Buried Depressed-Cladding Waveguides Inscribed in Nd3+ and Yb3+ Doped CLNGG Laser Crystals by Picosecond-Laser Beam Writing

Abstract

:1. Introduction

2. Materials and Methods

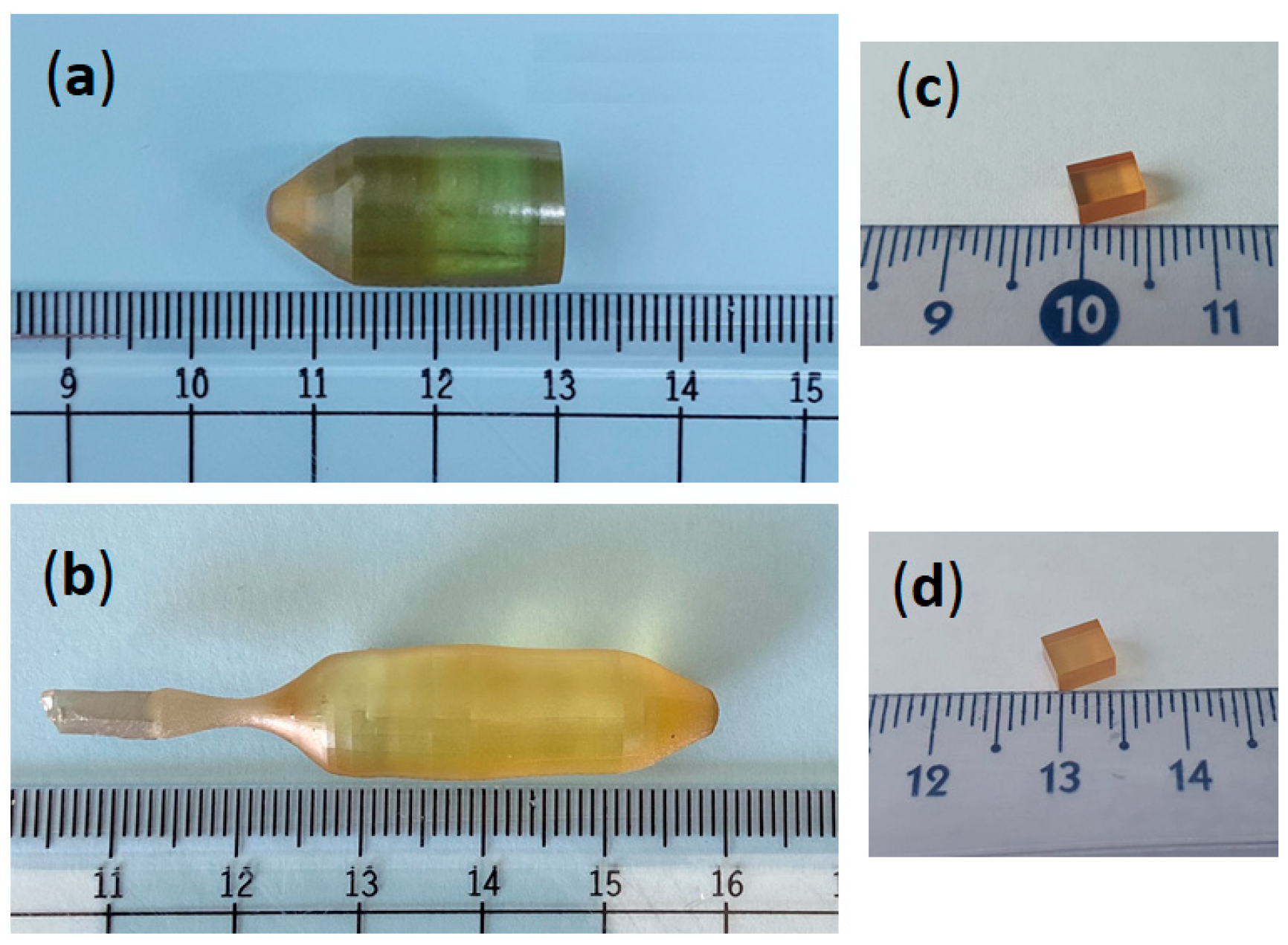

2.1. Crystal Growth

Ca3Li0.275Nb1.775Ga2.95O12·0.0128Nd3 Li0.275Nb0.275Ga4.45O12 + 3.13926CO2 ↑

Ca3Li0.275Nb1.775Ga2.95O12·0.08Yb3 Li0.275Nb0.275Ga4.45O12 + 3.1485CO2 ↑

2.2. Experimental Setup for Laser Emission

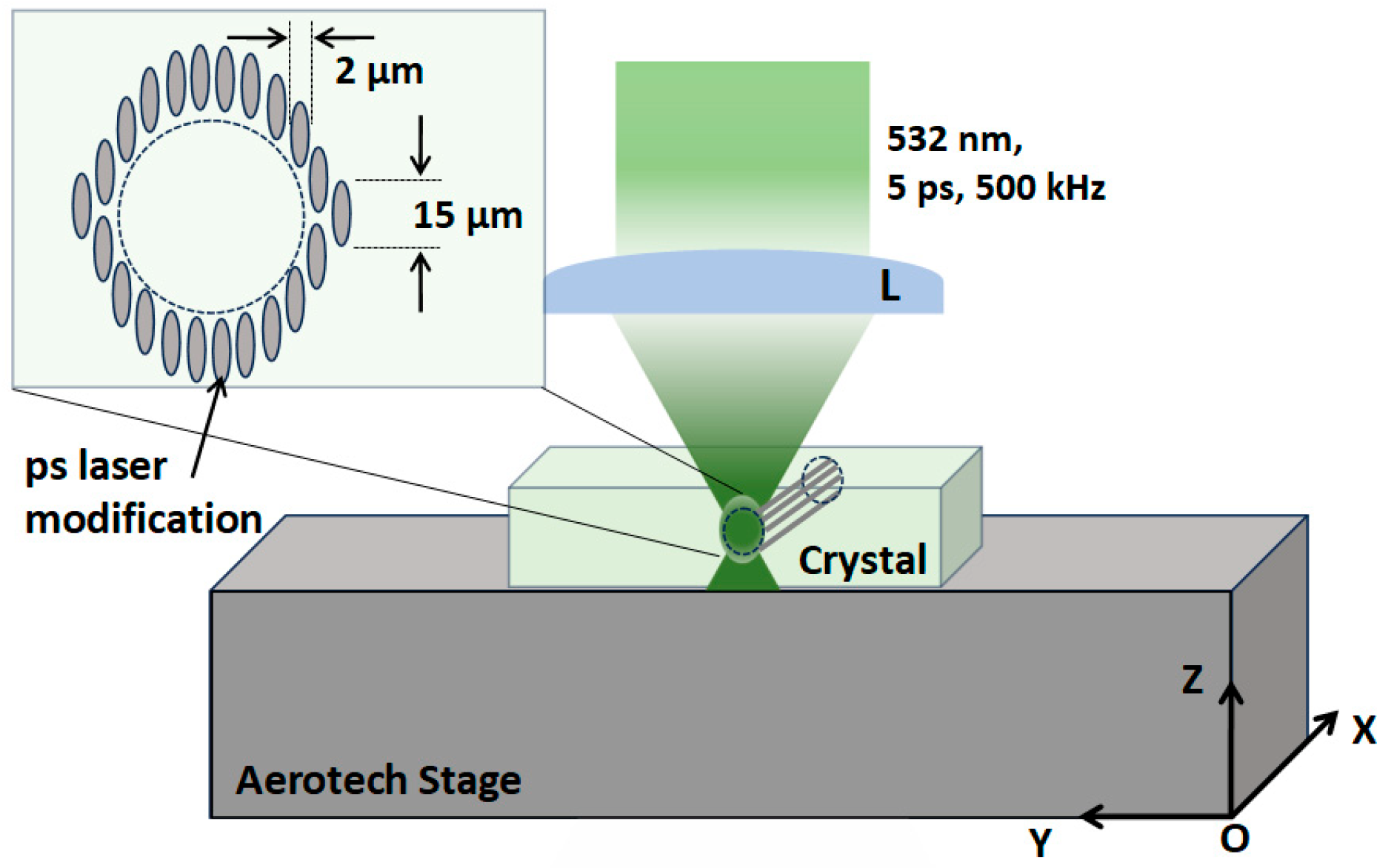

2.3. Waveguides Writing with Ps-Laser Pulses

3. Results

3.1. Characterization of Bulk Crystals

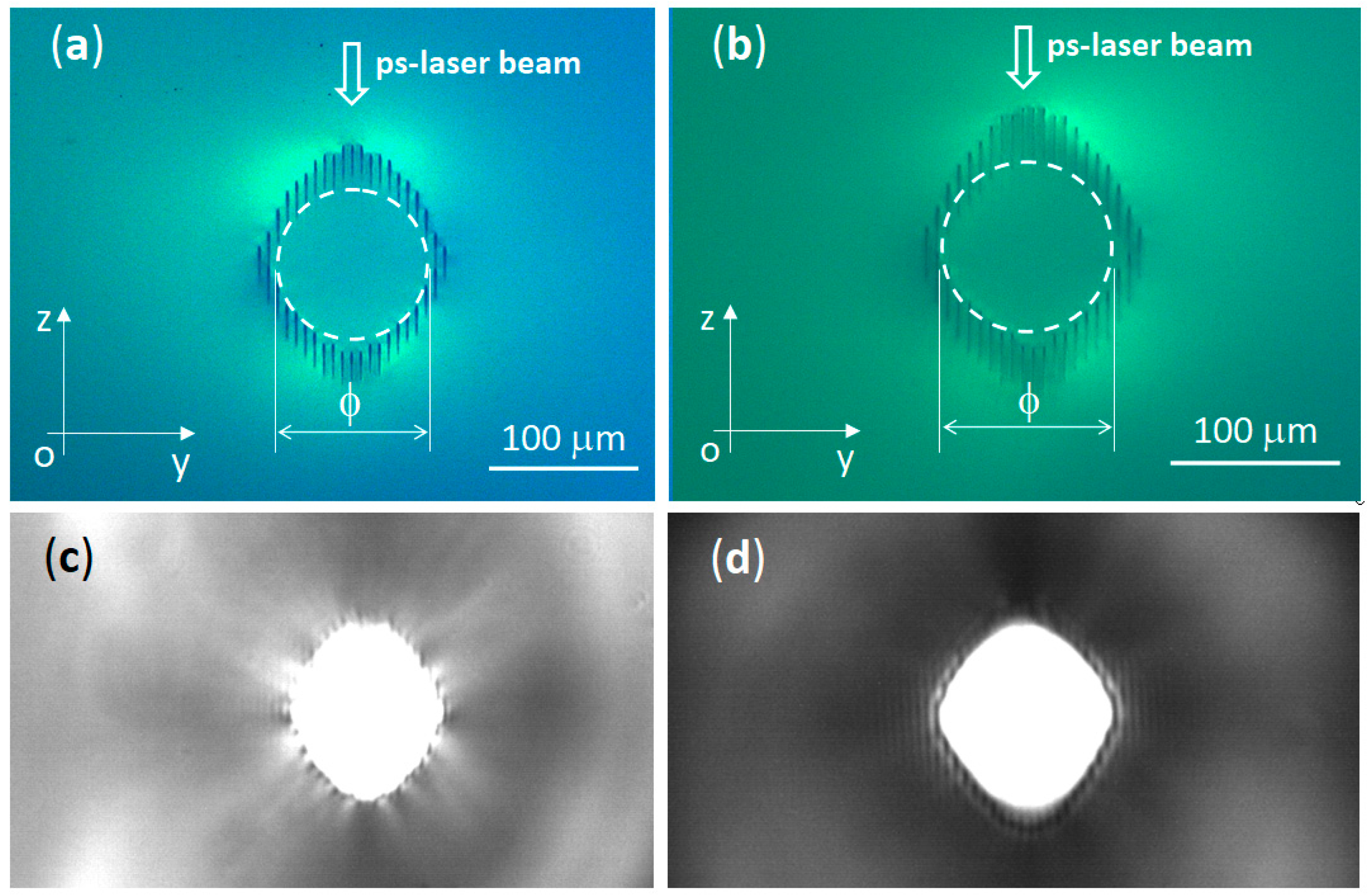

3.2. Waveguide Fabrication by Ps-Laser Irradiation

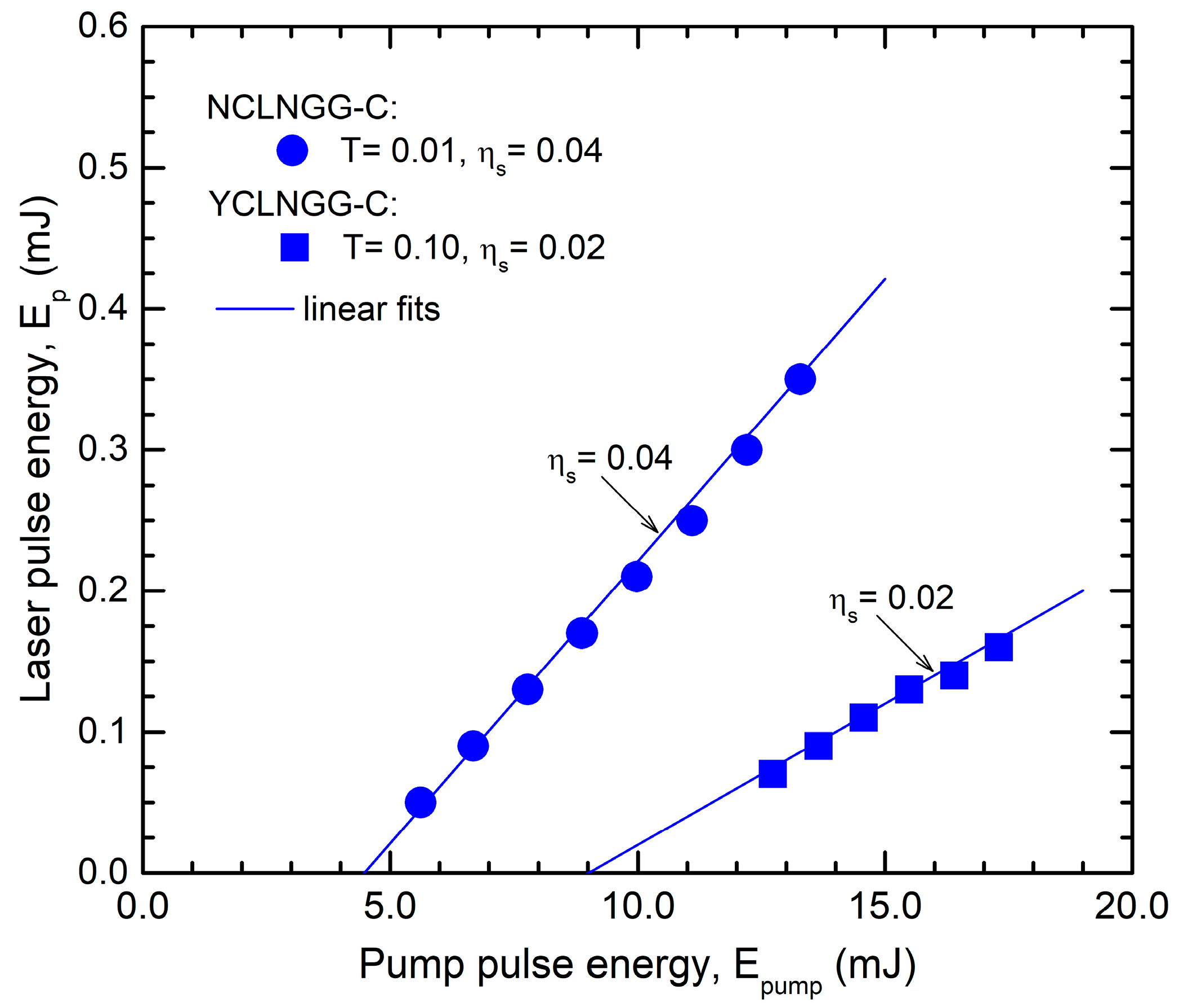

3.3. Laser Emission from Circular Waveguides

