Textured Lead-Free Piezoelectric Ceramics: A Review of Template Effects

Abstract

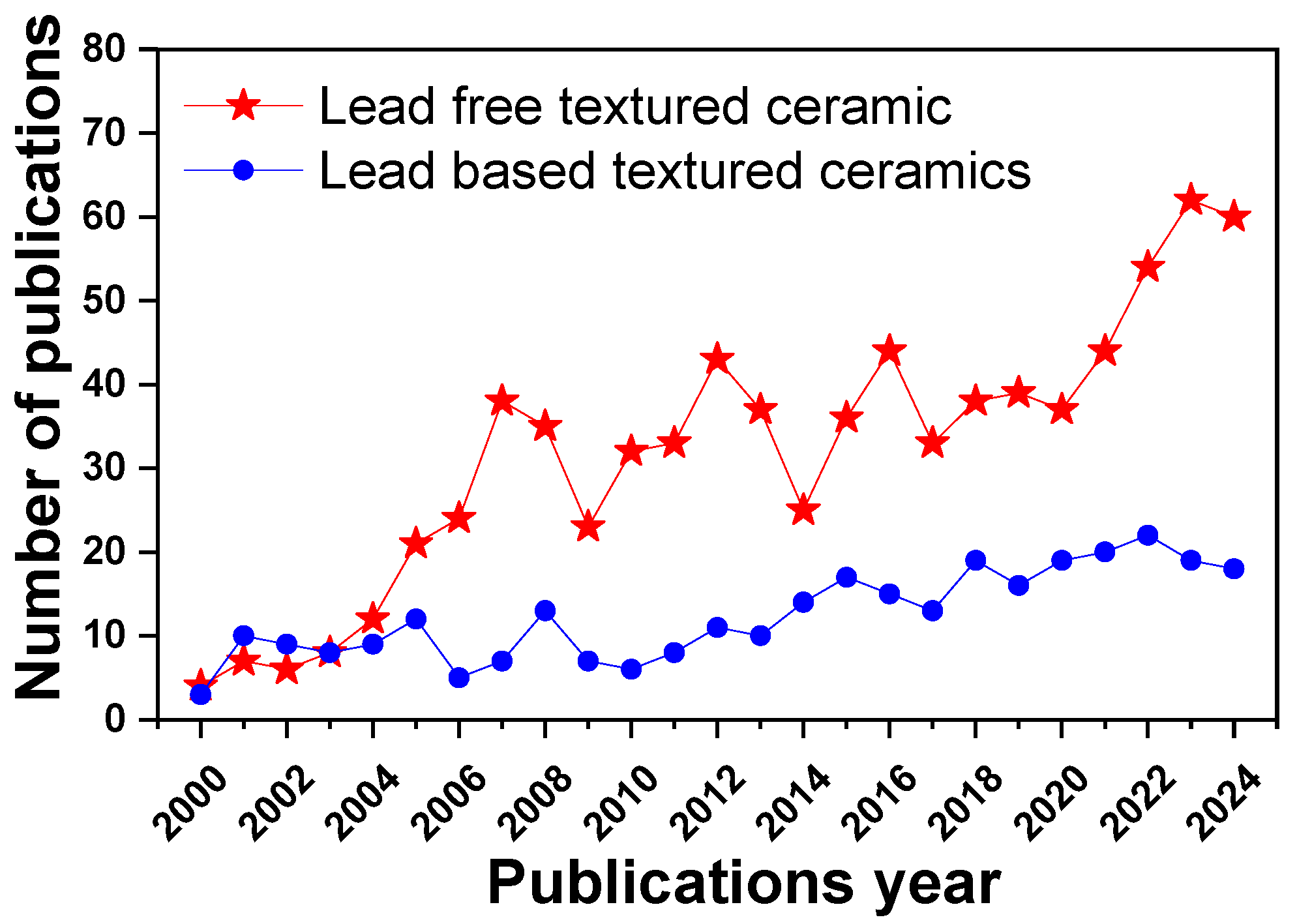

:1. Introduction

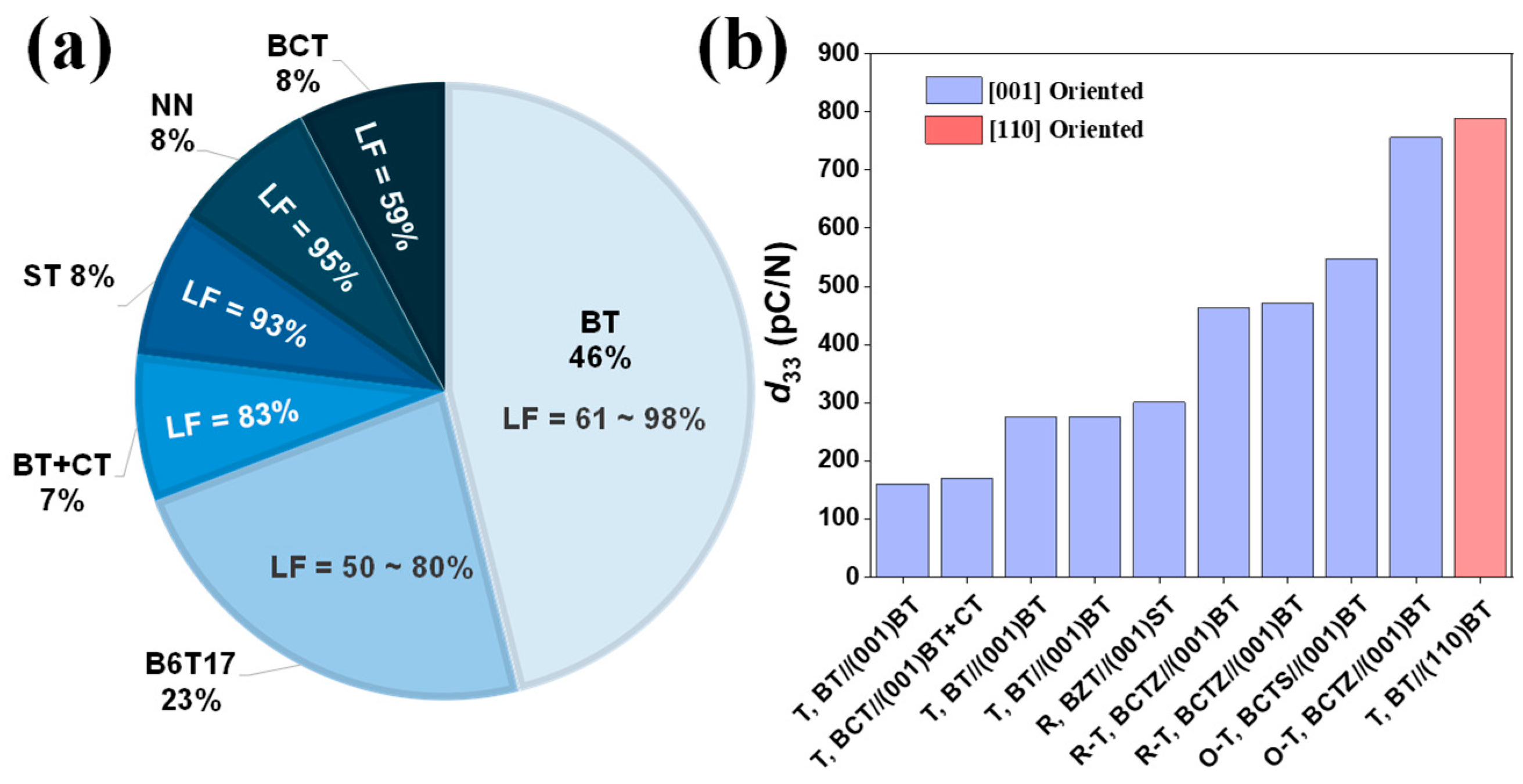

2. Textured BaTiO3-Based Ceramics

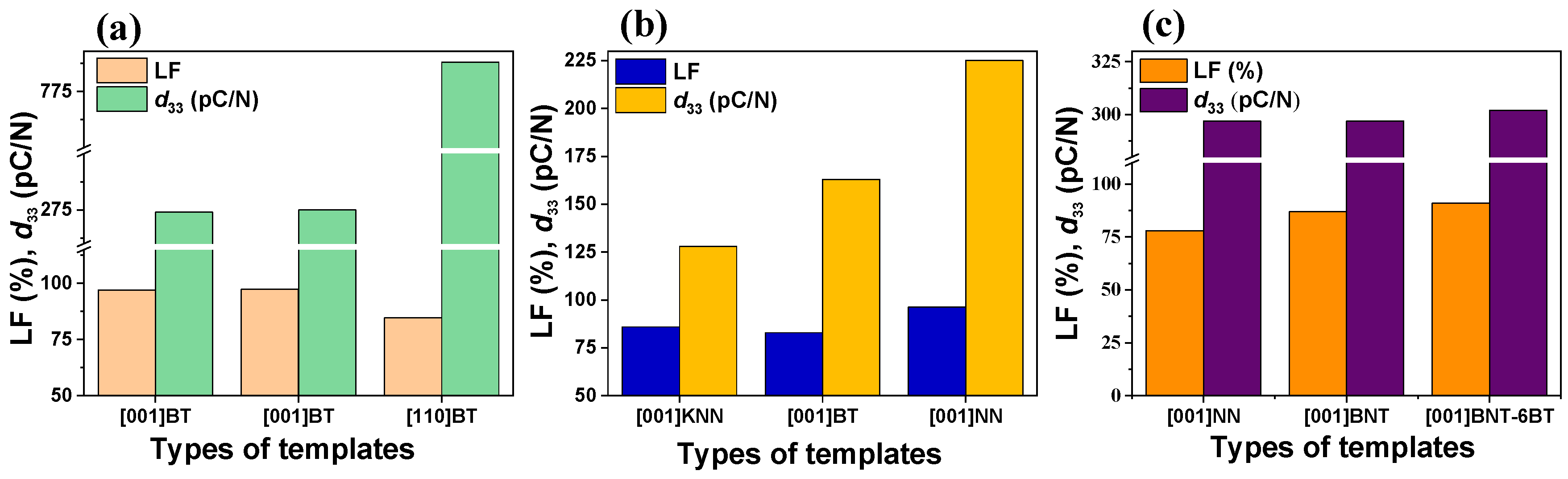

2.1. Template Chemistry Effect on Textured BaTiO3-Based Ceramics

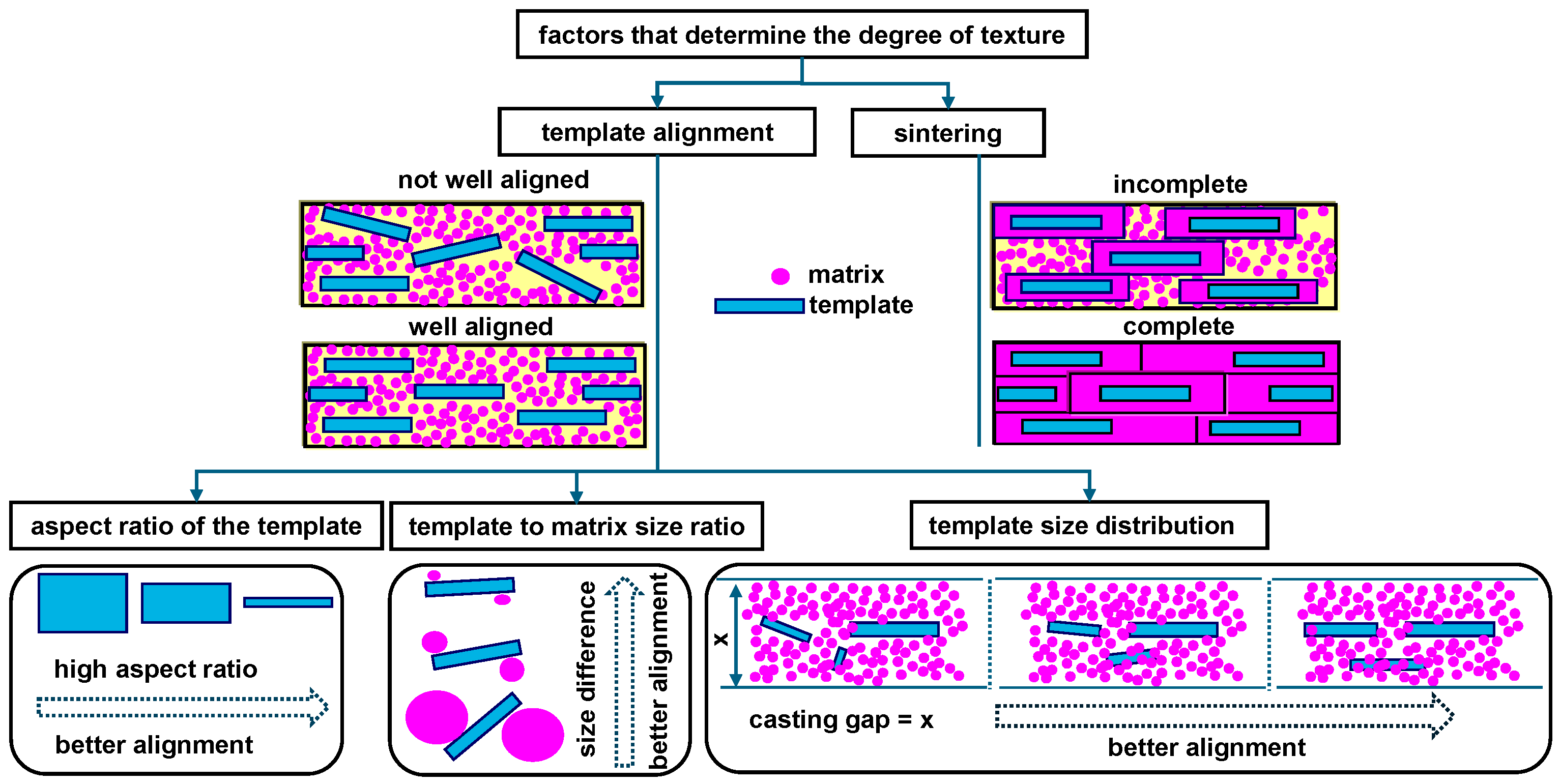

2.1.1. BT Templates for Texturing BT Ceramics

2.1.2. BT Templates for Texturing BCT Ceramics

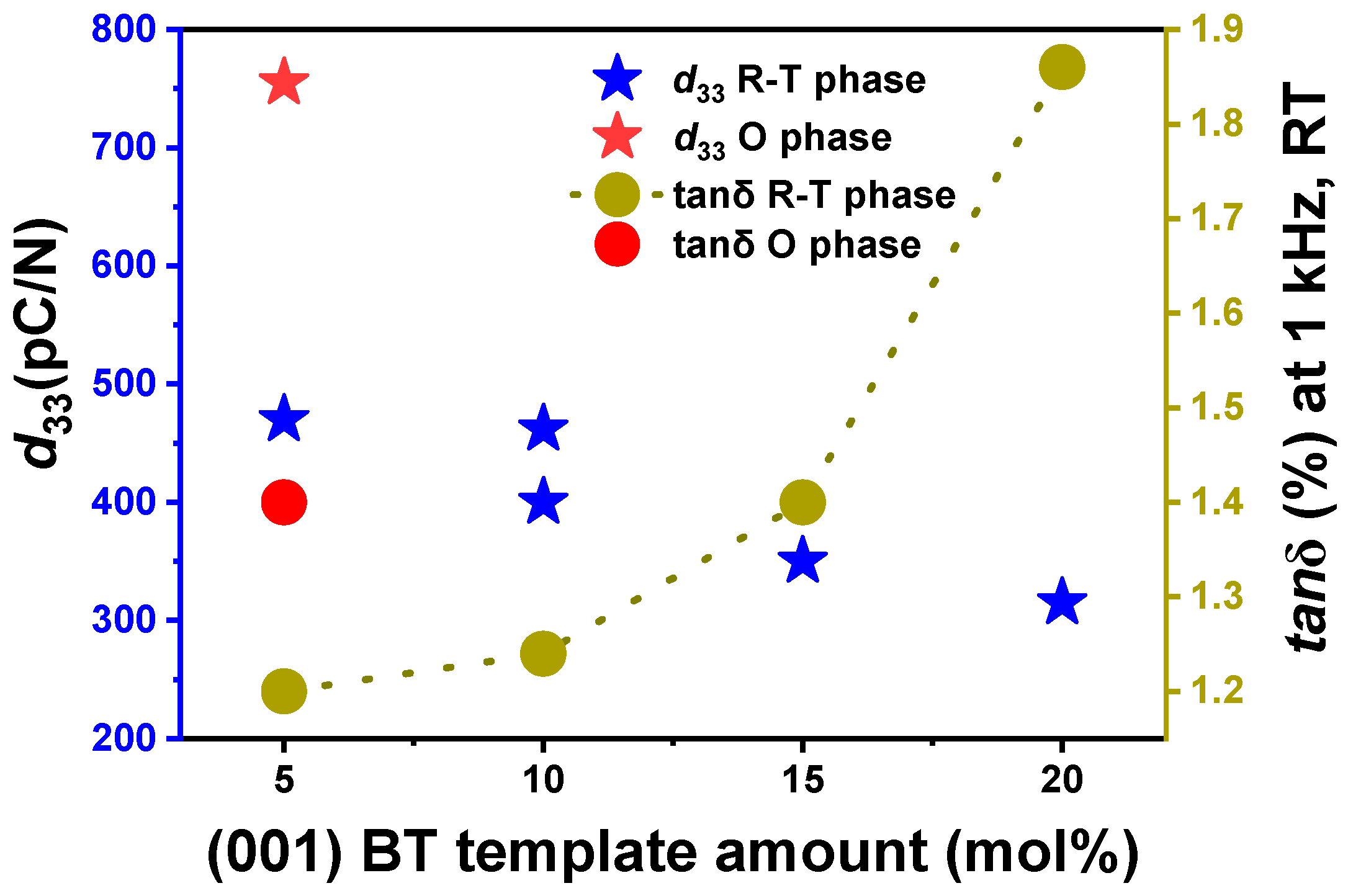

2.1.3. BT Templates for Texturing BCTZ Ceramics

2.1.4. ST Template in Texturing BZT and BST Ceramics

2.1.5. NN Template in Texturing BT Ceramics

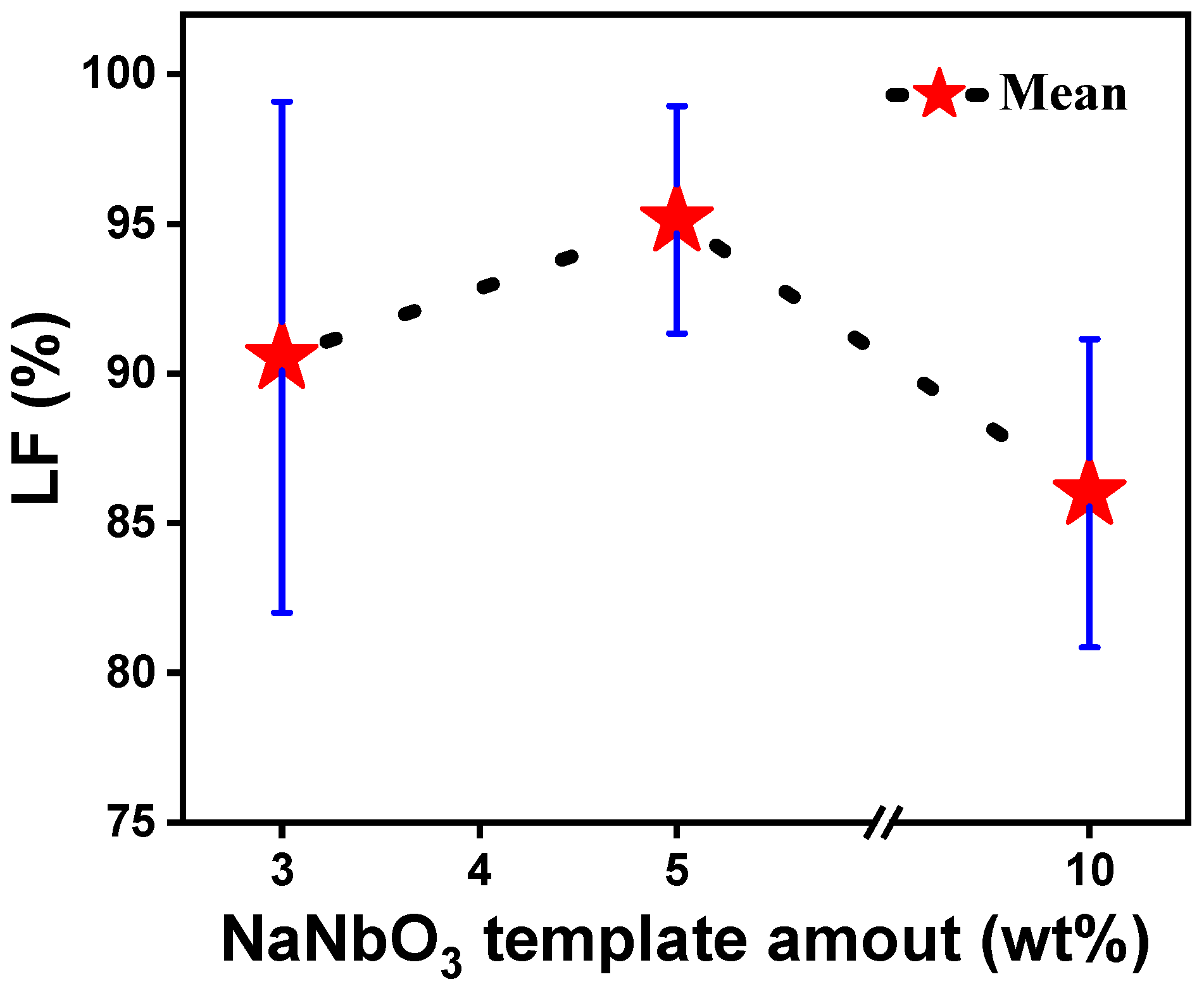

2.1.6. Summary of Template Chemistry Effects in BT-Based Ceramics

2.2. Effect of Texture Direction in BaTiO3-Based Ceramics

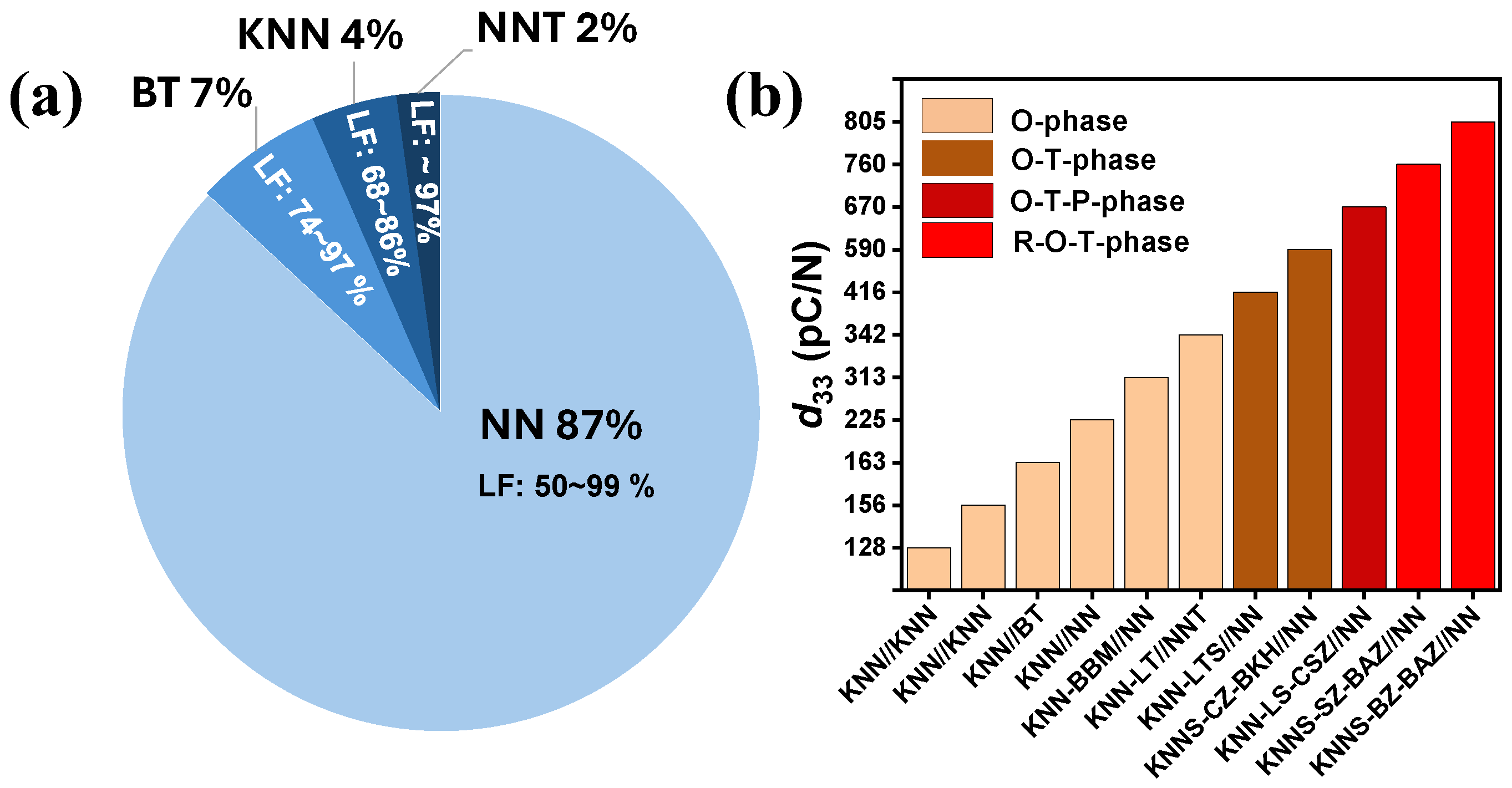

3. Textured K0.5Na0.5NbO3-Based Ceramics

3.1. Template Chemistry Effect on Textured KNN-Based Ceramics

3.1.1. NN Templates for Texturing KNN-Based Ceramics

3.1.2. KNN Templates for Texturing KNN-Based Ceramics

3.1.3. BT Templates for Texturing KNN-Based Ceramics

3.1.4. Summary of Template Chemistry Effects on Textured KNN

3.2. Effect of Texture Direction in KNN-Based Ceramics

4. Textured Na0.5Bi0.5TiO3-Based Ceramics

4.1. Template Chemistry Effect on Textured BNT-Based Ceramics

