Quasi-In Situ EBSD Investigation of Variant Evolution and Twin Formation in a Hot Isostatic Pressing-Treated Additively-Manufactured Titanium Alloy Under Tensile Loading

Abstract

1. Introduction

2. Materials and Methods

3. Results

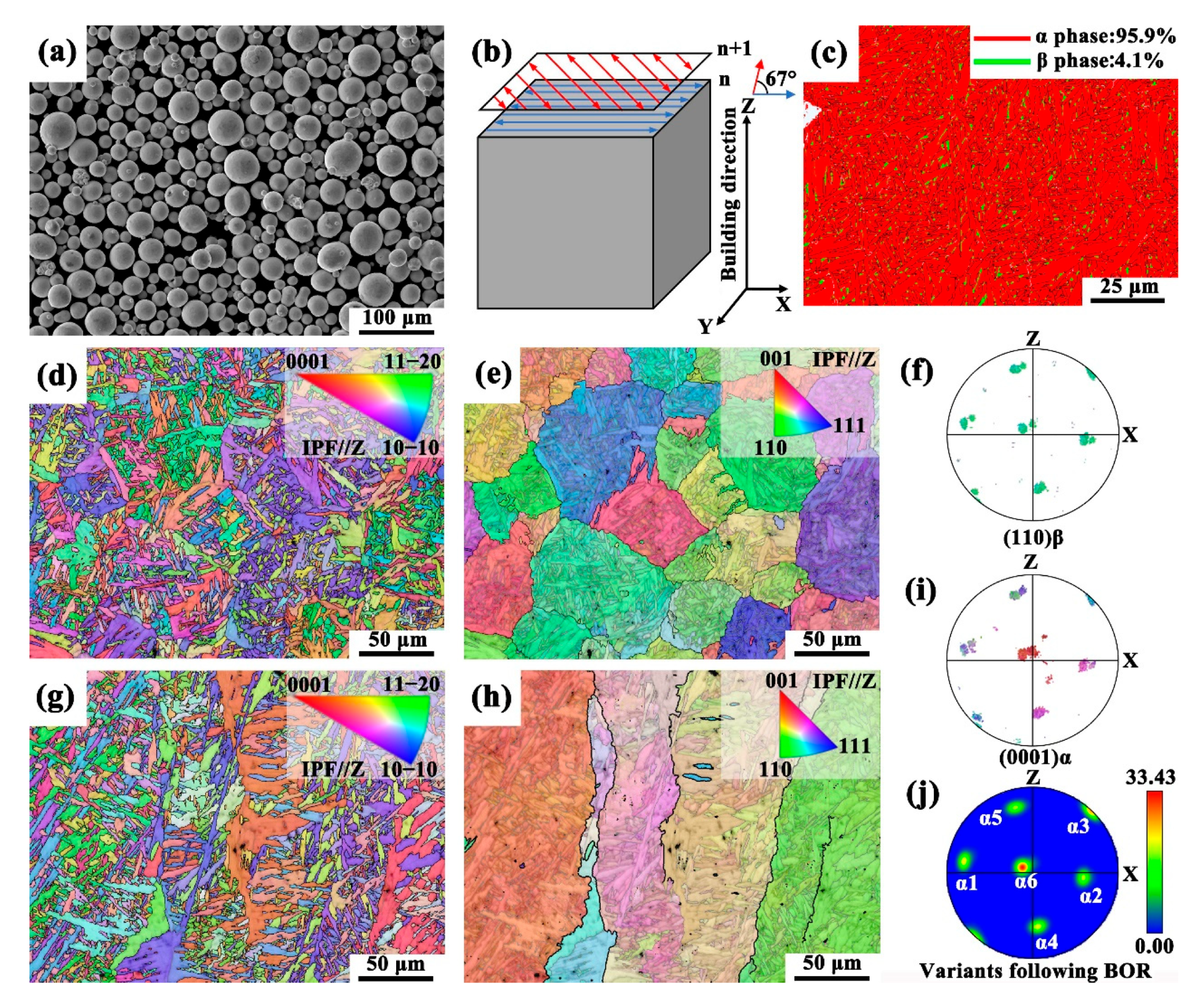