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corbari, C.; Champion, A.; Gecevičius, M.; Beresna, M.; Bellouard., Y.; Kazansky, P.G. Femtosecond versus picosecond laser machining of nano-gratings and micro-channels in silica glass. Opt. Express 2013, 21, 3946–3958. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Eaton, S.M.; Herman, P.R. Low-loss Type II waveguide writing in fused silica with single picosecond laser pulses. Opt. Express 2006, 14, 4826–4834. [Google Scholar] [CrossRef] [PubMed]

- McMillen, B.; Zhang, B.; Chen, K.P.; Benayas, A.; Jaque, D. Ultrafast laser fabrication of low-loss waveguides in chalcogenide glass with 0.65 dB/cm loss. Opt. Lett. 2012, 37, 1418–1420. [Google Scholar] [CrossRef] [PubMed]

- Grivas, C.; Corbari, C.; Brambilla, G.; Lagoudakis, P.G. Tunable, continuous-wave Ti:sapphire channel waveguide lasers written by femtosecond and picosecond laser pulses. Opt. Lett. 2012, 37, 4630–4632. [Google Scholar] [CrossRef]

- Matthäus, G.; Kämmer, H.; Lammers, K.A.; Vetter, C.; Watanabe, W.; Nolte, S. Inscription of silicon waveguides using picosecond pulses. Opt. Express 2018, 26, 24089–24097. [Google Scholar] [CrossRef] [PubMed]

- Voron’ko, Y.K.; Gessen, S.B.; Es’kov, N.A.; Sobol’, A.A.; Ushakov, S.N.; Tsymbal, L.I. Efficient active media based on Nd3+-activated calcium niobium gallium garnets. Sov. J. Quantum Electron. 1990, 20, 246–249. [Google Scholar] [CrossRef]