4.1.1. BiT Templates for Texturing BNT-Based Ceramics

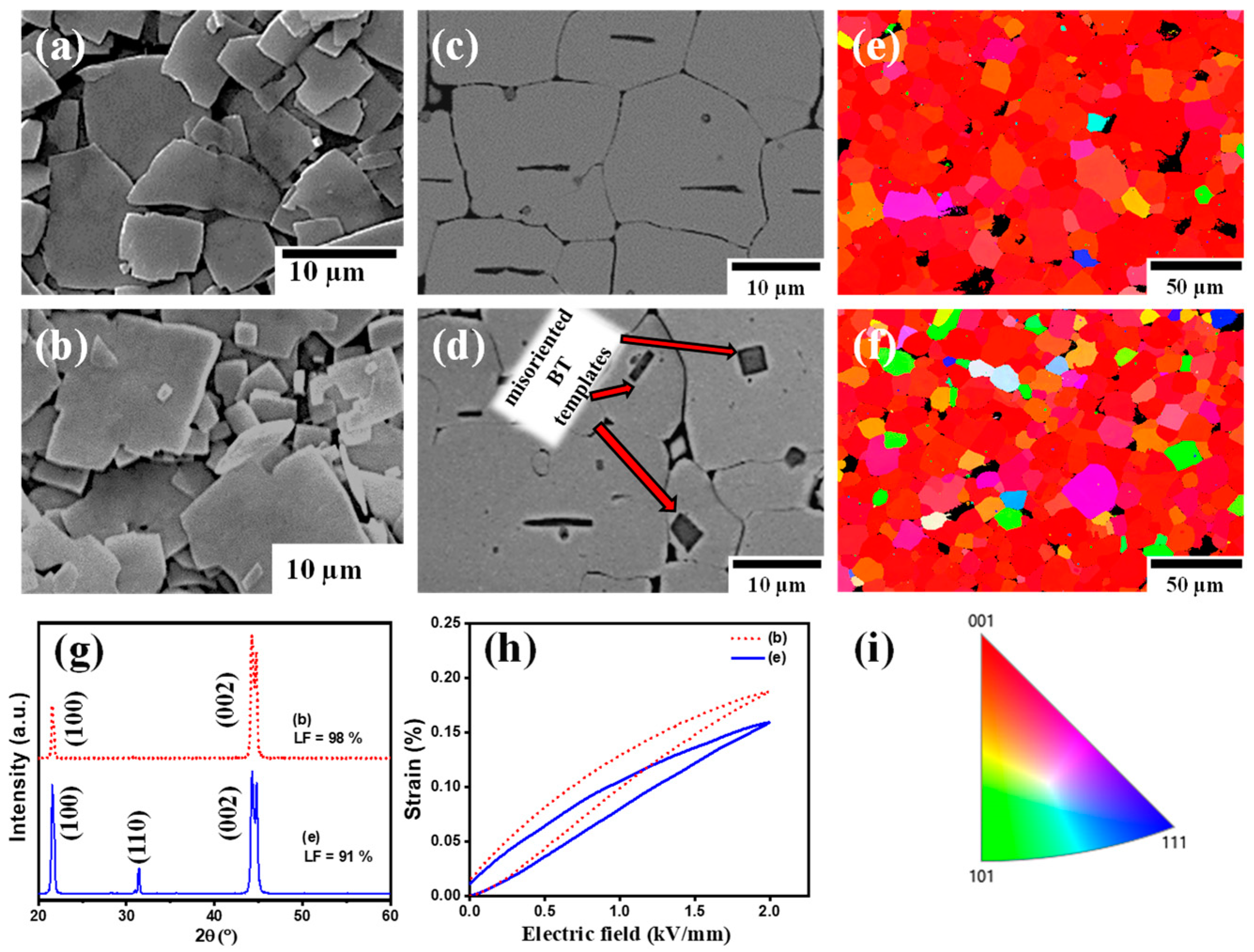

4.1.2. BT Templates for Texturing BNT-Based Ceramics

4.1.3. ST Template in Texturing BNT-Based Ceramics

4.1.4. BNT Template in Texturing BNT-Based Ceramics

4.1.5. BNT-BT Template in Texturing BNT-Based Ceramics

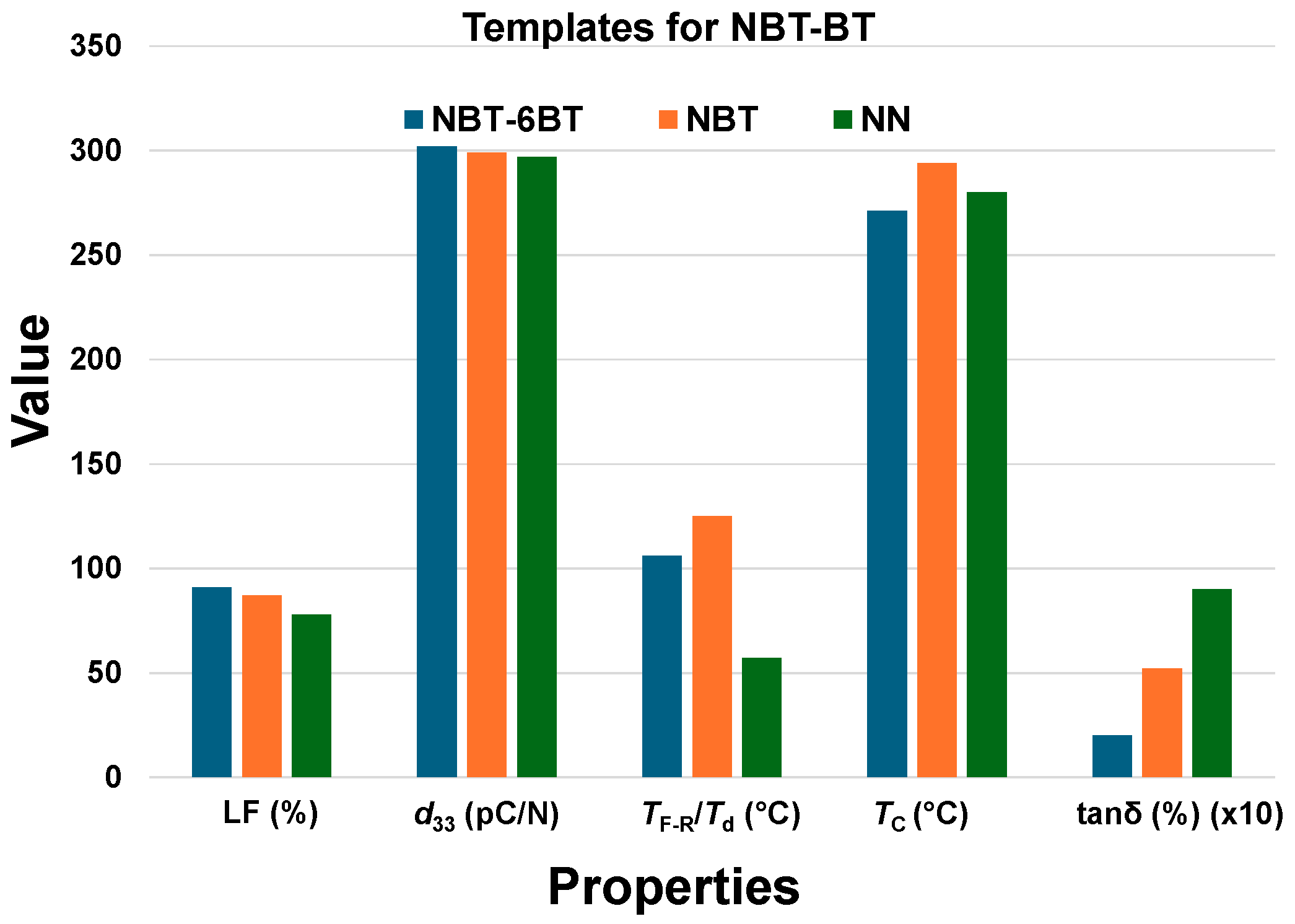

4.1.6. Summary of Template Chemistry Effects in BNT-BT

4.2. Effect of Texture Direction in BNT-Based Ceramics

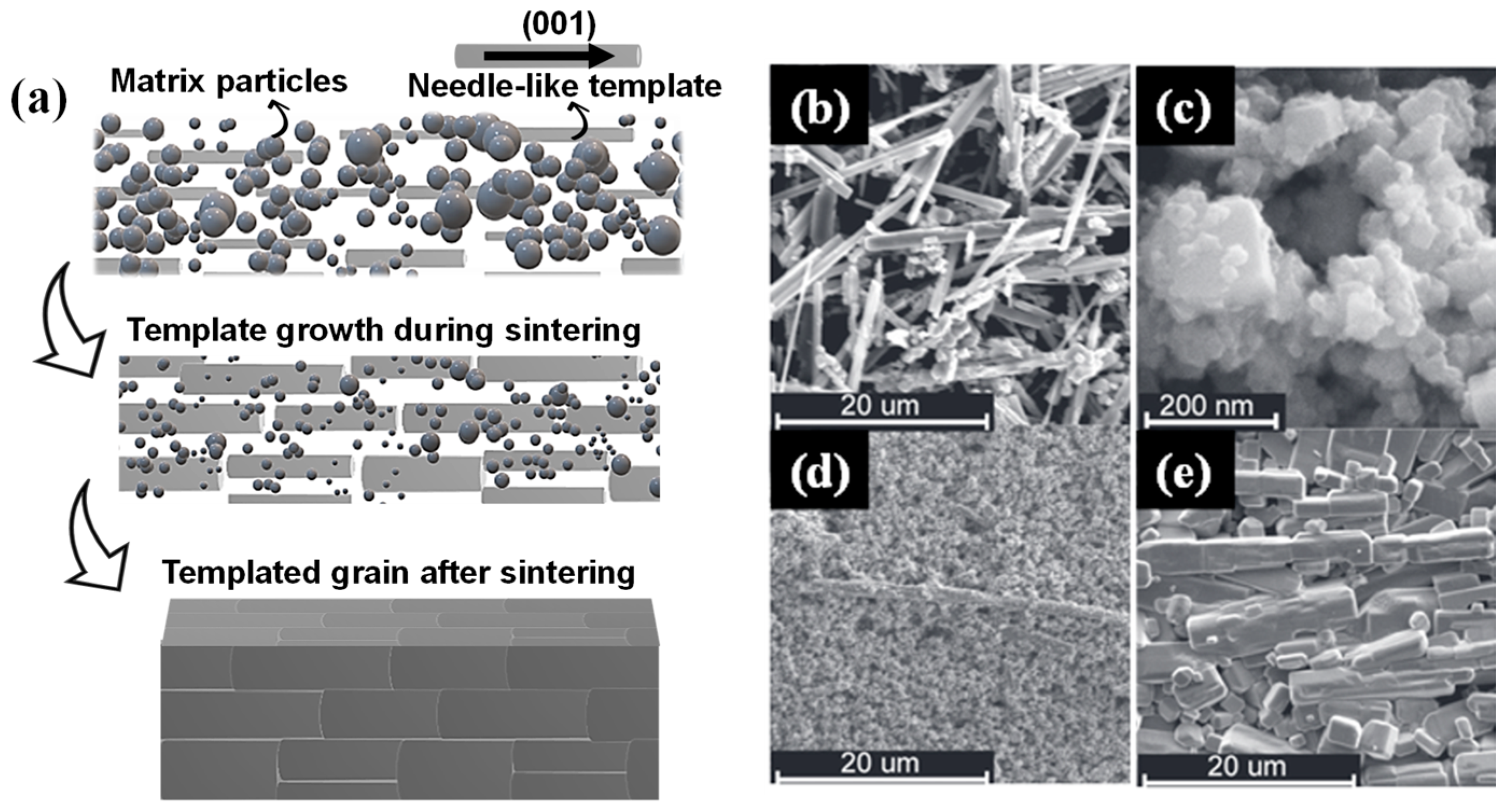

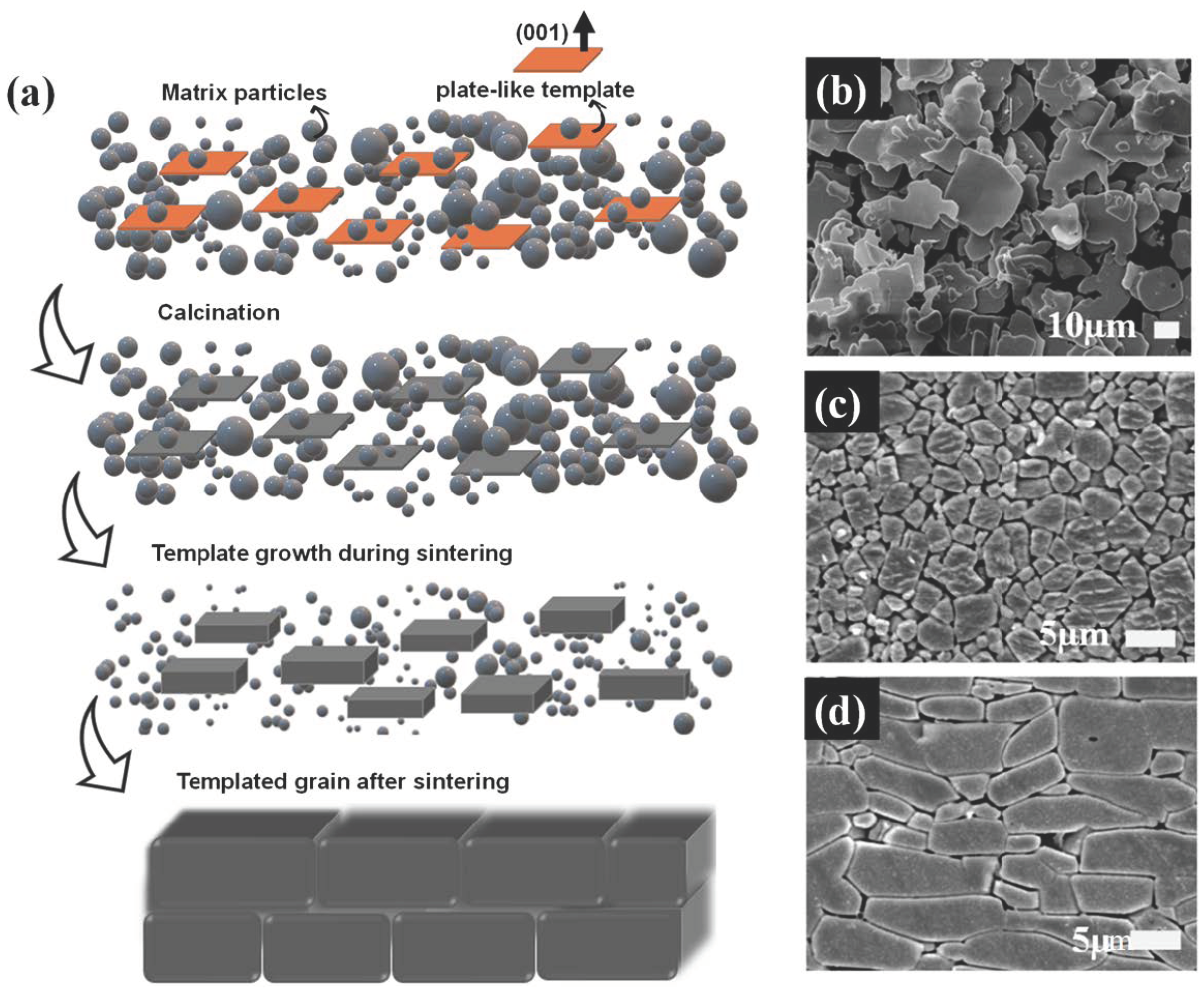

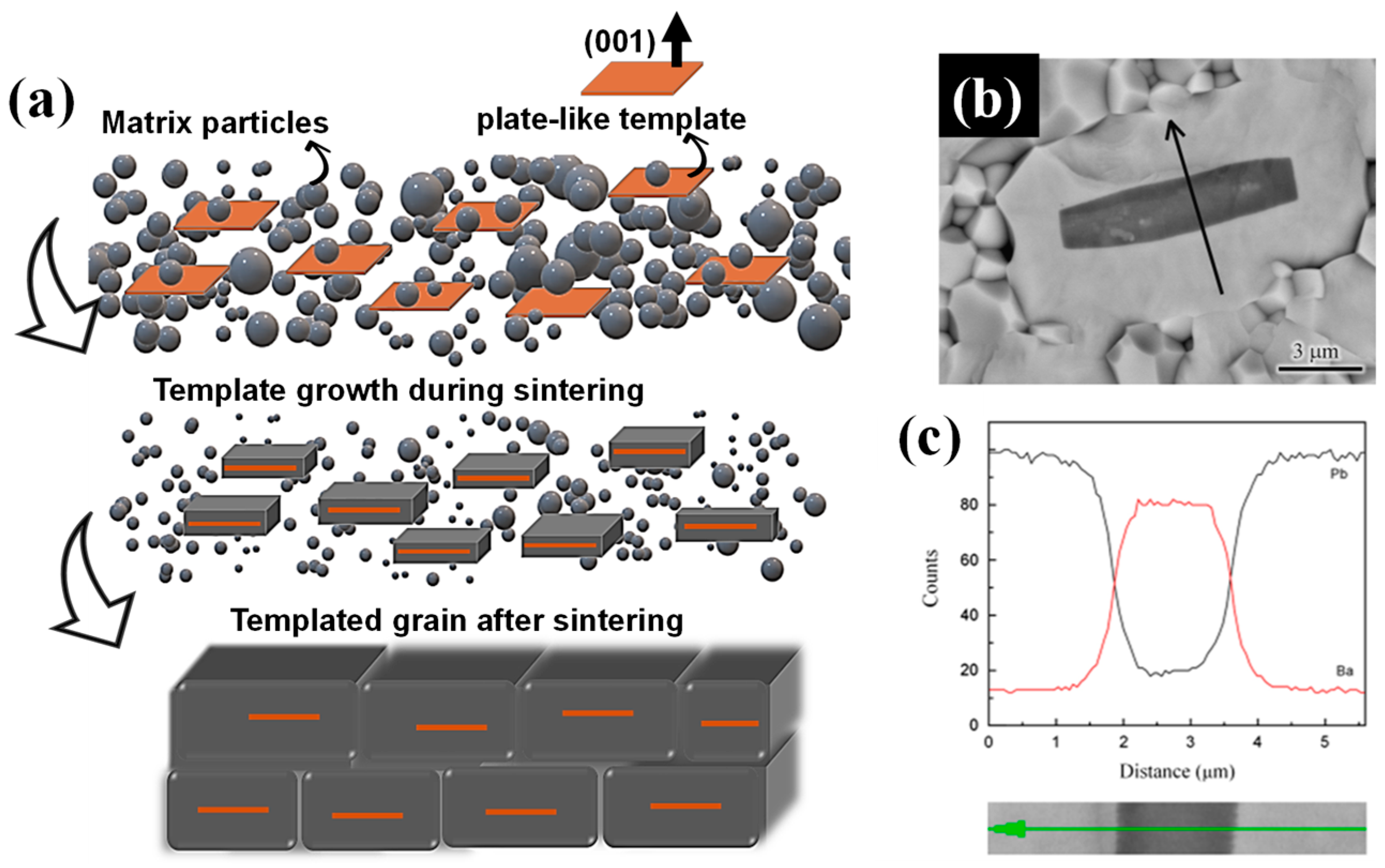

5. Effect of Template Morphology (Size and Shape) on Textured Ceramics

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Uchino, K. Glory of piezoelectric perovskites. Sci. Technol. Adv. Mater. 2015, 16, 046001. [Google Scholar] [CrossRef] [PubMed]

- Setter, N. Piezoelectric Materials in Devices; Swiss Institute of Technology: Zurih, Switzerland, 2002. [Google Scholar]

- Bell, A.J.; Deubzer, O. Lead-free piezoelectrics—The environmental and regulatory issues. MRS Bull. 2018, 43, 581–587. [Google Scholar] [CrossRef]

- Hong, C.H.; Kim, H.P.; Choi, B.Y.; Han, H.S.; Son, J.S.; Ahn, C.W.; Jo, W. Lead-free piezoceramics—Where to move on? J. Mater. 2016, 2, 1–24. [Google Scholar] [CrossRef]

- Sekhar, M.C.; Veena, E.; Kumar, N.S.; Naidu, K.C.B.; Mallikarjuna, A.; Basha, D.B. A Review on Piezoelectric Materials and Their Applications. Cryst. Res. Technol. 2023, 58, 2200130. [Google Scholar] [CrossRef]

