Structure and Properties of Strontium-Modified Zn–Al–Cu Alloys

Abstract

:1. Introduction

- the crystallization kinetics of the hypereutectic Zn–Al–Cu alloy solidifying between temperatures of 450 °C and 700 °C,

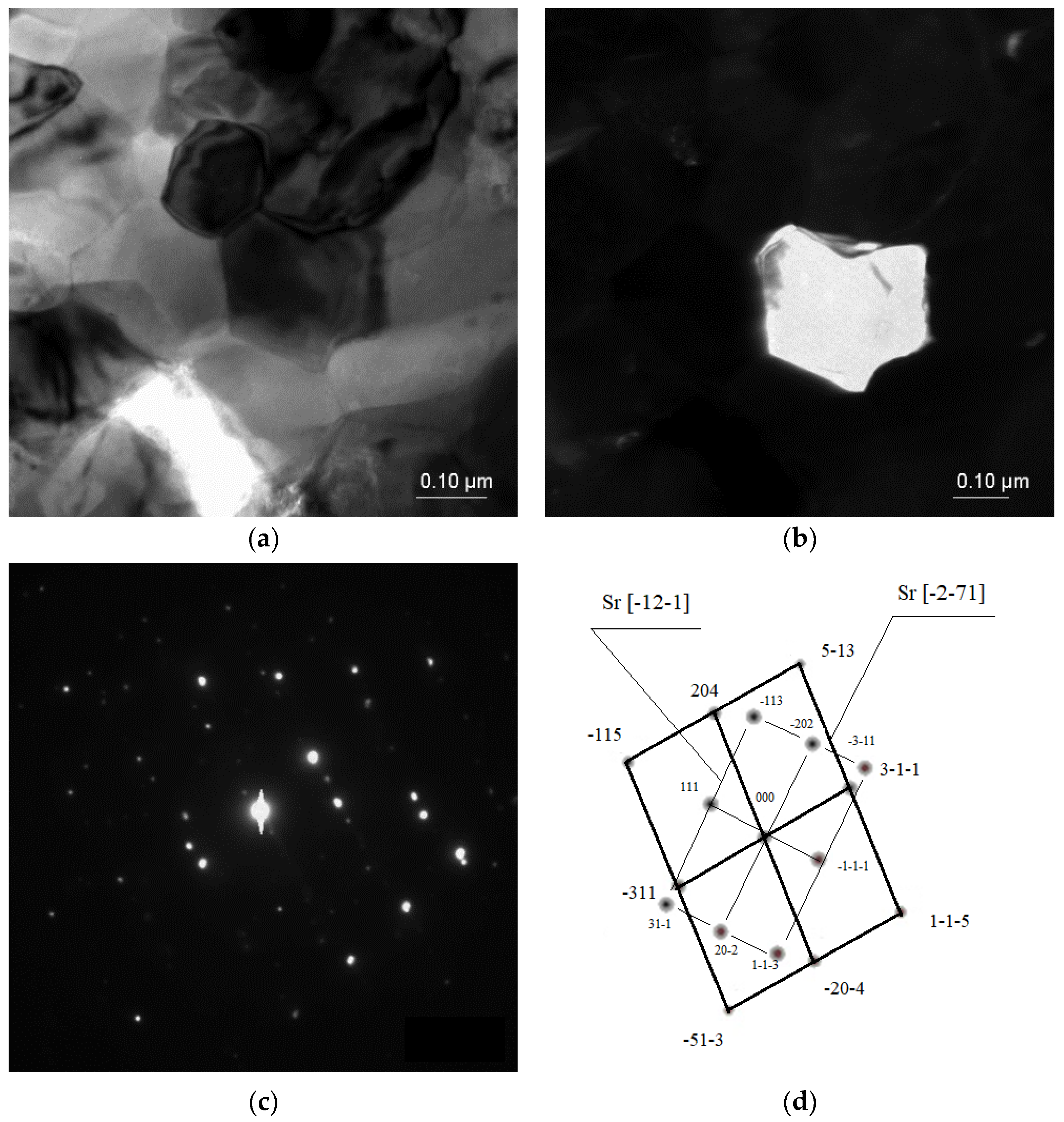

- the formation and distribution of Sr-containing intermetallic phases,

- the influence of the microstructure on the mechanical properties and corrosion resistance.

2. Materials and Methods

- A description of the designations in the formulas is as follows:

- Vc—loss of mass/g · (m2 · day)−1,

- ∆mk—sample mass change/g,

- A—active sample surface against corrosion/m2,

- tk—duration of corrosion/day,

- Vp—linear corrosion rate/mm · year−1,

- d—material density/g · (cm3)−1.

