Effects of Longitudinal External Magnetic Field on Metal Transfer Behavior and Spatter Formation in CO2 Arc Welding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Welding Conditions

2.2. Metal Transfer Observation

3. Results

3.1. Experimental Results

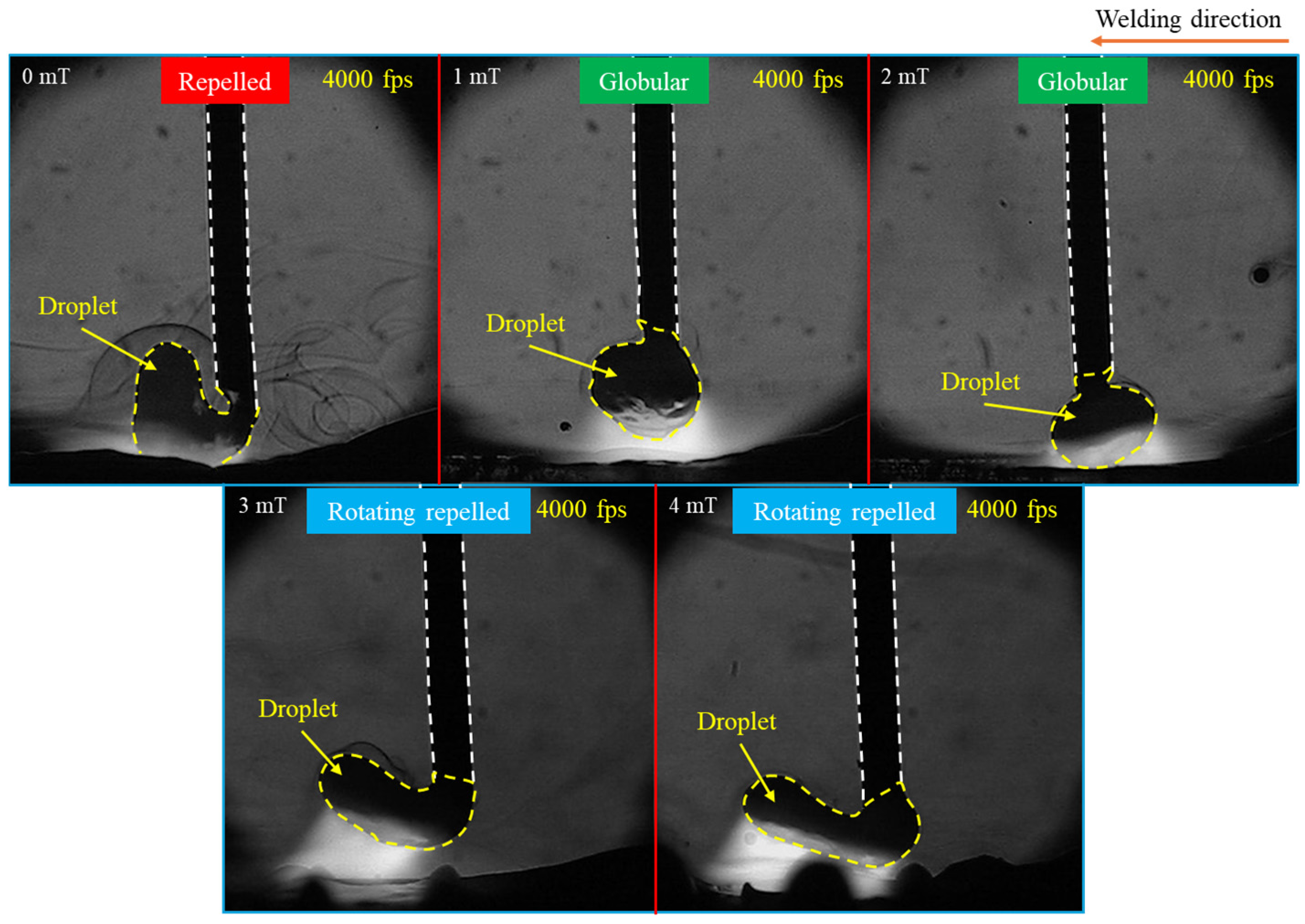

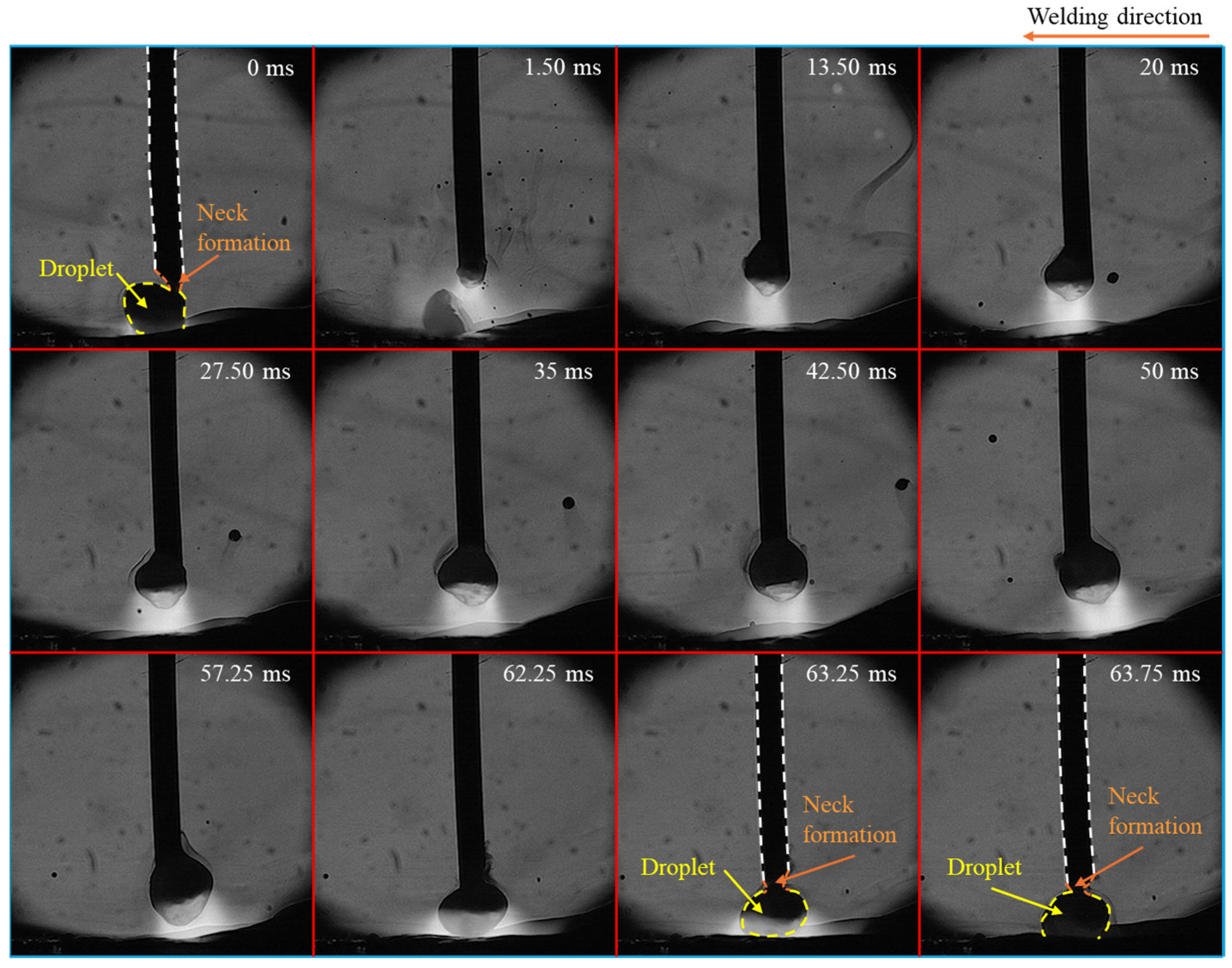

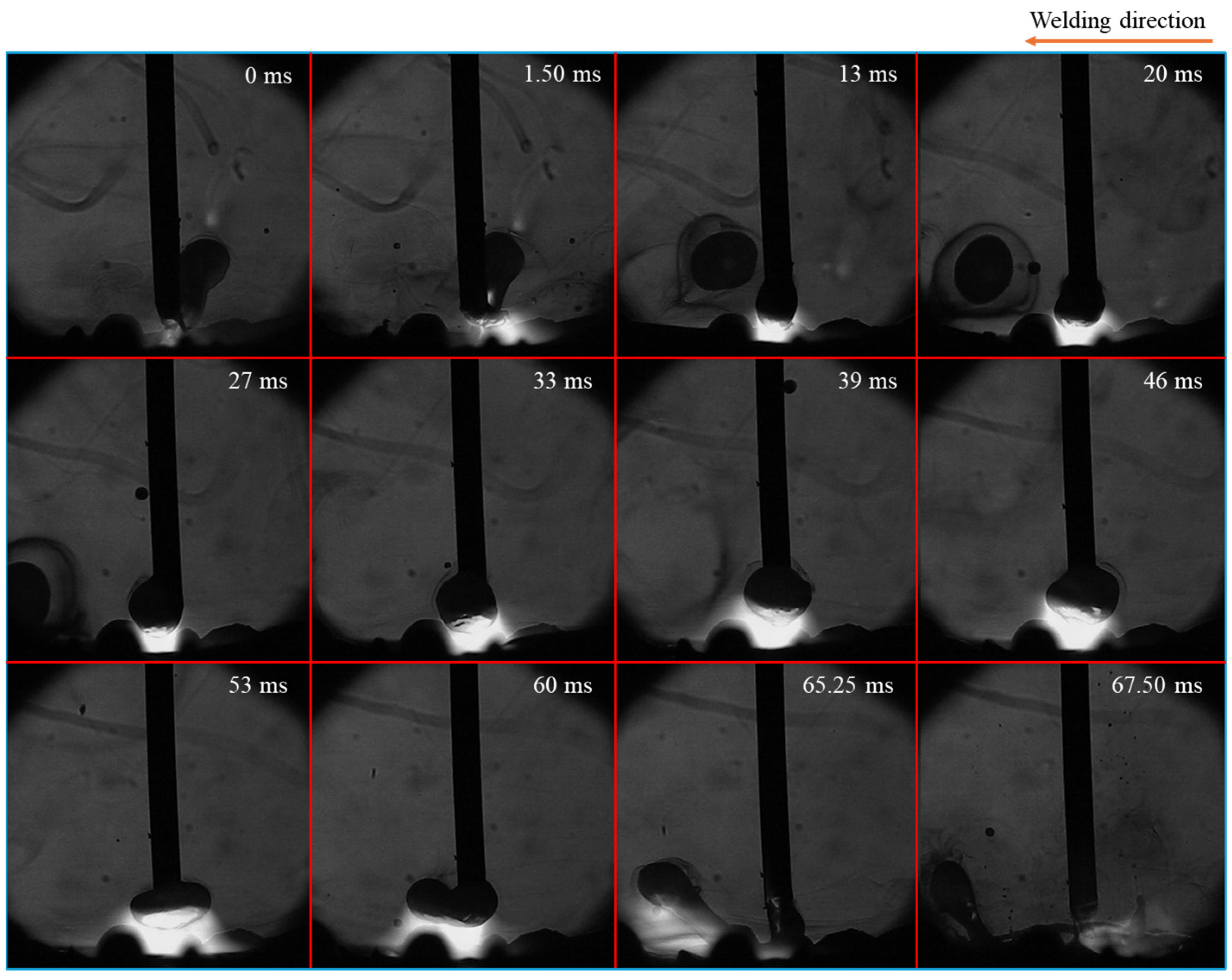

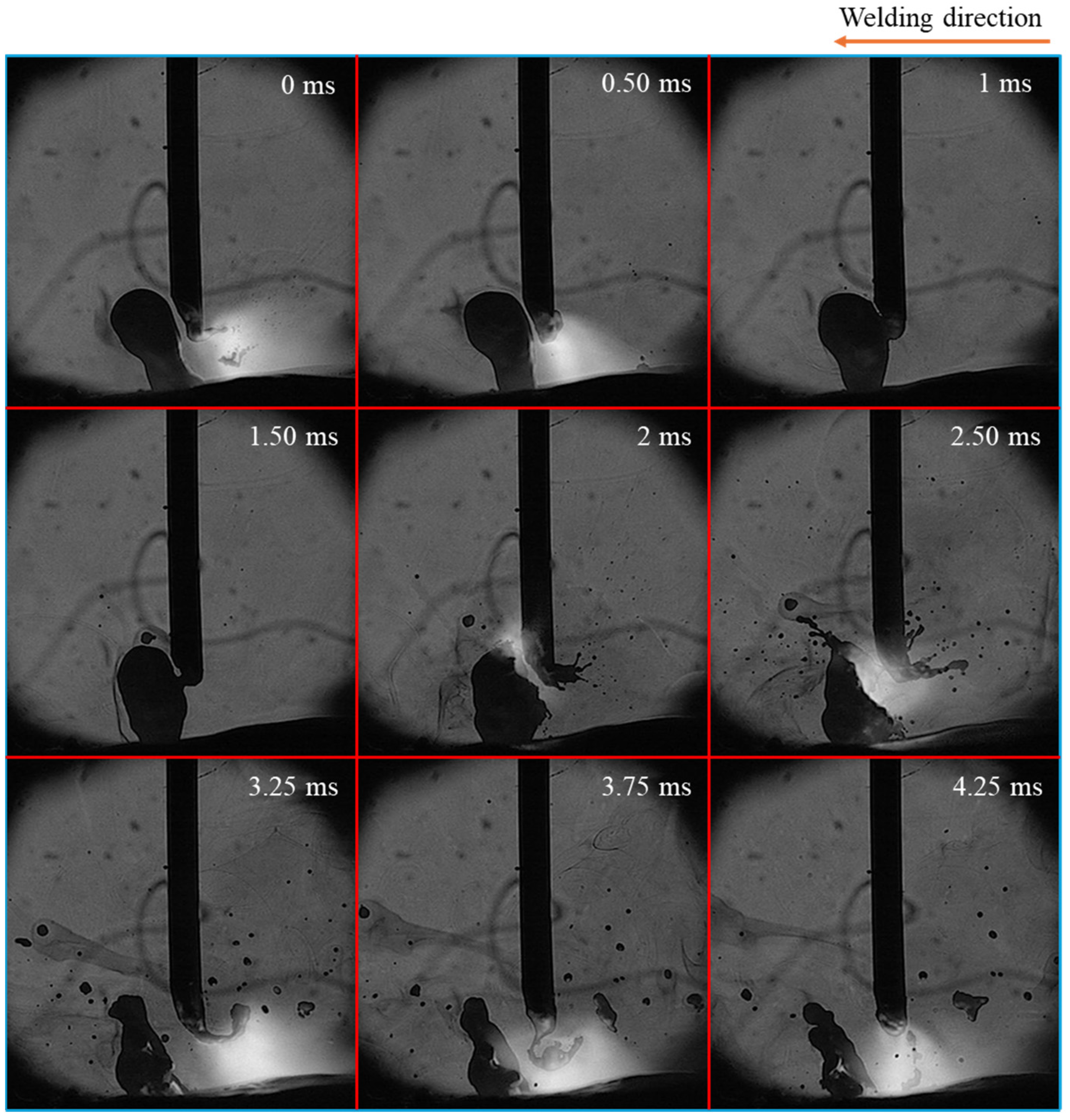