- Shi, Z.B.; Zhang, H.J.; Wang, J.Y.; Yu, Y.G.; Wang, Z.P.; Yu, H.H.; Sun, S.Q.; Xia, H.R.; Jiang, M.H. Growth and characterization of Nd:CLNGG crystal. J. Cryst. Growth 2009, 311, 3792–3796. [Google Scholar] [CrossRef]

- Yuxian, S.; Li, Q.; Zhang, D.; Feng, B.; Zhang, Z.; Zhang, H.; Wang, J. Comparison of 885 nm pumping and 808 nm pumping in Nd:CNGG laser operating at 1061 nm and 935 nm. Opt. Commun. 2010, 283, 2888–2891. [Google Scholar] [CrossRef]

- Lupei, V.; Lupei, A.; Gheorghe, C.; Gheorghe, L.; Achim, A.; Ikesue, A. Crystal field disorder effects in the optical spectra of Nd3+ and Yb3+-doped CLNGG laser crystals and ceramics. J. Appl. Phys. 2012, 112, 063110. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, H.; Wang, Z.; Wang, J.; Yu, Y.; Shi, Z.; Zhang, X.; Jiang, M. Continuous-wave and passively Q-switched laser performance with a disordered Nd:CLNGG crystal. Opt. Express 2009, 17, 19015–19020. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.L.; Loiko, P.; Zeng, H.J.; Xue, W.Z.; Zhang, G.; Normani, S.; Camy, P.; Petrov, V.; Mateos, X.; Lin, H.; et al. Kerr-lens mode-locking of an Yb:CLNGG laser. Opt. Express 2023, 31, 8575–8585. [Google Scholar] [CrossRef] [PubMed]

- Adair, R.; Chase, L.L.; Payne, A. Nonlinear refractive index of optical crystals. Phys. Rev. B 1989, 39, 3337–3350. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Kong, W.; Chen, F. Femtosecond laser-inscribed optical waveguides in dielectric crystals: A concise review and recent advances. Adv. Photon. 2022, 4, 024002. [Google Scholar] [CrossRef]

