Advanced Strategies for Enhancing the Biocompatibility and Antibacterial Properties of Implantable Structures

Abstract

1. Introduction

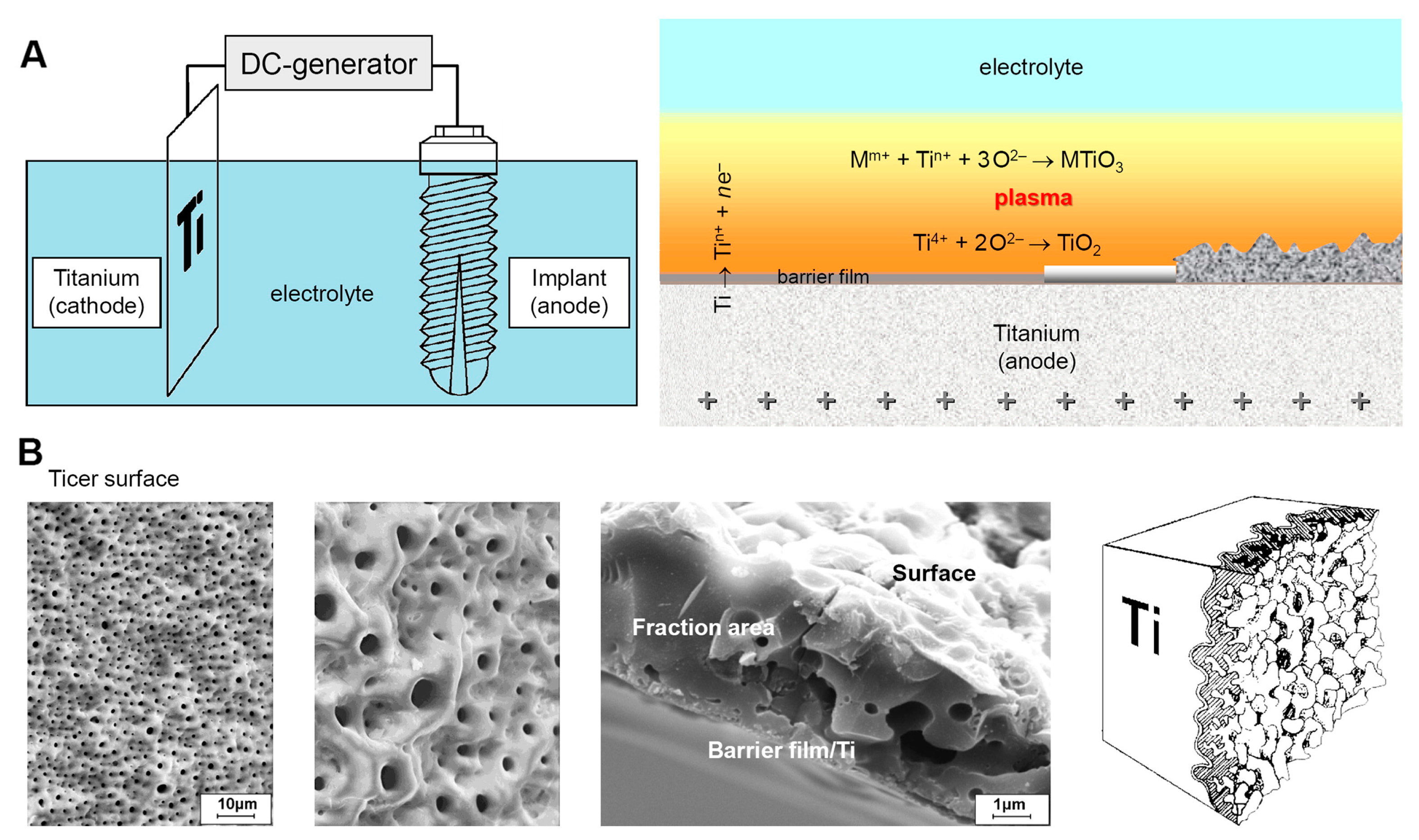

2. Osseointegration and Surface Quality Management

Reconciling Conflicting Findings on Surface Roughness and Coating Compositions

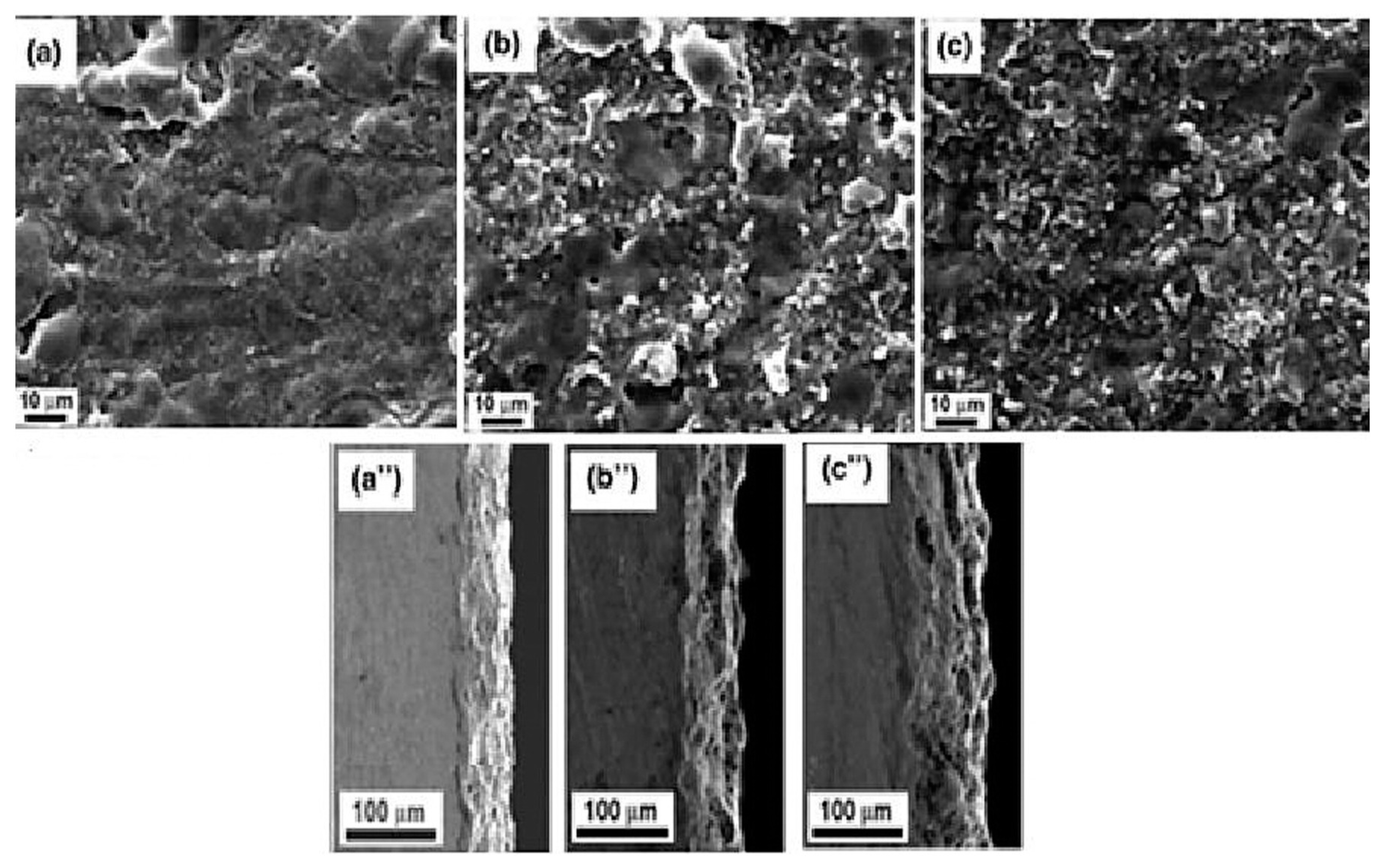

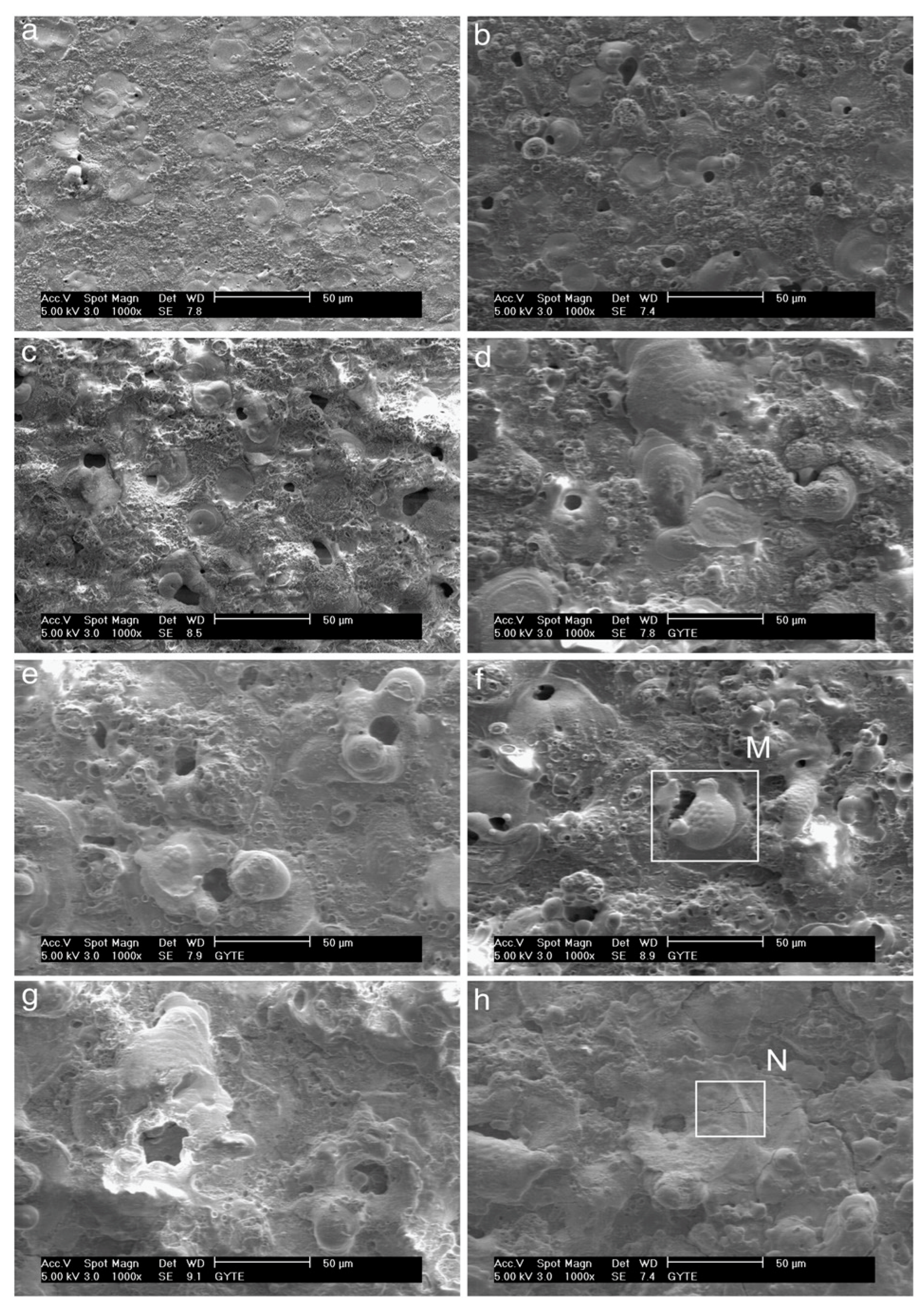

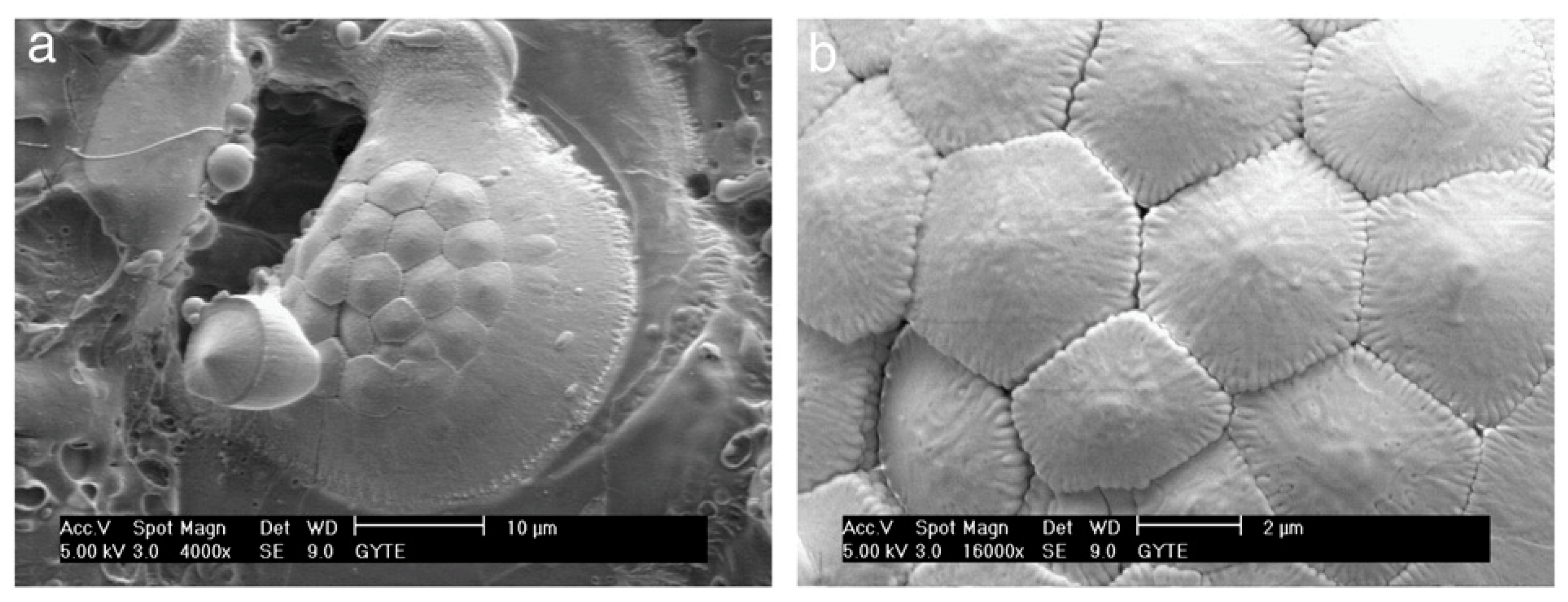

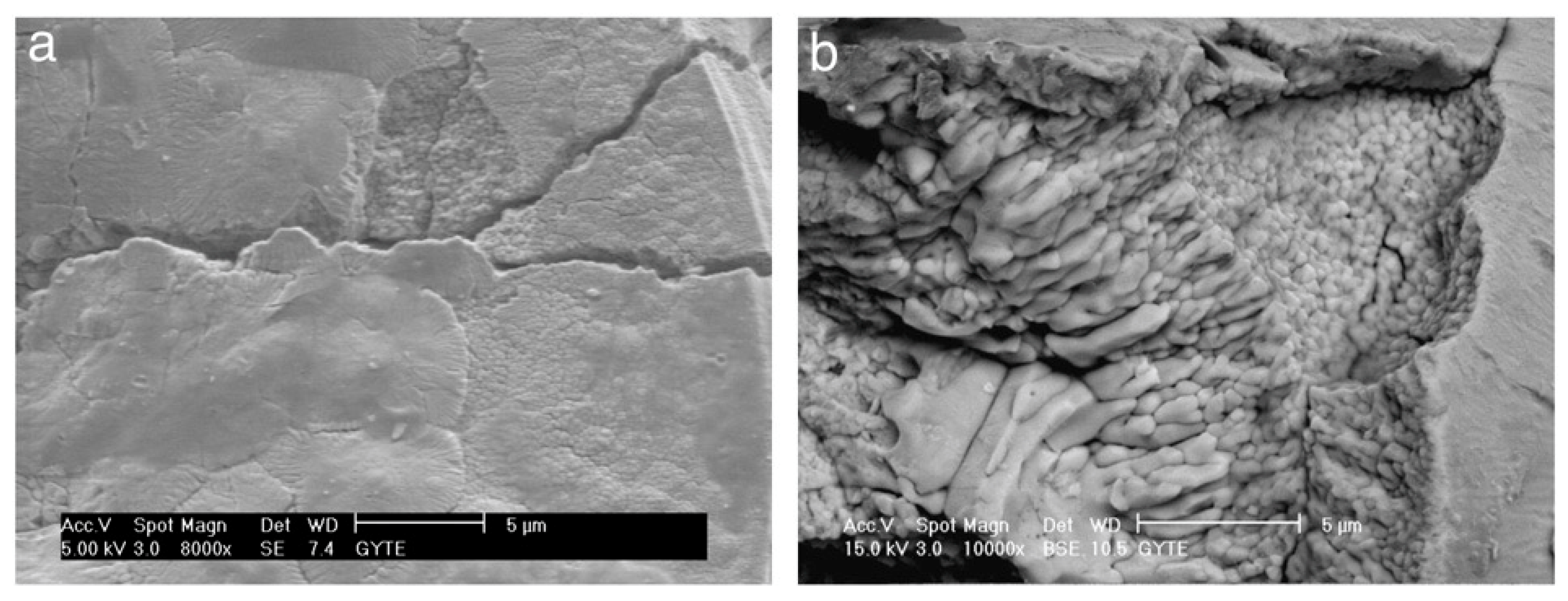

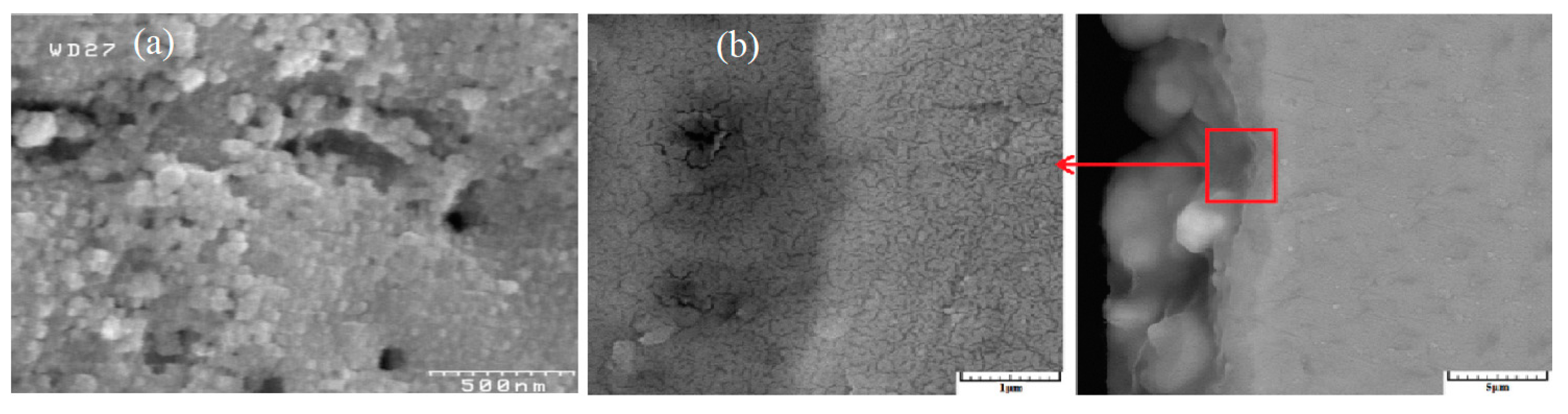

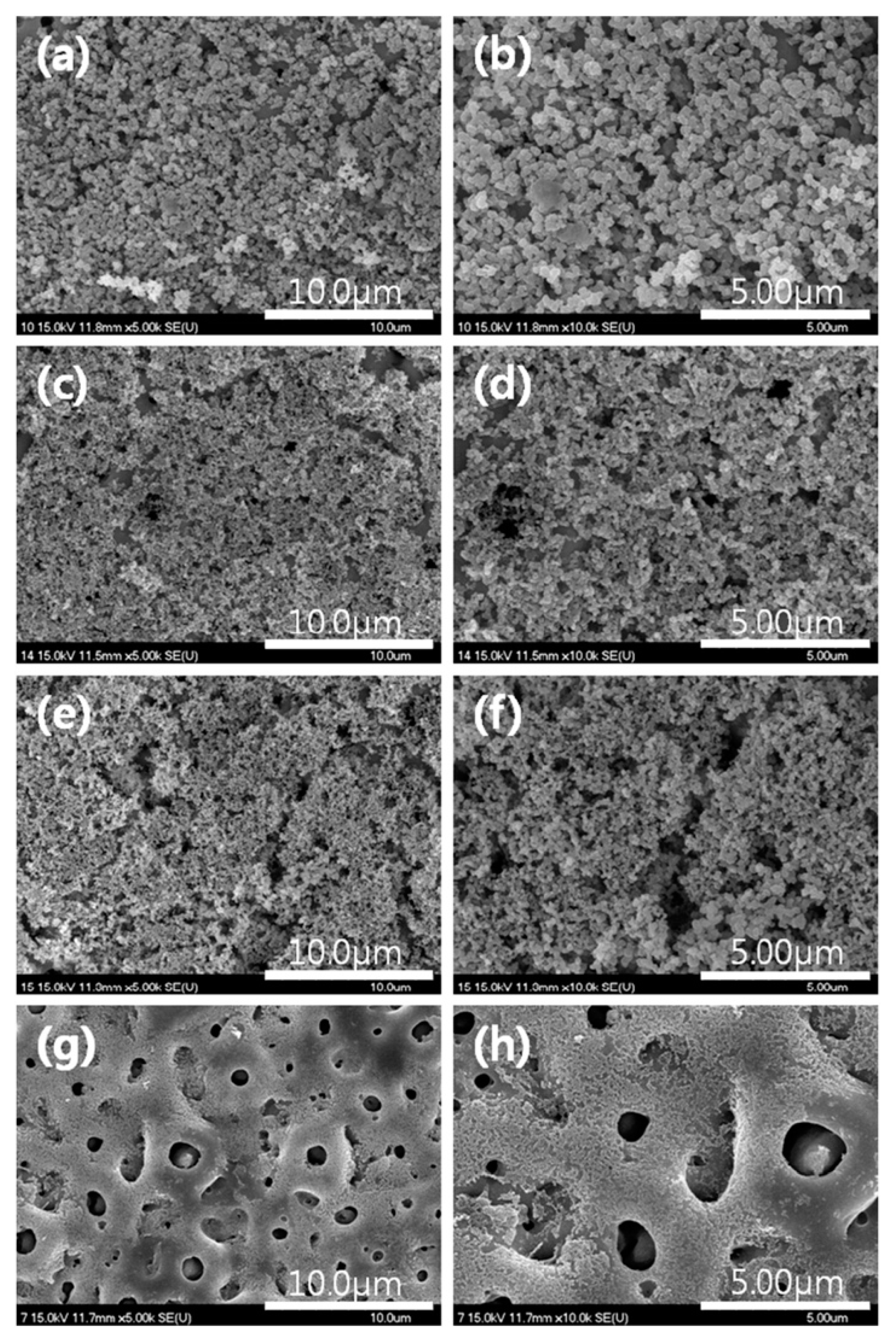