- Messing, G.L.; Trolier-McKinstry, S.; Sabolsky, E.M.; Duran, C.; Kwon, S.; Brahmaroutu, B.; Park, P.; Yilmaz, H.R.P.W.; Rehrig, P.W.; Eitel, K.B.; et al. Templated grain growth of textured piezoelectric ceramics. Crit. Rev. Solid State Mater. Sci. 2004, 29, 45–96. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.; Qiu, B.; Yang, Z.; Cai, D.; He, P.; Jia, D.; Zhou, Y. Preparation and anisotropic properties of textured structural ceramics: A review. J. Adv. Ceram. 2019, 8, 289–332. [Google Scholar] [CrossRef]

- Chang, Y.; Sun, Y.; Liu, L. Textured Piezoceramics: Processing, Properties and Applications. Piezoelectr. Mater. Fundam. Emerg. Appl. 2024, 1, 201–252. [Google Scholar]

- Wu, J.; Zhang, S.; Li, F. Prospect of texture engineered ferroelectric ceramics. Appl. Phys. Lett. 2022, 121, 120501. [Google Scholar] [CrossRef]

- Moriana, A.D.; Zhang, S. Lead-free textured piezoceramics using tape casting: A review. J. Mater. 2018, 4, 277–303. [Google Scholar] [CrossRef]

- Walton, R.L.; Kupp, E.R.; Messing, G.L. Additive manufacturing of textured ceramics: A review. J. Mater. Res. 2021, 36, 3591–3606. [Google Scholar] [CrossRef]

