Durable Structural Recycled Concrete for Different Exposure Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement and Chemical Admixtures

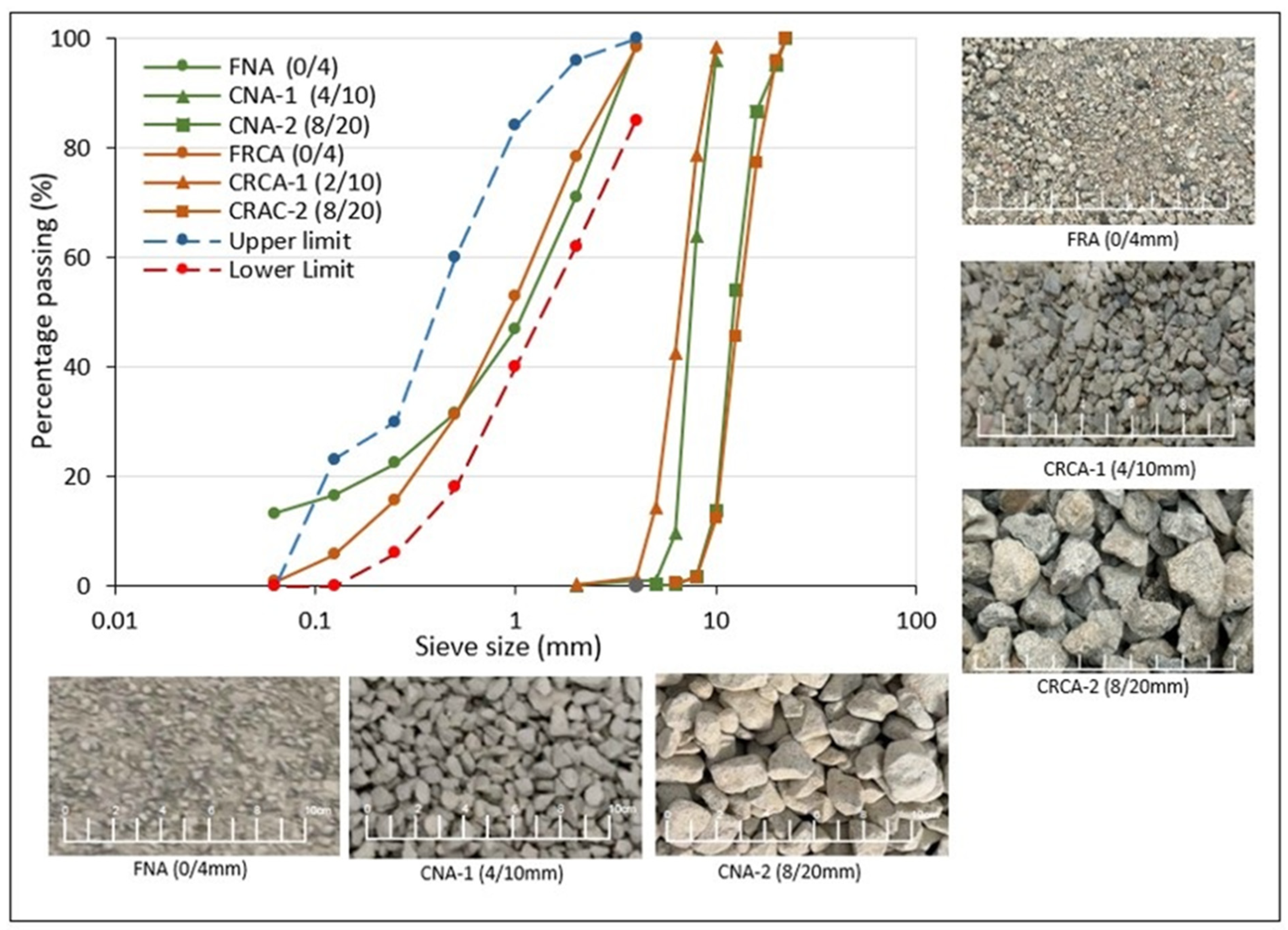

2.1.2. Natural Aggregates

2.1.3. Recycled Aggregates

2.2. Concrete Production and Test Procedures

2.2.1. Concrete Production

2.2.2. Test Procedure

| Parameter | Method | Samples | Information |

|---|---|---|---|

| Compressive Strength | EN 12390-3 | 3 cubic specimens measuring 100 × 100 × 100 mm, at 7, 28, and 56 days | Determination of the concrete’s load-bearing capacity using a compressive machine (capacity 3000 kN). The machine was configured to accommodate specimens and the load was applied uniformly at a rate of 0.5 MPa/s until failure. |

| Drying Shrinkage | EN 12390-16 | 2 specimens measuring 75 × 75 × 280 mm, monitored for 91 days | Determination of the concrete’s length and weight variations over time under controlled conditions. Environment: Controlled climate room at 20 ± 2 °C and 50 ± 5% RH. The specimens were demoulded at 24 h post-casting, weighed, and had their mass recorded, and the reference length (L0) was measured and documented. Subsequently, the specimens were placed in the drying room or chamber for the duration of the test. |

| Chloride Permeability | ASTM C1202 | 2 concrete disks (100Ø mm diameter, 50 mm thickness) at 28 and 56 days | Assessment of concrete’s resistance to chloride ion penetration. A potential difference of 60 V was applied across each side of the specimen, which was immersed in solutions containing sodium hydroxide (NaOH) and sodium chloride (NaCl). Measurement of the total charge (in Coulombs) passed during a 6-h testing period. |

| Chloride Profile | EN 12390-11 | Cubic specimens, 100 × 100 mm (Figure 3) | Determination of the chloride content at different depths across 8 layers (L1: 0–1, L2: 1–3, L3: 3–5, L4: 5–7, L5: 7–10, L6: 10–13, L7: 13–16, L8: 16–20 mm) in the depth of the concrete specimen. After curing, the specimens were exposed to a 3% NaCl solution for 91 days in a controlled environment at 23 ± 2 °C and 50 ± 5% relative humidity to simulate the conditions of Atlantic seawater, as per standard laboratory tests for concrete designed for marine environments [22]. The chloride concentration was measured using titration with a 0.02 N silver nitrate solution. |

