Evaluation of the Thermal Insulation Properties of Composites with ZrO2/Al Coatings Intended for the Construction of Protective Gloves

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. ZrO2/Al Coating Method

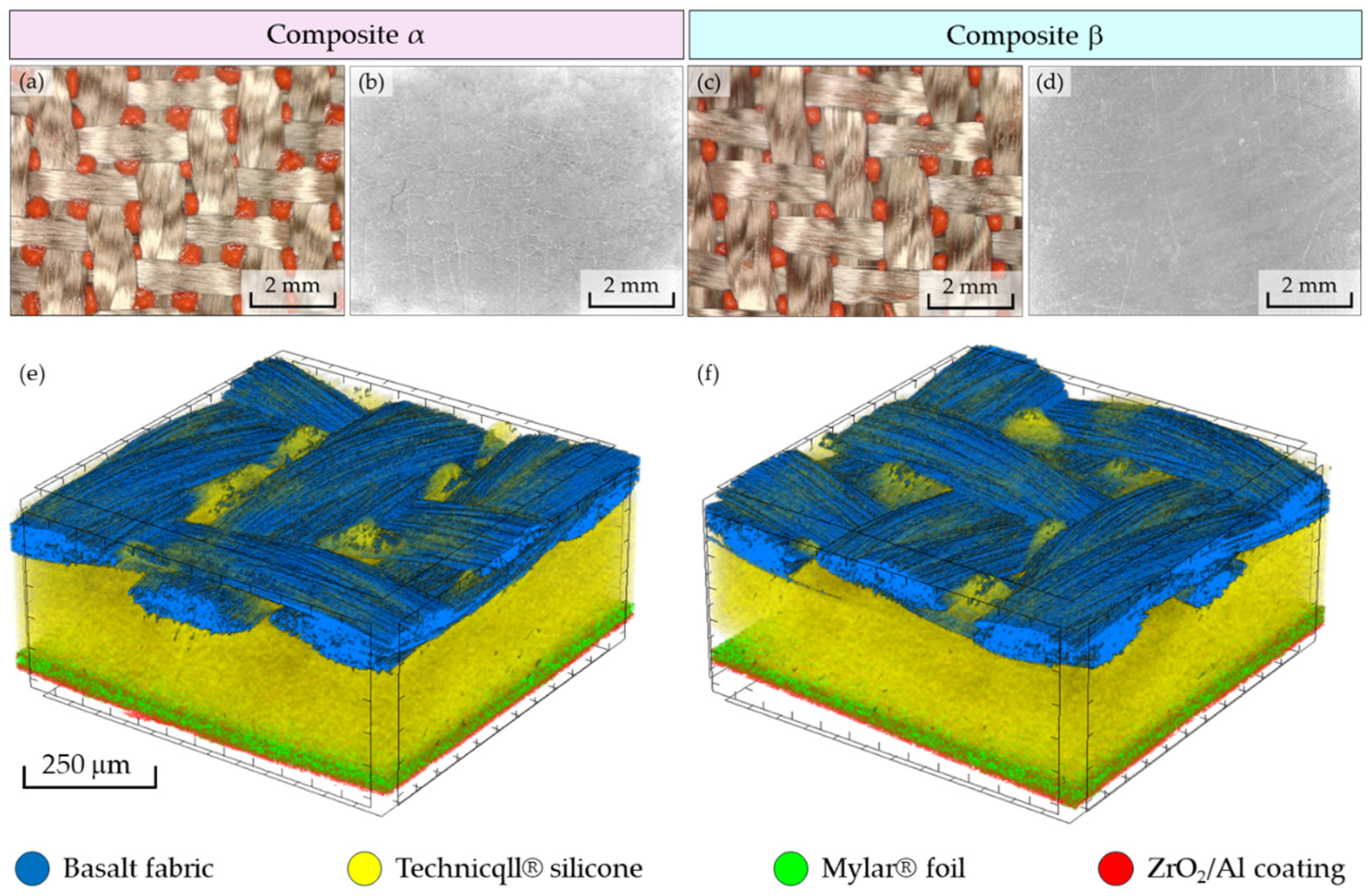

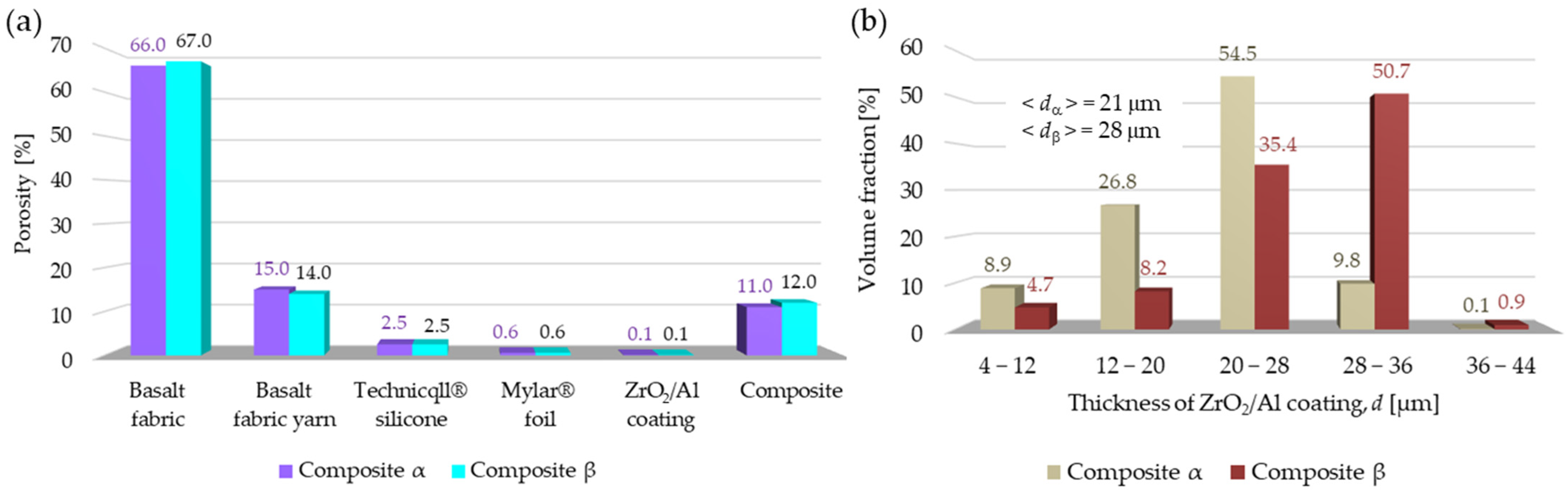

2.2.2. Assessment of Structural Properties of Composites

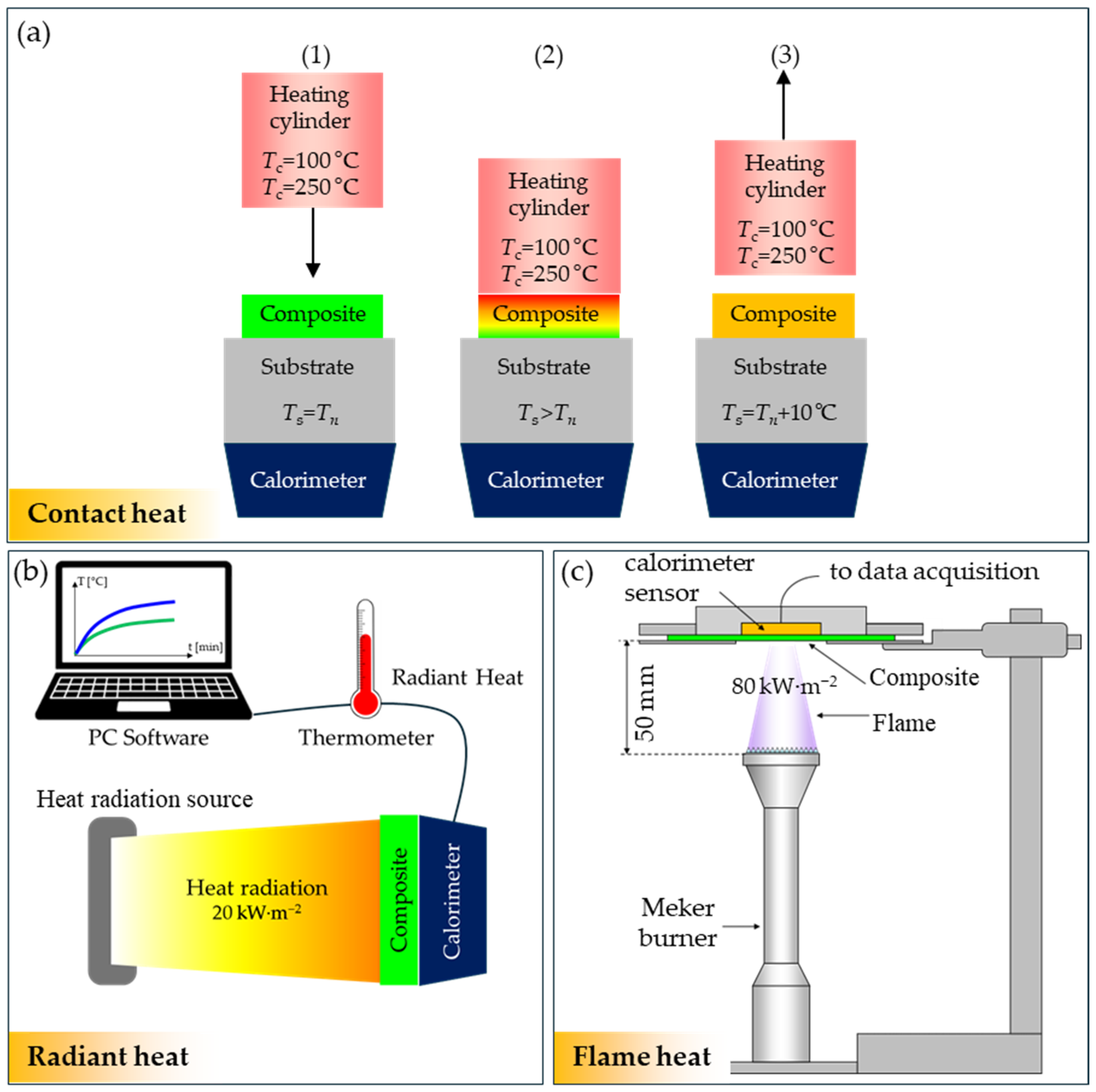

2.2.3. Evaluation of the Thermal Properties of Composites

Contact Heat

Radiant Heat

Flame Heat

3. Results and Discussion

4. Conclusions

- The analysis of the structure of both composites using micro-CT showed that in both tested composites the arrangement and morphology of the component layers is comparable, which proves the homogeneity of the raw materials used and the repeatability of composite formation.

- The performed micro-CT structural analysis of the ZrO2/Al coatings showed that their thicknesses determined in the PVD magnetron sputtering process did not differ significantly from the actual coating thicknesses obtained in both composites. The difference in the assumed and actual average thickness of the ceramic–metal coating was 5% for composite α and 7% for composite β.

- The results of the experiment in which the composites were exposed to contact heat show that both composites can be used for thermal protective gloves only up to a contact temperature of 100 °C (first performance level).

- The results of the experiment in which the composites were exposed to radiant heat show that both composites can be used for thermal protective gloves, and they reach the fourth performance level.