- Wada, S.; Takeda, K.; Muraishi, T.; Kakemoto, H.; Tsurumi, T.; Kimura, T. Preparation of [110] grain oriented barium titanate ceramics by templated grain growth method and their piezoelectric properties. Jpn. J. Appl. Phys. 2007, 46, 7039. [Google Scholar] [CrossRef]

- Li, P.; Gao, S.; Lu, G.; Zhao, Y.; Hao, J.; Fu, P.; Du, J.; Bai, W.; Li, W.; Zhai, J. Significantly enhanced piezoelectric temperature stability of KNN-based ceramics through multilayer textured thick films composite. J. Eur. Ceram. Soc. 2024, 44, 3861–3868. [Google Scholar] [CrossRef]

- Liu, Y.; Chang, Y.; Li, F.; Yang, B.; Sun, Y.; Wu, J.; Zhang, S.; Wang, R.; Cao, W. Exceptionally high piezoelectric coefficient and low strain hysteresis in grain-oriented (Ba,Ca)(Ti,Zr)O3 through integrating crystallographic texture and domain engineering. ACS Appl. Mater. Interfaces 2017, 9, 29863–29871. [Google Scholar] [CrossRef] [PubMed]

- Zate, T.T.; Sun, J.W.; Ko, N.R.; Yu, H.L.; Choi, W.J.; Jeon, J.H.; Jo, W. Guide for processing of textured piezoelectric ceramics through the template grain growth method. J. Korean Inst. Electr. Electron. Mater. Eng. 2023, 36, 341–350. [Google Scholar]

- Liu, L. Progress on the fabrication of lead-free textured piezoelectric ceramics: Perspectives over 25 years. J. Mater. Sci. Mater. Electron. 2015, 26, 4425–4437. [Google Scholar] [CrossRef]

