Progress and Challenges of Additive Manufacturing of Tungsten and Alloys as Plasma-Facing Materials

Abstract

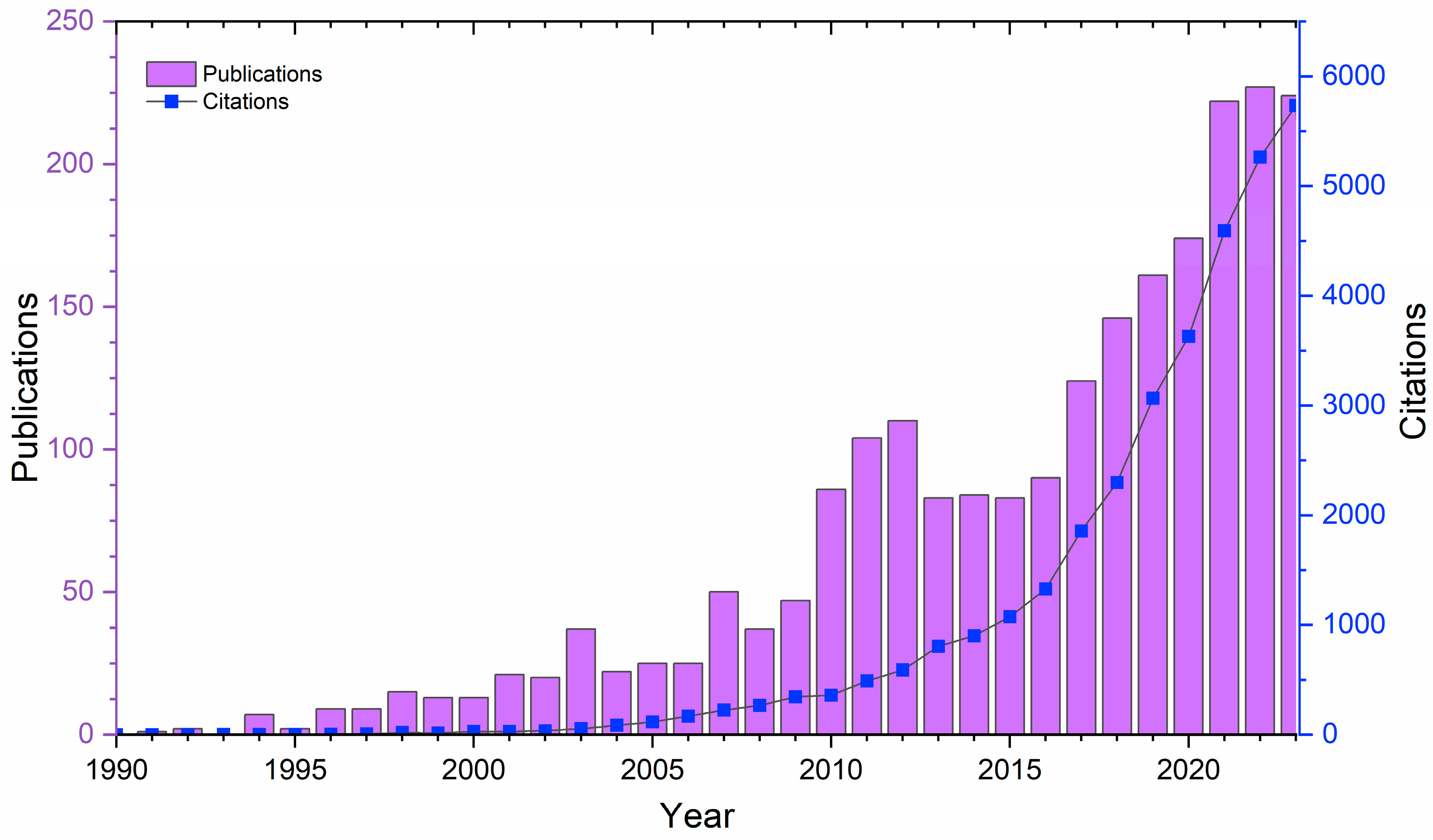

:1. Introduction

Challenges in Manufacturing Tungsten as a PFM

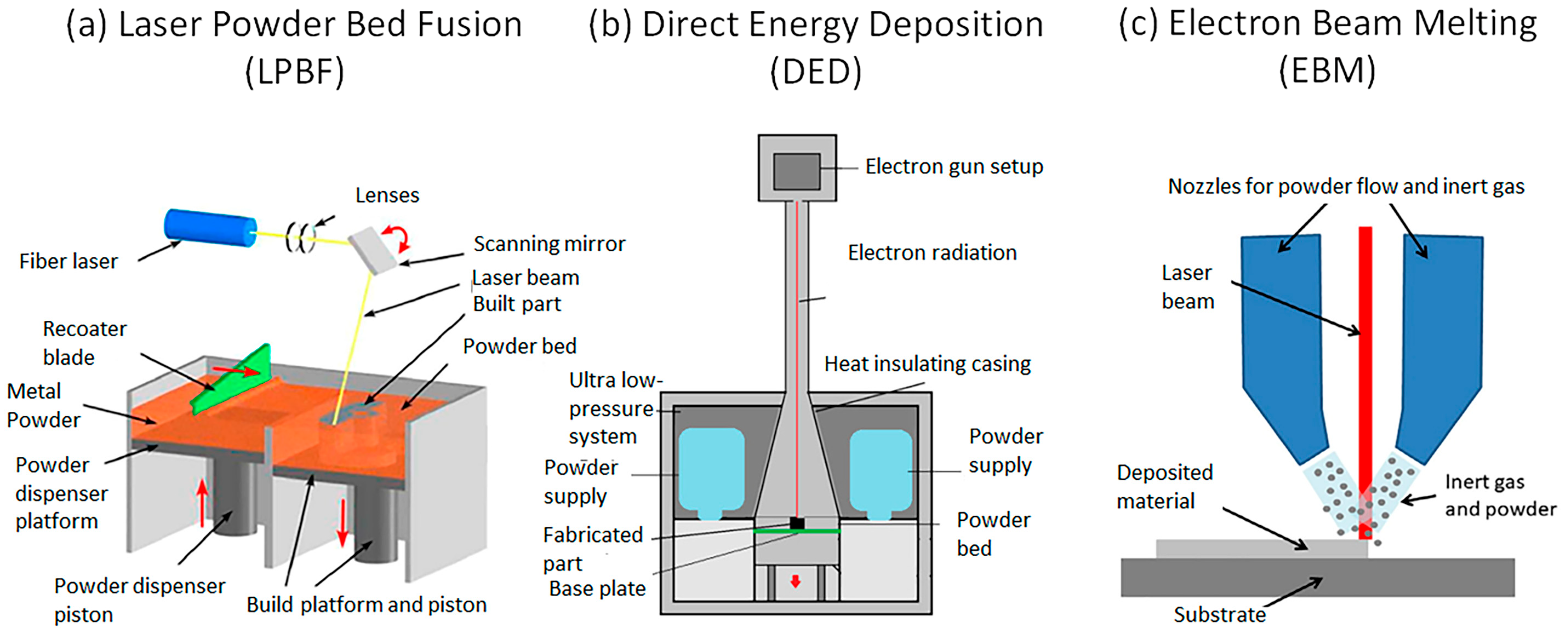

2. LPBF, DED, and EBM Techniques for AM of W

2.1. Raw Material Characteristics

2.2. LPBF

2.3. EBM

2.4. DED

3. Characterization, Properties, and Performance Evaluation of AM W and Alloys

3.1. Microstructures of LPBF

3.1.1. Alloying

3.1.2. Parameter Alterations

3.1.3. Remelting and Substrate Heating

3.2. Microstructures of EBM

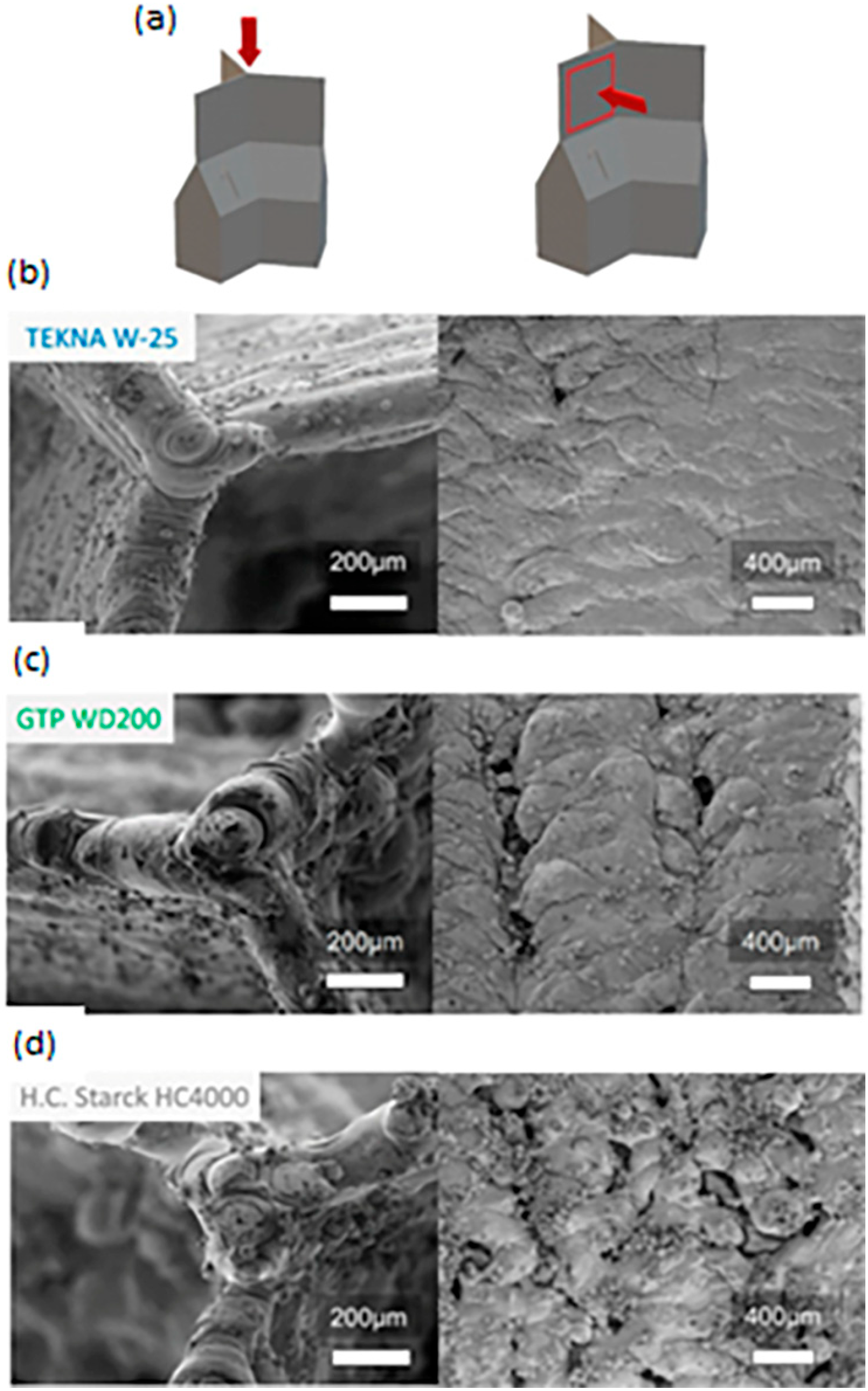

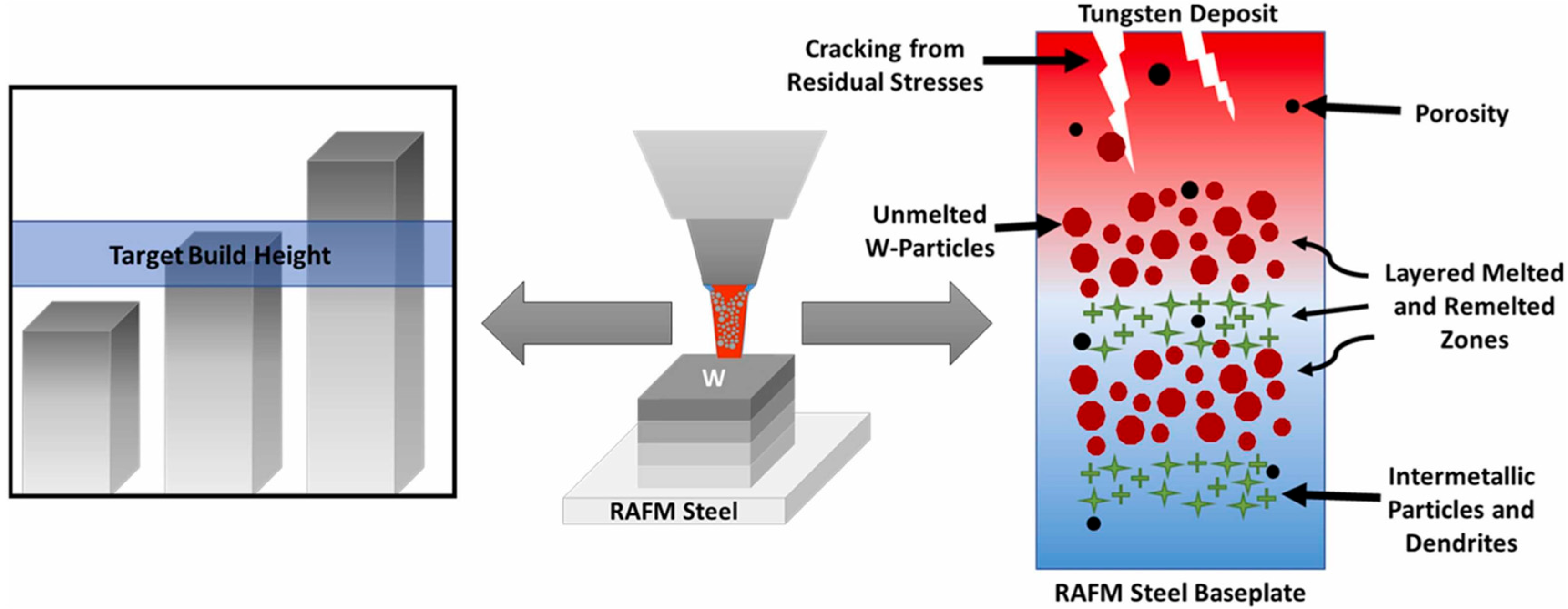

3.3. Microstructures of DED

3.4. Thermal Properties and Performance

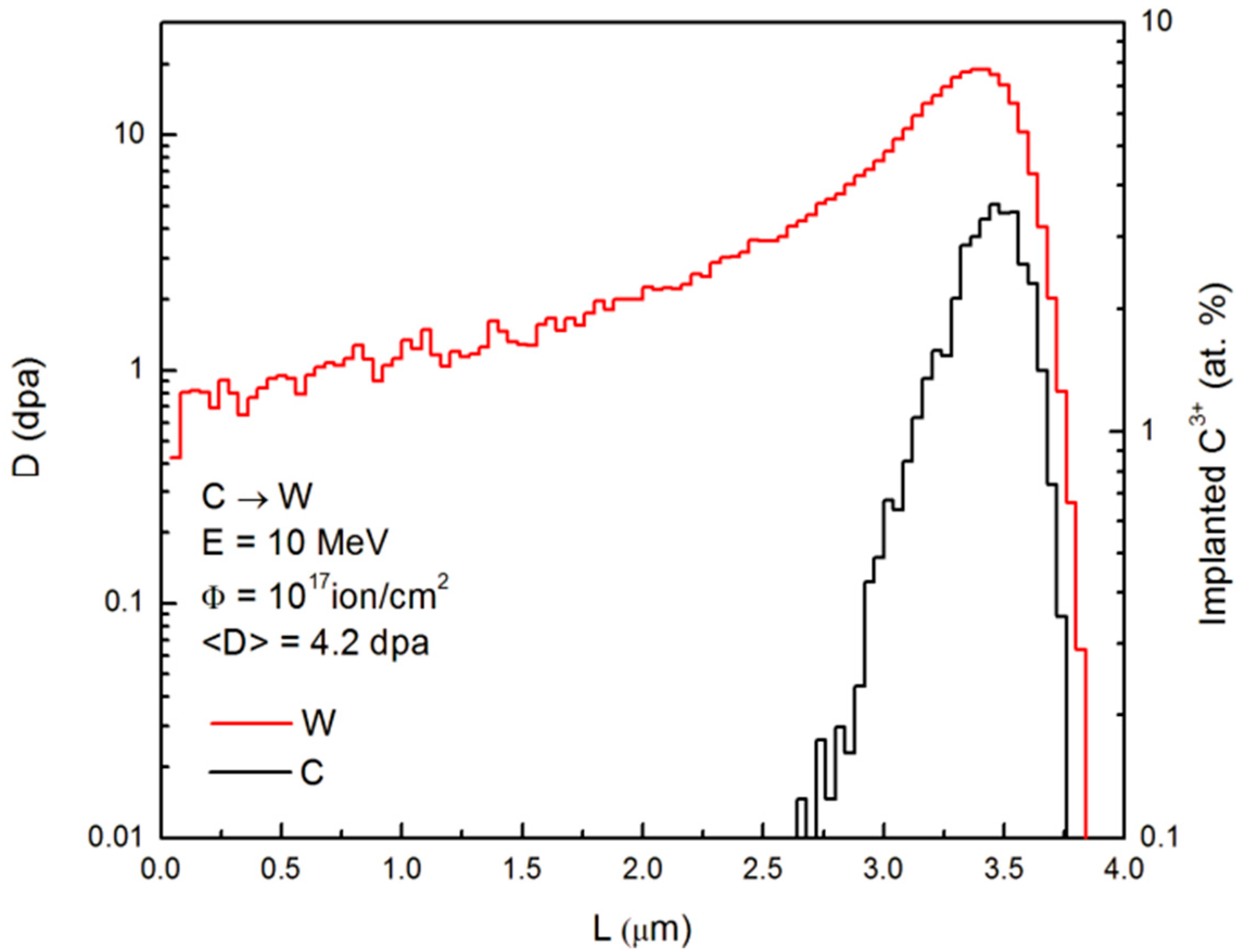

4. Irradiation Effects of W as PFM

4.1. Neutron and Ion Irradiation Effects on W

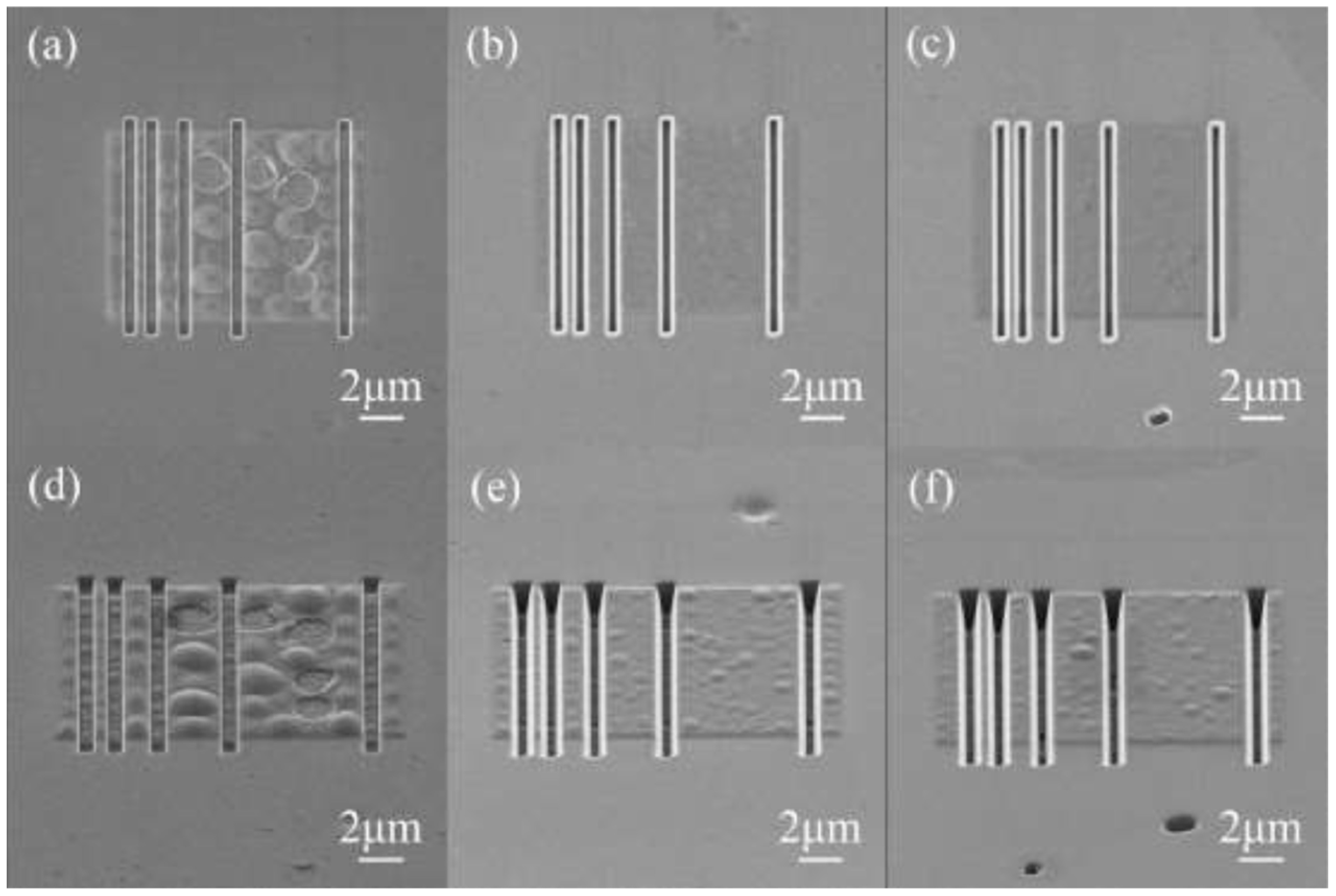