3.1.1. Metal Transfer Behavior

3.1.2. Arc Phenomenon

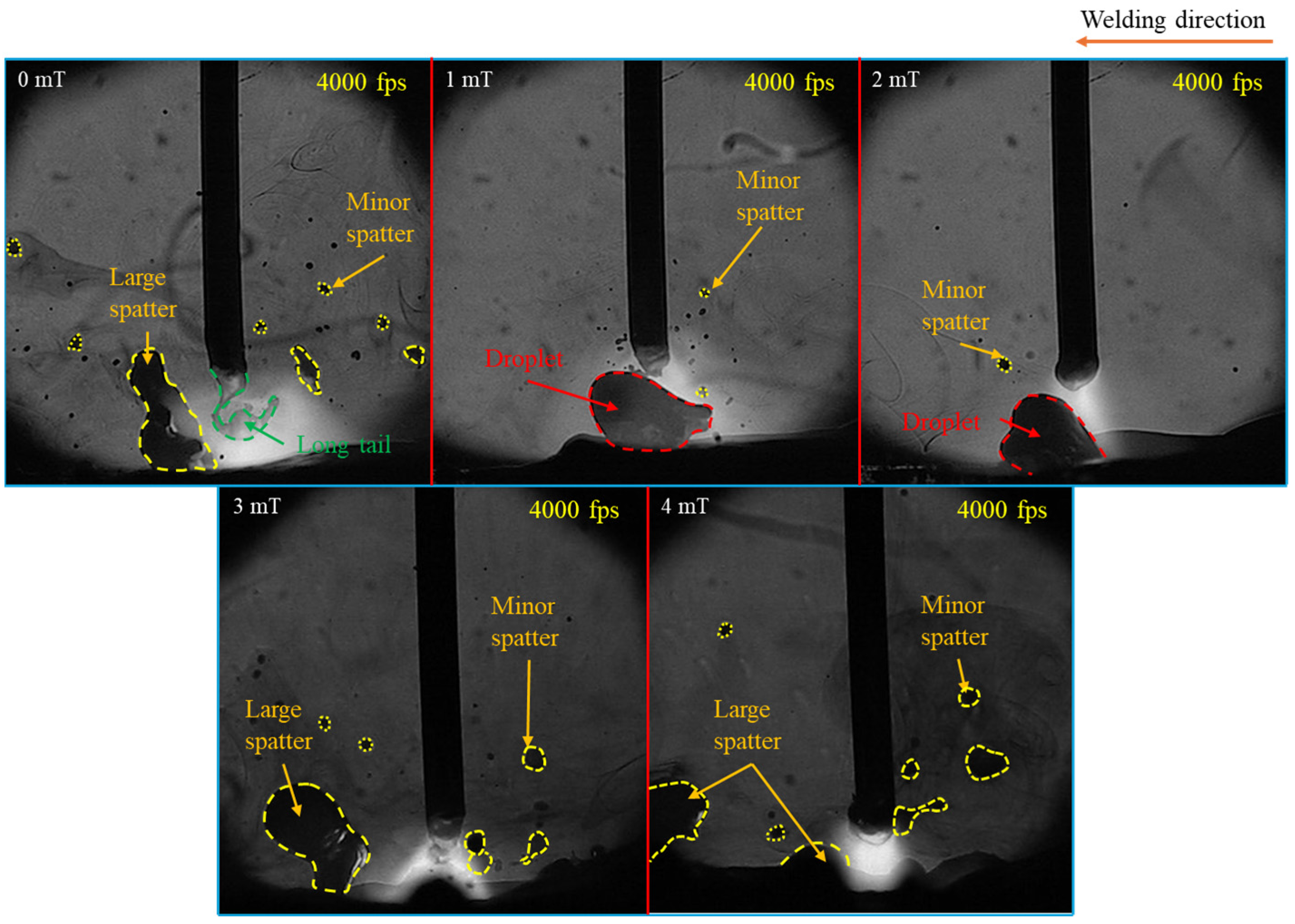

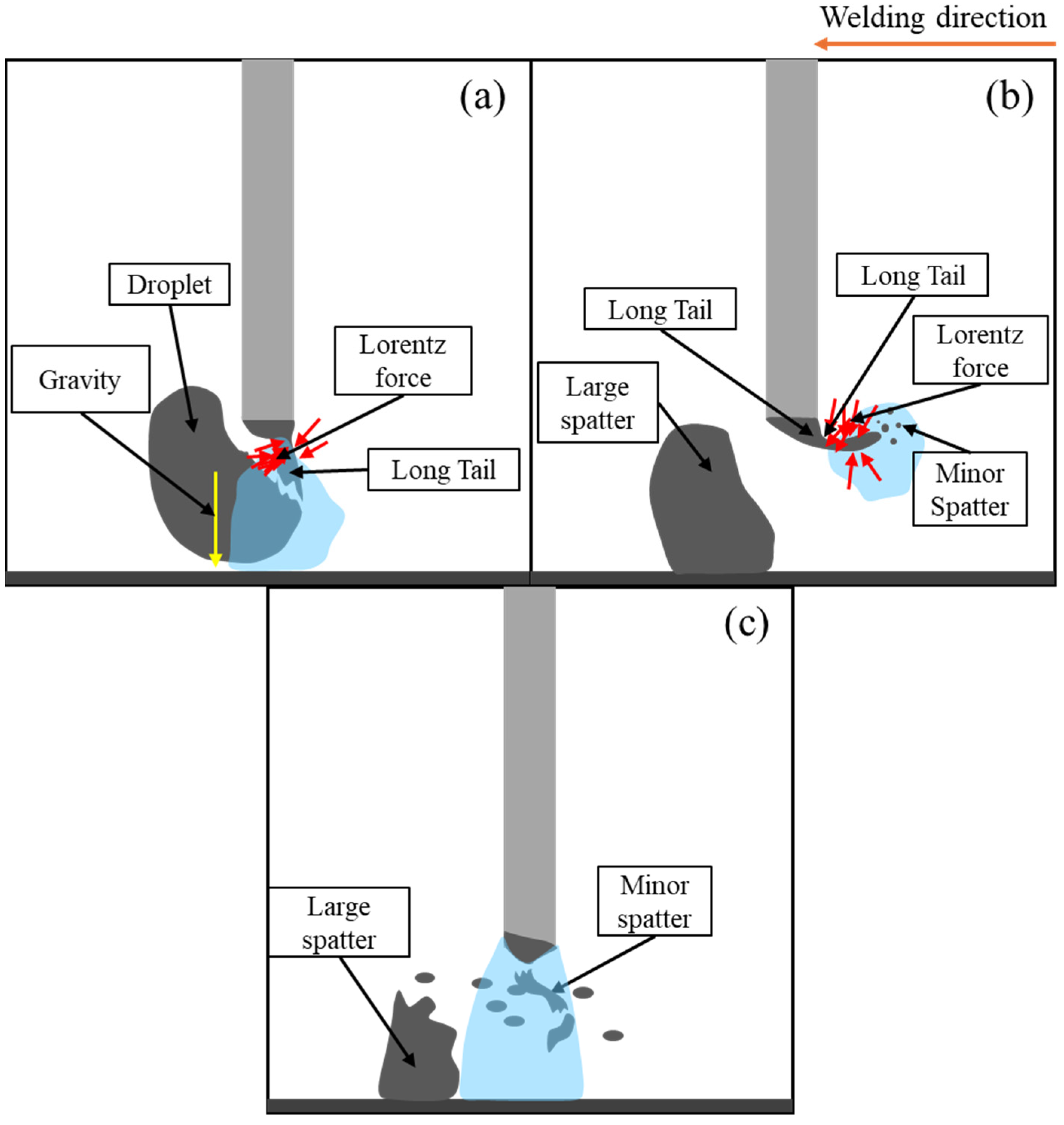

3.1.3. Spatter Formation

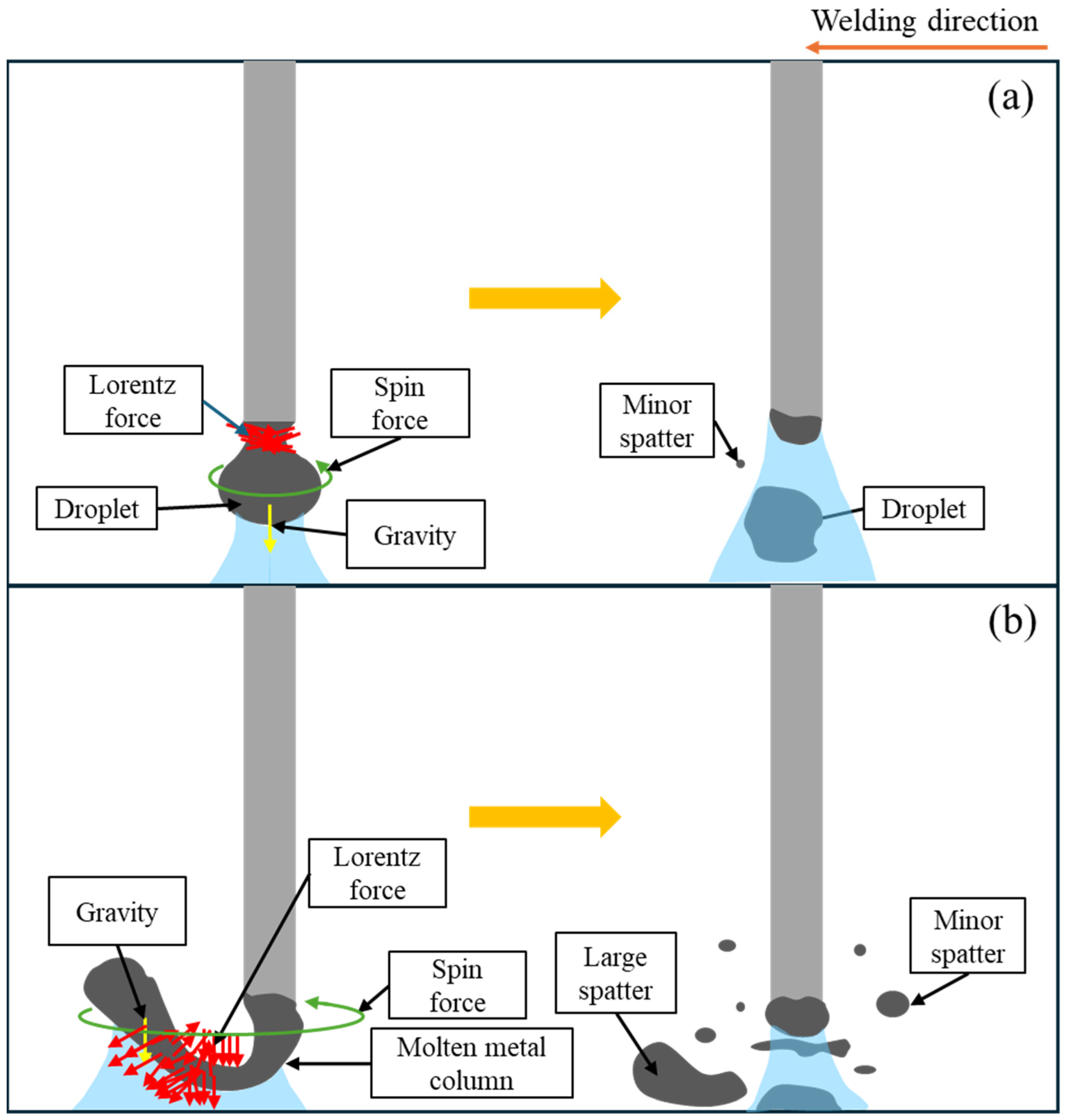

3.2. Simulation Model and Results

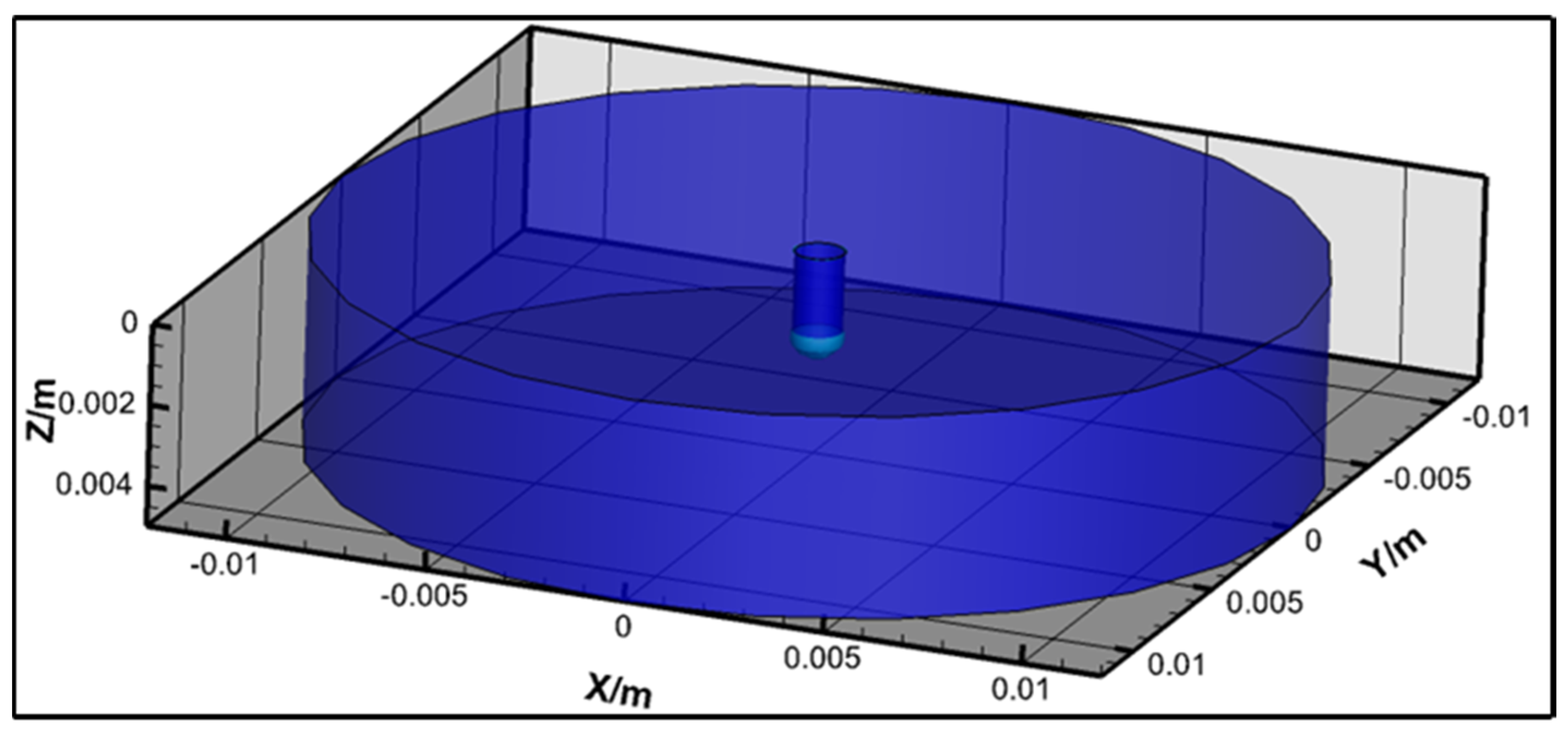

3.2.1. Simulation Model

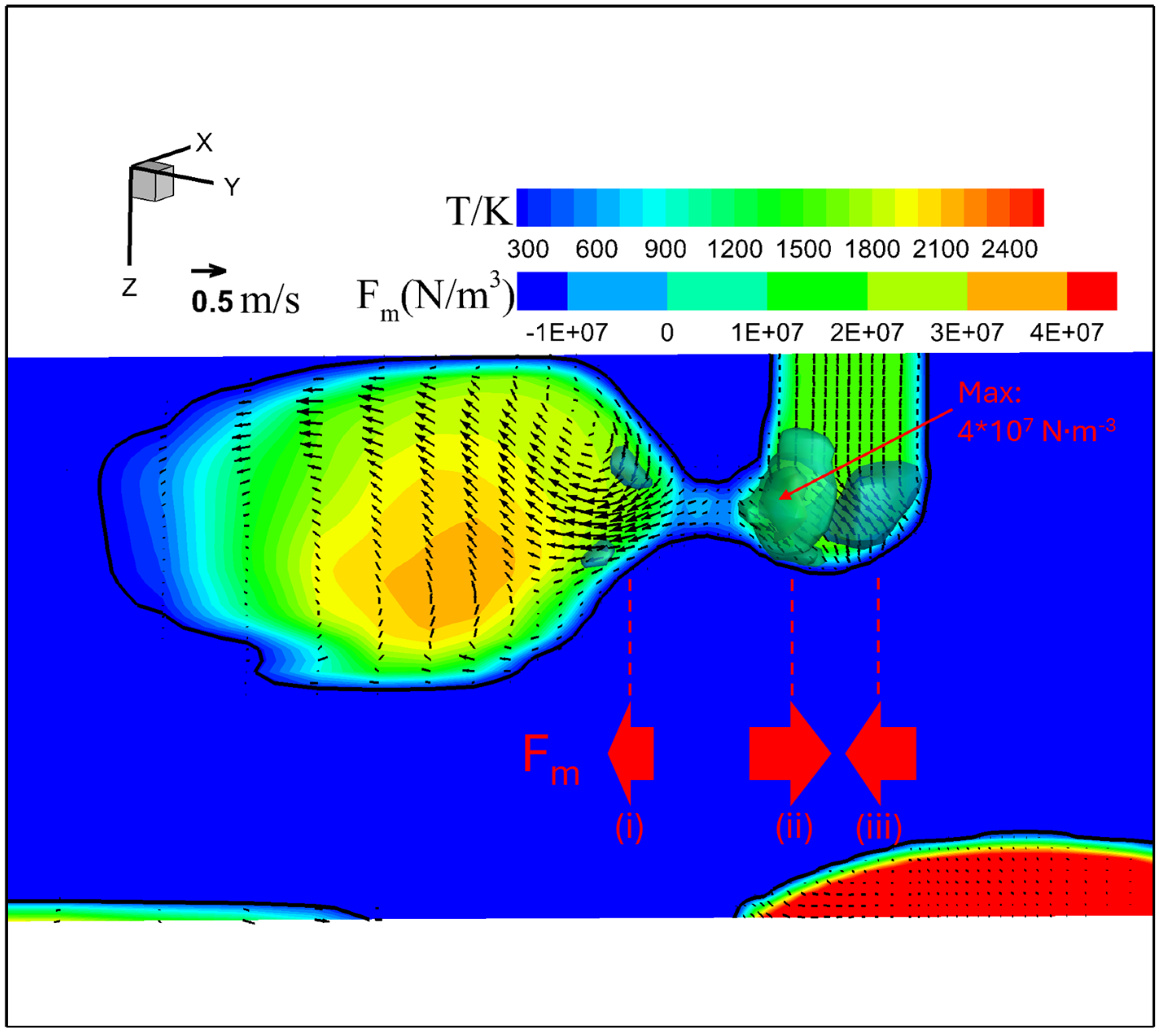

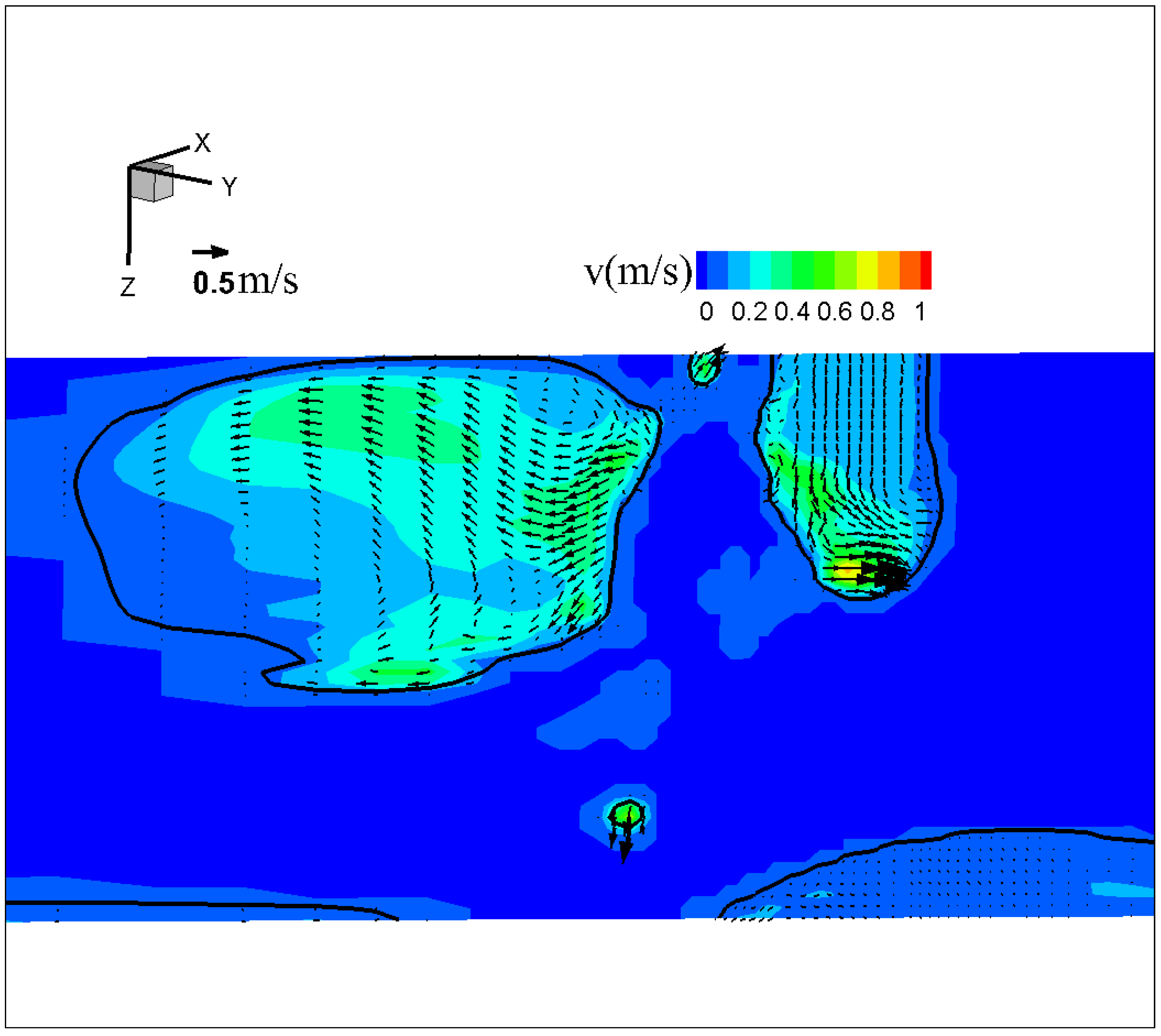

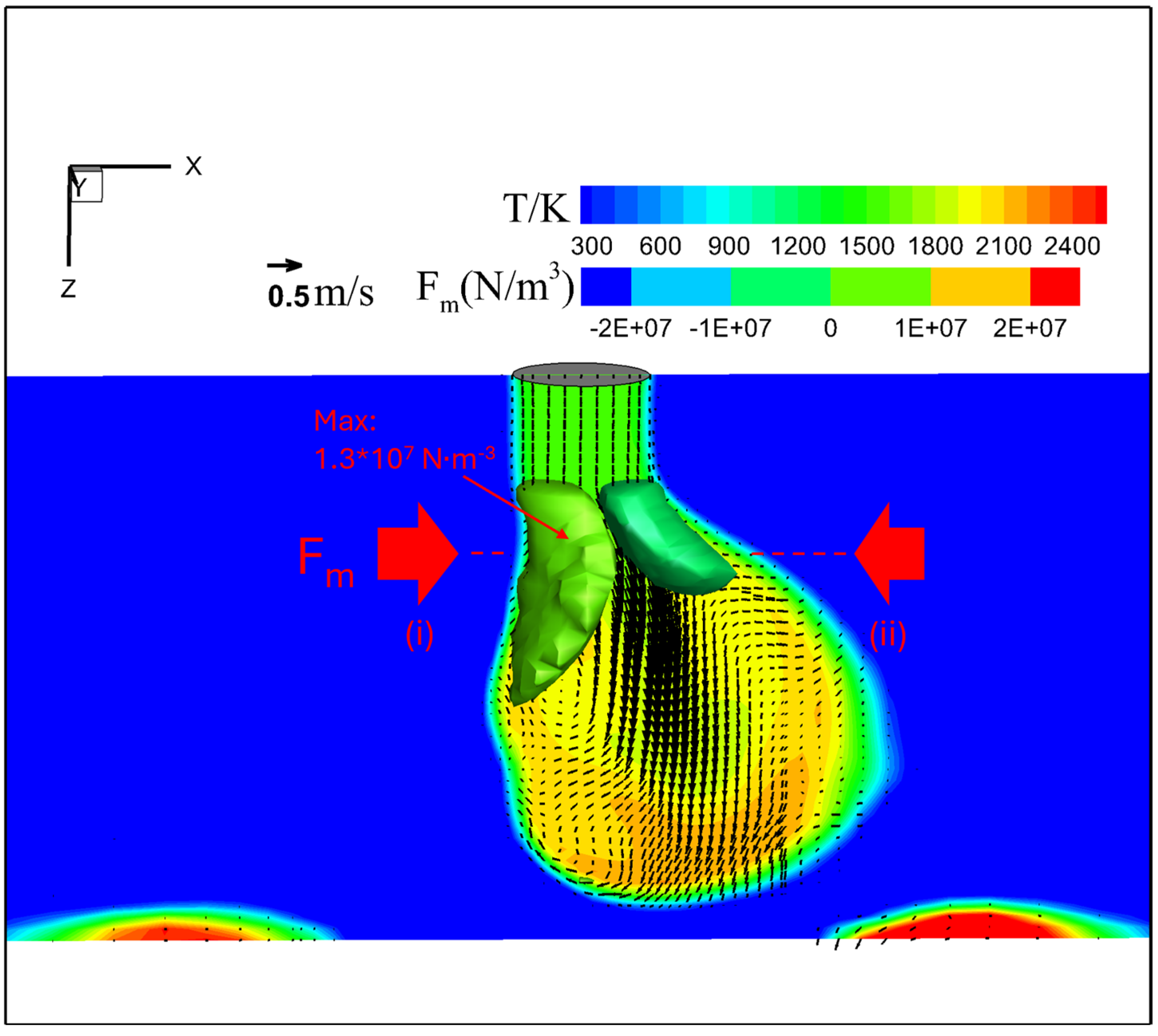