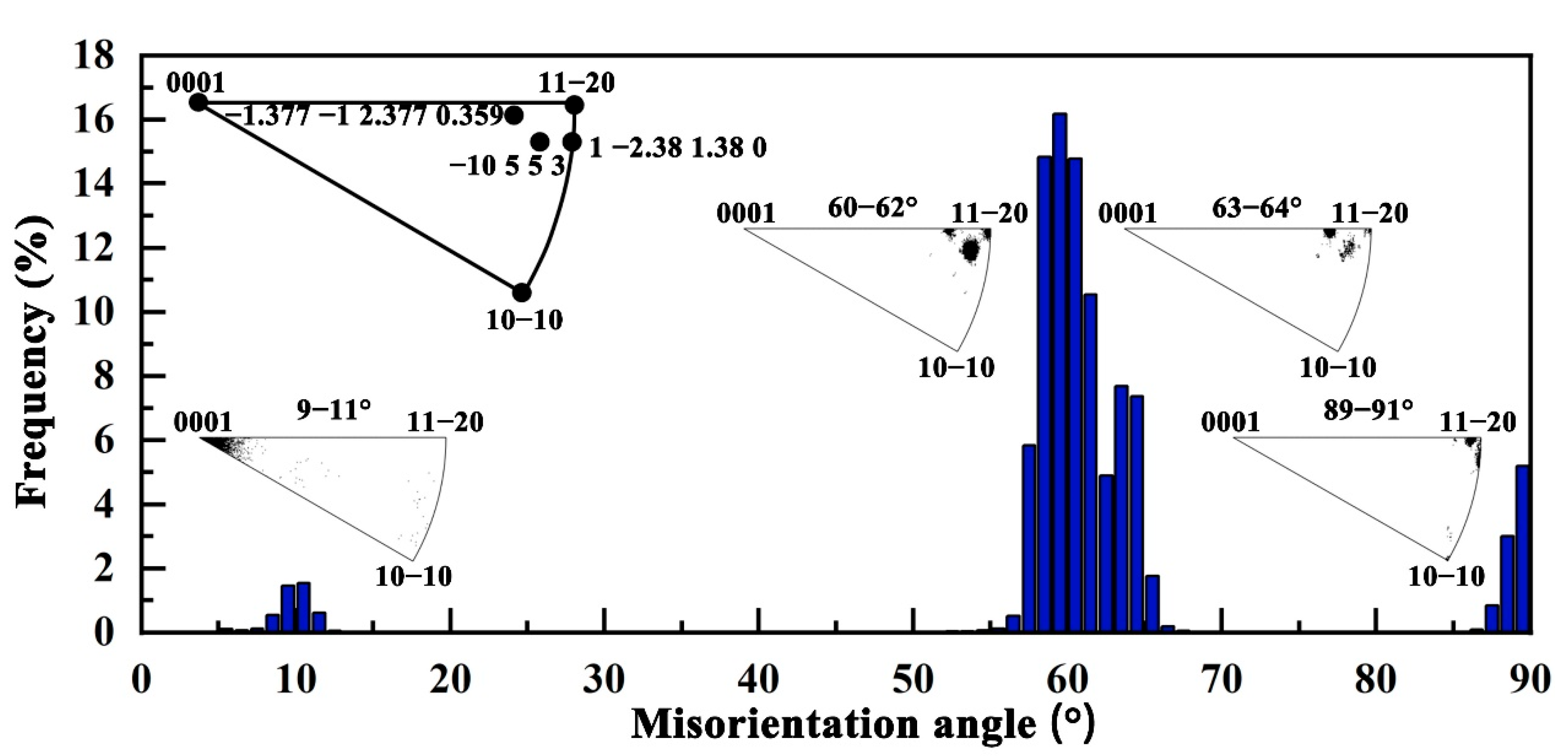

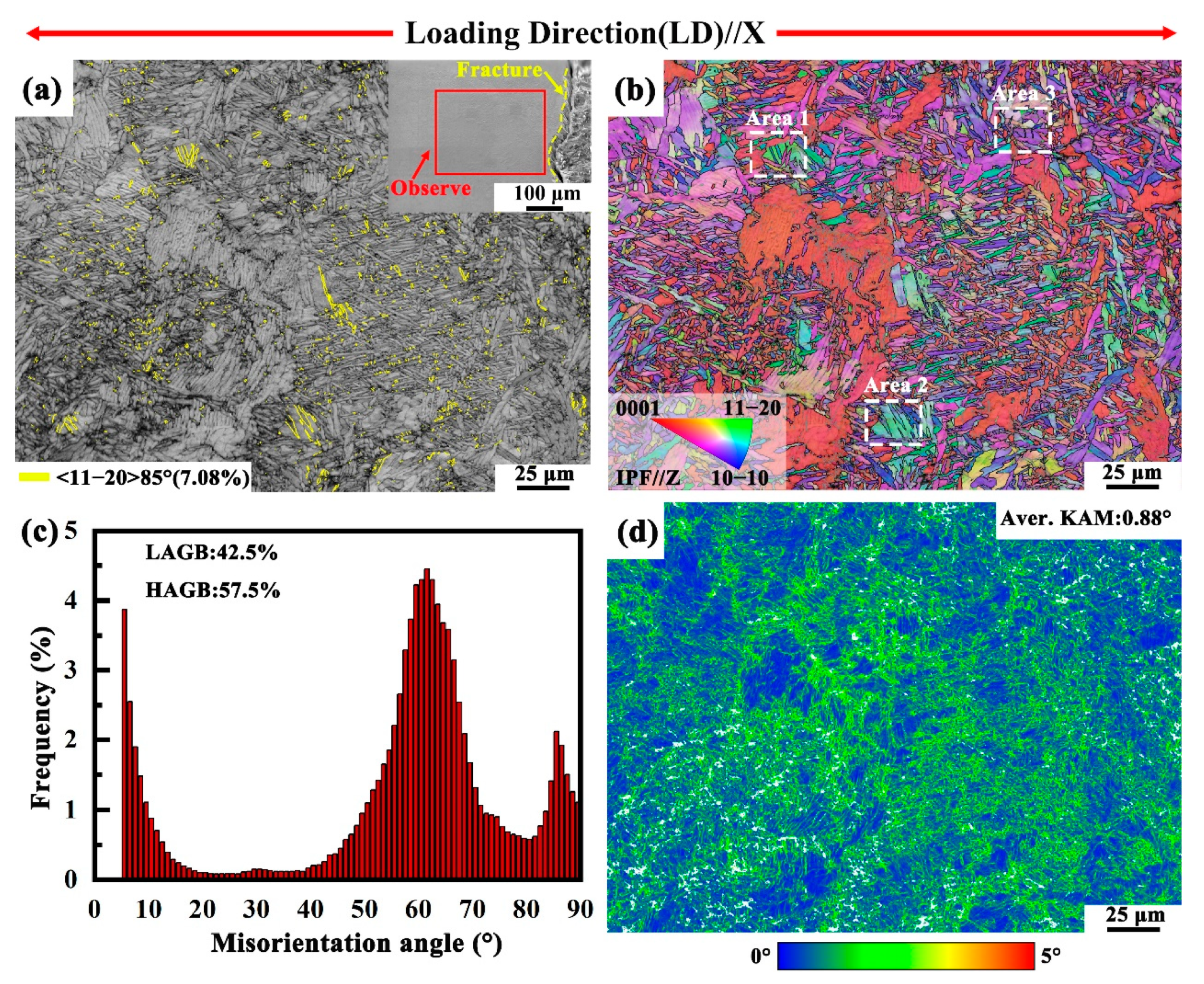

3.1. Initial Microstructure

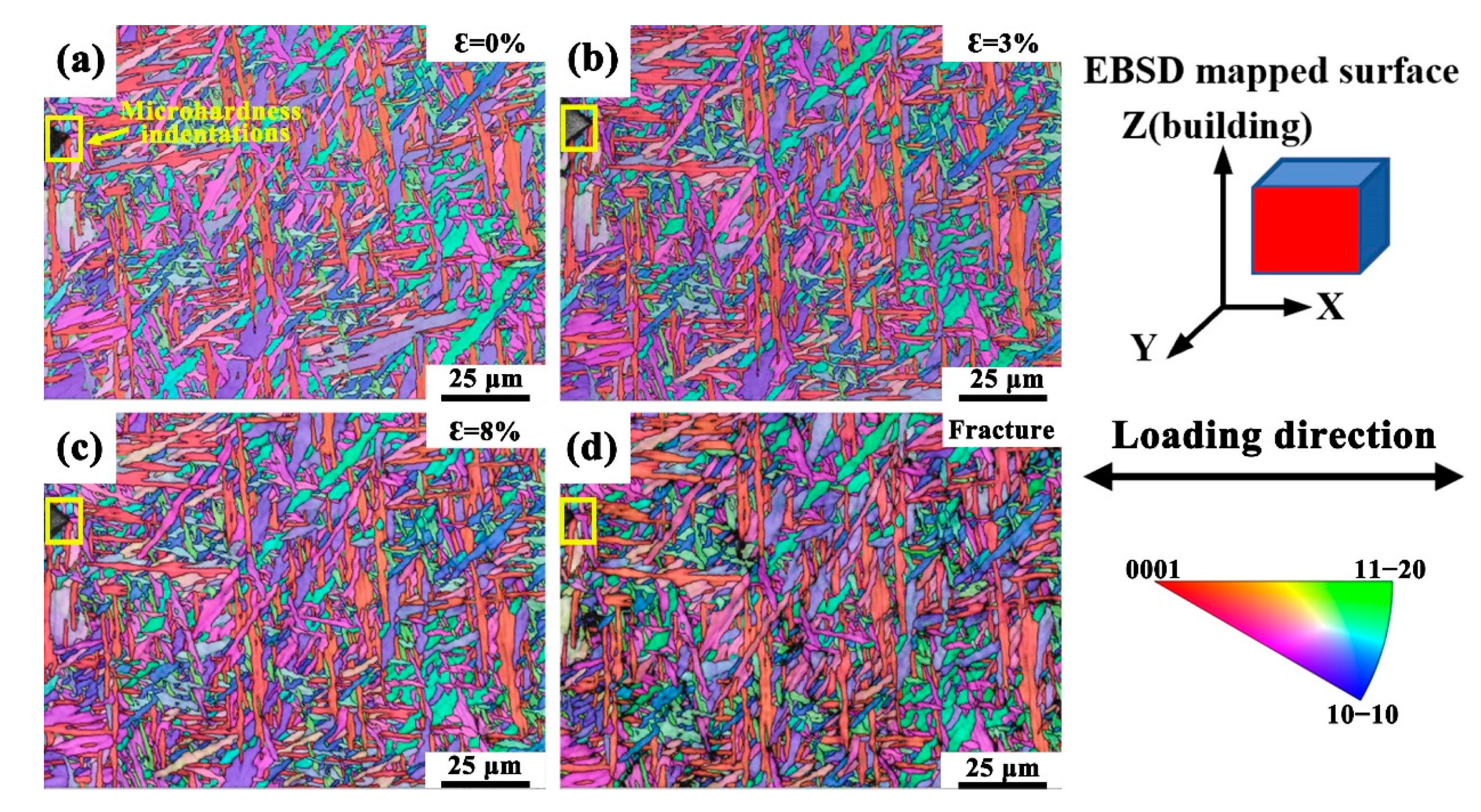

3.2. Quasi-In Situ EBSD

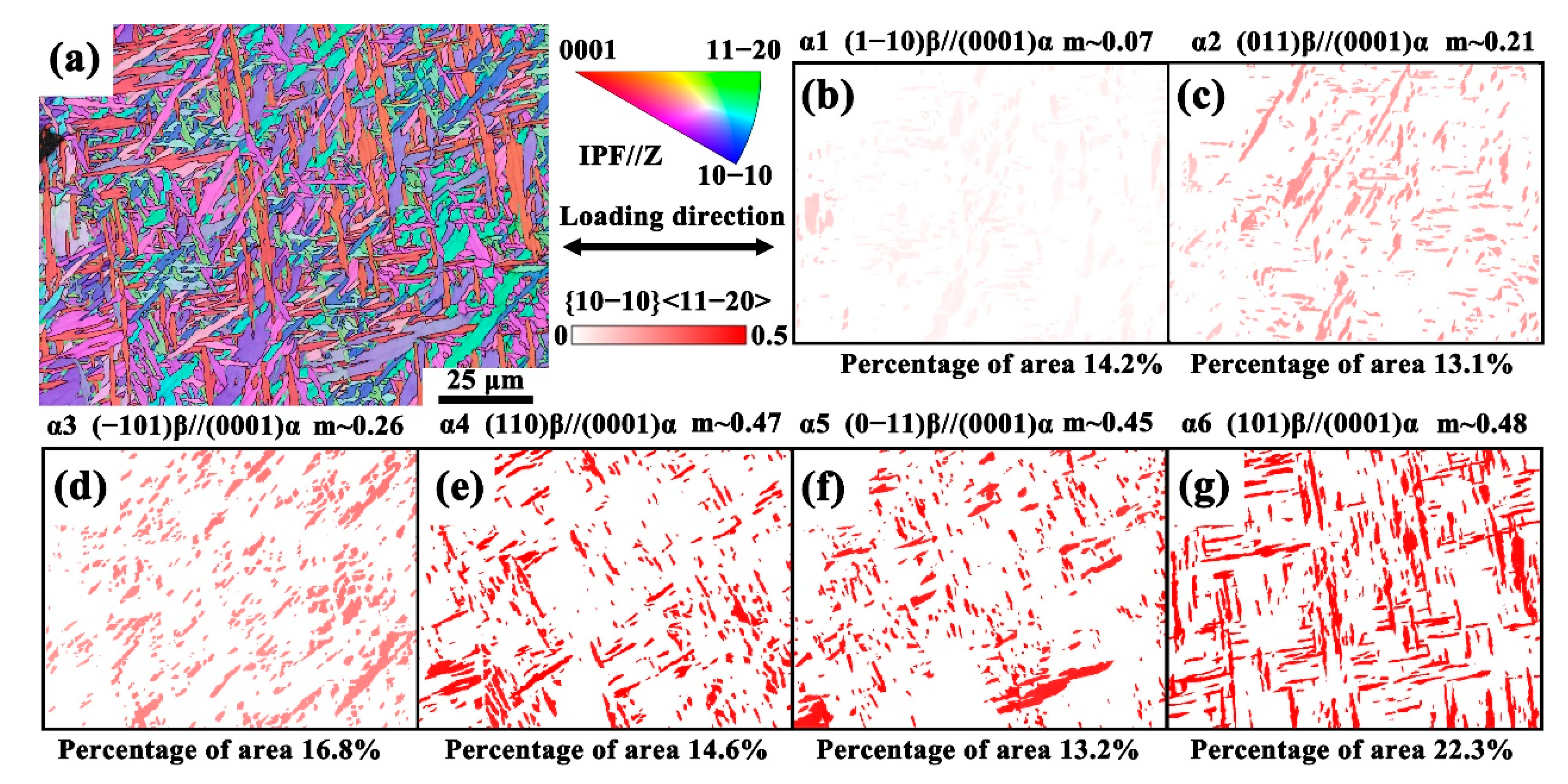

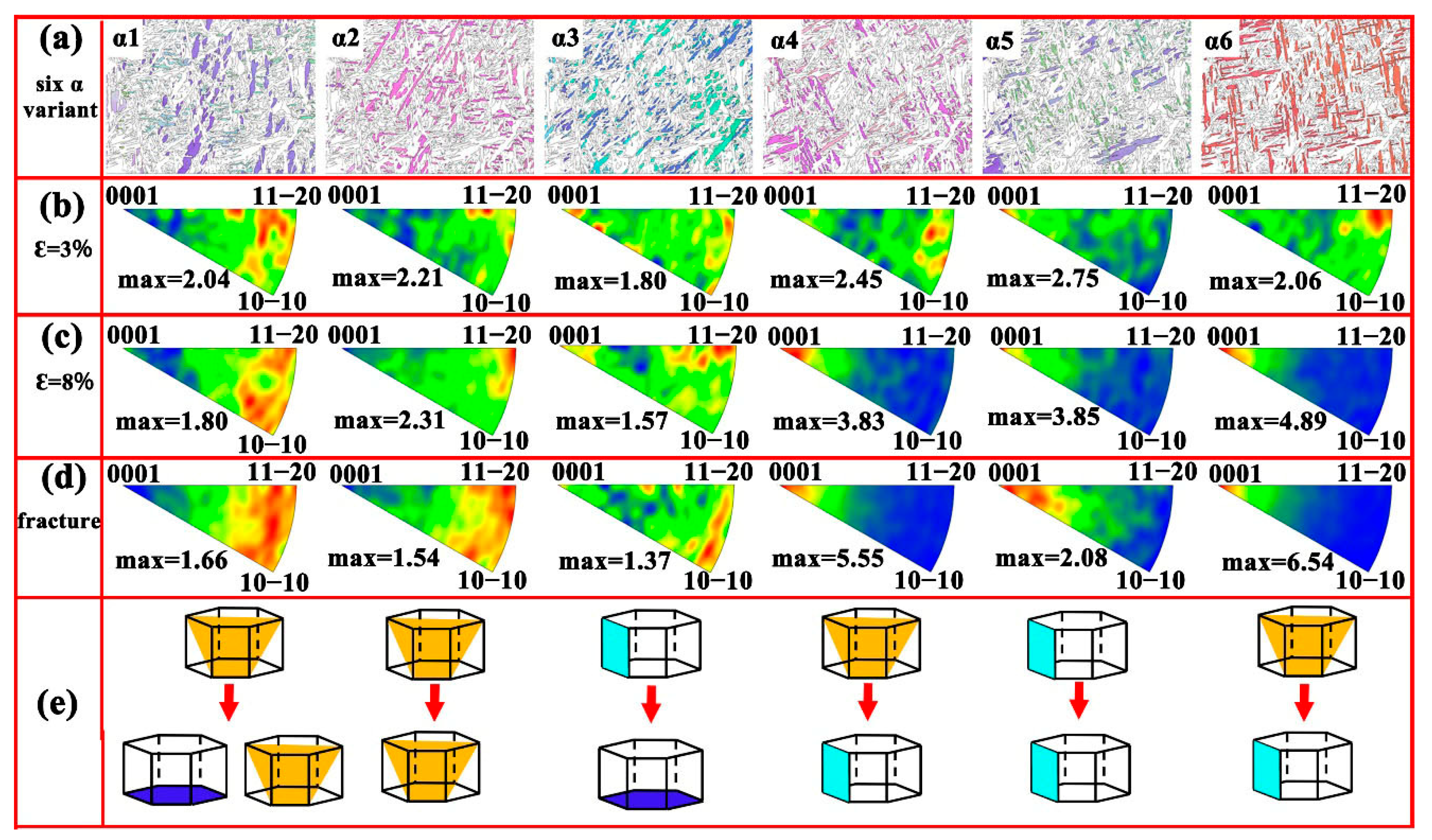

