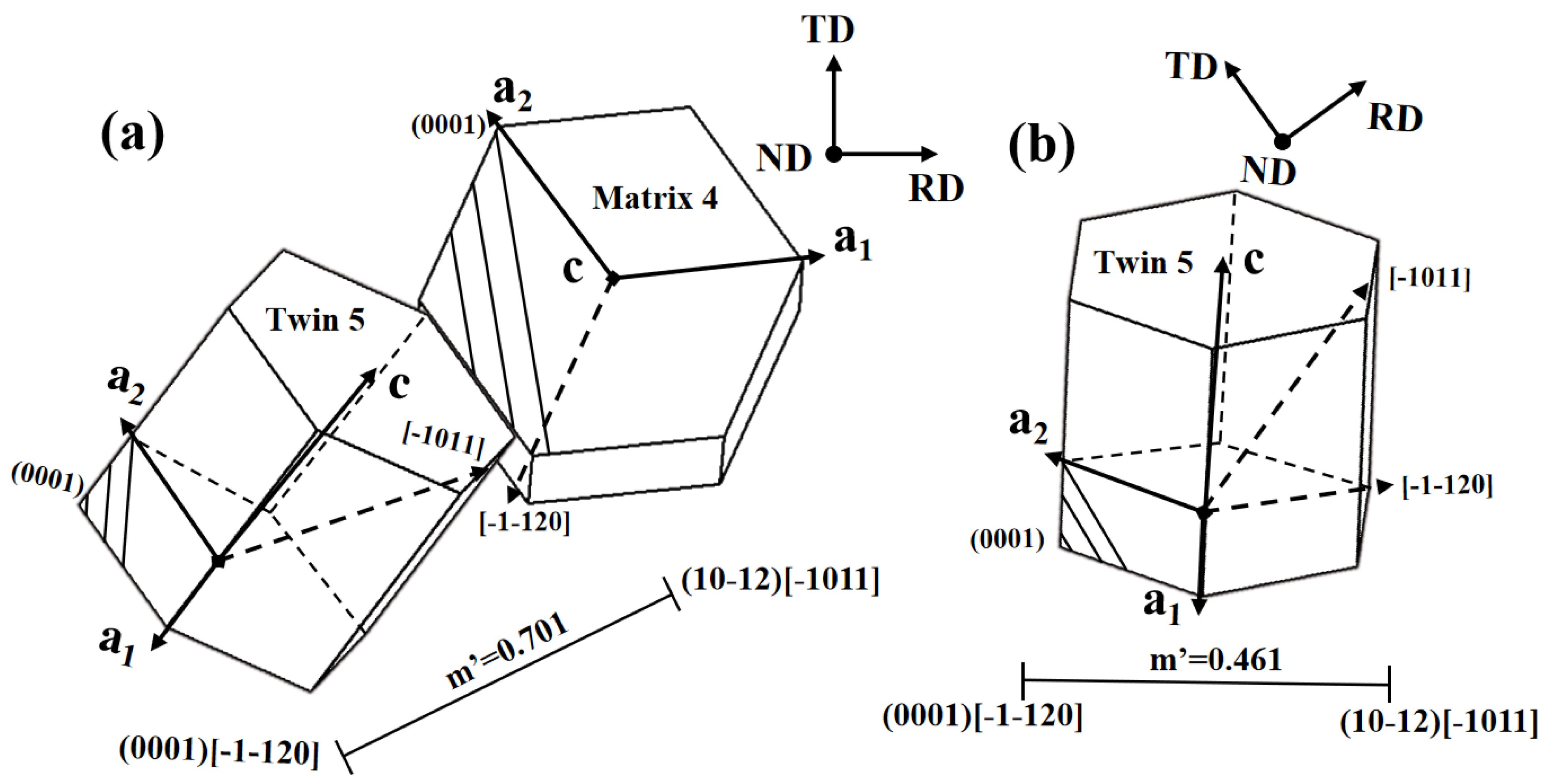

4.2. m’ Associated with Secondary Twin and Basal Slip within the Primary Twin

4.3. m’ Associated with Secondary Twin and Basal Slip in the Matrix

5. Conclusions

- (1)

- The lamellar secondary twin is activated inside the primary {10-11} CT. This morphological feature is similar to the previously discovered {10-12}-{10-12} STs. After misorientation calibration, it is found that this type of secondary twin is a {10-11}-{10-12} ST.

