Bond Performance of GFRP Bars in Glass and Basalt Fiber-Reinforced Geopolymer Concrete Under Hinged Beam Tests

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- SiO2: silicon dioxide;

- Na2O: sodium dioxide;

- FA: fly ash.

- lb: embedment length;

- fyd: design yield strength of the reinforcement;

- fctd: design tensile strength of the concrete used;

- Ø: reinforcement diameter.

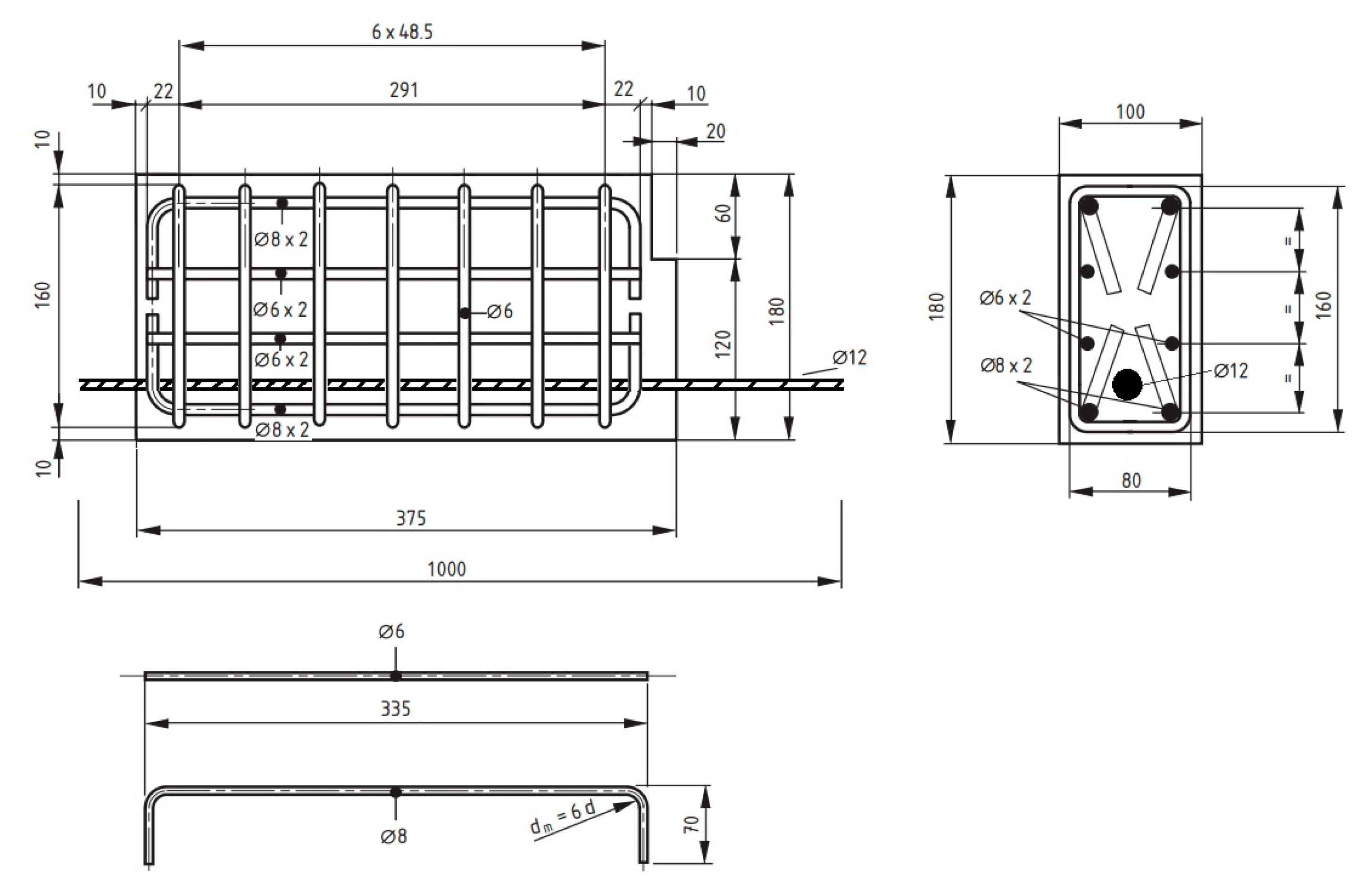

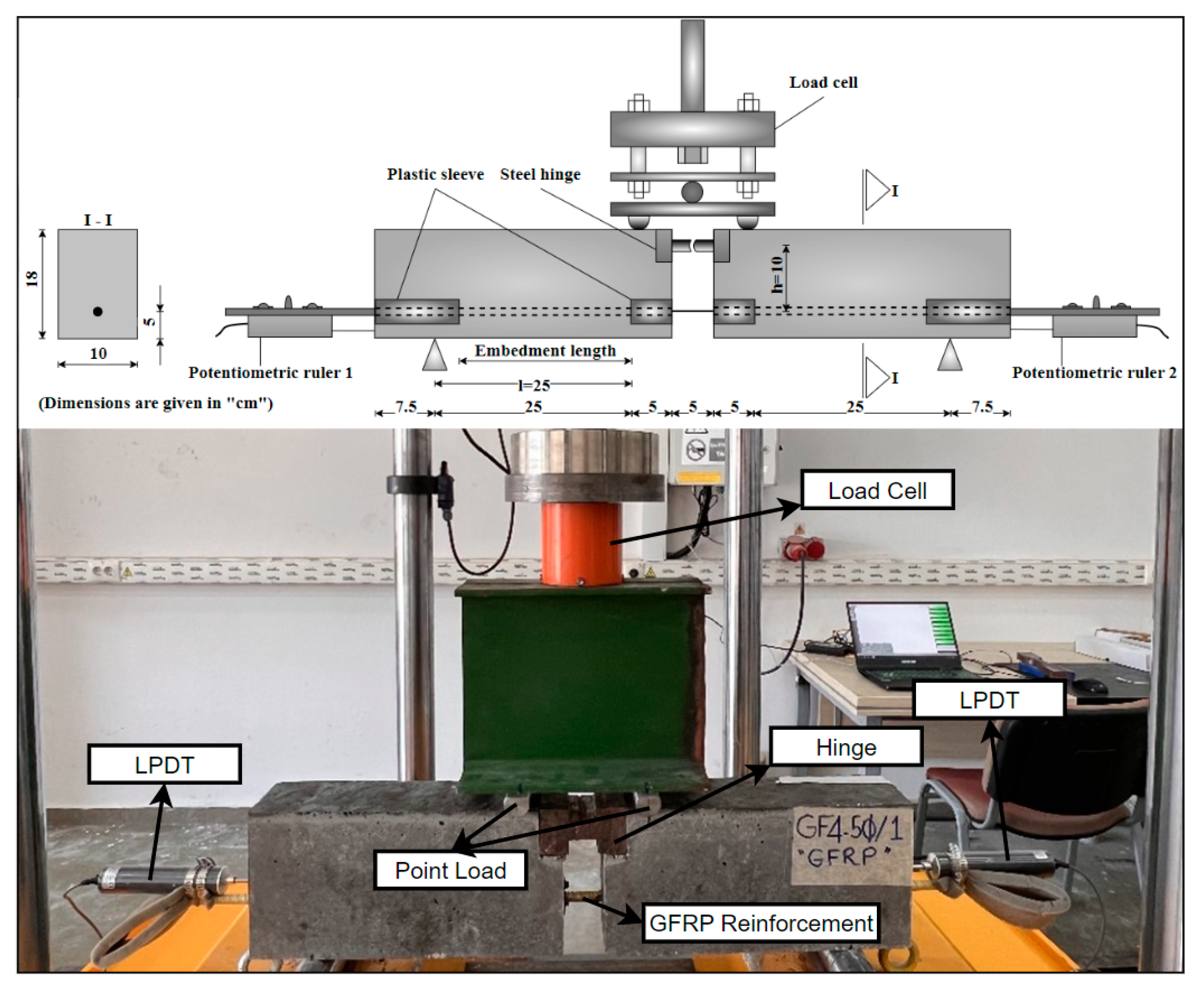

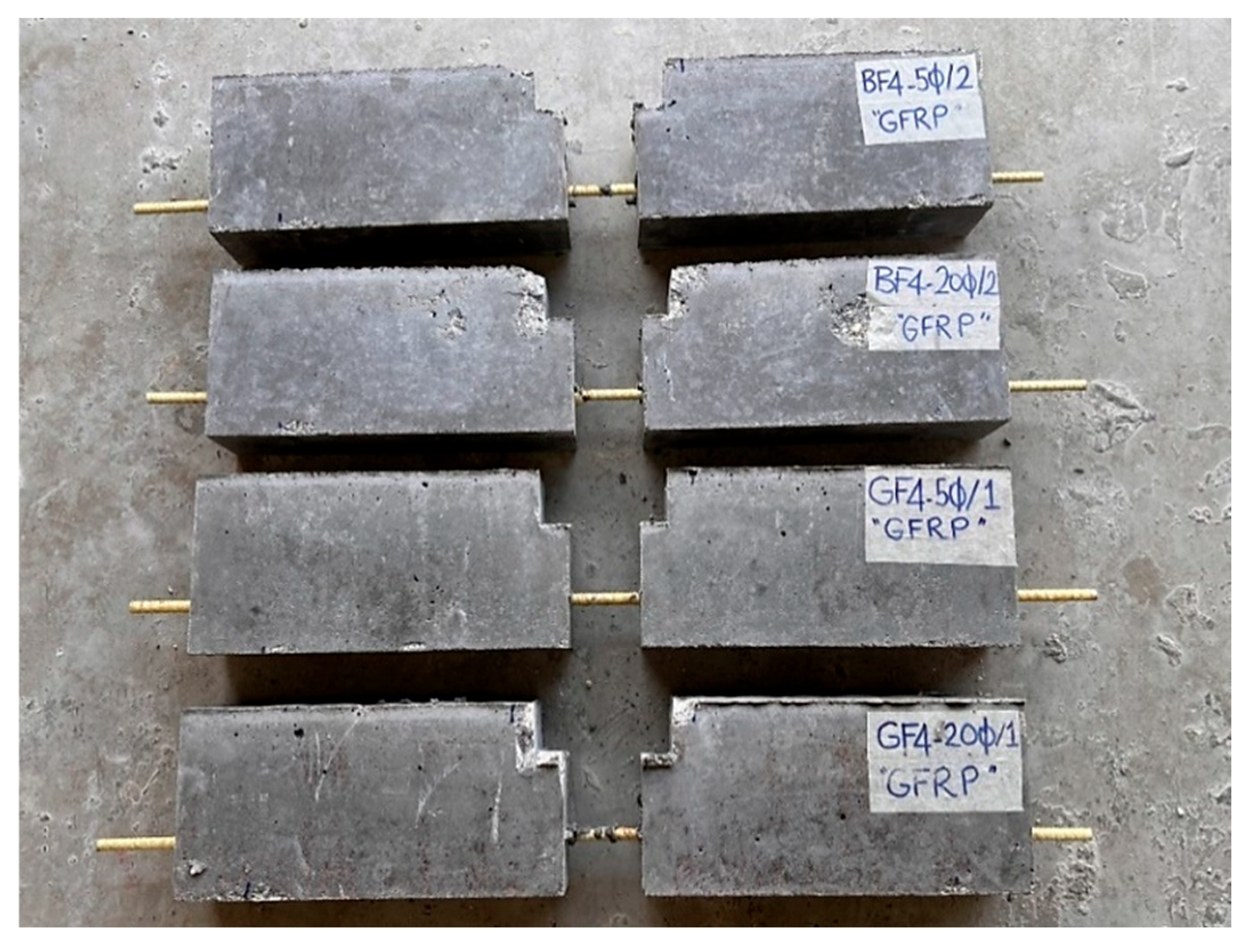

2.2. Methods

