Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design

Abstract

:1. Introduction

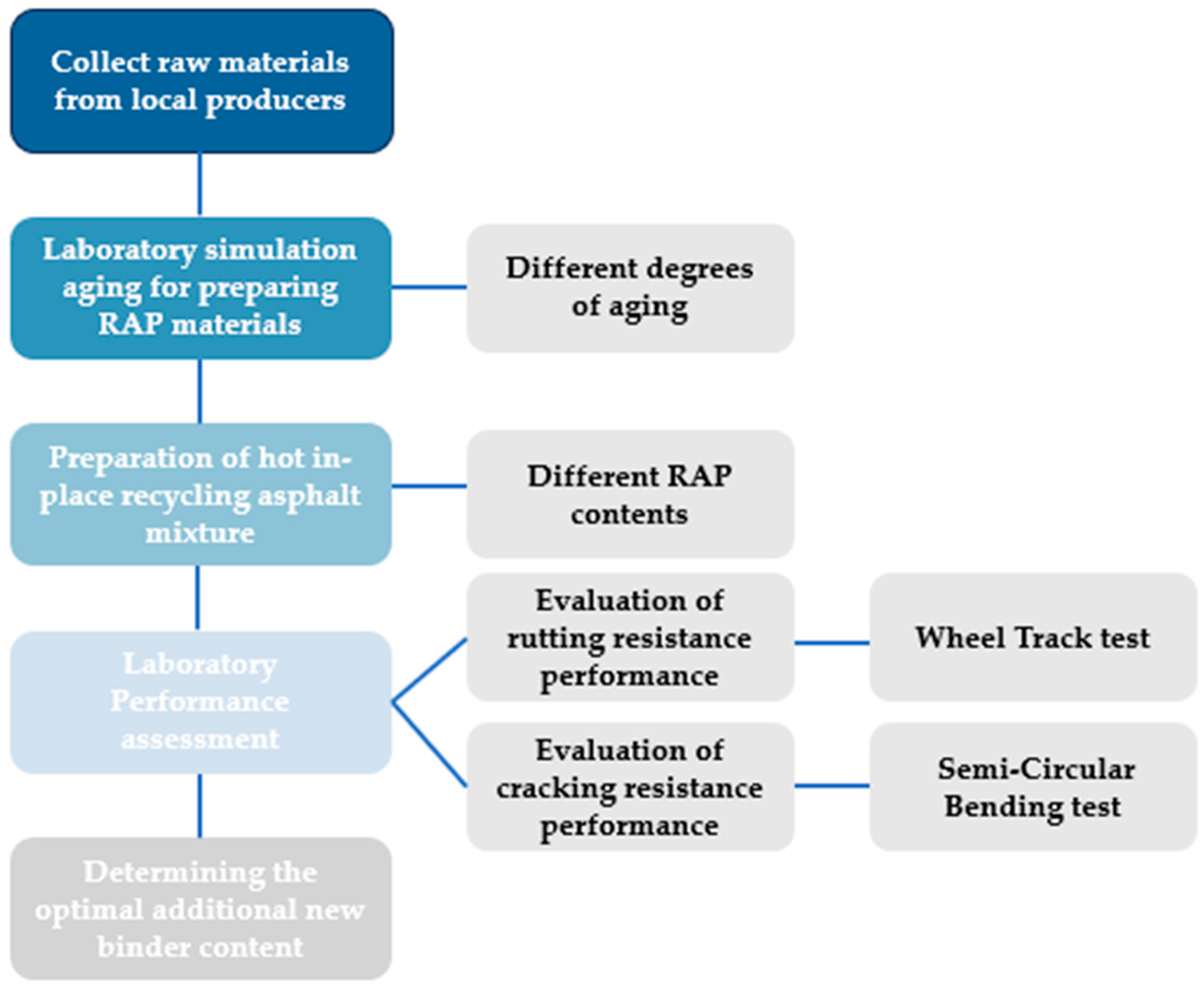

2. Laboratory Experimental Program

2.1. Properties of Raw Materials

2.1.1. Binder

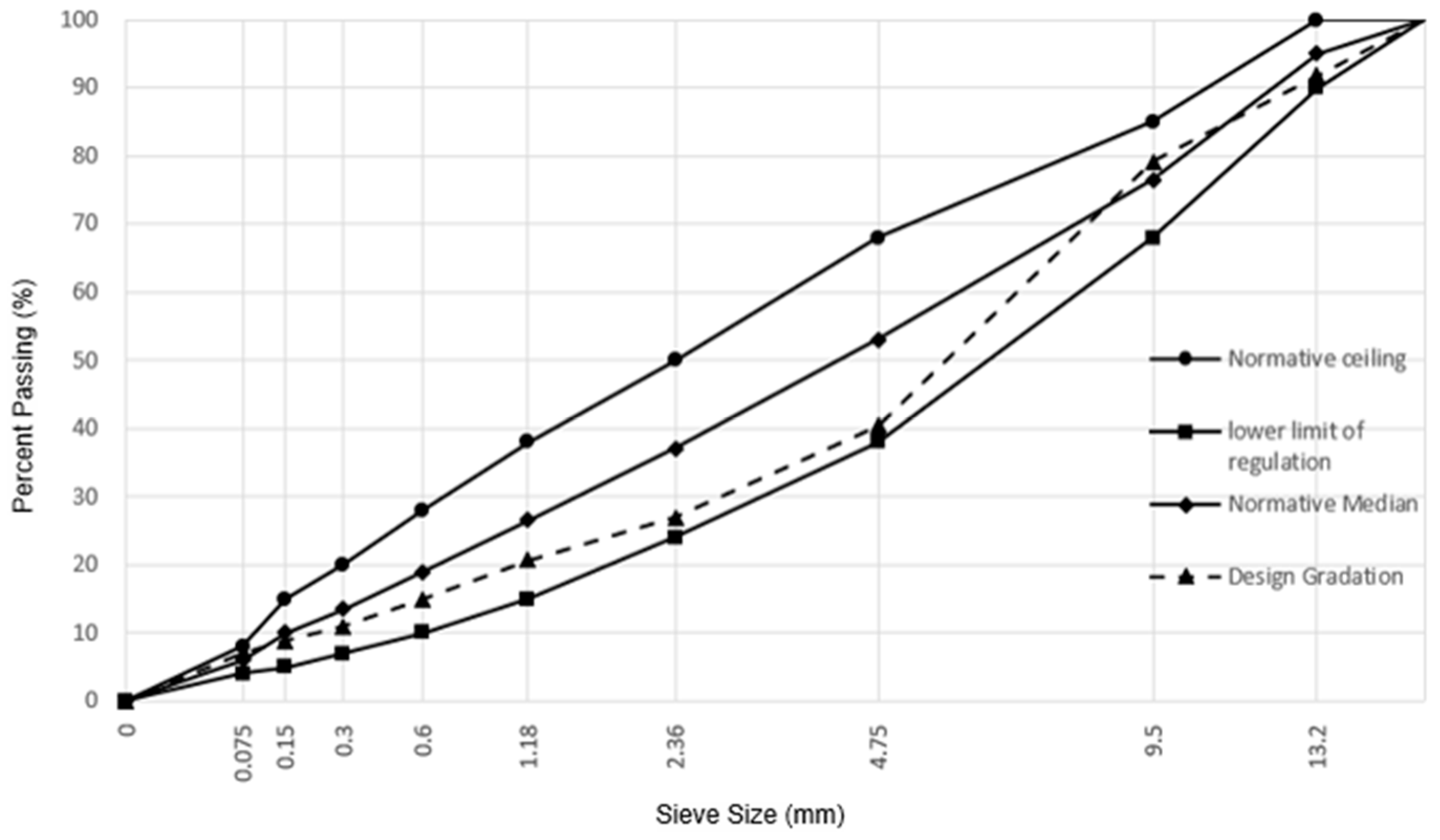

2.1.2. Mineral Material

2.1.3. Rejuvenator

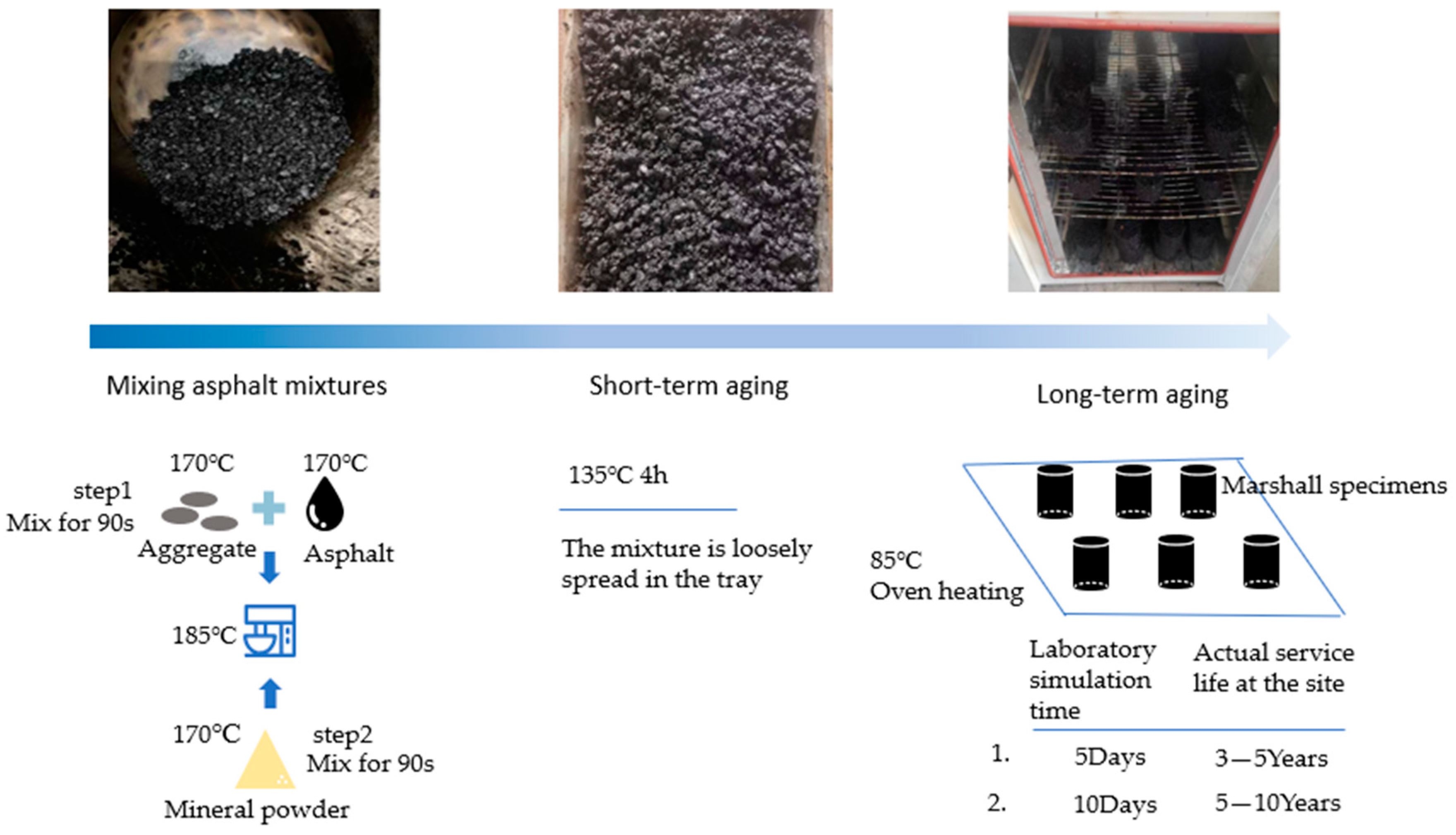

2.2. Lab Preparation of RAP

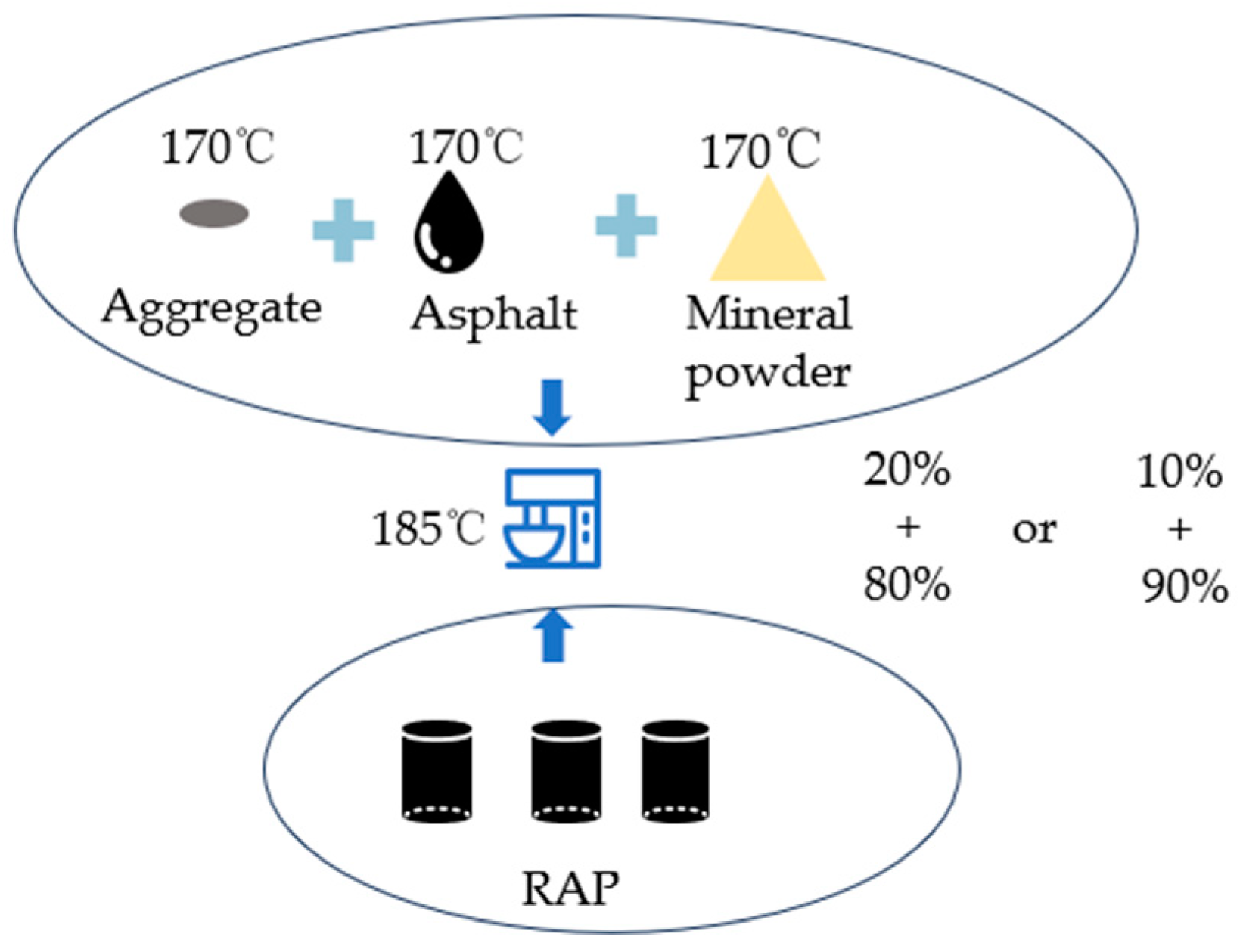

2.3. Lab-Prepared Hot In-Place Recycling Asphalt Mixture

2.3.1. Mix Proportion

2.3.2. The Binder Content of Recycling Asphalt Mixture

2.4. Selected Performance Tests and Indicators

2.4.1. Performance Assessment Tests

2.4.2. Performance Assessment Indicators

2.4.3. Designing Balanced Asphalt Mixture (BMD)

3. Results and Discussions

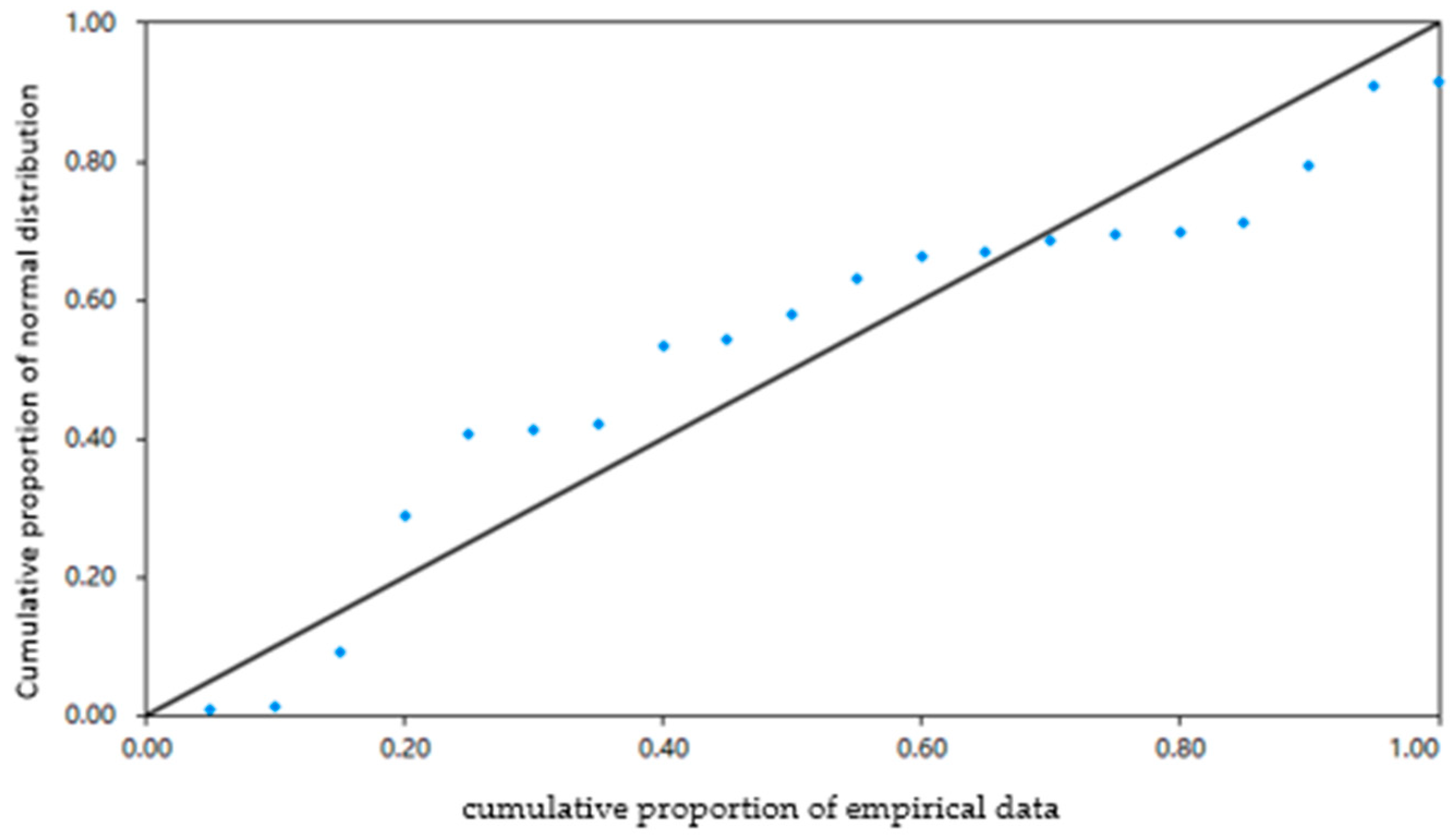

3.1. Evaluation of Rutting Resistance Performance

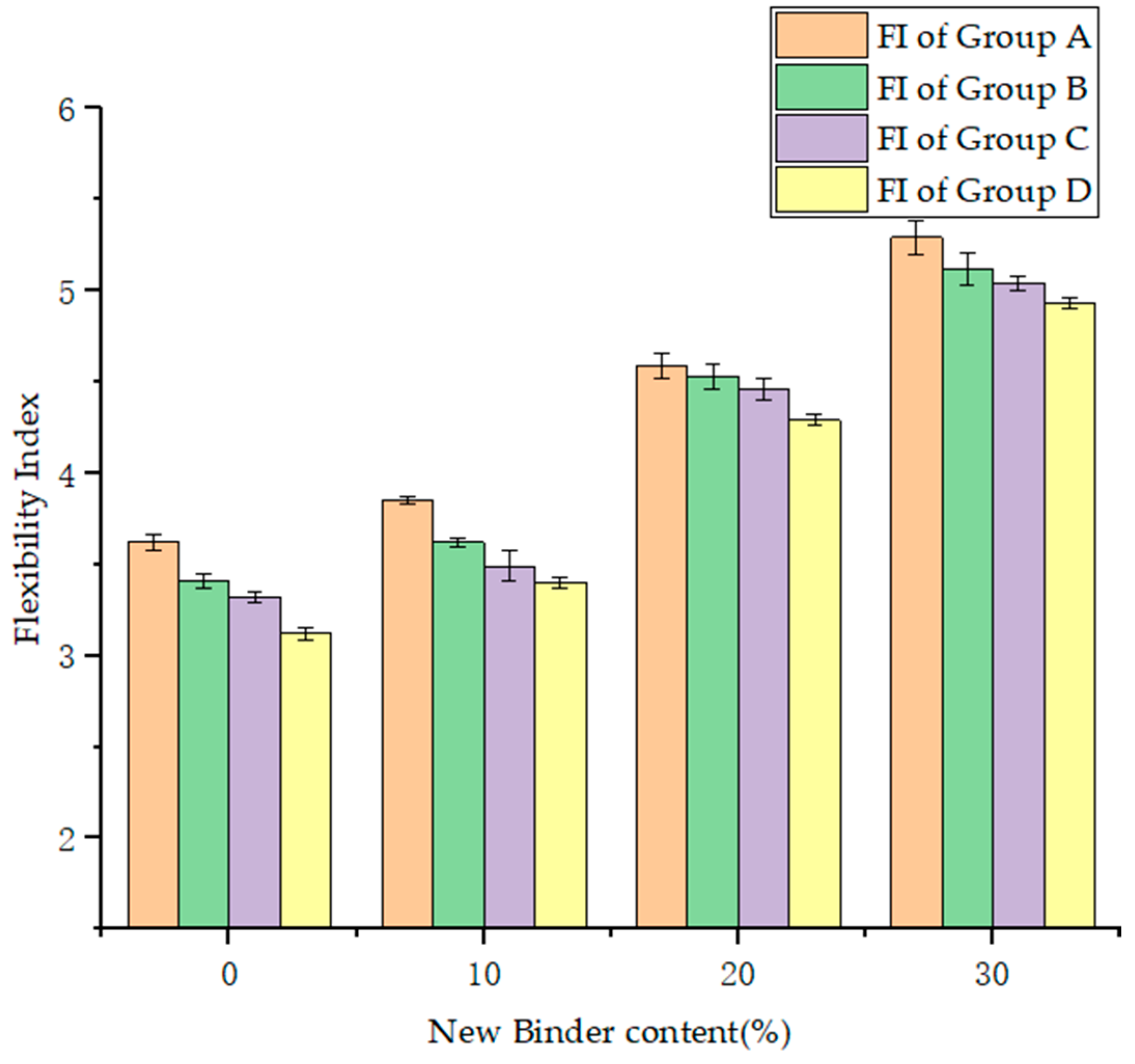

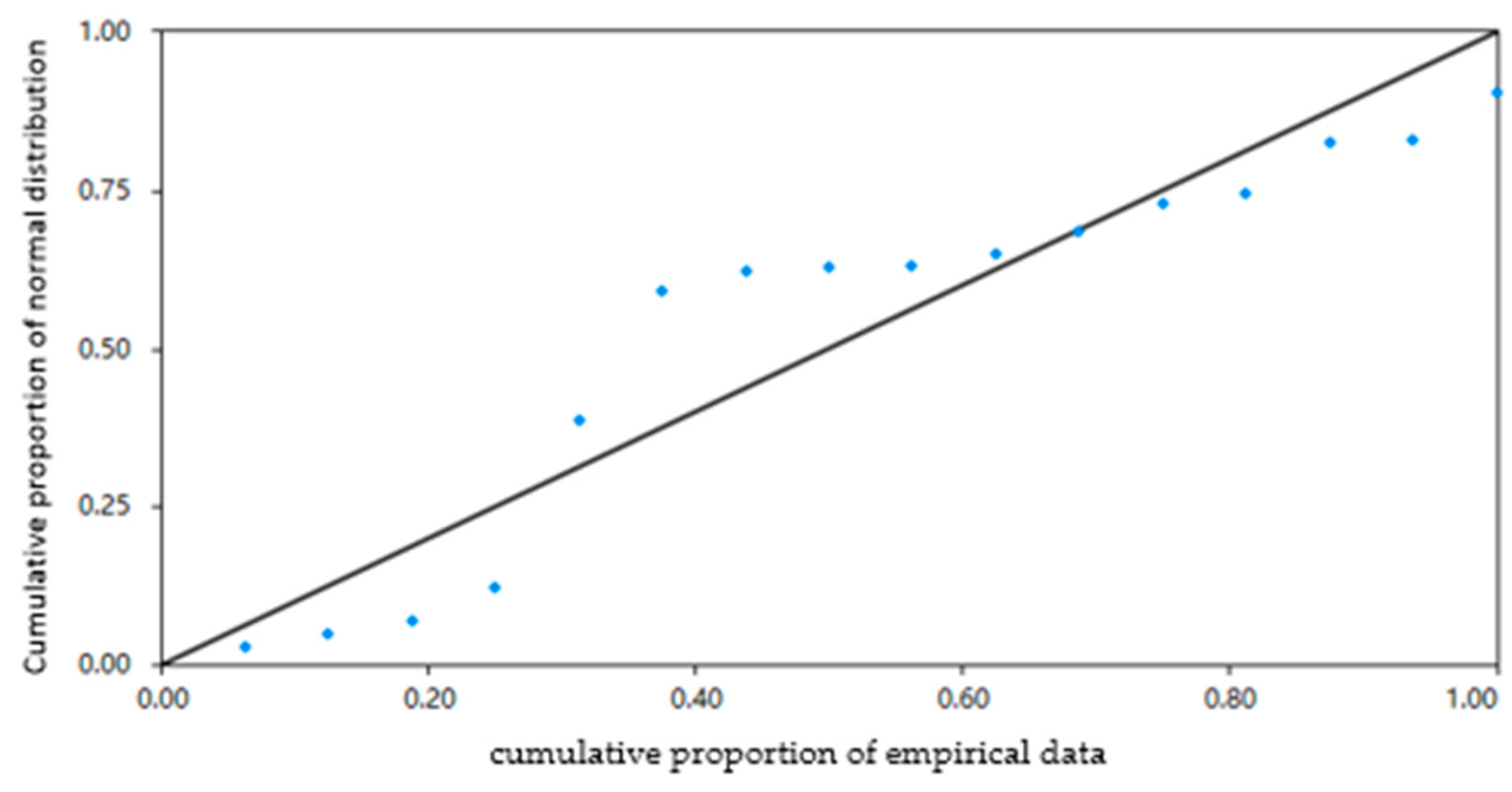

3.2. Evaluation of Cracking Resistance Performamce

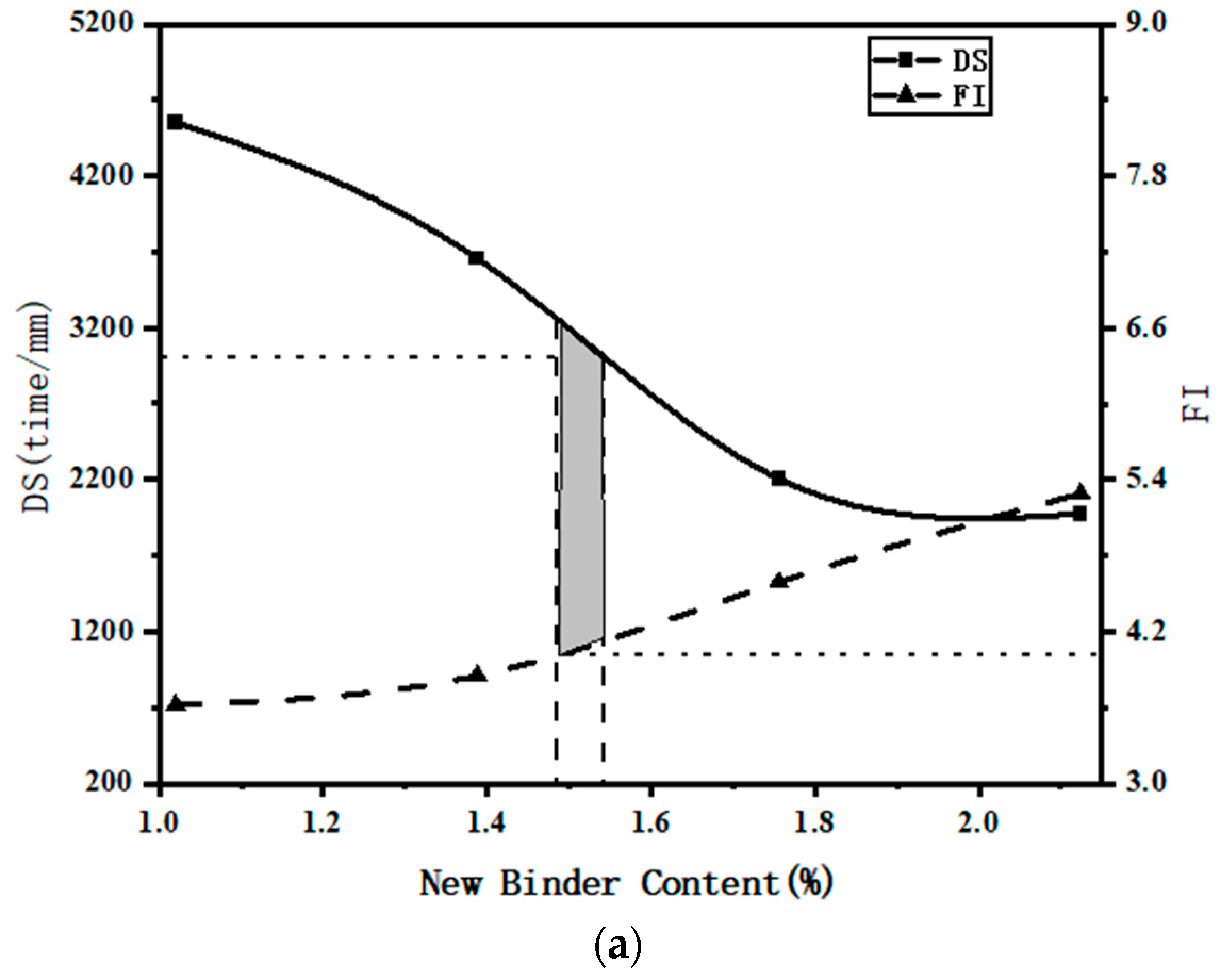

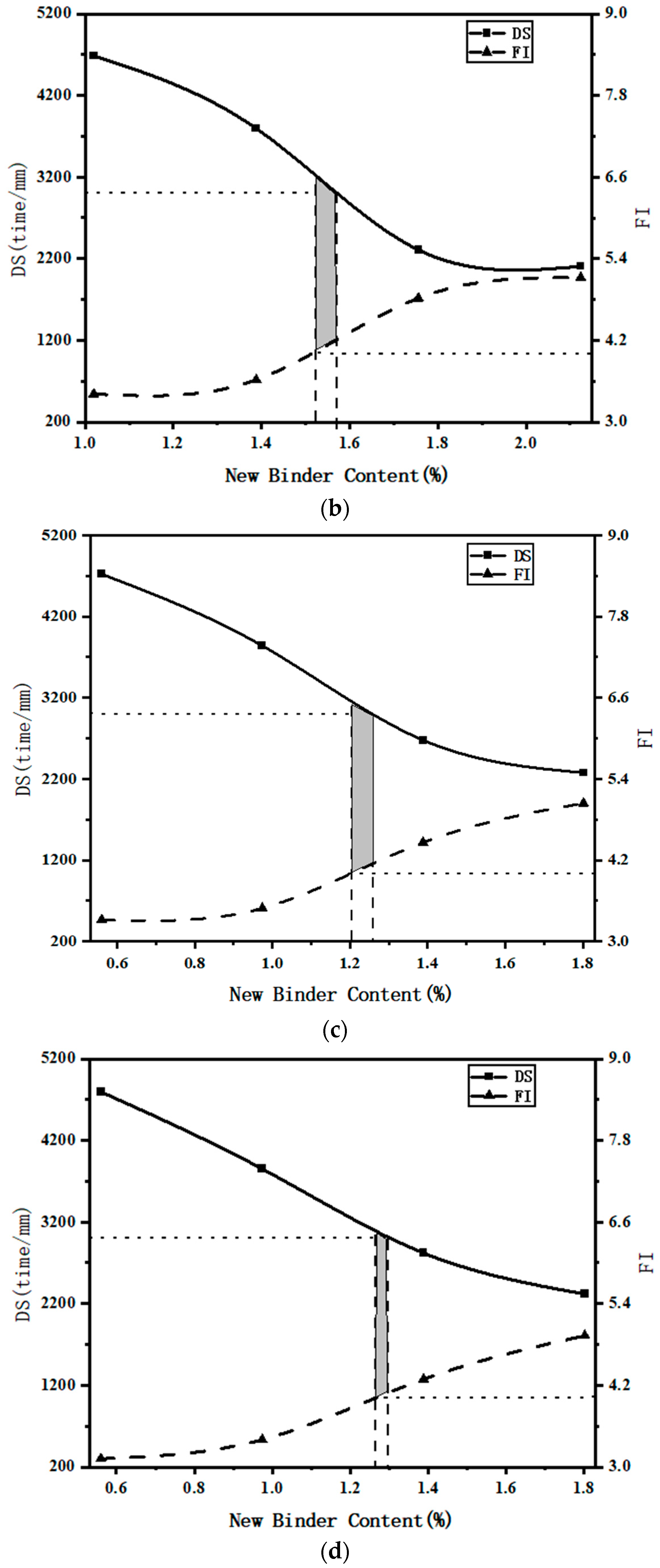

3.3. Determining the Optimal Binder Dosage

4. Conclusions and Recommendations

- (1)