- (2)

- Local strain accommodation plays an important role in the formation of the unusual {10-11}-{10-12} ST. The calculation analysis using the Schmid factor and geometric compatibility parameter concludes that during tensile loading, when the strain caused by the basal slip within the {10-11} primary twin cannot be effectively transmitted to the matrix, it induces the {10-11}-{10-12} secondary twin within the primary twin to reduce the local strain incompatibility at the twin boundary. Under compressive loading, the activation of certain slip systems within the matrix induces local strain at the primary twin boundary, leading to the activation of {10-11}-{10-12} secondary twins.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Carneiro, L.; Culbertson, D.; Yu, Q.; Jiang, Y.Y. Twinning in Rolled AZ31B Magnesium Alloy under Free-End Torsion. Mater. Sci. Eng. A 2021, 801, 140405. [Google Scholar] [CrossRef]

- Yang, P.F.; Yang, Z.Y.; Li, L.; Sun, Q.; Tan, L.; Ma, X.K.; Zhu, M.H. Towards Understanding Double Extension Twinning Behaviors in Magnesium Alloy during Uniaxial Tension Deformation. J. Alloys Compd. 2022, 894, 162491. [Google Scholar] [CrossRef]

- Liu, H.; Lin, F.X.; Liu, P.; Yue, Y.; Shin, K.S.; Peng, L.M.; Delannay, L.; Nie, J.F.; Moelans, N. Variant Selection of Primary–Secondary Extension Twin Pairs in Magnesium: An Analytical Calculation Study. Acta Mater. 2021, 219, 117221. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Lee, J.H.; Huh, Y.H. Texture Evolution of Rolled Mg–3Al–1Zn Alloy Undergoing a {10-12} Twinning Dominant Strain Path Change. J. Alloys Compd. 2015, 646, 573–579. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Zaefferer, S.; Schestakow, I.; Yi, S.; Gonzalez-Martinez, R. On the Role of Non-Basal Deformation Mechanisms for the Ductility of Mg and Mg–Y Alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

- Hou, X.L.; Liu, X.Q.; Wang, D.L.; Liu, Y.F.; Zhao, Q.Y.; Sun, Z.; Shang, Z.X.; Sun, Z.K. Insight into Double Twinning Behavior of Mg–Gd Rolled Alloy at the Nano Scale: Role of Micro-Texture Entropy. J. Alloys Compd. 2024, 983, 173835. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Tariq, H.M.R.; Zubair, M.; Ansari, N.; Jun, T.S. Implications of Twinning on the Microstructure Development, Crystallographic Texture and Mechanical Performance of Mg Alloys—A Critical Review. J. Magnes. Alloys 2023, 11, 4146–4165. [Google Scholar] [CrossRef]

- Wu, B.L.; Wan, G.; Zhang, Y.D.; Esling, C. Twinning Characteristics in Textured AZ31 Alloy under Impact Loading along Specified Direction. Mater. Lett. 2010, 64, 636–639. [Google Scholar] [CrossRef]

- Koike, J.; Fujiyama, N.; Ando, D.; Sutou, Y. Roles of Deformation Twinning and Dislocation Slip in the Fatigue Failure Mechanism of AZ31 Mg Alloys. Scr. Mater. 2010, 63, 747–750. [Google Scholar] [CrossRef]

- Yu, Q.; Jiang, Y.Y.; Wang, J. Cyclic Deformation and Fatigue Damage in Single-Crystal Magnesium under Fully Reversed Strain-Controlled Tension–Compression in the [101¯0] Direction. Scr. Mater. 2015, 96, 41–44. [Google Scholar] [CrossRef]

- Li, L.; Yang, J.; Yang, Z.Y.; Sun, Q.; Tan, L.; Zeng, Q.H.; Zhu, M.H. Towards Revealing the Relationship between Deformation Twin and Fatigue Crack Initiation in a Rolled Magnesium Alloy. Mater. Charact. 2021, 179, 111362. [Google Scholar] [CrossRef]