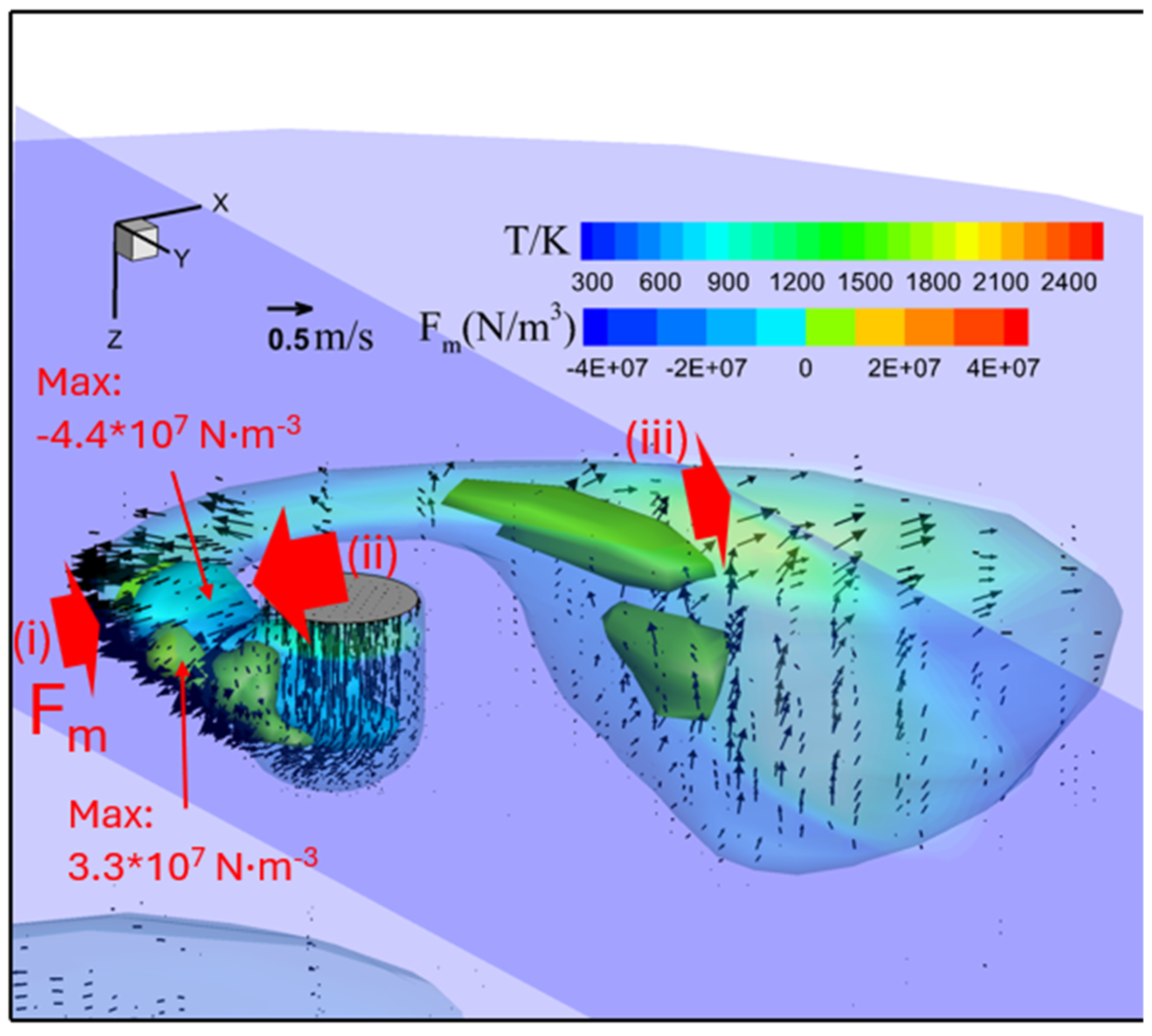

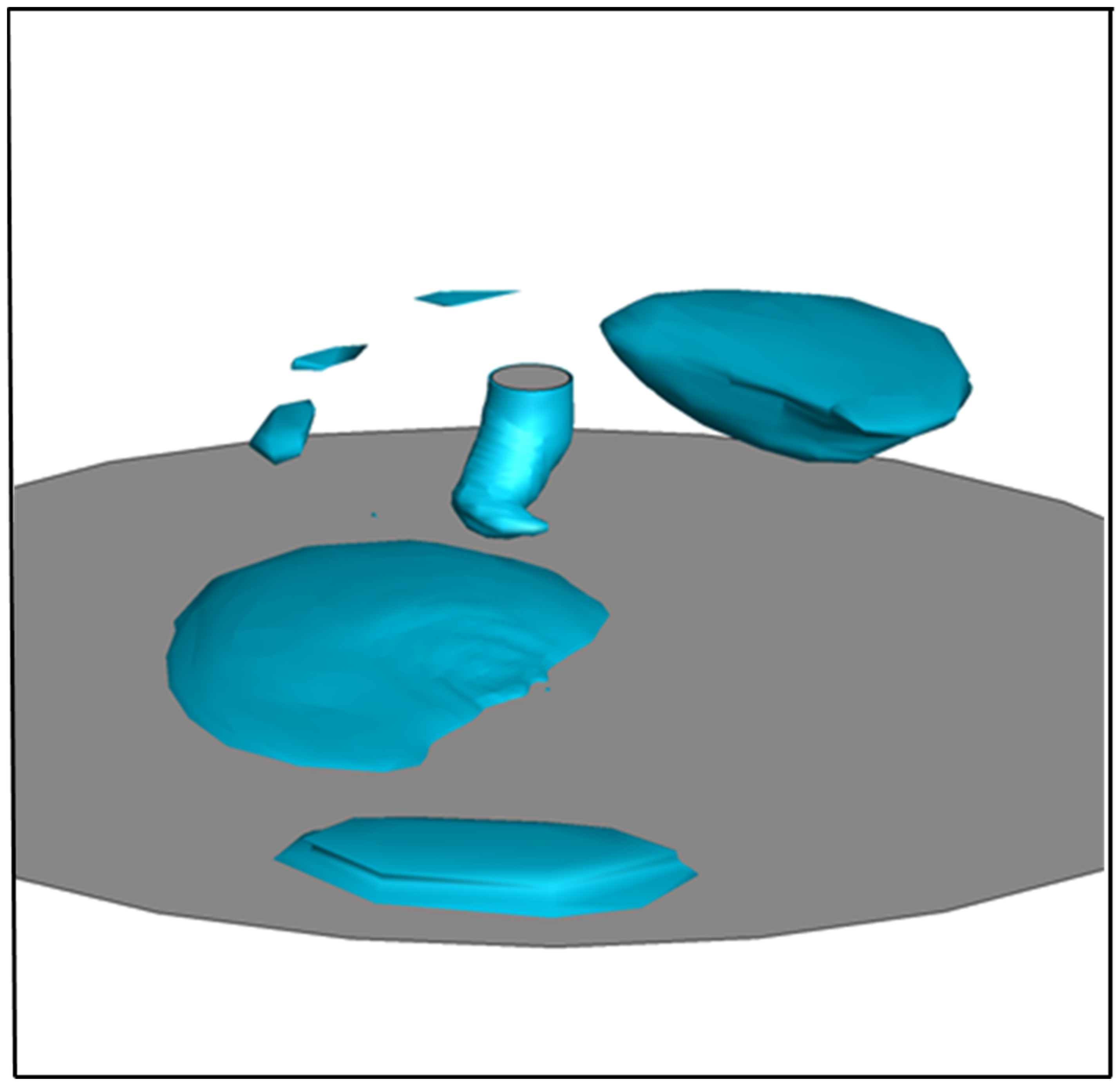

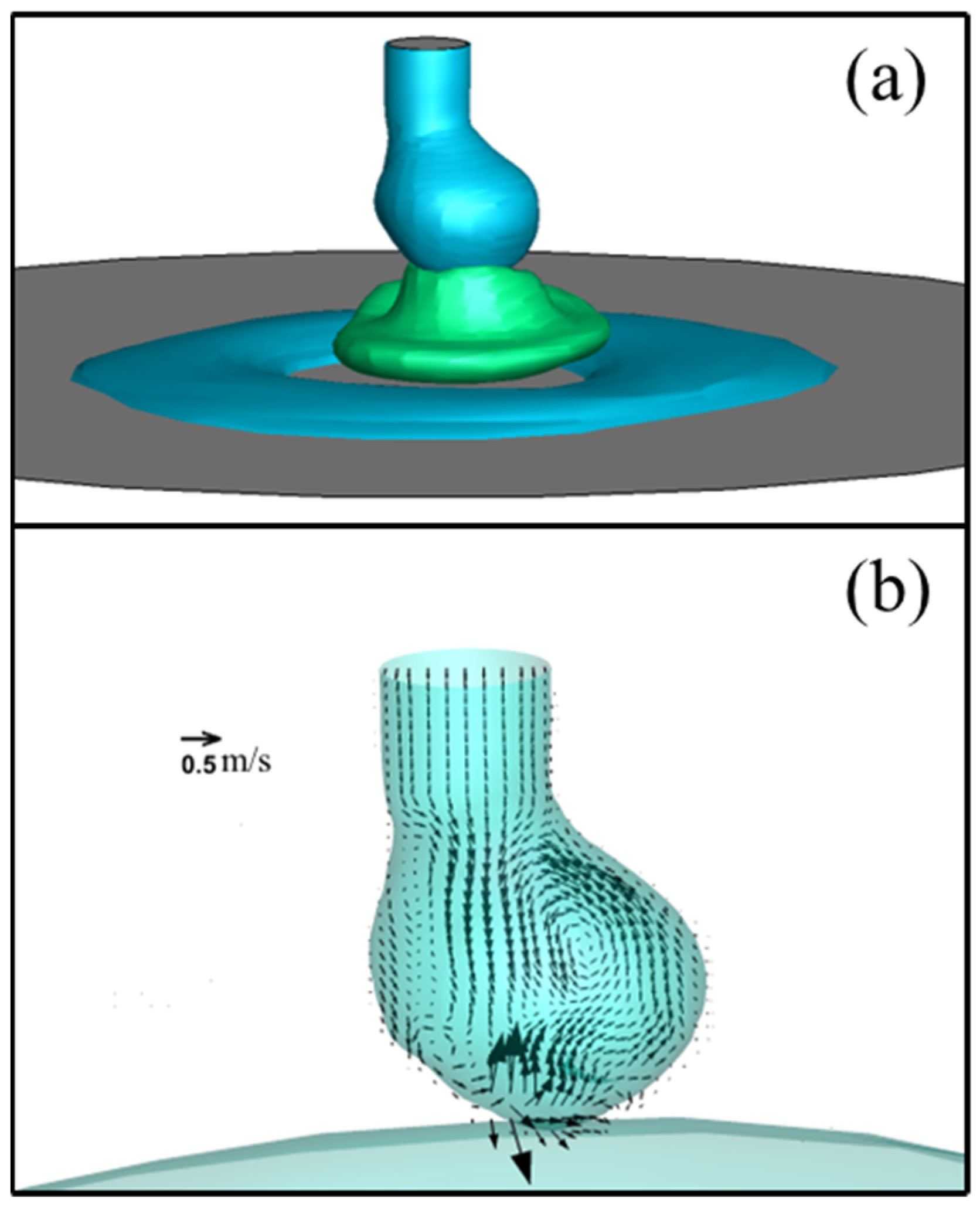

3.2.2. Simulation Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cary, H.B. Gas Metal ARC welding. In Welding HandBook, Welding Processes, Part 1, 9th ed.; O’Brien, A., Ed.; American Welding Society: Miami, FL, USA, 2004; Volume 2, pp. 147–205. [Google Scholar]

