Effect of Sn Addition on Microstructure and Mechanical Properties of Sintered Ti2AlNb-Based Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

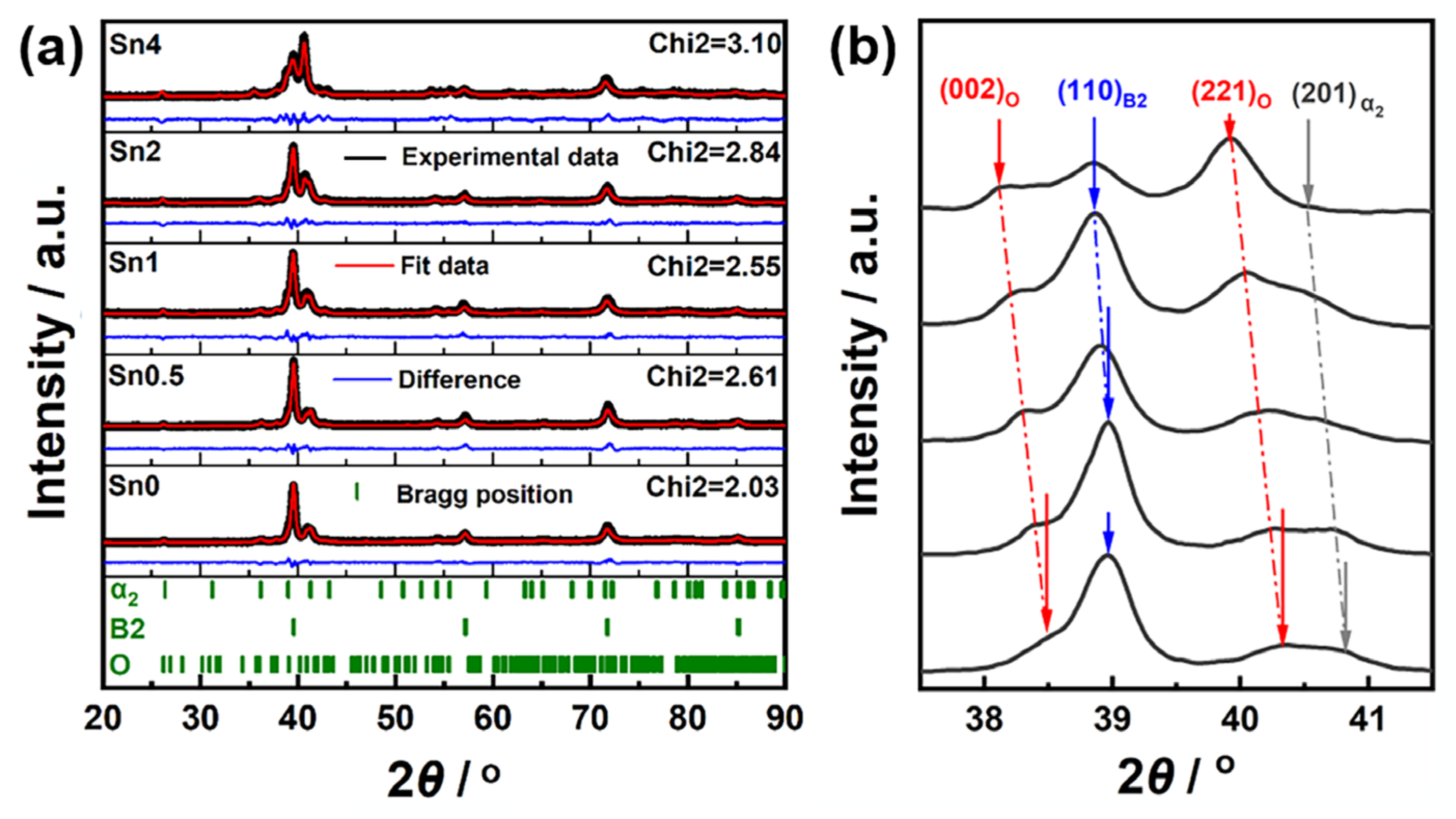

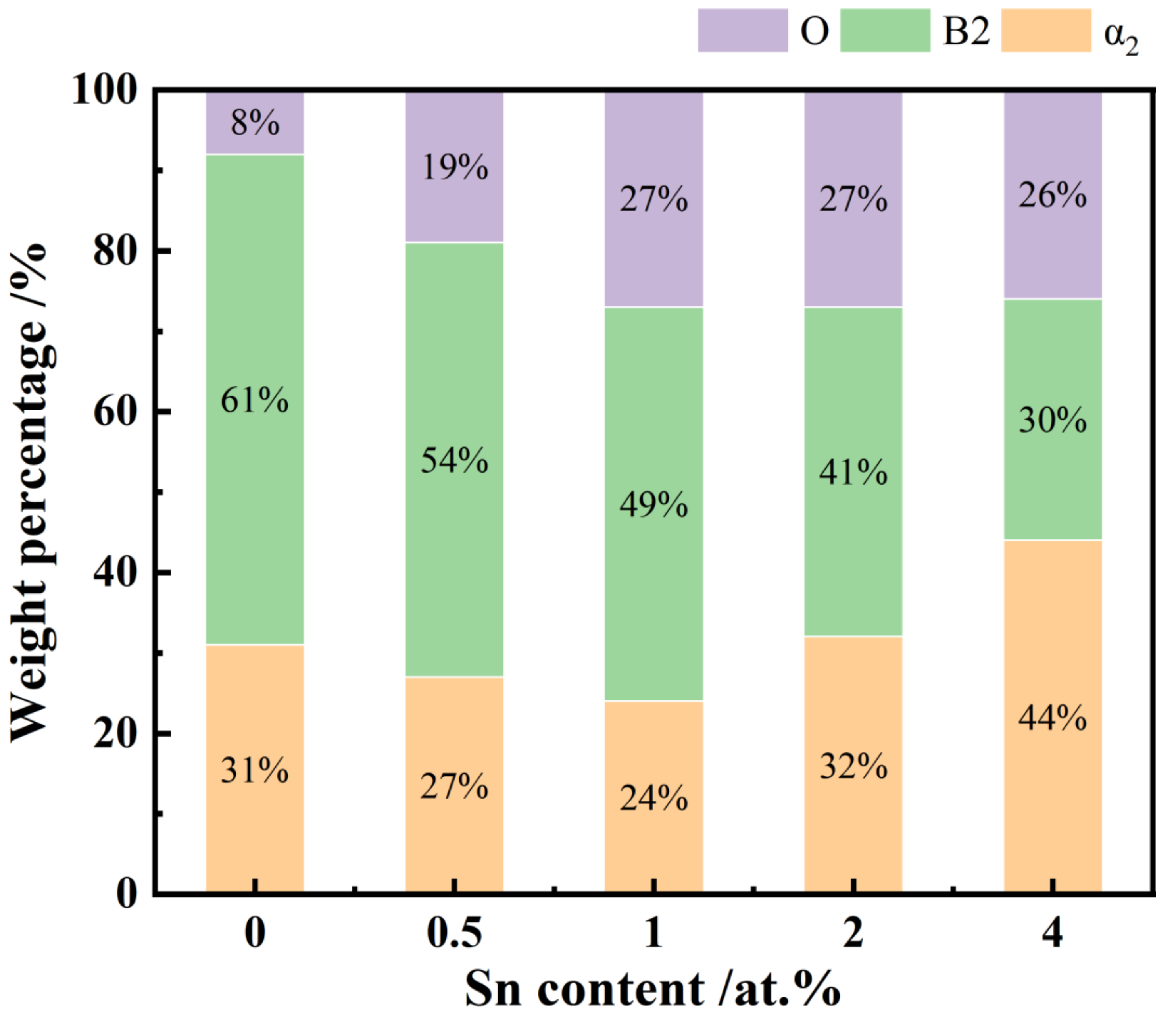

3.1. Effect of Sn Content on Phase Composition of Alloy

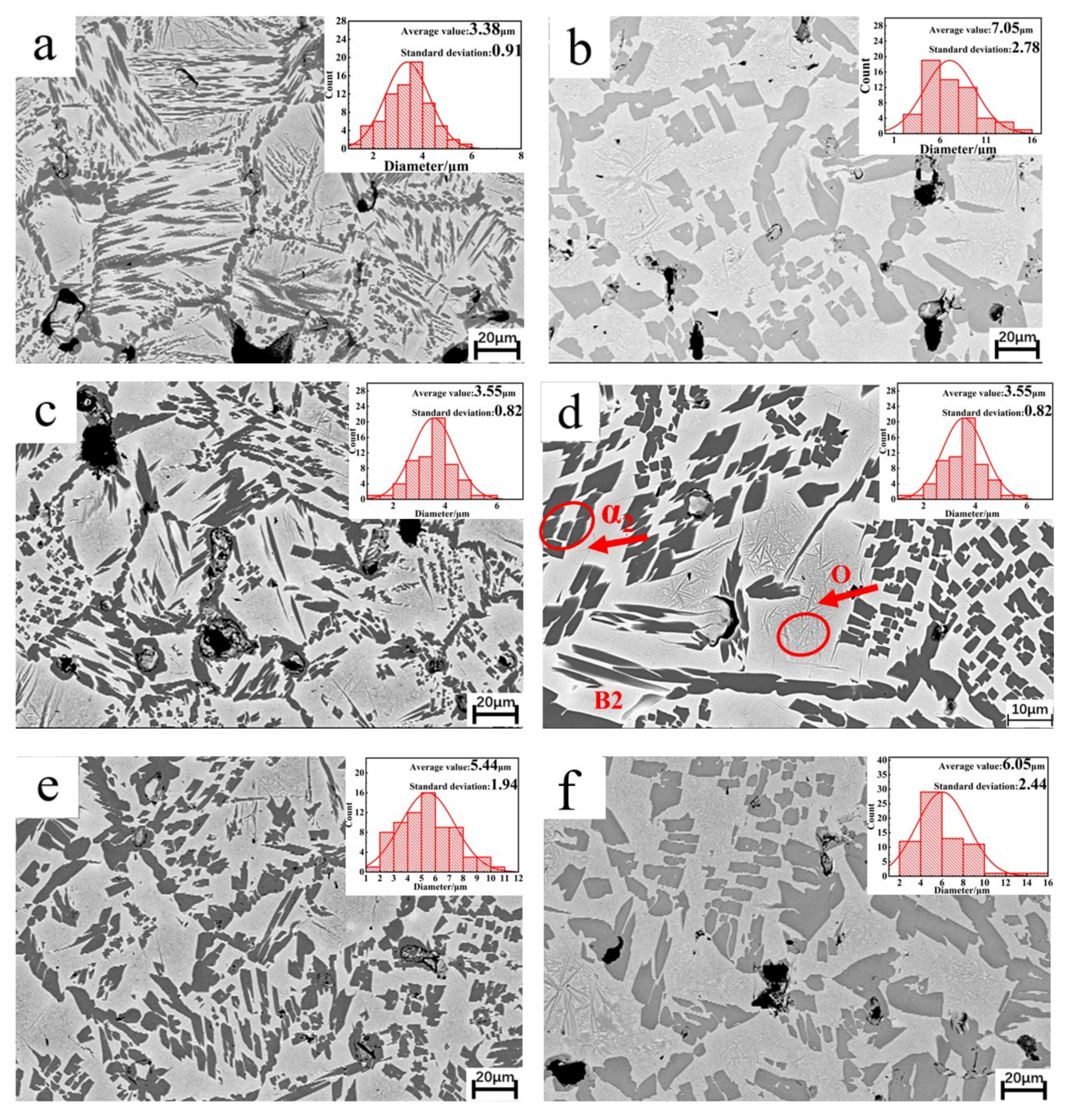