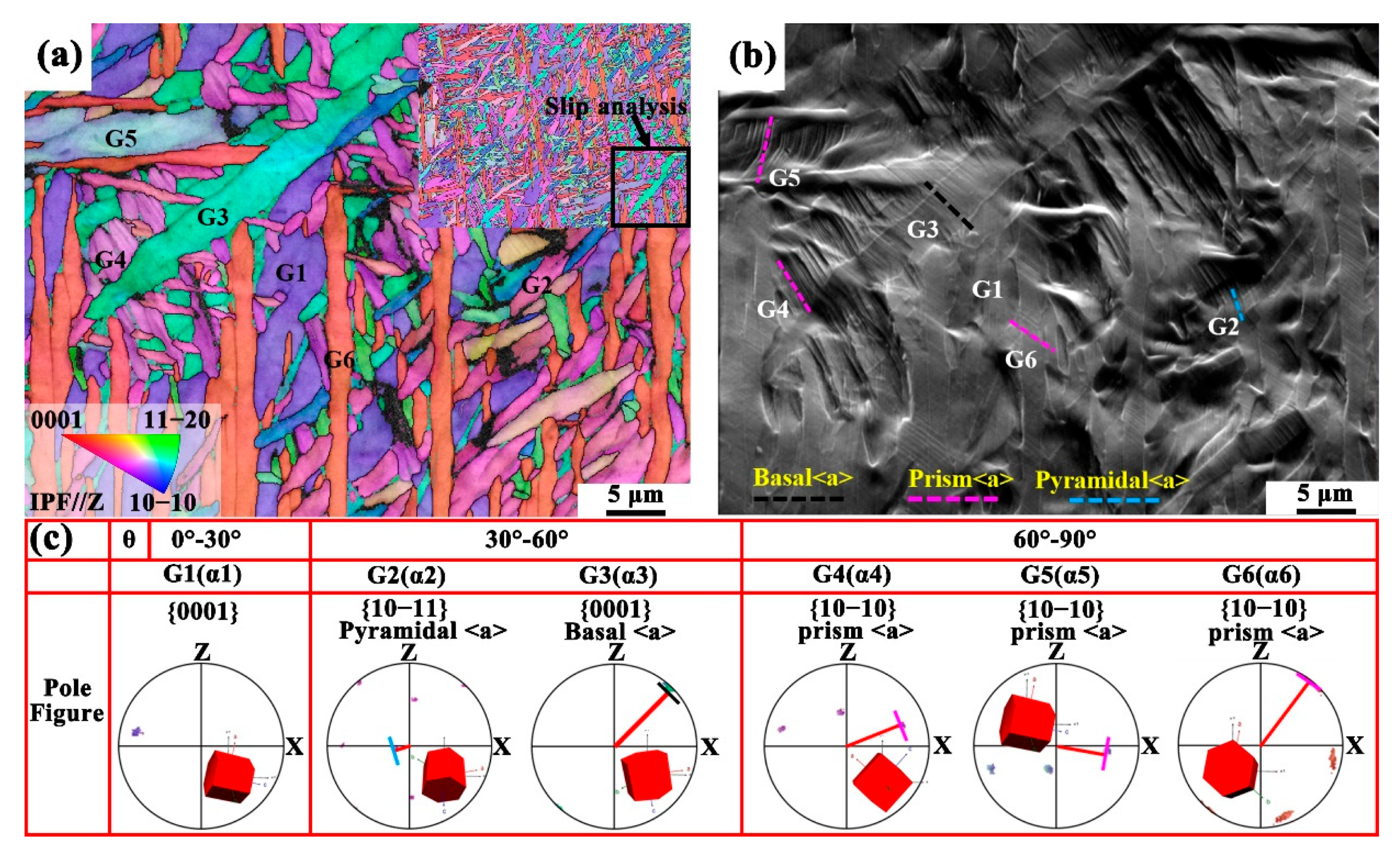

3.3. Slip Mechanisms of α Variants

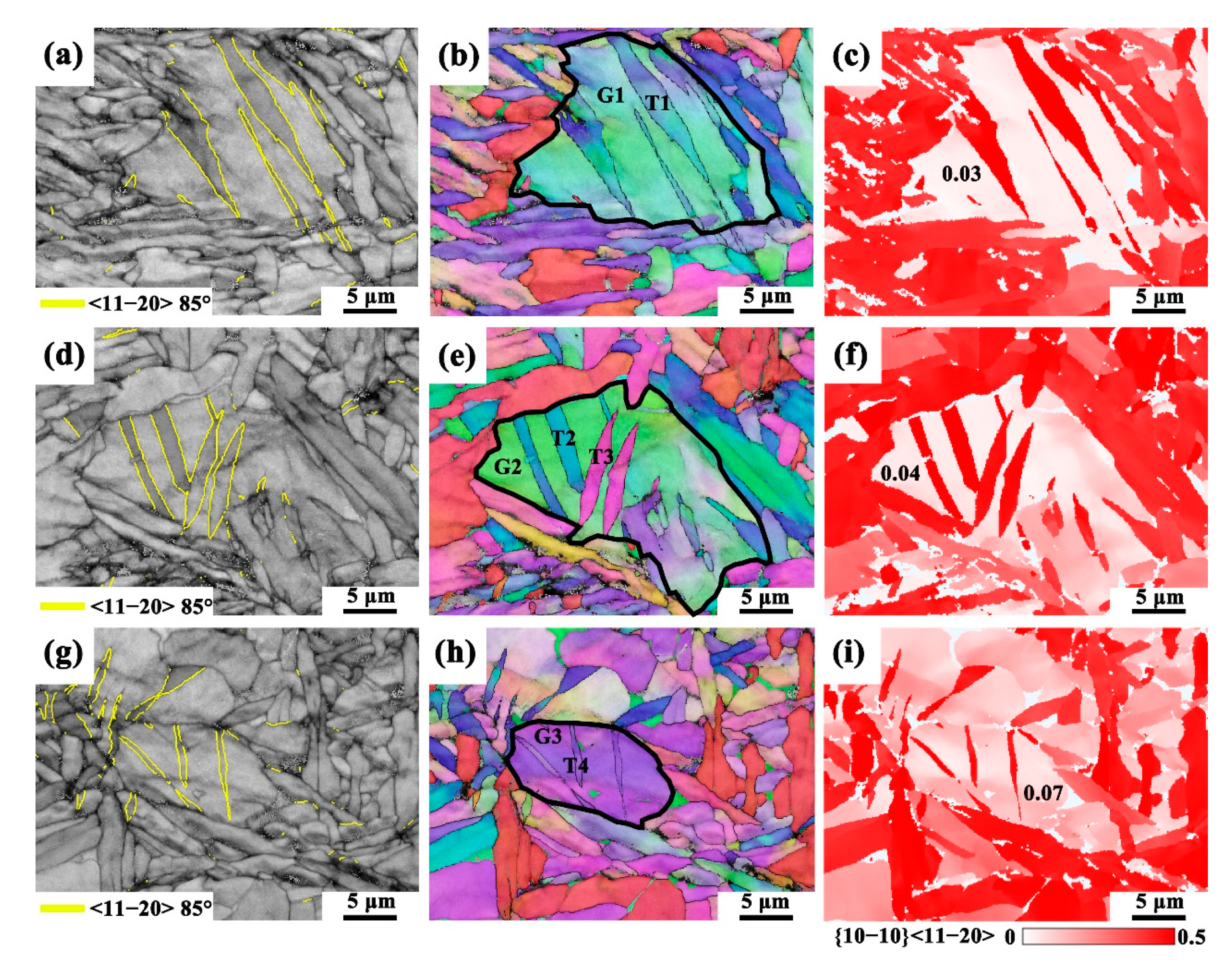

3.4. Twin Mechanisms

4. Conclusions

- (1)

- In the variant selection of the SEBM-fabricated TA15 alloy followed by HIP treatment, all six α variants were observed. Notably, the area percentage of the α6 variant was significantly higher than the theoretical value. Additionally, the length fraction of Type II ([11–20]/60°) α/α boundaries was higher than that of other boundary types.