4.2. Blistering

4.3. Transmutation

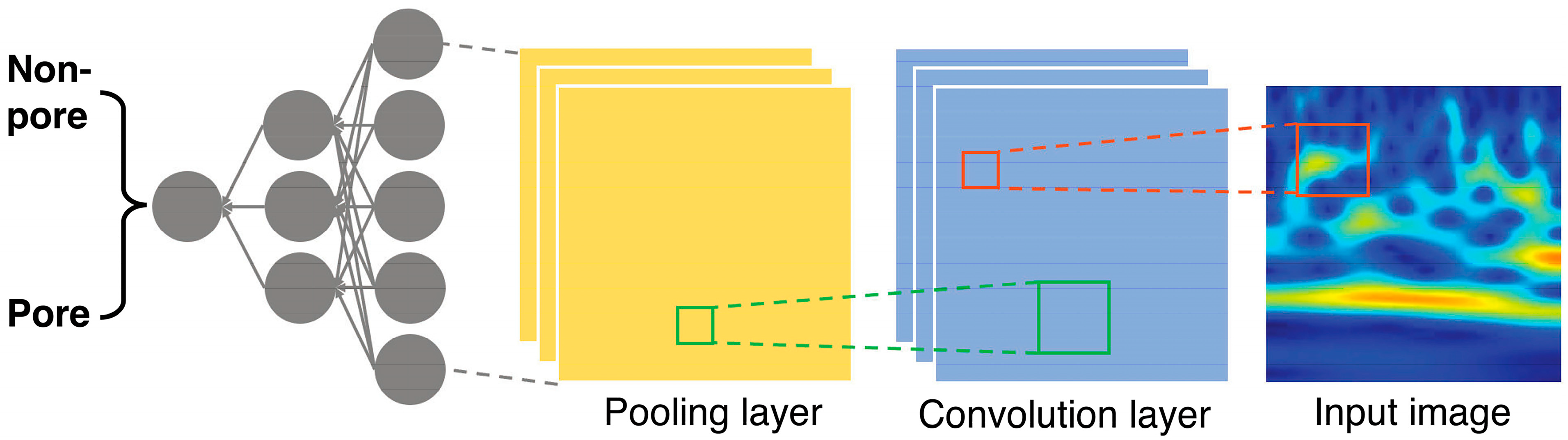

5. ML and Modeling of AM-Prepared Materials

6. Gaps and Recommendations

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| BCC | Body-Centered Cubic |

| D | Deuterium |

| DBTT | Ductile to Brittle Transition Temperature |

| DED | Direct Energy Deposition |

| DEMO | Demonstration Power Plant |

| DOE | Department of Energy |

| DL | Deep Learning |

| dpa | displacements per atom |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| EBM | Electron Beam Melting |

| EBSD | Electron Backscatter Diffraction |

| Fe | Iron |

| FEA | finite element analysis |

| Hf | Hafnium |

| He | Helium |

| H | Hydrogen |

| HCP | Hexagonal Close-Packed |

| IPF | Inverse Pole Figure |

| ITER | International Thermonuclear Experimental Reactor |

| KAM | Kernel Average Misorientation |

| LPBF | Laser Powder Bed Fusion |

| Li | Lithium |

| ML | Machine Learning |

| MD | Molecular Dynamics |

| Mo | Molybdenum |

| Nb | Niobium |

| N | Nitrogen |

| Ni | Nickle |

| Os | Osmium |

| O | Oxygen |

| P | Phosphorus |

| PALS | Positron Annihilation Lifetime Spectroscopy |

| PFC | Plasma-Facing Components |

| PFM | Plasma-Facing Materials |

| PKA | Primary Knock-On Atoms |

| PSD | Particle Size Distribution |

| Re | Rhenium |

| Ru | Ruthenium |

| SPS | Spark Plasma Sintering |

| Ta | Tantalum |

| TF | Toroidal Field |

| Tc | Technetium |

| Ti | Titanium |

| T | Tritium |

| V | Vanadium |

| W | Tungsten |

| XPS | Zirconium |

| Z | Nuclear Charge Number |

| Zr | Zirconium |

References

- Zhang, T.; Xie, Z.; Liu, C.; Xiong, Y.; Zhang, T.; Xie, Z.; Liu, C.; Xiong, Y. The Tungsten-Based Plasma-Facing Materials. In Fusion Energy; IntechOpen: London, UK, 2019. [Google Scholar]