- Tan, L.; Huang, X.Y.; Wang, Y.Z.; Sun, Q.; Zhang, Y.B.; Tu, J.; Zhou, Z.M. Activation Behavior of {10-12}-{10-12} Secondary Twins by Different Strain Variables and Different Loading Directions during Fatigue Deformation of AZ31 Magnesium Alloy. Metals 2022, 12, 1433. [Google Scholar] [CrossRef]

- Dang, K.; Graham, J.; McCabe, R.J.; Taupin, V.; Tomé, C.N.; Capolungo, L. Atomistic and Phase Field Simulations of Three Dimensional Interactions of {101-2} Twins with Grain Boundaries in Mg: Twin Transmission and Dislocation Emission. Materialia 2021, 20, 101247. [Google Scholar] [CrossRef]

- Guo, C.F.; Xin, R.L.; Ding, C.H.; Song, B.; Liu, Q. Understanding of Variant Selection and Twin Patterns in Compressed Mg Alloy Sheets via Combined Analysis of Schmid Factor and Strain Compatibility Factor. Mater. Sci. Eng. A 2014, 609, 92–101. [Google Scholar] [CrossRef]

- Mu, S.J.; Jonas, J.J.; Gottstein, G. Variant Selection of Primary, Secondary and Tertiary Twins in a Deformed Mg Alloy. Acta Mater. 2012, 60, 2043–2053. [Google Scholar] [CrossRef]

- Guan, D.K.; Rainforth, W.M.; Gao, J.H.; Sharp, J.; Wynne, B.; Ma, L. Individual Effect of Recrystallisation Nucleation Sites on Texture Weakening in a Magnesium Alloy: Part 1—Double Twins. Acta Mater. 2017, 135, 14–24. [Google Scholar] [CrossRef]

- Cizek, P.; Barnett, M.R. Characteristics of the Contraction Twins Formed Close to the Fracture Surface in Mg–3Al–1Zn Alloy Deformed in Tension. Scr. Mater. 2008, 59, 959–962. [Google Scholar] [CrossRef]

- Yin, D.D.; Boehlert, C.J.; Long, L.J.; Huang, G.H.; Zhou, H.; Zheng, J.; Wang, Q.D. Tension-Compression Asymmetry and the Underlying Slip/Twinning Activity in Extruded Mg–Y Sheets. Int. J. Plast. 2021, 136, 102878. [Google Scholar] [CrossRef]

- Shi, Z.Z.; Zhang, Y.D.; Wagner, F.; Juan, P.A.; Berbenni, S.; Capolungo, L.; Lecomte, J.S.; Richeton, T. On the Selection of Extension Twin Variants with Low Schmid Factors in a Deformed Mg Alloy. Acta Mater. 2015, 83, 17–28. [Google Scholar] [CrossRef]

- Zhou, B.J.; Wang, L.Y.; Jin, P.P.; Jia, H.L.; Roven, H.J.; Zeng, X.Q.; Li, Y.J. Revealing Slip-Induced Extension Twinning Behaviors Dominated by Micro Deformation in a Magnesium Alloy. Int. J. Plast. 2020, 128, 102669. [Google Scholar] [CrossRef]

- Agnew, S.R.; Tomé, C.N.; Brown, D.W.; Holden, T.M.; Vogel, S.C. Study of Slip Mechanisms in a Magnesium Alloy by Neutron Diffraction and Modeling. Scr. Mater. 2003, 48, 1003–1008. [Google Scholar] [CrossRef]

- Liu, G.D.; Xin, R.L.; Shu, X.G.; Wang, C.P.; Liu, Q. The Mechanism of Twinning Activation and Variant Selection in Magnesium Alloys Dominated by Slip Deformation. J. Alloys Compd. 2016, 687, 352–359. [Google Scholar] [CrossRef]

- Homayonifar, M.; Mosler, J. On the Coupling of Plastic Slip and Deformation-Induced Twinning in Magnesium: A Variationally Consistent Approach Based on Energy Minimization. Int. J. Plast. 2011, 27, 983–1003. [Google Scholar] [CrossRef]