- Messing, G.L.; Poterala, S.; Chang, Y.; Frueh, T.; Kupp, E.R.; Watson, B.H.; Walton, R.L.; Brova, M.J.; Hofer, A.K.; Bermejo, R.; et al. Texture-engineered ceramics—Property enhancements through crystallographic tailoring. J. Mater. Res. 2017, 32, 3219–3241. [Google Scholar] [CrossRef]

- Haugen, A.B.; Olsen, G.H.; Madaro, F.; Morozov, M.I.; Tutuncu, G.; Jones, J.L.; Grande, T.; Einarsrud, M.A. Piezoelectric K0.5Na0.5NbO3 ceramics textured using needlelike K0.5Na0.5NbO3 templates. JACerS 2014, 97, 3818–3825. [Google Scholar] [CrossRef]

- Cha, H.A.; Kim, Y.K.; Jeon, J.H. Mechanism of Bi0.5Na0.5TiO3 and Bi4.5Na0.5Ti4O15 template synthesis during topochemical microcrystal conversion and texturing of Bi0.5(Na0.8K0.2)0.5TiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 2017, 37, 967–974. [Google Scholar] [CrossRef]

- Yan, Y.; Cho, K.H.; Priya, S. Templated grain growth of <001>-textured 0.675Pb(Mg1/3Nb2/3)O3-0.325PbTiO3 piezoelectric ceramics for magnetic field sensors. JACerS 2011, 94, 1784–1793. [Google Scholar]

- Vriami, D.; Damjanovic, D.; Vleugels, J.; Van der Biest, O. Textured BaTiO3 by templated grain growth and electrophoretic deposition. J. Mater. Sci. 2015, 50, 7896–7907. [Google Scholar] [CrossRef]

- Mallik, H.S.; Fujii, I.; Khanal, G.P.; Kim, S.; Ueno, S.; Suzuki, T.S.; Wada, S. Fabrication of <111>-oriented BaTiO3 ceramics by high magnetic field electrophoretic deposition using hexagonal-tetragonal co-existing BaTiO3 powder. JCS Japan 2020, 128, 469–474. [Google Scholar]