- Khripunov, B.I.; Koidan, V.S.; Ryazanov, A.I.; Gureev, V.M.; Kornienko, S.N.; Latushkin, S.T.; Rupyshev, A.S.; Semenov, E.V.; Kulikauskas, V.S.; Zatekin, V.V. Study of Tungsten as a Plasma-facing Material for a Fusion Reactor. Phys. Procedia 2015, 71, 63–67. [Google Scholar] [CrossRef]

- Müller, A.V.; Schlick, G.; Neu, R.; Anstätt, C.; Klimkait, T.; Lee, J.; Pascher, B.; Schmitt, M.; Seidel, C. Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 °C. Nucl. Mater. Energy 2019, 19, 184–188. [Google Scholar] [CrossRef]

- Knaster, J.; Möslang, A.; Muroga, T. Materials research for fusion. Nat. Phys. 2016, 12, 424–434. [Google Scholar] [CrossRef]

- Linsmeier, C.; Rieth, M.; Aktaa, J.; Chikada, T.; Hoffmann, A.; Hoffmann, J.; Houben, A.; Kurishita, H.; Jin, X.; Li, M.; et al. Development of advanced high heat flux and plasma-facing materials. Nucl. Fusion 2017, 57, 092007. [Google Scholar] [CrossRef]

- Müller, A.V.; Dorow-Gerspach, D.; Balden, M.; Binder, M.; Buschmann, B.; Curzadd, B.; Loewenhoff, T.; Neu, R.; Schlick, G.; You, J.H. Progress in additive manufacturing of pure tungsten for plasma-facing component applications. J. Nucl. Mater. 2022, 566, 153760. [Google Scholar] [CrossRef]

- You, J.H.; Mazzone, G.; Visca, E.; Greuner, H.; Fursdon, M.; Addab, Y.; Bachmann, C.; Barrett, T.; Bonavolontà, U.; Böswirth, B.; et al. Divertor of the European DEMO: Engineering and technologies for power exhaust. Fusion Eng. Des. 2022, 175, 113010. [Google Scholar] [CrossRef]

- Davis, J.W.; Barabash, V.R.; Makhankov, A.; Plöchl, L.; Slattery, K.T. Assessment of tungsten for use in the ITER plasma facing components. J. Nucl. Mater. 1998, 258–263 Pt 1A, 308–312. [Google Scholar] [CrossRef]

- Ueda, Y.; Coenen, J.W.; De Temmerman, G.; Doerner, R.P.; Linke, J.; Philipps, V.; Tsitrone, E. Research status and issues of tungsten plasma facing materials for ITER and beyond. Fusion Eng. Des. 2014, 89, 901–906. [Google Scholar] [CrossRef]

- Gavish Segev, I.; Yahel, E.; Silverman, I.; Perry, A.; Weismann, L.; Makov, G. Hydrogen blister formation in single crystal and polycrystalline tungsten irradiated by MeV protons. J. Nucl. Mater. 2019, 513, 209–220. [Google Scholar] [CrossRef]

- Muller, A.V.; Ewert, D.; Galatanu, A.; Milwich, M.; Neu, R.; Pastor, J.Y.; Siefken, U.; Tejado, E.; You, J.H. Melt infiltrated tungsten–copper composites as advanced heat sink materials for plasma facing components of future nuclear fusion devices. Fusion Eng. Des. 2017, 124, 455–459. [Google Scholar] [CrossRef]

- You, J.H. Copper matrix composites as heat sink materials for water-cooled divertor target. Nucl. Mater. Energy 2015, 5, 7–18. [Google Scholar] [CrossRef]

- You, J.H.; Visca, E.; Barrett, T.; Böswirth, B.; Crescenzi, F.; Domptail, F.; Fursdon, M.; Gallay, F.; Ghidersa, B.E.; Greuner, H.; et al. European divertor target concepts for DEMO: Design rationales and high heat flux performance. Nucl. Mater. Energy 2018, 16, 1–11. [Google Scholar] [CrossRef]

- Gludovatz, B.; Wurster, S.; Weingärtner, T.; Hoffmann, A.; Pippan, R. Influence of impurities on the fracture behaviour of tungsten. Philos. Mag. 2011, 91, 3006–3020. [Google Scholar] [CrossRef]

- Funkenbusch, A.W.; Bacon, F.; Lee, D. The influence of microstructure on fracture of drawn tungsten wire. Metall. Trans. A 1979, 10, 1085–1091. [Google Scholar] [CrossRef]

- Setyawan, W.; Kurtz, R.J. Effects of transition metals on the grain boundary cohesion in tungsten. Scr. Mater. 2012, 66, 558–561. [Google Scholar] [CrossRef]

- Snead, L.L.; Hoelzer, D.T.; Rieth, M.; Nemith, A.A.N. Chapter 13—Refractory Alloys: Vanadium, Niobium, Molybdenum, Tungsten. In Structural Alloys for Nuclear Energy Applications; Odette, G.R., Zinkle, S.J., Eds.; Elsevier: Boston, MA, USA, 2019; pp. 585–640. [Google Scholar]

- Omole, S.; Lunt, A.; Kirk, S.; Shokrani, A. Advanced Processing and Machining of Tungsten and Its Alloys. J. Manuf. Mater. Process. 2022, 6, 15. [Google Scholar] [CrossRef]

- Vrancken, B.; Ganeriwala, R.K.; Matthews, M.J. Analysis of laser-induced microcracking in tungsten under additive manufacturing conditions: Experiment and simulation. Acta Mater. 2020, 194, 464–472. [Google Scholar] [CrossRef]

- Antusch, S.; Armstrong, D.E.J.; Britton, T.B.; Commin, L.; Gibson, J.S.K.L.; Greuner, H.; Hoffmann, J.; Knabl, W.; Pintsuk, G.; Rieth, M.; et al. Mechanical and microstructural investigations of tungsten and doped tungsten materials produced via powder injection molding. Nucl. Mater. Energy 2015, 3–4, 22–31. [Google Scholar] [CrossRef]

- Jaffee, R.I. Structural Considerations in Developing Refractory Metal Alloys; Hahn, G.T., Ed.; Defense Metals Information Center, Battelle Memorial Institute: Columbus, OH, USA, 1963. [Google Scholar]

- Aguirre, M.V.; Martín, A.; Pastor, J.Y.; Llorca, J.; Monge, M.A.; Pareja, R. Mechanical Behavior of W-Y2O3 and W-Ti Alloys from 25 °C to 1000 °C. Metall. Mater. Trans. A 2009, 40, 2283–2290. [Google Scholar] [CrossRef]

- Yin, C.; Terentyev, D.; Zhang, T.; Nogami, S.; Antusch, S.; Chang, C.-C.; Petrov, R.H.; Pardoen, T. Ductile to brittle transition temperature of advanced tungsten alloys for nuclear fusion applications deduced by miniaturized three-point bending tests. Int. J. Refract. Met. Hard Mater. 2021, 95, 105464. [Google Scholar] [CrossRef]

- Ellis, E.A.I.; Sprayberry, M.A.; Ledford, C.; Hankwitz, J.P.; Kirka, M.M.; Rock, C.D.; Horn, T.J.; Katoh, Y.; Dehoff, R.R. Processing of tungsten through electron beam melting. J. Nucl. Mater. 2021, 555, 153041. [Google Scholar] [CrossRef]

- Seeger, A. Peierls barriers, kinks, and flow stress: Recent progress. Int. J. Mater. Res. 2002, 93, 760–777. [Google Scholar] [CrossRef]

- Talignani, A.; Seede, R.; Whitt, A.; Zheng, S.; Ye, J.; Karaman, I.; Kirka, M.M.; Katoh, Y.; Wang, Y.M. A review on additive manufacturing of refractory tungsten and tungsten alloys. Addit. Manuf. 2022, 58, 103009. [Google Scholar] [CrossRef]