- The results of the experiment in which the composites were exposed to flame heat show that both composites can be used for thermal protective gloves, and they reach the third performance level.

- Summarizing the results of the three experiments, it can be stated that the presented four-layer textile composites equipped with ZrO2/Al coatings provide effective protection against contact heat, radiant heat, and flame heat and can be successfully used in the construction of the back part of metallurgical protective gloves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bartkowiak, G.; Miśkiewicz, P. Preferences of employees of metallurgy and welder industry in relation to underwear—Surveys. FTEE 2021, 29, 61–65. [Google Scholar]

- Gadeikyte, A.; Sandonavicius, D.; Rimavicius, V.; Barauskas, R. Finite element analysis of heat and mass exchange between human skin and textile structures. Balt. J. Mod. Comput. 2022, 10, 159–169. [Google Scholar] [CrossRef]

- Greszta, A.; Bartkowiak, G.; Dąbrowska, A.; Gliścińska, E.; Machnowski, W.; Kozikowski, P. Multilayer Nonwoven Inserts with Aerogel/PCMs for the Improvement of Thermophysiological Comfort in Protective Clothing against the Cold. Materials 2022, 15, 2307. [Google Scholar] [CrossRef] [PubMed]

- Hrynyk, R.; Frydrych, I.; Irzmańska, I.; Stefko, A. Thermal properties of aluminized and non-aluminized basalt fabrics. Text. Res. J. 2013, 83, 1860–1872. [Google Scholar] [CrossRef]

- Trybus, M.; Guzik, P. Hand injuries at work. Occup. Med. 2004, 55, 341–344. [Google Scholar]

- Militký, J.; Kovačič, V.; Rubnerowá, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Hrynyk, R.; Frydrych, I. Study on textile assemblies with aluminized basalt fabrics destined for protective gloves. Int. J. Cloth. Sci. Technol. 2015, 27, 705–719. [Google Scholar] [CrossRef]

- Kumbhar, V.P. An overview: Basalt rock fibers—New construction material. Acta Eng. Int. 2014, 2, 11–18. [Google Scholar]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber—A review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on basalt fiber composites and their applications in clean energy sector and power grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Y.; Du, H. The Influence of Two Types of Functional Particles on the Electromagnetic Properties and Mechanical Properties of Double-Layer Coated Basalt Fiber Fabrics. Text. Res. J. 2022, 92, 2591–2604. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Michałowski, S. Basalt Powder as an Eco-Friendly Filler for Epoxy Composites: Thermal and Thermomechanical Properties Assessment. Compos. Part B Eng. 2019, 164, 272–279. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Tokarska, M. Shaping of Thermal Protective Properties of Basalt Fabric-Based Composites by Direct Surface Modification Using Magnetron Sputtering Technique. AUTEX Res. J. 2024, 24, 20230029. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Meyyappan, P.L.; Jemimah, C.M. Studies on Strength Properties of Basalt Fibre Reinforced Concrete. Mater. Today Proc. 2024, 43, 2105–2108. [Google Scholar] [CrossRef]

- AZO Materials. Available online: https://www.azom.com/properties.aspx?ArticleID=133 (accessed on 11 November 2024).

- Unipretec. Available online: https://www.unipretec-ceramics.com/p/zirconium-dioxide-ceramic (accessed on 11 November 2024).

- Unipretec. Available online: https://www.ceramtec-industrial.com/en/materials/zirconium-oxide (accessed on 11 November 2024).

- Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/radiation-heat-emissivity-aluminum-d_433.html (accessed on 11 November 2024).