- Sakai, Y.; Futakuchi, T.; Adachi, M. Preparation of textured BaTiO3 thick films by screen printing. Jpn. J. Appl. Phys. 2011, 50, 09NA02. [Google Scholar] [CrossRef]

- Yu, H.L.; Ko, N.R.; Choi, W.J.; Zate, T.T.; Jo, W. A brief review of some challenging issues in textured piezoceramics via templated grain growth method. J. Sens. Technol. 2023, 32, 10–15. [Google Scholar] [CrossRef]

- Zate, T.T.; Ko, N.R.; Yu, H.L.; Choi, W.J.; Sun, J.W.; Jeon, J.H.; Jo, W. Textured Ceramics for Multilayered Actuator Applications: Challenges, Trends, and Perspectives. J. Korean Inst. Electr. Electron. Mater. Eng. 2023, 36, 214–225. [Google Scholar]

- Kang, W.-S.; Lee, T.-G.; Kang, J.-H.; Lee, J.-H.; Choi, G.; Kim, S.-W.; Nahm, S.; Jo, W. Bi-templated grain growth maximizing the effects of texture on piezoelectricity. J. Eur. Ceram. Soc. 2021, 41, 2482–2487. [Google Scholar] [CrossRef]

- Du, Q.; Zhang, C.; Liu, C.L.; Zhou, W.; Zeng, F.; Li, K.; Zou, K.; Fan, G.; Jiang, S.; Fu, Q.; et al. Highly <001>-textured BaTiO3 ceramics with high piezoelectric performance prepared by vat photopolymerization. Addit. Manuf. 2023, 66, 103454. [Google Scholar]

- Lv, D.; Zuo, R. Evolution of crystallographic grain orientation and anisotropic properties of (K0.5Na0.5)NbO3 ceramics using BaTiO3 templates by reactive templated grain growth. J. Alloys Compd. 2013, 560, 62–66. [Google Scholar] [CrossRef]

- Lv, D.; Zuo, R.; Su, S. Reactive templated grain growth and anisotropic electrical properties of (K0.5Na0.5)NbO3 ceramics without sintering aids. J. Mater. Sci. Mater. Electron. 2012, 23, 1367–1372. [Google Scholar] [CrossRef]

- Bai, W.; Wang, L.; Zheng, P.; Wen, F.; Zhai, J.; Ji, Z. Pairing high piezoelectric properties and enhanced thermal stability in grain-oriented BNT-based lead-free piezoceramics. Ceram. Int. 2018, 44, 11402–11409. [Google Scholar] [CrossRef]

- Zhao, W.; Ya, J.; Xin, Y.; E, L.; Zhao, D.; Zhou, H. Fabrication of Na0.5Bi0.5TiO3-BaTiO3-textured ceramics templated by plate-like Na0.5Bi0.5TiO3 particles. JACerS 2009, 92, 1607–1609. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, L.; Xie, H.; Zhang, Z.; Kou, Q.; Lv, R.; Yang, B.; Chang, Y.; Li, F. Enhanced piezoelectric properties and depolarization temperature in textured (Bi0.5Na0.5)TiO3-based ceramics via homoepitaxial templated grain growth. J. Mater. Sci. Technol. 2024, 176, 91–98. [Google Scholar] [CrossRef]

- Li, H.; Huang, R.; Lin, H.T.; Du, Z.; Dai, Y. Effect of the template particles size on structure and piezoelectric properties of <001>-textured BNT-based ceramics. JACerS 2024, 107, 3219–3229. [Google Scholar]

- Zate, T.T.; Kim, M.; Jeon, J.H. Outstanding unipolar strain of textured Pb(Mg1/3Nb2/3)O3–PbZrO3–PbTiO3 piezoelectric ceramics manufactured by particle size distribution control of the plate-like BaTiO3 template. Sens. Actuators A Phys. 2022, 335, 113373. [Google Scholar] [CrossRef]

- Meier, W.; Meyer, K.E.; Sava Gallis, D.F.; Blea-Kirby, M.A.; Roth, J.; Felman, D.; Breuer, T.; Dension, G.J.; Zutavern, F.J.; Huebner, W.; et al. Highly Textured BaTiO3 via templated grain growth and resulting polarization reversal dynamics. JACerS 2016, 99, 922–929. [Google Scholar] [CrossRef]

- Ye, S.K.; Fuh, J.Y.H.; Lu, L. Structure and electrical properties of <001> textured (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 lead-free piezoelectric ceramics. Appl. Phys. Lett. 2012, 100, 252906. [Google Scholar]

- Bai, W.; Chen, D.; Li, P.; Shen, B.; Zhai, J.; Ji, Z. Enhanced electromechanical properties in <00l>-textured (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead-free piezoceramics. Ceram. Int. 2016, 42, 3429–3436. [Google Scholar]

- Dehlia, E.B. Texturing of Lead Free Piezoelectric Ceramics. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2013. [Google Scholar]

- Xue, H.; Xiong, Z. The structure and dielectric tunable properties of <0 0 1> preferred oriented BST ceramics prepared by templated grain growth method. J. Alloys Compd. 2009, 467, 338–341. [Google Scholar]

- Schultheiß, J.; Clemens, O.; Zhukov, S.; von Seggern, H.; Sakamoto, W.; Koruza, J. Effect of degree of crystallographic texture on ferro- and piezoelectric properties of Ba0.85Ca0.15TiO3 piezoceramics. JACerS 2017, 100, 2098–2107. [Google Scholar] [CrossRef]

- Sugawara, T.; Nomura, Y.; Kimura, T.; Tani, T. Fabrication of <111> Oriented BaTiO3 Bulk Ceramic by Reactive Templated Grain Growth Method. JCS-Japan 2001, 109, 897–900. [Google Scholar]

- Kimura, T.; Miura, Y.; Fuse, K. Texture development in barium titanate and PMN-PT using hexabarium 17-titanate heterotemplates. Int. J. Appl. Ceram. Technol. 2005, 2, 15–23. [Google Scholar] [CrossRef]

- Sato, T.; Kimura, T. Preparation of <1 1 1>-textured BaTiO3 ceramics by templated grain growth method using novel template particles. Ceram. Int. 2008, 34, 757–760. [Google Scholar]

- Kamlo, A.N.; Geffroy, P.M.; Pham-Thi, M.; Marchet, P. {111}-Textured BaTiO3 ceramics elaborated by Templated Grain Growth using NaNbO3 templates. Mater. Lett. 2013, 113, 149–151. [Google Scholar] [CrossRef]

- Ye, S.; Fuh, J.; Lu, L.; Chang, Y.L.; Yang, J.R. Structure and properties of hot-pressed lead-free (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 piezoelectric ceramics. RSC Adv. 2013, 3, 20693–20698. [Google Scholar] [CrossRef]

- Haugen, A.B.; Morozov, M.I.; Johnsson, M.; Grande, T.; Einarsrud, M.A. Effect of crystallographic orientation in textured Ba0.92Ca0.08TiO3 piezoelectric ceramics. J. Appl. Phys. 2014, 116, 134102. [Google Scholar] [CrossRef]

- Sabolsky, E.M.; Maldonado, L.; Seabaugh, M.M.; Swartz, S.L. Textured-Ba(Zr,Ti)O3 piezoelectric ceramics fabricated by templated grain growth (TGG). J. Electroceram. 2010, 25, 77–84. [Google Scholar] [CrossRef]

- Takahashi, H.; Numamoto, Y.; Tani, J.; Tsurekawa, S. Piezoelectric properties of BaTiO3 ceramics with high performance fabricated by microwave sintering. Jpn. J. Appl. Phys. 2006, 45, 7405–7408. [Google Scholar] [CrossRef]

- Karaki, T.; Yan, K.; Miyamoto, T.; Adachi, M. Lead-free piezoelectric ceramics with large dielectric and piezoelectric constants manufactured from BaTiO3 nano-powder. Jpn. J. Appl. Phys. 2007, 46, L97. [Google Scholar] [CrossRef]

- Davis, M.; Budimir, M.; Damjanovic, D.; Setter, N. Rotator and extender ferroelectrics: Importance of the shear coefficient to the piezoelectric properties of domain-engineered crystals and ceramics. J. Appl. Phys. 2007, 101, 054112. [Google Scholar] [CrossRef]

- Go, S.H.; Kim, H.; Kim, D.S.; Eum, J.M.; Chae, S.J.; Kim, E.J.; Nahm, S. Improvement of piezoelectricity of (Na, K)Nb-based lead-free piezoceramics using [001]-texturing for piezoelectric energy harvesters and actuators. J. Eur. Ceram. Soc. 2022, 42, 6478–6492. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, L.F.; Tang, T.; Li, J.R.; Wang, L.; Liu, Y.X.; Hao, J.; Wang, S.; Wang, K. Textured Potassium Sodium Niobate Lead-Free Ceramics with High d33 and Qm for Meeting High-Power Applications. ACS Appl. Mater Interfaces 2024, 16, 7444–7452. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Q.; Cai, W.; Chen, G.; Li, X.; Gao, R.; Deng, X.; Fu, C. Achieving enhanced ferroelectricity and piezoelectric responses in <0 0 1>-textured KNN-BCZT ceramics with BaTiO3 microplates as template. Mater. Lett. 2023, 351, 135098. [Google Scholar]

- Purusothaman, Y.; Leng, H.; Nanda, A.; Levine, I.; Priya, S. Textured Lead-Free Piezoelectric Ceramics for Flexible Energy Harvesters. ACS Appl Mater Interfaces 2023, 15, 6584–6593. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhu, K.; Shen, B.; Ma, J.; Bian, L.; Zhang, R.; Cao, W. Broadband ultrasonic transducer based on textured lead-free NKN-based piezoceramics. Ceram. Int. 2023, 49, 40450–40456. [Google Scholar] [CrossRef]

- Go, S.H.; Chae, Y.G.; Chae, S.J.; Kim, E.J.; Yu, H.M.; Cho, W.H.; Nahm, S. Piezoelectric properties of [001]-textured (K,Na)(Nb,Sb)O3-CaZrO3-(Ag,Bi)ZrO3 ceramics and their application in panel loudspeakers. J. Alloys Compd. 2023, 968, 171958. [Google Scholar] [CrossRef]

- Go, S.H.; Park, S.J.; Kim, S.H.; Chae, S.J.; Kim, E.J.; Lee, G.S.; Nahm, S. [001]-texturing of (K, Na)NbO3-based piezoceramics with a pseudocubic structure and their application to piezoelectric devices. J. Mater. 2024, 10, 632–642. [Google Scholar] [CrossRef]