- Guo, M.; Gu, D.; Xi, L.; Zhang, H.; Zhang, J.; Yang, J.; Wang, R. Selective laser melting additive manufacturing of pure tungsten: Role of volumetric energy density on densification, microstructure and mechanical properties. Int. J. Refract. Met. Hard Mater. 2019, 84, 105025. [Google Scholar] [CrossRef]

- Rebesan, P.; Bonesso, M.; Gennari, C.; Dima, R.; Pepato, A.; Vedani, M.; Rebesan, P. Tungsten Fabricated by Laser Powder Bed Fusion. BHM Berg- Hüttenmännische Mon. 2021, 166, 263–269. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y.; Guan, K.; Wang, Z.; Ma, Z. Pure tungsten and oxide dispersion strengthened tungsten manufactured by selective laser melting: Microstructure and cracking mechanism. Addit. Manuf. 2020, 36, 101579. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Hao, T.; Zhou, Y.; Wang, X.P.; Fang, Q.F.; Liu, C.S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening. J. Nucl. Mater. 2014, 451, 35–39. [Google Scholar] [CrossRef]

- Edstrom, C.M.; Phillips, A.G.; Johnson, L.D.; Corle, R.R. Literature on Fabrication of Tungsten for Application in Pyrochemical Processing of Spent Nuclear Fuels; Office of Scientific and Technical Information (OSTI): Oak Ridge, TN, USA, 1980. [Google Scholar]

- Clarrivate. Web of Science Database; Clarivate: Philadelphia, PA, USA, 1997. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I.; du Plessis, A.; MacDonald, E. Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Iveković, A.; Omidvari, N.; Vrancken, B.; Lietaert, K.; Thijs, L.; Vanmeensel, K.; Vleugels, J.; Kruth, J.P. Selective laser melting of tungsten and tungsten alloys. Int. J. Refract. Met. Hard Mater. 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Wang, D.; Yu, C.; Zhou, X.; Ma, J.; Liu, W.; Shen, Z. Dense Pure Tungsten Fabricated by Selective Laser Melting. Appl. Sci. 2017, 7, 430. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Attard, B.; Zhang, P.; Kuang, T. Selective laser melting of high-performance pure tungsten: Parameter design, densification behavior and mechanical properties. Sci. Technol. Adv. Mater. 2018, 19, 370–380. [Google Scholar] [CrossRef]

- Morcos, P.; Elwany, A.; Karaman, I.; Arróyave, R. Review: Additive manufacturing of pure tungsten and tungsten-based alloys. J. Mater. Sci. 2022, 57, 9769–9806. [Google Scholar] [CrossRef]

- Doddapaneni, V.V.K.; Lee, K.; Aysal, H.E.; Paul, B.K.; Pasebani, S.; Sierros, K.A.; Okwudire, C.E.; Chang, C.-H. A Review on Progress, Challenges, and Prospects of Material Jetting of Copper and Tungsten. Nanomaterials 2023, 13, 2303. [Google Scholar] [CrossRef] [PubMed]

- Sibisi, P.N.; Popoola, A.P.I.; Arthur, N.K.K.; Pityana, S.L. Review on direct metal laser deposition manufacturing technology for the Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 1163–1178. [Google Scholar] [CrossRef]

- Seyam, M.S.; Koshy, P.; Elbestawi, M.A. Laser Powder Bed Fusion of Unalloyed Tungsten: A Review of Process, Structure, and Properties Relationships. Metals 2022, 12, 274. [Google Scholar] [CrossRef]

- Stawovy, M.T.; Myers, K.; Ohm, S. Binder jet printing of tungsten heavy alloy. Int. J. Refract. Met. Hard Mater. 2019, 83, 104981. [Google Scholar] [CrossRef]

- Robin, I.K.; Gräning, T.; Yang, Y.; Katoh, Y.; Zinkle, S.J. Microstructure and thermal stability of a structurally graded tungsten and reduced activation ferritic/martensitic steel joint. J. Mater. Res. Technol. 2024, 30, 3663–3674. [Google Scholar] [CrossRef]

- Gräning, T.; Tan, L.; Robin, I.; Katoh, Y.; Yang, Y. A novel design of transitional layer structure between reduced activation ferritic martensitic steels and tungsten for plasma facing materials. J. Mater. Res. Technol. 2023, 24, 4285–4299. [Google Scholar] [CrossRef]

- Ledford, C.; Fernandez-Zelaia, P.; Graening, T.; Campbell, Q.; Rojas, J.O.; Rossy, A.M.; Kato, Y.; Kirka, M.M. Microstructure and high temperature properties of tungsten processed via electron beam melting additive manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 113, 106148. [Google Scholar] [CrossRef]

- Martinho, P.G. Rapid manufacturing and tooling. In Design and Manufacturing of Plastics Products: Integrating Traditional Methods with Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 381–456. [Google Scholar]

- Sing, S.L.; Tey, C.F.; Tan, J.H.K.; Huang, S.; Yeong, W.Y. 2—3D printing of metals in rapid prototyping of biomaterials: Techniques in additive manufacturing. In Rapid Prototyping of Biomaterials, 2nd ed.; Narayan, R., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 17–40. [Google Scholar]

- Kumar, S.A.; Prasad, R.V.S. Chapter 2—Basic principles of additive manufacturing: Different additive manufacturing technologies. In Additive Manufacturing; Manjaiah, M., Raghavendra, K., Balashanmugam, N., Davim, J.P., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 17–35. [Google Scholar]

- Field, A.C.; Carter, L.N.; Adkins, N.J.E.; Attallah, M.M.; Gorley, M.J.; Strangwood, M. The Effect of Powder Characteristics on Build Quality of High-Purity Tungsten Produced via Laser Powder Bed Fusion (LPBF). Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 1367–1378. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling phenomena in selective laser melted tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Zi, X.; Chen, C.; Wang, X.; Wang, P.; Zhang, X.; Zhou, K. Spheroidisation of tungsten powder by radio frequency plasma for selective laser melting. Mater. Sci. Technol. 2017, 34, 735–742. [Google Scholar] [CrossRef]

- Kapranos, P.; Brabazon, D.; Midson, S.P.; Naher, S.; Haga, T. Advanced Casting Methodologies: Inert Environment Vacuum Casting and Solidification, Die Casting, Compocasting, and Roll Casting. Compr. Mater. Process. 2014, 5, 3–37. [Google Scholar]

- Zhang, Y.; Lee, W.H.; Wu, L.; Meng, L.; Jung, Y.G.; Zhang, J. Multiscale multiphysics modeling of laser powder bed fusion process. In Additive Manufacturing: Materials, Processes, Quantifications and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 215–259. [Google Scholar]

- Kumar, S. Selective Laser Sintering/Melting. Compr. Mater. Process. 2014, 10, 93–134. [Google Scholar]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Liu, S.Y.; Li, H.Q.; Qin, C.X.; Zong, R.; Fang, X.Y. The effect of energy density on texture and mechanical anisotropy in selective laser melted Inconel 718. Mater. Des. 2020, 191, 108642. [Google Scholar]

- Wang, D.; Wang, Z.; Li, K.; Ma, J.; Liu, W.; Shen, Z. Cracking in laser additively manufactured W: Initiation mechanism and a suppression approach by alloying. Mater. Des. 2019, 162, 384–393. [Google Scholar] [CrossRef]

- Sidambe, A.T.; Tian, Y.; Prangnell, P.B.; Fox, P. Effect of processing parameters on the densification, microstructure and crystallographic texture during the laser powder bed fusion of pure tungsten. Int. J. Refract. Met. Hard Mater. 2019, 78, 254–263. [Google Scholar] [CrossRef]

- Wen, S.; Wang, C.; Zhou, Y.; Duan, L.; Wei, Q.; Yang, S.; Shi, Y. High-density tungsten fabricated by selective laser melting: Densification, microstructure, mechanical and thermal performance. Opt. Laser Technol. 2019, 116, 128–138. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhang, P.; Tan, C.; Dong, D.; Ma, W.; Yu, K. Selective Laser Melting and Remelting of Pure Tungsten. Adv. Eng. Mater. 2020, 22, 1901352. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Stucker, B. Additive Manufacturing Technologies; Springer Publication: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Kirka, M.M.; Unocic, K.A.; Raghavan, N.; Medina, F.; Dehoff, R.R.; Babu, S.S. Microstructure Development in Electron Beam-Melted Inconel 718 and Associated Tensile Properties. JOM 2016, 68, 1012–1020. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kirka, M.M.; Ferguson, J.; Paquit, V.C. Correlations of cracking with scan strategy and build geometry in electron beam powder bed additive manufacturing. Addit. Manuf. 2020, 32, 101031. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural Control of Additively Manufactured Metallic Materials. Annu. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Xue, J.; Feng, Z.; Tang, J.; Tang, C.; Zhao, Z. Selective laser melting additive manufacturing of tungsten with niobium alloying: Microstructure and suppression mechanism of microcracks. J. Alloys Compd. 2021, 874, 159879. [Google Scholar] [CrossRef]