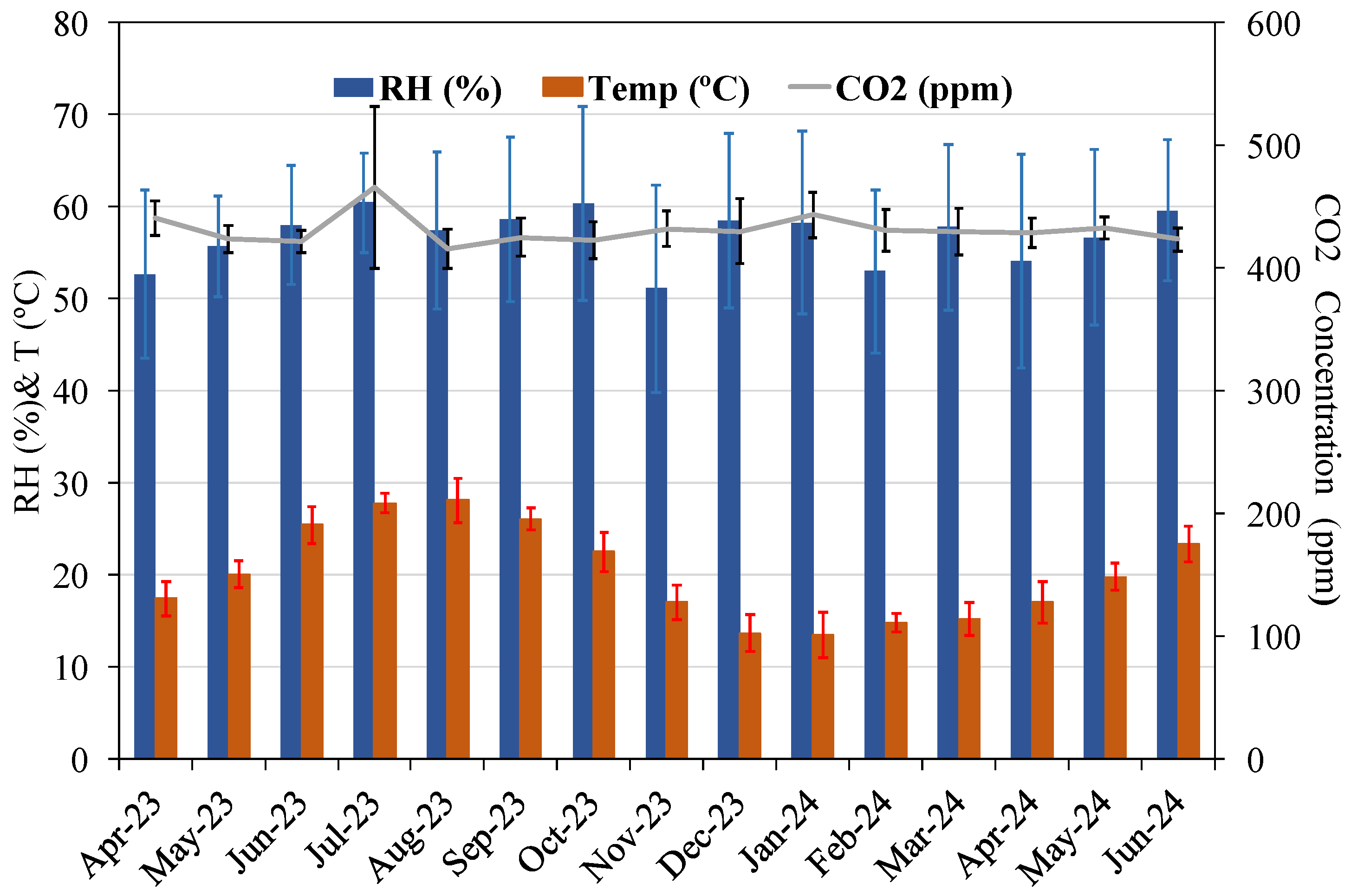

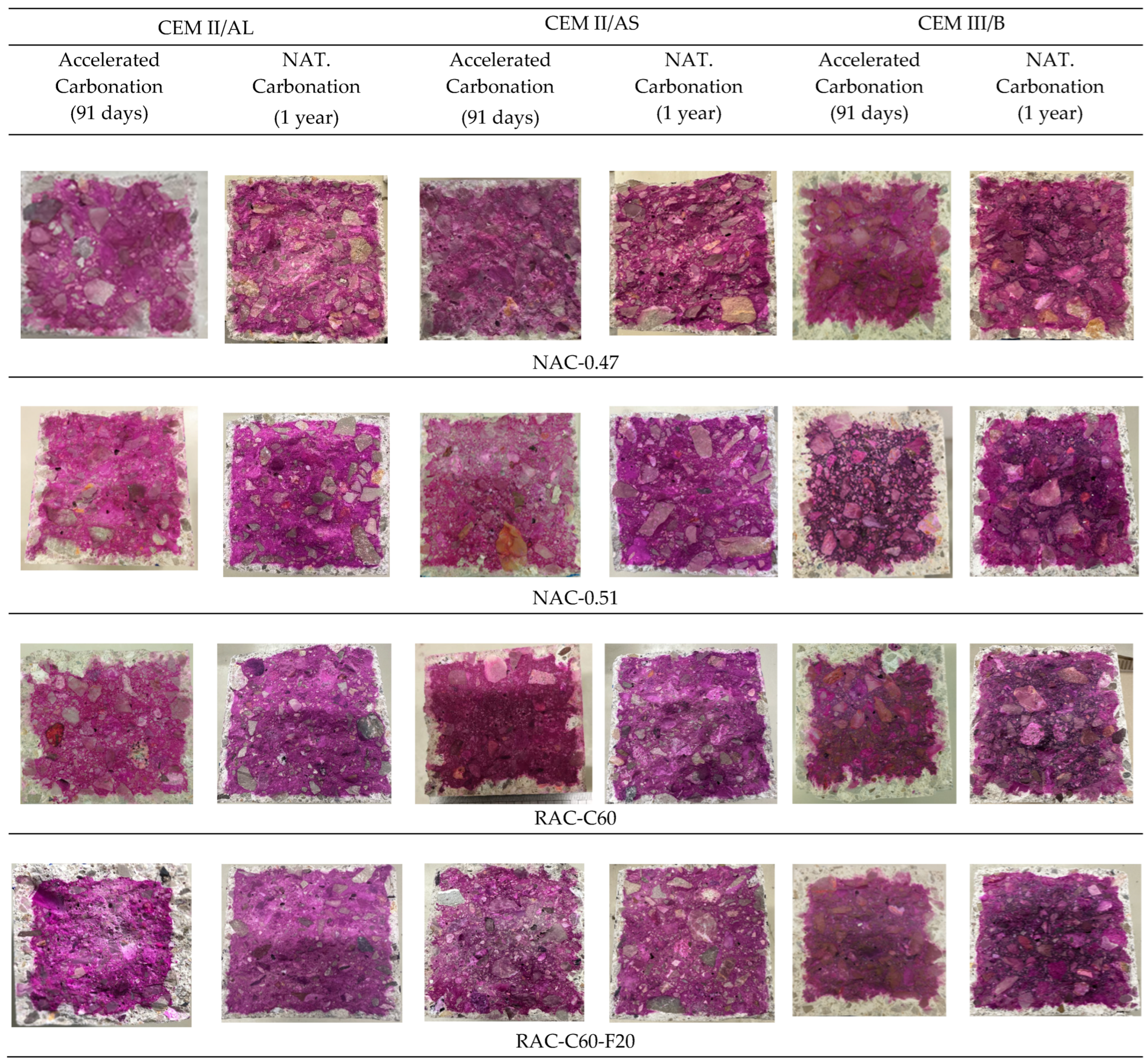

| Accelerated Carbonation Resistance | EN 12390-12 | 2 prismatic specimens of 100 × 100 × 300 mm, measured at intervals 0, 14, 28, 56, 70 and 91 days | Evaluation of concrete’s ability to withstand the carbonation process. Specimens were cured for 28 days in a humidity chamber, followed by 14-days of pre-conditioning at 20 ± 2 °C, 50–55% humidity, and a CO2 concentration of 425 ppm. Subsequently, it was exposed to 3% CO2 and 57% RH in a 20 °C chamber. The carbonation depth was determined using a solution of 1 g phenolphthalein in 70 g ethanol and 30 g water, as per UNE-EN 14630. |

| Natural Carbonation Resistance | UNE 83993-1 | 2 prismatic specimens of 100 × 100 × 400 mm, measured at intervals 0, 30, 90, 180 and 365 days | The specimens were cured for 4 days in a humidity chamber and then placed in a suitable plastic box in an outdoor environment. Solution: 1 g of phenolphthalein in 70 g of ethanol and 30 g of water, as per UNE-EN 14630. |