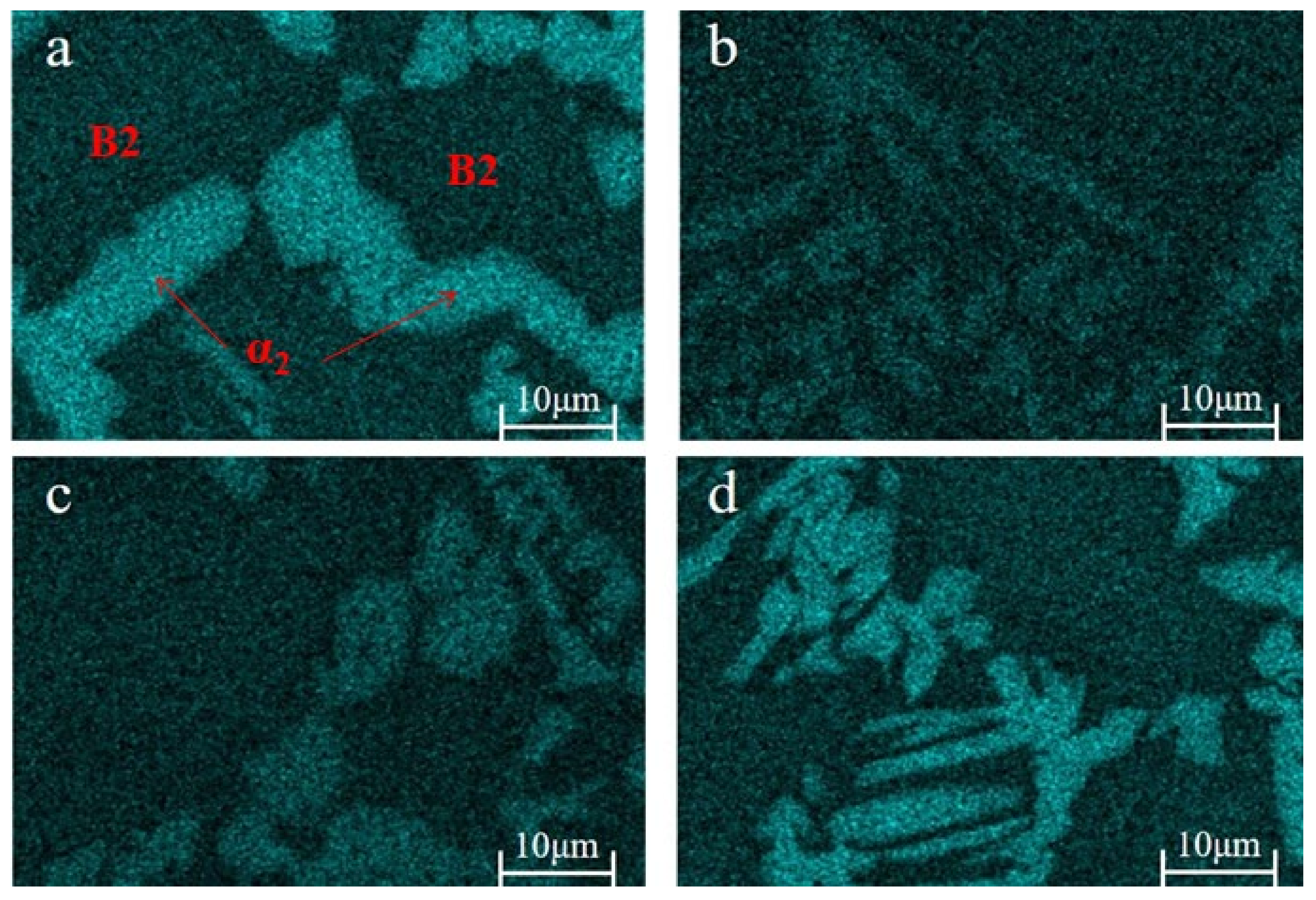

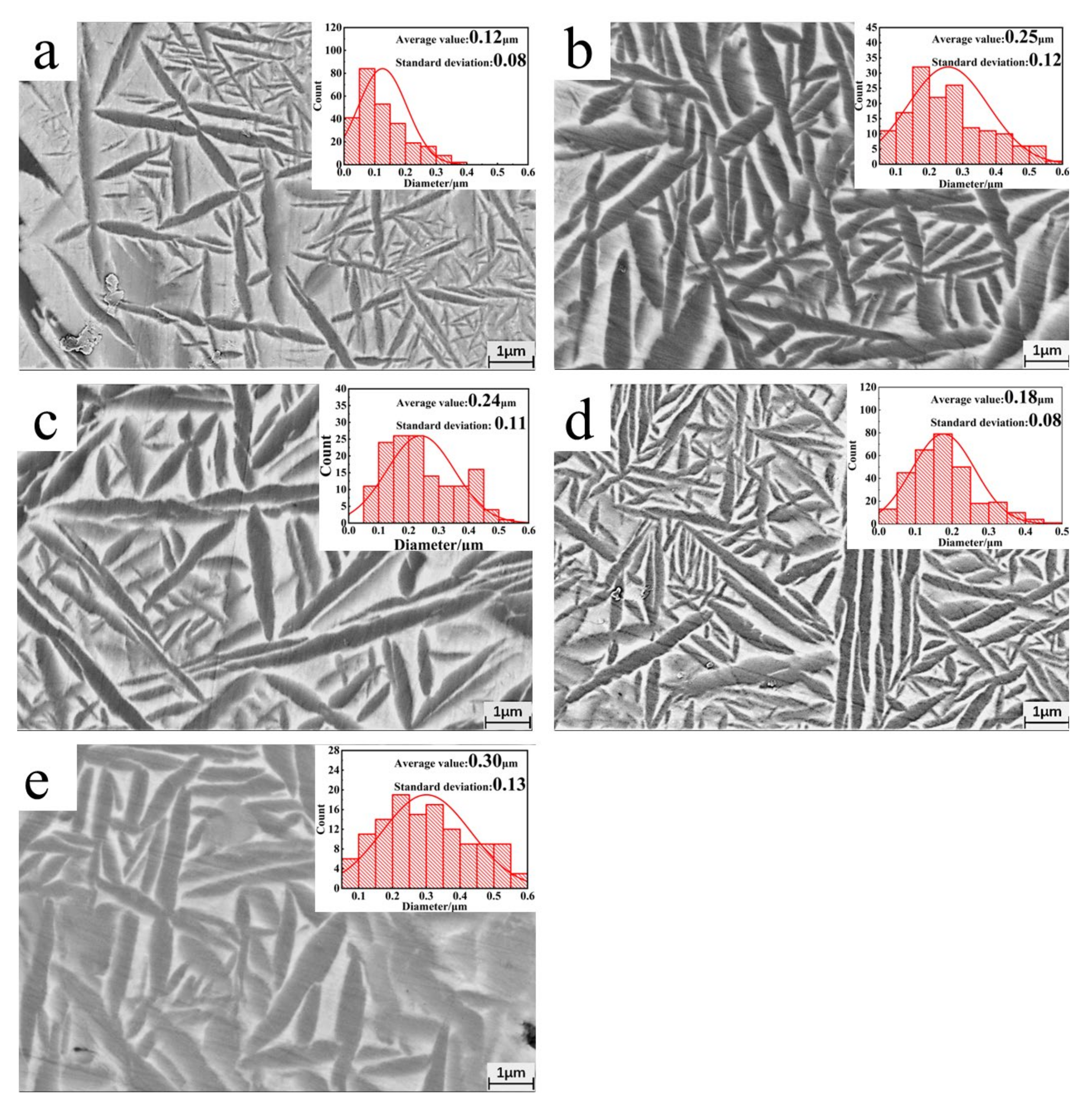

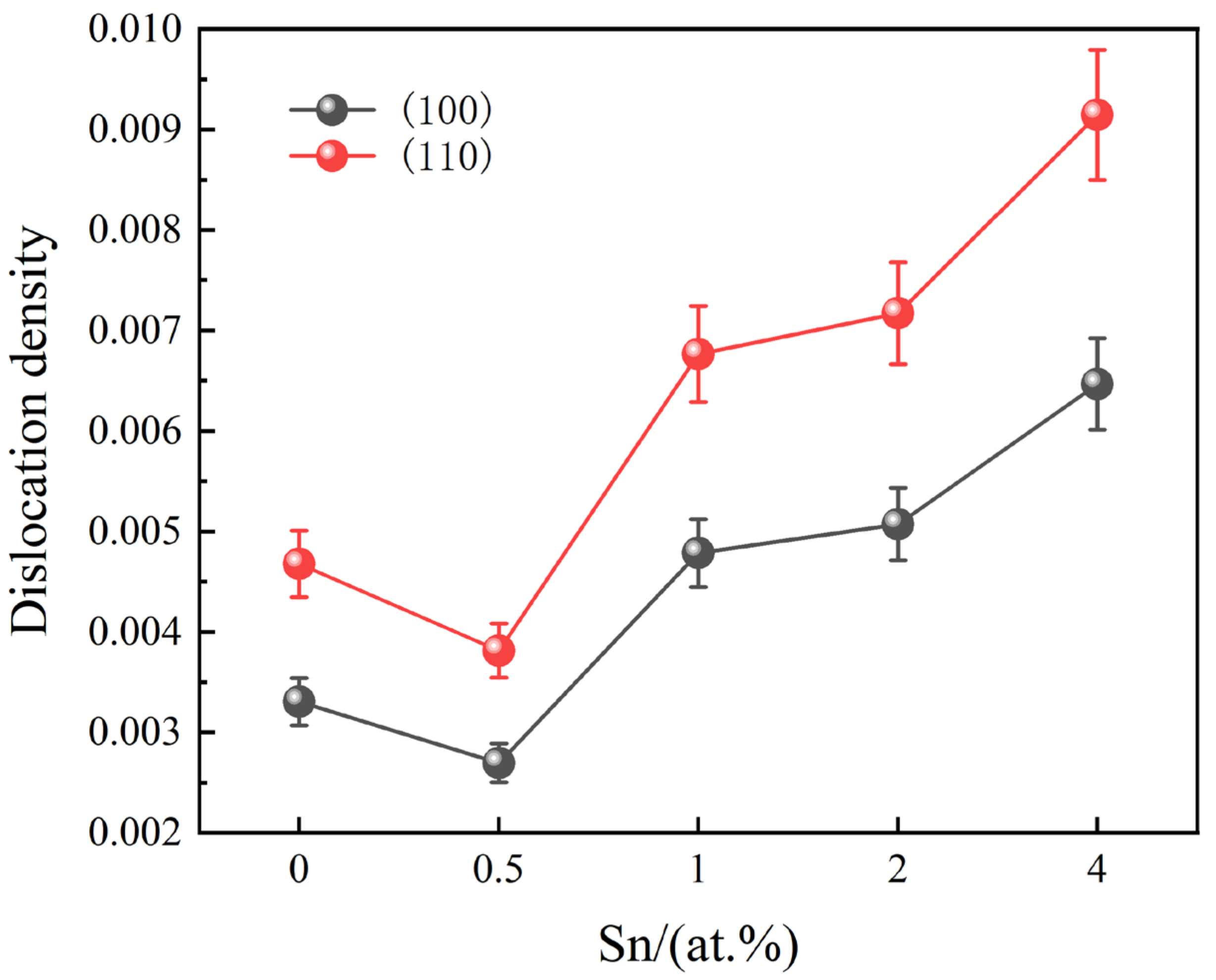

3.2. Effect of Sn Content on Microstructure of Alloys

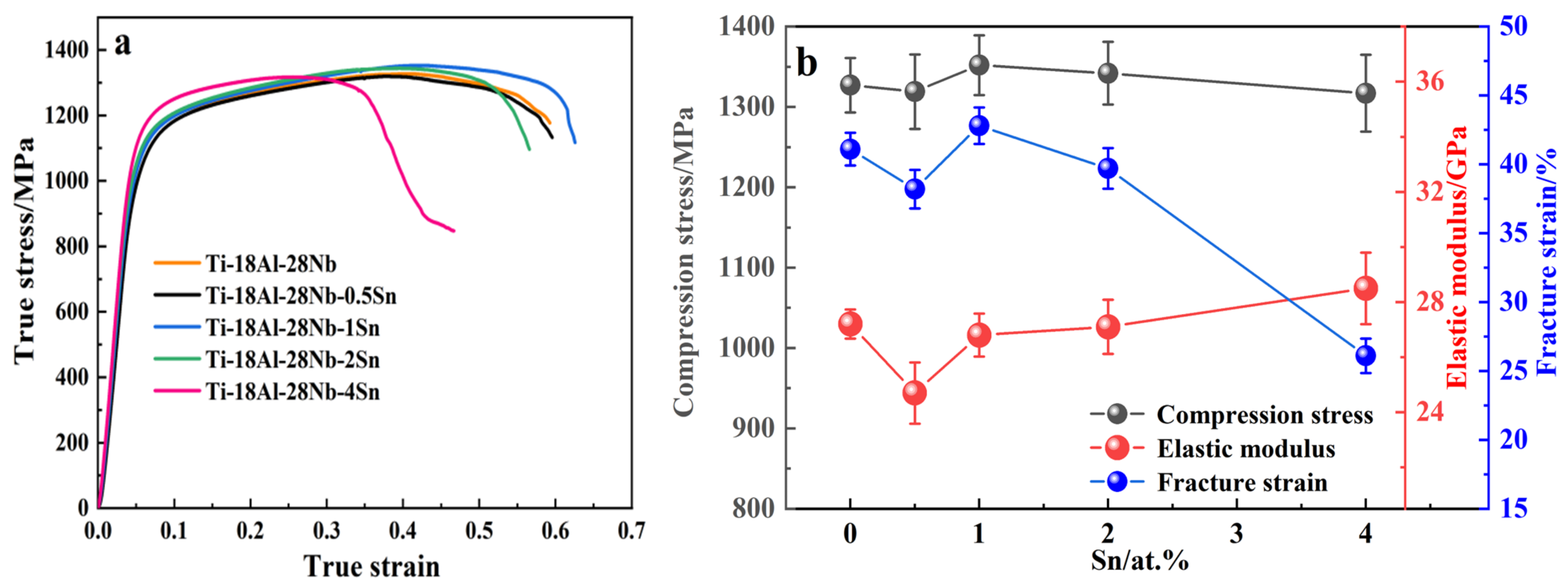

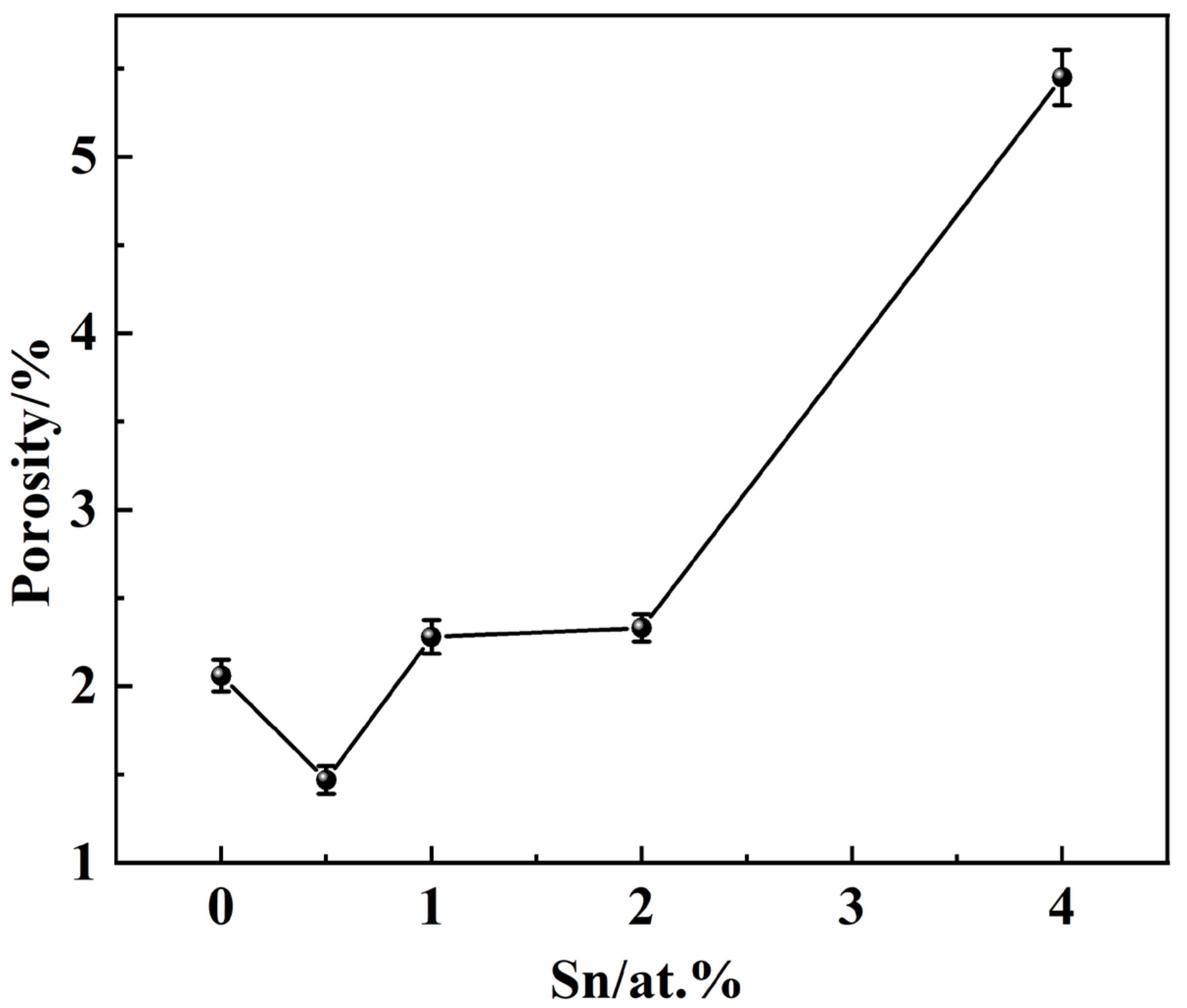

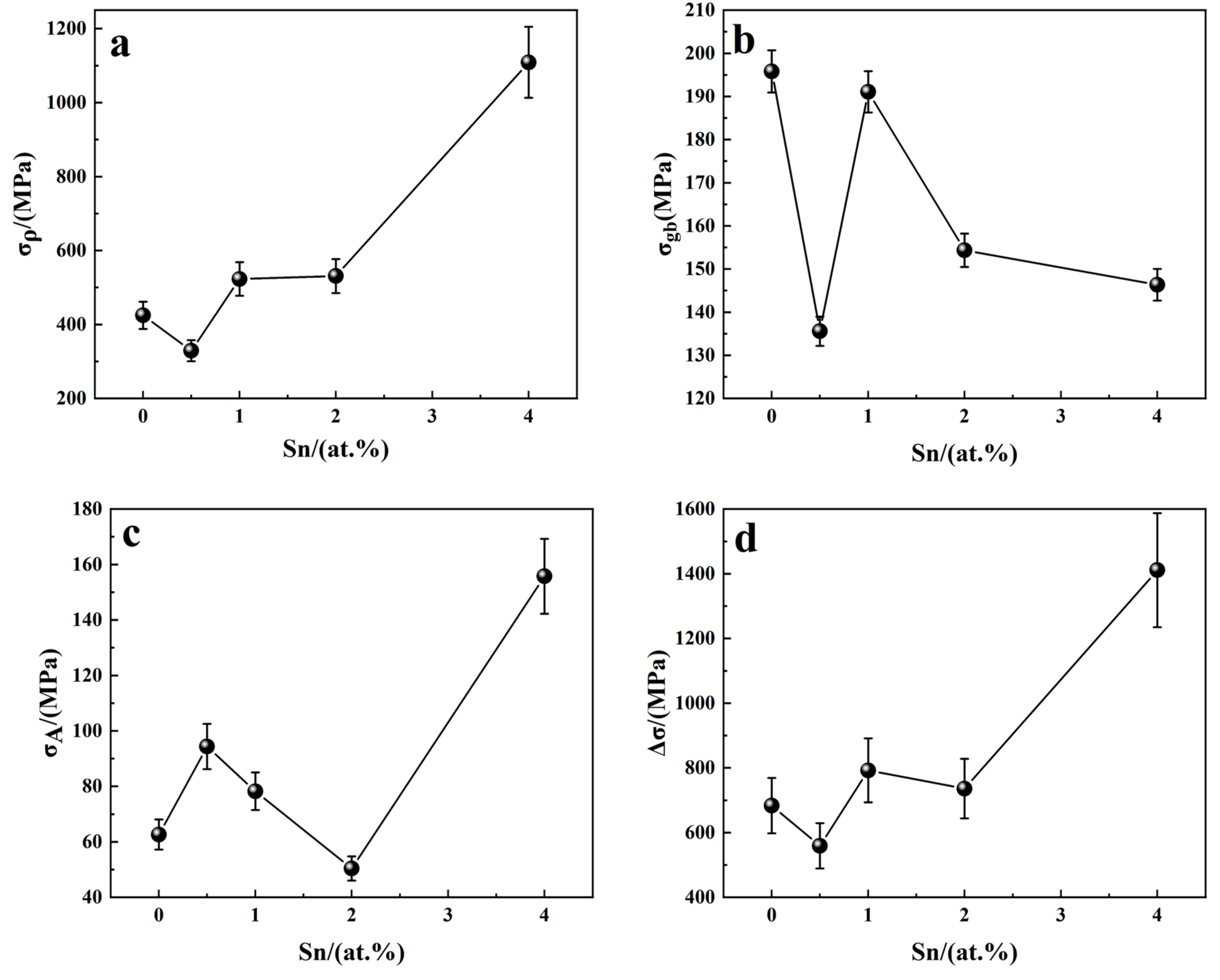

3.3. Effect of Sn Content on Compressive Mechanical Properties of Alloys

4. Conclusions

- The phase compositions of Ti-18Al-28Nb-xSn (x = 0, 0.5, 1.0, 2.0, and 4.0 at.%) alloys, fabricated through the powder metallurgical process of “cold isostatic pressing + atmospheric pressure sintering”, consist of α2, O, and B2 phases. As the Sn content increases, the proportion of the α2 phase decreases initially and then increases, ultimately adopting an isometric shape with a diffuse distribution. The proportion of the O phase increases before stabilizing, while the B2 phase content consistently decreases. The phase transformation sequence is B2 → O, α2 → O, and B2 → α2.

- The microstructure of the Ti-18Al-28Nb alloy without Sn addition exhibits a Widmanstätten structure composed of B2 + O phases, with an equiaxed α2 phase. The acicular O phase is diffusely distributed within the B2 matrix. The addition of Sn promotes the growth of the α2 phase at the grain boundaries, leading to an increase in the sizes of both the α2 and O phases at these boundaries.