- Dutta, B. Directed Energy Deposition (DED) Technology. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 66–84. [Google Scholar]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Naesstroem, H.; Brueckner, F.; Kaplan, A.F.H. Blown powder directed energy deposition on various substrate conditions. J. Manuf. Process. 2022, 73, 660–667. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Vrancken, B.; Cain, V.; Knutsen, R.; Van Humbeeck, J. Residual stress via the contour method in compact tension specimens produced via selective laser melting. Scr. Mater. 2014, 87, 29–32. [Google Scholar] [CrossRef]

- Vrancken, B.; King, W.E.; Matthews, M.J. In-situ characterization of tungsten microcracking in Selective Laser Melting. Procedia CIRP 2018, 74, 107–110. [Google Scholar] [CrossRef]

- Rindt, P.; Mata González, J.; Hoogerhuis, P.; Van Den Bosch, P.; Van Maris, M.; Terentyev, D.; Yin, C.; Wirtz, M.; Lopes Cardozo, N.J.; Van Dommelen, J.A.W.; et al. Using 3D-printed tungsten to optimize liquid metal divertor targets for flow and thermal stresses. Nucl. Fusion 2019, 59, 054001. [Google Scholar] [CrossRef]

- Nie, B.; Yang, L.; Huang, H.; Bai, S.; Wan, P.; Liu, J. Femtosecond laser additive manufacturing of iron and tungsten parts. Appl. Phys. A 2015, 119, 1075–1080. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Wang, Y.; Xing, L.; Yu, C.; Liu, H.; Ma, J.; Liu, W.; Shen, Z. The effect of hot isostatic pressing on thermal conductivity of additively manufactured pure tungsten. Int. J. Refract. Met. Hard Mater. 2020, 87, 105135. [Google Scholar] [CrossRef]

- Saraf, L. Kernel Average Misorientation Confidence Index Correlation from FIB Sliced Ni-Fe-Cr alloy Surface. Microsc. Microanal. 2011, 17, 2011. [Google Scholar] [CrossRef]

- Li, K.; Wang, D.; Xing, L.; Wang, Y.; Yu, C.; Chen, J.; Zhang, T.; Ma, J.; Liu, W.; Shen, Z. Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix. Int. J. Refract. Met. Hard Mater. 2019, 79, 158–163. [Google Scholar] [CrossRef]

- Braun, J.; Kaserer, L.; Stajkovic, J.; Leitz, K.H.; Tabernig, B.; Singer, P.; Leibenguth, P.; Gspan, C.; Kestler, H.; Leichtfried, G. Molybdenum and tungsten manufactured by selective laser melting: Analysis of defect structure and solidification mechanisms. Int. J. Refract. Met. Hard Mater. 2019, 84, 104999. [Google Scholar] [CrossRef]

- Stephens, J. Review of Deformation Behavior of Tungsten at Temperature Less than 0.2 Absolute Melting Temperature; National Aeronautics and Space Administration: Washington, DC, USA, 1972. [Google Scholar]

- Kim, S.; Kwon, T.; Kim, S.; Song, S.H.; Lee, D. Effect of nanopowder preparation method on the sintering behavior and microstructure of MoW alloy. Int. J. Refract. Met. Hard Mater. 2024, 118, 106491. [Google Scholar] [CrossRef]

- Yamamoto, T.; Hara, M.; Hatano, Y. Cracking behavior and microstructural, mechanical and thermal characteristics of tungsten–rhenium binary alloys fabricated by laser powder bed fusion. Int. J. Refract. Met. Hard Mater. 2021, 100, 105651. [Google Scholar] [CrossRef]

- Ramakrishnan, T.; Kumar, A.; Kumar, T.S.; Kwon, S.; Muniz-Lerma, J.A.; Gauvin, R.; Brochu, M. Crack-Free Tungsten Fabricated via Laser Powder Bed Fusion Additive Manufacturing. Adv. Funct. Mater. 2024, 34, 2309304. [Google Scholar] [CrossRef]

- Liu, S.; Guo, H. Balling Behavior of Selective Laser Melting (SLM) Magnesium Alloy. Materials 2020, 13, 3632. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, Q.; Liu, J. Formation of Nanocrystalline Tungsten by Selective Laser Melting of Tungsten Powder. Mater. Manuf. Process. 2012, 27, 1267–1270. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Yuan, T.; Chen, C.; Zhang, M.; Weng, Q.; Yuan, J. Selective laser melting of W-Ni-Cu composite powder: Densification, microstructure evolution and nano-crystalline formation. Int. J. Refract. Met. Hard Mater. 2018, 70, 9–18. [Google Scholar] [CrossRef]

- Ren, X.; Peng, H.; Li, J.; Liu, H.; Huang, L.; Yi, X. Selective Electron Beam Melting (SEBM) of Pure Tungsten: Metallurgical Defects, Microstructure, Texture and Mechanical Properties. Materials 2022, 15, 1172. [Google Scholar] [CrossRef]

- Stephens, J.R. Effects of Interstitial Impurities on the Low-Temperature Tensile Properties; National Aeronautics and Space Administration: Washington, DC, USA, 1964. [Google Scholar]

- Wang, D.Z.; Li, K.L.; Yu, C.F.; Ma, J.; Liu, W.; Shen, Z.J. Cracking Behavior in Additively Manufactured Pure Tungsten. Acta Metall. Sin. (Engl. Lett.) 2019, 32, 127–135. [Google Scholar] [CrossRef]

- Higashi, M.; Ozaki, T. Selective laser melting of pure molybdenum: Evolution of defect and crystallographic texture with process parameters. Mater. Des. 2020, 191, 108588. [Google Scholar] [CrossRef]

- Yang, G.; Yang, P.; Yang, K.; Liu, N.; Jia, L.; Wang, J.; Tang, H. Effect of processing parameters on the density, microstructure and strength of pure tungsten fabricated by selective electron beam melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 105040. [Google Scholar] [CrossRef]

- Wright, J. Additive Manufacturing of Tungsten via Selective Laser Melting and Electron Beam Melting; University of Sheffield: Sheffield, UK, 2019. [Google Scholar]

- Fernandez-Zelaia, P.; Ledford, C.; Ellis, E.A.I.; Campbell, Q.; Rossy, A.M.; Leonard, D.N.; Kirka, M.M. Crystallographic texture evolution in electron beam melting additive manufacturing of pure Molybdenum. Mater. Des. 2021, 207, 109809. [Google Scholar] [CrossRef]

- Ledford, C.; Rojas, P.F.-Z.J.O.; Campbell, Q.; Rossy, A.M.; Kirka, M.M. Electron Beam Powder Bed Fusion Additive Manufacturing of Refractory Metals, Proceedings of the Tenth International Conference on Tungsten, Refractory & Hardmaterials, Orlando, FL, USA, 20–23 June 2021; UT-Battelle, LLC: Oak Ridge, TN, USA, 2021. [Google Scholar]

- Sadhu, A.; Choudhary, A.; Sarkar, S.; Nair, A.M.; Nayak, P.; Pawar, S.D.; Muvvala, G.; Pal, S.K.; Nath, A.K. A study on the influence of substrate pre-heating on mitigation of cracks in direct metal laser deposition of NiCrSiBC-60%WC ceramic coating on Inconel 718. Surf. Coat. Technol. 2020, 389, 125646. [Google Scholar] [CrossRef]

- Ren, C.; Fang, Z.Z.; Koopman, M.; Butler, B.; Paramore, J.; Middlemas, S. Methods for improving ductility of tungsten—A review. Int. J. Refract. Met. Hard Mater. 2018, 75, 170–183. [Google Scholar] [CrossRef]

- Patra, A.; Saxena, R.; Karak, S.K. Combined effect of Ni and nano-Y2O3 addition on microstructure, mechanical and high temperature behavior of mechanically alloyed W-Mo. Int. J. Refract. Met. Hard Mater. 2016, 60, 131–146. [Google Scholar] [CrossRef]