3. Results and Discussion

3.1. Hardened Properties

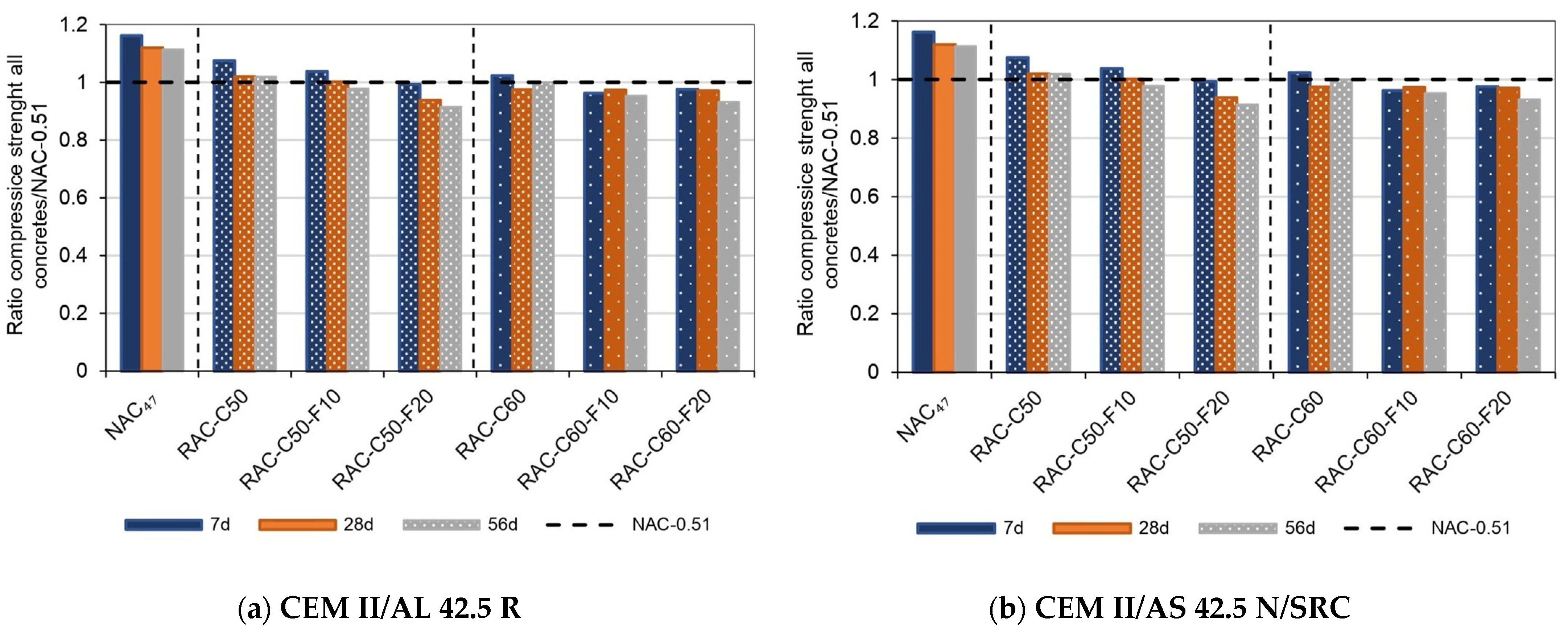

3.1.1. Compressive Strength

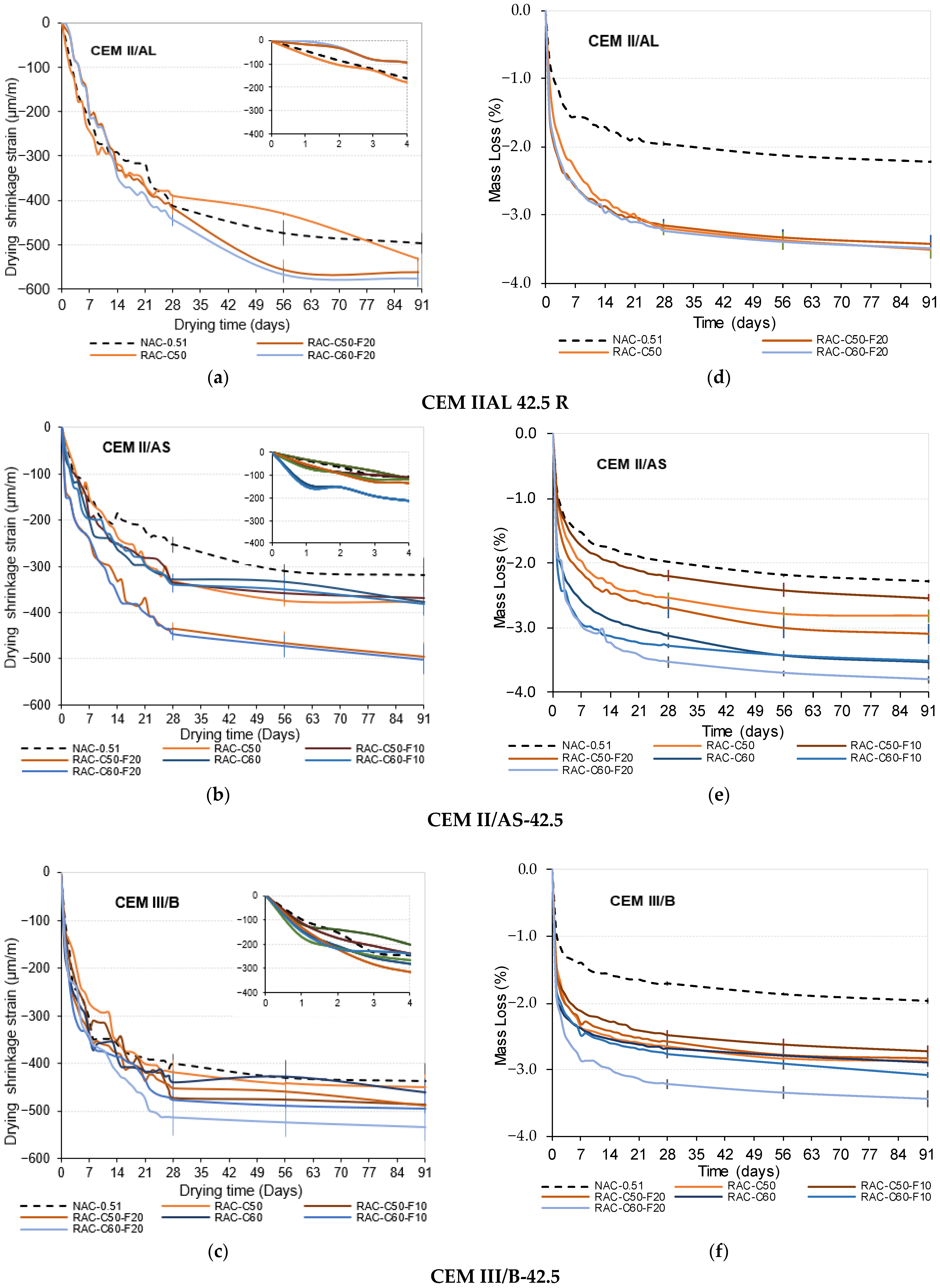

3.1.2. Drying Shrinkage

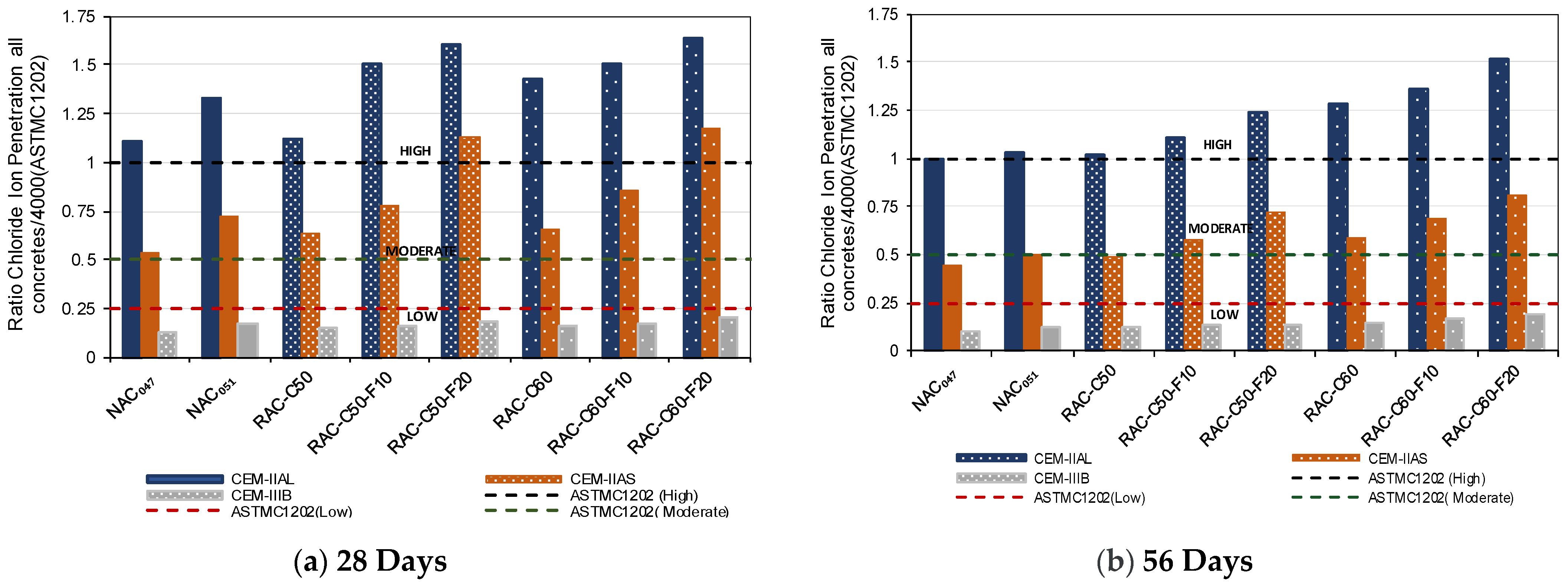

3.1.3. Chloride Ion Penetration

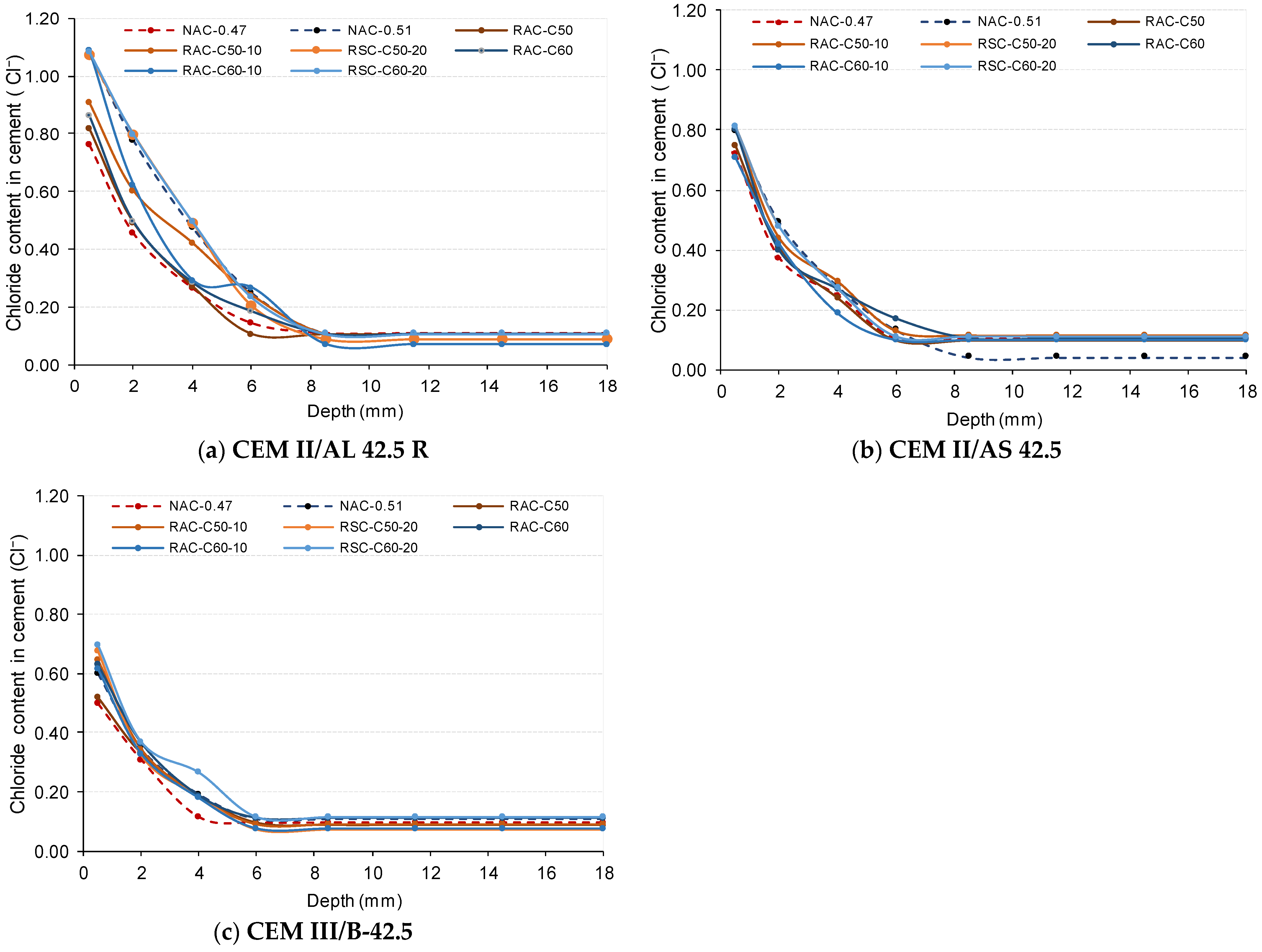

3.1.4. Chloride Penetration Depth

3.2. Carbonation Resistance

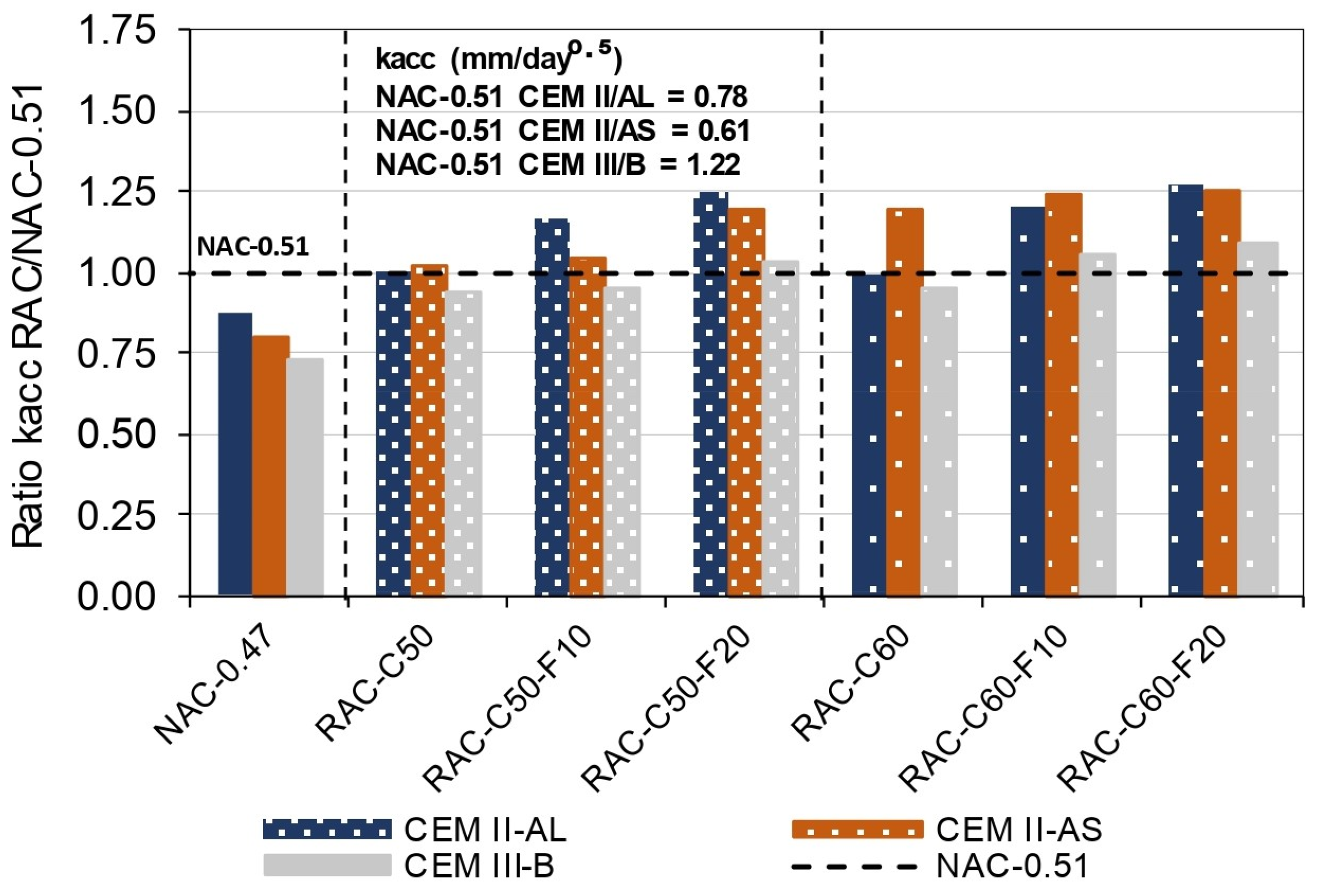

3.2.1. Accelerated Carbonation

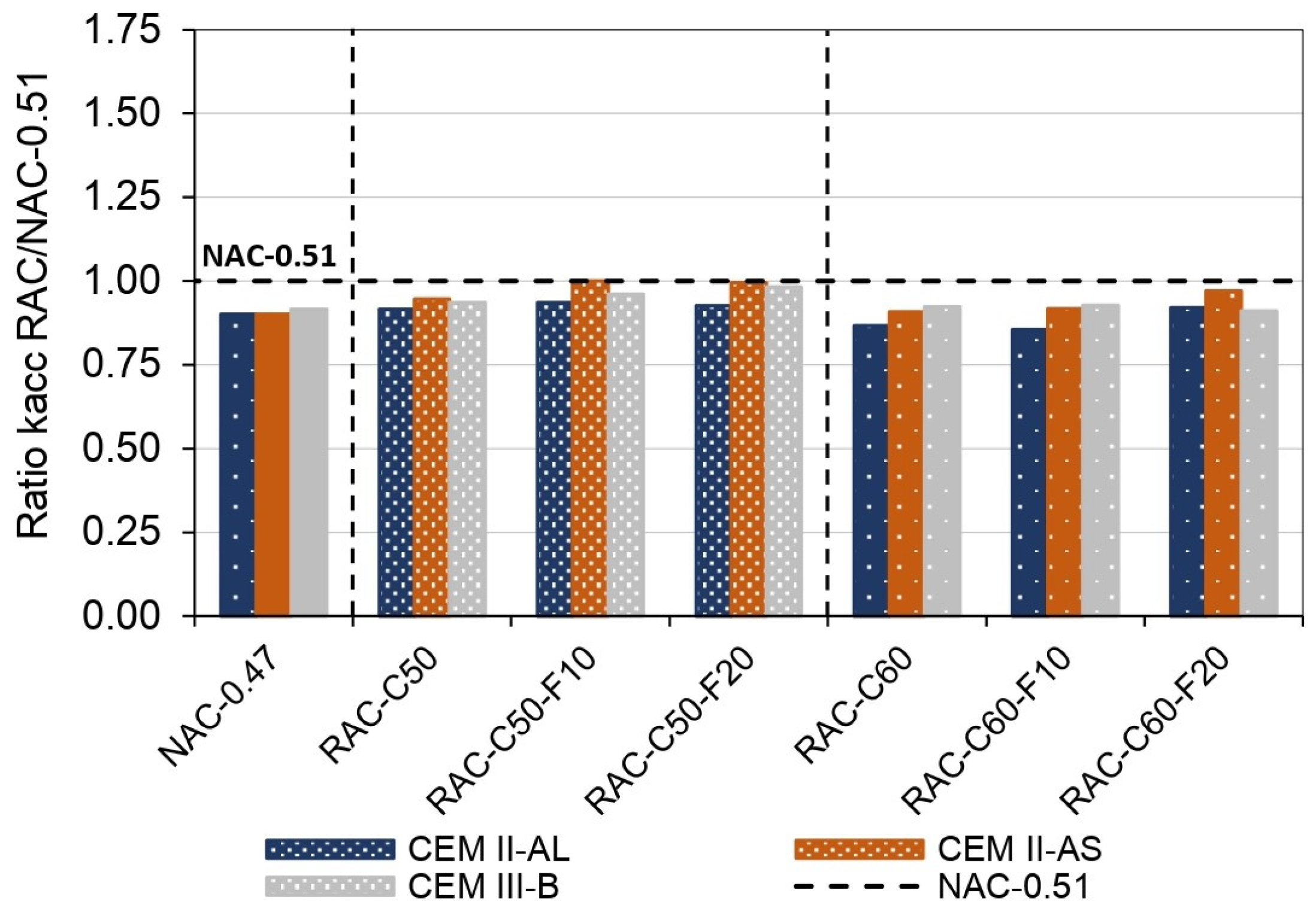

3.2.2. Natural Carbonation Resistance

3.2.3. Knat vs. KnatTHEO

3.2.4. Carbonation Analysis at 50 and 100 Years

4. Conclusions

- This study demonstrates that incorporating up to 60% CRCA and 20% FRCA can result in compressive strength levels comparable to those of NAC by lowering the RAC’s water–cement ratio by approximately 0.04. This underscores the potential of RCA as a sustainable alternative while maintaining structural integrity.

- Regarding the drying shrinkage:

- ○

- All RAC produced, with a maximum of 60% CRCA and 20% FRCA and independently of the cement type employed (IIAL, IIAS and IIIB), achieved admissible values at 91 days (maximum of −580 μm/m);

- ○

- The concrete produced using up to 60% CRCA achieved a similar shrinkage value to that of NAC-0.51 concrete produced with the same cement. However, the concrete using 20% FRCA (with 60% of CRCA) made with CEM II/AL, CEM II/AS, and CEM IIIB achieved 16.1%, 57.2%, and 22.1%, respectively, higher shrinkage than that of the NAC. However, all achieved lower drying shrinkage values than the acceptable values defined by the ACI (up to −800 μm/m);

- ○

- EC-02 is more accurate than SC-BOE in predicting the drying shrinkage of RAC regardless of the cement type used. Both standards fail to accurately estimate NAC-0.51 produced with CEM III/B, as they prioritize 28-day compressive strength over the initial shrinkage values. This underscores the need for more comprehensive models incorporating environmental factors and different cement and aggregate types.