- Yamazaki, K.; Suzuki, R.; Shimizu, H.; Koshiishi, F. Spatter and Fume Reduction in Co2 Gas- Shielded Arc Welding by Regulated Globular Transfer. Weld. World 2012, 56, 12–19. [Google Scholar] [CrossRef]

- Nakamura, T.; Hiraoka, K.; Zenitani, S. Improvement of MIG welding stability in pure Ar shielding gas using small amount of oxygen and coaxial hybrid solid wire. Sci. Technol. Weld. Join. 2008, 13, 25–32. [Google Scholar] [CrossRef]

- Luo, J.; Luo, Q.; Wang, X.; Wang, X. EMS-CO2 Welding: A New Approach to Improve Droplet Transfer Characteristics and Welding Formation. Mater. Manuf. Process. 2010, 25, 1233–1241. [Google Scholar] [CrossRef]

- Tokihiko, K.; Rinsei, I.; Koichi, Y.; Yoshinori, H. Development of low spatter CO2 arc welding process with high frequency pulse current. Sci. Technol. Weld. Join. 2009, 14, 740–746. [Google Scholar] [CrossRef]

- Miao, J.; Li, Y.; Zhang, S.; Zhao, H. Magnetic controlled arc welding technology: A review. Rapid Prototyp. J. 2024, 30, 1929–1955. [Google Scholar] [CrossRef]

- Wu, H.; Chang, Y.; Lu, L.; Bai, J. Review on magnetically controlled arc welding process. Int. J. Adv. Manuf. Technol. 2017, 91, 4263–4273. [Google Scholar] [CrossRef]

- Tsao, K.C.; Wu, C.S. Fluid Flow and Heat Transfer in GMA Weld Pools. Weld. Res. Suppl. 1988, 37, 70s–76s. [Google Scholar]

- Chang, Y.L.; Xiao, L.; Lu, L.; Babkin, A.S.; Lee, B.Y.; Gao, F. Impacts of external longitudinal magnetic field on arc plasma and droplet during short-circuit GMAW. Int. J. Adv. Manuf. Technol. 2014, 70, 1542–1553. [Google Scholar] [CrossRef]

- Chang, Y.; Liu, M.; Lu, L.; Babkin, A.S.; Lee, B.Y. The Influence of Longitudinal Magnetic Field on the CO2 Arc Shape. Plasma Sci. Technol. 2015, 17, 321–326. [Google Scholar] [CrossRef]

