Strength–Ductility Mechanism of CoCrFeMnNi High-Entropy Alloys with Inverse Gradient-Grained Structures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

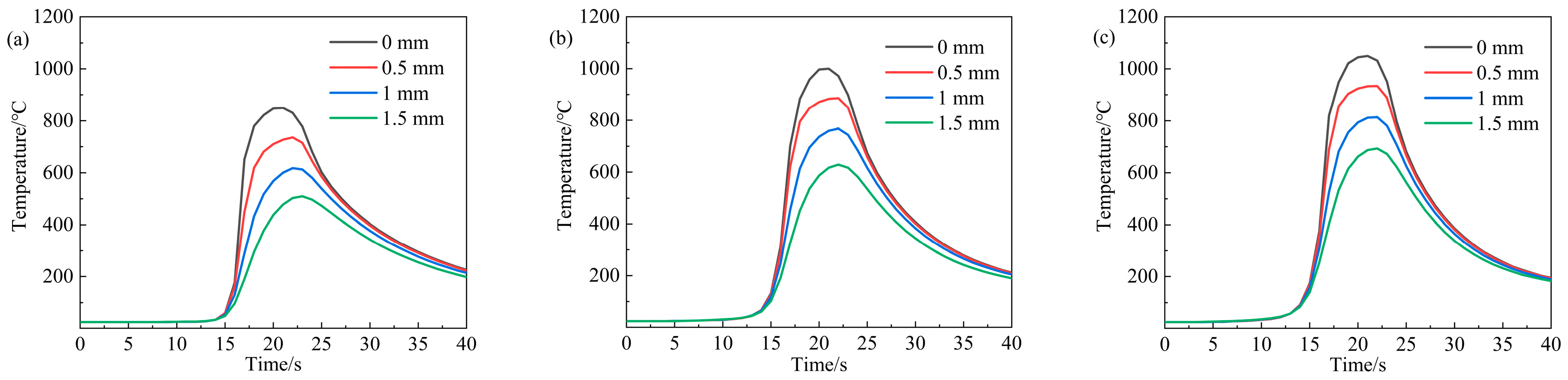

3.1. Distribution Characteristics of Grain Size

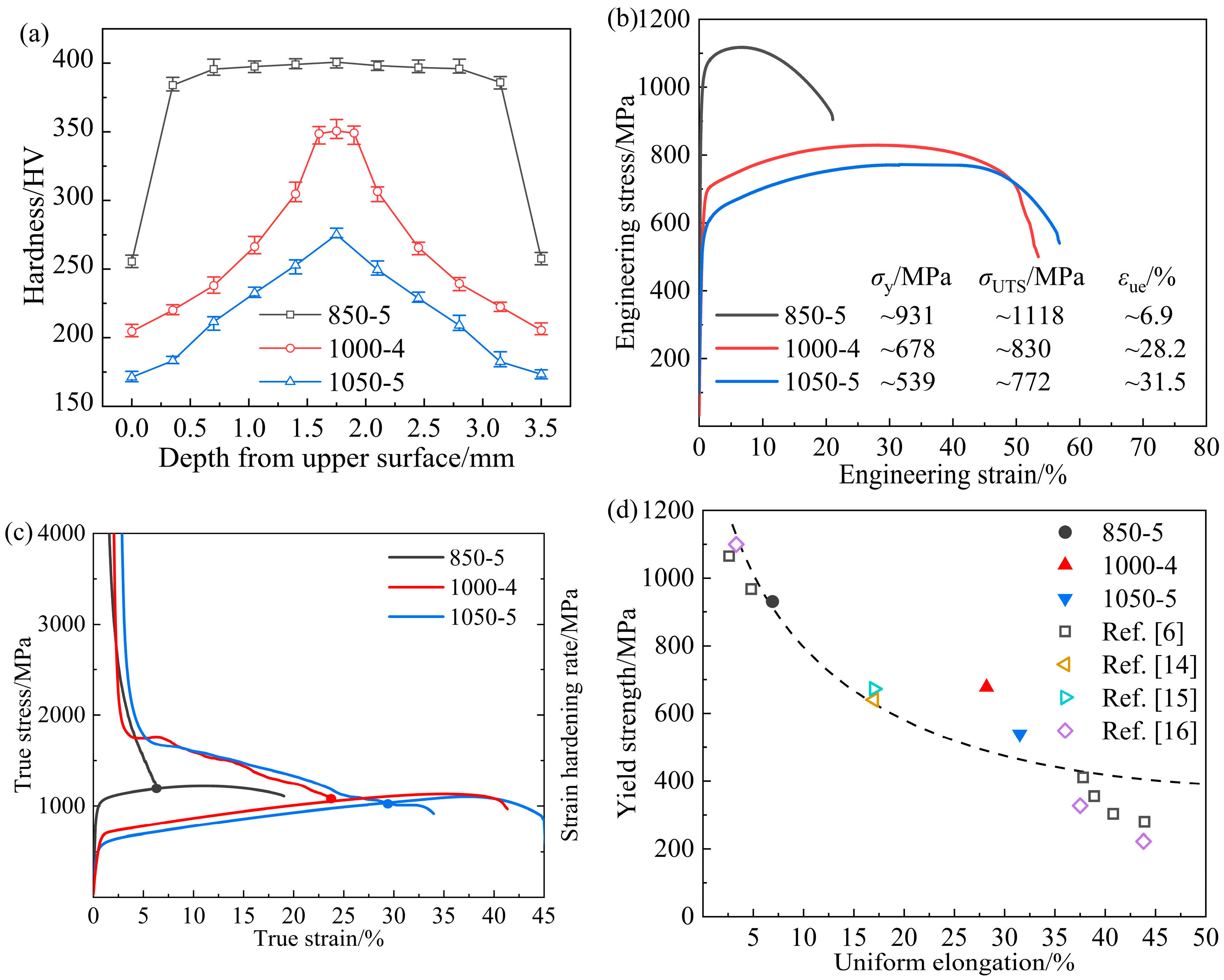

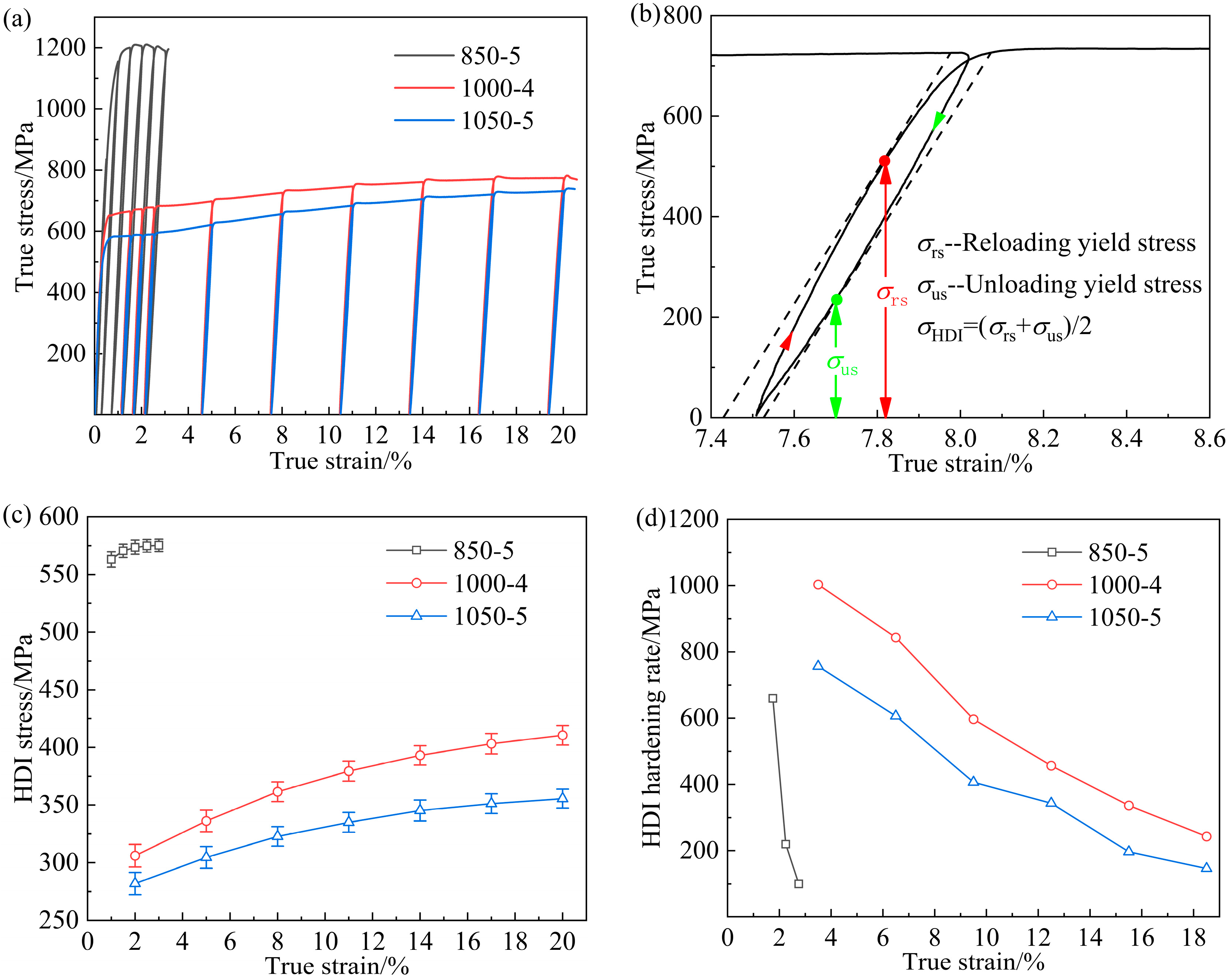

3.2. Mechanical Property

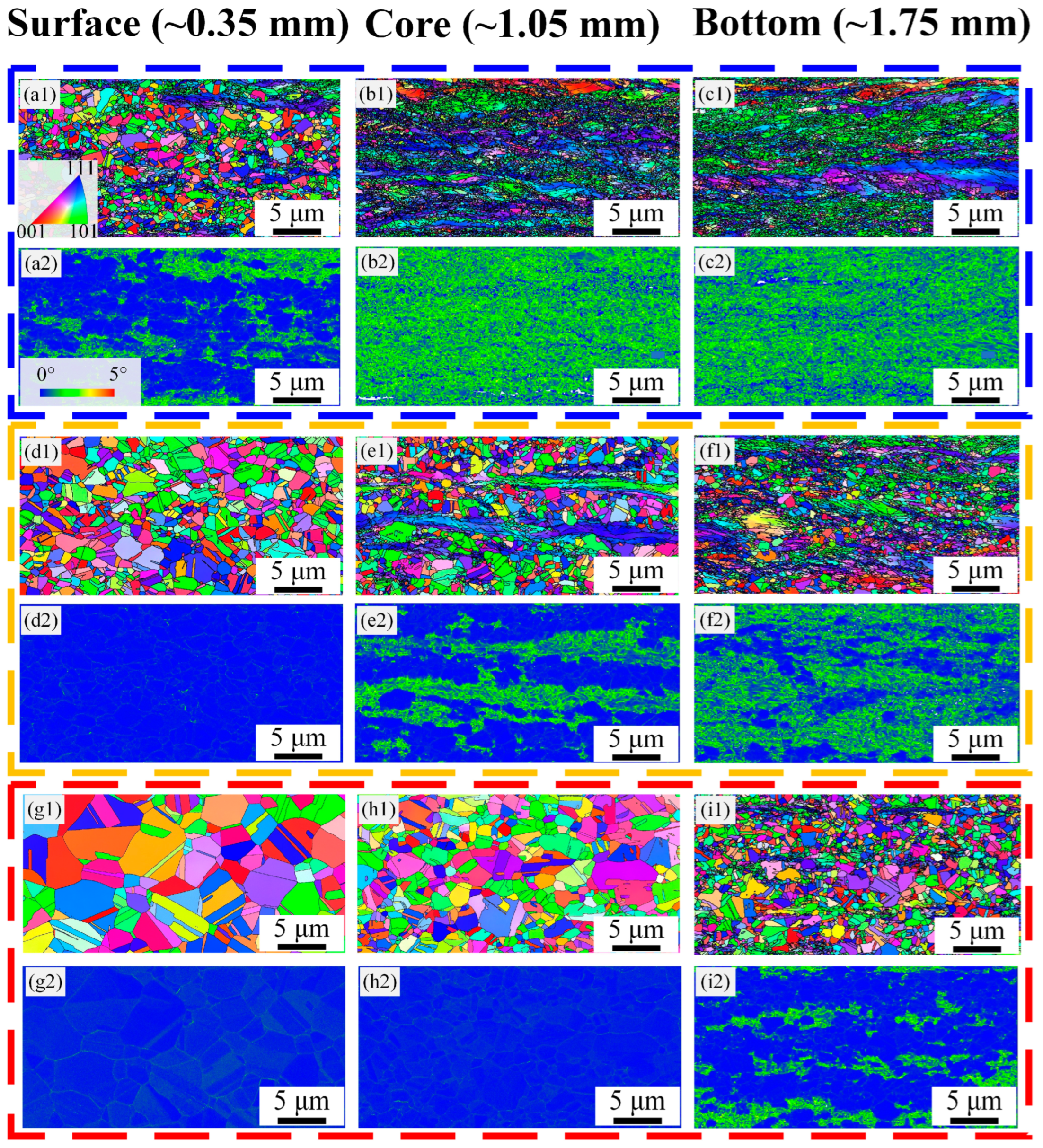