3. Results and Discussion

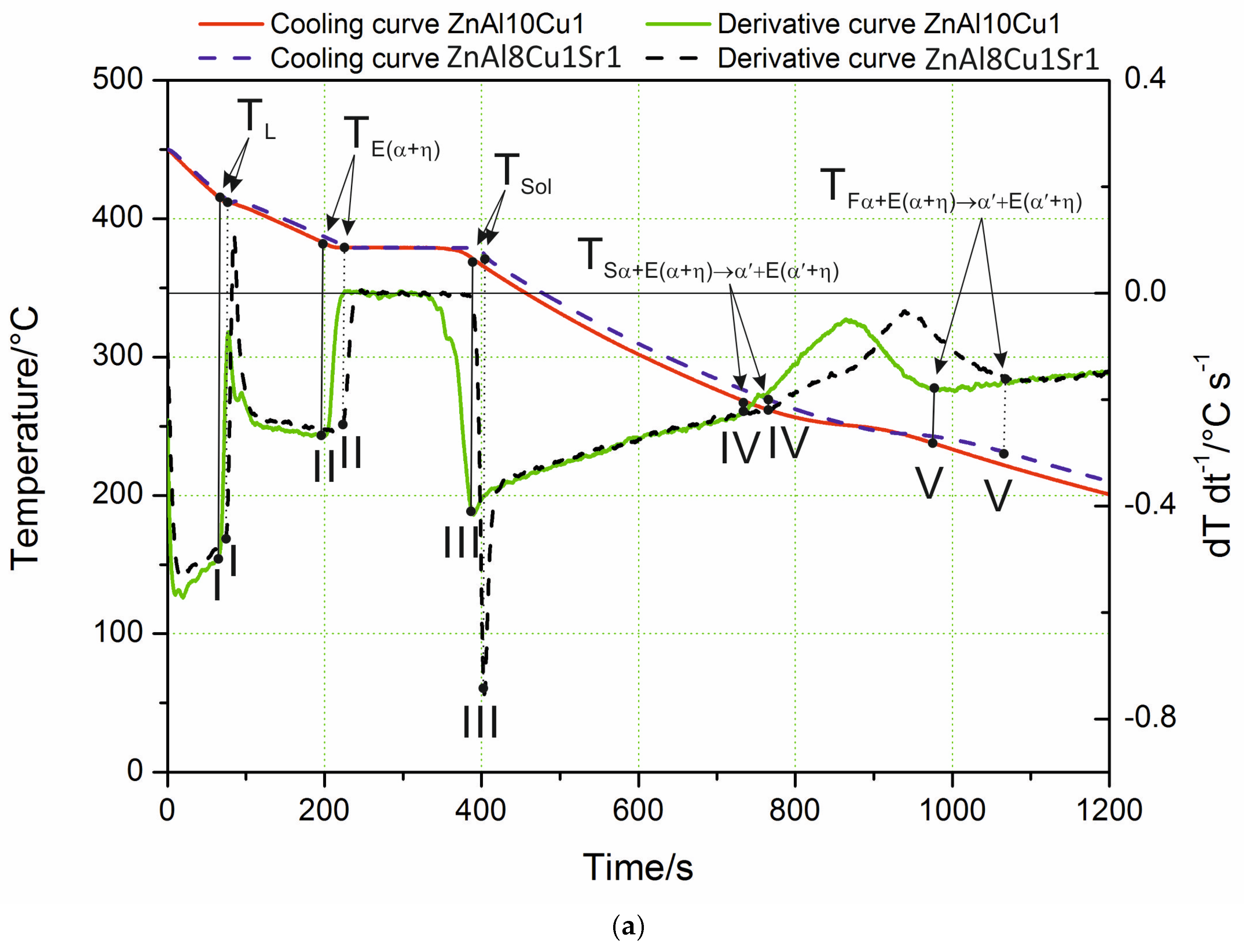

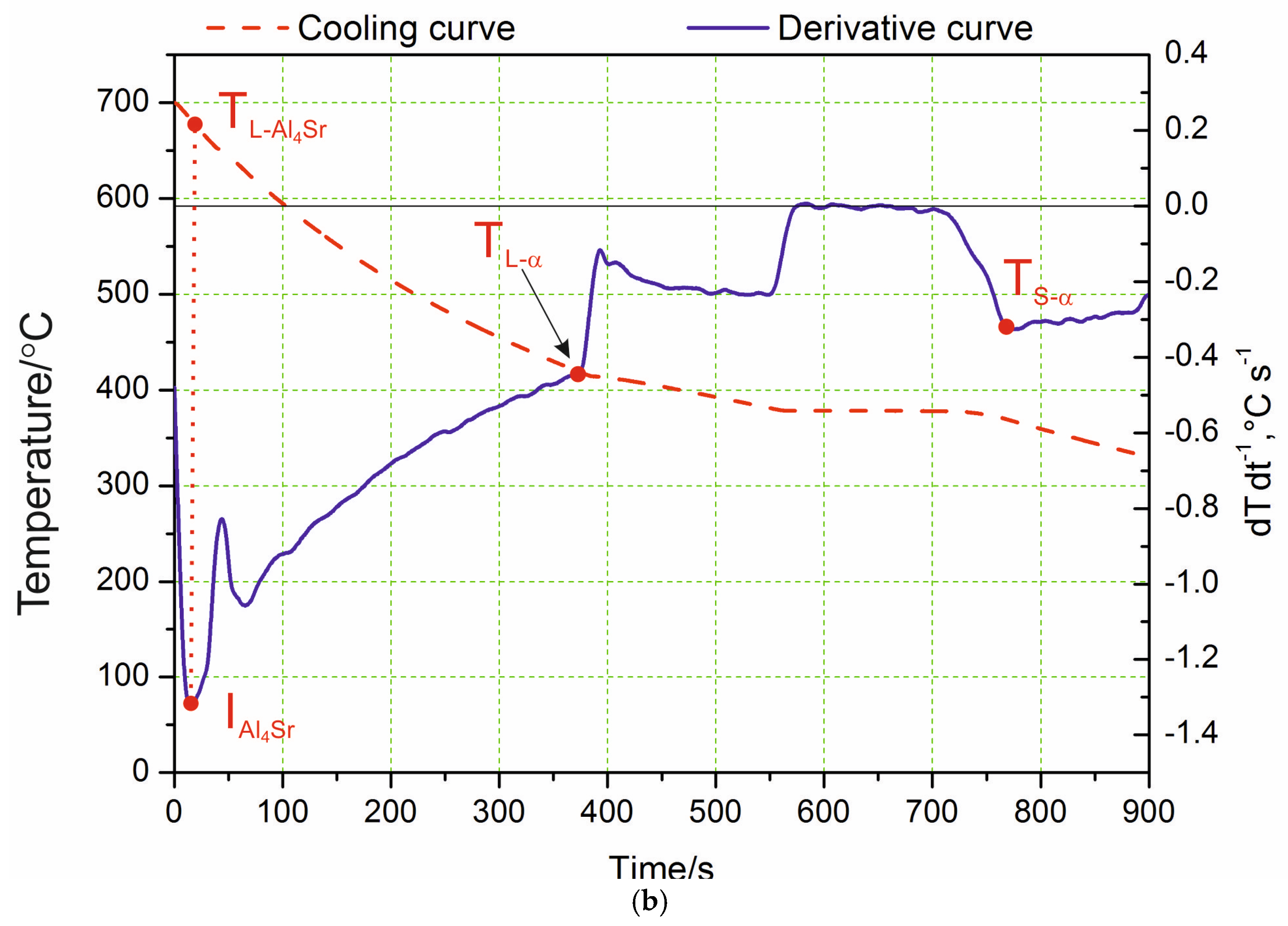

3.1. Thermo-Derivative Analysis (TDA)

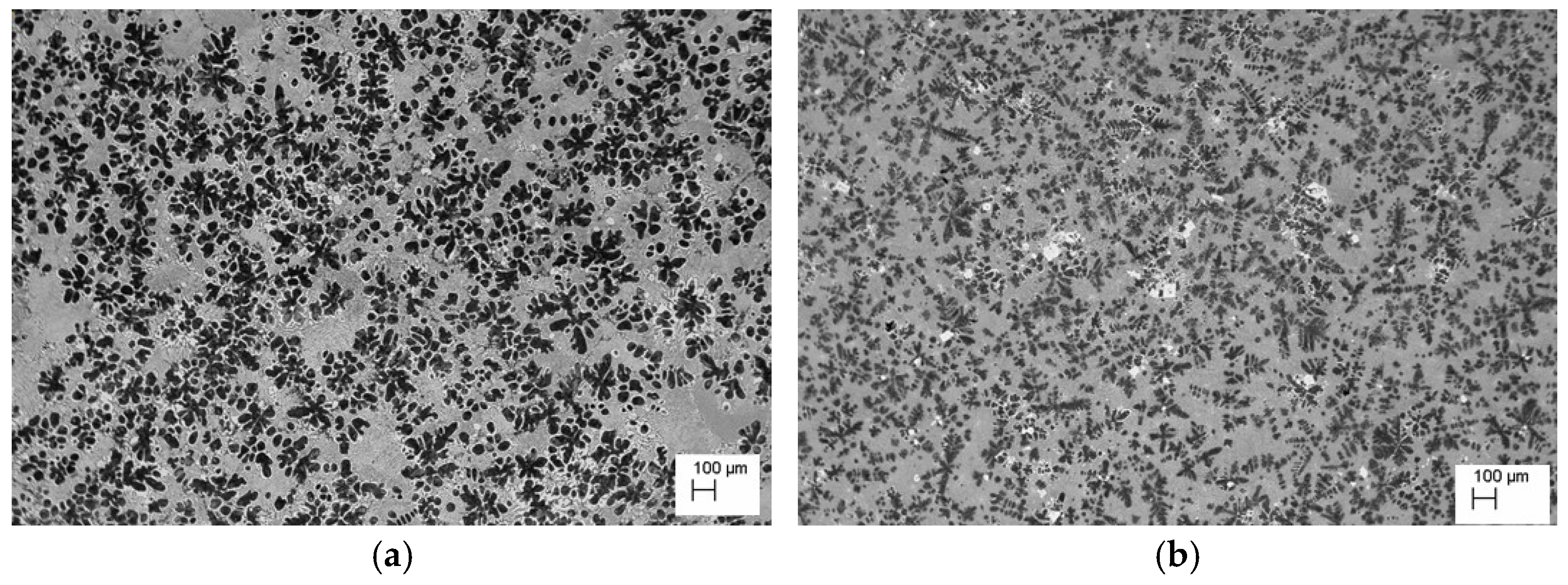

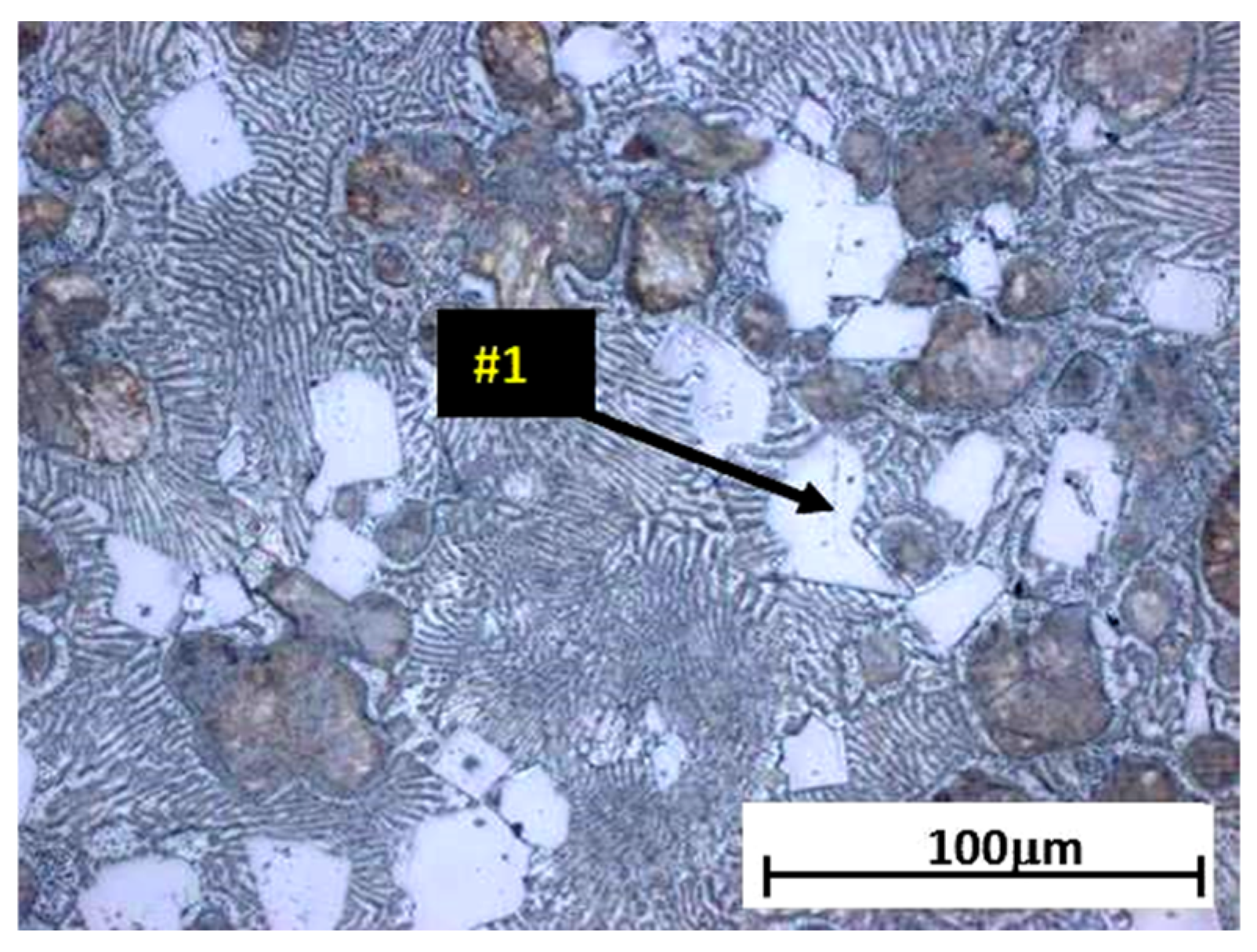

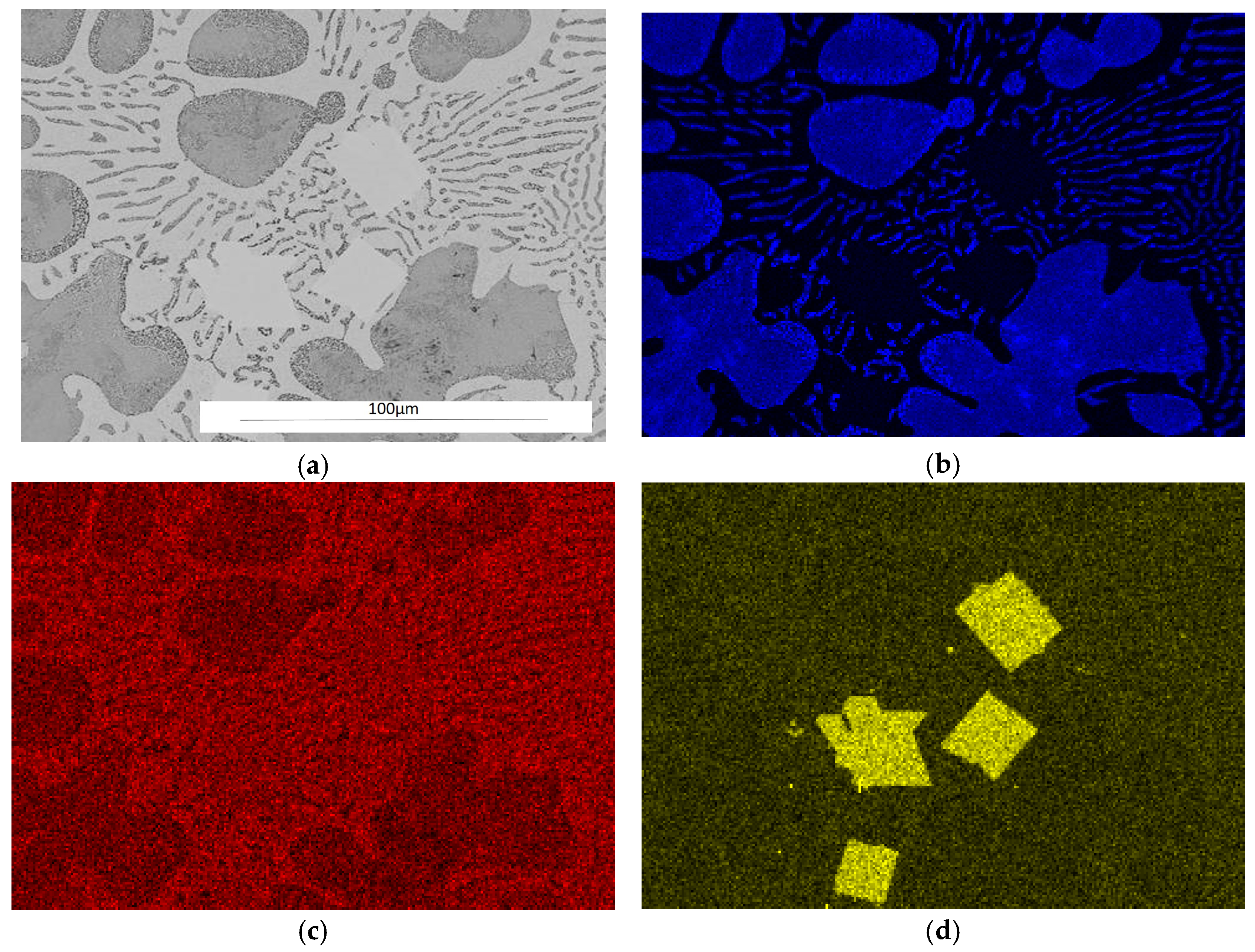