- Guan, D.K.; Wynne, B.; Gao, J.H.; Huang, Y.H.; Rainforth, W.M. Basal Slip Mediated Tension Twin Variant Selection in Magnesium WE43 Alloy. Acta Mater. 2019, 170, 1–14. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Eisenlohr, P.; Bieler, T.R.; Crimp, M.A.; Mason, D.E. Twin Nucleation by Slip Transfer across Grain Boundaries in Commercial Purity Titanium. Metall. Mater. Trans. A 2010, 41, 421–430. [Google Scholar] [CrossRef]

- Nan, X.L.; Wang, H.Y.; Zhang, L.; Li, J.B.; Jiang, Q.C. Calculation of Schmid Factors in Magnesium: Analysis of Deformation Behaviors. Scr. Mater. 2012, 67, 443–446. [Google Scholar] [CrossRef]

| Type of Twin | Twin Plane | Misorientation Axis | Misorientation Angle |

|---|---|---|---|

| Extension twin | {10-12} | <1-210> | 86.3° |

| Contraction twin | {10-11} | <1-210> | 56° |

| {10-13} | <1-210> | 64° | |

| Secondary twin | {10-11}-{10-12} | <1-210> | 38° |

| {10-13}-{10-12} | <1-210> | 22° | |

| {10-12}-{−1012} | <1-210> | 7.4° | |

| {10-12}-{01-12} | <1-210> | 60° | |

| {10-12}-{0-112} | <8-1-70> | 60.4° |

| SF | (01-11)[01-1-2] | (10-11)[10-1-2] | (1-101)[1-10-2] | (0-111)[0-11-2] | (−1011)[-101-2] | (−1101)[-110-2] |

|---|---|---|---|---|---|---|

| 1 (Matrix) | 0.466 | 0.428 | 0.365 | ② 0.343 | 0.390 | 0.450 |

| 2 (PT) | −0.004 | 0.127 | −0.124 | −0.464 | −0.088 | 0.121 |

| 3 (ST) | −0.057 | 0.095 | −0.125 | −0.481 | −0.113 | 0.092 |

| 4 (Matrix) | 0.482 | 0.445 | 0.356 | ⑤ 0.304 | 0.358 | 0.447 |

| 5 (PT) | 0.013 | 0.135 | −0.104 | −0.458 | −0.099 | 0.134 |

| 6 (ST) | 0.013 | 0.133 | −0.095 | −0.458 | −0.107 | 0.135 |

| 7 (Matrix) | ⑧ 0.451 | 0.435 | 0.394 | 0.370 | 0.390 | 0.430 |

| 8 | −0.343 | −0.022 | 0.251 | 0.207 | 0.251 | −0.027 |

| 9 | −0.393 | −0.054 | −0.164 | −0.421 | −0.065 | −0.146 |

| SF | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] |

|---|---|---|---|---|---|---|

| 1 | −0.493 | −0.494 | −0.485 | −0.479 | −0.490 | −0.495 |

| 2 | 0.255 | −0.035 | 0.016 | 0.308 | −0.011 | −0.012 |

| 3 | 0.299 | −0.001 | 0.032 | 0.348 | 0.023 | 0.007 |

| 4 | −0.483 | −0.488 | −0.477 | −0.463 | −0.478 | −0.488 |

| 5 | 0.240 | −0.035 | −0.005 | 0.294 | −0.008 | −0.032 |

| 6 | 0.240 | −0.030 | −0.011 | 0.294 | −0.002 | −0.037 |

| 7 | −0.498 | −0.498 | −0.494 | −0.489 | −0.493 | −0.498 |

| 8 | 0.113 | −0.122 | −0.151 | 0.050 | −0.153 | −0.119 |

| 9 | 0.488 | 0.071 | 0.187 | 0.491 | 0.072 | 0.185 |

| SF | (01-11)[01-1-2] | (10-11)[10-1-2] | (1-101)[1-10-2] | (0-111)[0-11-2] | (−1011)[−101-2] | (−1101)[−110-2] |

|---|---|---|---|---|---|---|

| 1 | −0.466 | −0.428 | −0.365 | −0.343 | −0.390 | −0.450 |

| 2 | 0.004 | −0.127 | 0.124 | 0.464 | 0.088 | −0.121 |