- Shen, Y.; Jia, Y.; Chen, F. Femtosecond laser-induced optical waveguides in crystalline garnets: Fabrication and application. Opt. Laser Technol. 2023, 164, 109528. [Google Scholar] [CrossRef]

- Baiocco, D.; Lopez-Quintas, I.; Vazquez de Aldana, J.R.; Tonelli, M.; Tredicucci, A. Diode-pumped visible lasing in femtosecond-laser-written Pr:LiLuF4 waveguide. Opt. Lett. 2023, 48, 1734–1737. [Google Scholar] [CrossRef] [PubMed]

- McDaniel, S.A.; Berrya, P.A.; Cooka, G.; Zelmona, D.; Meissnerc, S.; Meissnerc, H.; Muc, X. CW and passively Q-Switched operation of a Ho:YAG waveguide laser. Opt. Laser Technol. 2017, 91, 1–6. [Google Scholar] [CrossRef]

- Alvarez-Perez, J.O.; Cano-Torres, J.M.; Ruiz, A.; Serrano, M.D.; Cascales, C.; Zaldo, C. A roadmap for laser optimization of Yb:Ca3(NbGa)5O12-CNGG-type single crystal garnets. J. Mater. Chem. C 2021, 9, 4628. [Google Scholar] [CrossRef]

- Salamu, G.; Jipa, F.; Zamfirescu, M.; Pavel, N. Laser emission from diode-pumped Nd:YAG ceramic waveguide lasers realized by direct femtosecond-laser writing technique. Opt. Express 2014, 22, 5177–5182. [Google Scholar] [CrossRef] [PubMed]

- Salamu, G.; Jipa, F.; Zamfirescu, M.; Pavel, N. Cladding waveguides realized in Nd:YAG ceramic by direct femtosecond-laser writing with a helical movement technique. Opt. Mater. Express 2014, 4, 790–797. [Google Scholar] [CrossRef]

- Croitoru, G.; Anghel, I.; Voicu, F.M.; Greculeasa, M.; Broasca, A.; Gheorghe, L.M.; Pavel, N. Buried Depressed-Cladding Waveguides Fabricated in RE3+:CLNGG Laser Crystals using Direct Laser Writing Technique. In Proceedings of the Lasers and Electro-Optics/Europe-European Quantum Electronics Conferences (CLEO®/Europe-EQEC 2023), Munich, Germany, 26–30 June 2023. [Google Scholar] [CrossRef]

- Burghoff, J.; Nolte, S.; Tunnermann, A. Origins of waveguiding in femtosecond laser-structured LiNbO3. Appl. Phys. A 2007, 89, 127–132. [Google Scholar] [CrossRef]

- Campbell, S.; Thomson, R.R.; Hand, D.P.; Kar, A.K.; Reid, D.T.; Canalias, C.; Pasiskevicius, V.; Laurell, F. Frequency-doubling in femtosecond laser inscribed periodically-poled potassium titanyl phosphate waveguides. Opt. Express 2007, 15, 17146–17150. [Google Scholar] [CrossRef] [PubMed]

- Rodenas, A.; Kar, A.K. High-contrast step-index waveguides in borate nonlinear laser crystals by 3D laser writing. Opt. Express 2011, 19, 17820–17833. [Google Scholar] [CrossRef] [PubMed]

- He, R.; Hernández-Palmero, I.; Romero, C.; Vázquez de Aldana, J.R.; Chen, F. Three-dimensional dielectric crystalline waveguide beam splitters in mid-infrared band by direct femtosecond laser writing. Opt. Express 2014, 22, 31293–31298. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Zhang, B.; Liu, W.; Lu, Q.; Wang, L.; Chen, F. Recoverable and rewritable waveguide beam splitters fabricated by tailored femtosecond laser writing of lithium tantalate crystal. Opt. Laser Technol. 2022, 145, 107500. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Wang, L.; Chen, F. Femtosecond laser direct writing of Nd:YAG waveguide with Type I modification: Positive refractive index change in track. Opt. Mat. 2021, 113, 110844. [Google Scholar] [CrossRef]