- (2)

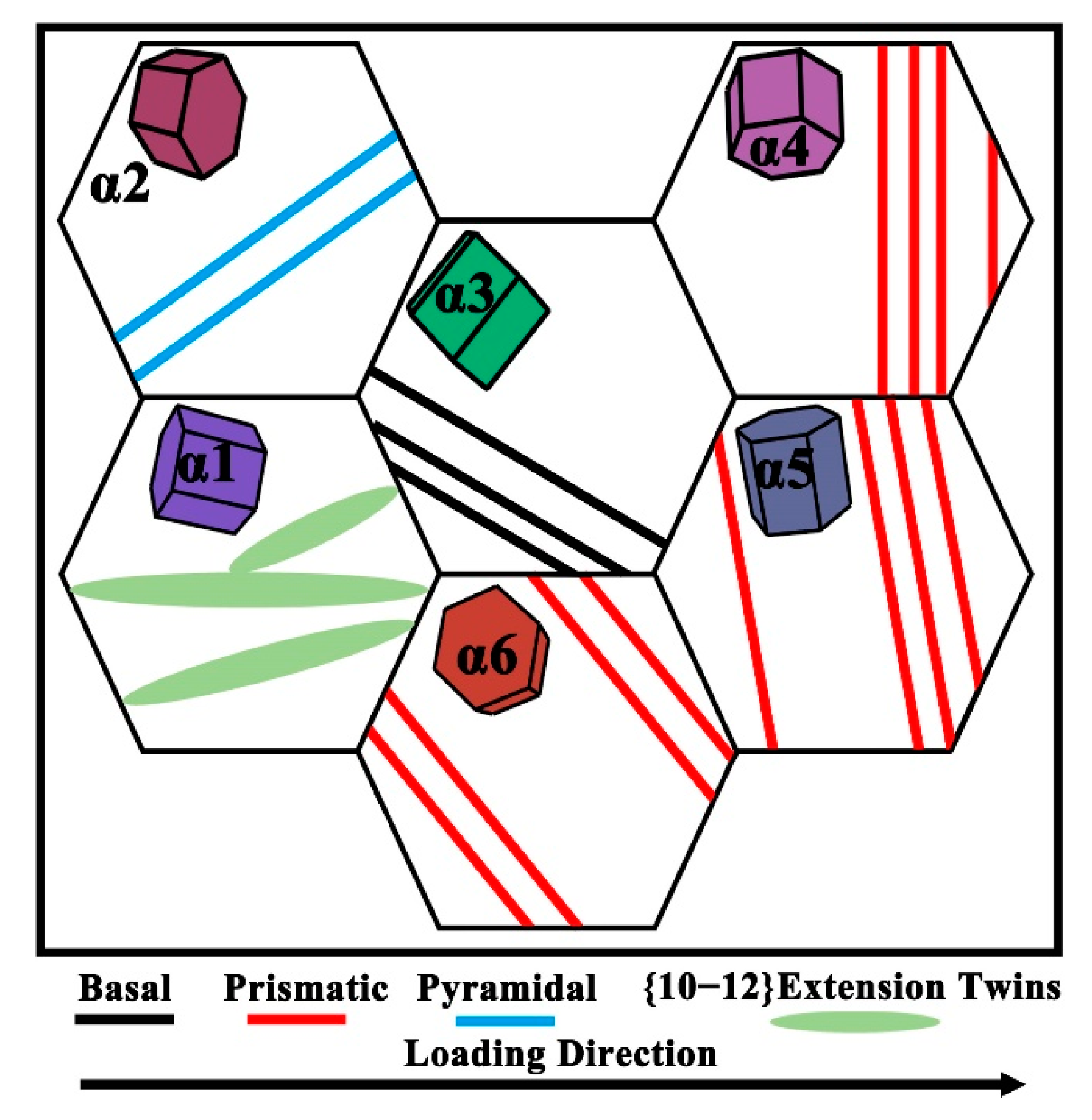

- The activation of slip systems within the β grain varies among different α variants. Through IGMA and slip trace analyses, it was found that the α2 variant predominantly activates pyramidal slip, the α3 variant primarily activates basal slip, and the α4–α6 variants largely activate prismatic slip. Conversely, the α1 variant demonstrates difficulty in slip activation.

- (3)

- The activation of {10–12}<10–11> extension twins is strongly influenced by grain orientation. Specifically, when the c-axis of α1 variants aligns parallel to the tensile loading direction, the resolved tensile stress along the c-axis is maximized. This orientation minimizes the critical resolved shear stress required for twinning, thereby facilitating the formation of {10–12}<10–11> extension twins.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| HIP | Hot isostatic pressing |

| SEBM | Selective electron beam melting |

| IGMA | In-grain misorientation axis |

| EBSD | Electron Backscatter Diffraction |

| CRSS | Critical resolved shear stress |

| IPF | Inverse pole figure |

| BC | Band contrast |

| FSD | Forward scattered detector |

| KAM | Kernel average misorientation |

References

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Childerhouse, T.; Jackson, M. Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes. Metals 2019, 9, 689. [Google Scholar] [CrossRef]

- Pasang, T.; Budiman, A.S.; Wang, J.C.; Jiang, C.P.; Boyer, R.; Williams, J.; Misiolek, W.Z. Additive manufacturing of titanium alloys—Enabling re-manufacturing of aerospace and biomedical components. Microelectron. Eng. 2023, 270, 111935. [Google Scholar] [CrossRef]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of heat treatment on mechanical properties of Ti–6Al–4V ELI alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Wang, C.; Qin, H.; Ma, L.; Chen, Y.; Li, C. Enhanced tensile properties of laser powder-bed fusion-manufactured TA15 alloy across a wide temperature range. Mater. Sci. Eng. A 2025, 926, 147950. [Google Scholar] [CrossRef]

- Wu, X.; Cai, C.; Yang, L.; Liu, W.; Li, W.; Li, M.; Liu, J.; Zhou, K.; Shi, Y. Enhanced mechanical properties of Ti-6Al-2Zr-1Mo-1V with ultrafine crystallites and nano-scale twins fabricated by selective laser melting. Mater. Sci. Eng. A 2018, 738, 10–14. [Google Scholar] [CrossRef]

- Ullah, R.; Xiebin, Z.; Rizwan, M.; Chen, J.; Dashun, F.; Zhang, Y. Investigation of inhomogeneous plastic deformation behavior of LDED TA15 alloy using in-situ EBSD tensile technique. Mater. Sci. Eng. A 2025, 934, 148301. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Ren, Y.; Song, M.; Baker, I.; Wu, H. Microstructural evolution and cryogenic and ambient temperature deformation behavior of the near-α titanium alloy TA15 fabricated by laser powder bed fusion. J. Alloys Compd. 2024, 1001, 175075. [Google Scholar] [CrossRef]

- Pramanik, A.; Littlefair, G. Machining of Titanium Alloy(Ti-6Al-4V)—Theory to Application. Mach. Sci. Technol. 2015, 19, 1–49. [Google Scholar] [CrossRef]

- Sun, Z.; Wu, H.; Sun, Q.; Yang, H. Tri-modal microstructure in high temperature toughening and low temperature strengthening treatments of near-β forged TA15 Ti-alloy. Mater. Charact. 2016, 121, 213–221. [Google Scholar] [CrossRef]

- Guo, C.; Ge, W.; Lin, F. Effects of scanning parameters on material deposition during Electron Beam Selective Melting of Ti-6Al-4V powder. J. Mater. Process. Technol. 2015, 217, 148–157. [Google Scholar] [CrossRef]