| 3 | 0.057 | −0.095 | 0.125 | 0.481 | 0.113 | −0.092 |

| 4 | −0.482 | −0.445 | −0.356 | −0.304 | −0.358 | −0.447 |

| 5 | −0.013 | −0.135 | 0.104 | 0.458 | 0.099 | −0.134 |

| 6 | −0.013 | −0.133 | 0.095 | 0.458 | 0.107 | −0.135 |

| 7 | −0.451 | −0.435 | −0.394 | −0.370 | −0.390 | −0.430 |

| 8 | 0.343 | 0.022 | −0.251 | −0.207 | −0.251 | 0.027 |

| 9 | 0.393 | 0.054 | 0.164 | 0.421 | 0.065 | 0.146 |

| SF | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] |

|---|---|---|---|---|---|---|

| 1 | 0.493 | 0.494 | 0.485 | 0.479 | 0.490 | 0.495 |

| 2 | −0.255 | 0.035 | −0.016 | −0.308 | ③ 0.011 | 0.012 |

| 3 | −0.299 | 0.001 | −0.032 | −0.348 | −0.023 | −0.007 |

| 4 | 0.483 | 0.488 | 0.477 | 0.463 | 0.478 | 0.488 |

| 5 | −0.240 | 0.035 | 0.005 | −0.294 | ⑥ 0.008 | 0.032 |

| 6 | −0.240 | 0.030 | 0.011 | −0.294 | 0.002 | 0.037 |

| 7 | 0.498 | 0.498 | 0.494 | 0.489 | 0.493 | 0.498 |

| 8 | −0.113 | 0.122 | 0.151 | −0.050 | 0.153 | 0.119 |

| 9 | −0.488 | −0.071 | −0.187 | −0.491 | −0.072 | −0.185 |

| M’ | Secondary Twin Variant | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | |

|---|---|---|---|---|---|---|---|---|

| basal slip system within primary twin | SF (tensile loading) | SF (compressive loading) | −0.308/0.308 | 0.011/−0.011 | 0.012/−0.012 | −0.255/0.255 | 0.035/−0.035 | −0.016/0.016 |

| (0001)[2-1-10] | −0.015 | 0.015 | 0.000 | −0.461 | −0.461 | 0.000 | 0.461 | 0.461 |

| (0001)[11-20] | −0.365 | 0.365 | −0.461 | −0.461 | 0.000 | 0.461 | 0.461 | 0.000 |

| (0001)[1-210] | 0.349 | −0.349 | 0.461 | 0.000 | −0.461 | −0.461 | 0.000 | 0.461 |

| (0001)[-12-10] | −0.349 | 0.349 | −0.461 | 0.000 | 0.461 | 0.461 | 0.000 | −0.461 |

| (0001)[-1-120] | 0.365 | −0.365 | 0.461 | 0.461 | 0.000 | −0.461 | −0.461 | 0.000 |

| (0001)[-2110] | 0.015 | −0.015 | 0.000 | 0.461 | 0.461 | 0.000 | −0.461 | −0.461 |

| m’ | Secondary Twin Variant | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | |

|---|---|---|---|---|---|---|---|---|

| basal slip system within primary twin | SF (tensile loading) | SF (compressive loading) | 0.295/−0.295 | −0.002/0.002 | −0.037/0.037 | 0.24/−0.24 | −0.03/0.03 | −0.011/0.011 |

| (0001)[2-1-10] | −0.005 | 0.005 | 0.000 | −0.461 | −0.461 | 0.000 | 0.461 | 0.461 |

| (0001)[11-20] | −0.368 | 0.368 | −0.461 | −0.461 | 0.000 | 0.461 | 0.461 | 0.000 |

| (0001)[1-210] | 0.363 | −0.363 | 0.461 | 0.000 | −0.461 | −0.461 | 0.000 | 0.461 |

| (0001)[-12-10] | −0.363 | 0.363 | −0.461 | 0.000 | 0.461 | 0.461 | 0.000 | −0.461 |

| (0001)[-1-120] | 0.368 | −0.368 | 0.461 | 0.461 | 0.000 | −0.461 | −0.461 | 0.000 |

| (0001)[-2110] | 0.005 | −0.005 | 0.000 | 0.461 | 0.461 | 0.000 | −0.461 | −0.461 |

