Fuel Characteristics and Phytotoxicity Assay of Biochar Derived from Rose Pruning Waste

Abstract

:1. Introduction

2. Materials and Methods

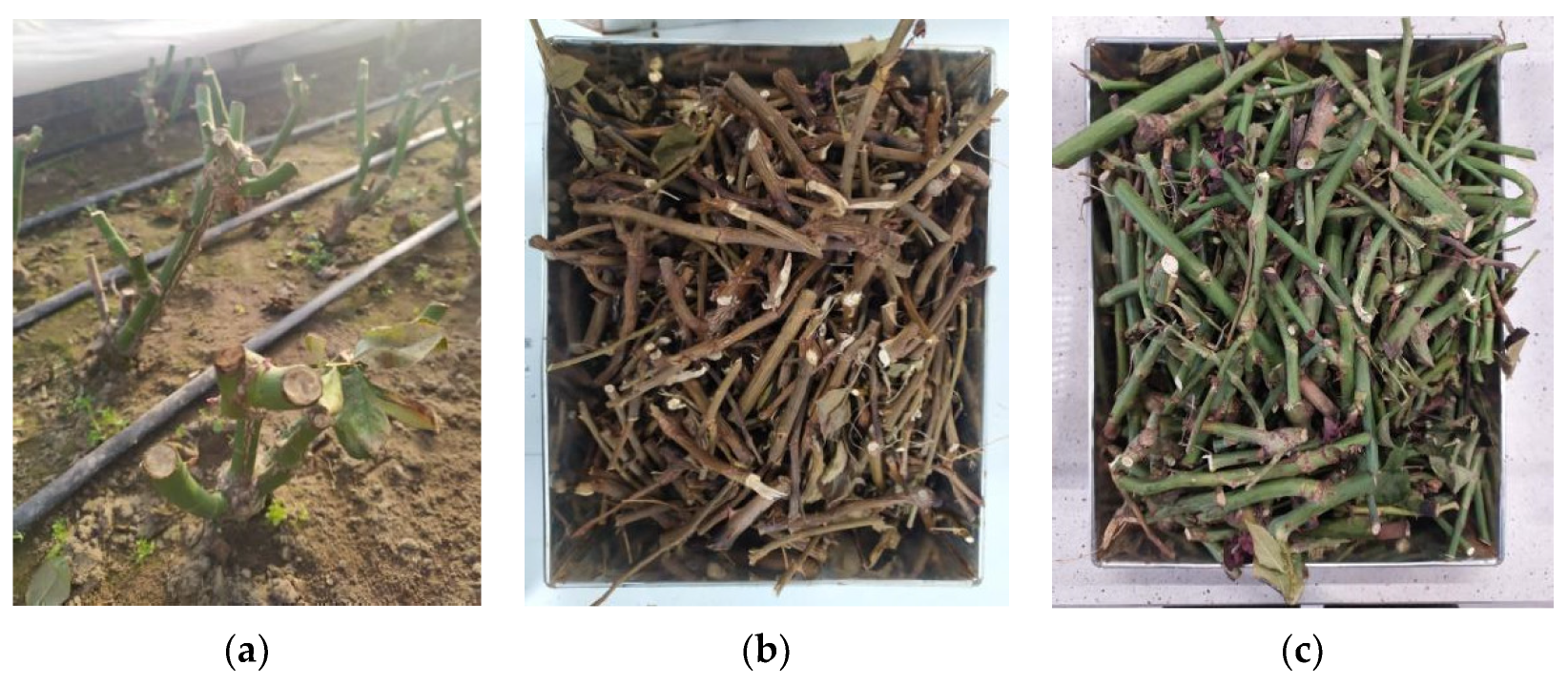

2.1. Rose Pruning Waste

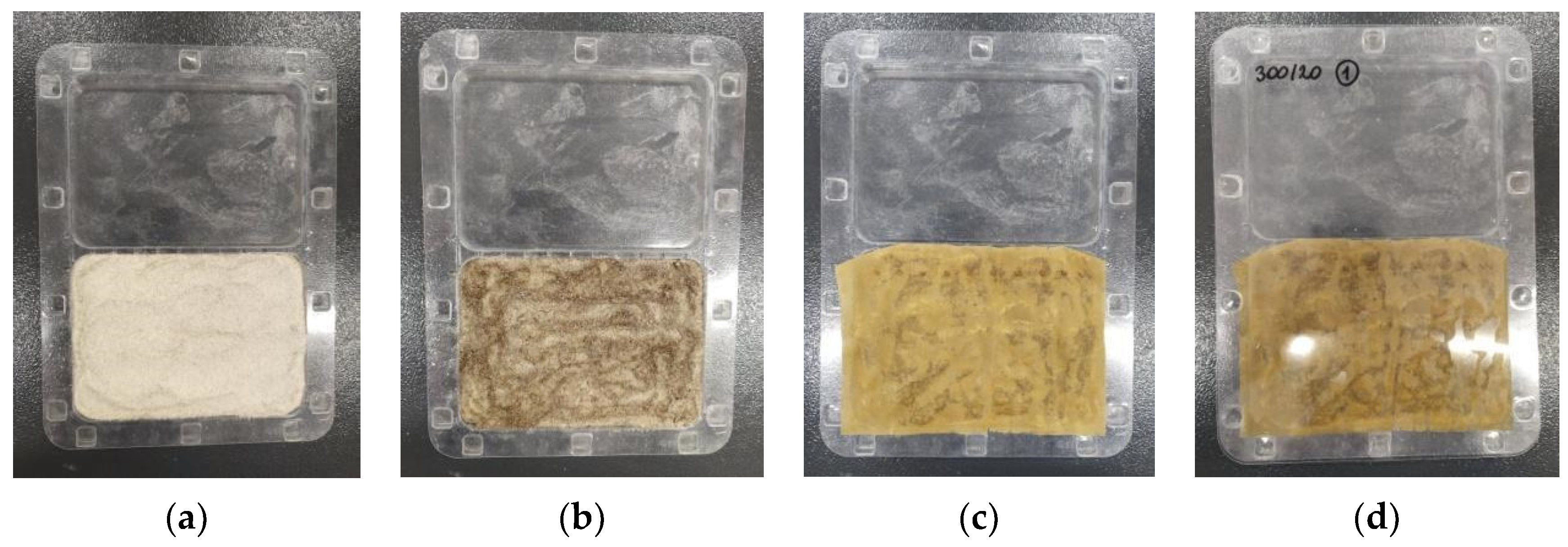

2.2. Pyrolysis of Rose Pruning Waste

2.3. Fuel Property Determination

2.4. Pollutant Elution and Heavy Metal Content

2.5. Phytotoxicity Tests

3. Results and Discussion

3.1. Pyrolysis of Rose Residues and Biochar Production

3.2. Biochar’s Fuel Properties

3.3. Pollutant Elution

3.4. Heavy Metal Content

3.5. Phytotoxicity Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Loyola, C.E.; Dole, J.M.; Dunning, R. North American Specialty Cut Flower Production and Postharvest Survey. Horttechnology 2019, 29, 338–359. [Google Scholar] [CrossRef]