- Xiao, L.; Fan, D.; Huang, J.K. Numerical Study on Arc Plasma Behaviors in GMAW with Applied Axial Magnetic Field. J. Phys. Soc. Jpn. 2019, 88, 074502. [Google Scholar] [CrossRef]

- Miao, J.; Li, Y.; Zhao, H.; Zhang, S.; Gong, Q.; Chang, Y. Study of CO2 welding arc with and without external magnetic field. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 681. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Wu, C.S.; Luan, S.C. Numerical analysis of arc and droplet behaviors in gas metal arc welding with external compound magnetic field. J. Mater. Process. Tech. 2020, 282, 116638. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Wu, C.S. Numerical investigation on the effect of process parameters on arc and metal transfer in magnetically controlled gas metal arc welding. Vacuum 2020, 177, 109391. [Google Scholar] [CrossRef]

- Xiao, L.; Fan, D.; Huang, J.; Tashiro, S.; Tanaka, M. Mild steel metal rotating spray transfer behavior in magnetically controlled gas metal arc welding. Mater. Today Commun. 2022, 31, 103352. [Google Scholar] [CrossRef]

- Ersoy, U.; Hu, S.J.; Kannatey-Asibu, E. Observation of Arc Start Instability and Spatter Generation in GMAW. Weld. J. 2008, 87, 51S–56S. [Google Scholar]

- Cai, Y.; Wang, G.; YANG, H.; Hua, X.; Wu, Y. Spatter Rate Estimation of GMAW-S based on Partial Least Square Regression. J. Shanghai Jiaotong Univ. (Sci.) 2008, 13, 695–701. [Google Scholar] [CrossRef]

- Era, T.; Ueyama, T. Spatter redution in GMAW by current waveform control. Weld. Int. 2007, 20, 496–501. [Google Scholar] [CrossRef]

- Fukuhisa, M.; Masao, U.; Hiroaki, N. Pulsed GMAW: Spattering in Pulsed CO2 Welding (Welding Physics, Process & Instrument). Trans. JWRI 1985, 14, 13–19. [Google Scholar]

- Kataoka, T.; Ikeda, R.; Yasuda, K.; Hirata, Y. Development of a low-spatter CO2 arc welding process with a high-frequency pulse current. Weld. Int. 2009, 23, 353–359. [Google Scholar] [CrossRef]

- Kang, S.; Kang, M.; Jang, Y.H.; Kim, C. Droplet transfer and spatter generation in DC-AC pulse tandem gas metal arc welding. Sci. Technol. Weld. Join. 2020, 27, 589–599. [Google Scholar] [CrossRef]

- Xue, L.; Wu, J.; Huang, J.; Huang, J.; Zou, Y.; Liu, J. Welding Polarity Effects on Welding Spatters and Bead Geometry of Hyperbaric Dry GMAW. Chin. J. Mech. Eng. 2016, 29, 351–356. [Google Scholar] [CrossRef]

- Suwannatee, N.; Yamamoto, M. Single-Pass Process of Square Butt Joints without Edge Preparation Using Hot-Wire Gas Metal Arc Welding. Metals 2023, 13, 1014. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Fu, F.; Mai, S.; Yang, Y.; Liu, Y.; Song, C. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties. Mater. Des. 2017, 117, 121–130. [Google Scholar] [CrossRef]

- Xiao, L.; Fan, D.; Huang, J.; Tashiro, S.; Tanaka, M. 3D Numerical Study of External Axial Magnetic Field-Controlled High-Current GMAW Metal Transfer Behavior. Materials 2020, 12, 5792. [Google Scholar] [CrossRef]

- Xiao, L.; Fan, D.; Huang, J.; Tashiro, S.; Tanaka, M. Numerical study on arc-droplet coupled behavior in magnetic field controlled GMAW process. J. Phys. D Appl. Phys. 2020, 53, 115202. [Google Scholar] [CrossRef]

- Tashiro, S.; Trinh, Q.N.; Le, D.K.; Suga, T.; Kakizaki, T.; Yamazaki, K.; Murphy, A.B.; Lervanichkool, A.; Bui, V.H.; Tanaka, M. Elucidation of droplet detachment mechanism in metal-cored arc welding. J. Manuf. Process. 2024, 124, 1583–1605. [Google Scholar] [CrossRef]

- Murphy, A.B. The effects of metal vapour in arc welding. J. Phys. D Appl. Phys. 2010, 43, 434001. [Google Scholar] [CrossRef]

- Menart, J.; Malik, S. Net emission coefficients for argon-iron thermal plasmas. J. Phys. D Appl. Phys. 2002, 35, 867. [Google Scholar] [CrossRef]

- Cram, L.E. Statistical evaluation of radiative power losses from thermal plasmas due to spectral lines. J. Phys. D Appl. Phys. 1985, 18, 401–411. [Google Scholar] [CrossRef]

- Ogino, Y.; Asai, S.; Hirata, Y. Visualization of arc plasma and molten wire behavior in CO2 arc welding process by three-dimensional numerical simulation. Weld World 2020, 64, 1789–1797. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Ti + Zr | Fe |

|---|---|---|---|---|---|---|---|

| Base material | 0.26 | 0.40 | - | 0.04 | 0.05 | - | Bal. |

| Filler material | 0.08 | 0.51 | 1.10 | 0.01 | 0.01 | 0.05 | Bal. |

| Item | Value |

|---|---|

| Welding current | 250 A |

| Arc voltage | 33.5 V–34.0 V |

| Welding velocity | |

| Shielding gas | |

| CTWD | 20 mm |

| Magnetic flux density | 0–4 mT |

| Nomenclature | Symbol | Unit | Gas Phase | Metal Phase |

|---|---|---|---|---|

| Density | [28] | 7200 | ||

| Dynamic viscosity | [28] | 0.006 | ||

| Specific heat | [28] | 780 | ||

| Thermal conductivity | [28] | 22 | ||

| Electrical conductivity | [28] | |||

| Net emission coefficient | [28] | - | ||

| Work function | - | 4.5 | ||

| Solidus temperature | K | - | 1750 | |

| Liquidus temperature | K | - | 1800 | |

| Vaporization temperature | K | - | 3050 | |

| Surface tension coefficient | - | 0.9 |

| Nomenclature | Value |

|---|---|

| Current | DC 250 A |

| Wire diameter | 1.2 mm |

| Wire feed rate | |

| Arc length | 3 mm |

| CO2 shielding gas flow rate | |

| Magnetic flux density | 2 mT and 4 mT |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, D.K.; Tashiro, S.; Xu, B.; Murphy, A.B.; Trinh, Q.N.; Bui, V.H.; Yuji, T.; Mamat, S.B.; Yamanaka, K.; Tanaka, M.; et al. Effects of Longitudinal External Magnetic Field on Metal Transfer Behavior and Spatter Formation in CO2 Arc Welding. Materials 2025, 18, 537. https://doi.org/10.3390/ma18030537

Le DK, Tashiro S, Xu B, Murphy AB, Trinh QN, Bui VH, Yuji T, Mamat SB, Yamanaka K, Tanaka M, et al. Effects of Longitudinal External Magnetic Field on Metal Transfer Behavior and Spatter Formation in CO2 Arc Welding. Materials. 2025; 18(3):537. https://doi.org/10.3390/ma18030537

Chicago/Turabian StyleLe, Dang Khoi, Shinichi Tashiro, Bin Xu, Anthony B. Murphy, Quang Ngoc Trinh, Van Hanh Bui, Toshifumi Yuji, Sarizam B. Mamat, Kenta Yamanaka, Manabu Tanaka, and et al. 2025. "Effects of Longitudinal External Magnetic Field on Metal Transfer Behavior and Spatter Formation in CO2 Arc Welding" Materials 18, no. 3: 537. https://doi.org/10.3390/ma18030537

APA StyleLe, D. K., Tashiro, S., Xu, B., Murphy, A. B., Trinh, Q. N., Bui, V. H., Yuji, T., Mamat, S. B., Yamanaka, K., Tanaka, M., & Xiao, L. (2025). Effects of Longitudinal External Magnetic Field on Metal Transfer Behavior and Spatter Formation in CO2 Arc Welding. Materials, 18(3), 537. https://doi.org/10.3390/ma18030537