- Regarding the durability properties:

- ○

- RACs with 50% and 60% CRCA (produced with an effective w/c ratio of 0.47) exhibit similar or higher resistance to chloride ion penetration and carbonation in comparison with NAC-0.51 (effective w/c ratio of 0.51) when they have similar compressive strengths;

- ○

- The concretes (including the RACs) produced with CEM III/B obtained a low chloride concentration at the concrete surface () and low non-steady state diffusion coefficient values. However, the use of 20% FRCA increased chloride ion penetration;

- ○

- RAC-C60-F20 achieves high durability in chloride-aggressive environments when it is produced using cements with high BFS content, such as CEM III/B. In addition, it achieves higher chloride resistance than that of NAC produced using CEM II/AL and CEM II/AS;

- ○

- RAC-C60-F10 produced with CEM II/AS achieves moderate chloride ion penetrability resistance, while any concrete, including NAC, produced with IIAL presents no resistance to chloride ions;

- ○

- The concretes made with CEM II/AS, followed by CEM II/AL and CEM III/B, achieved the highest carbonation resistance, independent of the type of aggregates used;

- ○

- The use of 20% FRCA increased the carbonation rate (up to 25%) compared with NAC-0.51 when an accelerated carbonation test was carried out. However, under natural conditions, these RAC concretes exhibited a lower carbonation rate than that of NAC-0.51;

- ○

- The obtained natural carbonation rate (Knat) values were between 2.0 and 2.8 times higher for NAC and between 1.6 and 2.4 times higher for RAC than the theoretical natural carbonation rate (knatTHEO) obtained from the accelerated carbonation test.