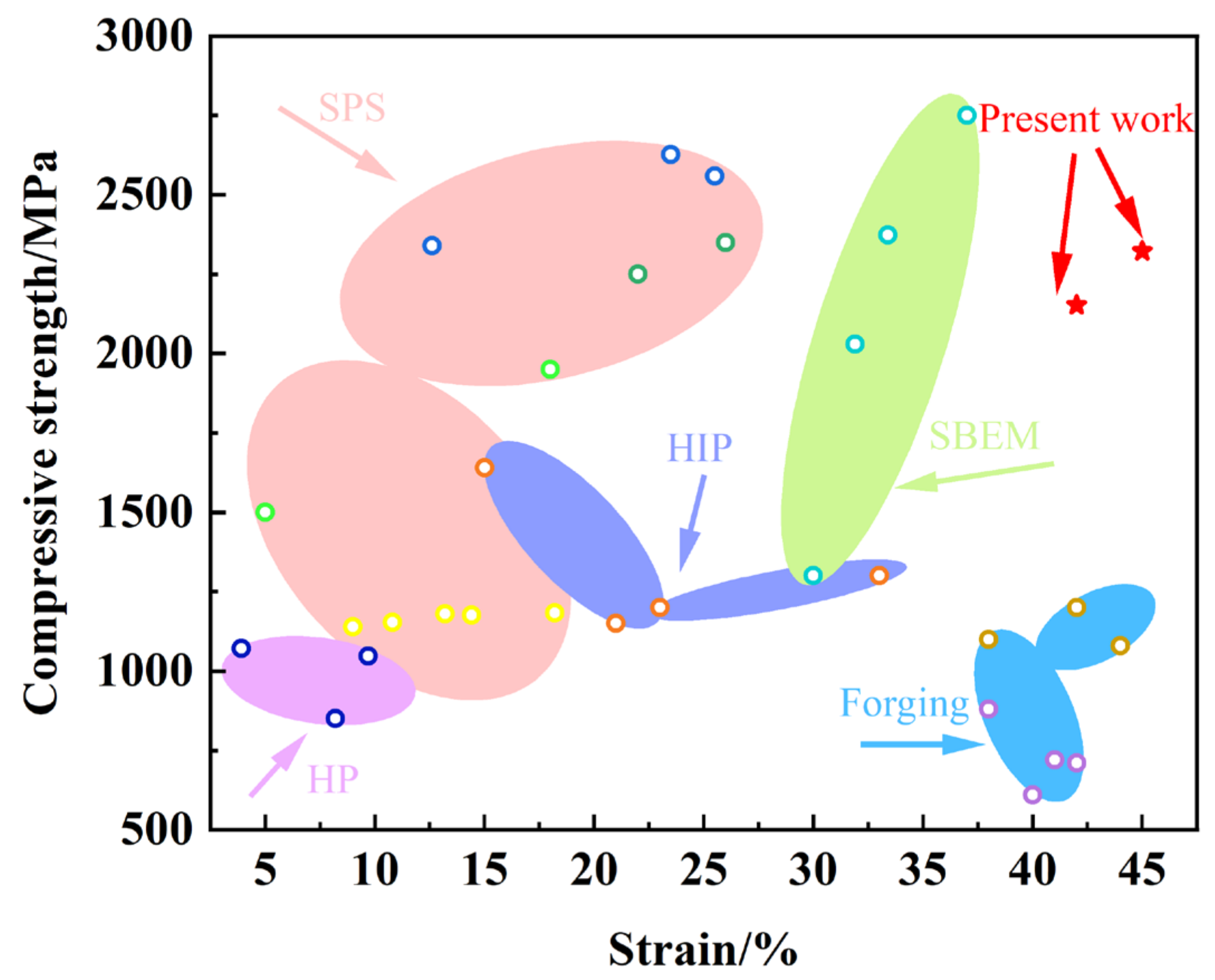

- The mechanical properties of the alloys are significantly enhanced with the addition of Sn. When the Sn content reaches 1 at.%, the alloy exhibits optimal overall mechanical properties, characterized by a favorable balance of elasticity, strength, and plasticity; at this time, the elastic modulus of the alloy is 26.8 GPa, with a compressive strength of up to 1352 MPa and a fracture strain of 42.8%. Further Sn addition results in reductions in strength and plasticity, although elasticity improves. Additionally, when Sn content exceeds 2 at.%, the alloy’s porosity increases substantially, leading to the formation of numerous micropores. These micropores are prone to coalescing into microcracks, which ultimately causes fracture, thereby compromising the alloy’s strength and plasticity and adversely affecting its performance. When the Sn content reaches 4 at.%, the compressive strength has already decreased by 10 MPa compared to the alloy without Sn, and the fracture strain has decreased by 15%, resulting in poorer alloy performance. This study investigates the effects of Sn on the liquid phase sintering behavior and enhancing mechanical properties of TiAl alloys containing high-melting-point Nb. When the Sn content is below 2 at.%, Ti-18Al-28Nb-xSn alloy shows excellent density and mechanical properties. This study demonstrates the advantages of the low-melting-point alloying element Sn combining cold isostatic pressing and pressureless sintering in the preparation of the Ti-18Al-28Nb alloys, and it narrows the effective range of Sn content that optimizes the properties in TiAlNb alloys. This study provides valuable insights for research on the replacement of SPS and HIP in specific situations such as complex component formation and offers a reference for the development of densification sintering of alloys with high-melting-point elements assisted by low-melting-point alloys.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ge, G.; Wang, Z.; Zhang, L.; Lin, J. Hot deformation behavior and artificial neural network modeling of β-γ TiAl alloy containing high content of Nb. Mater. Today Commun. 2021, 27, 102405. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ceylan, A.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, S.; Zhao, Y.; Wang, Z.; Liang, J.; Cai, Q.; Zhao, Q. Suppression of texture and enhancement of high-temperature tensile property in heavily deformed gradient Ti2AlNb alloy. J. Mater. Res. Technol. 2023, 26, 7665–7673. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Pan, X.; Mu, J.; Li, P.; Liu, Z. Microstructure and room/high-temperature tensile properties of γ-TiAlNb intermetallic compound subjected to heat treatment. Intermetallics 2024, 168, 108258. [Google Scholar] [CrossRef]

- Zeng, S.; Zhao, A.; Luo, L.; Jiang, H.; Zhang, L. Development of β-solidifying γ-TiAl alloys sheet. Mater. Lett. 2017, 198, 31–33. [Google Scholar] [CrossRef]

- Huang, H.; Ding, H.; Xu, X.; Zhang, X.; Chen, R.; Guo, J.; Fu, H. Strengthening effect of blocky phases and γ/γ interface in the directionally solidified high-Nb-containing TiAl alloy. Mater. Sci. Eng. A 2022, 853, 143792. [Google Scholar] [CrossRef]

- Nieh, T.G.; Hsiung, L.M.; Wadsworth, J. Superplastic behavior of a powder metallurgy TiAl alloy with a metastable microstructure. Intermetallics 1999, 7, 163–170. [Google Scholar] [CrossRef]