- Baptista, A.; Silva, F.; Poeteiro, J.; Miguez, J.; Pitno, G. Review Sputtering Physical Vapour Deposition (PVD)Coatings: A Critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Salguero, J.; Vazquez, J.M.; Batista, M.; Del Sol, I. Recent advances in surface functionalisation. Coatings 2023, 13, 530. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Puszkarz, A.K. Assessment of Insulation against Contact Heat and Radiant Heat of Composites with TiO2-ZrO2-Al and Parylene C Coatings Intended for Protective Gloves Supported by Computational Fluid Dynamics. Appl. Sci. 2023, 13, 12420. [Google Scholar] [CrossRef]

- Venkatachalam, S.; Depriester, M.; Hadj Sahraoui, A.; Capoen, B.; Ammar, M.R.; Hourlier, D. Thermal conductivity of Kapton-derived carbon. Carbon 2017, 114, 134–140. [Google Scholar] [CrossRef]

- Kanda, G.S.; Ravelli, L.; Löwe, B.; Keeble, D.J. Positron annihilation lifetime spectroscopy study of Kapton thin foils. J. Phys. D Appl. Phys. 2016, 49, 025305. [Google Scholar] [CrossRef]

- EN ISO 12127-1:2016-02; Heat and Flame Protective Clothing—Determination of Contact Heat Transfer through Protective Clothing or Protective Clothing Materials—Part 1: Contact Heat Generated by a Heating Cylinder. ISO: Geneva, Switzerland, 2016.

- EN ISO 6942; Protective Clothing—Protection Against Heat and Flame—Test Method: Evaluation of Materials and Assemblies of Materials Exposed to Thermal Radiation. ISO: Geneva, Switzerland, 2002.

- EN ISO 9151; Protective Clothing Against Heat and Flame. Determination of Heat Transmission on Exposure to Flame. ISO: Geneva, Switzerland, 2016.

- EN 407:2020-10; Protective Gloves and Other Means of Protecting Hands Against Thermal Hazards (Heat and/or Fire). ISO: Geneva, Switzerland, 2020.

| Composite | Layer | Composition | Layer/Composite Thickness [μm] | |

|---|---|---|---|---|

| α | Fabric | Basalt | 380 | 1315 |

| Silicone | Technicqll® | 830 | ||

| Foil | Mylar® | 85 | ||

| PVD Coating | ZrO2/Al | 10/10 | ||

| β | Fabric | Basalt | 380 | 1325 |

| Silicone | Technicqll® | 830 | ||

| Foil | Mylar® | 85 | ||

| PVD Coating | ZrO2/Al | 20/10 | ||

| Performance Level | Contact Heat | Radiant Heat | Flame Heat | |

|---|---|---|---|---|

| Tc [°C] | tt [s] | RHTI24 [s] | HTI24 [s] | |

| 1 | 100 | ≥15 | ≥7 | ≥4 |

| 2 | 250 | ≥15 | ≥20 | ≥7 |

| 3 | 350 | ≥15 | ≥50 | ≥10 |

| 4 | 500 | ≥15 | ≥95 | ≥18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miśkiewicz, P.; Puszkarz, A.K.; Makówka, M. Evaluation of the Thermal Insulation Properties of Composites with ZrO2/Al Coatings Intended for the Construction of Protective Gloves. Materials 2025, 18, 242. https://doi.org/10.3390/ma18020242

Miśkiewicz P, Puszkarz AK, Makówka M. Evaluation of the Thermal Insulation Properties of Composites with ZrO2/Al Coatings Intended for the Construction of Protective Gloves. Materials. 2025; 18(2):242. https://doi.org/10.3390/ma18020242

Chicago/Turabian StyleMiśkiewicz, Pamela, Adam K. Puszkarz, and Marcin Makówka. 2025. "Evaluation of the Thermal Insulation Properties of Composites with ZrO2/Al Coatings Intended for the Construction of Protective Gloves" Materials 18, no. 2: 242. https://doi.org/10.3390/ma18020242

APA StyleMiśkiewicz, P., Puszkarz, A. K., & Makówka, M. (2025). Evaluation of the Thermal Insulation Properties of Composites with ZrO2/Al Coatings Intended for the Construction of Protective Gloves. Materials, 18(2), 242. https://doi.org/10.3390/ma18020242