- With the increase in the additional new binder content, the cracking resistance of the recycling asphalt mixture has improved. Significant differences exist between the recycling asphalt mixture with a high new binder content (such as 20% and 30%) and the control group (0%).

- (2)

- As the additional binder content increases, the rutting resistance of recycling asphalt mixtures significantly decreases. With each 10% increase in new binder content, the dynamic stability of recycling asphalt mixtures decreases by nearly 19%. Additionally, the addition of new binder can enhance the crack resistance of high-dose RAP mixtures, but it reduces their rutting resistance, especially at high levels of new binder addition. For instance, when an extra 20% of new binder is added, the crack resistance of recycling asphalt mixtures increases by 27%, but their rutting resistance decreases by 51%.

- (3)

- The dynamic stability and flexibility index of the mixture exhibit a strong linear relationship with the dosage of new binder, the aging degree of RAP, and the dosage of RAP (R2 = 0.954, 0.956). Among these factors, the dosage of new binder has a significant impact.

- (4)

- Based on the balanced design of rutting and cracking resistance, the optimal new binder content for the Group A recycling asphalt mixture is 1.52%; for Group B, it is 1.55%; for Group C, it is 1.23%; and for Group D, it is 1.28%. As the RAP content increases, the rejuvenated aged binder positively influences the performance, reducing the amount of new binder added. However, the unactivated aged binder also increases, requiring more binder to meet the demand for crack resistance, leading to an overall increase in binder usage. With deeper binder aging and decreased viscosity, additional new binder is needed to restore the crack resistance, further contributing to the overall increase in binder consumption.

- (5)

- Adding additional new binder to a high dose of hot in-place recycling asphalt mixtures effectively enhances their crack resistance. However, since the RAP used in this study was prepared in the laboratory, future work should consider linking laboratory design with field experiments to balance the design of actual construction site RAP. This will advance the performance balance design of in-place