3. PEO, Aspects of Morphology

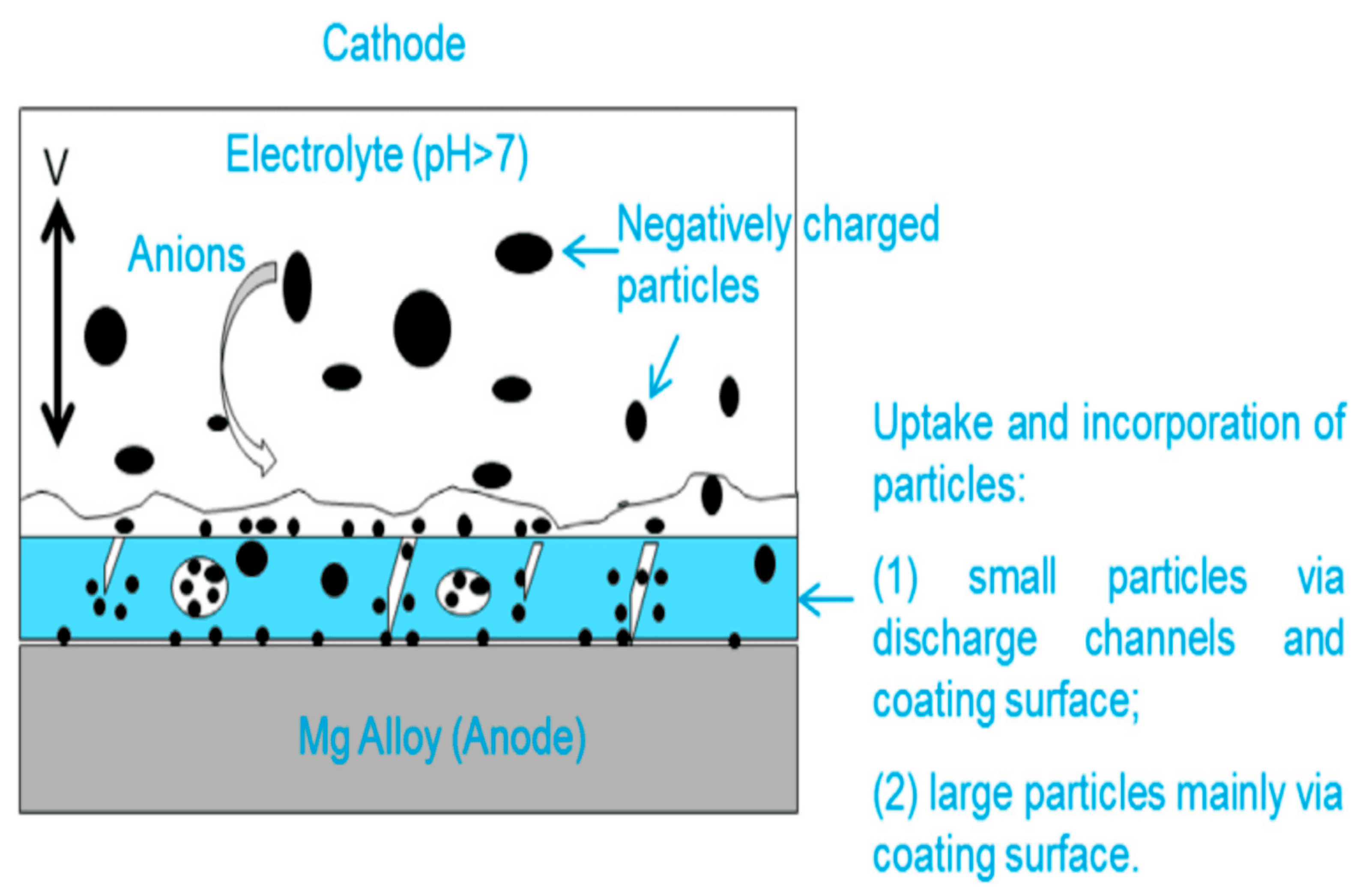

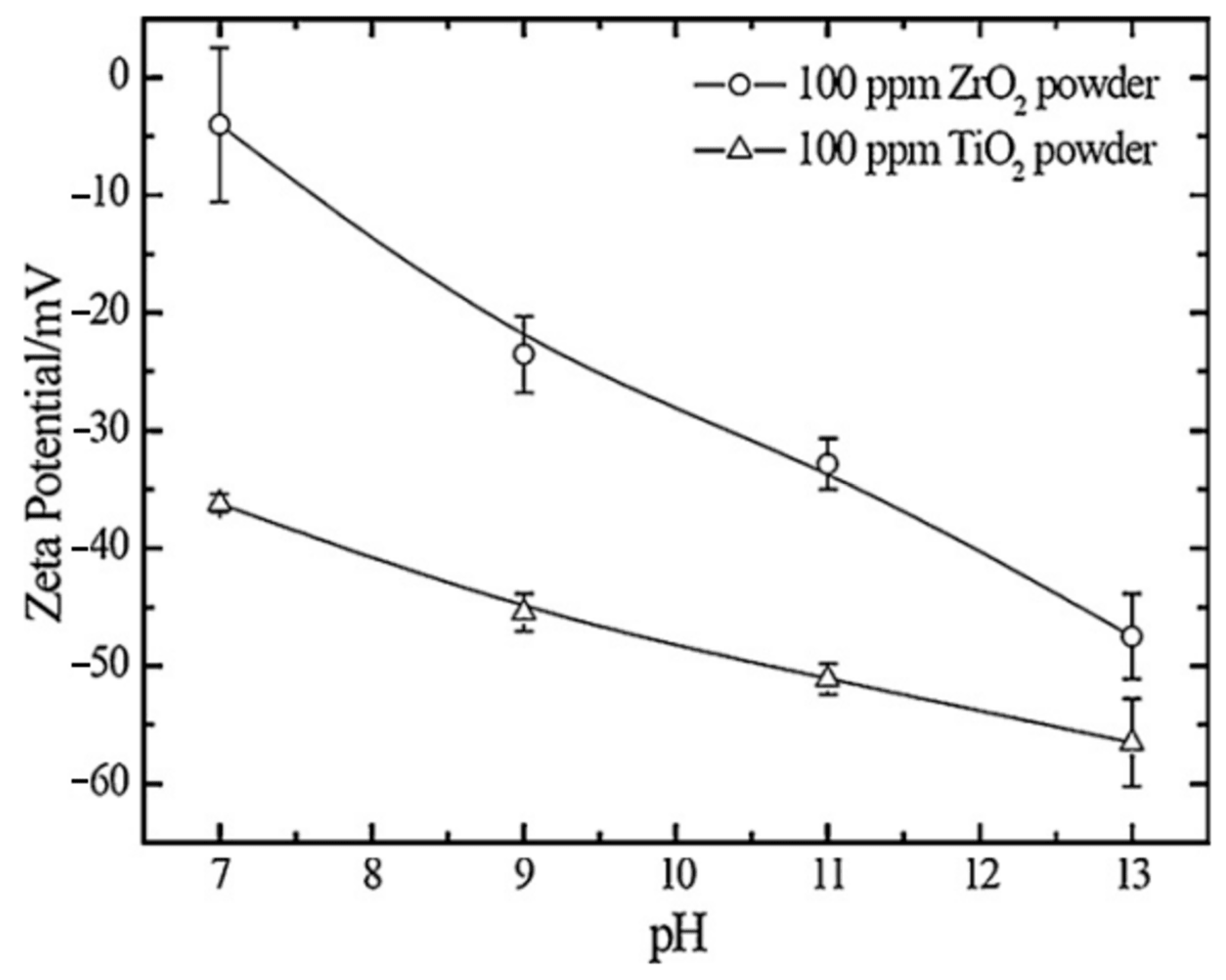

4. Effect of Adding Particles on Coating Composition, Microstructure, and Morphology

5. Coating Thickness

6. Crystallinity Features

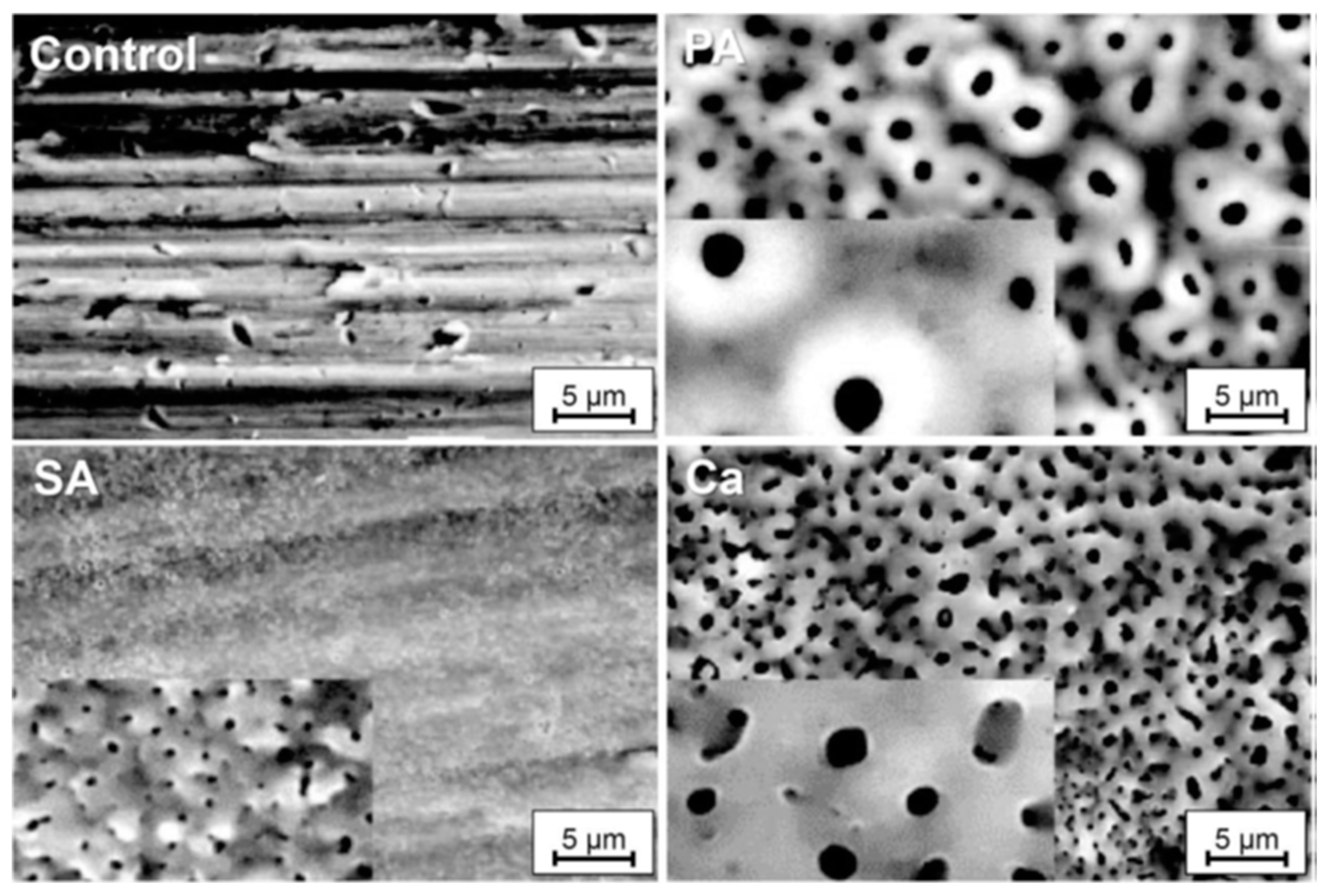

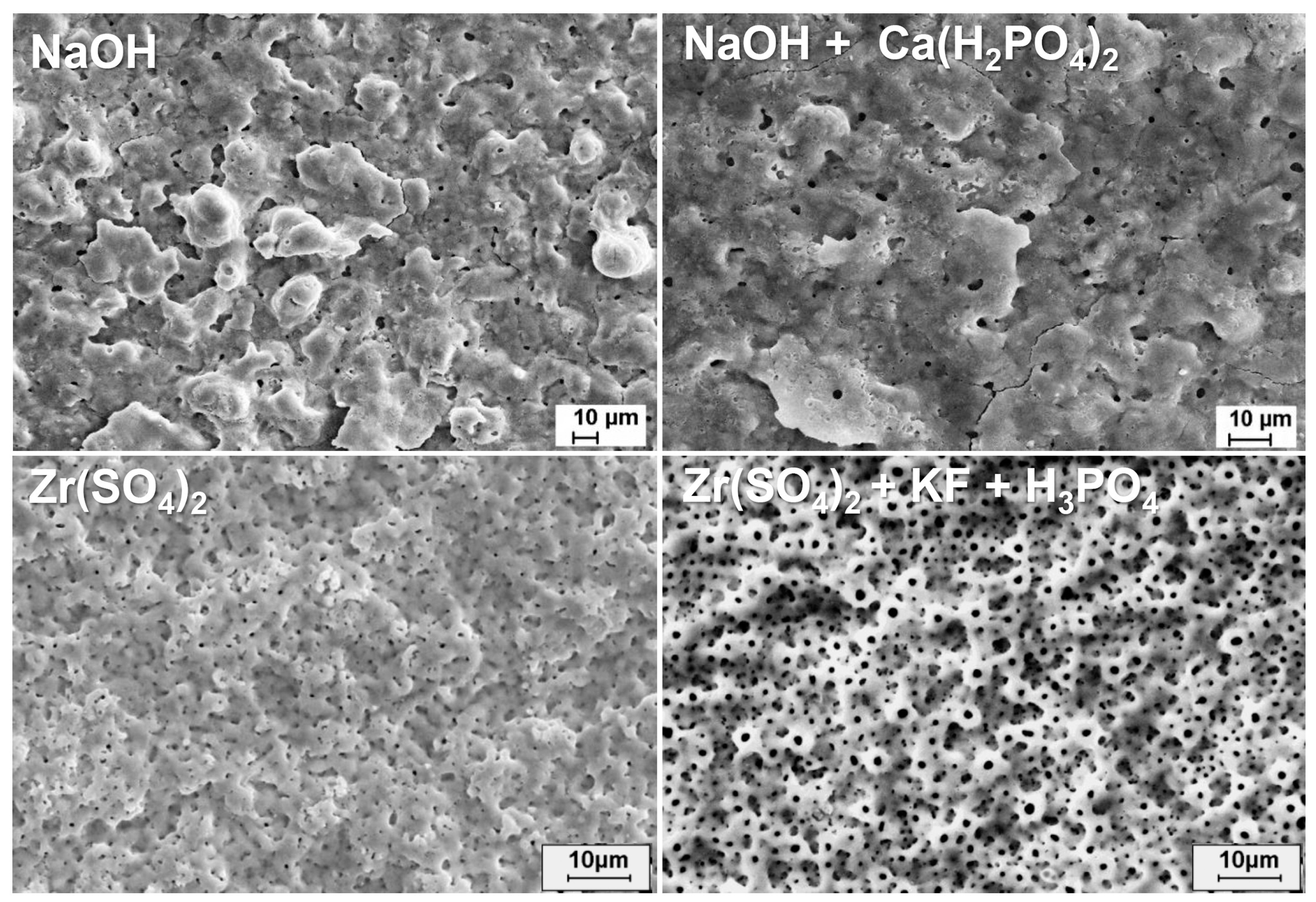

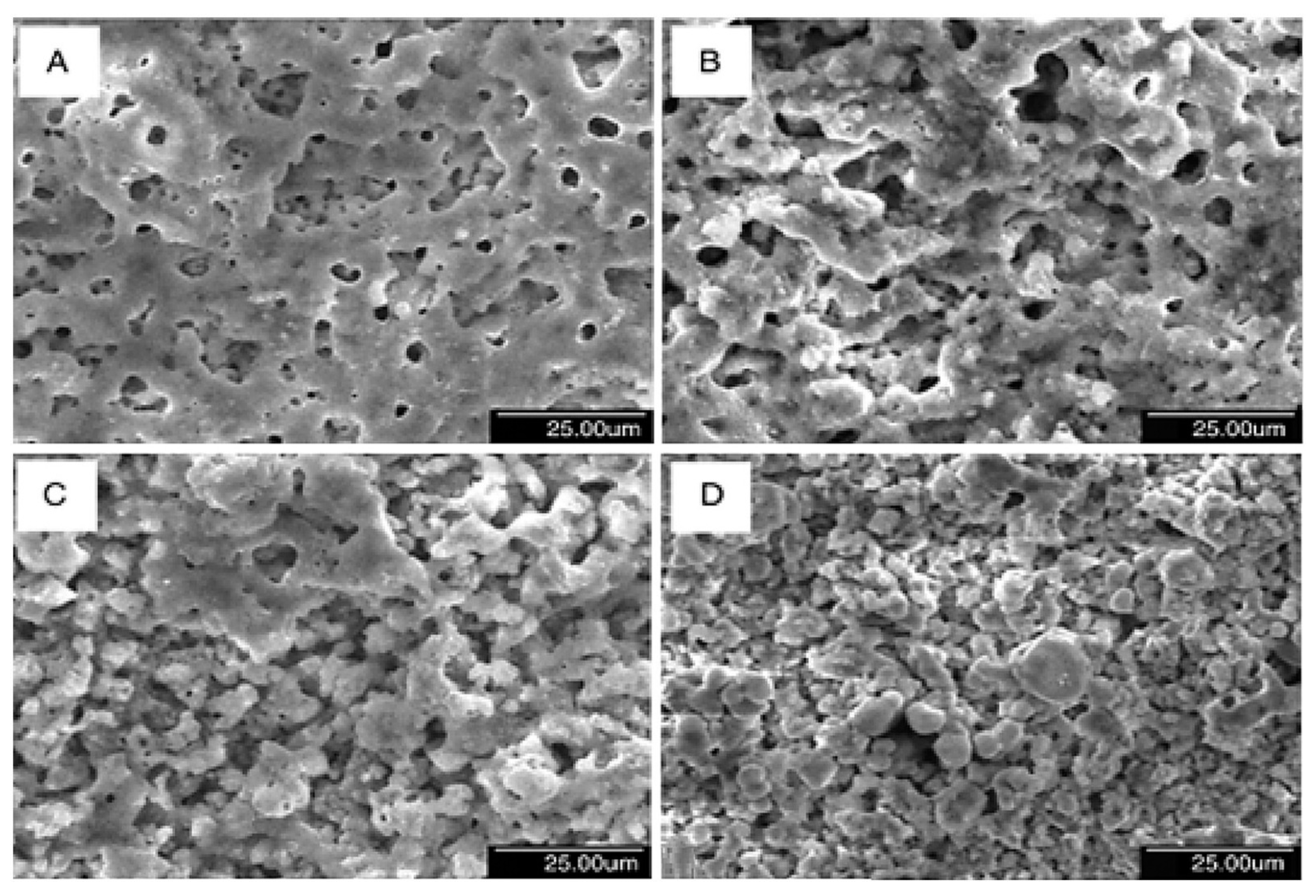

- The morphological characteristics of the surface during PEO are significantly influenced by the spark’s size and shape, as well as the chemical composition of the anodizing solution.