- ○

- RAC-C60-F20 produced with CEM II/AS cement achieved adequate carbonation resistance in XC3 and XC4 environments, ensuring a service life of 50 years. However, for chloride resistance, only concrete with up to 60% CRCA and 10% FRCA exhibited moderate chloride ion penetration values and lower chloride diffusion coefficients (Dnss) than those of CEM II/A-L cement;

- ○

- RAC-C60-F20 produced with CEM II/AL cement, while providing adequate carbonation resistance in XC4 environments, presented high chloride ion penetration and a high Dnss value, with values slightly higher than those of NAC-0.51;

- ○

- RAC-C60-F20 produced with CEM III/B exhibited low carbonation resistance and very high chloride penetration resistance, as indicated by lower surface chloride concentrations (Cs) and reduced Dnss values, similarly to NAC-0.51.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Kheetan, M.J.; Jweihan, Y.S.; Rabi, M.; Ghaffar, S.H.; Al-Kheetan, M.J.; Jweihan, Y.S.; Rabi, M.; Ghaffar, S.H. Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO. Buildings 2024, 14, 353. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Boletín Oficial del Estado (BOE) Structural Concrete Code. 2021. Available online: https://www.boe.es/eli/es/rd/2021/06/29/470 (accessed on 20 November 2024).

- Wang, D.; Lu, C.; Zhu, Z.; Zhang, Z.; Liu, S.; Ji, Y.; Xing, Z. Mechanical performance of recycled aggregate concrete in green civil engineering: Review. Case Stud. Constr. Mater. 2023, 19, e02384. [Google Scholar] [CrossRef]

- EN 1992-1-1:2004; Eurocode 2—Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. CEN (European Committee for Standardization): Brussels, Belgium, 2004.

- Simões Dos Reis, G.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Hoffmann Sampaio, C. materials Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- Wang, Q.; Dai, R.; Zhang, H.; Zheng, H.; Liang, X. Machine learning-based prediction method for drying shrinkage of recycled aggregate concrete. J. Build. Eng. 2024, 96, 110493. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Skaf, M.; Manso, J.M. Shrinkage prediction of recycled aggregate structural concrete with alternative binders through partial correction coefficients. Cem. Concr. Compos. 2022, 129, 104506. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Q.; Zhou, Y. Influence of Curing Time on the Drying Shrinkage of Concretes with Different Binders and Water-to-Binder Ratios. Adv. Mater. Sci. Eng. 2017, 2017, 2695435. [Google Scholar] [CrossRef]

- Hooton, R.D.; Stanish, K.; Angel, J.P.; Prusinski, J. The Effect of Ground Granulated Blast Furnace Slag (Slag Cement) on the Drying Shrinkage of Concrete—A Critical Review of the Literature. In SP-263: Slag Cement Concrete; ACI Special Publication; American Concrete Institute: Columbia, MD, USA, 2009; pp. 79–93. [Google Scholar] [CrossRef]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F.; Serrano-López, M.A.; Serna, P.; Castaño-Tabares, J.O. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Vintimilla, C.; Etxeberria, M. Limiting the maximum fine and coarse recycled aggregates-Type A used in structural concrete. Constr. Build. Mater. 2023, 380, 131273. [Google Scholar] [CrossRef]

- Mcdonald, D.B.; Brooks, J.J.; Burg, R.G.; Daye, M.A.; Gardner, N.J.; Novak, L.C. Report on Factors Affecting Shrinkage and Creep of Hardened Concrete Reported by ACI Committee 209. 2014. Available online: https://scholar.google.es/scholar?hl=es&as_sdt=0%2C5&q=Mcdonald%2C+D.B.%3B+Brooks%2C+J.J.%3B+Burg%2C+R.G.%3B+Daye%2C+M.A.%3B+Gardner%2C+N.J.%3B+Novak%2C+L.C.+Report+on+Factors+Affecting+Shrinkage+and+Creep+of+Hardened+Concrete+Reported+by+ACI+Committee+20 (accessed on 31 October 2024).

- Şimşek, O.; Pourghadri Sefidehkhan, H.; Gökçe, H.S. Performance of fly ash-blended Portland cement concrete developed by using fine or coarse recycled concrete aggregate. Constr. Build. Mater. 2022, 357, 129431. [Google Scholar] [CrossRef]

- Sosa, M.E.; Zega, C.J. Experimental and Estimated Evaluation of Drying Shrinkage of Concrete Made with Fine Recycled Aggregates. Sustainability 2023, 15, 7666. [Google Scholar] [CrossRef]

- Zega, C.J.; Santillán, L.R.; Sosa, M.E.; Villagrán Zaccardi, Y.A. Durable Performance of Recycled Aggregate Concrete in Aggressive Environments. J. Mater. Civ. Eng. 2020, 32, 03120002. [Google Scholar] [CrossRef]

- Xiao, J.; Lu, D.; Ying, J. Durability of recycled aggregate concrete: An overview. J. Adv. Concr. Technol. 2013, 11, 347–359. [Google Scholar] [CrossRef]

- Bu, C.; Liu, L.; Lu, X.; Zhu, D.; Sun, Y.; Yu, L.; Ouyang, Y.; Cao, X.; Wei, Q. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef]

- Silva, R.V.; Neves, R.; De Brito, J.; Dhir, R.K. Carbonation behaviour of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- Jakobsen, U.H.; De Weerdt, K.; Geiker, M.R. Elemental zonation in marine concrete. Cem. Concr. Res. 2016, 85, 12–27. [Google Scholar] [CrossRef]

- De Weerdt, K.; Lothenbach, B.; Geiker, M.R. Comparing chloride ingress from seawater and NaCl solution in Portland cement mortar. Cem. Concr. Res. 2019, 115, 80–89. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chotithanorm, C.; Cao, H.T.; Sirivivatnanon, V. Influence of fly ash fineness on the chloride penetration of concrete. Constr. Build. Mater. 2007, 21, 356–361. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Adessina, A.; Ben Fraj, A.; Barthélémy, J.-F. Improvement of the compressive strength of recycled aggregate concretes and relative effects on durability properties. Constr. Build. Mater. 2023, 384, 131447. [Google Scholar] [CrossRef]

- Velardo, P.; Sáez del Bosque, I.F.; Sánchez de Rojas, M.I.; De Belie, N.; Medina, C. Durability of concrete bearing polymer-treated mixed recycled aggregate. Constr. Build. Mater. 2022, 315, 125781. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Zeng, W.; Poon, C.S. Carbonation treatment of recycled concrete aggregate: Effect on transport properties and steel corrosion of recycled aggregate concrete. Cem. Concr. Compos. 2019, 104, 103360. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Le, H.-B.B.; Bui, Q.-B.B. Recycled aggregate concretes—A state-of-the-art from the microstructure to the structural performance. Constr. Build. Mater. 2020, 257, 119522. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Lotfi, S.; Eggimann, M.; Wagner, E.; Mróz, R.; Deja, J. Performance of recycled aggregate concrete based on a new concrete recycling technology. Constr. Build. Mater. 2015, 95, 243–256. [Google Scholar] [CrossRef]

- Sucic, A.; Lotfy, A. Effect of new paste volume on performance of structural concrete using coarse and granular recycled concrete aggregate of controlled quality. Constr. Build. Mater. 2016, 108, 119–128. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef] [PubMed]

- Kirthika, S.K.; Singh, S.K. Durability studies on recycled fine aggregate concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Pinto, S.R.; da Luz, A.; Guilherme, C.; Medeiros-Junio, R.A. Resistance of phosphogypsum-based supersulfated cement to carbonation and chloride ingress. Constr. Build. Mater. 2020, 263, 120640. [Google Scholar] [CrossRef]

- Nishida, T.; Otsuki, N.; Ohara, H.; Garba-Say, Z.M.; Nagata, T. Some considerations for the applicability of seawater as mixing water in concrete. Sustain. Constr. Mater. Technol. 2013, 27, B4014004. [Google Scholar] [CrossRef]

- De Weerdt, K.; Wilson, W.; Machner, A.; Georget, F. Chloride profiles—What do they tell us and how should they be used? Cem. Concr. Res. 2023, 173, 107287. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the carbonation of concrete with supplementary cementitious materials: A critical review by RILEM TC 281-CCC. Mater. Struct. 2020, 53, 136. [Google Scholar] [CrossRef]

- Medvedev, V.; Pustovgar, A. A Review of Concrete Carbonation and Approaches to Its Research under Irradiation. Buildings 2023, 13, 1998. [Google Scholar] [CrossRef]

- Gomes, M.; De Brito, J. Structural concrete with incorporation of coarse recycled concrete and ceramic aggregates: Durability performance. Mater. Struct. Constr. 2009, 42, 663–675. [Google Scholar] [CrossRef]

- Xiao, J.; Lei, B.; Zhang, C. On carbonation behavior of recycled aggregate concrete. Sci. China Technol. Sci. 2012, 55, 2609–2616. [Google Scholar] [CrossRef]

- Zeng, X. Progress in the research of carbonation resistance of RAC. Constr. Build. Mater. 2020, 230, 116976. [Google Scholar] [CrossRef]

- Etxeberria, M. Evaluation of eco-efficient concretes produced with fly ash and uncarbonated recycled aggregates. Materials 2021, 14, 7499. [Google Scholar] [CrossRef]

- Leemann, A.; Loser, R. Carbonation resistance of recycled aggregate concrete. Constr. Build. Mater. 2019, 204, 335–341. [Google Scholar] [CrossRef]

- Qu, F.; Xia, W.; Sun, C.; Hou, H.; Huang, B.; Wang, G.; Hu, S. Modeling carbonation depth of recycled aggregate concrete containing chlorinated salts. Constr. Build. Mater. 2024, 430, 136478. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Performance of concrete made with aggregates recycled from precasting industry waste: Influence of the crushing process. Mater. Struct. 2015, 48, 3965–3978. [Google Scholar] [CrossRef]