- Kendİrlİ, B.; Çakmak, B. Economics of Cut Flower Production in Greenhouses: Case Study from Turkey. Agric. J. 2007, 2, 499–502. [Google Scholar]

- Usman, M.; Ashfaq, M.; Taj, S. An Economic Analysis of Cut-Rose Flower in Punjab, Pakistan. Artic. J. Anim. Plant Sci. 2014, 24, 651–655. [Google Scholar]

- Jabłońska, L.; Gunerka, L.; Filipiak, T. Efektywność Ekonomiczna Gospodarstw Ogrodniczych Wybranych Krajach Unii Europejskiej. Ann. Pol. Assoc. Agric. Agribus. Econ. 2017, XIX, 77–82. [Google Scholar] [CrossRef]

- Jabłońska, L.; Olewnicki, D. Zmiany w Powierzchni Upraw Ogrodniczych Pod Osłonami w Polsce w Pierwszej Dekadzie XXI w. Zeszyty Naukowe SGGW w Warszawie. Problemy Rolnictwa Światowego 2011, 11, 89–97. [Google Scholar] [CrossRef]

- Sharma, G.; Chaudhary, S.V.S.; Gupta, Y.C.; Dhiman, S.R.; Dogra, R.K.; Gupta, R.K. Effect of Microwave Oven Drying on Production of Quality Dry Flowers of Roses. Int. J. Curr. Microbiol. Appl. Sci 2019, 8, 300–308. [Google Scholar] [CrossRef]

- Szmagara, M. The Influence of the Forming Methods on Yielding and Quality of Roses in an Unheated Foil Tunnel. Ann. Hortic. 2020, 30, 5–16. [Google Scholar] [CrossRef]

- Muhammad Bilal, H.; Tahir, R.; Adnan, M.; Mukarram Ali, S.; Islam, H.; Shakeeb Umer, M.; Ali Mir, F.; Iklaq Ahmed, R.; Iftikhar, M. Does Foliar Application of Macro and Micronutrients Have Any Impact on Roses Production? A Review. Ann. Rev. Res. 2020, 6, 555677. [Google Scholar] [CrossRef]

- dos Reis, M.V.; Figueiredo, J.R.M.; Paiva, R.; da Silva, D.P.C.; de Faria, C.V.N.; Rouhana, L.V. Salinity in Rose Production. Ornam. Hortic. 2016, 22, 228–234. [Google Scholar] [CrossRef]

- Arin, A.; Aydin, H.R.; Erbas, S.; Coskan, A. The Effect of Biochar Obtained From Pruning Residue of Oil-Bearing Rose on Flower Yield and Essential Oil Content of Oil-Bearing Rose. Araştırma Makal. 2018, 444–449. [Google Scholar]

- Idrovo-Novillo, J.; Gavilanes-Terán, I.; Veloz-Mayorga, N.; Erazo-Arrieta, R.; Paredes, C. Closing the Cycle for the Cut Rose Industry by the Reuse of Its Organic Wastes: A Case Study in Ecuador. J. Clean Prod. 2019, 220, 910–918. [Google Scholar] [CrossRef]

- Onursal, E.; Ekinci, K. Co-Composting of Rose Oil Processing Waste with Caged Layer Manure and Straw or Sawdust: Effects of Carbon Source and C/N Ratio on Decomposition. Waste Manag. Res. 2015, 33, 332–338. [Google Scholar] [CrossRef]

- Sahle, A.; Potting, J. Environmental Life Cycle Assessment of Ethiopian Rose Cultivation. Sci. Total Environ. 2013, 443, 163–172. [Google Scholar] [CrossRef]

- Wang, B.; Gao, B.; Fang, J. Recent Advances in Engineered Biochar Productions and Applications. Crit. Rev. Environ. Sci. Technol. 2017, 47, 2158–2207. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Hussain, Q.; Usman, A.R.A.; Ahmad, M.; Abduljabbar, A.; Sallam, A.S.; Ok, Y.S. Impact of Biochar Properties on Soil Conditions and Agricultural Sustainability: A Review. Land Degrad. Dev. 2018, 29, 2124–2161. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar Impacts on Soil Physical Properties and Greenhouse Gas Emissions. Agronomy 2013, 3, 313–339. [Google Scholar] [CrossRef]

- Clough, T.J.; Condron, L.M.; Kammann, C.; Müller, C. A Review of Biochar and Soil Nitrogen Dynamics. Agronomy 2013, 3, 275–293. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, B.; Zhu, L.; Xing, B. Effects and Mechanisms of Biochar-Microbe Interactions in Soil Improvement and Pollution Remediation: A Review. Environ. Pollut. 2017, 227, 98–115. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Plasencia, P.; Gascó, G.; Méndez, A. Biochar from Pyrolysis of Deinking Paper Sludge and Its Use in the Remediation of Zn-Polluted Soils. Land Degrad. Dev. 2017, 28, 355–360. [Google Scholar] [CrossRef]

- Jeffery, S.; Verheijen, F.G.A.; van der Velde, M.; Bastos, A.C. A Quantitative Review of the Effects of Biochar Application to Soils on Crop Productivity Using Meta-Analysis. Agric. Ecosyst. Environ. 2011, 144, 175–187. [Google Scholar] [CrossRef]

- Ali, S.; Rizwan, M.; Qayyum, M.F.; Ok, Y.S.; Ibrahim, M.; Riaz, M.; Arif, M.S.; Hafeez, F.; Al-Wabel, M.I.; Shahzad, A.N. Biochar Soil Amendment on Alleviation of Drought and Salt Stress in Plants: A Critical Review. Environ. Sci. Pollut. Res. Int. 2017, 24, 12700–12712. [Google Scholar] [CrossRef]

- Fahad, S.; Hussain, S.; Saud, S.; Tanveer, M.; Bajwa, A.A.; Hassan, S.; Shah, A.N.; Ullah, A.; Wu, C.; Khan, F.A.; et al. A Biochar Application Protects Rice Pollen from High-Temperature Stress. Plant Physiol. Biochem. 2015, 96, 281–287. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. Pyrolysis of Biomass. In Biomass, Biofuels, Biochemicals: Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels; Academic Press: Cambridge, MA, USA, 2019; pp. 217–244. [Google Scholar] [CrossRef]