3.2. Microstructure and Phase Composition

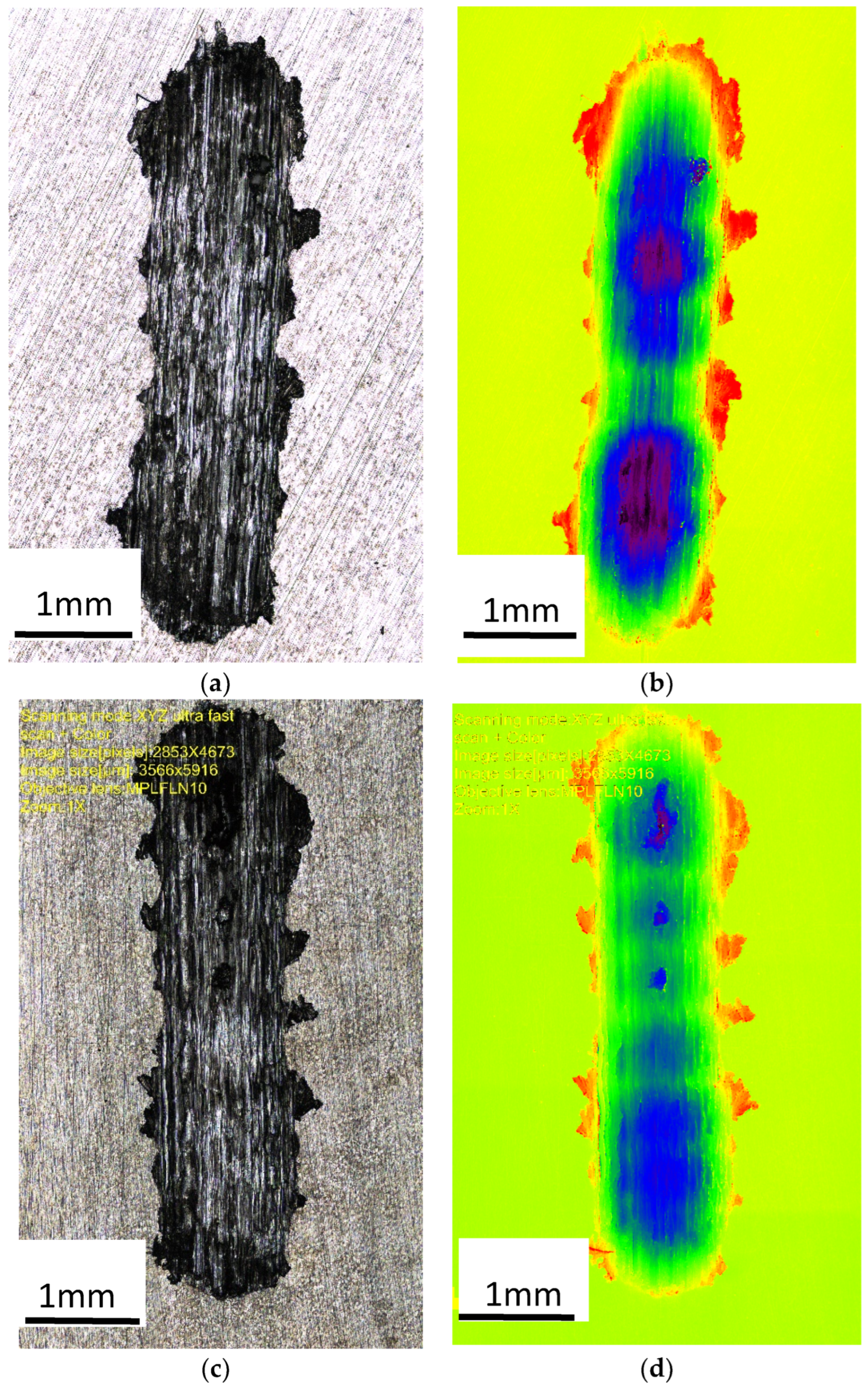

3.3. Erosion Wear Resistance Results

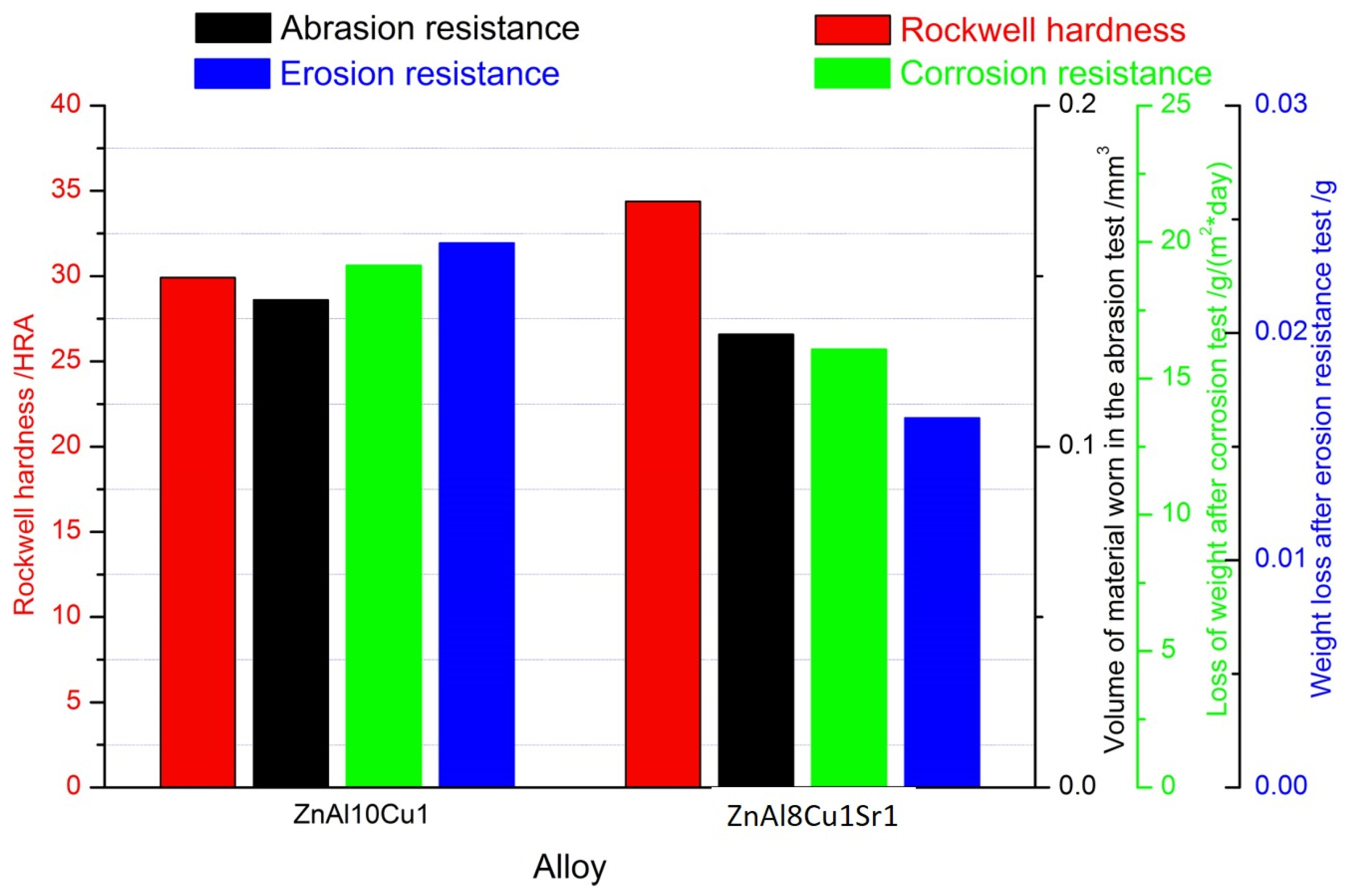

3.4. Hardness Results

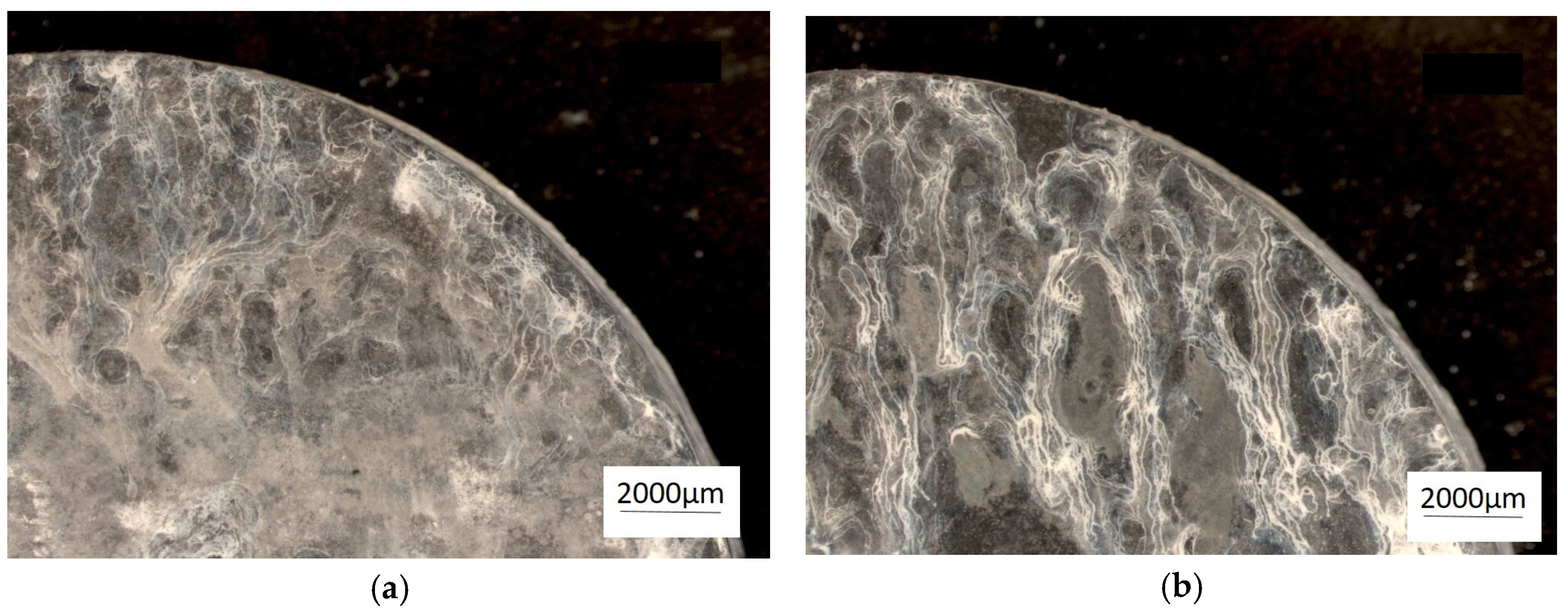

3.5. Corrosion Results

4. Conclusions

- in Zn–Al–Cu alloys modified with Sr, the structural components, i.e., α′ and the α′ + η eutectic, were not modified, and the temperature of the beginning and end of crystallization of the phases and eutectic did not change either.

- the change in the mass concentration of Al (in the range from 8 to 10 wt.%) in eutectic Zn–Al–Cu alloys did not change the start and end temperatures of solidification of the α′ phase and α′ + η eutectic. It changed the area between the derivation and calorimetric curves, which changed the share of individual phases.