- Dhir, R.K.; Limbachiya, M.C.; Leelawat, T. Suitability of recycled concrete aggregate for use in BS 5328 designated mixes. Proc. Inst. Civ. Eng. Struct. Build. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Vintimilla, C.; Etxeberria, M.; Li, Z. Durable Structural Concrete Produced with Coarse and Fine Recycled Aggregates Using Different Cement Types. Sustainability 2023, 15, 14272. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O.; Quainoo, H.; Kruger, D. Model for predicting compressive strength and elastic modulus of recycled concrete made with treated coarse aggregate: Empirical approach. Constr. Build. Mater. 2022, 320, 126240. [Google Scholar] [CrossRef]

- Leemann, A.; Nygaard, P.; Kaufmann, J.; Loser, R. Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem. Concr. Compos. 2015, 62, 33–43. [Google Scholar] [CrossRef]

- Ngala, V.T.; Page, C.L. Effects of Carbonation on Pore Structure and Diffusional Properties of Hydrated Cement Pastes. Cem. Concr. Res. 1997, 27, 995–1007. [Google Scholar] [CrossRef]

- Sideris, K.K.; Manita, P. Influence of Blended Cements on the Service Life of Reinforced Concrete Structures against Carbonation Induced Corrosion. In International RILEM Conference on Synergising Expertise Towards Sustainability and Robustness of CBMs and Concrete Structures; Springer: Cham, Switzerland, 2023; pp. 1048–1054. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Jędrzejewska, A.; Kanavaris, F.; Azenha, M.; Benboudjema, F.; Schlicke, D. International RILEM Conference on Synergising Expertise Towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures: Synercrete’23; Springer: Cham, Switzerland, 2023; Volume 1. [Google Scholar]

- Saillio, M.; Baroghel-Bouny, V.; Pradelle, S.; Bertin, M.; Vincent, J.; d’Espinose de Lacaillerie, J.B. Effect of supplementary cementitious materials on carbonation of cement pastes. Cem. Concr. Res. 2021, 142, 106358. [Google Scholar] [CrossRef]

- EN. 197-1. C.P. 1; Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2001.

- UNE-EN 933-1; Determination of Particle Size Distribution—Sieving Method. AENOR: Madrid, Spain, 2012. Available online: www.aenor.es (accessed on 1 November 2024).

- UNE-EN 12620: 2003+A1; Aggregates for Concrete. AENOR: Madrid, Spain, 2009. Available online: www.aenor.es (accessed on 1 November 2024).

- UNE-EN 1097-6; Determination of Particle Density and Water Absorption. AENOR: Madrid, Spain, 2014. Available online: www.aenor.es (accessed on 1 November 2024).

- UNE-EN 933-8: 2012+A1; Tests for Geometrical Properties of Aggregates—Part 8: Assessment of Fines—Sand Equivalent Test. AENOR: Madrid, Spain, 2015. Available online: www.aenor.es (accessed on 1 November 2024).

- UNE-EN 1097-2; Methods for the Determination of Resistance to Fragmentation. AENOR: Madrid, Spain, 2010. Available online: www.aenor.es.

- UNE-EN 933-3; Determination of Particle Shape—Flakiness Index. AENOR: Madrid, Spain, 2012. Available online: www.aenor.es (accessed on 1 November 2024).

- UNE 146508:2023; Determination of the Alkali-Silica and Alkali-Silicate Potential Reactivity of Aggregates. Accelerated Mortar Bar Test. AENOR: Madrid, Spain, 2023. Available online: www.aenor.es (accessed on 1 November 2024).

- Etxeberria, M.; Konoiko, M.; Garcia, C.; Perez, M.Á. Water-Washed Fine and Coarse Recycled Aggregates for Real Scale Concretes Production in Barcelona. Sustainability 2022, 14, 708. [Google Scholar] [CrossRef]

- UNE-EN 933-11; Classification Test for the Constituents of Coarse Recycled Aggregate. AENOR: Madrid, Spain, 2009. Available online: www.aenor.es (accessed on 10 October 2024).

- Specification, Performance, Production and Conformit. UNE-EN 206: 2013+A1. AENOR: Madrid, Spain, 2013. Available online: www.aenor.es (accessed on 10 October 2024).

- Plaza, P.; Sáez del Bosque, I.F.; Frías, M.; Sánchez de Rojas, M.I.; Medina, C. Use of recycled coarse and fine aggregates in structural eco-concretes. Physical and mechanical properties and CO2 emissions. Constr. Build. Mater. 2021, 285, 122926. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, Á.A. Use of recycled fine aggregate in concretes with durable requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef] [PubMed]

- Sosa, M.E.; Villagrán Zaccardi, Y.A.; Zega, C.J. A critical review of the resulting effective water-to-cement ratio of fine recycled aggregate concrete. Constr. Build. Mater. 2021, 313, 125536. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- UNE-EN 12350-2:2020; Testing Fresh Concrete—Part 2: Slump Test. AENOR: Madrid, Spain, 2020. Available online: www.aenor.es (accessed on 1 November 2024).

- Estudi Comparatiu Experimental de Mètodes per al Disseny de Mescles de Formigó. Available online: https://upcommons.upc.edu/handle/2099.1/15823 (accessed on 6 December 2024).

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Morandeau, A.; Thiéry, M.; Dangla, P. Investigation of the carbonation mechanism of CH and C-S-H in terms of kinetics, microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Evaluating fracture parameters of basalt fiber reinforced and pozzolana slurry modified recycled concrete produced from waste. Structures 2023, 50, 1476–1492. [Google Scholar] [CrossRef]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A.; Raza, S.S. Effect of recycled fine aggregates on performance of Reactive Powder Concrete. Constr. Build. Mater. 2020, 243, 118223. [Google Scholar] [CrossRef]

- Borges, P.H.R.; Costa, J.O.; Milestone, N.B.; Lynsdale, C.J.; Streatfield, R.E. Carbonation of CH and C-S-H in composite cement pastes containing high amounts of BFS. Cem. Concr. Res. 2010, 40, 284–292. [Google Scholar] [CrossRef]

- Ortiz, J.; Aguado, A.; Agulló, L.; García, T. Influence of environmental temperatures on the concrete compressive strength: Simulation of hot and cold weather conditions B. Cem. Concr. Res. 2005, 35, 1970–1979. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Lehman, D.E.; Xiao, W.; Zheng, S.; Fan, B. Mechanical and durability behaviours of concrete made with recycled coarse and fine aggregates. Eur. J. Environ. Civ. Eng. 2020, 24, 171–189. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, 44, 102631. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Sharaky, I.; Issa, U.; Alwetaishi, M.; Abdelhafiz, A.; Shamseldin, A.; Al-Surf, M.; Al-Harthi, M.; Balabel, A. Strength and water absorption of sustainable concrete produced with recycled basaltic concrete aggregates and powder. Sustainability 2021, 13, 6277. [Google Scholar] [CrossRef]

- Ju, M.; Jeong, J.G.; Palou, M.; Park, K. Mechanical behavior of fine recycled concrete aggregate concrete with the mineral admixtures. Materials 2020, 13, 2264. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Corominas, A.; Etxeberria, M. Effects of using recycled concrete aggregates on the shrinkage of high performance concrete. Constr. Build. Mater. 2016, 115, 32–41. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. The assessment of ceramic and mixed recycled aggregates for high strength and low shrinkage concretes. Mater. Struct. Constr. 2018, 51, 129. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Wang, Y.; Zhang, H. Drying shrinkage model for recycled aggregate concrete accounting for the influence of parent concrete. Eng. Struct. 2019, 202, 109888. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wang, X.; Gu, L. Durability evaluation of recycled aggregate concrete in a complex environment. J. Clean. Prod. 2020, 273, 122569. [Google Scholar] [CrossRef]

- Vázquez, E.; Barra, M.; Aponte, D.; Jiménez, C.; Valls, S. Improvement of the durability of concrete with recycled aggregates in chloride exposed environment. Constr. Build. Mater. 2014, 67, 61–67. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Rahman, M. Effects of Cement Types on Chloride Ingress in Concrete. In Proceedings of the 3rd ACF Symposium 2019, Sapporo, Japan, 10–11 September 2019. [Google Scholar]

- Kopecskó, K.; Balázs, G.L. Concrete with Improved Chloride Binding and Chloride Resistivity by Blended Cements. Adv. Mater. Sci. Eng. 2017, 2017, 7940247. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhu, P.; Feng, J.; Hu, K. Mechanical Properties and ITZ Microstructure of Recycled Aggregate Concrete Using Carbonated Recycled Coarse Aggregate. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2018, 33, 648–653. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. Properties of Plain Concrete Produced Employing Recycled Aggregates and Sea Water. Int. J. Civ. Eng. 2018, 16, 993–1003. [Google Scholar] [CrossRef]

- Alexander, M.G. Durability performance potential and strength of blended Portland limestone cement concrete. Cem. Concr. Compos. 2013, 39, 115–121. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Effect of chemical composition of slag on chloride penetration resistance of concrete. Cem. Concr. Compos. 2013, 46, 56–64. [Google Scholar] [CrossRef]

- Etxeberria, M.; Castillo, S. How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete. Sustainability 2023, 15, 3169. [Google Scholar] [CrossRef]

- EN 12390-11:2015; Testing Hardened Concrete—Part 11: Determination of the Chloride Resistance of Concrete, Unidirectional Diffusion. AENOR: Madrid, Spain, 2015. Available online: www.aenor.es (accessed on 1 November 2024).

- Hassani, M.S.; Asadollahfardi, G.; Saghravani, S.F.; Jafari, S.; Peighambarzadeh, F.S. The difference in chloride ion diffusion coefficient of concrete made with drinking water and wastewater. Constr. Build. Mater. 2020, 231, 117182. [Google Scholar] [CrossRef]

- Tang, L.; Sørensen, H.E. Precision of the Nordic test methods for measuring the chloride diffusion/migration coefficients of concrete. Mater. Struct. Constr. 2001, 34, 479–485. [Google Scholar] [CrossRef]

- Maes, M.; De Belie, N. Resistance of concrete and mortar against combined attack of chloride and sodium sulphate. Cem. Concr. Compos. 2014, 53, 59–72. [Google Scholar] [CrossRef]

- Nilsson, L.-O. Prediction Models for Chloride Ingress and Corrosion Initiation in Concrete Structures. 2001. Available online: https://portal.research.lu.se/ws/files/5640644/3920795.pdf (accessed on 5 November 2024).