- Uslu, A.; Faaij, A.P.C.; Bergman, P.C.A. Pre-Treatment Technologies, and Their Effect on International Bioenergy Supply Chain Logistics. Techno-Economic Evaluation of Torrefaction, Fast Pyrolysis and Pelletisation. Energy 2008, 33, 1206–1223. [Google Scholar] [CrossRef]

- Santos, L.B.; Striebeck, M.V.; Crespi, M.S.; Capela, J.M.V.; Ribeiro, C.A.; De Julio, M. Energy Evaluation of Biochar Obtained from the Pyrolysis of Pine Pellets. J. Therm. Anal. Calorim. 2016, 126, 1879–1887. [Google Scholar] [CrossRef]

- Amalina, F.; Syukor Abd Razak, A.; Krishnan, S.; Sulaiman, H.; Zularisam, A.W.; Nasrullah, M. Advanced Techniques in the Production of Biochar from Lignocellulosic Biomass and Environmental Applications. Clean. Mater. 2022, 6, 100137. [Google Scholar] [CrossRef]

- Wang, L.; Olsen, M.N.P.; Moni, C.; Dieguez-Alonso, A.; de la Rosa, J.M.; Stenrød, M.; Liu, X.; Mao, L. Comparison of Properties of Biochar Produced from Different Types of Lignocellulosic Biomass by Slow Pyrolysis at 600 °C. Appl. Energy Combust. Sci. 2022, 12, 100090. [Google Scholar] [CrossRef]

- He, X.; Liu, Z.; Niu, W.; Yang, L.; Zhou, T.; Qin, D.; Niu, Z.; Yuan, Q. Effects of Pyrolysis Temperature on the Physicochemical Properties of Gas and Biochar Obtained from Pyrolysis of Crop Residues. Energy 2018, 143, 746–756. [Google Scholar] [CrossRef]

- Sabri, M.A.; Ibrahim, T.H.; Khamis, M.I.; Ludwick, A.; Nancarrow, P. Sustainable Management of Cut Flowers Waste by Activation and Its Application in Wastewater Treatment Technology. Environ. Sci. Pollut. Res. 2021, 28, 31803–31813. [Google Scholar] [CrossRef]

- Świechowski, K.; Stępień, P.; Syguła, E.; Koziel, J.A.; Białowiec, A. Lab-Scale Study of Temperature and Duration Effects on Carbonized Solid Fuels Properties Produced from Municipal Solid Waste Components. Materials 2021, 14, 1191. [Google Scholar] [CrossRef]

- Polish Committee for Standardization PN-EN 14346:2011; Determination of the Moisture Content of Fraction Samples Directed for Stabilisation. 2011. Available online: https://sklep.pkn.pl/pn-en-14346-2011p.html (accessed on 18 February 2024).

- Torquato, L.D.M.; Crnkovic, P.M.; Ribeiro, C.A.; Crespi, M.S. New Approach for Proximate Analysis by Thermogravimetry Using CO2 Atmosphere: Validation and Application to Different Biomasses. J. Therm. Anal. Calorim. 2017, 128, 1–14. [Google Scholar] [CrossRef]

- Polish Committee for Standardization PN-Z-15008-03:1993; Municipal Solid Waste. Analysis of Combustible and Non-Combustible Content. 1993. Available online: https://sklep.pkn.pl/pn-z-15008-03-1993p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 15169:2011; Waste Characteristics. Determination of Organic Matter Content for Waste, Slurry and Sludge. 2011. Available online: https://sklep.pkn.pl/pn-en-15169-2011p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. 2017. Available online: https://sklep.pkn.pl/pn-en-iso-18125-2017-07p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-Z-15009:1997; Solid Waste—Preparation of a Water Extract. 1997. Available online: https://sklep.pkn.pl/pn-z-15009-1997p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 25663:2001; Water Quality—Determination of Kjeldahl Nitrogen—Method after Mineralization with Selenium. 2001. Available online: https://sklep.pkn.pl/pn-en-25663-2001p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-C-04576-4: 1994; Water and Sewage. Tests for the Content of Nitrogen Compounds. Determination of Ammoniacal Nitrogen in Water by Direct Nesslerization. 1994. Available online: https://sklep.pkn.pl/pn-c-04576-4-1994p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-C-04576-08:1982. 1982. Available online: https://sklep.pkn.pl/pn-c-04576-08-1982p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 1189:2000; Water Quality—Determination of Phosphorus—Ammonium Molybdate Spectrophotometric Method. 2000. Available online: https://sklep.pkn.pl/pn-en-1189-2000p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN ISO 5814:2013-04E; Dissolved Oxygen Concentration. Electrochemical Method. 2013. Available online: https://sklep.pkn.pl/pn-en-iso-5814-2013-04e.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 1899-1:2002; Water Quality—Determination of Biochemical Oxygen Demand after n Days (BODn)—Part 1: Dilution and Inoculation Method with the Addition of Allylthiourea. 2002. Available online: https://sklep.pkn.pl/pn-en-1899-1-2002p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-ISO 15705:2005; Water Quality—Determination of the Chemical Oxygen Demand Index (SP-COD)—Minimized Method with the Use of Sealed Tubes. 2005. Available online: https://sklep.pkn.pl/pn-iso-15705-2005p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 872:2007; Water Quality—Determination of Suspended Solids—Method Using Filtration through Glass Fiber Filters. 2007. Available online: https://sklep.pkn.pl/pn-en-872-2007p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN ISO 9963-1:2001; Water Quality—Determination of Alkalinity—Part 1: Determination of Total Alkalinity and Alkalinity against Phenolphthalein. 2001. Available online: https://sklep.pkn.pl/pn-en-iso-9963-1-2001p.html (accessed on 18 February 2024).

- Polish Committee for Standardization PN-EN 27888:1999; Water Quality—Determination of the Electrical Conductivity. 1999. Available online: https://sklep.pkn.pl/pn-en-27888-1999p.html (accessed on 18 February 2024).