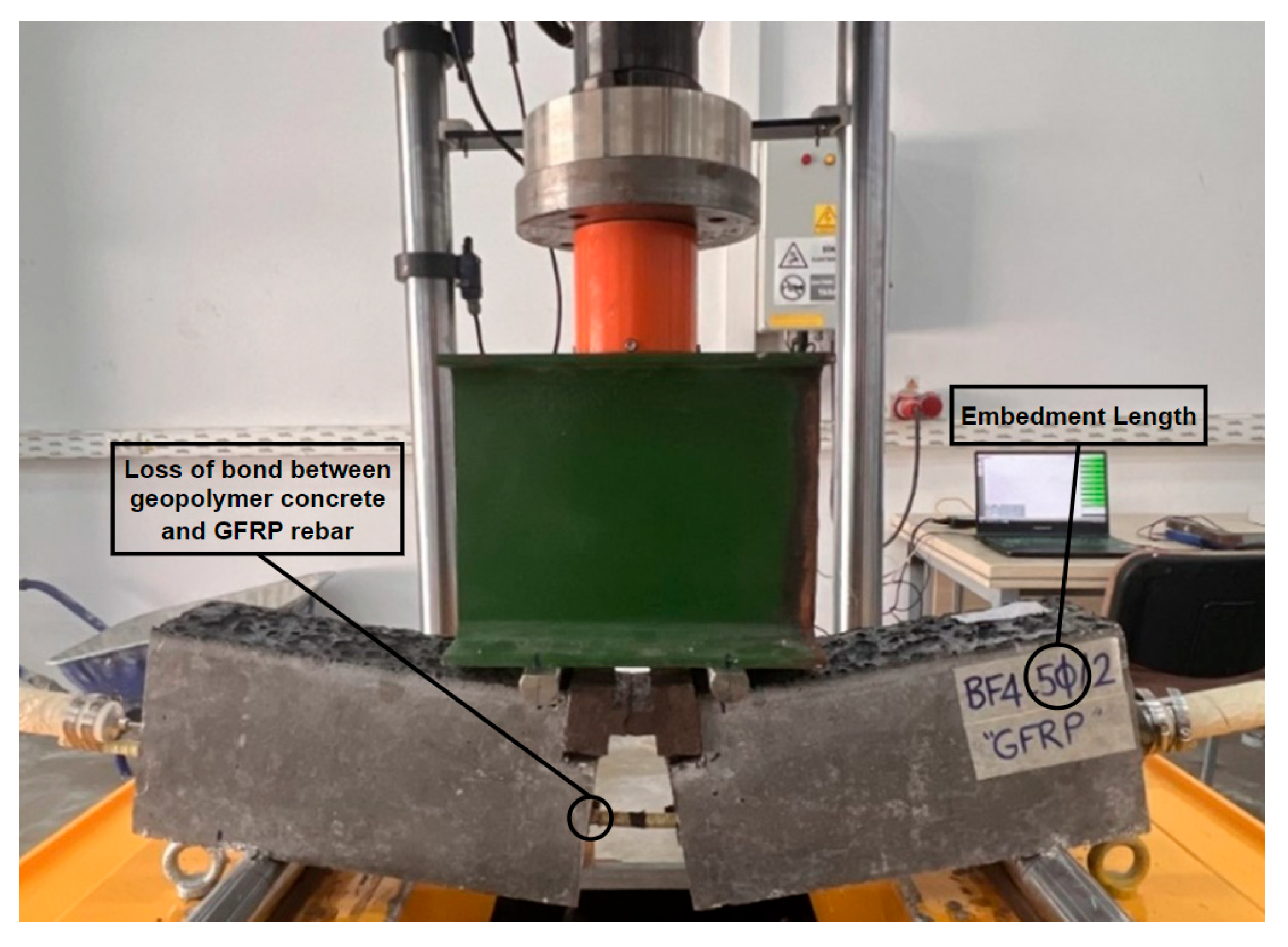

3. Results and Discussion

3.1. Preliminary Experiment Results

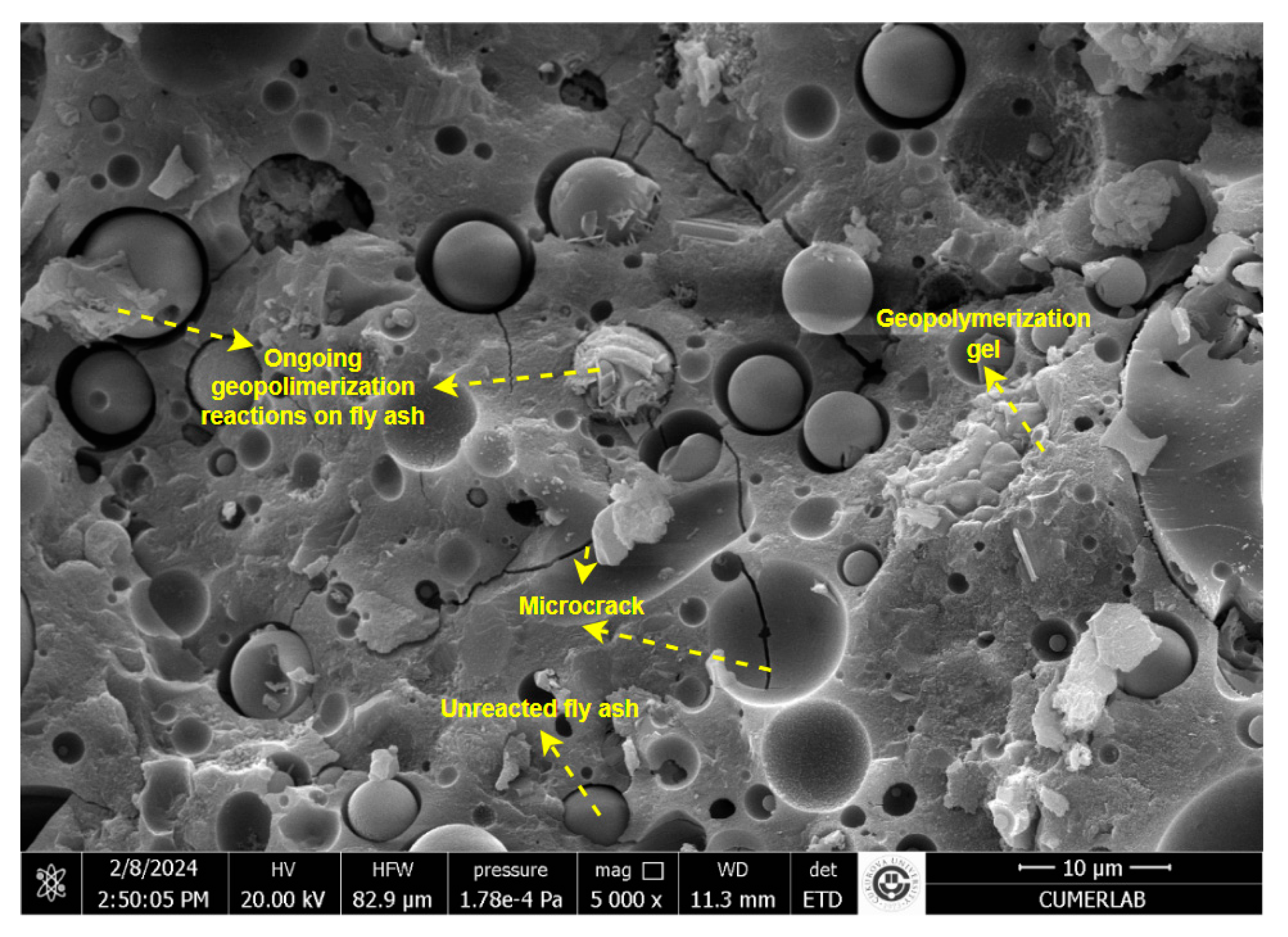

3.2. SEM Analysis of Geopolymer Concrete

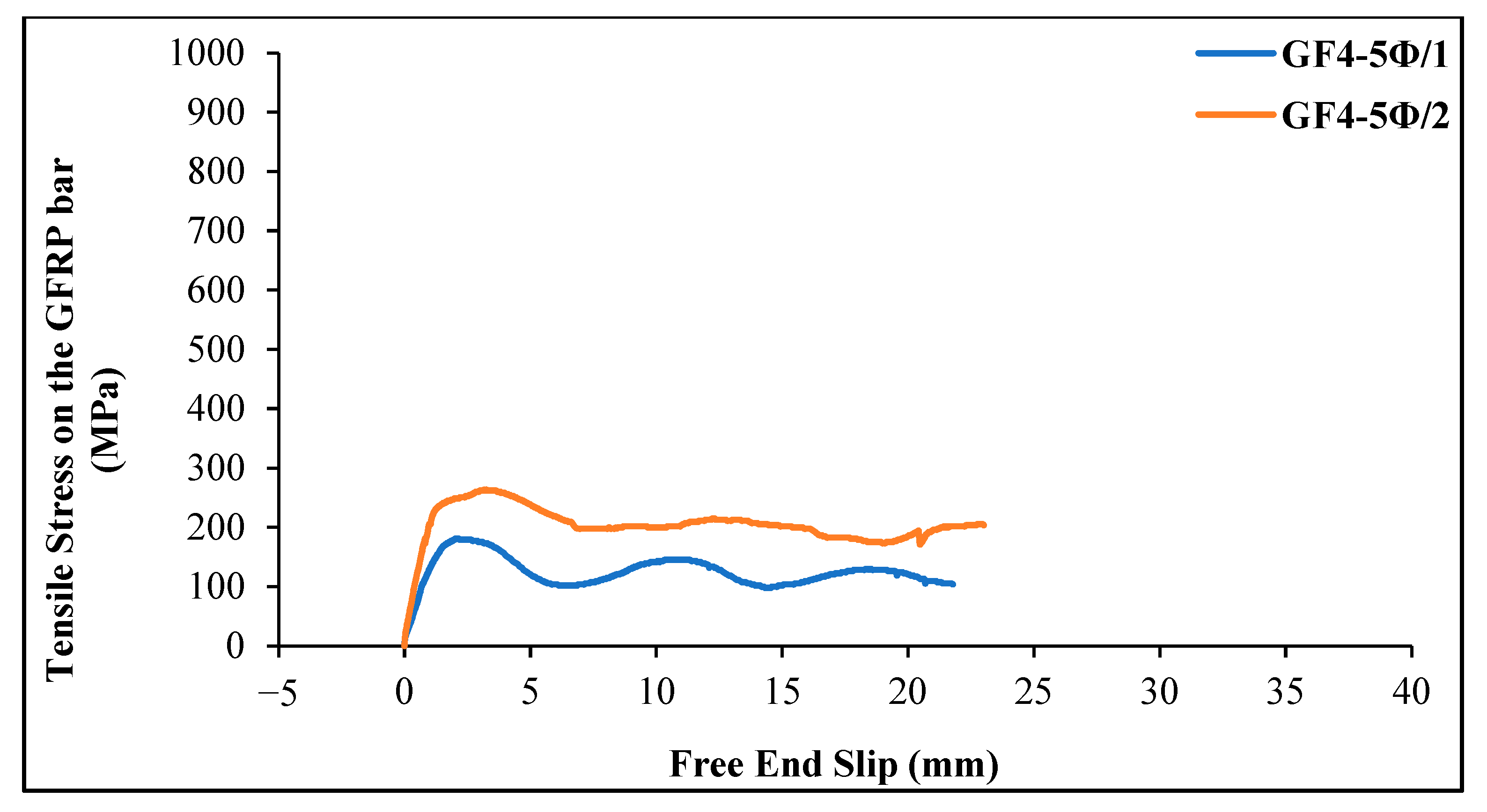

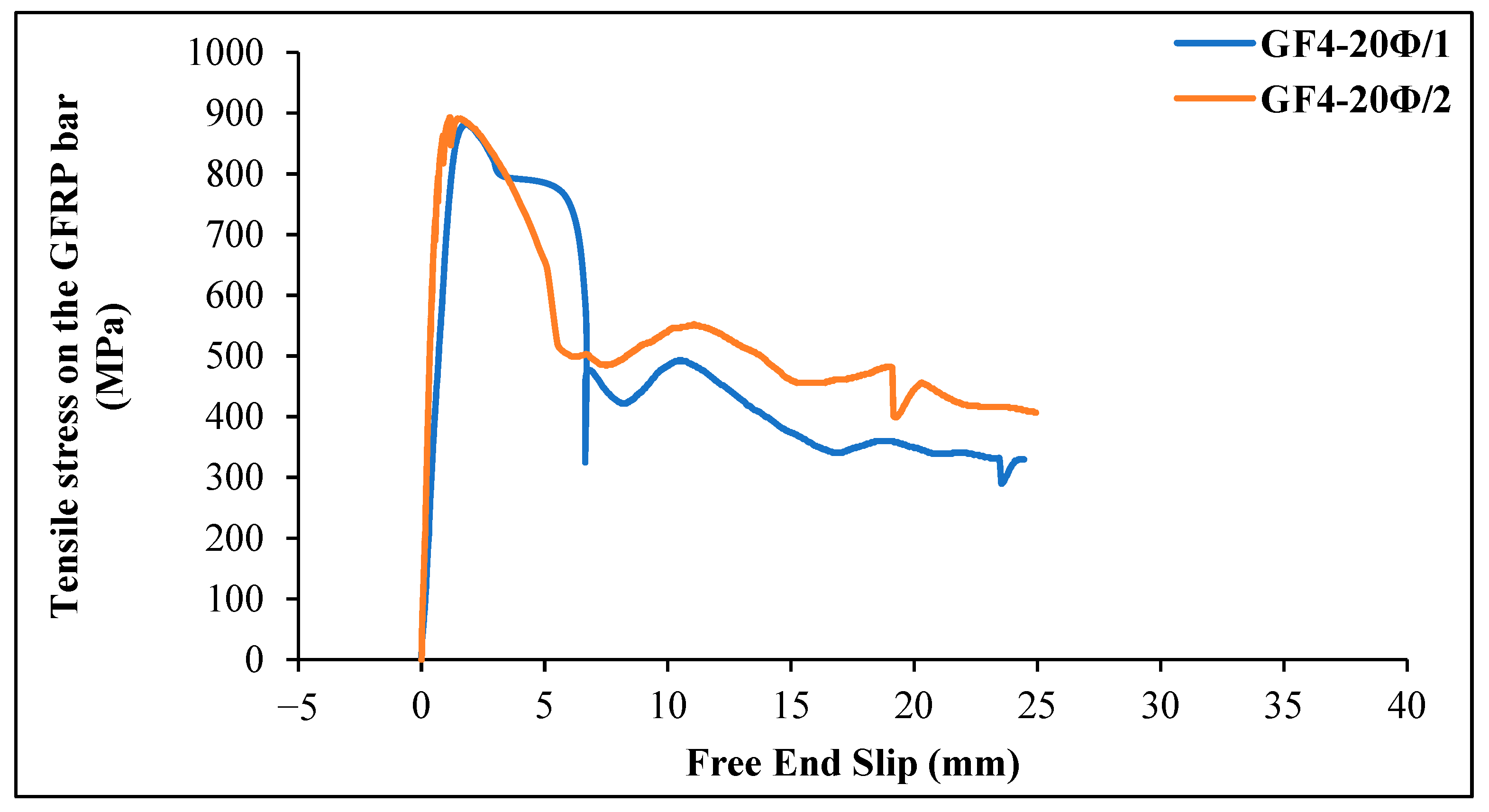