- Moreno-Juez, J.; Caneda-Martínez, L.; Vigil de la Villa, R.; Vegas, I.; Frías, M. Durability of Construction and Demolition Waste-Bearing Ternary Eco-Cements. Materials 2022, 15, 2921. [Google Scholar] [CrossRef]

- Etxeberria, M. Carbonation Resistance of Recycled Aggregate Concrete Using Different Cement Types. In International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures. SynerCrete 2023; RILEM Bookseries; Springer: Cham, Switzerland, 2023; Volume 44, pp. 1065–1076. [Google Scholar]

- Parrott, L.J.; Cement and Concrete Association; Building Research Establishment. A Review of Carbonation in Reinforced Concrete; Cement and Concrete Association: Wexham Springs, UK, 1987; Available online: http://worldcat.org/isbn/072101365 (accessed on 15 June 2024).

- Van den Heede, P.; De Belie, N. A service life based global warming potential for high-volume fly ash concrete exposed to carbonation. Constr. Build. Mater. 2014, 55, 183–193. [Google Scholar] [CrossRef]

- Leemann, A.; Moro, F. Carbonation of concrete: The role of CO2 concentration, relative humidity and CO2 buffer capacity. Mater. Struct. 2016, 50, 30. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Barbara, A.V.; Ruben, L.; Haufe, S.J. The pore solution of blended cements: A review. Mater. Struct. 2016, 49, 3341–3367. [Google Scholar] [CrossRef]

- Sojobi, A.O.; Xuan, D.; Li, L.; Liu, S.; Poon, C.S. Optimization of gas-solid carbonation conditions of recycled aggregates using a linear weighted sum method. Dev. Built Environ. 2021, 7, 100053. [Google Scholar] [CrossRef]

- Jorat, M.E.; Kraavi, K.E.; Manning, D.A.C. Removal of atmospheric CO2 by engineered soils in infrastructure projects. J. Environ. Manag. 2022, 314, 115016. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Zhang, W.; Jiang, H.; Ju, X.; Guan, L.; Liu, H.; Chen, S. Synergistic Effects of Environmental Relative Humidity and Initial Water Content of Recycled Concrete Aggregate on the Improvement in Properties via Carbonation Reactions. Materials 2023, 16, 5251. [Google Scholar] [CrossRef]

- Yu, B.; Fang, Z.; Gao, Y.; Yang, W.; Wang, C.; Zhou, S. Carbonation of supersulfated cement concrete after 8 years of natural exposure. Cem. Concr. Compos. 2023, 142, 105165. [Google Scholar] [CrossRef]

- Vanoutrive, H.; Van den Heede, P.; Alderete, N.; Andrade, C.; Bansal, T.; Camões, A.; Cizer, Ö.; De Belie, N.; Ducman, V.; Etxeberria, M.; et al. Report of RILEM TC 281-CCC: Outcomes of a round robin on the resistance to accelerated carbonation of Portland, Portland-fly ash and blast-furnace blended cements. Mater. Struct. 2022, 55, 99. [Google Scholar] [CrossRef]

- Neves, R.; Branco, F.; De Brito, J. Field assessment of the relationship between natural and accelerated concrete carbonation resistance. Cem. Concr. Compos. 2013, 41, 9–15. [Google Scholar] [CrossRef]

| Cement | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | K2O | TIO2 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| CEM II/AL 42.5 R | 61.47 | 17.87 | 3.61 | 2.64 | 3.69 | 1.45 | 0.736 | 0.183 | 0.228 |

| (88% clinker, 12% limestone, excluding the set regulator, added in 5%) | |||||||||

| High initial strength, ideal for applications requiring rapid setting | |||||||||

| CEM II/AS 42.5 N/SRC | 59.97 | 21.66 | 4.35 | 3.75 | 3.47 | 2.1 | 0.395 | 0.327 | 0.314 |

| (83% clinker, 12% blast furnace slag (BFS) and 5% minority component) | |||||||||

| Providing moderate sulfate resistance and enhanced durability | |||||||||

| CEM III/B 42.5 N-LH/SR | 49.4 | 27.8 | 8.41 | 1.96 | 3.96 | 4.65 | 0.48 | 0.457 | 0.365 |

| (27% clinker, 70% BFS and 3% minority component) | |||||||||

| Low heat development and sulphate resistance | |||||||||

| Property | Density (Kg/m3) | Water Absorption (%) | Humidity (%) | Sand Equivalent (%) | Los Angeles Coefficient (%) | Flakiness Index (%) | Alkali–Aggregate Reaction (%) |

|---|---|---|---|---|---|---|---|

| Standard | EN 1097-6 [62] | EN 1097-6 [62] | EN-933-8 [63] | EN 1097-2 [64] | EN 933-3 [65] | UNE-146508 [66] | |

| FNA (0/4) | 2.67 | 0.95 | 0.37 | 100 | |||

| CNA-1 (4/10) | 2.65 | 0.77 | 0.16 | ||||

| CNA-2 (8/20) | 2.68 | 0.73 | 0.1 | ||||

| FRCA (0/4) | 2.32 | 5.73 | 2.73 | 35.77 | 0.042 | ||

| CRCA-1 (2/10) | 2.33 | 5.62 | 4.50 | ||||

| CRCA-2 (8/20) | 2.36 | 5.16 | 4.55 | 12.81 | |||

| SC-BOE 1 | 2.1 * | <7 | >70 | <40 | <35 | <0.10 |

| Materials | Concrete Types | |||||||

|---|---|---|---|---|---|---|---|---|

| (kg) | NAC-0.51 | NAC-0.47 | RAC-C50 | RAC-C50-F10 | RAC-C50-F20 | RCA-C60 | RCA-C60-F10 | RCA-C60-F20 |

| Cement | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Total water | 165 | 150 | 175.8 | 179.5 | 182.3 | 180.8 | 184.34 | 187.48 |

| CNA-1 | 354.5 | 360.1 | 180.5 | 180.5 | 180.5 | 144.4 | 144.4 | 144.4 |

| CNA-2 | 723.68 | 737.2 | 369.3 | 369.3 | 369.3 | 295.5 | 295.5 | 295.5 |

| FNA | 954.1 | 971.9 | 1014.2 | 875.7 | 778.4 | 973 | 875.7 | 778.4 |

| CRCA-1 | - | - | 165.8 | 165.2 | 165.6 | 198.9 | 198.6 | 199.7 |

| CRCA-2 | - | - | 338.8 | 339.1 | 337.2 | 406.0 | 406.1 | 404.2 |

| FRCA | - | - | - | 87.1 | 174.1 | - | 87.1 | 174.1 |

| P (%) | 1/0.7 1 | 1 | 1/0.6 1 | 1/0.5 1 | 1/0.3 1 | 1/0.3 1 | 1/0.3 1 | 1/0.3 1 |

| S (%) | 1 | 1 | 1/1.5 1 | 1/1.5 1 | 1/1.5 1 | 1/1.5 1 | 1/1.5 1 | 1/1.5 1 |

| effective w/c | 0.51 | 0.47 | 0.47 | 0.47 | 0.47 | 0.47 | 0.47 | 0.47 |

| Slump-IIAS (mm) | 175 | 145 | 150 | 155 | 150 | 175 | 155 | 160 |

| Slump-IIIB (mm) | 175 | 160 | 135 | 150 | 150 | 140 | 150 | 125 |

| Slump-IIAL (mm) | 175 | 150 | 190 | 200 | 195 | 180 | 210 | 195 |

| Concrete Reference | IIAL | IIAS | IIIB | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 7d | 28d | 56d | 7d | 28d | 56d | 7d | 28d | 56d | |

| NAC-0.47 | 52.5 (1.3) | 62.9 (1.3) | 65.5 (1.0) | 54.5 (1.3) | 69.8 (1) | 71.3 (1.9) | 53.1 (0.8) | 67.2 (0.4) | 69.9 (0.9) |

| NAC-0.51 | 45.2 (2.0) | 56.2 (1.6) | 58.8 (1.0) | 54.1 (2.0) | 59.2 (0.5) | 64.7 (0.2) | 51.5 (0.1) | 57.2 (1.2) | 59.9 (0.9) |

| RAC-C50 | 48.6 (2.5) | 57.3 (1.0) | 59.9 (1.7) | 53.9 (2.5) | 59.2 (2.3) | 62.8 (1.2) | 53.7 (0.3) | 61.4 (3.0) | 62.0 (1.0) |

| RAC-C50-F10 | 46.9 (1.8) | 56.3 (1.5) | 57.5 (0.3) | 52.4 (1.8) | 59.7 (1.3) | 59.9 (0.2) | 53.4 (2.8) | 60.6 (1.7) | 61.6 (0.7) |

| RAC-C50-F20 | 44.9 (2.4) | 52.7 (0.3) | 53.8 (0.4) | 50.2 (2.4) | 60.7 (0) | 63.7 (1.2) | 53.6 (1.5) | 62.8 (1.4) | 62.9 (1.3) |

| RAC-C60 | 46.3 (0.1) | 54.8 (0.8) | 58.8 (0.3) | 51.6 (1.2) | 60.2 (0.9) | 60.9 (0.2) | 50.7 (0.9) | 58.8 (0.6) | 59 (0.1) |

| RAC-C60-F10 | 43.5 (0.6) | 54.7 (1.0) | 56.1 (0.0) | 49.8 (0.5) | 59.2 (0.4) | 62.2 (0.3) | 48.2 (1.6) | 58.2 (2.0) | 64.3 (1.9) |