recycling asphalt mixtures with a high RAP content in the highway industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.Y. Experimental Study on Regeneration Method of Asphalt Pavement. Master’s Thesis, Dalian University of Technology, Dalian, China, 2011. [Google Scholar]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; No. FHWA-HRT-11-021; United States Federal Highway Administration, Office of Research, Development, and Technology: McLean, VA, USA, 2011.

- Sapkota, K.; Yaghoubi, E.; Wasantha, P.L.P.; Van Staden, R.; Fragomeni, S. Mechanical Characteristics and Durability of HMA Made of Recycled Aggregates. Sustainability 2023, 15, 5594. [Google Scholar] [CrossRef]

- Claine, P.J. Chemical composition of asphalt as related to asphalt durability: State of the Art. Transp. Res. Rec. 1984, 999, 13–30. [Google Scholar]

- Qian, R.Y.; Ji, X.W.; Shen, J.N. Experimental Study on Fatigue Life of In-Situ Thermally Recycled Asphalt Mixtures; Shanxi Construction: Xi’an, China, 2021; pp. 103–106. [Google Scholar]

- Qin, Y.C.; Huang, S.C.; Xu, J. Research on the integration of new and aged binder in plant-mixed warm recycled asphalt mixtures. Highw. Transp. Sci. Technol. 2015, 32, 24–28+52. [Google Scholar]