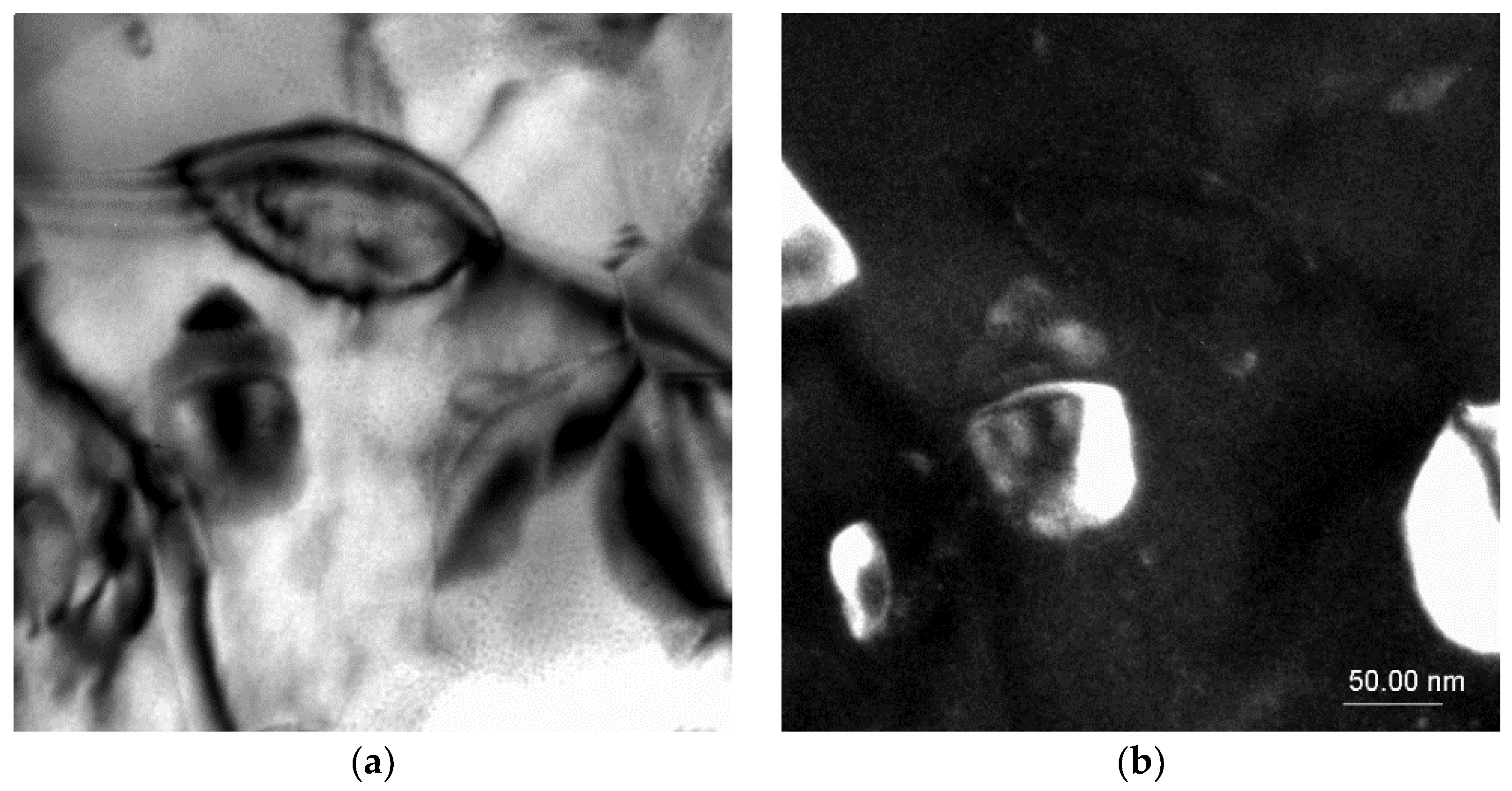

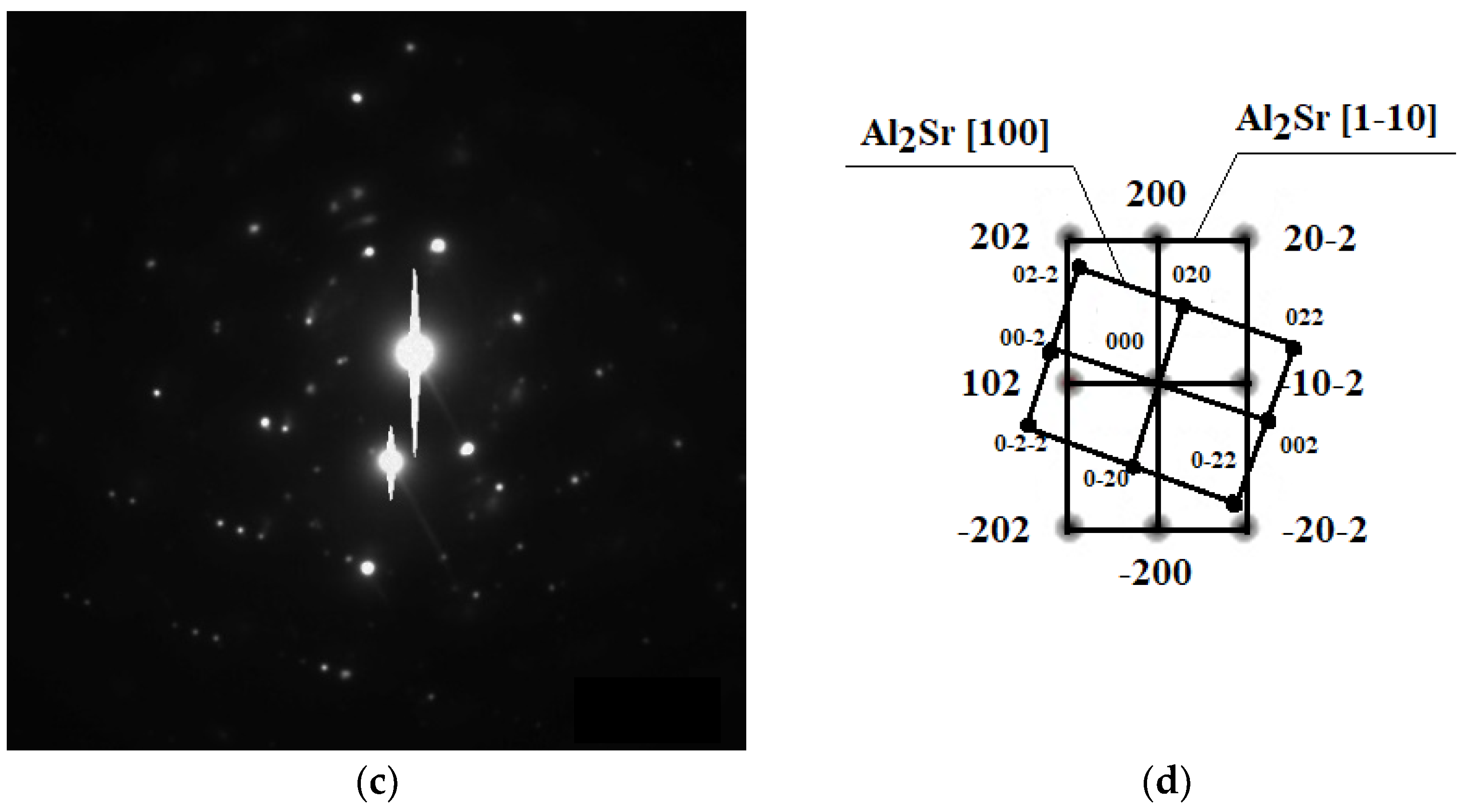

- the improvement in mechanical properties occurred as a result of the presence of the primary Al2Sr and secondary Al4Sr phases (in alloys melted at 700 °C), as well as intermetallic phases (Zn13Sr).

- in the alloy structure, in addition to the aluminum–strontium phases, there were also pure Sr phases. These hard intermetallic phases improved the mechanical properties, while not worsening the resistance to corrosion.

- the difference in corrosion resistance measured according to the standard ISO 9227: 2006: (Corrosion tests in artificial atmospheres—Salt spray tests) [19] did not exceed 9%, the alloy with Sr being more resistant.

- the addition of Sr also caused a shift in the end temperature of the monotectoid transformation TFα+E(α+η)→α′+E(α′+η) by about 12 °C and also caused a shift in time toward higher values compared with the alloy without the addition of strontium.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pola, A.; Tocci, M.; Goodwin, F.E. Review of Microstructures and Properties of Zinc Alloys. Materials 2020, 10, 253. [Google Scholar] [CrossRef]

- Krupinski, M. Crystallization kinetics and microstructural analysis of lanthanum-modified zinc alloys. J. Alloys Compd. 2021, 890, 161784. [Google Scholar] [CrossRef]

- Krupinski, M. Effect of addition Ce on crystallisation kinetics and structure of Zn-Al-Cu alloys. Arch. Met. Mater. 2018, 63, 1173–1178. [Google Scholar] [CrossRef] [PubMed]

- Bäckerud, L.; Król, E.; Tamminen, J. Solidification Characteristics of Aluminum Alloys 1; Skanaluminium: Oslo, MN, USA, 1986. [Google Scholar]

- Bäckerud, L.; Chai, G.; Tamminen, J. Solidification Characteristics of Aluminum Alloys 2; Skanaluminium: Des Plaines, IL, USA, 1990. [Google Scholar]

- Krupiński, M.; Labisz, K.; Tański, T.; Krupińska, B.; Król, M.; Polok-Rubiniec, M. Influence of Mg addition on crystallisation kinetics and structure of the Zn-Al-Cu alloy. Arch. Met. Mater. 2016, 61, 785–790. [Google Scholar]

- Ghosh, G.; Humbeeck, J.V. Ternary alloys. In Aluminium—Copper—Zinc, MSIT, 187 Landolt-Börnste in New Series IV/11A2, Updated by Pierre Perrot; Northwestern University: Evanston, IL, USA, 1992; p. 203. [Google Scholar]

- Krajewski, W.K.; Greer, A.L.; Krajewski, P.K. Trends in the development of high-aluminium zinc alloys of stable structure and properties. Arch. Met. Mater. 2013, 58, 845–847. [Google Scholar] [CrossRef]