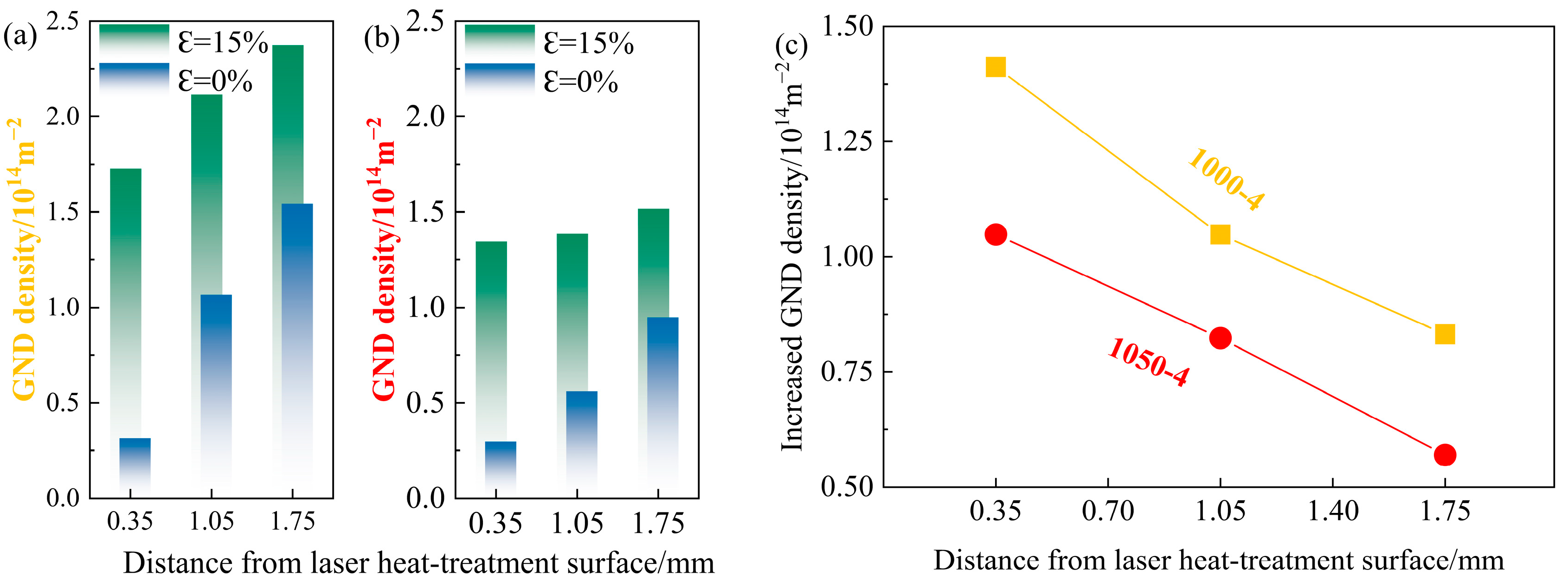

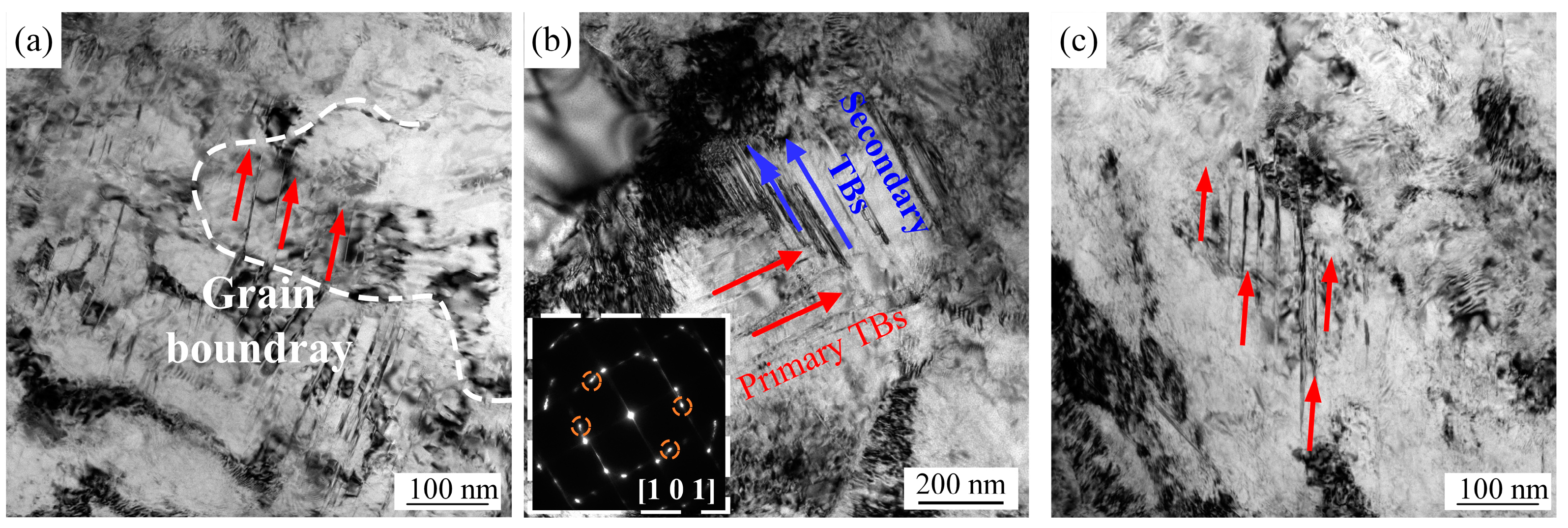

3.3. Microstructural Evolution during Tensile Deformation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, R.E.; Gu, G.H.; Choi, Y.T.; Lee, J.A.; Kim, H.S. Superior tensile properties and formability synergy of high-entropy alloys through inverse-gradient structures via laser surface treatment. Scripta Mater. 2023, 234, 115587. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Heidarzadeh, A. On the Real-Time Atomistic Deformation of the CoNiCrFeMn High-Entropy Alloy with Gradient Structures. Phys. Status Solidi (A) 2021, 218, 2100336. [Google Scholar] [CrossRef]

- Rambabu, K.; Gandhi, P.; Susmitha, M.; Sravanthi, K. A review on different techniques to produce gradient structured material. Mater. Today Proc. 2022, 60, 2262–2265. [Google Scholar] [CrossRef]

- Li, X.Y.; Lu, L.; Li, J.G.; Zhang, X.; Gao, H.J. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706–723. [Google Scholar] [CrossRef]

- Long, Q.Y.; Lu, J.X.; Fang, T.H. Microstructure and mechanical properties of AISI 316L steel with an inverse gradient nanostructure fabricated by electro-magnetic induction heating. Mater. Sci. Eng. A 2019, 751, 42–50. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, H.F.; Lu, Q.H.; Gao, H.J.; Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 2018, 362, eaau1925. [Google Scholar] [CrossRef]

- Zhang, B.H.; Chen, J.; Wang, P.F.; Sun, B.T.; Cao, Y. Enhanced strength-ductility of CoCrFeMnNi high-entropy alloy with inverse gradient-grained structure prepared by laser surface heat-treatment technique. J. Mater. Sci. Technol. 2022, 111, 111–119. [Google Scholar] [CrossRef]