- Anodic coatings produced in the P-Si solution exhibited lower porosity than those formed in other solutions, enhanced corrosion resistance, and increased hardness. Conversely, coatings created in the P-S solution demonstrated high surface porosity, with a morphology resembling bone structures. In the P solution, circular pore structures were predominantly observed.

- The anatase crystalline phase was the dominant structure in anodic coatings developed with the P and P-Si electrodes, with only a tiny amount of the rutile phase present. In contrast, the primary crystalline phase in coatings formed in the P-S solution was distinctly different.

- Potentiostatic coatings outperformed those produced under galvanostatic control in terms of tribological properties. This was particularly evident in the anodic coatings obtained in the P solution at 250 V and in the P-Si solution at 400 V, both of which exhibited the lowest wear rates [387].

7. PEO Using Microparticles and Elements

8. PEO—Aspects of Surface Strength

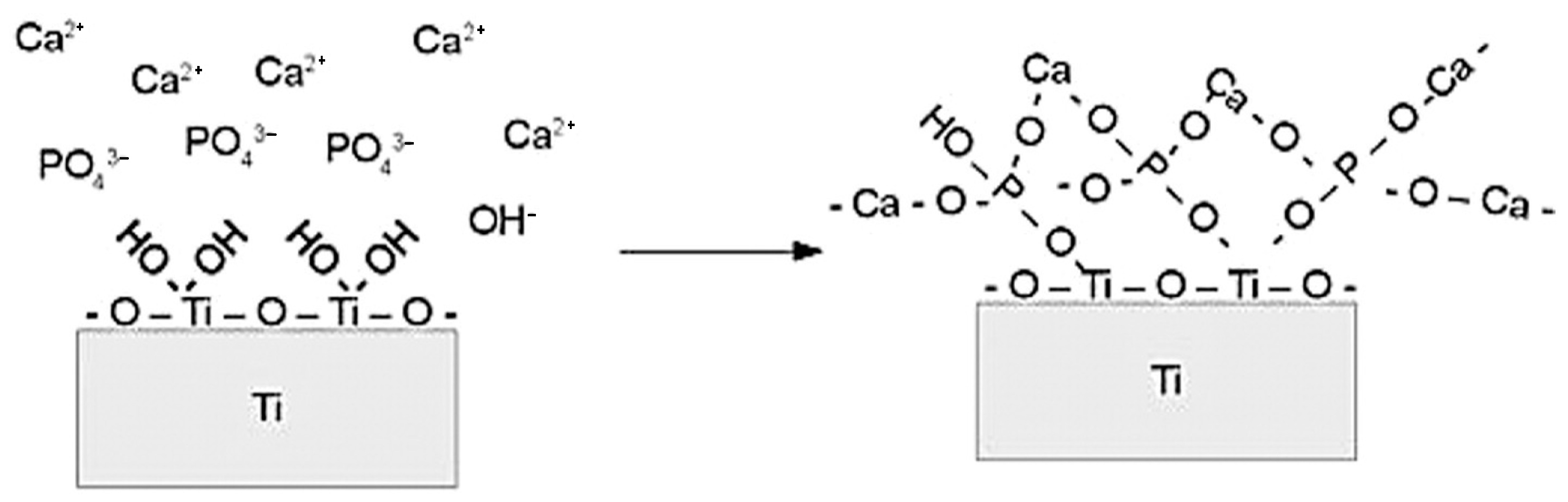

9. Plasma Electrolytic Oxidation Method Calcium-Phosphate-Base Composite Layer via PEO