- Xie, J.; Lu, H.; Lu, J.; Song, X.; Wu, S.; Lei, J. Additive manufacturing of tungsten using directed energy deposition for potential nuclear fusion application. Surf. Coat. Technol. 2021, 409, 126884. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W.; Ning, G.; Yang, L.; Chen, Y. Laser direct manufacturing of tungsten nickel collimation component. J. Mater. Process. Technol. 2004, 147, 167–173. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, S.; Wei, M.; Liang, J.; Liu, C.; Wang, M. Microstructure and properties of 24CrNiMoY alloy steel prepared by direct laser deposited under different preheating temperatures. Mater. Charact. 2019, 158, 109931. [Google Scholar] [CrossRef]

- Fallah, V.; Alimardani, M.; Corbin, S.F.; Khajepour, A. Impact of localized surface preheating on the microstructure and crack formation in laser direct deposition of Stellite 1 on AISI 4340 steel. Appl. Surf. Sci. 2010, 257, 1716–1723. [Google Scholar] [CrossRef]

- Bieg, F.; Scheider, D.; Kledwig, C.; Maucher, C.; Möhring, H.-C.; Reisacher, M. Development of a laser preheating concept for directed energy deposition. J. Laser Appl. 2023, 35, 042052. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Jeong, W.; Kwon, Y.-S.; Kim, D. Three-dimensional printing of tungsten structures by directed energy deposition. Mater. Manuf. Process. 2019, 34, 986–992. [Google Scholar] [CrossRef]

- Dorow-Gerspach, D.; Kirchner, A.; Loewenhoff, T.; Pintsuk, G.; Weißgärber, T.; Wirtz, M. Additive manufacturing of high density pure tungsten by electron beam melting. Nucl. Mater. Energy 2021, 28, 101046. [Google Scholar] [CrossRef]

- Wampler, W.R.; Doerner, R.P. The influence of displacement damage on deuterium retention in tungsten exposed to plasma. Nucl. Fusion 2009, 49, 115023. [Google Scholar] [CrossRef]

- Roth, J.; Schmid, K. Hydrogen in tungsten as plasma-facing material. Phys. Scr. 2011, 2011, 014031. [Google Scholar] [CrossRef]

- Was, G.S.; Averback, R.S. 1.07—Radiation Damage Using Ion Beams. In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Oxford, UK, 2012; pp. 195–221. [Google Scholar]

- Hasegawa, A.; Fukuda, M.; Nogami, S.; Yabuuchi, K. Neutron irradiation effects on tungsten materials. Fusion Eng. Des. 2014, 89, 1568–1572. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- Xiao, S.; Ma, Y.; Tian, L.; Li, M.; Qi, C.; Wang, B. Decrease of blistering on Helium irradiated tungsten surface via transversal release of helium from the grooved surfaces. Nucl. Mater. Energy 2020, 23, 100746. [Google Scholar] [CrossRef]

- Papadakis, D.; Dellis, S.; Chatzikos, V.; Manios, E.; Stamatelatos, I.E.; Messoloras, S.; Mergia, K. Neutron irradiation effects in different tungsten microstructures. Phys. Scr. 2021, 96, 124041. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys, 2nd ed.; Springer: New York, NY, USA, 2017. [Google Scholar]

- Lang, E.; Reid, N.; Garrison, L.; Parish, C.; Allain, J.P. Pre-Irradiation Comparison of W-Based Alloys for the PHENIX Campaign: Microstructure, Composition, and Mechanical Properties. Fusion Sci. Technol. 2019, 75, 533–541. [Google Scholar] [CrossRef]

- Taylor, C.N.; Shimada, M.; Merrill, B.J. Deuterium retention and blistering in tungsten foils. Nucl. Mater. Energy 2017, 12, 689–693. [Google Scholar] [CrossRef]

- Abernethy, R.G.; Gibson, J.S.K.L.; Giannattasio, A.; Murphy, J.D.; Wouters, O.; Bradnam, S.; Packer, L.W.; Gilbert, M.R.; Klimenkov, M.; Rieth, M.; et al. Effects of neutron irradiation on the brittle to ductile transition in single crystal tungsten. J. Nucl. Mater. 2019, 527, 151799. [Google Scholar] [CrossRef]

- Klimenkov, M.; Jäntsch, U.; Rieth, M.; Schneider, H.C.; Armstrong, D.E.J.; Gibson, J.; Roberts, S.G. Effect of neutron irradiation on the microstructure of tungsten. Nucl. Mater. Energy 2016, 9, 480–483. [Google Scholar] [CrossRef]

- Krautwasser, P.; Derz, H.; Kny, E. Influence of Fast Neutron Fluence on the DBTT of Tungsten, W10Re and W34Ni16Fe; International Nuclear Information System: Vienna, Austria, 1995; p. 9. [Google Scholar]

- Hwang, T.; Fukuda, M.; Nogami, S.; Hasegawa, A.; Usami, H.; Yabuuchi, K.; Ozawa, K.; Tanigawa, H. Effect of self-ion irradiation on hardening and microstructure of tungsten. Nucl. Mater. Energy 2016, 9, 430–435. [Google Scholar] [CrossRef]

- Gao, L.; von Toussaint, U.; Jacob, W.; Balden, M.; Manhard, A. Suppression of hydrogen-induced blistering of tungsten by pre-irradiation at low temperature. Nucl. Fusion 2014, 54, 122003. [Google Scholar] [CrossRef]

- Shu, W.M.; Wakai, E.; Yamanishi, T. Blister bursting and deuterium bursting release from tungsten exposed to high fluences of high flux and low energy deuterium plasma. Nucl. Fusion 2007, 47, 201. [Google Scholar] [CrossRef]

- Hladschik, T.; Schoepf, K. TF-Ripple Loss Reduced Alpha Heating. Fusion Technol. 1994, 26, 588–592. [Google Scholar] [CrossRef]

- Ueda, Y.; Fukumoto, M.; Yoshida, J.; Ohtsuka, Y.; Akiyoshi, R.; Iwakiri, H.; Yoshida, N. Simultaneous irradiation effects of hydrogen and helium ions on tungsten. J. Nucl. Mater. 2009, 386–388, 725–728. [Google Scholar] [CrossRef]

- Miyamoto, M.; Nishijima, D.; Ueda, Y.; Doerner, R.P.; Kurishita, H.; Baldwin, M.J.; Morito, S.; Ono, K.; Hanna, J. Observations of suppressed retention and blistering for tungsten exposed to deuterium–helium mixture plasmas. Nucl. Fusion 2009, 49, 065035. [Google Scholar] [CrossRef]

- Venhaus, T.; Causey, R.; Doerner, R.; Abeln, T. Behavior of tungsten exposed to high fluences of low energy hydrogen isotopes. J. Nucl. Mater. 2001, 290–293, 505–508. [Google Scholar] [CrossRef]

- Wang, W.; Roth, J.; Lindig, S.; Wu, C.H. Blister formation of tungsten due to ion bombardment. J. Nucl. Mater. 2001, 299, 124–131. [Google Scholar] [CrossRef]

- Ye, M.Y.; Kanehara, H.; Fukuta, S.; Ohno, N.; Takamura, S. Blister formation on tungsten surface under low energy and high flux hydrogen plasma irradiation in NAGDIS-I. J. Nucl. Mater. 2003, 313–316, 72–76. [Google Scholar] [CrossRef]

- Luo, G.N.; Umstadter, K.; Shu, W.M.; Wampler, W.; Lu, G.H. Behavior of tungsten with exposure to deuterium plasmas. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2009, 267, 3041–3045. [Google Scholar] [CrossRef]

- Balden, M.; Rohde, V.; Lindig, S.; Manhard, A.; Krieger, K. Blistering and re-deposition on tungsten exposed to ASDEX Upgrade divertor plasma. J. Nucl. Mater. 2013, 438, S220–S223. [Google Scholar] [CrossRef]

- Manhard, A.; Balden, M.; von Toussaint, U. Blister formation on rough and technical tungsten surfaces exposed to deuterium plasma. Nucl. Fusion 2017, 57, 126012. [Google Scholar] [CrossRef]

- Qin, W.; Ren, F.; Doerner, R.P.; Wei, G.; Lv, Y.; Chang, S.; Tang, M.; Deng, H.; Jiang, C.; Wang, Y. Nanochannel structures in W enhance radiation tolerance. Acta Mater. 2018, 153, 147–155. [Google Scholar] [CrossRef]

- Gilbert, M.R.; Sublet, J.C. Neutron-induced transmutation effects in W and W-alloys in a fusion environment. Nucl. Fusion 2011, 51, 043005. [Google Scholar] [CrossRef]

- Wen, S.; Pan, M. Effect of transmutation rhenium on tensile properties of tungsten by molecular dynamics simulation. Phys. Scr. 2024, 99, 035413. [Google Scholar] [CrossRef]