- Neelam, N.S.; S, B.; Bhattacharjee, A.; Gvs, N.R.; Zafir, M.A. Comparison of the isothermal and cyclic oxidation behavior of Cr and Mo containing γ-TiAlNb alloys. Corros. Sci. 2020, 163, 108300. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. Strengthening a high-strength TiAl alloy by hot-forging. Intermetallics 2003, 11, 299–306. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhang, C.J.; Du, Z.X.; Hou, Z.P.; Lin, P.; Chen, Y.Y. Microstructure and tensile properties of hot fogred high Nb containing TiAl based alloy with initial near lamellar microstructure. Mater. Sci. Eng. A 2015, 642, 16–21. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, N.; Liang, H.; Liu, Y. Phase transformation and microstructure control of Ti2AlNb-based alloys: A review. J. Mater. Sci. Technol. 2021, 80, 203–216. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, R.; Yang, Y.; Guo, J.; Su, Y.; Ding, H.; Fu, H. Effects of V and B, Y additions on the microstructure and creep behaviour of high-Nb TiAl alloys. J. Alloys Compd. 2018, 747, 640–647. [Google Scholar] [CrossRef]

- Cui, N.; Kong, F.; Wang, X.; Chen, Y.; Zhou, H. Microstructural evolution, hot workability, and mechanical properties of Ti–43Al–2Cr–2Mn–0.2Y alloy. Mater. Des. 2016, 89, 1020–1027. [Google Scholar] [CrossRef]

- Song, L.; Zhang, L.Q.; Xu, X.J.; Sun, J.; Lin, J.P. Omega phase in as-cast high-Nb-containing TiAl alloy. Scr. Mater. 2013, 68, 929–932. [Google Scholar] [CrossRef]

- Xia, Y.; Qiu, D.; Qian, M. The crystallographic features of τ3 phase in a powder metallurgy nickel-doped Ti–45Al–5Nb–0.2C–0.2B–1.25Ni alloy. Intermetallics 2016, 71, 65–72. [Google Scholar] [CrossRef]

- Xia, Y.; Yu, P.; Schaffer, G.B.; Qian, M. Cobalt-doped Ti–48Al–2Cr–2Nb alloy fabricated by cold compaction and pressureless sintering. Mater. Sci. Eng. A 2013, 574, 176–185. [Google Scholar] [CrossRef]

- Xia, Y.; Luo, S.D.; Wu, X.; Schaffer, G.B.; Qian, M. The sintering densification, microstructure and mechanical properties of gamma Ti–48Al–2Cr–2Nb alloy with a small addition of copper. Mater. Sci. Eng. A 2013, 559, 293–300. [Google Scholar] [CrossRef]

- Ye, X.X.; Chen, B.; Shen, J.H.; Umeda, J.; Kondoh, K. Microstructure and strengthening mechanism of ultrastrong and ductile Ti-xSn alloy processed by powder metallurgy. J. Alloys Compd. 2017, 709, 381–393. [Google Scholar] [CrossRef]

- Zhang, C.; Pan, Y.; Hui, T.; Xu, W.; Zhang, S.; Mughal, M.A.; Zhang, J.; Lu, X. The sintering densification, microstructure and mechanical properties of Ti–48Al–2Cr–2Nb by a small addition of Sn–Al powder. J. Mater. Res. Technol. 2021, 15, 6947–6955. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, S.; Pan, Y.; Xu, W.; Singh, H.-p.; Liu, B.; Lu, D.; Wang, H.; Zhang, J.; Lu, X. Effect of Sn addition on the mechanical properties and high-temperature oxidation resistance of intermetallic TiAl alloys by first principles study and experimental investigation. J. Mater. Res. Technol. 2022, 21, 3666–3677. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Li, J. The Effect of Refined Coherent Grain Boundaries on High-Temperature Oxidation Behavior of TiAl-Based Alloys through Cyclic Heat Treatment. Metals 2024, 14, 521. [Google Scholar] [CrossRef]

- Bolzoni, L.; Raynova, S.; Yang, F.; Dahm, K. Behavior of Different β Stabilizers on the Microstructure and Properties of Ternary Ti-3Sn-X Alloys. Adv. Eng. Mater. 2024, 26, 2301503. [Google Scholar] [CrossRef]

- Trofimov, D.M.; Imayev, V.M.; Imayev, R.M. Preliminary study of the effect of Sn addition on microstructure and creep resistance of a β-solidifying TiAl alloy. Intermetallics 2024, 169, 108310. [Google Scholar] [CrossRef]

- Duan, Q.; Luan, Q.; Liu, J.; Peng, L. Microstructure and mechanical properties of directionally solidified high-Nb containing Ti–Al alloys. Mater. Des. 2010, 31, 3499–3503. [Google Scholar] [CrossRef]

- Sui, X.; Lin, J.; Cheng, S.; Wang, G.; Li, Z. Hot pack rolling the Ti2AlNb alloy prepared by SPS: Testing of the high-temperature properties of the alloy directly without the prior heat treatment. J. Mater. Res. Technol. 2024, 30, 7635–7643. [Google Scholar] [CrossRef]

- Fu, Y.; Su, Z. Elemental Composition, Phase Diagram, Microstructure, Fabrication Processes, and Mechanical Properties of Ti2AlNb Alloy: A Review. J. Mater. Eng. Perform. 2024, 33, 12819–12846. [Google Scholar] [CrossRef]

- Qian, M. Cold compaction and sintering of titanium and its alloys for near-net-shape or preform fabrication. Int. J. Powder Metall. 2010, 46, 29–44. [Google Scholar]

- Liu, X.; Wang, J.; Li, Y.; Li, S.; Cai, Q. Densification mechanism of Ti-Al-Nb alloys pressurelessly sintered from Al-Nb master alloy powder for cost-effective manufacturing. J. Alloys Compd. 2023, 936, 168307. [Google Scholar] [CrossRef]

- Cai, Q.; Yu, Q.; Li, X.; Lu, Y.; Li, Y.; Cui, G. In situ investigation on densification mechanism of Ti-20Al-19Nb (at.%) alloy by TiH2-assisted pressureless sintering. J. Mater. Sci. Technol. 2023, 165, 170–186. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, X.; Liu, X.; Zhu, L.; Ding, X.; Lu, X. Large area hole defect repair of titanium alloys by powder pressing and vacuum sintering. Vacuum 2024, 222, 113005. [Google Scholar] [CrossRef]

- Pan, Y.; Lu, X.; Liu, C.; Sun, J.; Tong, J.; Xu, W.; Qu, X. Effect of Sn Addition on Densification and Mechanical Properties of Sintered TiAl Base Alloys. Jinshu Xuebao/Acta Metall. Sin. 2018, 54, 93–99. [Google Scholar] [CrossRef]

- Banerjee, D. The intermetallic Ti2AlNb. Prog. Mater. Sci. 1997, 42, 135–158. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanabe, S.; Hanada, S. α′ Martensite Ti–V–Sn alloys with low Young’s modulus and high strength. Mater. Sci. Eng. A 2007, 448, 39–48. [Google Scholar] [CrossRef]