- Phytotoxkit. Seed Germination and Early Growth Microbiotest with Higher Plants. Standard Operational Procedure; MicroBioTest Inc.: Gent, Belgium, 2004. [Google Scholar]

- Ma, Z.; Yang, Y.; Wu, Y.; Xu, J.; Peng, H.; Liu, X.; Zhang, W.; Wang, S. In-Depth Comparison of the Physicochemical Characteristics of Bio-Char Derived from Biomass Pseudo Components: Hemicellulose, Cellulose, and Lignin. J. Anal. Appl. Pyrolysis 2019, 140, 195–204. [Google Scholar] [CrossRef]

- Gopalan, J.; Buthiyappan, A.; Abdul Raman, A.A. Insight into Metal-Impregnated Biomass Based Activated Carbon for Enhanced Carbon Dioxide Adsorption: A Review. J. Ind. Eng. Chem. 2022, 113, 72–95. [Google Scholar] [CrossRef]

- da Silva Veiga, P.A.; Schultz, J.; da Silva Matos, T.T.; Fornari, M.R.; Costa, T.G.; Meurer, L.; Mangrich, A.S. Production of High-Performance Biochar Using a Simple and Low-Cost Method: Optimization of Pyrolysis Parameters and Evaluation for Water Treatment. J. Anal. Appl. Pyrolysis 2020, 148, 104823. [Google Scholar] [CrossRef]

- Torres-Sciancalepore, R.; Asensio, D.; Nassini, D.; Fernandez, A.; Rodriguez, R.; Fouga, G.; Mazza, G. Assessment of the Behavior of Rosa Rubiginosa Seed Waste during Slow Pyrolysis Process towards Complete Recovery: Kinetic Modeling and Product Analysis. Energy Convers. Manag. 2022, 272, 116340. [Google Scholar] [CrossRef]

- Cifuentes, A.R.; Avila, K.; García, J.C.; Daza, C.E. The Pyrolysis of Rose Stems to Obtain Activated Carbons: A Study on the Adsorption of Ni(II). Ind. Eng. Chem. Res. 2013, 52, 16197–16205. [Google Scholar] [CrossRef]

- Mokrzycki, J.; Gazińska, M.; Fedyna, M.; Karcz, R.; Lorenc-Grabowska, E.; Rutkowski, P. Pyrolysis and Torrefaction of Waste Wood Chips and Cone-like Flowers Derived from Black Alder (Alnus glutinosa L. Gaertn.) for Sustainable Solid Fuel Production. Biomass Bioenergy 2020, 143, 105842. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and Chemical Characterization of Biochars Derived from Different Agricultural Residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Katyal, S.; Thambimuthu, K.; Valix, M. Carbonisation of Bagasse in a Fixed Bed Reactor: Influence of Process Variables on Char Yield and Characteristics. Renew. Energy 2003, 28, 713–725. [Google Scholar] [CrossRef]

- Kujawska, J. Content of Heavy Metals in Various Biochar and Assessment Environmental Risk. J. Ecol. Eng. 2023, 24, 287–295. [Google Scholar] [CrossRef]

- Dai, Y.; Zheng, H.; Jiang, Z.; Xing, B. Combined Effects of Biochar Properties and Soil Conditions on Plant Growth: A Meta-Analysis. Sci. Total Environ. 2020, 713, 136635. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.S.; Mehmood, M.A.; Al Ayed, O.S.; Ye, G.; Luo, H.; Ibrahim, M.; Rashid, U.; Arbi Nehdi, I.; Qadir, G. Kinetic Analyses and Pyrolytic Behavior of Para Grass (Urochloa mutica) for Its Bioenergy Potential. Bioresour. Technol. 2017, 224, 708–713. [Google Scholar] [CrossRef] [PubMed]

- Keiluweit, M.; Nico, P.S.; Johnson, M.; Kleber, M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef] [PubMed]

- Anyikude, K.U. Analysis of Pollutants in Biochars and Hydrochars Produced by Pyrolysis and Hydrothermal Carbonization of Waste Biomass. Ph.D. Thesis, University of Leeds, Leeds, UK, 2016. [Google Scholar]

- Cao, X.; Harris, W. Properties of Dairy-Manure-Derived Biochar Pertinent to Its Potential Use in Remediation. Bioresour. Technol. 2010, 101, 5222–5228. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Liu, L.; Tan, Z.; Zhang, L.; Huang, Q. Effects of Pyrolysis Conditions on Migration and Distribution of Biochar Nitrogen in the Soil-Plant-Atmosphere System. Sci. Total Environ. 2020, 723, 138006. [Google Scholar] [CrossRef] [PubMed]

- Yao, F.X.; Arbestain, M.C.; Virgel, S.; Blanco, F.; Arostegui, J.; Maciá-Agulló, J.A.; Macías, F. Simulated Geochemical Weathering of a Mineral Ash-Rich Biochar in a Modified Soxhlet Reactor. Chemosphere 2010, 80, 724–732. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Hale, L.; Kar, G.; Soolanayakanahally, R.; Adl, S. Phosphorus Recovery and Reuse by Pyrolysis: Applications for Agriculture and Environment. Chemosphere 2018, 194, 682–691. [Google Scholar] [CrossRef] [PubMed]

- Ronsse, F.; van Hecke, S.; Dickinson, D.; Prins, W. Production and Characterization of Slow Pyrolysis Biochar: Influence of Feedstock Type and Pyrolysis Conditions. GCB Bioenergy 2013, 5, 104–115. [Google Scholar] [CrossRef]

- Saidi, M. Experimental Studies on Effect of Heavy Metals Presence in Industrial Wastewater on Biological Treatment. Int. J. Environ. Sci. 2010, 1, 666–676. [Google Scholar]

- Latif, U.; Dickert, F.L. Chemical Oxygen Demand. In Environmental Analysis by Electrochemical Sensors and Biosensors: Applications; Moretto, L.M., Kalcher, K., Eds.; Springer: New York, NY, USA, 2015; pp. 719–728. ISBN 978-1-4939-1301-5. [Google Scholar]

- Rehrah, D.; Reddy, M.R.; Novak, J.M.; Bansode, R.R.; Schimmel, K.A.; Yu, J.; Watts, D.W.; Ahmedna, M. Production and Characterization of Biochars from Agricultural By-Products for Use in Soil Quality Enhancement. J. Anal. Appl. Pyrolysis 2014, 108, 301–309. [Google Scholar] [CrossRef]

- Qi, F.; Dong, Z.; Lamb, D.; Naidu, R.; Bolan, N.S.; Ok, Y.S.; Liu, C.; Khan, N.; Johir, M.A.H.; Semple, K.T. Effects of Acidic and Neutral Biochars on Properties and Cadmium Retention of Soils. Chemosphere 2017, 180, 564–573. [Google Scholar] [CrossRef] [PubMed]

- Bachmann, H.J.; Bucheli, T.D.; Dieguez-Alonso, A.; Fabbri, D.; Knicker, H.; Schmidt, H.P.; Ulbricht, A.; Becker, R.; Buscaroli, A.; Buerge, D.; et al. Toward the Standardization of Biochar Analysis: The COST Action TD1107 Interlaboratory Comparison. J. Agric. Food Chem. 2016, 64, 513–527. [Google Scholar] [CrossRef] [PubMed]