- Vignesh, M.; Ranjith Kumar, G.; Sathishkumar, M.; Manikandan, M.; Rajyalakshmi, G.; Ramanujam, R.; Arivazhagan, N. Development of Biomedical Implants through Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2021, 30, 4735–4744. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Li, P.; Zhang, Z.; Zhao, C.; Zhao, Y.; Zhang, Y.; Liang, Y.; Lin, J. Fabrication of high strength TiAl alloy with nano-lamellar and ultra-fine-grained microstructure by selective electron beam melting. J. Mater. Res. Technol. 2025, 35, 7156–7166. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, K.; Meng, Z.; Zhang, K.; Hodgson, P.; Birbilis, N.; Weyland, M.; Fraser, H.L.; Lim, S.C.V.; Peng, H.; et al. Ultrastrong nanotwinned titanium alloys through additive manufacturing. Nat. Mater. 2022, 21, 1258–1262. [Google Scholar] [CrossRef]

- Garcia-Hernandez, C.; Garcia-Cabezon, C.; Gonzalez-Diez, F.; Ampudia, M.; Juanes-Gusano, D.; Rodriguez-Cabello, J.C.; Martin-Pedrosa, F. Effect of processing on microstructure, mechanical properties, corrosion and biocompatibility of additive manufacturing Ti-6Al-4V orthopaedic implants. Sci. Rep. 2025, 15, 14087. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- Szymczyk-Ziolkowska, P.; Hoppe, V.; Rusinska, M.; Gasiorek, J.; Ziolkowski, G.; Dydak, K.; Czajkowska, J.; Junka, A. The Impact of EBM-Manufactured Ti6Al4V ELI Alloy Surface Modifications on Cytotoxicity toward Eukaryotic Cells and Microbial Biofilm Formation. Materials 2020, 13, 2822. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Gu, J.; Song, M. Recent advances on defects, microstructures and mechanical properties of additively manufactured titanium alloys. Mater. Today Commun. 2025, 42, 111312. [Google Scholar] [CrossRef]

- Mukherjee, T.; Elmer, J.W.; Wei, H.L.; Lienert, T.J.; Zhang, W.; Kou, S.; DebRoy, T. Control of grain structure, phases, and defects in additive manufacturing of high-performance metallic components. Prog. Mater. Sci. 2023, 138, 101153. [Google Scholar] [CrossRef]

- Benzing, J.; Hrabe, N.; Quinn, T.; White, R.; Rentz, R.; Ahlfors, M. Hot isostatic pressing (HIP) to achieve isotropic microstructure and retain as-built strength in an additive manufacturing titanium alloy (Ti-6Al-4V). Mater. Lett. 2019, 257, 126690. [Google Scholar] [CrossRef] [PubMed]

- Squillaci, L.; Neikter, M.; Hansson, T.; Pederson, R.; Moverare, J. Microstructure and mechanical properties of Ti-6Al-4V alloy fabricated using powder bed fusion—Laser beam additive manufacturing process: Effect of hot isostatic pressing. Mater. Sci. Eng. A 2025, 931, 148226. [Google Scholar] [CrossRef]

- Wang, S.C.; Aindow, M.; Starink, M.J. Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater. 2003, 51, 2485–2503. [Google Scholar] [CrossRef]

- Stephenson, P.L.; Haghdadi, N.; DeMott, R.; Liao, X.Z.; Ringer, S.P.; Primig, S. Effect of scanning strategy on variant selection in additively manufactured Ti-6Al-4V. Addit. Manuf. 2020, 36, 101581. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Wang, Q.J.; Hu, Q.M.; Liu, J.R.; Yu, B.B.; Yang, R. Effect of β (110) texture intensity on α-variant selection and microstructure morphology during β→α phase transformation in near α titanium alloy. Acta Mater. 2017, 126, 372–382. [Google Scholar] [CrossRef]

- Shi, R.; Dixit, V.; Fraser, H.L.; Wang, Y. Variant selection of grain boundary α by special prior β grain boundaries in titanium alloys. Acta Mater. 2014, 75, 156–166. [Google Scholar] [CrossRef]

- Ho, A.; Zhao, H.; Fellowes, J.W.; Martina, F.; Davis, A.E.; Prangnell, P.B. On the origin of microstructural banding in Ti-6Al4V wire-arc based high deposition rate additive manufacturing. Acta Mater. 2019, 166, 306–323. [Google Scholar] [CrossRef]

- Qiu, D.; Shi, R.; Zhang, D.; Lu, W.; Wang, Y. Variant selection by dislocations during α precipitation in α/β titanium alloys. Acta Mater. 2015, 88, 218–231. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, J.; Lu, X.; Tan, H.; Lin, X.; Huang, W. Formation mechanism of the α variant and its influence on the tensile properties of laser solid formed Ti-6Al-4V titanium alloy. Mater. Sci. Eng. A 2017, 691, 16–24. [Google Scholar] [CrossRef]

- Karthikeyan, T.; Dasgupta, A.; Khatirkar, R.; Saroja, S.; Samajdar, I.; Vijayalakshmi, M. Effect of cooling rate on transformation texture and variant selection during β→α transformation in Ti–5Ta–1.8Nb alloy. Mater. Sci. Eng. A 2010, 528, 549–558. [Google Scholar] [CrossRef]

- Obasi, G.C.; Birosca, S.; Leo Prakash, D.G.; Quinta da Fonseca, J.; Preuss, M. The influence of rolling temperature on texture evolution and variant selection during α → β → α phase transformation in Ti–6Al–4V. Acta Mater. 2012, 60, 6013–6024. [Google Scholar] [CrossRef]

- Xiang, H.; Van Paepegem, W.; Kestens, L.A.I. Variant selection during BCC to HCP phase transformation in selective laser melted Ti-6Al-4V. Materialia 2022, 24, 101470. [Google Scholar] [CrossRef]

- Fu, M.; Yuan, Y.; Ma, X.; Lin, X. A study of α variant selection in laser solid forming Ti-6Al-4V. J. Alloys Compd. 2019, 792, 1261–1266. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Li, J.; Wang, Z.; Wang, J. Variant selection within one β grain in laser solid formed Ti-6Al-4V alloys. Mater. Charact. 2022, 185, 111744. [Google Scholar] [CrossRef]

- Li, Y.; Gao, P.; Yu, J.; Jin, S.; Chen, S.; Zhan, M. Mesoscale deformation mechanisms in relation with slip and grain boundary sliding in TA15 titanium alloy during tensile deformation. J. Mater. Sci. Technol. 2022, 98, 72–86. [Google Scholar] [CrossRef]

- Rizwan, M.; Lu, J.; Ullah, R.; Zhang, Y.; Zhang, Z. Microstructural and texture evolution investigation of laser melting deposited TA15 alloy at 500 °C using in-situ EBSD tensile test. Mater. Sci. Eng. A 2022, 857, 144062. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, G.; Tasan, C.C. Slip-twinning interdependent activation across phase boundaries: An in-situ investigation of a Ti-Al-V-Fe (α + β) alloy. Acta Mater. 2021, 206, 116520. [Google Scholar] [CrossRef]

- Nadammal, N.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Kromm, A.; Haberland, C.; Dolabella Portella, P.; Bruno, G. Critical role of scan strategies on the development of microstructure, texture, and residual stresses during laser powder bed fusion additive manufacturing. Addit. Manuf. 2021, 38, 101792. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Daymond, M.R.; Holt, R.A.; Cai, S.; Mosbrucker, P.; Vogel, S.C. Texture inheritance and variant selection through an hcp–bcc–hcp phase transformation. Acta Mater. 2010, 58, 4053–4066. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Qu, S.; Feng, A.; Mi, G.; Shen, J.; Huang, X.; Chen, D. Multiple α sub-variants and anisotropic mechanical properties of an additively-manufactured Ti-6Al-4V alloy. J. Mater. Sci. Technol. 2021, 70, 113–124. [Google Scholar] [CrossRef]

- Lei, L.; Zhao, Q.; Wu, C.; Zhao, Y.; Huang, S.; Jia, W.; Zeng, W. Variant selection, coarsening behavior of α phase and associated tensile properties in an α + β titanium alloy. J. Mater. Sci. Technol. 2022, 99, 101–113. [Google Scholar] [CrossRef]