- Cheng, P.F.; Xiang, Y.J.; Kao, H.Y.; Zhou, Y.Z. Effect of waste asphalt mixture blending on mixing and compaction temperature of hot recycled modified asphalt mixture. Sci. Technol. Eng. 2018, 18, 273–279. [Google Scholar]

- Zhang, K.; Zheng, X.; Zhang, X. Experimental study on fatigue characteristics of hot recycled asphalt mixtures. Highw. Eng. 2017, 228–232. [Google Scholar]

- Li, L.; Yin, Y.X. Research on the integration of new and old materials and factory production parameters of thermally recycled SMA mixes with high proportion of RAP admixture. Highw. Eng. 2016, 41, 6. [Google Scholar]

- Li, M.X.; Wang, X.C. Effect of newly added asphalt grade on the strength and fatigue performance of high dosage RAP recycled mix. J. Chang. Univ. 2017, 37, 9–15. [Google Scholar]

- Zhang, W.D.; Dai, W.J.; Zhou, Y. Research on road performance of in-situ thermally regenerated mix. East China Highw. 2018, 6, 101–105. [Google Scholar]

- Ma, Y.; Polaczyk, P.; Hu, W.; Zhang, M.; Huang, B. Quantifying the effective mobilized RAP content during hot in-place recycling techniques. J. Clean. Prod. 2021, 314, 127953. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative evaluation of blending and diffusion in high RAP and RAS mixtures. Mater. Des. 2016, 89, 1161–1170. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X. Characterizing blending efficiency of plant produced asphalt paving mixtures containing high RAP. Constr. Build. Mater. 2016, 126, 172–178. [Google Scholar] [CrossRef]

- Lo Presti, D.; Vasconcelos, K.; Orešković, M.; Pires, G.M.; Bressi, S. On the degree of binder activity of reclaimed asphalt and degree of blending with recycling agents. Road Mater. Pavement Des. 2020, 21, 2071–2090. [Google Scholar] [CrossRef]

- Mccarthy, L.M.; Callans, J.; Quigley, R. Performance Specifications for Asphalt Mixtures, NCHRP SYNTHESIS 492; Transportation Research Board: Washington, DC, USA, 2016. [Google Scholar]

- Bayomy, F.; Mull-Aglan, M.A.; Abdo, A.A.; Santi, M.J. Evaluation of hot mix asphalt(HMA) fracture resistance using the critical strain energy release rate, Jc. In Proceedings of the Transportation Research Board 85th Annual Meeting, Washington, DC, USA, 22–26 January 2006. [Google Scholar]