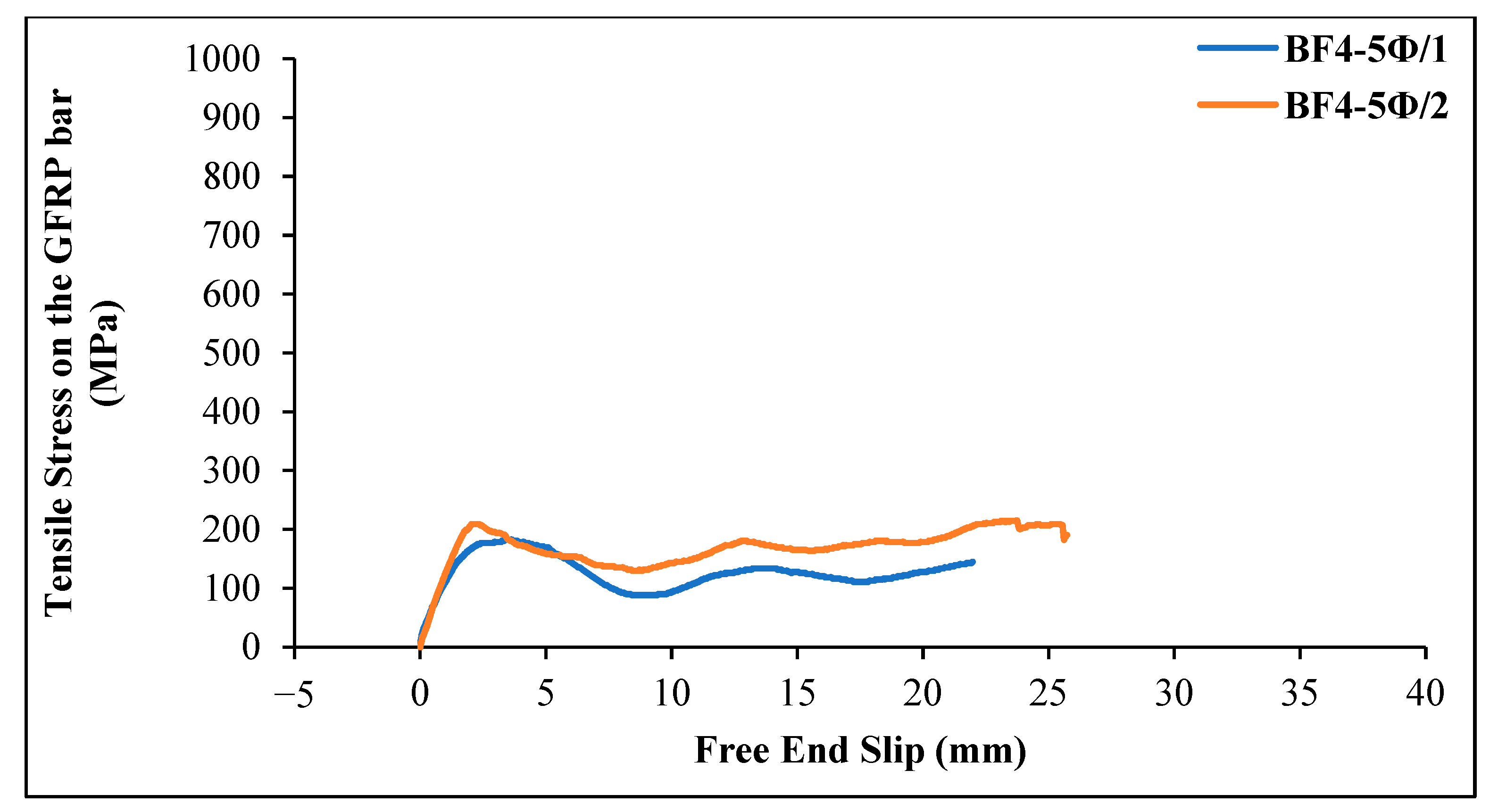

3.3. Bond-Slip Behavior of GFRP Rebar in Glass and Basalt Fiber-Reinforced Geopolymer Concrete

4. Conclusions

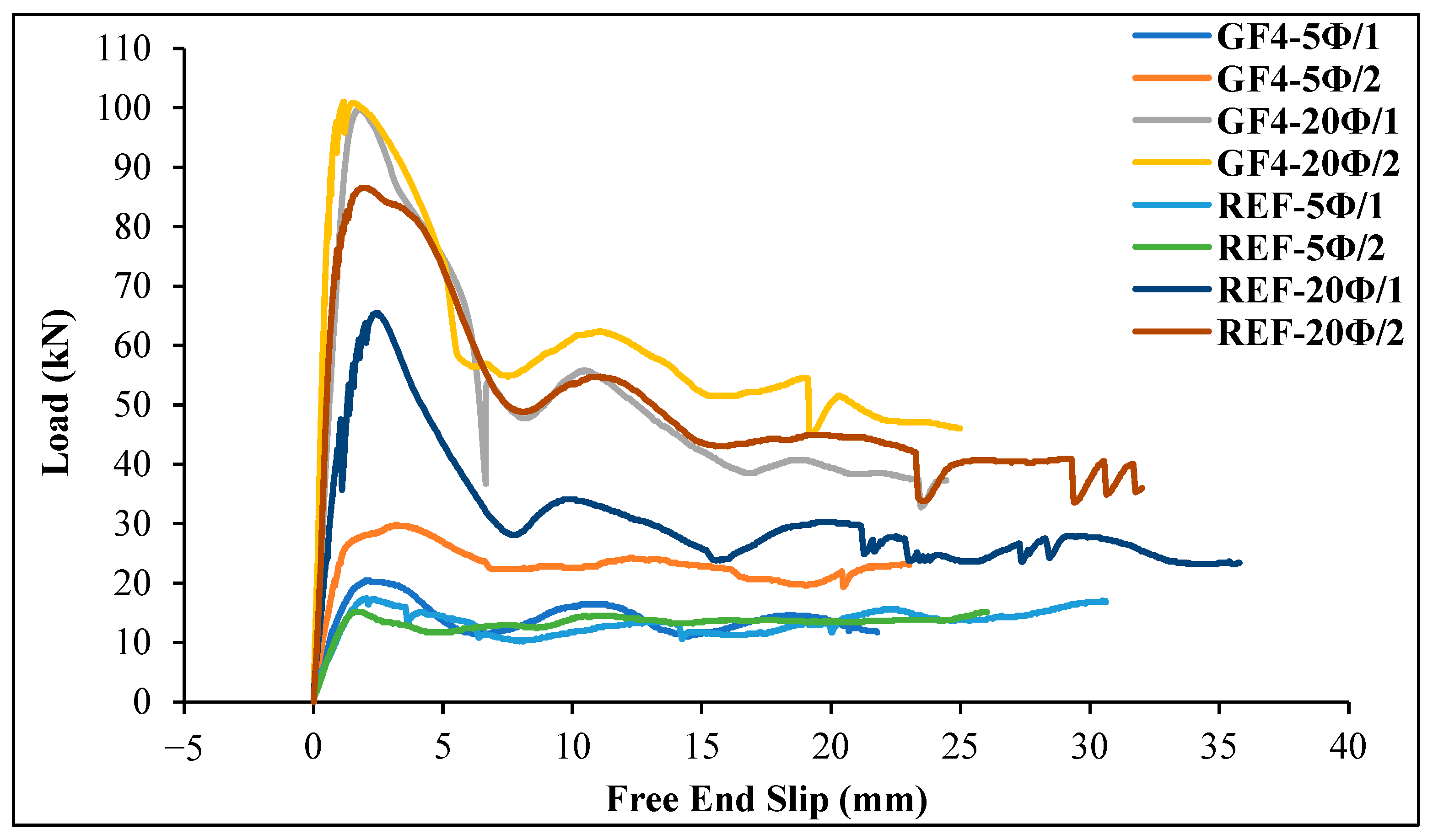

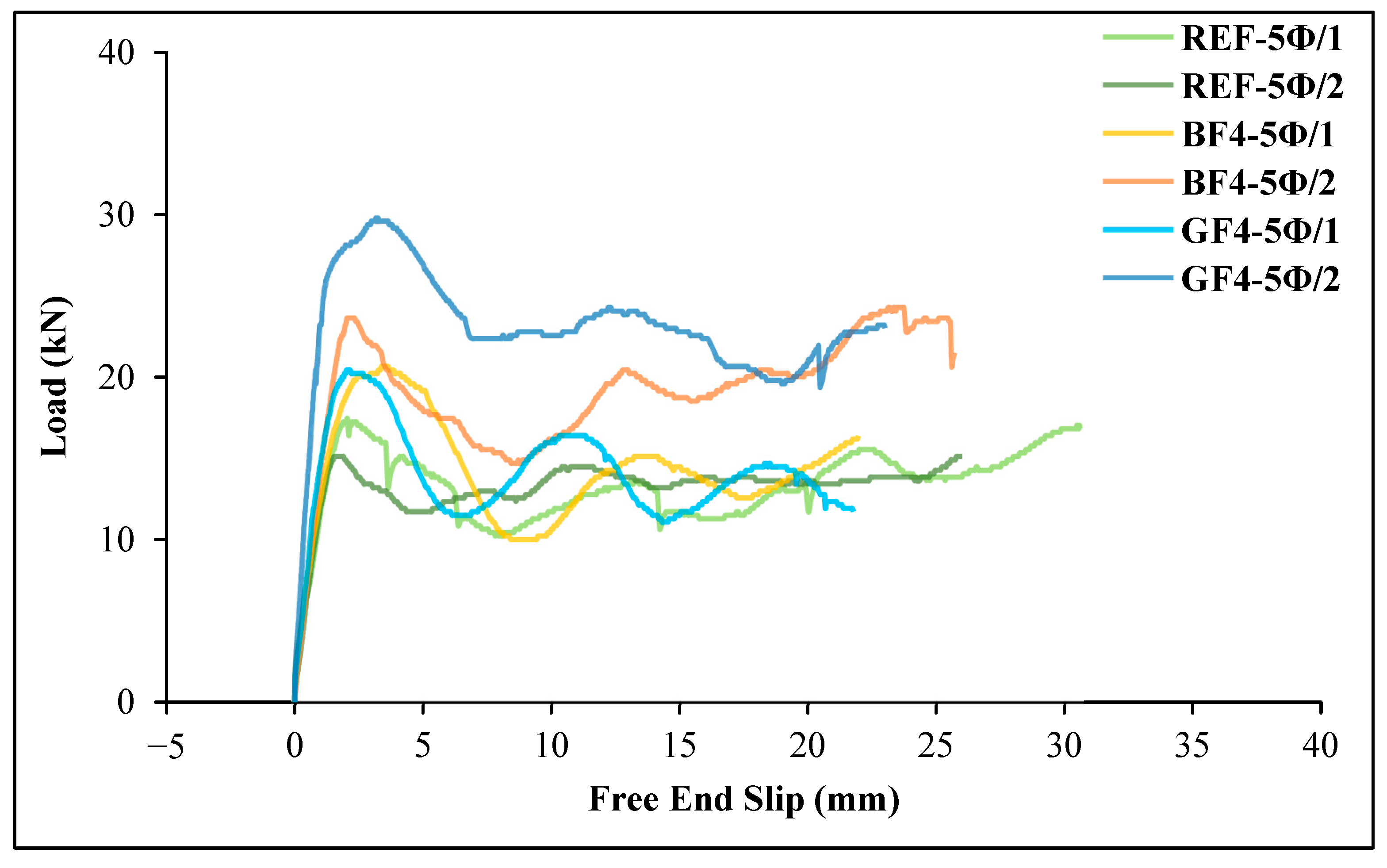

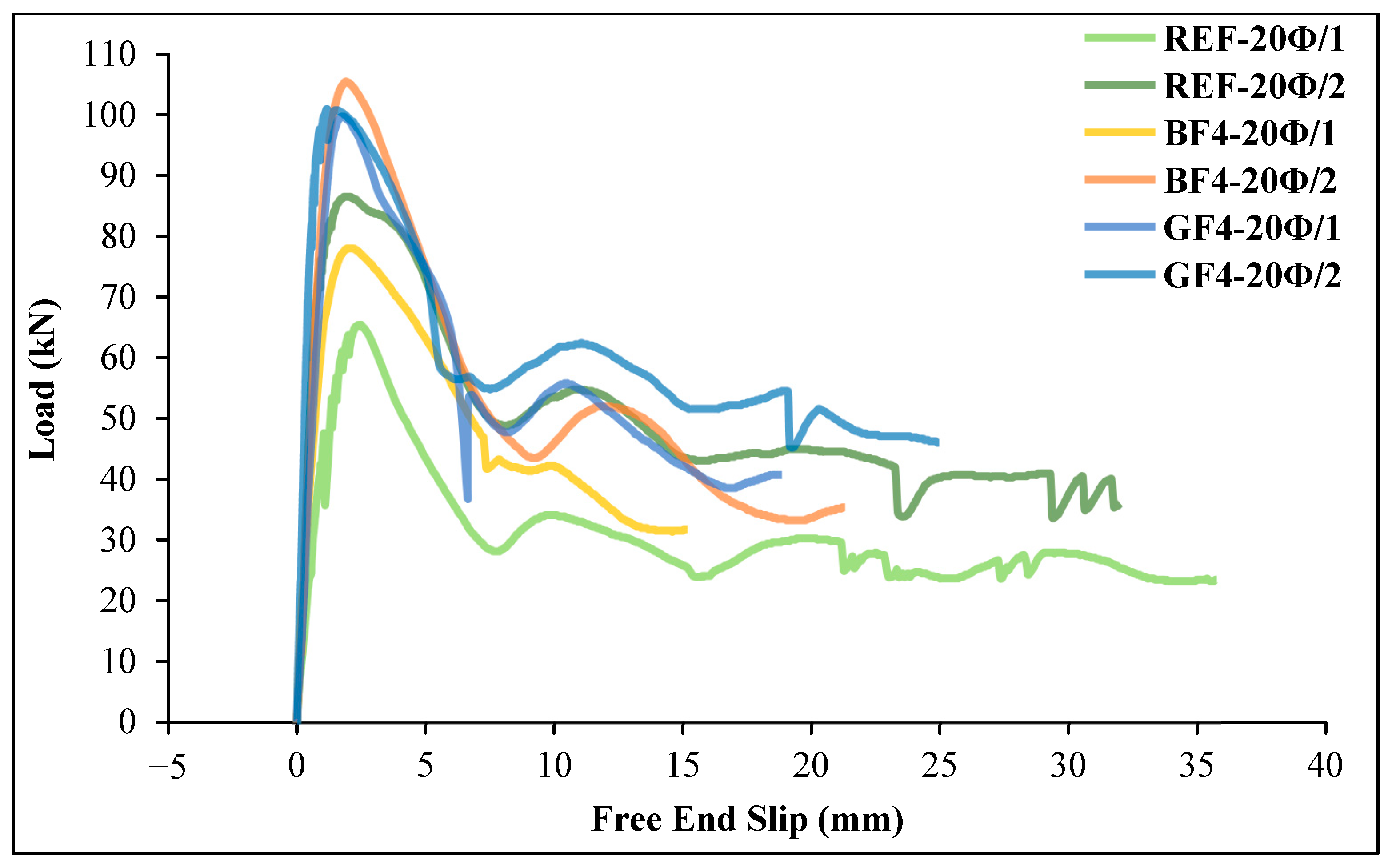

- The ultimate load values of GFRP bars in fiber-reinforced geopolymer concrete beams increase with the embedment length, but the maximum bond stress is higher for glass fiber-reinforced geopolymer concrete compared to basalt fiber-reinforced concrete.