10. PEO—Antibacterial Effect

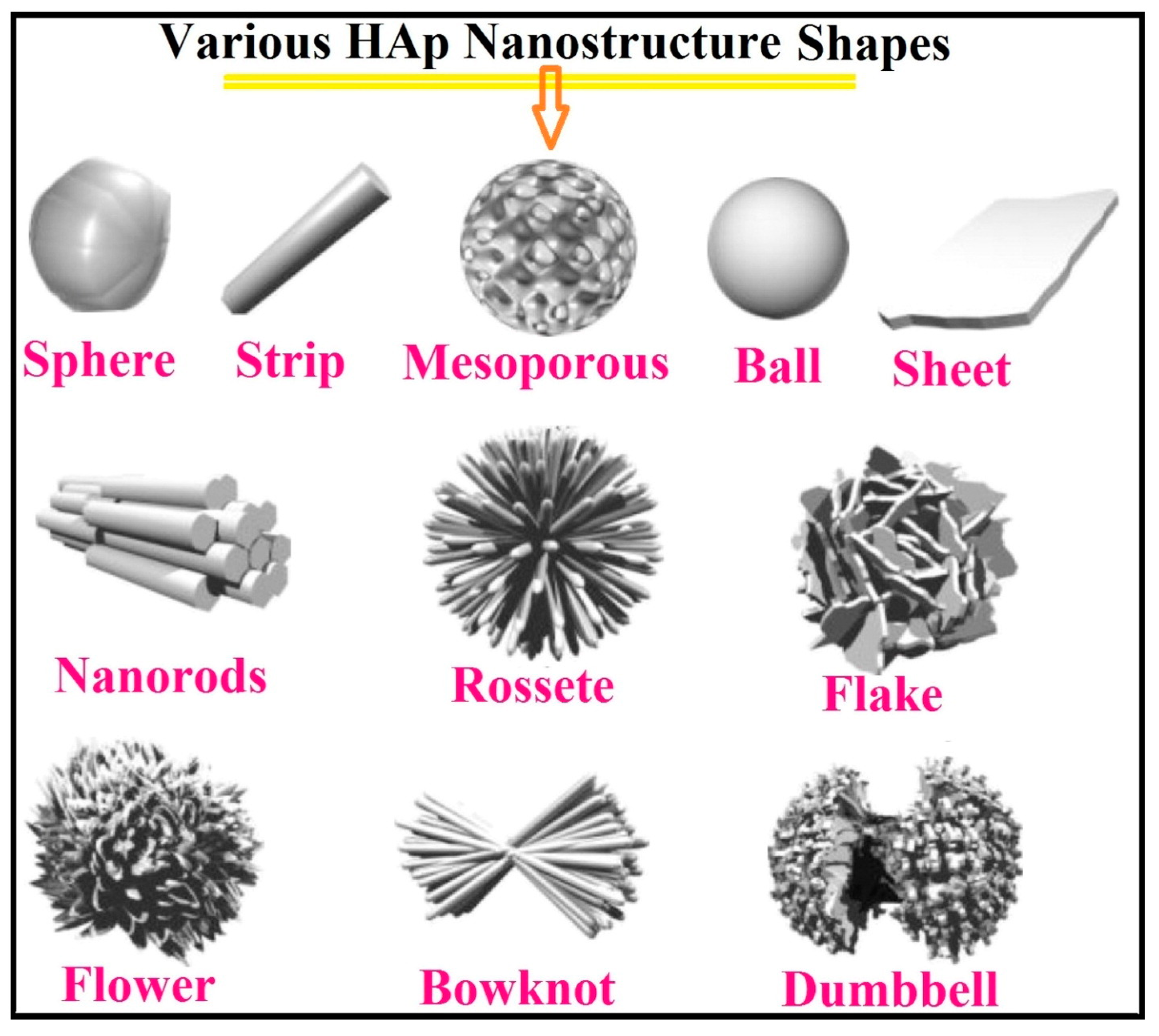

11. PEO with the Inclusion of Nanocomponents

12. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.; Liao, X.; Fok, A.; Ning, C.; Ng, P.; Wang, Y. Effect of Crystalline Phase Changes in Titania (TiO2) Nanotube Coatings on Platelet Adhesion and Activation. Mater. Sci. Eng. C 2018, 82, 91–101. [Google Scholar] [CrossRef]

- Mishchenko, O.; Solodovnik, O.; Oleshko, O. Osteointegration of Dental Implants with Different Surface Types. Bukovinian Med. Bull. 2020, 24, 79–89. [Google Scholar] [CrossRef]