- Go, S.H.; Kim, D.S.; Chae, Y.G.; Chae, S.J.; Kim, E.J.; Yu, H.M.; Kim, B.J.; Park, S.J.; Lee, J.H.; Nahm, S. Effect of the crystal structure on the piezoelectricity of [001]-textured (Na,K)(Nb,Sb)O3-SrZrO3-(Bi,Ag)ZrO3 lead-free piezoelectric thick film. Actuators 2023, 12, 66. [Google Scholar] [CrossRef]

- Wang, B.; Huangfu, G.; Zheng, Z.; Guo, Y. Giant Electric Field-Induced Strain with High Temperature-Stability in Textured KNN-Based Piezoceramics for Actuator Applications. Adv. Funct. Mater. 2023, 33, 221443. [Google Scholar] [CrossRef]

- Lv, D.; Ye, Z.; Jin, W.; Hua, F.; Zhang, Z.; Wu, K. Effect of calcination temperature on the structural and electrical properties of low temperature sintered the (Na0.52K0.44Li0.04)(Nb0.88Sb0.08Ta0.04)O3 textured ceramics. Ferroelectrics 2023, 603, 308–315. [Google Scholar] [CrossRef]

- Quan, Y.; Wang, L.; Ren, W.; Zhao, J.; Zhuang, J.; Zheng, K.; Wang, Z.; Ren, M.X.; Karaki, T.; Jiang, Z.; et al. Effect of template amounts on the orientation degree and electrical properties of lead-free piezoelectric textured KNN-based ceramics. J. Appl. Phys. 2022, 131, 094101. [Google Scholar] [CrossRef]

- Lin, J.; Cao, Y.; Zhu, K.; Yan, F.; Shi, C.; Bai, H.; Ge, G.; Yang, J.; Yang, W.; Li, G.; et al. Ultrahigh energy harvesting properties in temperature-insensitive eco-friendly high-performance KNN-based textured ceramics. J. Mater. Chem. A Mater. 2022, 10, 7978–7988. [Google Scholar] [CrossRef]

- Chae, S.J.; Kim, D.S.; Kim, H.; Go, S.H.; Kim, S.W.; Kim, E.J.; Eum, J.M.; Kim, I.S.; Nahm, S. Structural and piezoelectric properties of textured NLKNS-CZ thick films and their application in planar piezoactuator. JACerS 2022, 105, 1185–1197. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, R.; Qu, J.; Gao, S.; Zhang, Y.; Yan, J.; Hao, J.; Li, P.; Li, W. Enhanced piezoelectric properties and temperature stability in KNN-based textured ceramics. J. Adv. Dielectr. 2022, 12, 2244006. [Google Scholar] [CrossRef]

- Nan, W. Fabrication of Textured (K,Na)NbO3-Based Piezoceramics by Using NaNbO3 Templates Prepared with Hydrothermal Method. Ph.D. Thesis, Toyama Prefectural University, Toyama, Japan, 2023. [Google Scholar]

- Haugen, A.B.; Ringgaard, E.; Levassort, F. Textured, lead-free piezoelectric ceramics with high figure of merit for energy harvesting. J. Phys. Mater. 2021, 4, 044002. [Google Scholar] [CrossRef]

- Li, P.; Huan, Y.; Yang, W.; Zhu, F.; Li, X.; Zhang, X.; Shen, B.; Zhai, J. High-performance potassium-sodium niobate lead-free piezoelectric ceramics based on polymorphic phase boundary and crystallographic texture. Acta Mater. 2019, 165, 486–495. [Google Scholar] [CrossRef]

- Li, P.; Liu, B.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Mechanism of significantly enhanced piezoelectric performance and stability in textured potassium-sodium niobate piezoelectric ceramics. J. Eur. Ceram. Soc. 2018, 38, 75–83. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Fan, P.; Marwat, M.A.; Ma, W.; Liu, K.; Liu, H.; Xie, B.; Wang, K.; Koruza, J. Temperature-insensitive electric-field-induced strain and enhanced piezoelectric properties of <001> textured (K,Na)NbO3-based lead-free piezoceramics. Acta Mater. 2018, 156, 389–398. [Google Scholar]

- Li, P.; Zhai, J.; Shen, B.; Zhang, S.; Li, X.; Zhu, F.; Zhang, X. Ultrahigh piezoelectric properties in textured (K,Na)NbO3-based lead-free ceramics. Adv. Mater. 2018, 30, 1705171. [Google Scholar] [CrossRef] [PubMed]

- Ishii, K.; Morimoto, T. Orientation factor and piezoelectric property in textured (K,Na)NbO3 system ceramics with minimal templates. Jpn. J. Appl. Phys. 2018, 57, 11UD02. [Google Scholar] [CrossRef]

- Liu, B.; Li, P.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Simultaneously enhanced piezoelectric response and piezoelectric voltage coefficient in textured KNN-based ceramics. JACerS 2018, 101, 265–273. [Google Scholar] [CrossRef]

- Quan, Y.; Ren, W.; Niu, G.; Wang, L.; Zhao, J.; Zhang, N.; Liu, M.; Ye, Z.G.; Liu, L.; Karaki, T. Large Piezoelectric Strain with Superior Thermal Stability and Excellent Fatigue Resistance of Lead-Free Potassium Sodium Niobate-Based Grain Orientation-Controlled Ceramics. ACS Appl. Mater. Interfaces 2018, 10, 10220–10226. [Google Scholar] [CrossRef]

- Liu, B.; Li, P.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Enhanced piezoelectric properties and temperature-insensitive strain behavior of <001>-textured KNN-based ceramics. Ceram. Int. 2017, 43, 8004–8009. [Google Scholar] [CrossRef]

- Liu, B.; Liu, X.; Li, P.; Li, F.; Shen, B.; Zhai, J. Improving piezoelectric properties by controlling phase structure and crystal orientation. RSC Adv. 2017, 7, 41788–41795. [Google Scholar] [CrossRef]

- Ishii, K.; Tashiro, S. Orientation control of (K,Na)NbO3 ceramics using platelike NaNbO3 templates prepared by single-step molten salt synthesis with mixed salt. Jpn. J. Appl. Phys. 2016, 55, 10TD01. [Google Scholar] [CrossRef]

- Kong, Y.; Hao, J.; Xu, D. Synthesis of anisotropic NaNbO3 seed crystals and fabrication of textured (K0.5 Na0.5)NbO3-based ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 11256–11261. [Google Scholar] [CrossRef]

- Mensur-Alkoy, E.; Berksoy-Yavuz, A.; Alkoy, S. Processing and properties of textured potassium sodium niobate [K,Na]NbO3 ceramic ribbons by alginate gelation method. JACerS 2014, 97, 3425–3433. [Google Scholar] [CrossRef]

- Li, Y.; Hui, C.; Wu, M.; Li, Y.; Wang, Y. Textured (K0.5Na0.5)NbO3 ceramics prepared by screen-printing multilayer grain growth technique. Ceram. Int. 2012, 38, S283–S286. [Google Scholar] [CrossRef]

- Fu, F.; Shen, B.; Zhai, J.; Xu, Z.; Yao, X. Influence of Mn2+ on the electrical properties of textured KNN thick films. Ceram. Int. 2012, 38, S287–S290. [Google Scholar] [CrossRef]

- Hao, J.; Ye, C.; Shen, B.; Zhai, J. Enhanced piezoelectric properties of <001> textured lead-free (KxNa1−x)0.946Li0.054NbO3 ceramics with large strain. Phys. Status Solidi A 2012, 209, 1343–1349. [Google Scholar]

- Chang, Y.; Poterala, S.; Yang, Z.; Messing, G.L. Enhanced electromechanical properties and temperature stability of textured (K0.5Na0.5)NbO3-based piezoelectric ceramics. JACerS 2011, 94, 2494–2498. [Google Scholar] [CrossRef]

- Fu, F.; Zhai, J.; Xu, Z.; Yao, X. Preparation of (h00)-oriented K0.5Na0.5NbO3 ceramics and its electrical properties. Ferroelectrics 2011, 413, 142–147. [Google Scholar] [CrossRef]

- Cao, M.; Li, F.; Lv, M.; Hao, H.; Yu, Z.; Yao, Z.; Liu, H. The effect of template morphologies on microstructure and properties of textured K0.5Na0.5NbO3 ceramics by RTGG method. In Proceedings of the 2011 International Symposium on Applications of Ferroelectrics (ISAF/PFM) and 2011 International Symposium on Piezoresponse Force Microscopy and Nanoscale Phenomena in Polar Materials, Vancouver, BC, Canada, 24–27 July 2011; pp. 1–4. [Google Scholar]

- Chang, Y.; Poterala, S.F.; Yang, Z.; Trolier-McKinstry, S.; Messing, G.L. Microstructure development and piezoelectric properties of highly textured CuO-doped KNN by templated grain growth. J. Mater. Res. 2010, 25, 687–694. [Google Scholar] [CrossRef]

- Cao, M.; Li, Z.; Chen, Q.; Hao, H.; Yu, Z.; Liu, H. Preparation and characterization of textured (K0.5Na0.5)NbO3 ceramics by reactive templated grain growth. Ferroelectrics 2010, 404, 207–212. [Google Scholar] [CrossRef]

- Chang, Y.; Poterala, S.F.; Yang, Z.; Trolier-McKinstry, S.; Messing, G.L. <001> textured (K0.5 Na0.5)(Nb0.97Sb0.03)O3 piezoelectric ceramics with high electromechanical coupling over a broad temperature range. Appl. Phys. Lett. 2009, 95, 232905. [Google Scholar]

- Takao, H.; Saito, Y.; Aoki, Y.; Horibuchi, K. Microstructural evolution of crystalline-oriented (K0.5Na0.5)NbO3 piezoelectric ceramics with a sintering aid of CuO. JACerS 2006, 89, 1951–1956. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Y.; Jiang, X.; Hou, Z. Oriented and ultrafine-grain potassium sodium niobate piezoelectric ceramics prepared by heterogeneous microcrystalline transformation. Ceram. Int. 2023, 49, 30897–30904. [Google Scholar] [CrossRef]

- Park, S.; Jang, J.; Ahn, C.W.; Hahn, B.D.; Yoon, W.H.; Lee, J.W.; Choi, J.J.; Min, Y. Buffered template strategy for improving texture quality and piezoelectric properties of heterogeneous templated grain growth (K,Na)NbO3-based ceramics through interface engineering. J. Eur. Ceram. Soc. 2023, 43, 1932–1940. [Google Scholar] [CrossRef]