- Kloss, S.; Zehetner, F.; Dellantonio, A.; Hamid, R.; Ottner, F.; Liedtke, V.; Schwanninger, M.; Gerzabek, M.H.; Soja, G. Characterization of Slow Pyrolysis Biochars: Effects of Feedstocks and Pyrolysis Temperature on Biochar Properties. J. Environ. Qual. 2012, 41, 990–1000. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.N.; Ganesan, P. Effect of Process Parameters on Production of Biochar from Biomass Waste through Pyrolysis: A Review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Larina, O.M.; Zaichenko, V.M. Influence of Pyrolysis on Evaporation and Solubility of Heavy Metals in Sewage Sludge. J. Phys. Conf. Ser. 2020, 1556, 012017. [Google Scholar] [CrossRef]

- Chandra, S.; Bhattacharya, J. Influence of Temperature and Duration of Pyrolysis on the Property Heterogeneity of Rice Straw Biochar and Optimization of Pyrolysis Conditions for Its Application in Soils. J. Clean Prod. 2019, 215, 1123–1139. [Google Scholar] [CrossRef]

- Rashid, A.; Schutte, B.J.; Ulery, A.; Deyholos, M.K.; Sanogo, S.; Lehnhoff, E.A.; Beck, L. Heavy Metal Contamination in Agricultural Soil: Environmental Pollutants Affecting Crop Health. Agronomy 2023, 13, 1521. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development. Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 Regarding the Implementation of Certain Provisions of the Act on Fertilizers and Fertilization (No. 119 Item 765). Available online: https://isap.sejm.gov.pl/isap.nsf/ByYear.xsp?type=WDU&year=2008&vol=119 (accessed on 20 February 2024).

- Rombolà, A.G.; Marisi, G.; Torri, C.; Fabbri, D.; Buscaroli, A.; Ghidotti, M.; Hornung, A. Relationships between Chemical Characteristics and Phytotoxicity of Biochar from Poultry Litter Pyrolysis. J. Agric. Food Chem. 2015, 63, 6660–6667. [Google Scholar] [CrossRef] [PubMed]

- Gezahegn, S.; Sain, M.; Thomas, S.C. Phytotoxic Condensed Organic Compounds Are Common in Fast but Not Slow Pyrolysis Biochars. Bioresour. Technol. Rep. 2021, 13, 100613. [Google Scholar] [CrossRef]

| Pollution Indicator | Determination Method |

|---|---|

| Total organic carbon (TOC), total carbon (TC), and total inorganic carbon (IC) | Sievers InnovOx Labolatory TOC analyzer (GE, Analyttical Instruments, General electric, Co., Ltd., Boston, MA, USA) |

| Total nitrogen, mg N × dm−3 | The sum of all forms of nitrogen |

| Kjeldahl nitrogen, mg N × dm−3 | PN-EN 25663:2001 [37] |

| Organic nitrogen, mg Norg × dm−3 | Indirectly (difference between Kjeldahl and ammonium nitrogen) |

| Ammoniacal nitrogen, mg NNH4 × dm−3 | PN-C04576-4:1994 [38] |

| Nitric nitrogen, mg NNO3 × dm−3 | PN-C-04576-08:1982 [39] |

| Total phosphorus, mg P × dm−3 | PN-EN 1189-2000 [40] |

| Dissolved oxygen, mg O2 × dm−3 | PN-EN ISO 5814:2013-04E [41] |

| BOD5, mg O2 × dm−3 | PN-EN 1899-1:2002 [42] |

| COD (Cr), mg O2 × dm−3 | PN ISO 15705:2005 [43] |

| General dissolved substances, mg × dm−3 | By weight, after the evaporation of the filtered sample |

| General suspensions, mg × dm−3 | PN-EN 872:2007 [44] |

| pH | PN-EN ISO 9963-1:2001 [45] |

| Conductivity, μS × cm−1 | PN-EN 27888:1999P [46] |

| Sodium, mg Na × dm−3 | Atomic emission spectrometry (AAS, according to standards provided by Spectro-Lab Ltd., Los Angeles, CA, USA) |