- Mouhyi, J.; Dohan Ehrenfest, D.M.; Albrektsson, T. The Peri-Implantitis: Implant Surfaces, Microstructure, and Physicochemical Aspects. Clin. Implant Dent. Relat. Res. 2012, 14, 170–183. [Google Scholar] [CrossRef] [PubMed]

- Carmona, G.; Rodriguez, A.; Juarez, D.; Corzo, G.; Villegas, E. Improved Protease Stability of the Antimicrobial Peptide Pin2 Substituted with D-Amino Acids. Protein J. 2013, 32, 456–466. [Google Scholar] [CrossRef] [PubMed]

- Smeets, R.; Henningsen, A.; Jung, O.; Heiland, M.; Hammächer, C.; Stein, J.M. Definition, Etiology, Prevention and Treatment of Peri-Implantitis—A Review. Head Face Med. 2014, 10, 34. [Google Scholar] [CrossRef] [PubMed]

- Arciola, C.R.; Campoccia, D.; Ehrlich, G.D.; Montanaro, L. Biofilm-Based Implant Infections in Orthopaedics. Adv. Exp. Med. Biol. 2015, 830, 29–46. [Google Scholar] [CrossRef]

- Prathapachandran, J.; Suresh, N. Management of Peri-Implantitis. Dent. Res. J. 2012, 9, 516–521. [Google Scholar] [CrossRef] [PubMed]

- Katsikogianni, M.; Missirlis, Y.F.; Harris, L.; Douglas, J. Concise Review of Mechanisms of Bacterial Adhesion to Biomaterials and of Techniques Used in Estimating Bacteria-Material Interactions. Eur. Cells Mater. 2004, 8, 37–57. [Google Scholar] [CrossRef]

- Orapiriyakul, W.; Young, P.S.; Damiati, L.; Tsimbouri, P.M. Antibacterial Surface Modification of Titanium Implants in Orthopaedics. J. Tissue Eng. 2018, 9, 2041731418789838. [Google Scholar] [CrossRef]

- Romanò, C.L.; Scarponi, S.; Gallazzi, E.; Romanò, D.; Drago, L. Antibacterial Coating of Implants in Orthopaedics and Trauma: A Classification Proposal in an Evolving Panorama. J. Orthop. Surg. Res. 2015, 10, 157. [Google Scholar] [CrossRef] [PubMed]

- Hasan, J.; Crawford, R.J.; Ivanova, E.P. Antibacterial Surfaces: The Quest for a New Generation of Biomaterials. Trends Biotechnol. 2013, 31, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Tsimbouri, P.M.; Fisher, L.; Holloway, N.; Sjostrom, T.; Nobbs, A.H.; Meek, R.M.D.; Su, B.; Dalby, M.J. Osteogenic and Bactericidal Surfaces from Hydrothermal Titania Nanowires on Titanium Substrates. Sci. Rep. 2016, 6, 36857. [Google Scholar] [CrossRef] [PubMed]

- Colon, G.; Ward, B.C.; Webster, T.J. Increased Osteoblast and Decreased Staphylococcus epidermidis Functions on Nanophase ZnO and TiO2. J. Biomed. Mater. Res. Part A 2006, 78A, 595–604. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Xiong, W.; Fang, Z.; Guan, H.; Wu, W.; Li, Y.; Zhang, Y.; Alvarez, M.M.; Gao, B.; Huo, K.; et al. Strontium (Sr) and Silver (Ag) Loaded Nanotubular Structures with Combined Osteoinductive and Antimicrobial Activities. Acta Biomater. 2016, 31, 388–400. [Google Scholar] [CrossRef] [PubMed]

- Huo, K.; Zhang, X.; Wang, H.; Zhao, L.; Liu, X.; Chu, P.K. Osteogenic Activity and Antibacterial Effects on Titanium Surfaces Modified with Zn-Incorporated Nanotube Arrays. Biomaterials 2013, 34, 3467–3478. [Google Scholar] [CrossRef]

- Ferraris, S.; Spriano, S.; Miola, M.; Bertone, E.; Allizond, V.; Cuffini, A.M.; Banche, G. Surface Modification of Titanium Surfaces through a Modified Oxide Layer and Embedded Silver Nanoparticles: Effect of Reducing/Stabilizing Agents on Precipitation and Properties of the Nanoparticles. Surf. Coat. Technol. 2018, 344, 177–189. [Google Scholar] [CrossRef]

- Mas-Moruno, C.; Espanol, M.; Montufar, E.B.; Mestres, G.; Aparicio, C.; Gil, F.J.; Ginebra, M.P. Bioactive Ceramic and Metallic Surfaces for Bone Engineering. Biomater. Surf. Sci. 2013, 12, 337–374. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Sharonova, A.A.; Chernousova, S.; Prymak, O.; Loza, K.; Tkachev, M.S.; Shulepov, I.A.; Epple, M.; Surmenev, R.A. Incorporation of Silver Nanoparticles into Magnetron-Sputtered Calcium Phosphate Layers on Titanium as an Antibacterial Coating. Colloids Surf. B Biointerfaces 2017, 156, 104–113. [Google Scholar] [CrossRef] [PubMed]

- Besinis, A.; Hadi, S.D.; Le, H.R.; Tredwin, C.; Handy, R.D. Antibacterial Activity and Biofilm Inhibition by Surface Modified Titanium Alloy Medical Implants Following Application of Silver, Titanium Dioxide and Hydroxyapatite Nanocoatings. Nanotoxicology 2017, 11, 327–338. [Google Scholar] [CrossRef]

- Harrison, R.G. On the Stereotropism of Embryonic Cells. Science 1911, 34, 279–281. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, C.D.W.; Dalby, M.; Curtis, A.S.G. Making Structures for Cell Engineering. Eur. Cells Mater. 2004, 8, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Denis, F.A.; Hanarp, P.; Sutherland, D.S.; Gold, J.; Mustin, C.; Rouxhet, P.G.; Dufrêne, Y.F. Protein Adsorption on Model Surfaces with Controlled Nanotopography and Chemistry. Langmuir 2002, 18, 819–828. [Google Scholar] [CrossRef]

- Meyer, E.; Hegner, M.; Gerber, C.; Güntherodt, H.-J. Proceedings of the International Conference on Nanoscience and Technology (ICN&T 2006) (30 July to 4 August 2006, Basel, Switzerland). J. Phys. Conf. Ser. 2007, 61, E01. [Google Scholar] [CrossRef]

- Yim, E.K.F.; Reano, R.M.; Pang, S.W.; Yee, A.F.; Chen, C.S.; Leong, K.W. Nanopattern-Induced Changes in Morphology and Motility of Smooth Muscle Cells. Biomaterials 2005, 26, 5405–5413. [Google Scholar] [CrossRef] [PubMed]

- Rottmar, M.; Müller, E.; Guimond-Lischer, S.; Stephan, M.; Berner, S.; Maniura-Weber, K. Assessing the Osteogenic Potential of Zirconia and Titanium Surfaces with an Advanced in Vitro Model. Dent. Mater. 2019, 35, 74–86. [Google Scholar] [CrossRef] [PubMed]

- Patelli, A.; Mussano, F.; Brun, P.; Genova, T.; Ambrosi, E.; Michieli, N.; Mattei, G.; Scopece, P.; Moroni, L. Nanoroughness, Surface Chemistry, and Drug Delivery Control by Atmospheric Plasma Jet on Implantable Devices. ACS Appl. Mater. Interfaces 2018, 10, 39512–39523. [Google Scholar] [CrossRef] [PubMed]

- Kong, F.; Nie, Z.; Liu, Z.; Hou, S.; Ji, J. Developments of Nano-TiO2 Incorporated Hydroxyapatite/PEEK Composite Strut for Cervical Reconstruction and Interbody Fusion after Corpectomy with Anterior Plate Fixation. J. Photochem. Photobiol. B Biol. 2018, 187, 120–125. [Google Scholar] [CrossRef]

- Xu, R.; Hu, X.; Yu, X.; Wan, S.; Wu, F.; Ouyang, J.; Deng, F. Micro-/Nano-Topography of Selective Laser Melting Titanium Enhances Adhesion and Proliferation and Regulates Adhesion-Related Gene Expressions of Human Gingival Fibroblasts and Human Gingival Epithelial Cells. Int. J. Nanomed. 2018, 13, 5045–5057. [Google Scholar] [CrossRef] [PubMed]

- Smeets, R.; Stadlinger, B.; Schwarz, F.; Beck-Broichsitter, B.; Jung, O.; Precht, C.; Kloss, F.; Gröbe, A.; Heiland, M.; Ebker, T. Impact of Dental Implant Surface Modifications on Osseointegration. Biomed. Res. Int. 2016, 2016, 6285620. [Google Scholar] [CrossRef]

- Jiang, X.; Yao, Y.; Tang, W.; Han, D.; Zhang, L.; Zhao, K.; Wang, S.; Meng, Y. Design of Dental Implants at Materials Level: An Overview. J. Biomed. Mater. Res. Part A 2020, 108, 1634–1661. [Google Scholar] [CrossRef]

- Liu, X.Y.; Sawant, P.D. Mechanism of the Formation of Self-Organized Microstructures in Soft Functional Materials. Adv. Mater. 2002, 14, 421–426. [Google Scholar] [CrossRef]

- Vercaigne, S.; Wolke, J.G.C.; Naert, I.; Jansen, J.A. Histomorphometrical and Mechanical Evaluation of Titanium Plasma-Spray-Coated Implants Placed in the Cortical Bone of Goats. J. Biomed. Mater. Res. 1998, 41, 41–48. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing. In Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier Inc.: Amsterdam, The Netherlands, 2010; pp. 301–331. ISBN 9780815520375. [Google Scholar]

- LeClair, P.; Berera, G.P.; Moodera, J.S. Titanium Nitride Thin Films Obtained by a Modified Physical Vapor Deposition Process. Thin Solid Films 2000, 1-2, 9–15. [Google Scholar] [CrossRef]

- Arregui, M.; Latour, F.; Gil, F.J.; Pérez, R.A.; Giner-Tarrida, L.; Delgado, L.M. Ion Release from Dental Implants, Prosthetic Abutments and Crowns under Physiological and Acidic Conditions. Coatings 2021, 11, 98. [Google Scholar] [CrossRef]