- Shi, R.; Wang, Y. Variant selection during α precipitation in Ti–6Al–4V under the influence of local stress—A simulation study. Acta Mater. 2013, 61, 6006–6024. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Chen, Z.; Qu, S.J.; Feng, A.H.; Mi, G.B.; Shen, J.; Huang, X.; Chen, D.L. Microstructure and cyclic deformation behavior of a 3D-printed Ti–6Al–4V alloy. J. Alloys Compd. 2020, 825, 153971. [Google Scholar] [CrossRef]

- Obasi, G.C.; Birosca, S.; Quinta da Fonseca, J.; Preuss, M. Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti–6 Al–4 V. Acta Mater. 2012, 60, 1048–1058. [Google Scholar] [CrossRef]

- Lu, S.L.; Todaro, C.J.; Sun, Y.Y.; Song, T.; Brandt, M.; Qian, M. Variant selection in additively manufactured alpha-beta titanium alloys. J. Mater. Sci. Technol. 2022, 113, 14–21. [Google Scholar] [CrossRef]

- Cai, C.; Gao, X.; Teng, Q.; Kiran, R.; Liu, J.; Wei, Q.; Shi, Y. Hot isostatic pressing of a near α-Ti alloy: Temperature optimization, microstructural evolution and mechanical performance evaluation. Mater. Sci. Eng. A 2021, 802, 140426. [Google Scholar] [CrossRef]

- Ci, S.; Hu, J.; Cheng, Z.; Liu, Q.; Xie, S.; Cai, X.; Dong, D.; Wang, Q. Impact of Hot Isostatic Pressing Temperature on Tensile Properties of TA15 Titanium Alloy Produced via Laser Powder Bed Fusion. Coatings 2023, 13, 1742. [Google Scholar] [CrossRef]

- Lu, S.L.; Tang, H.P.; Ning, Y.P.; Liu, N.; StJohn, D.H.; Qian, M. Microstructure and Mechanical Properties of Long Ti-6Al-4V Rods Additively Manufactured by Selective Electron Beam Melting Out of a Deep Powder Bed and the Effect of Subsequent Hot Isostatic Pressing. Met. Mater. Trans. A 2015, 46, 3824–3834. [Google Scholar] [CrossRef]

- Beladi, H.; Rohrer, G.S.; Rollett, A.D.; Tari, V.; Hodgson, P.D. The distribution of intervariant crystallographic planes in a lath martensite using five macroscopic parameters. Acta Mater. 2014, 63, 86–98. [Google Scholar] [CrossRef]

- Huang, D.-m.; Wang, H.-l.; Chen, X.; Chen, Y.; Guo, H. Influence of forging process on microstructure and mechanical properties of large section Ti−6.5Al−1Mo−1V−2Zr alloy bars. Trans. Nonferrous Met. Soc. China 2013, 23, 2276–2282. [Google Scholar] [CrossRef]

- Jiang, J.; Ren, Z.; Ma, Z.; Zhang, T.; Zhang, P.; Zhang, D.Z.; Mao, Z. Mechanical properties and microstructural evolution of TA15 Ti alloy processed by selective laser melting before and after annealing. Mater. Sci. Eng. A 2020, 772, 138742. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Zhang, H.; Yang, Y.; Zhu, Y.; Huang, A.; Zhang, K. Martensite decomposition and its effect on mechanical performance in laser powder bed fusion Ti–6.5Al–2Zr–1Mo–1V alloy. Mater. Sci. Eng. A 2025, 937, 148449. [Google Scholar] [CrossRef]

- Lv, X.; Lu, J.; Chai, R.; Fu, H. In-situ SEM-EBSD tensile study at room temperature of additive manufactured TA15 alloy: Microstructure, texture and mechanical behavior. Mater. Today Commun. 2025, 45, 112402. [Google Scholar] [CrossRef]

- Wang, C.; Yang, Z.; Wang, Y.; Yi, J.; Yang, G.; He, B. Effect of annealing treatment on the phase transformation and mechanical properties of TA15 alloy fabricated by WAAM. Intermetallics 2025, 177, 108590. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, X.; Kou, H.; Chang, J.; Yin, Z.; Li, J. Improvement of microstructure homogenous and tensile properties of powder hot isostatic pressed TA15 titanium alloy via heat treatment. Mater. Lett. 2022, 311, 131585. [Google Scholar] [CrossRef]

- Yang, S.; Sun, Q.; Zhou, S.; Li, W.; Wang, X.; Luo, J.; Zhang, J.; Chen, C.; Qi, J.; Tao, R. Mechanical properties and microstructural evolution of near α titanium alloy TA15 manufactured via laser powder bed fusion before and after heat treatment. Mater. Today Commun. 2025, 46, 112616. [Google Scholar] [CrossRef]

- Li, H.; Yu, J.; Jia, W.; Lin, Q.; Wu, J.; Chen, G. Experimental and mechanistic investigation on the plastic anisotropic deformation behavior of α-phase titanium alloy Ti-2Al-2.5Zr. J. Mater. Sci. Technol. 2025, 212, 17–34. [Google Scholar] [CrossRef]

- Wang, P.; Mao, P.; Wei, Z.; Zhou, L.; Wang, Z.; Wang, F.; Yi, H.; Liu, Z. Detwinning behavior of TA2 pure titanium during in-situ tensile. J. Alloys Compd. 2025, 1026, 180234. [Google Scholar] [CrossRef]

- Xiaoyu, J.; Jianwei, X.; Hui, Z.; Jingyao, D.; Weidong, Z.; Wanglei, W. Plastic deformation mechanism of TA1 pure titanium plate using SEM-EBSD in-situ tensile testing. Mater. Sci. Eng. A 2024, 908, 146768. [Google Scholar] [CrossRef]

- Amouzou, K.E.K.; Richeton, T.; Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A. Micromechanical modeling of hardening mechanisms in commercially pure a-titanium in tensile condition. Int. J. Plast. 2016, 80, 222–240. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Phukan, H.; Kenesei, P.; Park, J.S.; Lind, J.; Suter, R.M.; Bieler, T.R. Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater. 2017, 132, 598–610. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.; He, B.; Li, Z.; Zhu, Y.; Zheng, D.; Tian, X.; Zhang, S. Effect of α texture on the anisotropy of yield strength in Ti–6Al–2Zr–1Mo–1V alloy fabricated by laser directed energy deposition technique. Mater. Sci. Eng. A 2021, 824, 141771. [Google Scholar] [CrossRef]

- Chun, Y.B.; Battaini, M.; Davies, C.H.J.; Hwang, S.K. Distribution Characteristics of In-Grain Misorientation Axes in Cold-Rolled Commercially Pure Titanium and Their Correlation with Active Slip Modes. Metall. Mater. Trans. A 2010, 41, 3473–3487. [Google Scholar] [CrossRef]

- Li, C.; Sun, J.; Feng, A.; Wang, H.; Zhang, X.; Zhang, C.; Zhao, F.; Cao, G.; Qu, S.; Chen, D. Active Slip Mode Analysis of an Additively Manufactured Ti-6Al-4V Alloy via In-Grain Misorientation Axis Distribution. Metals 2022, 12, 532. [Google Scholar] [CrossRef]

- Lin, X.; Chen, Z.; Shao, J.; Xiong, J.; Hu, Z.; Liu, C. Deformation mechanism, orientation evolution and mechanical properties of annealed cross-rolled Mg-Zn-Zr-Y-Gd sheet during tension. J. Magnes. Alloys 2023, 11, 2340–2350. [Google Scholar] [CrossRef]

- Wang, P.; Wei, Z.; Mao, P.; Le, Z.; Wang, Z.; Wang, F.; Liu, X.; Liu, Z. Investigation of active slip modes via in-grain misorientation axis and strain compatibility of TA2 alloy during in-situ tensile deformation. J. Alloys Compd. 2024, 984, 173970. [Google Scholar] [CrossRef]