- Since all experiments resulted in the pull-out of GFRP bars for all types of specimens, no meaningful relations were found between the embedment length and the average bond stress values. However, it can be said that increasing the embedment length does not significantly affect the average bond stress values for all specimen types examined in the study.

- Glass fiber-reinforced geopolymer concrete showed 49% higher bond strength than geopolymer without fiber for samples with 20 Ø embedment length, while basalt fiber-reinforced geopolymer concrete showed a 37% increase. This means that glass fiber was found to be more effective than basalt fiber in improving the bond strength of GFRP geopolymer.

- The study suggests that the surface type of GFRP bars plays a key role in bond performance, especially at the 20 Ø embedment length.

- The bond performance of FRP bars is complex, and findings from this study contribute to the ongoing debate in the field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRP | Fiber-reinforced polymer |

| AFRP | Aramid fiber-reinforced polymer |

| GFRP | Glass fiber-reinforced polymer |

| CFRP | Carbon fiber-reinforced polymer |

| BFRP | Basalt fiber-reinforced polymer |

| HFRP | Hybrid fiber-reinforced polymer |

References

- Laxmi, G.; Patil, S.G. Effect of fiber types, shape, aspect ratio and volume fraction on properties of geopolymer concrete—A review. Mater. Today Proc. 2022, 65, 1086–1094. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, R.; Ma, B.; Si, R.; Zeng, X. Mechanical and fracture properties of fly ash-based geopolymer concrete with different fibers. J. Build. Eng. 2023, 63, 105281. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Lee, Y.T.; Lee, J.H.; Hwang, H.S.; Kim, Y.D. Performance of concrete structures retrofitted with fiber reinforce polymers. Mag. Korean ConcInst 2022, 14, 89–96. [Google Scholar]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Characterization of self-compacting concretes prepared with different fibers and mineral additions. Cem. Concr. Compos. 2011, 33, 596–601. [Google Scholar] [CrossRef]

- Kızılkanat, A.B.; Kabay, N.; Akyüncü, V.; Erdoğan, G. Basalt fibers and mechanical properties of basalt fiber reinforced concrete. Sigma J. Eng. Nat. Sci. 2014, 32, 444–452. [Google Scholar]

- Won, J.-P.; Park, C.-G.; Kim, H.-H.; Lee, S.-W.; Jang, C.-I. Effect of fibers on the bonds between FRP reinforcing bars and high-strength concrete. Compos. Part B Eng. 2008, 39, 747–755. [Google Scholar] [CrossRef]

- Prasad, B.V.; Anand, N.; Kanagaraj, B.; Kiran, T.; Lubloy, E.; Naser, M.Z.; Arumairaj, P.D.; Andrushia, D. Investigation on residual bond strength and microstructure characteristics of fiber-reinforced geopolymer concrete at elevated temperature. Case Stud. Constr. Mater. 2023, 19, e02526. [Google Scholar] [CrossRef]

- ACI 440 1R-15; Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2015.

- Mosley, C.P.; Tureyen, A.K.; Frosch, R.J. Bond Strength of Nonmetallic Reinforcing Bars. ACI Struct. J. 2008, 105, 634. [Google Scholar] [CrossRef]

- Garbacz, A.; Urbański, M.; Łapko, A. BFRP bars as an alternative reinforcement of concrete structures—Compatibility and adhesion ıssues. Adv. Mater. Res. 2015, 1129, 233–241. [Google Scholar] [CrossRef]

- Başaran, B.; Kalkan, I.; Beycioğlu, A.; Kasprzyk, I. A Review on the Physical Parameters Affecting the Bond Behavior of FRP Bars Embedded in Concrete. Polymers 2022, 14, 1796. [Google Scholar] [CrossRef] [PubMed]

- Szmigiera, E.D.; Protchenko, K.; Urbański, M.; Garbacz, A. Mechanical Properties of Hybrid FRP Bars and Nano-Hybrid FRP Bars. Arch. Civ. Eng. 2019, 65, 97–110. [Google Scholar] [CrossRef]

- Ogrodowska, K.; Łuszcz, K.; Garbacz, A. Nanomodification, Hybridization and Temperature Impact on Shear Strength of Basalt Fiber-Reinforced Polymer Bars. Polymers 2021, 13, 2585. [Google Scholar] [CrossRef]

- Uğur, A.E.; Ünal, A.; Akgöbek, B.A.; Kamanlı, M.; Cengiz, S. Use of GFRP Bar in Civil Engineering. In Proceedings of the 4th International Symposium on Innovative Approaches in Engineering and Natural Sciences, SETSCI Conference Proceedings, Samsun, Turkey, 22–24 November 2019; Volume 9, pp. 95–100. [Google Scholar]

- Sarıer, Z. Flexural Behavior of GFRP Reinforced Hybrid Beams Used in Different Concrete Grades. Master’s Thesis, Kırıkkale University, Kırıkkale, Turkey, 2018. [Google Scholar]

- Kaya, N.; Avanoğlu, E.; Er, Ş.; Kopraman, Y.; Büyükkaragoz, A. Hibrit (GFRP-Çelik) donatılı kirişlerde donatı oranının eğilme dav-ranışına etkileri. Politek. Derg. 2021, 24, 1109–1119. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Benmokrane, B.; Elgabbas, F.; Ahmed, E.A.; Cousin, P. Characterization and Comparative Durability Study of Glass/Vinylester, Basalt/Vinylester, and Basalt/Epoxy FRP Bars. J. Compos. Constr. 2015, 19, 04015008. [Google Scholar] [CrossRef]

- Ehsani, M.R.; Saadatmanesh, H.; Tao, S. Bond Behavior of Deformed GFRP Rebars. J. Compos. Mater. 1997, 31, 1413–1430. [Google Scholar] [CrossRef]

- Tastani, S.P.; Pantazopoulou, S.J. Bond of GFRP Bars in Concrete: Experimental Study and Analytical Interpretation. J. Compos. Constr. 2006, 10, 381–391. [Google Scholar] [CrossRef]

- Wambeke, B.W.; Shield, C.K. Development length of glass fiber-reinforced polymer bars in concrete. ACI Mater. J. 2006, 103, 11–17. [Google Scholar]

- Mazaheripour, H.B.J.A.O.; Barros, J.A.; Sena-Cruz, J.M.; Pepe, M.; Martinelli, E. Experimental study on bond performance of GFRP bars in self-compacting steel fiber reinforced concrete. Compos. Struct. 2013, 95, 202–212. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, X.; Wang, Z.; Feng, S.; Gong, X.; Shumuye, E.D. Experimental study on bond performance of carbon- and glass-fiber reinforced polymer (CFRP/GFRP) bars and steel strands to concrete. Materials 2021, 14, 1268. [Google Scholar] [CrossRef]

- Başaran, B.; Kartal, S.; Kalkan, İ. Determination of the GFRP Reinforcement-Concrete Bond Strength from Pull-Out Tests Resulting in the Debonding Failure. UUJFE 2019, 24, 203–216. [Google Scholar] [CrossRef]

- Ling, Y.; Zhang, X.; Wu, Y.; Zou, W.; Wang, C.; Li, C.; Li, W. Evaluation of Bonding Behavior between Engineered Geopolymer Composites with Hybrid PE/PVA Fibers and Concrete Substrate. Materials 2024, 17, 3778. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Shi, J.; Wang, L.; Huang, C.; Tao, X.; Li, C.; Chen, Z. Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites. Materials 2024, 17, 4356. [Google Scholar] [CrossRef]