- Cha, H.A.; Jeon, J.H. Texturing behaviours of (K0.47Na0.51Li0.02)(Nb0.8Ta0.2)O3 piezoelectric ceramics produced using NaNb1−xTaxO3 templates. J. Eur. Ceram. Soc. 2018, 38, 1442–1449. [Google Scholar] [CrossRef]

- Tutuncu, G.; Chang, Y.; Poterala, S.; Messing, G.L.; Jones, J.L. In situ observations of templated grain growth in (Na0.5K0.5) 0.98Li0.02NbO3 piezoceramics: Texture development and template-matrix interactions. JACerS 2012, 95, 2653–2659. [Google Scholar] [CrossRef]

- Kim, D.S.; Eum, J.M.; Go, S.H.; Shin, H.S.; Kim, H.; Chae, S.J.; Kim, S.W.; Kim, E.J.; Woo, J.U.; Nahm, S. Remarkable piezoelectric performance and good thermal stability of <001>-textured 0.96(K0.5Na0.5)(Nb1−ySby)O3-0.04SrZrO3 lead-free piezoelectric ceramics. J. Alloys Compd. 2021, 882, 160662. [Google Scholar]

- Bai, W.; Chen, D.; Zheng, P.; Zhang, J.; Shen, B.O.; Zhai, J.; Ji, Z. Grain-orientated lead-free BNT-based piezoceramics with giant electrostrictive effect. Ceram. Int. 2017, 43, 3339–3345. [Google Scholar] [CrossRef]

- Zou, H.; Sui, Y.; Zhu, X.; Liu, B.; Xue, J.; Zhang, J. Texture development and enhanced electromechanical properties in <00l>-textured BNT-based materials. Mater. Lett. 2016, 184, 139–142. [Google Scholar] [CrossRef]

- Bai, W.; Li, H.; Xi, J.; Zhang, J.; Shen, B.; Zhai, J. Effect of different templates and texture on structure evolution and strain behavior of <001>-textured lead-free piezoelectric BNT-based ceramics. J. Alloys Compd. 2016, 656, 13–23. [Google Scholar] [CrossRef]

- Zhang, L.; Li, G.; Lin, J.; Qian, J.; Wang, S.; Jia, J.; Chen, C.; Xu, L.; Shen, B.; Zhai, J. Ultra-high electro-strain and low hysteresis lead-free piezoelectric ceramics obtained by a novel texture engineering strategy. Ceram. Int. 2024, 50, 3967–3974. [Google Scholar] [CrossRef]

- Bai, W.; Xi, J.; Zhang, J.; Shen, B.; Zhai, J.; Yan, H. Effect of different templates on structure evolution and large strain response under a low electric field in <00l>-textured lead-free BNT-based piezoelectric ceramics. J. Eur. Ceram. Soc. 2015, 35, 2489–2499. [Google Scholar] [CrossRef]

- Bai, W.; Li, L.; Li, W.; Shen, B.; Zhai, J.; Chen, H. Effect of SrTiO3 template on electric properties of textured BNT-BKT ceramics prepared by templated grain growth process. J. Alloys Compd. 2014, 603, 149–157. [Google Scholar] [CrossRef]

- Bai, W.; Hao, J.; Fu, F.; Li, W.; Shen, B.; Zhai, J. Structure and strain behavior of <00l> textured BNT-based ceramics by template grain growth. Mater Lett. 2013, 97, 137–140. [Google Scholar]

- Yilmaz, H.; Messing, G.L.; Trolier-McKinstry, S. Textured Sodium Bismuth Titanate (Na1/2Bi1/2)0.945Ba0.055TiO3 Ceramics by Templated Grain Growth. In Proceedings of the ISAF 2000. Proceedings of the 2000 12th IEEE International Symposium on Applications of Ferroelectrics (IEEE Cat. No.00CH37076), Honolulu, HI, USA, 21 July–2 August 2000. [Google Scholar]

- Hussain, A.; Maqbool, A.; Malik, R.A.; Ahmed, T.; Lee, S.; Kim, M.H. Texture performance of lead-free Bi1/2Na1/2TiO3–BaZrO3 ceramics. Ceram. Int. 2023, 49, 10073–10082. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, P.; Patterson, E.; Zang, J.; Jiang, S.; Rödel, J. Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Fancher, C.M.; Blendell, J.E.; Bowman, K.J. Poling effect on d33 in textured Bi0.5Na0.5TiO3-based materials. Scr. Mater. 2013, 68, 443–446. [Google Scholar] [CrossRef]

- Jiang, C.; Zhou, X.; Zhou, K.; Chen, C.; Luo, H.; Yuan, X.; Zhang, D. Grain oriented Na0.5Bi0.5TiO3-BaTiO3 ceramics with giant strain response derived from single-crystalline Na0.5Bi0.5TiO3-BaTiO3 templates. J. Eur. Ceram. Soc. 2016, 36, 1377–1383. [Google Scholar] [CrossRef]

- Machado, R.; dos Santos, V.B.; Ochoa, D.A.; Cerdeiras, E.; Mestres, L.; García, J.E. Elastic, dielectric and electromechanical properties of (Bi0.5Na0.5)TiO3-BaTiO3 piezoceramics at the morphotropic phase boundary region. J. Alloys Compd. 2017, 690, 568–574. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Q.; Kim, B.H.; Ahn, B.K.; Ko, J.H.; Kang, W.J.; Nam, O.J. Structure and electrical properties of (Na0.5Bi0.5)1−xBaxTiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 2008, 28, 843–849. [Google Scholar] [CrossRef]

- Picht, G.; Töpfer, J.; Hennig, E. Structural properties of (Bi0.5Na0.5)1−xBaxTiO3 lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 2010, 30, 3445–3453. [Google Scholar] [CrossRef]

- Takenaka, T.; Maruyama, K.I.M.K.I.; Sakata, K.S.K. (Bi1/2Na1/2)TiO3-BaTiO3 System for Lead-Free Piezoelectric Ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236. [Google Scholar] [CrossRef]

- Maurya, D.; Zhou, Y.; Yan, Y.; Priya, S. Synthesis mechanism of grain-oriented lead-free piezoelectric Na0.5Bi0.5TiO3-BaTiO3 ceramics with giant piezoelectric response. J. Mater. Chem. C Mater. 2013, 1, 2102–2111. [Google Scholar] [CrossRef]

- Kimura, T.; Takahashi, T.; Tani, T.; Saito, Y. Preparation of crystallographically textured Bi0.5Na0.5TiO3-BaTiO3 ceramics by reactive-templated grain growth method. Ceram. Int. 2004, 30, 1161–1167. [Google Scholar]

- Chen, P.Y.; Chen, C.S.; Tu, C.S.; Chen, P.H.; Anthoniappen, J. Effects of texture on microstructure, Raman vibration, and ferroelectric properties in 92.5%(Bi0.5Na0.5)TiO3-7.5%BaTiO3 ceramics. J. Eur. Ceram. Soc. 2016, 36, 1613–1622. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, H.; Yan, Y. Preparation and characterization of textured Bi0.5(Na0.8K0.2)0.5TiO3 ceramics by reactive templated grain growth. Mater. Lett. 2008, 62, 1219–1222. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Ye, M.Y.; Ji, H.M.; Li, X.L.; Zhang, X.; Dai, Y. Enhanced piezoelectric properties and strain response in <001> textured BNT-BKT-BT ceramics. Mater. Des. 2018, 137, 184–191. [Google Scholar]

- Ji, C.; Chen, G.; Wang, J.; Bai, X.; Zhang, Z.; Chen, C.; Cai, W.; Gao, R.; Deng, X.; Fu, C. Superior energy storage performance of <001> -oriented NBT-BY-STO relaxor ferroelectric textured ceramics. J. Eur. Ceram. Soc. 2023, 43, 957–965. [Google Scholar]

- Chen, G.; Bai, X.; Ji, C.; Zhou, Z.; Zhang, Z.; Chen, C.; Fu, C. Synergistic effect to improve energy storage performance in <111> textured BNT-based ceramics under low electric field via orientation engineering as well as co-doping BY and STO. Mater. Res. Bull. 2024, 180, 113065. [Google Scholar]

- Li, J.; Shen, Z.; Chen, X.; Yang, S.; Zhou, W.; Wang, M.; Li, F. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 2020, 19, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Pavlacka, R.J.; Messing, G.L. Processing and mechanical response of highly textured Al2O3. J. Eur. Ceram. Soc. 2010, 30, 2917–2925. [Google Scholar] [CrossRef]

- Suvaci, E.; Messing, G.L. Critical factors in the templated grain growth of textured reaction-bonded alumina. JACerS 2000, 83, 2041–2048. [Google Scholar] [CrossRef]

- Zhou, J.E.; Yan, Y.; Priya, S.; Wang, Y.U. Computational study of textured ferroelectric polycrystals: Texture development during templated grain growth. J. Appl. Phys. 2017, 121, 064108. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L. Phase field simulation of template growth process in textured ceramics. Model Simul. Mat. Sci. Eng. 2018, 26, 015008. [Google Scholar] [CrossRef]

- Zate, T.T.; Ko, N.R.; Yu, H.L.; Sun, J.W.; Jo, W.; Jeon, J.H. Textured Pb(Mg1/3Nb2/3)O3−Pb(In1/2Nb1/2)O3−PbTiO3 ceramics with enhanced piezoelectric properties and high Curie temperature prepared by low-temperature sintering. Sens. Actuators A Phys. 2024, 366, 113929. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zate, T.T.; Abdurrahmanoglu, C.; Esposito, V.; Haugen, A.B. Textured Lead-Free Piezoelectric Ceramics: A Review of Template Effects. Materials 2025, 18, 477. https://doi.org/10.3390/ma18030477

Zate TT, Abdurrahmanoglu C, Esposito V, Haugen AB. Textured Lead-Free Piezoelectric Ceramics: A Review of Template Effects. Materials. 2025; 18(3):477. https://doi.org/10.3390/ma18030477

Chicago/Turabian StyleZate, Temesgen Tadeyos, Cenk Abdurrahmanoglu, Vincenzo Esposito, and Astri Bjørnetun Haugen. 2025. "Textured Lead-Free Piezoelectric Ceramics: A Review of Template Effects" Materials 18, no. 3: 477. https://doi.org/10.3390/ma18030477

APA StyleZate, T. T., Abdurrahmanoglu, C., Esposito, V., & Haugen, A. B. (2025). Textured Lead-Free Piezoelectric Ceramics: A Review of Template Effects. Materials, 18(3), 477. https://doi.org/10.3390/ma18030477