- Okhrimchuk, A.G.; Shestakov, A.V.; Khrushchev, I.; Mitchell, J. Depressed cladding, buried waveguide laser formed in a YAG:Nd3+ crystal by femtosecond laser writing. Opt. Lett. 2005, 30, 2248–2250. [Google Scholar] [CrossRef]

- Siebenmorgen, J.; Calmano, T.; Petermann, K.; Huber, G. Highly efficient Yb:YAG channel waveguide laser written with a femtosecond-laser. Opt. Express 2010, 18, 16035–16041. [Google Scholar] [CrossRef] [PubMed]

- Nie, W.; He, R.; Cheng, C.; Rocha, U.; Vázquez de Aldana, J.R.; Jaque, D.; Chen, F. Optical lattice-like cladding waveguides by direct laser writing: Fabrication, luminescence, and lasing. Opt. Lett. 2016, 41, 2169–2172. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, F.; Vázquez de Aldana, J.R.; Yu, H.; Zhang, H. Tri-wavelength laser generation based on neodymium doped disordered crystal waveguide. Opt. Express 2013, 21, 22263. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Chen, F.; Vázquez de Aldana, J.R.; Yu, H.; Zhang, H. Quasi-three-level laser emissions of neodymium doped disordered crystal waveguides. IEEE J. Sel. Top. Quant. 2014, 21, 1601905. [Google Scholar] [CrossRef]

- Okhrimchuk, A.; Mezentsev, V.; Shestakov, A.; Bennion, I. Low loss depressed cladding waveguide inscribed in YAG:Nd single crystal by femtosecond laser pulses. Opt. Express 2012, 20, 3832–3843. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Jia, Y.; Vázquez de Aldana, J.R.; Jaque, D.; Chen, F. Femtosecond laser inscribed cladding waveguides in Nd:YAG ceramics: Fabrication, fluorescence imaging and laser performance. Opt. Express 2012, 20, 18620–18629. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Jia, Y.; Chen, F.; Vázquez de Aldana, J.R. Continuous wave laser operation in Nd:GGG depressed tubular cladding waveguides produced by inscription of femtosecond laser pulses. Opt. Express 2013, 3, 278–283. [Google Scholar] [CrossRef]

- Liu, H.; Tan, Y.; Vázquez de Aldana, J.R.; Chen, F. Efficient laser emission from cladding waveguide inscribed in Nd:GdVO4 crystal by direct femtosecond laser writing. Opt. Lett. 2014, 39, 4553–4556. [Google Scholar] [CrossRef] [PubMed]

- Pavel, N.; Salamu, G.; Jipa, F.; Zamfirescu, M. Diode-laser pumping into the emitting level for efficient lasing of depressed cladding waveguides realized in Nd:YVO4 by the direct femtosecond-laser writing technique. Opt. Express 2014, 22, 23057–23065. [Google Scholar] [CrossRef]

- Croitoru, G.; Jipa, F.; Pavel, N. Laser emission from buried depressed-cladding waveguides inscribed in Nd:YAG ceramics by picosecond-laser beam writing. Opt. Mater. 2024, 148, 114772. [Google Scholar] [CrossRef]

- Sun, X.; Sun, S.; Romero, C.; Vázquez de Aldana, J.R.; Liu, F.; Jia, Y.; Chen, F. Femtosecond laser direct writing of depressed cladding waveguides in Nd:YAG with “ear-like” structures: Fabrication and laser generation. Opt. Express 2021, 29, 4296–4307. [Google Scholar] [CrossRef] [PubMed]

- Baillard, A.; Loiko, P.; Romero, C.; Arroyo, V.; Vázquez de Aldana, J.R.; Fromager, M.; Benayad, A.; Braud, A.; Camy, P.; Mateos, X. Orange surface waveguide laser in Pr:LiYF4 produced by a femtosecond laser writing. Opt. Lett. 2023, 48, 6212–6215. [Google Scholar] [CrossRef] [PubMed]

- Gattass, R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photon. 2007, 2, 219–225. [Google Scholar] [CrossRef]