- Luo, R.; Liu, R.; Qin, G.; Jiang, M.; Wu, Y.; Guo, Y. Study on High-Ductility Geopolymer Concrete: The Influence of Oven Heat Curing Conditions on Mechanical Properties and Microstructural Development. Materials 2024, 17, 4011. [Google Scholar] [CrossRef]

- Rameshwaran, P.M.; Madhavi, T.C. Flexural behaviour of fly ash based geopolymer concrete. Mater. Today Proc. 2021, 46, 3423–3425. [Google Scholar] [CrossRef]

- Ürünveren, H.; Beycioğlu, A.; Resuloğulları, E.Ç.; Dişken, N.B. A comparative investigation of eco-friendly fly ash-based geopolymer mortar produced by using electrical and heat curing: Mechanical properties, energy consumption and cost. Constr. Build. Mater. 2024, 439, 137200. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, Y.; Yu, Z. Influence of Ambient Relative Humidity on the Shrinkage Strain of Engineered Geopolymer Composites Based on Orthogonal Experimental Design. Materials 2024, 17, 4321. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Li, Y.; Maimait, A.; Cheng, J.; Duan, Y.; Chen, Y.; Dong, H. Properties of Fiber-Reinforced Geopolymer Mortar Using Coal Gangue and Aeolian Sand. Materials 2024, 17, 3225. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Qu, S.; Bao, J.; Zhang, P. Bond performance of steel bar and fly ash-based geopolymer concrete in beam end tests. Polymers 2022, 14, 2012. [Google Scholar] [CrossRef] [PubMed]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Structural performance of reinforced geopolymer concrete members: A review. Constr. Build. Mater. 2016, 120, 251–264. [Google Scholar] [CrossRef]

- Sani, M.A.; Muhamad, R. Bond behaviour of geopolymer concrete in structural application: A review. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012017. [Google Scholar] [CrossRef]

- Bayrak, B.; Akarsu, O.; Kılıç, M.; Alcan, H.G.; Çelebi, O.; Kaplan, G.; Aydın, A.C. Experimental study of bond behavior of geopolymer concrete under different curing condition using a pull-out test. Constr. Build. Mater. 2024, 439, 137357. [Google Scholar] [CrossRef]

- Özdemir, M.H.S.; Bayrak, B.; Aydın, A.C. Bond performance of geopolymer concrete with bazalt/glass fiber under elevated temperature. Eng. Struct. 2025, 324, 119368. [Google Scholar] [CrossRef]

- Romanazzi, V.; Leone, M.; Aiello, M.; Pecce, M.R. Bond behavior of geopolymer concrete with steel and GFRP bars. Compos. Struct. 2022, 300, 116150. [Google Scholar] [CrossRef]

- Albidah, A.; Altheeb, A.; Alrshoudi, F.; Abadel, A.; Abbas, H.; Al-Salloum, Y. Bond performance of GFRP and steel rebars embedded in metakaolin based geopolymer concrete. Structures 2020, 27, 1582–1593. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Cai, Y.-J.; Xie, Z.-H.; Xiao, S.-H.; Zhuo, K.-X.; Cai, P.-D.; Lin, J.-X. Experimental investigation of GFRP bar bonding in geopolymer concrete using hinged beam tests. Eng. Struct. 2025, 322, 119036. [Google Scholar] [CrossRef]

- TS500; Reinforced Concrete Structures Design and Construction Rules. Turkish Standards Institute: Ankara, Turkey, 2002.

- BS 4449:2005+A2:2009; Steel for the Reinforcement of Concrete—Weldable Reinforcing Steel—Bar, Coil and Decoiled Product—Specification. British Standards Institution: London, UK, 2009.

- Soleymani Ashtiani, M.; Dhakal, R.; Scott, A.; Bull, D. Cyclic beam bending test for assessment of bond–slip behaviour. Eng. Struct. 2013, 56, 1684–1697. [Google Scholar] [CrossRef]

- Panda, S.; Alnounou, M.A.; Jawhara, B.; Sarkar, P. Bond strength and corrosion behavior of rebar embedded in copper slag concrete composites. Constr. Build. Mater. 2024, 416, 135134. [Google Scholar] [CrossRef]

- Tugrul Tunc, E.; Alyamaç, K.E.; İnce, R.; Ulucan, Z. Relationship between Reinforcement Diameter and Bond Stress in High Performance Lightweight Concrete. Eur. J. Sci. Technol. 2021, 23, 851–860. [Google Scholar] [CrossRef]

- Seis, M.; Beycioğlu, A. Bond performance of basalt fiber-reinforced polymer bars in conventional Portland cement concrete: A relative comparison with steel rebar using the hinged beam approach. Sci. Eng. Compos. Mater. 2017, 24, 909–918. [Google Scholar] [CrossRef]

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Gültekin, A.; Beycioğlu, A.; Arslan, M.E.; Serdar, A.H.; Dobiszewska, M.; Ramyar, K. Fresh properties and fracture energy of basalt and glass fiber–reinforced self-compacting concrete. J. Mater. Civ. Eng. 2022, 34, 04021406. [Google Scholar] [CrossRef]

- Kartal, S.; Kalkan, I.; Beycioglu, A.; Dobiszewska, M. Load-Deflection Behavior of Over- and Under-Reinforced Concrete Beams with Hybrid FRP-Steel Reinforcements. Materials 2020, 14, 5341. [Google Scholar] [CrossRef]

- Ertürkmen, D.; Ürünveren, H.; Beycioğlu, A. Effect of Glass and Basalt Fibers on the Bond–Slip Behavior of Steel Rebar in Eco-Friendly Fly Ash–Based Geopolymer Concrete: A Relative Comparison Using the Hinged Beam Approach. J. Mater. Civ. Eng. 2025, 37, 04024545. [Google Scholar] [CrossRef]

| Aggregate | Density (kg/m3) (STD) | Water Absorption (%) (STD) | Stock Humidity (%) (STD) |

|---|---|---|---|

| Coarse (4.75–12.7 mm) | 2670 (0.82) | 1.11 (0.01) | 0.15 (0.01) |

| Fine (0–4.75 mm) | 2660 (1.89) | 2.64 (0.03) | 0.24 (0.01) |

| Chemical Composition | (%) |

|---|---|

| Al2O3 | 21.00 |

| SiO2 | 53.00 |

| SO3 | 1.50 |

| K2O | 2.70 |

| CaO | 4.95 |

| TiO2 | 1.31 |

| Fe2O3 | 13.83 |

| Na2O | 0.69 |

| MgO | 0.09 |

| Others | 0.93 |

| Loss on Ignition | 1.32 |

| Ms | Materials (kg/m3) | Dry Mixture | Activator | |||

|---|---|---|---|---|---|---|

| Fly Ash | Aggregate | Sodium Silicate (Na2SiO3) | Sodium Hydroxide (NaOH) | |||

| 1.2 | 497.81 | 1493.43 | 270.92 | 27.88 | 1991.20 | 298.80 |

| Properties | Values |

|---|---|

| Tensile strength | 800–1300 MPa |

| Modulus of elasticity | 55,000 MPa |

| Specimen Code Name | Fiber Type | Fiber Length | Fiber Amount | Embedment Length |

|---|---|---|---|---|

| REF-5Ø/1 (GFRP) REF-5Ø/2 (GFRP) | Non- Fiber | - | - | 5 Ø |

| REF-20Ø/1 (GFRP) REF-20Ø/2 (GFRP) | 20 Ø | |||

| GF4-5Ø/1 (GFRP) GF4-5Ø/2 (GFRP) | Chopped Glass | 6 mm | 4 kg/m3 | 5 Ø |

| GF4-20Ø/1 (GFRP) GF4-20Ø/2 (GFRP) | 20 Ø | |||

| BF4-5Ø/1 (GFRP) BF4-5Ø/2 (GFRP) | Chopped Basalt | 6 mm | 4 kg/m3 | 5 Ø |

| BF4-20Ø/1 (GFRP) BF4-20Ø/2 (GFRP) | 20 Ø |

| Samples | Compressive Strength (MPa) (STD) | Flexural Tensile Strength (MPa) | Flow Diameter (cm) |