- Mitamura, Y.; Hosooka, K.; Matsumoto, T.; Otaki, K.; Sakai, K.; Tanabe, T.; Yuta, T.; Mikami, T. Development of a Ceramic Heart Valve. J. Biomater. Appl. 1989, 4, 33–55. [Google Scholar] [CrossRef]

- Ghadai, R.K.; Logesh, K.; Čep, R.; Chohan, J.S.; Kalita, K. Influence of Deposition Time on Titanium Nitride (TiN) Thin Film Coating Synthesis Using Chemical Vapour Deposition. Materials 2023, 16, 4611. [Google Scholar] [CrossRef]

- Ballo, A.M.; Bjöörn, D.; Åstrand, M.; Palmquist, A.; Lausmaa, J.; Thomsen, P. Bone Response to Physical-Vapour-Deposited Titanium Dioxide Coatings on Titanium Implants. Clin. Oral Implants Res. 2013, 24, 1009–1017. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Ren, X.; Wang, B.; Cai, Y.; Song, Q.; Wan, Y. Coating-Thickness-Dependent Physical Properties and Cutting Temperature for Cutting Inconel 718 with TiAlN Coated Tools. J. Adv. Res. 2021, 38, 191–199. [Google Scholar] [CrossRef] [PubMed]

- Jinno, Y.; Jimbo, R.; Hjalmarsson, J.; Johansson, K.; Stavropoulos, A.; Becktor, J.P. Impact of Surface Contamination of Implants with Saliva during Placement in Augmented Bone Defects in Sheep Calvaria. Br. J. Oral Maxillofac. Surg. 2019, 57, 41–46. [Google Scholar] [CrossRef]

- Korzec, D.; Andres, T.; Brandes, E.; Nettesheim, S. Visualization of Activated Area on Polymers for Evaluation of Atmospheric Pressure Plasma Jets. Polymers 2021, 13, 2711. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Gong, H.; Li, D.; Dong, L.; Zhao, M.; Wan, R.; Gu, H. Ag+ Implantation Induces Mechanical Properties, Cell Adhesion and Antibacterial Effects of TiN/Ag Multilayers In Vitro. Nanomedicine 2017, 12, 2257–2268. [Google Scholar] [CrossRef] [PubMed]

- Kasemo, B.; Lausmaa, J. Biomaterial and Implant Surfaces: On the Role of Cleanliness, Contamination, and Preparation Procedures. J. Biomed. Mater. Res. 1988, 22, 145–158. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.C.; Pilliar, R.M.; Metson, J.B.; McIntyre, N.S. Dental Implant Materials. II. Preparative Procedures and Surface Spectroscopic Studies. J. Biomed. Mater. Res. 1991, 25, 1069–1084. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.C.; Pilliar, R.M.; Chernecky, R. Dental Implant Materials. I. Some Effects of Preparative Procedures on Surface Topography. J. Biomed. Mater. Res. 1991, 25, 1045–1068. [Google Scholar] [CrossRef] [PubMed]

- Aronsson, B.-O.; Lausmaa, J.; Kasemo, B. Glow Discharge Plasma Treatment for Surface Cleaning and Modification of Metallic Biomaterials. J. Biomed. Mater. Res. 1997, 35, 49–73. [Google Scholar] [CrossRef]

- Sobiecki, J.R.; Wierzchoń, T.; Rudnicki, J. The Influence of Glow Discharge Nitriding, Oxynitriding and Carbonitriding on Surface Modification of Ti-1Al-1Mn Titanium Alloy. Vacuum 2001, 64, 41–46. [Google Scholar] [CrossRef]

- Jagielski, J.; Piatkowska, A.; Aubert, P.; Thomé, L.; Turos, A.; Abdul Kader, A. Ion Implantation for Surface Modification of Biomaterials. Surf. Coat. Technol. 2006, 22-23, 6355–6361. [Google Scholar] [CrossRef]

- Shi, M.; Mo, W.; Qi, H.; Ni, Y.; Wang, R.; Shen, K.; Zhang, F.; Jiang, S.; Zhang, X.; Chen, L.; et al. Oxygen Ion Implantation Improving Cell Adhesion on Titanium Surfaces through Increased Attraction of Fibronectin PHSRN Domain. Adv. Healthc. Mater. 2022, 11, 2101983. [Google Scholar] [CrossRef] [PubMed]

- Chen, K. Bonding Characteristics of TiC and TiN. Model. Numer. Simul. Mater. Sci. 2013, 3, 7–11. [Google Scholar] [CrossRef]

- Hanawa, T.; Ukai, H.; Murakami, K. X-Ray Photoelectron Spectroscopy of Calcium-Ion-Implanted Titanium. J. Electron Spectros. Relat. Phenom. 1993, 63, 347–354. [Google Scholar] [CrossRef]

- Yang, P.; Huang, N.; Leng, Y.X.; Chen, J.Y.; Sun, H.; Wang, J.; Chen, F.; Chu, P.K. In Vivo Study of Ti–O Thin Film Fabricated by PIII. Surf. Coat. Technol. 2002, 156, 284–288. [Google Scholar] [CrossRef]

- Berberich, F.; Matz, W.; Kreissig, U.; Richter, E.; Schell, N.; Möller, W. Structural Characterisation of Hardening of Ti–Al–V Alloys after Nitridation by Plasma Immersion Ion Implantation. Appl. Surf. Sci. 2001, 179, 13–19. [Google Scholar] [CrossRef]

- Wen, F.; Dai, H.; Huang, N.; Sun, H.; Leng, Y.X.; Chu, P.K. Controlling Synthesis of Ti–O/Ti–N Gradient Films by PIII. Surf. Coat. Technol. 2002, 156, 208–213. [Google Scholar] [CrossRef]

- Yatsuzuka, M.; Miki, S.; Morita, R.; Azuma, K.; Fujiwara, E.; Uchida, H. Enhanced Corrosion Resistance of TiN Prepared by Plasma-Based Ion Implantation. Vacuum 2000, 59, 330–337. [Google Scholar] [CrossRef]

- Krupa, D.; Jezierska, E.; Baszkiewicz, J.; Wierzchoń, T.; Barcz, A.; Gawlik, G.; Jagielski, J.; Sobczak, J.W.; Biliński, A.; Larisch, B. Effect of Carbon Ion Implantation on the Structure and Corrosion Resistance of OT-4-0 Titanium Alloy. Surf. Coat. Technol. 1999, 114, 250–259. [Google Scholar] [CrossRef]

- Hanawa, T.; Kamiura, Y.; Yamamoto, S.; Kohgo, T.; Amemiya, A.; Ukai, H.; Murakami, K.; Asaoka, K. Early Bone Formation around Calcium-Ion-Implanted Titanium Inserted into Rat Tibia. J. Biomed. Mater. Res. 1997, 36, 131–136. [Google Scholar] [CrossRef]

- Hanawa, T. In Vivo Metallic Biomaterials and Surface Modification. Mater. Sci. Eng. A 1999, 267, 260–266. [Google Scholar] [CrossRef]

- Yoshinari, M.; Oda, Y.; Ueki, H.; Yokose, S. Immobilization of Bisphosphonates on Surface Modified Titanium. Biomaterials 2001, 22, 709–715. [Google Scholar] [CrossRef] [PubMed]

- Krupa, D.; Baszkiewicz, J.; Kozubowski, J.A.; Barcz, A.; Sobczak, J.W.; Biliński, A.; Lewandowska-Szumieł, M.; Rajchel, B. Effect of Phosphorus-Ion Implantation on the Corrosion Resistance and Biocompatibility of Titanium. Biomaterials 2002, 23, 3329–3340. [Google Scholar] [CrossRef]

- Tsyganov, I.; Wieser, E.; Matz, W.; Reuther, H.; Richter, E. Modification of the Ti–6Al–4V Alloy by Ion Implantation of Calcium and/or Phosphorus. Surf. Coat. Technol. 2002, 158-159, 318–323. [Google Scholar] [CrossRef]

- Wieser, E.; Tsyganov, I.; Matz, W.; Reuther, H.; Oswald, S.; Pham, T.; Richter, E. Modification of Titanium by Ion Implantation of Calcium and/or Phosphorus. Surf. Coat. Technol. 1999, 111, 103–109. [Google Scholar] [CrossRef]

- Baumann, H.; Bethge, K.; Bilger, G.; Jones, D.; Symietz, I. Thin Hydroxyapatite Surface Layers on Titanium Produced by Ion Implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2002, 196, 286–292. [Google Scholar] [CrossRef]

- Pham, M.T.; Maitz, M.F.; Matz, W.; Reuther, H.; Richter, E.; Steiner, G. Promoted Hydroxyapatite Nucleation on Titanium Ion-Implanted with Sodium. Thin Solid Films 2000, 379, 50–56. [Google Scholar] [CrossRef]

- Maitz, M.F.; Pham, M.T.; Matz, W.; Reuther, H.; Steiner, G. Promoted Calcium-Phosphate Precipitation from Solution on Titanium for Improved Biocompatibility by Ion Implantation. Surf. Coat. Technol. 2002, 158-159, 151–156. [Google Scholar] [CrossRef]

- Maitz, M.F.; Pham, M.T.; Matz, W.; Reuther, H.; Steiner, G.; Richter, E. Ion Beam Treatment of Titanium Surfaces for Enhancing Deposition of Hydroxyapatite from Solution. Biomol. Eng. 2002, 19, 269–272. [Google Scholar] [CrossRef] [PubMed]

- Yoshinari, M.; Oda, Y.; Kato, T.; Okuda, K. Influence of Surface Modifications to Titanium on Antibacterial Activity In Vitro. Biomaterials 2001, 22, 2043–2048. [Google Scholar] [CrossRef]

- Balasundaram, G.; Webster, T.J. A Perspective on Nanophase Materials for Orthopedic Implant Applications. J. Mater. Chem. 2006, 16, 3737–3745. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Dobrzańska-Danikiewicz, A.D.; Dobrzański, L.B. Effect of Biomedical Materials in the Implementation of a Long and Healthy Life Policy. Processes 2021, 9, 865. [Google Scholar] [CrossRef]

- Zhang, L.; Webster, T.J. Nanotechnology and Nanomaterials: Promises for Improved Tissue Regeneration. Nano Today 2009, 4, 66–80. [Google Scholar] [CrossRef]