- Eaton, S.M.; Cerullo, G.; Osellame, R. Fundamentals of Femtosecond Laser Modification of Bulk Dielectrics. In Femtosecond Laser Micromachining; Osellame, R., Cerullo, G., Ramponi, R., Eds.; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 2012; Volume 123, pp. 3–18. [Google Scholar] [CrossRef]

- Benayas, A.; Silva, W.F.; Ródenas, A.; Jacinto, C.; Vázquez de Aldana, J.R.; Chen, F.; Tan, T.; Thomsom, R.R.; Psaila, N.D.; Reid, D.T.; et al. Ultrafast laser writing of optical waveguides in ceramic Yb:YAG: A study of thermal and non-thermal regimes. Appl. Phys. A. 2011, 104, 301–309. [Google Scholar] [CrossRef]

| Laser Crystal | Absorbed Pump Pulse Energy, Eabs (mJ) | Absorption Efficiency, ηa | Laser Pulse Energy, Ep (mJ) | Optical Efficiency, ηoa | Slope Efficiency, ηsa |

|---|---|---|---|---|---|

| 0.7-at.% Nd:CLNGG | 6.90 | 0.52 | 2.0 | 0.29 | 0.32 |

| 7.28-at.% Yb:CLNGG | 11.20 | 0.88 | 2.20 | 0.27 | 0.27 |

| Laser Crystal | Waveguide Diameter, ϕ (μm) | Propagation Loss (dB/cm) | Characteristics of the Writing Beam | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|

| Bulk | Waveguide | λ (nm) | tp | Ep (μJ) | f (kHz) | Writing Speed | |||

| Nd:YAG crystal | elliptical 116 μm × 110 μm | - | 0.12 | 800 | 110 fs | 1.2–1.5 | 1.0 | 0.5–0.7 mm/s | [32] * |

| Nd:YAG ceramic | ~100 | - | 0.8 | 800 | 120 fs | 0.2–0.4 | 1.0 | 700 μm/s | [33] |

| Nd:GGG crystal | 90 120 150 | - | 2.5 2.0 1.7 | 795 | 120 fs | 2.1 | 1.0 | 500 μm/s | [34] |

| Nd:GdVO4 | 150 | 0.7 | 795 | 120 fs | 1.68 | 1.0 | 500 μm/s | [35] | |

| Nd:YVO4 | 100 | - | 1.5–2.4 | 775 | 200 fs | 0.3 | 1.0 | 50 μm/s | [36] |

| Nd:YAG ceramic | 50 100 | 0.2 | 1.0–1.2 1.5–1.8 | 775 | 200 fs | 1 | 2.0 | 50 μm/s | [18] |

| Nd:YAG ceramic | 100 | 0.3 | 0.9 | 532 | 5 ps | 0.2 | 500 | 1 mm/s | [37] |

| Nd:CLNGG Yb:CLNGG | 100 | 0.4 0.8 | 0.9 2.5 | 532 | 5 ps | 0.15 | 500 | 1 mm/s | this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Croitoru, G.; Jipa, F.; Greculeasa, M.; Broasca, A.; Voicu, F.; Gheorghe, L.; Pavel, N. Buried Depressed-Cladding Waveguides Inscribed in Nd3+ and Yb3+ Doped CLNGG Laser Crystals by Picosecond-Laser Beam Writing. Materials 2024, 17, 1758. https://doi.org/10.3390/ma17081758

Croitoru G, Jipa F, Greculeasa M, Broasca A, Voicu F, Gheorghe L, Pavel N. Buried Depressed-Cladding Waveguides Inscribed in Nd3+ and Yb3+ Doped CLNGG Laser Crystals by Picosecond-Laser Beam Writing. Materials. 2024; 17(8):1758. https://doi.org/10.3390/ma17081758

Chicago/Turabian StyleCroitoru, Gabriela, Florin Jipa, Madalin Greculeasa, Alin Broasca, Flavius Voicu, Lucian Gheorghe, and Nicolaie Pavel. 2024. "Buried Depressed-Cladding Waveguides Inscribed in Nd3+ and Yb3+ Doped CLNGG Laser Crystals by Picosecond-Laser Beam Writing" Materials 17, no. 8: 1758. https://doi.org/10.3390/ma17081758