|---|---|---|---|

| REF | 56.53 (1.55) | 3.54 (0.07) | 57 (0.25) |

| GF4 | 61.84 (2.05) | 6.62 (0.11) | 46 (0.5) |

| BF4 | 56.39 (1.82) | 5.76 (0.08) | 43 (0.5) |

| Specimen Code | Ultimate Load (kN) | Average Ultimate Load (kN) | Ultimate Stress on Rebar (MPa) | Average Ultimate Stress on Rebar (MPa) | Ultimate Bond Stress (MPa) | Average Bond Stress (MPa) | Slip at Ultimate Stress (mm) | Average Slip at Ultimate Stress (mm) | First Slip Stress (MPa) | Failure Type |

|---|---|---|---|---|---|---|---|---|---|---|

| REF-5Ø/1 | 17.47 | 16.30 | 154.52 | 144.16 | 7.73 | 7.21 | 2.05 | 1.98 | 9.42 | Pull-out |

| REF-5Ø/2 | 15.13 | 133.80 | 6.69 | 1.90 | 5.65 | |||||

| REF-20Ø/1 | 47.53 | 67.03 | 420.23 | 592.66 | 5.25 | 7.40 | 1.05 | 1.57 | 11.31 | Pull-out |

| REF-20Ø/2 | 86.53 | 765.08 | 9.56 | 2.08 | 11.31 | |||||

| GF4-5Ø/1 | 20.46 | 25.15 | 180.91 | 222.37 | 9.05 | 11.12 | 2.16 | 2.66 | 9.42 | Pull-out |

| GF4-5Ø/2 | 29.84 | 263.82 | 13.19 | 3.16 | 11.31 | |||||

| GF4-20Ø/1 | 99.74 | 100.38 | 881.92 | 887.57 | 11.02 | 11.09 | 1.84 | 1.51 | 20.72 | Pull-out |

| GF4-20Ø/2 | 101.02 | 893.22 | 11.17 | 1.17 | 28.27 | |||||

| BF4-5Ø/1 | 20.67 | 22.17 | 182.79 | 195.98 | 9.14 | 9.94 | 3.64 | 2.98 | 9.42 | Pull-out |

| BF4-5Ø/2 | 23.67 | 209.17 | 10.74 | 2.32 | 7.54 | |||||

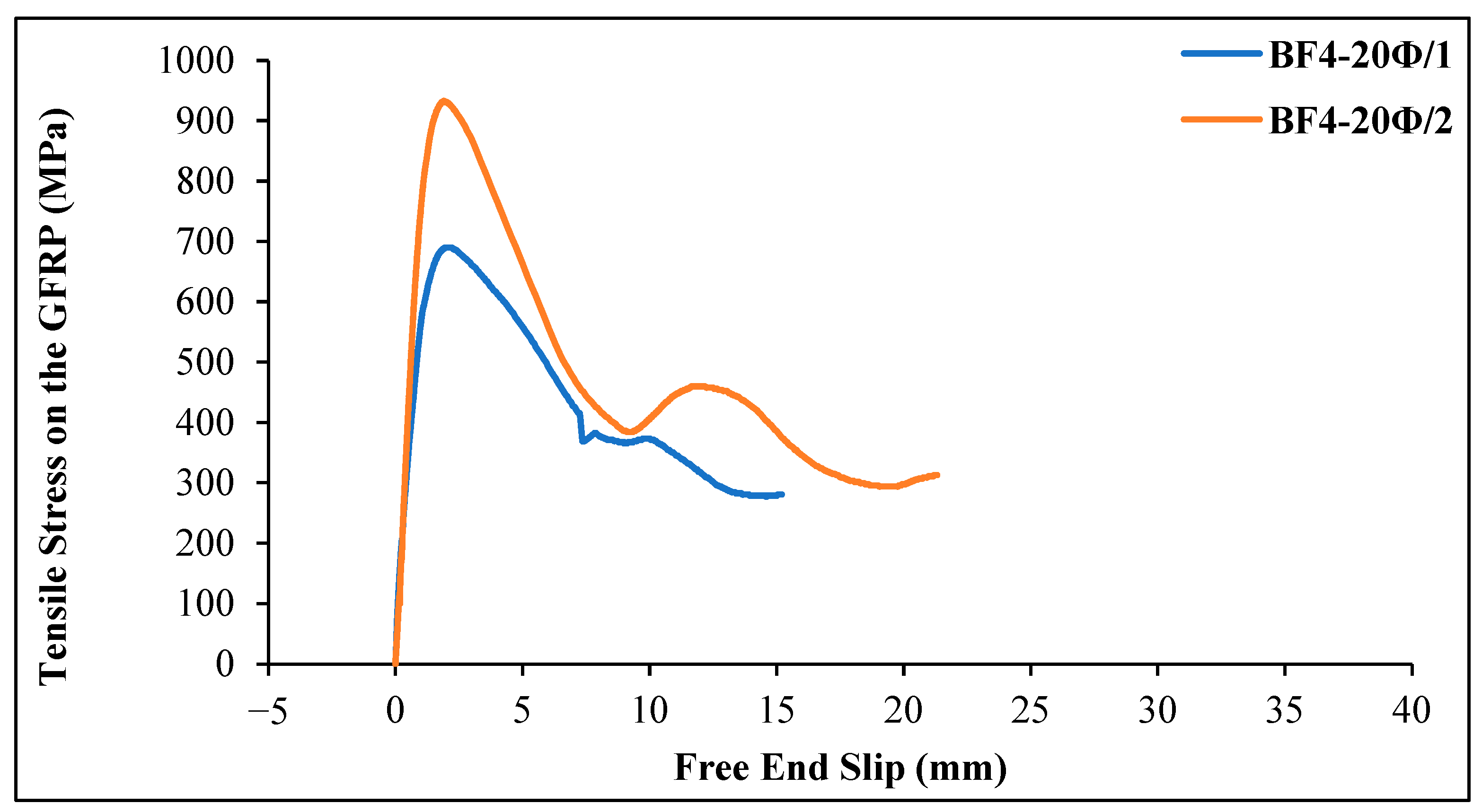

| BF4-20Ø/1 | 78.00 | 91.75 | 689.70 | 811.25 | 8.62 | 10.14 | 2.21 | 2.07 | 13.19 | Pull-out |

| BF4-20Ø/2 | 105.5 | 932.80 | 11.66 | 1.92 | 13.19 |

| Specimen Code | Ultimate Load (kN) | Average Ultimate Load (kN) | Ultimate Stress on Rebar (MPa) | Average Ultimate Stress on Rebar (MPa) | Ultimate Bond Stress (MPa) | Average Bond Stress (MPa) | Slip at Ultimate Stress (mm) | Average Slip at Ultimate Stress (mm) | First Slip Stress (MPa) | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|---|

| ADDS-20Ø/1 | 83.12 | 79.175 | 734.93 | 700.070 | 9.19 | 8.755 | 0 | 0 | 712.32 | Bar rupture |

| ADDS-20Ø/2 | 75.23 | 665.21 | 8.32 | 0 | 665.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ertürkmen, D.; Ürünveren, H.; Beycioğlu, A.; Ibadov, N.; Aruntaş, H.Y.; Garbacz, A. Bond Performance of GFRP Bars in Glass and Basalt Fiber-Reinforced Geopolymer Concrete Under Hinged Beam Tests. Materials 2025, 18, 498. https://doi.org/10.3390/ma18030498

Ertürkmen D, Ürünveren H, Beycioğlu A, Ibadov N, Aruntaş HY, Garbacz A. Bond Performance of GFRP Bars in Glass and Basalt Fiber-Reinforced Geopolymer Concrete Under Hinged Beam Tests. Materials. 2025; 18(3):498. https://doi.org/10.3390/ma18030498

Chicago/Turabian StyleErtürkmen, Duygu, Hüsamettin Ürünveren, Ahmet Beycioğlu, Nabi Ibadov, Hüseyin Yılmaz Aruntaş, and Andrzej Garbacz. 2025. "Bond Performance of GFRP Bars in Glass and Basalt Fiber-Reinforced Geopolymer Concrete Under Hinged Beam Tests" Materials 18, no. 3: 498. https://doi.org/10.3390/ma18030498

APA StyleErtürkmen, D., Ürünveren, H., Beycioğlu, A., Ibadov, N., Aruntaş, H. Y., & Garbacz, A. (2025). Bond Performance of GFRP Bars in Glass and Basalt Fiber-Reinforced Geopolymer Concrete Under Hinged Beam Tests. Materials, 18(3), 498. https://doi.org/10.3390/ma18030498