| Potassium, mg K × dm−3 | |

| Calcium, mg Ca × dm−3 | |

| Magnesium, mg Mg × dm−3 | |

| Zinc, μg Zn × dm−3 | |

| Copper, μg Cu × dm−3 | |

| Nickel, μg Ni × dm−3 | |

| Cadmium, μg Cd × dm−3 | |

| Chromium, μg Cr × dm−3 | |

| Manganese, mg Mn × dm−3 | |

| Iron, mg Fe × dm−3 | |

| Lead, μg Pb × dm−3 |

| 20 min | 40 min | 60 min | |

|---|---|---|---|

| 200 °C |  |  |  |

| 250 °C |  |  |  |

| 300 °C |  |  |  |

| 350 °C |  |  |  |

| 400 °C |  |  |  |

| 450 °C |  |  |  |

| 500 °C |  |  |  |

| T, °C | t, min | MY, % | EDr, - | EY, % | EG, % |

|---|---|---|---|---|---|

| 200 | 20 | 97.7 ± 0.2 | 1.01 ± 0.00 | 98.6 ± 0.2 | 41.2 ± 3.1 |

| 40 | 96.2 ± 0.8 | 1.03 ± 0.00 | 98.9 ± 0.8 | 74.9 ± 14.9 | |

| 60 | 92.1 ± 0.3 | 1.06 ± 0.00 | 97.5 ± 0.4 | 74.1 ± 3.1 | |

| 250 | 20 | 92.9 ± 1.3 | 1.02 ± 0.00 | 94.9 ± 1.3 | 30.7 ± 5.5 |

| 40 | 81.0 ± 3.0 | 1.17 ± 0.00 | 95.0 ± 3.5 | 92.5 ± 14.8 | |

| 60 | 72.9 ± 0.6 | 1.18 ± 0.00 | 86.1 ± 0.7 | 66.8 ± 1.5 | |

| 300 | 20 | 77.3 ± 1.5 | 1.10 ± 0.00 | 84.8 ± 1.7 | 43.2 ± 2.9 |

| 40 | 54.9 ± 0.9 | 1.35 ± 0.00 | 74.1 ± 1.2 | 77.6 ± 1.5 | |

| 60 | 50.4 ± 1.0 | 1.37 ± 0.00 | 69.1 ± 1.3 | 74.8 ± 1.5 | |

| 350 | 20 | 56.2 ± 3.4 | 1.26 ± 0.00 | 70.8 ± 4.3 | 59.9 ± 4.7 |

| 40 | 45.4 ± 3.0 | 1.36 ± 0.00 | 61.6 ± 4.1 | 65.7 ± 3.8 | |

| 60 | 43.5 ± 0.4 | 1.38 ± 0.00 | 60.1 ± 0.5 | 67.7 ± 0.5 | |

| 400 | 20 | 47.9 ± 2.3 | 1.23 ± 0.00 | 58.7 ± 2.9 | 43.7 ± 1.9 |

| 40 | 41.2 ± 0.4 | 1.34 ± 0.00 | 55.3 ± 0.6 | 58.0 ± 0.4 | |

| 60 | 38.3 ± 1.6 | 1.45 ± 0.00 | 55.6 ± 2.3 | 72.8 ± 2.0 | |

| 450 | 20 | 42.8 ± 1.2 | 1.31 ± 0.00 | 55.9 ± 1.5 | 53.4 ± 1.1 |

| 40 | 35.4 ± 0.6 | 1.42 ± 0.00 | 50.1 ± 0.8 | 64.4 ± 0.6 | |

| 60 | 34.2 ± 0.3 | 1.47 ± 0.00 | 50.3 ± 0.4 | 71.9 ± 0.3 | |

| 500 | 20 | 36.5 ± 0.5 | 1.41 ± 0.00 | 51.5 ± 0.7 | 64.6 ± 0.5 |

| 40 | 32.9 ± 0.4 | 1.48 ± 0.00 | 48.8 ± 0.5 | 71.9 ± 0.4 | |

| 60 | 32.0 ± 0.5 | 1.50 ± 0.00 | 48.0 ± 0.7 | 73.4 ± 0.5 |

| T, °C | t, min | VS, % | VM, % | FC, % | AC, % | HHV, J × g−1 |

|---|---|---|---|---|---|---|

| Raw | Raw | 97.2 ± 0.4 | 75.5 ± 0.5 | 21.7 ± 0.7 | 2.8 ± 0.4 | 18,312 ± 235 |

| 200 | 20 | 97.1 ± 0.2 | 75.0 ± 0.6 | 22.1 ± 0.7 | 2.9 ± 0.2 | 18,484 ± 413 |

| 40 | 97.2 ± 0.4 | 72.8 ± 0.7 | 24.3 ± 0.8 | 2.8 ± 0.4 | 18,820 ± 247 | |

| 60 | 96.7 ± 0.2 | 69.6 ± 0.6 | 27.1 ± 0.8 | 3.3 ± 0.2 | 19,389 ± 450 | |

| 250 | 20 | 97.1 ± 0.0 | 73.2 ± 1.6 | 23.9 ± 1.6 | 2.9 ± 0.0 | 18,704 ± 646 |

| 40 | 96.0 ± 0.4 | 65.0 ± 0.6 | 31.0 ± 0.8 | 4.0 ± 0.4 | 21,463 ± 396 | |

| 60 | 96.2 ± 0.3 | 54.8 ± 0.5 | 41.4 ± 0.7 | 3.8 ± 0.3 | 21,633 ± 431 | |

| 300 | 20 | 94.7 ± 0.5 | 64.5 ± 1.1 | 30.2 ± 1.3 | 5.3 ± 0.5 | 20,102 ± 377 |

| 40 | 94.1 ± 0.5 | 45.9 ± 0.7 | 48.2 ± 0.9 | 5.9 ± 0.5 | 24,720 ± 267 | |

| 60 | 92.9 ± 0.3 | 40.6 ± 0.3 | 52.3 ± 0.1 | 7.1 ± 0.3 | 25,113 ± 731 | |

| 350 | 20 | 89.8 ± 3.5 | 37.4 ± 0.9 | 52.3 ± 2.6 | 10.2 ± 3.5 | 23,096 ± 251 |

| 40 | 92.0 ± 1.5 | 36.1 ± 1.4 | 55.9 ± 2.2 | 8.0 ± 1.5 | 24,862 ± 601 | |

| 60 | 91.7 ± 1.1 | 46.9 ± 0.8 | 44.8 ± 1.3 | 8.3 ± 1.1 | 25,324 ± 49 | |

| 400 | 20 | 91.8 ± 1.8 | 43.9 ± 3.4 | 47.8 ± 1.6 | 8.2 ± 1.8 | 22,478 ± 811 |

| 40 | 91.0 ± 2.7 | 34.7 ± 1.5 | 56.3 ± 1.9 | 9.0 ± 2.7 | 24,548 ± 594 | |

| 60 | 90.1 ± 1.6 | 40.0 ± 0.6 | 50.0 ± 1.0 | 9.9 ± 1.6 | 26,531 ± 251 | |

| 450 | 20 | 90.7 ± 2.1 | 36.2 ± 1.7 | 54.5 ± 1.1 | 9.3 ± 2.1 | 23,903 ± 846 |

| 40 | 88.5 ± 1.1 | 25.0 ± 2.0 | 63.5 ± 3.1 | 11.5 ± 1.1 | 25,926 ± 417 | |

| 60 | 89.3 ± 3.4 | 32.9 ± 1.0 | 56.4 ± 4.1 | 10.7 ± 3.4 | 26,979 ± 400 | |

| 500 | 20 | 87.8 ± 1.9 | 30.0 ± 1.1 | 57.8 ± 2.9 | 12.2 ± 1.9 | 25,815 ± 348 |

| 40 | 88.8 ± 0.5 | 26.5 ± 0.0 | 62.2 ± 0.5 | 11.2 ± 0.5 | 27,139 ± 452 | |

| 60 | 85.9 ± 2.1 | 29.0 ± 0.2 | 56.9 ± 1.9 | 14.1 ± 2.1 | 27,443 ± 168 |

| T, °C | t, min | Total Carbon Content, ppm | Organic Carbon Content, ppm | Inorganic Carbon Content, ppm | Total Nitro-gen, mg N × dm−3 | Kjeldahl Nitrogen, mg N × dm−3 | Organic Nitrogen, mg Norg × dm−3 | Ammonical Nitrogen, mg NNH4 × dm−3 | Nitric Nitrogen, mg NNO3 × dm−3 | Total Phosphorus, mg P × dm−3 | Dissolved Oxygen, mg O2 × dm−3 | BOD5, mg O2 × dm−3 | COD (Cr), mg O2 × dm−3 | General Suspensions, mg × dm−3 | General Dis-solved Sub-stances, mg × dm−3 | pH | Conductivity, μS × cm−1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | Raw | 4680 ± 18 | 4760 ± 25 | 80 ± 7 | 224.79 | 216.51 | 164.91 | 51.60 | 8.28 | 86.69 | 0.0 | 3048 | 6850 | 1865 | 4250 | 5.5 | 2530 |

| 200 | 20 | 2948 ± 36 | 3028 ± 27 | 81 ± 9 | 422.04 | 353.50 | 299.05 | 54.49 | 68.5 | 37.70 | 1.2 | 1320 | 12,074 | 1610 | 9210 | 5.8 | 2890 |