| RAC-C60-F20 | 44.1 (0.6) | 54.6 (0.8) | 54.8 (0.1) | 45.1 (0.9) | 58.7 (0.8) | 61.7 (2.0) | 47.5 (1.2) | 61.4 (0.5) | 64.1 (0.9) |

| IIAL | IIAS | IIIB | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Concrete Types | (Coulombs) | ∆ (%) | (Coulombs) | ∆ (%) | (Coulombs) | ∆ (%) | |||

| 28d | 56d | 28d | 56d | 28d | 56d | ||||

| NAC-0.47 | 4451 (194) | 3971 (94) | 11 | 2145 (281) | 1766 (44) | 18 | 530 (2) | 408 (5) | 23 |

| NAC-0.51 | 5314 (2) | 4096 (271) | 23 | 2897 (111) | 1976 (129) | 32 | 674 (15) | 501 (12) | 26 |

| RAC-C50 | 4479 (441) | 4065 (71) | 9 | 2535 (136) | 1962 (80) | 23 | 610 (9) | 503 (8) | 18 |

| RAC-C50-F10 | 6038 (596) | 4448 (97) | 26 | 3130 (58) | 2293 (5) | 27 | 626 (16) | 531 (15) | 15 |

| RAC-C50-F20 | 6401 (569) | 4944 (178) | 23 | 4515 (91) | 2866 (66) | 37 | 740 (40) | 532 (18) | 28 |

| RAC-C60 | 5726 (250) | 5140 (636) | 10 | 2648 (71) | 2329 (28) | 12 | 651 (4) | 570 (4) | 12 |

| RAC-C60-F10 | 6009 (197) | 5454 (33) | 9 | 3425 (78) | 2736 (64) | 20 | 707 (44) | 668 (14) | 6 |

| RAC-C60-F20 | 6549 (567) | 6048 (43) | 8 | 4696 (17) | 3239 (119) | 31 | 843 (69) | 767 (3) | 9 |

| CEM II/AL | CEM II/AS | CEM III/B | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cs | Dnss | Cs | Dnss | Cs | Dnss | ||||

| % | m2/s | R2 | % | m2/s | R2 | % | m2/s | R2 | |

| NAC-0.47 | 0.483 | 1.51 × 10−12 | 0.95 | 0.49 | 1.18 × 10−12 | 0.95 | 0.35 | 7.00 × 10−13 | 0.89 |

| NAC-0.51 | 0.748 | 1.75 × 10−12 | 0.98 | 0.61 | 1.19 × 10−12 | 0.99 | 0.46 | 7.10 × 10−13 | 0.98 |

| RAC-C50 | 0.697 | 1.68 × 10−12 | 0.89 | 0.58 | 1.10 × 10−12 | 0.95 | 0.47 | 7.07 × 10−13 | 0.99 |

| RAC-C50-F10 | 0.765 | 1.83 × 10−12 | 0.97 | 0.58 | 1.22 × 10−12 | 0.96 | 0.48 | 7.19 × 10−13 | 0.98 |

| RAC-C50-F20 | 0.977 | 1.87 × 10−12 | 0.95 | 0.64 | 1.30 × 10−12 | 0.93 | 0.49 | 7.18 × 10−13 | 0.98 |

| RAC-C60 | 0.751 | 1.76 × 10−12 | 0.90 | 0.56 | 1.28 × 10−12 | 0.99 | 0.50 | 7.09 × 10−13 | 0.98 |

| RAC-C60-F10 | 0.768 | 1.91 × 10−12 | 0.94 | 0.60 | 1.29 × 10−12 | 0.88 | 0.52 | 7.61 × 10−13 | 0.98 |

| RAC-C60-F20 | 0.984 | 1.97 × 10−12 | 0.95 | 0.66 | 1.31 × 10−12 | 0.84 | 0.54 | 7.68 × 10−13 | 0.96 |

| Concrete Types | Carbonation Depth(mm) at 91 Days | Carbonation Coefficient | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Kacc (mm/day0.5) | KnatTHEO (mm/year0.5) | ||||||||

| II AL | II AS | III B | II AL | II AS | III B | II AL | II AS | III B | |

| NAC-0.47 | 6.5 (0.1) | 4.9 (0.2) | 10 (0.3) | 0.68 | 0.49 | 0.90 | 1.55 | 1.12 | 2.06 |

| NAC-0.51 | 7.7 (0.1) | 6 (0.1) | 12 (0.4) | 0.78 | 0.61 | 1.22 | 1.78 | 1.39 | 2.80 |

| RAC-C50 | 8 (0.4) | 6.1 (0.2) | 12.1 (0.2) | 0.78 | 0.62 | 1.15 | 1.78 | 1.43 | 2.62 |

| RAC-C50-F10 | 8.7 (0.2) | 6.3 (0) | 12.1 (0.1) | 0.91 | 0.64 | 1.16 | 2.09 | 1.46 | 2.64 |

| RAC-C50-F20 | 9.8 (0) | 7.2 (0.2) | 12.9 (0.1) | 0.97 | 0.73 | 1.26 | 2.22 | 1.66 | 2.87 |

| RAC-C60 | 7.3 (0.5) | 6.34 (0.3) | 11.8 (0.2) | 0.77 | 0.65 | 1.17 | 1.76 | 1.49 | 2.67 |

| RAC-C60-F10 | 9.3 (0) | 7.41 (0.1) | 12.18 (0.1) | 0.94 | 0.75 | 1.29 | 2.15 | 1.72 | 2.95 |

| RAC-C60-F20 | 10.4 (1.6) | 7.53 (0) | 12.59 (0.1) | 0.99 | 0.77 | 1.34 | 2.28 | 1.75 | 3.06 |

| Concrete Types | Carbonation Depth (mm) at 1 Year | Carbonation Coefficient | ||||

|---|---|---|---|---|---|---|

| Knat (mm/year0.5) | ||||||

| II AL | II AS | III B | II AL | II AS | III B | |

| NAC-0.47 | 4.2 (0) | 3.5 (0.04) | 5.1 (0.09) | 3.82 | 3.16 | 5.08 |

| NAC-0.51 | 4.2 (0.02) | 3.7 (0.04) | 5.7 (0.11) | 4.24 | 3.50 | 5.55 |

| RAC-C50 | 4.2 (0.02) | 3.5 (0.42) | 5.2 (0.15) | 3.89 | 3.32 | 5.19 |

| RAC-C50-F10 | 4.2 (0.15) | 3.7 (0.04) | 5.3 (0.1) | 3.97 | 3.50 | 5.33 |

| RAC-C50-F20 | 4.2 (0.09) | 3.6 (0.09) | 5.4 (0.31) | 3.93 | 3.49 | 5.45 |

| RAC-C60 | 4.0 (0.11) | 3.5 (0.04) | 5.1 (0.04) | 3.68 | 3.18 | 5.12 |

| RAC-C60-F10 | 4.1 (0.02) | 3.5 (0.02) | 5.1 (0.04) | 3.63 | 3.21 | 5.15 |

| RAC-C60-F20 | 4.2 (0.15) | 3.7 (0.15) | 5.2 (0.04) | 3.90 | 3.40 | 5.05 |

| Knat and KnatTHEO Relationship | |||

|---|---|---|---|

| MIX | CEM II/AL | CEM II/AS | CEM III/B |

| NAC-0.47 | 2.5 | 2.8 | 2.5 |

| NAC-0.51 | 2.4 | 2.5 | 2.0 |

| RAC-C50 | 2.2 | 2.3 | 2.0 |

| RAC-C50-F10 | 1.9 | 2.4 | 2.0 |

| RAC-C50-F20 | 1.8 | 2.1 | 1.9 |

| RAC-C60 | 2.1 | 1.9 | 1.9 |

| RAC-C60-F10 | 1.7 | 1.9 | 1.7 |

| RAC-C60-F20 | 1.7 | 1.9 | 1.6 |

| Concrete Types | knat (50 years) | knat (100 years) | |||||

|---|---|---|---|---|---|---|---|

| II AL | II AS | III B | II AL | II AS | III B | ||

| NAC-0.47 | 27.0 | 22.3 | 35.9 | 38.2 | 31.6 | 50.8 | |

| NAC-0.51 | 30.0 | 24.8 | 39.2 | 42.4 | 35.0 | 55.5 | |

| RAC-C50 | 27.5 | 23.5 | 36.7 | 38.9 | 33.2 | 51.9 | |

| RAC-C50-F10 | 28.1 | 24.8 | 37.7 | 39.7 | 35.0 | 53.3 | |

| RAC-C50-F20 | 27.8 | 24.6 | 38.5 | 39.3 | 34.9 | 54.5 | |

| RAC-C60 | 26.0 | 22.5 | 36.2 | 36.8 | 31.8 | 51.2 | |

| RAC-C60-F10 | 25.6 | 22.7 | 36.4 | 36.3 | 32.1 | 51.5 | |

| RAC-C60-F20 | 27.6 | 24.0 | 35.7 | 39.0 | 34.0 | 50.5 | |

| Min. Cover (mm) | XC3 | 20 + 5 * | 25 + 5 * | ||||

| XC4 | 30 + 5 * | 35 + 5 * | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vintimilla, C.; Etxeberria, M. Durable Structural Recycled Concrete for Different Exposure Environments. Materials 2025, 18, 587. https://doi.org/10.3390/ma18030587

Vintimilla C, Etxeberria M. Durable Structural Recycled Concrete for Different Exposure Environments. Materials. 2025; 18(3):587. https://doi.org/10.3390/ma18030587

Chicago/Turabian StyleVintimilla, Carla, and Miren Etxeberria. 2025. "Durable Structural Recycled Concrete for Different Exposure Environments" Materials 18, no. 3: 587. https://doi.org/10.3390/ma18030587

APA StyleVintimilla, C., & Etxeberria, M. (2025). Durable Structural Recycled Concrete for Different Exposure Environments. Materials, 18(3), 587. https://doi.org/10.3390/ma18030587