- Deng, H.; Chen, A.; Chen, L.; Wei, Y.; Xia, Z.; Tang, J. Bulk nanostructured Ti-45Al-8Nb alloy fabricated by cryomilling and Spark Plasma Sintering. J. Alloys Compd. 2019, 772, 140–149. [Google Scholar] [CrossRef]

- Sim, K.-H.; Wang, G.; Son, R.-C.; Choe, S.-L. Influence of mechanical alloying on the microstructure and mechanical properties of powder metallurgy Ti2AlNb-based alloy. Powder Technol. 2017, 317, 133–141. [Google Scholar] [CrossRef]

- Sim, K.H.; Wang, G.; Ju, J.M.; Yang, J.; Li, X. Microstructure and mechanical properties of a Ti−22Al−25Nb alloy fabricated from elemental powders by mechanical alloying and spark plasma sintering. J. Alloys Compd. 2017, 704, 425–433. [Google Scholar] [CrossRef]

- Wang, Y.H.; Lin, J.P.; He, Y.H.; Wang, Y.L.; Chen, G.L. Microstructures and mechanical properties of Ti–45Al–8.5Nb–(W,B,Y) alloy by SPS–HIP route. Mater. Sci. Eng. A 2008, 489, 55–61. [Google Scholar] [CrossRef]

- Liu, T.; Luo, L.S.; Zhang, D.H.; Wang, L.; Li, X.Z.; Chen, R.R.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Comparison of microstructures and mechanical properties of as-cast and directionally solidified Ti-47Al-1W-0.5Si alloy. J. Alloys Compd. 2016, 682, 663–671. [Google Scholar] [CrossRef]

- Bilous, O.O.; Artyukh, L.V.; Bondar, A.A.; Velikanova, T.Y.; Burka, M.P.; Brodnikovskyi, M.P.; Fomichov, O.S.; Tsyganenko, N.I.; Firstov, S.O. Effect of boron on the structure and mechanical properties of Ti–6Al and Ti–6Al–4V. Mater. Sci. Eng. A 2005, 402, 76–83. [Google Scholar] [CrossRef]

- Tang, H.P.; Yang, G.Y.; Jia, W.P.; He, W.W.; Lu, S.L.; Qian, M. Additive manufacturing of a high niobium-containing titanium aluminide alloy by selective electron beam melting. Mater. Sci. Eng. A 2015, 636, 103–107. [Google Scholar] [CrossRef]

- Yang, K.; Wang, J.; Tang, H.; Li, Y. Additive manufacturing of in-situ reinforced Ti–35Nb–5Ta–7Zr (TNTZ) alloy by selective electron beam melting (SEBM). J. Alloys Compd. 2020, 826, 154178. [Google Scholar] [CrossRef]

- Wu, J.; Guo, R.; Xu, L.; Lu, Z.; Cui, Y.; Yang, R. Effect of Hot Isostatic Pressing Loading Route on Microstructure and Mechanical Properties of Powder Metallurgy Ti2AlNb Alloys. J. Mater. Sci. Technol. 2017, 33, 172–178. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, L.; Guan, Y.; Zhang, B.; Li, J. Tougher TiAl alloy via integration of hot isostatic pressing and heat treatment. Mater. Sci. Eng. A 2017, 688, 371–377. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, E.-P.; Song, Y.-B.; Lee, S.H.; Kwon, Y.-S. Microstructure and mechanical properties of hot isostatically pressed Ti–6Al–4V alloy. J. Alloys Compd. 2014, 603, 207–212. [Google Scholar] [CrossRef]

- Li, Q.; Huang, S.; Gao, Y.; Ramamurty, U. Deformation, fracture, and fatigue crack growth behavior in TiB-reinforced near-α Ti matrix composites fabricated using powder metallurgy technique. Mater. Sci. Eng. A 2024, 916, 147351. [Google Scholar] [CrossRef]

- Najafizadeh, M.; Bozorg, M.; Yazdi, S.; Sarrafan, N.; Ghasempour-Mouziraji, M.; Goulas, C.; Cavaliere, P. Mechanical and Biocorrosion Properties of Ti-XSn (X = 0, 5, 10, 15 wt.%) Alloys for Biomedical Application Fabricated by Powder Metallurgy. Metallogr. Microstruct. Anal. 2024, 13, 18–28. [Google Scholar] [CrossRef]

- Gölbaşı, Z.; Öztürk, B.; İçin, K.; Sünbül, S.E. Effect of Sn addition on mechanical, wear, and electrochemical properties of Ti-Al-Sn alloys. Powder Technol. 2024, 444, 119966. [Google Scholar] [CrossRef]

| Element Content (at.%) | ||||

|---|---|---|---|---|

| Alloy | Ti | Al | Nb | Sn |

| S1 | 54 | 18 | 28 | 0 |

| S2 | 53.5 | 18 | 28 | 0.5 |

| S3 | 53 | 18 | 28 | 1 |

| S4 | 52 | 18 | 28 | 2 |

| S5 | 50 | 18 | 28 | 4 |

| Element Content (at.%) | ||||

|---|---|---|---|---|

| Alloy (α2) | Ti | Al | Nb | Sn |

| S2 | 61.32 | 16.94 | 13.29 | 8.45 |

| S3 | 62.56 | 22.11 | 12.99 | 2.34 |

| S4 | 63.09 | 20.87 | 12.28 | 3.77 |

| S5 | 61.10 | 17.66 | 13.70 | 7.54 |

| Element Content (at.%) | ||||

|---|---|---|---|---|

| Alloy (O) | Ti | Al | Nb | Sn |

| S2 | 49.73 | 17.73 | 28.83 | 3.71 |

| S3 | 54.98 | 18.82 | 24.83 | 1.37 |

| S4 | 53.86 | 18.87 | 25.01 | 2.26 |

| S5 | 49.12 | 19.02 | 28.29 | 3.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, Y.; Yan, X.; Xia, G.; Yu, Q.; Li, X.; Cai, Q. Effect of Sn Addition on Microstructure and Mechanical Properties of Sintered Ti2AlNb-Based Alloys. Materials 2025, 18, 715. https://doi.org/10.3390/ma18030715

Li Z, Zhang Y, Yan X, Xia G, Yu Q, Li X, Cai Q. Effect of Sn Addition on Microstructure and Mechanical Properties of Sintered Ti2AlNb-Based Alloys. Materials. 2025; 18(3):715. https://doi.org/10.3390/ma18030715

Chicago/Turabian StyleLi, Zhu, Yaran Zhang, Xifeng Yan, Guoqing Xia, Qilin Yu, Xinze Li, and Qi Cai. 2025. "Effect of Sn Addition on Microstructure and Mechanical Properties of Sintered Ti2AlNb-Based Alloys" Materials 18, no. 3: 715. https://doi.org/10.3390/ma18030715

APA StyleLi, Z., Zhang, Y., Yan, X., Xia, G., Yu, Q., Li, X., & Cai, Q. (2025). Effect of Sn Addition on Microstructure and Mechanical Properties of Sintered Ti2AlNb-Based Alloys. Materials, 18(3), 715. https://doi.org/10.3390/ma18030715