| 40 | 2468 ± 2 | 2544 ± 4 | 78 ± 5 | 213.33 | 130.53 | 127.43 | 3.10 | 82.8 | 78.04 | 1.4 | 692 | 4674 | 20 | 6420 | 5.8 | 2080 | |

| 60 | 4840 ± 61 | 4920 ± 61 | 90 ± 0 | 154.49 | 108.19 | 93.91 | 14.28 | 46.3 | 90.94 | 1.0 | 812 | 2804 | 375 | 5595 | 6.0 | 2480 | |

| 250 | 20 | 4400 ± 25 | 4520 ± 25 | 88 ± 0 | 330.40 | 265.60 | 255.2 | 10.4 | 64.8 | 80.61 | 1.6 | 548 | 8335 | 795 | 5870 | 5.7 | 1240 |

| 40 | 2896 ± 38 | 2980 ± 39 | 84 ± 1 | 315.33 | 239.93 | 234.33 | 5.60 | 75.4 | 135.8 | 1.2 | 604 | 7946 | 360 | 9105 | 5.6 | 2770 | |

| 60 | 4360 ± 129 | 4440 ± 140 | 91 ± 10 | 240.14 | 139.04 | 129.66 | 9.38 | 101.1 | 93.94 | 1.4 | 722 | 3895 | 470 | 6530 | 5.8 | 1587 | |

| 300 | 20 | 1756 ± 100 | 1912 ± 78 | 153 ± 22 | 263.53 | 190.96 | 180.08 | 10.88 | 72.57 | 49.62 | 1.8 | 281 | 7011 | 240 | 9235 | 5.7 | 1351 |

| 40 | 1625 ± 98 | 1760 ± 98 | 135 ± 1 | 87.20 | 77.85 | 75.62 | 2.23 | 0.56 | 93.26 | 3.8 | 1672 | 7646 | 212 | 5694 | 5.8 | 3310 | |

| 60 | 700 ± 37 | 752 ± 42 | 56 ± 5 | 69.71 | 67.47 | 65.99 | 1.48 | 0.38 | 81.1 | 3.0 | 1866 | 5470 | 47 | 5576 | 6.3 | 3100 | |

| 350 | 20 | 520 ± 19 | 572 ± 14 | 51 ± 5 | 113.90 | 105.51 | 103.49 | 2.02 | 8.39 | 97.62 | 4.2 | 1408 | 5764 | 735 | 5955 | 5.9 | 2330 |

| 40 | 2332 ± 37 | 2380 ± 35 | 48 ± 2 | 113.20 | 33.91 | 33.25 | 0.66 | 79.29 | 45.99 | 4.6 | 108 | 1664 | 160 | 2430 | 7.6 | 1838 | |

| 60 | 266 ± 10 | 324 ± 10 | 58 ± 0 | 32.80 | 24.43 | 24.07 | 0.36 | 8.38 | 23.49 | 4.4 | 400 | 1149 | 140 | 1725 | 7.7 | 1533 | |

| 400 | 20 | 139 ± 0 | 212 ± 0 | 72 ± 0 | 149.55 | 87.05 | 86.26 | 0.79 | 62.5 | 9.63 | 4.4 | 1056 | 6070 | 170 | 6210 | 5.8 | 2380 |

| 40 | 50 ± 3 | 94 ± 2 | 44 ± 2 | 18.02 | 10.65 | 10.57 | 0.08 | 7.37 | 15.55 | 3.6 | 158 | 579 | 100 | 1230 | 8.6 | 1163 | |

| 60 | 892 ± 16 | 1040 ± 10 | 149 ± 6 | 11.74 | 5.12 | 5.10 | 0.02 | 6.62 | 4.60 | 5.0 | 132 | 231 | 50 | 955 | 7.5 | 1127 | |

| 450 | 20 | 190 ± 7 | 373 ± 1 | 183 ± 8 | 58.75 | 41.30 | 40.76 | 0.54 | 0.2 | 33.42 | 4.6 | 1034 | 2112 | 62 | 2139 | 7.0 | 1636 |

| 40 | 134 ± 0 | 278 ± 0 | 143 ± 1 | 16.71 | 15.98 | 15.83 | 0.15 | nf | 9.52 | 6.0 | 275 | 594 | 705 | 830 | 9.7 | 1368 | |

| 60 | 230 ± 4 | 352 ± 5 | 122 ± 10 | 12.49 | 12.27 | 12.11 | 0.16 | 0.22 | 13.71 | 6.0 | 196 | 2373 | 560 | 733 | 10.8 | 2040 | |

| 500 | 20 | 200 ± 10 | 346 ± 9 | 146 ± 1 | 17.52 | 17.31 | 17.21 | 0.10 | 0.21 | 13.88 | 6.2 | 202 | 439 | 134 | 517 | 8.4 | 796 |

| 40 | 158 ± 13 | 323 ± 3 | 164 ± 10 | 18.26 | 14.81 | 14.69 | 0.12 | 0.15 | 13.52 | 6.0 | 63 | 102 | 1046 | 1051 | 10.6 | 2050 | |

| 60 | 4680 ± 18 | 4760 ± 25 | 80 ± 7 | 87.20 | 13.63 | 75.62 | 0.13 | 0.15 | 12.42 | 5.8 | 45 | 375 | 107 | 1170 | 10.8 | 2190 |

| T, °C | t, min | Sodium, mg Na × dm−3 | Potassium, mg K ×·dm−3 | Calcium, mg Ca ×·dm−3 | Magnesium, mg Mg ×·dm−3 | Zinc, μg Zn ×·dm−3 | Copper, μg Cu ×·dm−3 | Cadmium, μg Cd ×·dm−3 | Lead, μg Pb ×·dm−3 | Chromium, μg Cr ×·dm−3 | Nickel, μg Ni ×·dm−3 | Manganese, mg Mn ×·dm−3 | Iron, mg Fe ×·dm−3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | Raw | 21.6 | 504.4 | 71.7 | 58.6 | 1464.0 | 312.5 | nf | nf | 133.0 | 31.6 | 2.7 | 1.15 |

| 200 | 20 | 31.0 | 675.0 | 173.2 | 85.9 | 2335.8 | 1311.0 | 13.5 | nf | 389.0 | 156.5 | 5.86 | 2.36 |

| 40 | 29.5 | 685.1 | 152.8 | 73.2 | 1829.5 | 1535.0 | 1.5 | nf | 187.5 | 570.0 | 5.0 | 2.53 | |

| 60 | 29.1 | 650.8 | 143.1 | 64.0 | 1547.5 | 646.5 | 10.5 | nf | 268.5 | 20.0 | 3.88 | 2.1 | |

| 250 | 20 | 31.0 | 676.4 | 158.0 | 84.4 | 2442.5 | 318.0 | nf | nf | 250.0 | nf | 6.42 | 3.19 |