- Hasan, M.N.; Liu, Y.F.; An, X.H.; Gu, J.; Song, M.; Cao, Y.; Li, Y.S.; Zhu, Y.T.; Liao, X.Z. Simultaneously enhancing strength and ductility of a high-entropy alloy via gradient hierarchical microstructures. Int. J. Plast. 2019, 123, 178–195. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, M.S.; Fang, X.T.; Guo, F.J.; Liu, H.Q.; Scattergood, R.O.; Huang, C.X.; Zhu, Y.T. Extra strengthening in a coarse/ultrafine grained laminate: Role of gradient interfaces. Int. J. Plast. 2019, 123, 196–207. [Google Scholar] [CrossRef]

- Kim, J.G.; Bae, J.W.; Park, J.M.; Woo, W.; Harjo, S.; Lee, S.; Kim, H.S. Efect of the Diference in Strength of Hard and Soft Components on the Synergetic Strengthening of Layered Materials. Met. Mater. Int. 2021, 27, 376–383. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.J.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2020, 9, 1–31. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, Y.; Kim, E.S.; Zargaran, A.; Sathiyamoorthi, P.; Park, J.M.; Jeong, S.G.; Gu, G.H.; Amanov, A.; Ungar, T.; et al. Gradient heterostructured laser-powder bed fusion processed CoCrFeMnNi high entropy alloy. Addit. Manuf. 2022, 59, 103131. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.X.; Zou, Q.; Huang, G.S.; Liu, S.S.; Zhang, J.L.; Tang, A.T.; Jiang, B.; Pan, F.S. Design of pure aluminum laminates with heterostructures for extraordinary strength-ductility synergy. J. Mater. Sci. Technol. 2022, 100, 193–205. [Google Scholar] [CrossRef]

- Shi, P.J.; Ren, W.L.; Zheng, T.X.; Ren, Z.M.; Hou, X.L.; Peng, J.C.; Hu, P.F.; Gao, Y.F.; Zhong, Y.B.; Liaw, P.K. Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat. Commun. 2019, 10, 489. [Google Scholar] [CrossRef] [PubMed]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Wang, P.F.; Chen, J.; Sun, B.T.; Zhu, D.H.; Cao, Y. Effects of annealing process parameters on microstructural evolution and strength-ductility combination of CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2022, 840, 142880. [Google Scholar] [CrossRef]

- Kamaya, M.; Maekawa, N. A procedure to obtain correlation curve between local misorientation and plastic strain. Mater. Charact. 2023, 198, 112725. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Choe, J.; Lee, K.-A. Selective laser melted equiatomic CoCrFeMnNi high-entropy alloy: Microstructure, anisotropic mechanical response, and multiple strengthening mechanism. J. Alloys Compd. 2019, 805, 680–691. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Kim, H.S. High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties. Prog. Mater. Sci. 2022, 123, 100709. [Google Scholar] [CrossRef]

- Lee, H.H.; Park, H.K.; Jung, J.; Amanov, A.; Kim, H.S. Multi-layered gradient structure manufactured by single-roll angular-rolling and ultrasonic nanocrystalline surface modification. Scr. Mater. 2020, 186, 52–56. [Google Scholar] [CrossRef]

- Ghosh, S.; Bibhanshu, N.; Suwas, S.; Chatterjee, K. Surface mechanical attrition treatment of additively manufactured 316L stainless steel yields gradient nanostructure with superior strength and ductility. Mater. Sci. Eng. A 2021, 820, 141540. [Google Scholar] [CrossRef]

- Mortazavi, S.A.; Raeissi, M.; Sharifi, H.; Saeidi, N.; Pirgazi, H. Microstructure and mechanical properties of bimetallic copper/brass laminates fabricated via accumulative press bonding. Mater. Sci. Eng. A 2021, 803, 140710. [Google Scholar] [CrossRef]

- Kim, R.E.; Karthik, G.M.; Amanov, A.; Heo, Y.-K.; Jeong, S.G.; Gu, G.H.; Park, H.; Kim, E.S.; Lee, D.W.; Kim, H.S. Superior gradient heterostructured alloys fabricated by laser powder bed fusion via annealing and ultrasonic nanocrystal surface modification. Scr. Mater. 2023, 230, 115422. [Google Scholar] [CrossRef]