- Savaskan, T.; Pürçek, G.; Murphy, S. Sliding wear of cast zinc-based alloy bearings under static and dynamic loading conditions. Wear 2002, 252, 693–703. [Google Scholar] [CrossRef]

- Krajewski, W.K. Structure and properties of high-aluminium zinc alloys inoculated with Ti addition. Arch. Foundry 2005, 5, 231–240. [Google Scholar]

- Yang, L.J. The effect of casting temperature on the properties of squeeze cast aluminium and zinc alloys. J. Mater. Process Technol. 2003, 140, 391–396. [Google Scholar] [CrossRef]

- Krupinski, M.; Krol, M.; Krupinska, B.; Mazur, K.; Labisz, K. Influence of Sr addition on microstructure of the hypereutectic Zn-Al-Cu alloy. J. Therm. Anal. Calorim. 2018, 133, 255–260. [Google Scholar] [CrossRef]

- Lipiński, T. Effect of combinative cooled addition of strontium and aluminium on mechanical properties AlSi12 alloy. J. Achiev. Mater. Manuf. Eng. 2017, 83, 5–11. [Google Scholar] [CrossRef]

- Choudhury, P.; Das, S. Effect of microstructure on the corrosion behavior of a zinc–aluminium alloy. J. Mater. Sci. 2005, 40, 805–807. [Google Scholar] [CrossRef]

- Babić, M.; Mitrović, S.; Jeremic, B. The influence of heat treatment on the sliding wear behavior of a ZA-27 alloy. Tribol. Int. 2010, 43, 16–21. [Google Scholar] [CrossRef]

- Agapie, M.; Varga, B. Dendritic Segregation of Zn-Al Eutectoid Alloys. Metals 2018, 8, 924. [Google Scholar] [CrossRef]

- Boncel, S.; Zniszczoł, A.; Pawlyta, M.; Labisz, K.; Dzido, G. Heat transfer nanofluid based on curly ultra-long multi-wall carbon nanotubes. Heat. Mass. Transf. 2017, 54, 333–339. [Google Scholar] [CrossRef]

- ASTM G76-95; Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO 9227: 2006; Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. International Organization for Standardization: Geneva, Switzerland, 2006.

- Zobac, O.; Kroupa, A.; Richter, K.W. Experimental study of the Al–Cu–Zn ternary phase diagram. J. Mater. Sci. 2020, 55, 10796–10810. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, H. Al-Sr (Aluminum-Strontium). J. Phase Equilibria Diffus. 2005, 26, 394. [Google Scholar] [CrossRef]

- Kaewmaneekul, T.; Lothongkum, G. Effect of aluminium on the passivation of zinc–aluminium alloys in artificial seawater at 80 °C. Corros. Sci. 2013, 66, 67–77. [Google Scholar] [CrossRef]

- Osório, W.R.; Freire, C.M.; Garcia, A. The effect of the dendritic microstructure on the corrosion resistance of Zn–Al alloys. J. Alloys Compd. 2005, 397, 179–191. [Google Scholar] [CrossRef]