| 40 | 26.3 | 550.5 | 145.8 | 74.3 | 2104.5 | 222.5 | 5.0 | nf | 145.0 | nf | 6.07 | 0.93 | |

| 60 | 30.1 | 693.5 | 164.1 | 81.0 | 1834.0 | 218.0 | nf | nf | 366.0 | 105.0 | 5.4 | 4.6 | |

| 300 | 20 | 32.0 | 677.9 | 178.1 | 92.9 | 2113.5 | 299.0 | 1.5 | nf | 534.0 | 143.0 | 7.44 | 1.7 |

| 40 | 28.9 | 331.3 | 186.9 | 57.2 | 1999.5 | 76.3 | 1.6 | nf | 83.2 | 85.8 | 7.7 | 0.21 | |

| 60 | 25.3 | 338.3 | 172.6 | 49.3 | 474.6 | 56.5 | 1.4 | nf | 80.4 | 73.9 | 4.07 | 0.13 | |

| 350 | 20 | 22.2 | 578.9 | 77.8 | 65.6 | 1706.5 | 300.0 | nf | nf | 125.0 | 22.4 | 2.94 | 0.55 |

| 40 | 18.4 | 496.2 | 40.8 | 27.7 | 852.5 | 234.5 | nf | nf | 103.5 | 16.0 | 0.6 | 0.63 | |

| 60 | 17.5 | 392.6 | 42.2 | 29.0 | 784.0 | 214.5 | nf | nf | 85.5 | 18.0 | 1.02 | 0.53 | |

| 400 | 20 | 24.5 | 562.0 | 117.8 | 72.0 | 1354.5 | 288.0 | nf | nf | 75.5 | 23.9 | 4.87 | 0.87 |

| 40 | 14.7 | 328.3 | 19.4 | 15.7 | 757.5 | 202.0 | nf | nf | 66.0 | nf | 0.27 | 0.38 | |

| 60 | 11.5 | 305.9 | 12.5 | 9.7 | 727.0 | 212.5 | nf | nf | 105.5 | nf | 0.12 | 12.15 | |

| 450 | 20 | 14.6 | 305.6 | 59.2 | 24.5 | 135.6 | 52.1 | nf | nf | 65.7 | 51.3 | 0.77 | 0.04 |

| 40 | 10.5 | 284.8 | 10.6 | 7.8 | 125.9 | 33.3 | nf | nf | 52.7 | 40.7 | 0.06 | 2.92 | |

| 60 | 13.2 | 314.5 | 11.5 | 6.1 | 118.8 | 38.3 | nf | nf | 57.6 | 37.0 | 0.02 | 0.29 | |

| 500 | 20 | 7.0 | 232.4 | 9.9 | 10.2 | 120.3 | 35.2 | 0.7 | nf | 71.7 | 62.3 | 0.14 | 0.27 |

| 40 | 10.5 | 302.9 | 11.2 | 7.5 | 102.3 | 36.7 | 0.9 | nf | 55.4 | 32.4 | 0.03 | 0.13 | |

| 60 | 12.7 | 315.2 | 8.9 | 5.6 | 97.1 | 39.4 | nf | nf | 61.5 | 35.0 | 0.01 | 0.08 |

| T, °C | t, min | Average Root Length, mm | Inhibition of Root Elongation, % | Average Seed Germination, % |

|---|---|---|---|---|

| 200 | 20 | 17.08 ± 3.56 | 68.83 ± 3.56 | 13.33 ± 3.56 |

| 40 | 21.92 ± 6.06 | 60.00 ± 6.06 | 53.33 ± 6.06 | |

| 60 | 41.61 ± 14.46 | 24.07 ± 14.46 | 73.33 ± 14.46 | |

| 250 | 20 | 26.19 ± 11.50 | 52.21 ± 11.50 | 36.67 ± 11.50 |

| 40 | 41.58 ± 19.21 | 24.12 ± 19.21 | 83.33 ± 19.21 | |

| 60 | 55.67 ± 15.84 | −1.59 ± 15.84 | 80.00 ± 15.84 | |

| 300 | 20 | 36.53 ± 18.48 | 33.34 ± 18.48 | 86.67 ± 18.48 |

| 40 | 51.8 ± 14.96 | 5.47 ± 14.96 | 96.67 ± 14.96 | |

| 60 | 52.35 ± 23.77 | 4.47 ± 23.77 | 90.00 ± 23.77 | |

| 350 | 20 | 44.85 ± 21.33 | 18.15 ± 21.33 | 90.00 ± 21.33 |

| 40 | 44.75 ± 19.25 | 18.34 ± 19.25 | 96.67 ± 19.25 | |

| 60 | 54.02 ± 17.38 | 1.42 ± 17.38 | 90.00 ± 17.38 | |

| 400 | 20 | 66.98 ± 7.35 | −22.23 ± 7.35 | 93.33 ± 7.35 |

| 40 | 64.16 ± 16.79 | −17.09 ± 16.79 | 86.67 ± 16.79 | |

| 60 | 57.38 ± 21.09 | −4.71 ± 21.09 | 93.33 ± 21.09 | |

| 450 | 20 | 59.61 ± 20.48 | −8.78 ± 20.48 | 96.67 ± 20.48 |

| 40 | 72.16 ± 14.67 | −31.68 ± 14.67 | 96.67 ± 14.67 | |

| 60 | 52.56 ± 23.34 | 4.08 ± 23.34 | 90.00 ± 23.34 | |

| 500 | 20 | 57.95 ± 24.47 | −5.75 ± 24.47 | 86.67 ± 24.47 |

| 40 | 64.05 ± 24.14 | −16.88 ± 24.14 | 100.00 ± 24.14 | |

| 60 | 56.69 ± 20.12 | −3.45 ± 20.12 | 90.00 ± 20.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stefanów, J.; Sobieraj, K.; Hejna, M.; Pawęska, K.; Świechowski, K. Fuel Characteristics and Phytotoxicity Assay of Biochar Derived from Rose Pruning Waste. Materials 2024, 17, 1895. https://doi.org/10.3390/ma17081895

Stefanów J, Sobieraj K, Hejna M, Pawęska K, Świechowski K. Fuel Characteristics and Phytotoxicity Assay of Biochar Derived from Rose Pruning Waste. Materials. 2024; 17(8):1895. https://doi.org/10.3390/ma17081895

Chicago/Turabian StyleStefanów, Julia, Karolina Sobieraj, Małgorzata Hejna, Katarzyna Pawęska, and Kacper Świechowski. 2024. "Fuel Characteristics and Phytotoxicity Assay of Biochar Derived from Rose Pruning Waste" Materials 17, no. 8: 1895. https://doi.org/10.3390/ma17081895