- Kim, R.E.; Kim, E.S.; Karthik, G.M.; Gu, G.H.; Ahn, S.Y.; Park, H.; Moon, J.; Kim, H.S. Heterostructured alloys with enhanced strength-ductility synergy through laser-cladding. Scr. Mater. 2022, 215, 114732. [Google Scholar] [CrossRef]

- Moon, J.; Parka, J.M.; Bae, J.W.; Kang, N.; Oh, J.; Shin, H.; Kima, H.S. Hetero-deformation-induced strengthening by twin-mediated martensitic transformation in an immiscible medium-entropy alloy. Scr. Mater. 2020, 186, 24–28. [Google Scholar] [CrossRef]

- Talebi, F.; Jamaati, R.; Hosseinipour, S.J. A low-cost strategy to enhance strength-ductility balance in AISI1045 steel. J. Mater. Res. Technol. 2023, 27, 2751–2764. [Google Scholar] [CrossRef]

- Moering, J.; Ma, X.L.; Malkin, J.; Yang, M.X.; Zhu, Y.T.; Mathaudhu, S. Synergetic strengthening far beyond rule of mixtures in gradient structured aluminum rod. Scr. Mater. 2016, 122, 106–109. [Google Scholar] [CrossRef]

- Taali, S.; Toroghinejad, M.R.; Kuglstatter, M.; Hoppel, H.W. Grain boundary engineering in roll-bonded copper to overcome the strength-ductility dilemma. J. Mater. Res. Technol. 2022, 17, 3198–3204. [Google Scholar] [CrossRef]

- Sun, L.G.; Li, D.F.; Zhu, L.L.; Ruan, H.H.; Lu, J. Size-dependent formation and thermal stability of high-order twins in hierarchical nanotwinned metals. Int. J. Plast. 2020, 128, 102685. [Google Scholar] [CrossRef]

- Rahman, K.M.; Vorontsov, V.A.; Dye, D. The effect of grain size on the twin initiation stress in a TWIP steel. Acta Mater. 2015, 89, 247–257. [Google Scholar] [CrossRef]

- Szczerba, M.S.; Szczerba, M.J. The effect of temperature on detwinning and mechanical properties of face-centered cubic deformation twins. Acta Mater. 2024, 263, 119491. [Google Scholar] [CrossRef]

- Rizi, M.S.; Minouei, H.; Lee, B.J.; Pouraliakbar, H.; Toroghinejad, M.R.; Hong, S.I. Hierarchically activated deformation mechanisms to form ultra-fine grain microstructure in carbon containing FeMnCoCr twinning induced plasticity high entropy alloy. Mater. Sci. Eng. A 2021, 824, 141803. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Hu, Y.; Wang, P.; Li, J.; Zheng, Y.; Lu, C.; Zhang, B.; Shen, J.; Cao, Y. Strength–Ductility Mechanism of CoCrFeMnNi High-Entropy Alloys with Inverse Gradient-Grained Structures. Materials 2024, 17, 1695. https://doi.org/10.3390/ma17071695

Chen J, Hu Y, Wang P, Li J, Zheng Y, Lu C, Zhang B, Shen J, Cao Y. Strength–Ductility Mechanism of CoCrFeMnNi High-Entropy Alloys with Inverse Gradient-Grained Structures. Materials. 2024; 17(7):1695. https://doi.org/10.3390/ma17071695

Chicago/Turabian StyleChen, Jie, Yongqiang Hu, Pengfei Wang, Jingge Li, Yu Zheng, Chengtong Lu, Bohong Zhang, Jiahai Shen, and Yu Cao. 2024. "Strength–Ductility Mechanism of CoCrFeMnNi High-Entropy Alloys with Inverse Gradient-Grained Structures" Materials 17, no. 7: 1695. https://doi.org/10.3390/ma17071695

APA StyleChen, J., Hu, Y., Wang, P., Li, J., Zheng, Y., Lu, C., Zhang, B., Shen, J., & Cao, Y. (2024). Strength–Ductility Mechanism of CoCrFeMnNi High-Entropy Alloys with Inverse Gradient-Grained Structures. Materials, 17(7), 1695. https://doi.org/10.3390/ma17071695