- Li, C.; Luo, J. Deformation anisotropy and lamellar α re-orientation of TC17 alloy under the different slip modes of HCP structure. J. Mater. Res. Technol. 2024, 33, 5339–5348. [Google Scholar] [CrossRef]

- Bridier, F.; Villechaise, P.; Mendez, J. Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation. Acta Mater. 2005, 53, 555–567. [Google Scholar] [CrossRef]

- Meng, Z.C.; Zhang, J.H.; Li, D.; Guo, H.; Wang, H.; Xu, D.S.; Zhao, Z.B.; Wang, Q.J.; Yang, R. Formation mechanism of three-fold {101‾1}α twins during β to α phase transformation in titanium. J. Mater. Sci. Technol. 2024, 194, 138–141. [Google Scholar] [CrossRef]

- Guan, X.R.; Chen, Q.; Qu, S.J.; Cao, G.J.; Wang, H.; Ran, X.D.; Feng, A.H.; Chen, D.L. High-strain-rate deformation: Stress-induced phase transformation and nanostructures in a titanium alloy. Int. J. Plast. 2023, 169, 103707. [Google Scholar] [CrossRef]

- Lan, L.; Xin, R.; Jin, X.; Gao, S.; He, B.; Rong, Y.; Min, N. Effects of Laser Shock Peening on Microstructure and Properties of Ti-6Al-4V Titanium Alloy Fabricated via Selective Laser Melting. Materials 2020, 13, 3261. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Sun, B.; Zhang, S.; Liu, Y.; Sun, W.; Cui, N.; Lv, B. The 332<113> Twinning Behavior of a Ti-15Mo Medical Alloy during Cyclic Deformation and Its Effect on Microstructure and Performance. Materials 2024, 17, 1462. [Google Scholar] [CrossRef]

- Fu, Y.; Cheng, Y.; Cui, Y.; Xin, Y.; Zeng, Y.; Liu, X.; Chen, G. Deformation mechanism of commercially pure titanium under biaxial loading at ambient and elevated temperatures. J. Mater. Sci. Technol. 2022, 126, 237–251. [Google Scholar] [CrossRef]

- Yan, C.K.; Feng, A.H.; Qu, S.J.; Cao, G.J.; Sun, J.L.; Shen, J.; Chen, D.L. Dynamic recrystallization of titanium: Effect of pre-activated twinning at cryogenic temperature. Acta Mater. 2018, 154, 311–324. [Google Scholar] [CrossRef]

- Gengor, G.; Mohammed, A.S.K.; Sehitoglu, H. {101¯2} Twin interface structure and energetics in HCP materials. Acta Mater. 2021, 219, 117256. [Google Scholar] [CrossRef]

- Humbert, M.; Germain, L.; Gey, N.; Bocher, P.; Jahazi, M. Study of the variant selection in sharp textured regions of bimodal IMI 834 billet. Mater. Sci. Eng. A 2006, 430, 157–164. [Google Scholar] [CrossRef]

- Whittaker, R.; Fox, K.; Walker, A. Texture variations in titanium alloys for aeroengine applications. Mater. Sci. Technol. 2010, 26, 676–684. [Google Scholar] [CrossRef]

- Huang, L.; Sun, Z.; Cao, J.; Yin, Z. The formation and evolution of macrozone in Ti-6242S alloy during thermo-mechanical processing. J. Alloys Compd. 2021, 861, 158533. [Google Scholar] [CrossRef]

- Guan, X.R.; Chen, Q.; Qu, S.J.; Cao, G.J.; Wang, H.; Feng, A.H.; Chen, D.L. Adiabatic shear instability in a titanium alloy: Extreme deformation-induced phase transformation, nanotwinning, and grain refinement. J. Mater. Sci. Technol. 2023, 150, 104–113. [Google Scholar] [CrossRef]

- Chen, J.; An, Q.; Deng, L.; Ye, P.; Wang, C.; Chen, J.; Xiao, L.; Wang, B. Activation mechanism of multiple twin variants during uniaxial compression in pure titanium. J. Alloys Compd. 2025, 1024, 180280. [Google Scholar] [CrossRef]

| Variant | Plane Parallel | Direction Parallel | Percentage of Area | ||

|---|---|---|---|---|---|

| α1 | V1 | (1–10)β//(0001)α | [111]β//[11–20]α | 9.3% | 14.2% |

| V2 | (1–10)β//(0001)α | [11–1]β//[11–20]α | 4.9% | ||

| α2 | V3 | (011)β//(0001)α | [11–1]β//[11–20]α | 8.0% | 13.1% |

| V4 | (011)β//(0001)α | [1–11]β//[11–20]α | 5.1% | ||

| α3 | V5 | (10–1)β//(0001)α | [1–11]β//[[11–20]α | 9.4% | 16.8% |

| V6 | (10–1)β//(0001)α | [111]β//[11–20]α | 7.4% | ||

| α4 | V7 | (110)β//(0001)α | [1–11]β//[11–20]α | 10.0 | 14.6% |

| V8 | (110)β//(0001)α | [–111]β//[[11–20]α | 4.6% | ||

| α5 | V9 | (01–1)β//(0001)α | [–111]β//[11–20]α | 5.4% | 13.2% |

| V10 | (01–1)β//(0001)α | [111]β//[11–20]α | 7.8% | ||

| α6 | V11 | (101)β//(0001)α | [11–1]β//[11–20]α | 14.4% | 22.3% |

| V12 | (101)β//(0001)α | [–111]β//[11–20]α | 7.9% | ||

| Slip Mode | Slip Plane | α1 | α2 | α3 | α4 | α5 | α6 | CRSS |

|---|---|---|---|---|---|---|---|---|

| Prismatic <a> | {10–10}<11–20> | 0.07 | 0.21 | 0.26 | 0.47 | 0.45 | 0.48 | 96 MPa |

| Basal <a> | {0001}<11–20> | 0.34 | 0.46 | 0.48 | 0.07 | 0.23 | 0.15 | 127 MPa |

| Pyramidal Ⅰ <a> | {10–11}<11–20> | 0.19 | 0.36 | 0.39 | 0.43 | 0.46 | 0.47 | 140 MPa |

| Pyramidal Ⅱ <c+a> | {10–11}<11–2–3> | 0.49 | 0.42 | 0.37 | 0.45 | 0.48 | 0.48 | 240 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Liang, J.; Cao, G.; Feng, A.; Wang, H.; Qu, S.; Chen, D. Quasi-In Situ EBSD Investigation of Variant Evolution and Twin Formation in a Hot Isostatic Pressing-Treated Additively-Manufactured Titanium Alloy Under Tensile Loading. Materials 2025, 18, 3169. https://doi.org/10.3390/ma18133169

Zhu F, Liang J, Cao G, Feng A, Wang H, Qu S, Chen D. Quasi-In Situ EBSD Investigation of Variant Evolution and Twin Formation in a Hot Isostatic Pressing-Treated Additively-Manufactured Titanium Alloy Under Tensile Loading. Materials. 2025; 18(13):3169. https://doi.org/10.3390/ma18133169

Chicago/Turabian StyleZhu, Fengli, Jiahong Liang, Guojian Cao, Aihan Feng, Hao Wang, Shoujiang Qu, and Daolun Chen. 2025. "Quasi-In Situ EBSD Investigation of Variant Evolution and Twin Formation in a Hot Isostatic Pressing-Treated Additively-Manufactured Titanium Alloy Under Tensile Loading" Materials 18, no. 13: 3169. https://doi.org/10.3390/ma18133169

APA StyleZhu, F., Liang, J., Cao, G., Feng, A., Wang, H., Qu, S., & Chen, D. (2025). Quasi-In Situ EBSD Investigation of Variant Evolution and Twin Formation in a Hot Isostatic Pressing-Treated Additively-Manufactured Titanium Alloy Under Tensile Loading. Materials, 18(13), 3169. https://doi.org/10.3390/ma18133169