| m’ | Secondary Twin Variant | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | |

|---|---|---|---|---|---|---|---|---|

| basal slip system within matrix | SF (tensile loading) | SF (compressive loading) | −0.308/0.308 | 0.011/−0.011 | 0.012/−0.012 | −0.255/0.255 | 0.036/−0.036 | −0.016/0.016 |

| (0001)[2-1-10] | −0.024 | 0.024 | −0.037 | −0.456 | −0.079 | 0.000 | 0.080 | 0.418 |

| (0001)[11-20] | 0.083 | −0.083 | −0.842 | −0.674 | −0.076 | 0.022 | −0.003 | −0.269 |

| (0001)[1-210] | −0.107 | 0.107 | 0.805 | 0.218 | −0.004 | −0.021 | 0.083 | 0.687 |

| (0001)[-12-10] | 0.107 | −0.107 | −0.805 | −0.218 | 0.004 | 0.021 | −0.083 | −0.687 |

| (0001)[-1-120] | −0.083 | 0.083 | 0.842 | 0.674 | 0.076 | −0.022 | 0.003 | 0.269 |

| (0001)[-2110] | 0.024 | −0.024 | 0.037 | 0.456 | 0.079 | 0.000 | −0.080 | −0.418 |

| m’ | Secondary Twin Variant | (01-12)[0-111] | (10-12)[−1011] | (1-102)[−1101] | (0-112)[01-11] | (−1012)[10-11] | (−1102)[1-101] | |

|---|---|---|---|---|---|---|---|---|

| basal slip system within matrix | SF (tensile loading) | SF (compressive loading) | −0.295/0.295 | 0.002/−0.002 | 0.037/−0.037 | −0.24/0.24 | 0.03/−0.03 | 0.011/−0.011 |

| (0001)[2-1-10] | −0.002 | 0.002 | −0.012 | −0.460 | −0.115 | 0.000 | 0.114 | 0.448 |

| (0001)[11-20] | 0.137 | −0.137 | −0.852 | −0.701 | −0.105 | 0.007 | 0.007 | −0.256 |

| (0001)[1-210] | −0.139 | 0.139 | 0.840 | 0.240 | −0.009 | −0.007 | 0.108 | 0.705 |

| (0001)[-12-10] | 0.139 | 0.139 | −0.840 | −0.240 | 0.009 | 0.007 | −0.108 | −0.705 |

| (0001)[-1-120] | −0.137 | 0.137 | 0.852 | 0.701 | 0.105 | −0.007 | −0.007 | 0.256 |

| (0001)[-2110] | 0.002 | −0.002 | 0.012 | 0.460 | 0.115 | 0.000 | −0.114 | −0.448 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, Y.; Tan, L.; Yan, Y.; Zhou, T.; Yang, P.; Tu, J.; Zhou, Z. Towards Understanding {10-11}-{10-12} Secondary Twinning Behaviors in AZ31 Magnesium Alloy during Fatigue Deformation. Materials 2024, 17, 1594. https://doi.org/10.3390/ma17071594

You Y, Tan L, Yan Y, Zhou T, Yang P, Tu J, Zhou Z. Towards Understanding {10-11}-{10-12} Secondary Twinning Behaviors in AZ31 Magnesium Alloy during Fatigue Deformation. Materials. 2024; 17(7):1594. https://doi.org/10.3390/ma17071594

Chicago/Turabian StyleYou, Yunxiang, Li Tan, Yuqin Yan, Tao Zhou, Pengfei Yang, Jian Tu, and Zhiming Zhou. 2024. "Towards Understanding {10-11}-{10-12} Secondary Twinning Behaviors in AZ31 Magnesium Alloy during Fatigue Deformation" Materials 17, no. 7: 1594. https://doi.org/10.3390/ma17071594

APA StyleYou, Y., Tan, L., Yan, Y., Zhou, T., Yang, P., Tu, J., & Zhou, Z. (2024). Towards Understanding {10-11}-{10-12} Secondary Twinning Behaviors in AZ31 Magnesium Alloy during Fatigue Deformation. Materials, 17(7), 1594. https://doi.org/10.3390/ma17071594