- Buttlar, W.G.; Roque, R.; Kim, N. Accurate asphalt mixture tensile strength. In Proceedings of the Materials Engineering Conference, Washington, DC, USA, 10–14 November 1996. [Google Scholar]

- AASHTO322; Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- Molenaar, A.A.A.; Scarpas, A.; Liu, X.; Erkens, S.M.J.G. Semi-circular bending test; simple but useful. Asph. Paving Technol. Assoc. Asph. Paving Technol. 2002, 71, 794–815. [Google Scholar]

- Mitchell, M.R.; Link, R.E.; Huang, L.; Cao, K.; Zeng, M. Evaluation of semicircular bending test for determining tensile strength and stiffness modulus of asphalt mixtures. J. Test. Eval. 2009, 37, 122–128. [Google Scholar]

- Hofman, R.; Oosterbaan, B.; Erkens, S.M.J.G.; Van der Kooij, J. Semi-circular bending test to assess the resistance against crack growth. In Proceedings of the 6th International Rilem Symposium, Zurich, Switzerland, 14–16 April 2003; pp. 257–263. [Google Scholar]

- West, R.C.; Copeland, A. High RAP Asphalt Pavements: Japan practice-lessons learned. Natl. Asph. Pavement Assoc. 2015, 139, 62. [Google Scholar]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E.; Daniel, J.S.; Salari, S. Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- West, R.C.; Winkle, C.V.; Maghsoodloo, S.; Dixon, S. Relationships between simple asphalt mixture cracking tests using ndesign specimens and fatigue cracking at fhwa’s accelerated loading facility. Road Mater. Pavement Des. 2017, 86, 579–602. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Ozer, H.; Lambros, J.; Khatib, A.E.; Singhvi, P.; Khan, T.; Rivera-Perez, J.; Doll, B. Testing Protocols to Ensure Performance of High Asphalt Binder Replacement Mixes Using RAP and RAS; Illinois Center for Transportation Series No. 15-017; Illinois Center for Transportation: Urbana, IL, USA, 2015. [Google Scholar]

- Majidifard, H.; Jahangiri, B.; Rath, P.; Buttlar, W.G. Development of a balanced cracking index for asphalt mixtures tested in semi-circular bending with load-LLD measurements. Measurement 2021, 173, 108658. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 86, 549–577. [Google Scholar] [CrossRef]

- Alkuime, H.; Tousif, F.; Kassem, E.; Bayomy, F.M. Review and evaluation of intermediate temperature monotonic cracking performance assessment testing standards and indicators for asphalt mixes. Constr. Build. Mater. 2020, 263, 120121. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Al-Rousan, T.; Mujalli, R.O.; Alshraiedeh, K.A. Accounting for the effect of air voids on asphalt mix monotonic cracking testing results. J. Test. Eval. 2023, 51, 3662–3681. [Google Scholar] [CrossRef]

- Alkuime, H. Impact of testing and specimen configurations on monotonic high-temperature indirect tensile(high-IDT) rutting assessment test. Int. J. Pavement Res. Technol. 2023, 1–18. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Bayomy, F.M.; Nielsen, R.J. Development of a multi-stage semi-circle bending cyclic test to evaluate the cracking resistance of asphalt mixtures. Road Mater. Pavement Des. 2022, 23, 1–21. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E. Comprehensive evaluation of wheel-tracking rutting performance assessment tests. Int. J. Pavement Res. Technol. 2020, 13, 334–347. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Bayomy, F.M.S.; Nielsen, R.J. Evaluation and development of performance-engineered specifications for monotonic loading cracking performance assessment tests and indicators. J. Test. Eval. 2021, 49, 4151–4169. [Google Scholar] [CrossRef]

- Zhou, F.J.; Hu, S.; Scullion, T. Integrated Asphalt (Overlay) Mixture Design, Balancing Rutting and Cracking Requirements; FHWA/TX-06/0-5123-1; Texas Transportation Institute: Bryan, TX, USA, 2006. [Google Scholar]

- Feng, X.J.; Cha, X.D.; Wang, W.Y. Balanced design of asphalt mixtures based on rutting and cracking resistance. J. Wuhan Univ. Technol. 2011, 33, 5. [Google Scholar]

- Walubita, L.; Hu, X.D.; Scullion, T. Laboratory evaluation of two different HMA MixDesign Methods and Test Procedures. Asfaltosy Pavimentos Magazine, 4–16 June 2012; Edition 24. [Google Scholar]

- Zhou, F.J.; Hu, S.; Das, G.; Lee, R.; Scullion, T.; Claros, G. Successful high RAP mixes designed with balanced rutting and cracking requirements. Asph. Paving Technol. Assoc. Asph. Paving Technol.-Proc. Tech. Sess. 2012, 81, 477–505. [Google Scholar]

- JTG E20-2011; Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Communications Press: Beijing, China, 2011.

- Qian, R.Y.; Shen, J.N. Long-Term Performance Study of In-Place Hot Recycled Asphalt Mixtures. Master’s Thesis, Suzhou University of Science and Technology, Suzhou, China, 2021. [Google Scholar]

- Q/SJKG YH B2-001-2020; Jiangsu Provincial Department of Transportation. Standardization Guidelines for Highway Construction in Jiangsu Province. Pavement Engineering. People’s Communications Press: Beijing, China, 2012.

- Yu, D. Research on Balanced Design Method of Recycled Asphalt Mixture Based on Uniaxial Penetration Test. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2018. [Google Scholar]

- Luo, P. Research on Fracture Test Method and Evaluation Index of Asphalt Mixture Based on Semi-Circular Bending Test. Master’s Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Feng, D.; Cui, S.; Yi, J.; Chen, Z.; Qin, W. Research on Evaluation Index of Low-temperature Performance of Asphalt Mixture Based on SCB Test. China J. Highw. Transp. 2020, 33, 50–57. [Google Scholar]

- Chen, Z.; Zhu, Y.; Zhang, H.; Song, B. Medium Temperature Cracking Resistance of Recycled Asphalt Mixture Based on Fracture Test. J. Hefei Univ. Technol. 2017, 40, 1260–1263+1288. [Google Scholar]

- JTGF40-2004; Ministry of Transport of the People’s Republic of China. Technical Specification for Highway Asphalt Pavement Construction. People’s Communications Press: Beijing, China, 2005.