- Gutiérrez-Menchaca, J.; Torres-Torres, D.; Garay-Tapia, A.M. Microstructural, mechanical and thermodynamic study of the as-cast Zn–Al–Sr alloys at high Sr content 829. J. Alloys Compd. 2020, 829, 154511. [Google Scholar] [CrossRef]

| Alloy | Alloy Description | Mass Concentration of Alloying Elements, % | |||

|---|---|---|---|---|---|

| Al | Cu | Sr | Zn | ||

| 1 | ZnAl8Cu1Sr1 | 8.51 | 0.93 | 1.02 | balance |

| 2 | ZnAl10Cu1 | 10.02 | 0.98 | - | balance |

| Markings on Figure 2a,b | Reaction | Temperature, °C | ||

|---|---|---|---|---|

| ZnAl8Cu1Sr1 | ZnAl10Cu1 | ZnAl8Cu1Sr1 | ZnAl10Cu1 | |

| IAl4Sr | L → Al4Sr | - | 657 | - |

| I | L → α | L → α | 415 | 415 |

| II | L → E(α+η) | L → E(α+η) | 411 | 410 |

| III | L → Sol | L → Sol | 372 | 370 |

| IV | Sα+E(α+η)→α′+E(α′+η) | Sα+E(α+η)→α′+E(α′+η) | 273 | 270 |

| V | Fα+E(α+η)→α′+E(α′+η) | Fα+E(α+η)→α′+E(α′+η) | 224 | 236 |

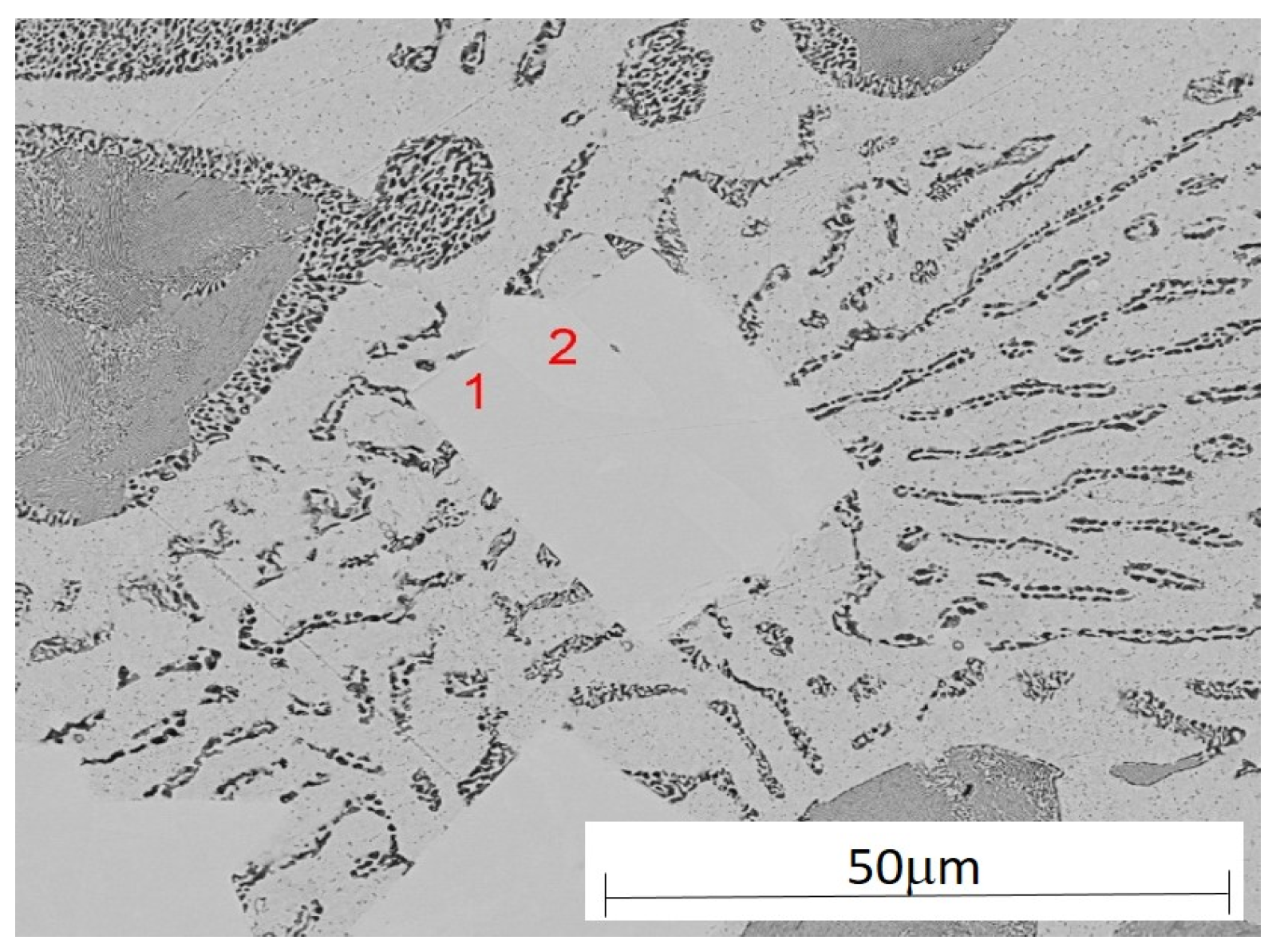

| Analysis Point | Mass Concentration of the Element, % | |||

|---|---|---|---|---|

| Al | Sr | Cu | Zn | |

| 1 | 5.3 | 23.6 | 3.2 | 67.9 |

| 2 | 5.7 | 25.3 | 2.1 | 66.9 |

| Alloy | The Volume of Material Worn in the Abrasion Test | Volume Difference Compared with the Sample Without Modification | |

|---|---|---|---|

| mm3 | mm3 | % | |

| ZnAl10Cu1 | 0.14 | 0 | 0 |

| ZnAl8Cu1Sr1 | 0.13 | −0.01 | −7.4 |

| Alloy | Hardness Mean Value, HRA | Standard Deviation | Change of the Average Hardness Value, % |

|---|---|---|---|

| ZnAl10Cu1 | 29.91 | 1.43 | 0.00 |

| ZnAl8Cu1Sr1 | 35.29 | 2.38 | 17.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krupiński, M.; Labisz, K.; Krupińska, B. Structure and Properties of Strontium-Modified Zn–Al–Cu Alloys. Materials 2025, 18, 797. https://doi.org/10.3390/ma18040797

Krupiński M, Labisz K, Krupińska B. Structure and Properties of Strontium-Modified Zn–Al–Cu Alloys. Materials. 2025; 18(4):797. https://doi.org/10.3390/ma18040797

Chicago/Turabian StyleKrupiński, Mariusz, Krzysztof Labisz, and Beata Krupińska. 2025. "Structure and Properties of Strontium-Modified Zn–Al–Cu Alloys" Materials 18, no. 4: 797. https://doi.org/10.3390/ma18040797

APA StyleKrupiński, M., Labisz, K., & Krupińska, B. (2025). Structure and Properties of Strontium-Modified Zn–Al–Cu Alloys. Materials, 18(4), 797. https://doi.org/10.3390/ma18040797