- Tanno, T.; Hasegawa, A.; He, J.-C.; Fujiwara, M.; Nogami, S.; Satou, M.; Shishido, T.; Abe, K. Effects of Transmutation Elements on Neutron Irradiation Hardening of Tungsten. Mater. Trans. 2007, 48, 2399–2402. [Google Scholar] [CrossRef]

- Wen, S.; Hu, K.; Pan, M.; Huang, Z.; Cao, Z.; Lv, Y.; Zhao, Y.; Deng, H. Effect of transmutation elements Re and Ta on the vacancy formation and dissociation behaviors in W bulk. Comput. Mater. Sci. 2020, 179, 109624. [Google Scholar] [CrossRef]

- Drescher, P.; Sarhan, M.; Seitz, H. An Investigation of Sintering Parameters on Titanium Powder for Electron Beam Melting Processing Optimization. Materials 2016, 9, 974. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Zhang, Z.; Huang, M.; Ouyang, X. Effects of transmutation elements in tungsten. Comput. Mater. Sci. 2019, 162, 133–139. [Google Scholar] [CrossRef]

- Hu, X.; Parish, C.M.; Wang, K.; Koyanagi, T.; Eftink, B.P.; Katoh, Y. Transmutation-induced precipitation in tungsten irradiated with a mixed energy neutron spectrum. Acta Mater. 2019, 165, 51–61. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, X.; Zhou, W.; Cheng, T.; Chen, L.; Guo, Z.; Han, B.; Lu, L. Digital Twins for Additive Manufacturing: A State-of-the-Art Review. Appl. Sci. 2020, 10, 8350. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Matthews, M.J.; DebRoy, T. The case for digital twins in metal additive manufacturing. J. Phys. Mater. 2021, 4, 040401. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards developing multiscale-multiphysics models and their surrogates for digital twins of metal additive manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- Jain, S.; Narayanan, A. Digital Twin–Enabled Machine Learning for Smart Manufacturing. Smart Sustain. Manuf. Syst. 2023, 7, 111–128. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Cummins, S.J.; Lemiale, V.; Delaney, G.W.; Nguyen, V.; Feng, Y. Aiming for Modeling-Assisted Tailored Designs for Additive Manufacturing, Proceedings of the TMS 2017 146th Annual Meeting & Exhibition Supplemental Proceedings, San Diego, CA, USA, 26 February–2 March 2017; Tms, T.M.M., Materials, S., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 91–102. [Google Scholar]

- Mukherjee, T.; DebRoy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Yavari, R.; Riensche, A.; Tekerek, E.; Jacquemetton, L.; Halliday, H.; Vandever, M.; Tenequer, A.; Perumal, V.; Kontsos, A.; Smoqi, Z.; et al. Digitally twinned additive manufacturing: Detecting flaws in laser powder bed fusion by combining thermal simulations with in-situ meltpool sensor data. Mater. Des. 2021, 211, 110167. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Keutayeva, A.; Kazbek, G.; Ali, M.H.; Shehab, E. Integrating Machine Learning Model and Digital Twin System for Additive Manufacturing. IEEE Access 2023, 11, 71113–71126. [Google Scholar] [CrossRef]

- Song, H.; Song, M.; Liu, X. Online autonomous calibration of digital twins using machine learning with application to nuclear power plants. Appl. Energy 2022, 326, 119995. [Google Scholar] [CrossRef]

- Ren, Z.; Gao, L.; Clark, S.J.; Fezzaa, K.; Shevchenko, P.; Choi, A.; Everhart, W.; Rollett, A.D.; Chen, L.; Sun, T. Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion. Science 2023, 379, 89–94. [Google Scholar] [CrossRef]

- Schmidt, J.; Marques, M.R.G.; Botti, S.; Marques, M.A.L. Recent advances and applications of machine learning in solid-state materials science. NPJ Comput. Mater. 2019, 5, 83. [Google Scholar] [CrossRef]

- Singh, G.; Waas, A.M.; Sundararaghavan, V. Understanding defect structures in nanoscale metal additive manufacturing via molecular dynamics. Comput. Mater. Sci. 2021, 200, 110807. [Google Scholar] [CrossRef]

- Rahmani, F.; Jeon, J.; Jiang, S.; Nouranian, S. Melting and solidification behavior of Cu/Al and Ti/Al bimetallic core/shell nanoparticles during additive manufacturing by molecular dynamics simulation. J. Nanoparticle Res. 2018, 20, 133. [Google Scholar] [CrossRef]

- Nandy, J.; Sahoo, S.; Yedla, N.; Sarangi, H. Molecular dynamics simulation of coalescence kinetics and neck growth in laser additive manufacturing of aluminum alloy nanoparticles. J. Mol. Model. 2020, 26, 125. [Google Scholar] [CrossRef]

- Yeh, I.-C.; Lenhart, J.L.; Rutledge, G.C.; Andzelm, J.W. Molecular Dynamics Simulation of the Effects of Layer Thickness and Chain Tilt on Tensile Deformation Mechanisms of Semicrystalline Polyethylene. Macromolecules 2017, 50, 1700–1712. [Google Scholar] [CrossRef]

- Etesami, S.A.; Laradji, M.; Asadi, E. Reliability of molecular dynamics interatomic potentials for modeling of titanium in additive manufacturing processes. Comput. Mater. Sci. 2020, 184, 109883. [Google Scholar] [CrossRef]

- Doerr, S.; Majewski, M.; Pérez, A.; Krämer, A.; Clementi, C.; Noe, F.; Giorgino, T.; De Fabritiis, G. TorchMD: A Deep Learning Framework for Molecular Simulations. J. Chem. Theory Comput. 2021, 17, 2355–2363. [Google Scholar] [CrossRef] [PubMed]

- Noé, F.; Tkatchenko, A.; Müller, K.-R.; Clementi, C. Machine Learning for Molecular Simulation. Annu. Rev. Phys. Chem. 2020, 71, 361–390. [Google Scholar] [CrossRef]

- Li, T.; Tian, C.; Moridi, A.; Yeo, J. Elucidating Interfacial Dynamics of Ti–Al Systems Using Molecular Dynamics Simulation and Markov State Modeling. ACS Appl. Mater. Interfaces 2023, 15, 50489–50498. [Google Scholar] [CrossRef] [PubMed]

- Rosenthal, I.; Weaver, J.S.; Moylan, S. The influence of the melt pool structure on the mechanical properties of laser powder bed fusion Nickel Superalloy 625. Mater. Today Commun. 2023, 36, 106810. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Q.; Michaleris, P. A Physics-Informed Two-Level Machine-Learning Model for Predicting Melt-Pool Size in Laser Powder Bed Fusion. J. Dyn. Syst. Meas. Control. 2021, 143, 121006. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, Z.; Yan, J. Machine learning for metal additive manufacturing: Predicting temperature and melt pool fluid dynamics using physics-informed neural networks. Comput. Mech. 2021, 67, 619–635. [Google Scholar] [CrossRef]

- Zhang, W.; Mehta, A.; Desai, P.S.; Higgs, P.C.F. Machine Learning Enabled Powder Spreading Process Map for Metal Additive Manufacturing (AM); University of Texas at Austin: Austin, TX, USA, 2017. [Google Scholar]

- Raimondeau, S.; Vlachos, D.G. Low-Dimensional Approximations of Multiscale Epitaxial Growth Models for Microstructure Control of Materials. J. Comput. Phys. 2000, 160, 564–576. [Google Scholar] [CrossRef]

- Burger, G.B.; Gupta, A.K.; Jeffrey, P.W.; Lloyd, D.J. Microstructural control of aluminum sheet used in automotive applications. Mater. Charact. 1995, 35, 23–39. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Howard, L.; Parker, G.D.; Yu, X.-Y. Progress and Challenges of Additive Manufacturing of Tungsten and Alloys as Plasma-Facing Materials. Materials 2024, 17, 2104. https://doi.org/10.3390/ma17092104

Howard L, Parker GD, Yu X-Y. Progress and Challenges of Additive Manufacturing of Tungsten and Alloys as Plasma-Facing Materials. Materials. 2024; 17(9):2104. https://doi.org/10.3390/ma17092104

Chicago/Turabian StyleHoward, Logan, Gabriel D. Parker, and Xiao-Ying Yu. 2024. "Progress and Challenges of Additive Manufacturing of Tungsten and Alloys as Plasma-Facing Materials" Materials 17, no. 9: 2104. https://doi.org/10.3390/ma17092104

APA StyleHoward, L., Parker, G. D., & Yu, X.-Y. (2024). Progress and Challenges of Additive Manufacturing of Tungsten and Alloys as Plasma-Facing Materials. Materials, 17(9), 2104. https://doi.org/10.3390/ma17092104