- NCHRP. Development of a Framework for Balanced Mix Design; National Center for Asphalt Technology at Auburn University: Auburn, AL, USA, 2018. [Google Scholar]

- Alkuime, H.; Kassem, E.; Alshraiedeh, K.A.; Bustanji, M.; Aleih, A.; Abukhamseh, F. Performance Assessment of Waste Cooking Oil-Modified Asphalt Mixtures. Appl. Sci. 2024, 14, 1228. [Google Scholar] [CrossRef]

- Cao, K.; Xu, W.; Chen, D. Study on High Temperature Performance of Silica/SBS Composite Modified Asphalt Mixture. New Build. Mater. 2018, 45, 55–58. [Google Scholar]

- Zhang, C.; Li, T.; Ding, W. Study on the Performance of High-viscosity and High-elastic Asphalt Mixture for Ultra-thin Wear-resistant Layer. Sci. Technol. Eng. 2023, 23, 12241–12249. [Google Scholar]

- Luo, L.; Ye, Q. Study on the Influence of Temperature and Asphalt Content Ratio on the Performance of Asphalt Mixtures for Ultra-thin Wear-resistant Layers. J. China Foreign Highw. 2013, 33, 242–244. [Google Scholar]

- Liu, J.X.; Tong, S.J. Study on the Factors Influencing the High-Temperature Performance of Asphalt Mixtures under Ultraviolet Aging. Highway 2016, 61, 201–205. [Google Scholar]

- Ma, T.; Wang, H.; Huang, X.; Wang, Z.; Xiao, F. Laboratory performance characteristics of high modulus asphalt mixture with high-content RAP. Constr. Build. Mater. 2015, 101, 975–982. [Google Scholar] [CrossRef]

- Busang, S.; Maina, J. Influence of aggregates properties on microstructural properties and mechanical performance of asphalt mixtures. Constr. Build. Mater. 2022, 318, 126002. [Google Scholar] [CrossRef]

- Sharma, A.; Naga, G.R.R.; Kumar, P.; Rai, P. Mix design, development, production and policies of recycled hot mix asphalt: A review. J. Traffic Transp. Eng. 2022, 9, 765–794. [Google Scholar] [CrossRef]

- Stimilli, A.; Canestrari, F.; Teymourpour, P.; Bahia, H.U. Low-temperature mechanics of hot recycled mixtures through Asphalt Thermal Cracking Analyzer (ATCA). Constr. Build. Mater. 2015, 84, 54–65. [Google Scholar] [CrossRef]

| Item | 25 °C Penetration Degree/(0.1 mm) | Softening Point/°C | 5 °C Ductility/cm | Residue after RTFOT | ||

|---|---|---|---|---|---|---|

| Mass Change/% | Penetration Ratio/% | 5 °C Residual Ductility/cm | ||||

| Specification | 30–70 | >65 | >20 | ≤±1.0 | ≥65 | ≥15 |

| Test results | 54 | 78 | 36 | 0.22 | 73 | 25 |

| Test methods | T0604 | T0606 | T0605 | T0609 | T0604 | T0605 |

| Sieve Size/mm | Percentage Passing/%. | ||||

|---|---|---|---|---|---|

| 10–15 mm | 5–10 mm | 3–5 mm | 0–3 mm | Mineral Powder | |

| 16 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| 13.2 | 62.8 | 100.0 | 100.0 | 100.0 | 100.0 |

| 9.5 | 11.5 | 96.6 | 100.0 | 100.0 | 100.0 |

| 4.75 | 0.2 | 7.1 | 93.6 | 100.0 | 100.0 |

| 2.36 | 0.2 | 0.2 | 5.5 | 83.5 | 100.0 |

| 1.18 | 0.2 | 0.2 | 1.6 | 62.1 | 100.0 |

| 0.6 | 0.2 | 0.2 | 1.1 | 41.7 | 100.0 |

| 0.3 | 0.2 | 0.2 | 1.1 | 27.8 | 100.0 |

| 0.15 | 0.2 | 0.2 | 1.1 | 20.0 | 100.0 |

| 0.075 | 0.2 | 0.2 | 1.1 | 13.8 | 98.3 |

| Test Item | Test Results | Technical Requirement |

|---|---|---|

| 60 °C viscosity/(mm2·s−1) | 59.2 | 50~175 |

| Flash point/°C | 242 | ≥220 |

| Saturated fraction/% | 17.31 | ≤30 |

| 25 °C density/(g·cm−3) | 1.017 | Actual measurement |

| Film oven viscosity ratio | 1.22 | ≤3 |

| Quality change in film oven/% | −1.174 | ≤4, ≥−4 |

| Appearance | Brown-black viscous liquid | |

| RAP Content | 80% | 90% | |

|---|---|---|---|

| Degree of Aging | |||

| 5 Days | A | C | |

| 10 Days | B | D | |

| Estimated Total Binder Content/% | RAP Content/% | Aged Binder Content/% | Estimated New Binder Content/% | New Binder Addition Content/% |

|---|---|---|---|---|

| 4.7 | 80 | 4.6 | 1.02 | 1.02 |

| 1.388 | ||||

| 1.756 | ||||

| 2.124 | ||||

| 4.7 | 90 | 4.6 | 0.56 | 0.56 |

| 0.974 | ||||

| 1.388 | ||||

| 1.802 |

| Model | B | p-Value (P) | Variance Inflation Factor (VIF) | R2 |

|---|---|---|---|---|

| Constant | 2329.425 | / | / | 0.954 |

| The amount of new binder | −88.395 | 0.001 | 1.000 | |

| The degree of RAP aging | 19.350 | 0.460 | 1.000 | |

| The content of RAP | 2515.000 | 0.071 | 1.000 |

| Model | B | p-Value (P) | Variance Inflation Factor (VIF) | R2 |

|---|---|---|---|---|

| Constant | 5.557 | / | / | 0.956 |

| The amount of new binder | 0.061 | 0.001 | 1.000 | |

| The degree of RAP aging | −0.031 | 0.094 | 1.000 | |

| The content of RAP | −2.475 | 0.013 | 1.000 |

| RAP Content/% | Degree of Aging/Days | New Binder Content When FI = 4/% | New Binder Content When DS = 3000 times/mm/% | Optimal New Binder Content/% | Total Binder Content/% |

|---|---|---|---|---|---|

| 80 | 5 | 1.49 | 1.54 | 1.52 | 5.20 |

| 80 | 10 | 1.52 | 1.57 | 1.55 | 5.23 |

| 90 | 5 | 1.20 | 1.26 | 1.23 | 5.37 |

| 90 | 10 | 1.26 | 1.30 | 1.28 | 5.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Shen, J.; Wang, W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials 2024, 17, 2096. https://doi.org/10.3390/ma17092096

Jiang L, Shen J, Wang W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials. 2024; 17(9):2096. https://doi.org/10.3390/ma17092096

Chicago/Turabian StyleJiang, Lei, Junan Shen, and Wei Wang. 2024. "Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design" Materials 17, no. 9: 2096. https://doi.org/10.3390/ma17092096

APA StyleJiang, L., Shen, J., & Wang, W. (2024). Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials, 17(9), 2096. https://doi.org/10.3390/ma17092096