- Stevens, M.M.; George, J.H. Exploring and Engineering the Cell Surface Interface. Science 2005, 310, 1135–1138. [Google Scholar] [CrossRef] [PubMed]

- Wilson, C.J.; Clegg, R.E.; Leavesley, D.I.; Pearcy, M.J. Mediation of Biomaterial-Cell Interactions by Adsorbed Proteins: A Review. Tissue Eng. 2005, 11, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.J.; Ejiofor, J.U. Increased Osteoblast Adhesion on Nanophase Metals: Ti, Ti6Al4V, and CoCrMo. Biomaterials 2004, 25, 4731–4739. [Google Scholar] [CrossRef] [PubMed]

- Price, R.L.; Waid, M.C.; Haberstroh, K.M.; Webster, T.J. Selective Bone Cell Adhesion on Formulations Containing Carbon Nanofibers. Biomaterials 2003, 24, 1877–1887. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.J.; Smith, T.A. Increased Osteoblast Function on PLGA Composites Containing Nanophase Titania. J. Biomed. Mater. Res. A 2005, 74, 677–686. [Google Scholar] [CrossRef] [PubMed]

- Manjubala, I.; Scheler, S.; Bössert, J.; Jandt, K.D. Mineralisation of Chitosan Scaffolds with Nano-Apatite Formation by Double Diffusion Technique. Acta Biomater. 2006, 2, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Desai, T.A. Micro- and Nanoscale Structures for Tissue Engineering Constructs. Med. Eng. Phys. 2000, 22, 595–606. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.J.; Ergun, C.; Doremus, R.H.; Siegel, R.W.; Bizios, R. Enhanced Osteoclast-like Cell Functions on Nanophase Ceramics. Biomaterials 2001, 22, 1327–1333. [Google Scholar] [CrossRef] [PubMed]

- Elias, K.L.; Price, R.L.; Webster, T.J. Enhanced Functions of Osteoblasts on Nanometer Diameter Carbon Fibers. Biomaterials 2002, 23, 3279–3287. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.J.; Hellenmeyer, E.L.; Price, R.L. Increased Osteoblast Functions on Theta+delta Nanofiber Alumina. Biomaterials 2005, 26, 953–960. [Google Scholar] [CrossRef] [PubMed]

- Gutwein, L.G.; Webster, T.J. Increased Viable Osteoblast Density in the Presence of Nanophase Compared to Conventional Alumina and Titania Particles. Biomaterials 2004, 25, 4175–4183. [Google Scholar] [CrossRef] [PubMed]

- Balasundaram, G.; Sato, M.; Webster, T.J. Using Hydroxyapatite Nanoparticles and Decreased Crystallinity to Promote Osteoblast Adhesion Similar to Functionalizing with RGD. Biomaterials 2006, 27, 2798–2805. [Google Scholar] [CrossRef] [PubMed]

- Ergun, C.; Liu, H.; Webster, T.J.; Olcay, E.; Yilmaz, Ş.; Sahin, F.C. Increased Osteoblast Adhesion on Nanoparticulate Calcium Phosphates with Higher Ca/P Ratios. J. Biomed. Mater. Res. A 2008, 85, 236–241. [Google Scholar] [CrossRef] [PubMed]

- Brammer, K.S.; Oh, S.; Cobb, C.J.; Bjursten, L.M.; van der Heyde, H.; Jin, S. Improved Bone-Forming Functionality on Diameter-Controlled TiO2 Nanotube Surface. Acta Biomater. 2009, 5, 3215–3223. [Google Scholar] [CrossRef]

- Oh, S.; Daraio, C.; Chen, L.H.; Pisanic, T.R.; Fiñones, R.R.; Jin, S. Significantly Accelerated Osteoblast Cell Growth on Aligned TiO2 Nanotubes. J. Biomed. Mater. Res. Part A 2006, 78A, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Popat, K.C.; Daniels, R.H.; Dubrow, R.S.; Hardev, V.; Desai, T.A. Nanostructured Surfaces for Bone Biotemplating Applications. J. Orthop. Res. 2006, 24, 619–627. [Google Scholar] [CrossRef] [PubMed]

- Popat, K.C.; Leoni, L.; Grimes, C.A.; Desai, T.A. Influence of Engineered Titania Nanotubular Surfaces on Bone Cells. Biomaterials 2007, 28, 3188–3197. [Google Scholar] [CrossRef] [PubMed]

- Swan, E.E.L.; Popat, K.C.; Grimes, C.A.; Desai, T.A. Fabrication and Evaluation of Nanoporous Alumina Membranes for Osteoblast Culture. J. Biomed. Mater. Res. A 2005, 72, 288–295. [Google Scholar] [CrossRef] [PubMed]

- McNamara, L.E.; McMurray, R.J.; Biggs, M.J.P.; Kantawong, F.; Oreffo, R.O.C.; Dalby, M.J. Nanotopographical Control of Stem Cell Differentiation. J. Tissue Eng. 2010, 2010, 120623. [Google Scholar] [CrossRef] [PubMed]

- Li, W.J.; Laurencin, C.T.; Caterson, E.J.; Tuan, R.S.; Ko, F.K. Electrospun Nanofibrous Structure: A Novel Scaffold for Tissue Engineering. J. Biomed. Mater. Res. 2002, 60, 613–621. [Google Scholar] [CrossRef]

- Khanna, A.; Zamani, M.; Huang, N.F. Extracellular Matrix-Based Biomaterials for Cardiovascular Tissue Engineering. J. Cardiovasc. Dev. Dis. 2021, 8, 137. [Google Scholar] [CrossRef] [PubMed]

- Sato, M.; Slamovich, E.B.; Webster, T.J. Enhanced Osteoblast Adhesion on Hydrothermally Treated Hydroxyapatite/Titania/Poly(Lactide-Co-Glycolide) Sol–Gel Titanium Coatings. Biomaterials 2005, 26, 1349–1357. [Google Scholar] [CrossRef] [PubMed]

- Sato, M.; Sambito, M.A.; Aslani, A.; Kalkhoran, N.M.; Slamovich, E.B.; Webster, T.J. Increased Osteoblast Functions on Undoped and Yttrium-Doped Nanocrystalline Hydroxyapatite Coatings on Titanium. Biomaterials 2006, 27, 2358–2369. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.J.; Chen, J.; Karageorgiou, V.; Altman, G.H.; Kaplan, D.L. Human Bone Marrow Stromal Cell Responses on Electrospun Silk Fibroin Mats. Biomaterials 2004, 25, 1039–1047. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.J.; Park, J.; Valluzzi, R.; Cebe, P.; Kaplan, D.L. Biomaterial Films of Bombyx Mori Silk Fibroin with Poly(Ethylene Oxide). Biomacromolecules 2004, 5, 711–717. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Webster, T.J. Anodization: A Promising Nano-Modification Technique of Titanium Implants for Orthopedic Applications. J. Nanosci. Nanotechnol. 2006, 6, 2682–2692. [Google Scholar] [CrossRef]

- Yao, C.; Slamovich, E.B.; Webster, T.J. Enhanced Osteoblast Functions on Anodized Titanium with Nanotube-like Structures. J. Biomed. Mater. Res. A 2008, 85, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Khang, D.; Lu, J.; Yao, C.; Haberstroh, K.M.; Webster, T.J. The Role of Nanometer and Sub-Micron Surface Features on Vascular and Bone Cell Adhesion on Titanium. Biomaterials 2008, 29, 970–983. [Google Scholar] [CrossRef] [PubMed]

- Gimble, J.M.; Guilak, F.; Nuttall, M.E.; Sathishkumar, S.; Vidal, M.; Bunnell, B.A. In Vitro Differentiation Potential of Mesenchymal Stem Cells. Transfus. Med. Hemother. 2008, 35, 228–238. [Google Scholar] [CrossRef] [PubMed]

- Usmaniya, N.; Shishir, R.; Ponnilavan, V.; Rameshbabu, N. Development of hydroxyapatite/bioactive glass incorporated chitosan layer on plasma electrolytic oxidised ZM21 alloy for temporary implant applications. J. Alloys Compd. 2024, 1004, 175723. [Google Scholar] [CrossRef]

- Dolatshahi-Pirouz, A.; Jensen, T.; Kraft, D.C.; Foss, M.; Kingshott, P.; Hansen, J.L.; Larsen, A.N.; Chevallier, J.; Besenbacher, F. Fibronectin Adsorption, Cell Adhesion, and Proliferation on Nanostructured Tantalum Surfaces. ACS Nano 2010, 4, 2874–2882. [Google Scholar] [CrossRef]

- Yin, Z.; Chen, X.; Chen, J.L.; Shen, W.L.; Hieu Nguyen, T.M.; Gao, L.; Ouyang, H.W. The Regulation of Tendon Stem Cell Differentiation by the Alignment of Nanofibers. Biomaterials 2010, 31, 2163–2175. [Google Scholar] [CrossRef] [PubMed]

- Dalby, M.J.; Gadegaard, N.; Tare, R.; Andar, A.; Riehle, M.O.; Herzyk, P.; Wilkinson, C.D.W.; Oreffo, R.O.C. The Control of Human Mesenchymal Cell Differentiation Using Nanoscale Symmetry and Disorder. Nat. Mater. 2007, 6, 997–1003. [Google Scholar] [CrossRef] [PubMed]

- Yim, E.K.F.; Darling, E.M.; Kulangara, K.; Guilak, F.; Leong, K.W. Nanotopography-Induced Changes in Focal Adhesions, Cytoskeletal Organization, and Mechanical Properties of Human Mesenchymal Stem Cells. Biomaterials 2010, 31, 1299–1306. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Bauer, S.; Von Der Mark, K.; Schmuki, P. Nanosize and Vitality: TiO2 Nanotube Diameter Directs Cell Fate. Nano Lett. 2007, 7, 1686–1691. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.Q.; Jiang, X.Q.; Zhang, F.Q.; Xu, L. The Effect of Anatase TiO2 Nanotube Layers on MC3T3-E1 Preosteoblast Adhesion, Proliferation, and Differentiation. J. Biomed. Mater. Res. Part A 2010, 94A, 1012–1022. [Google Scholar] [CrossRef]

- Oh, S.; Brammer, K.S.; Li, Y.S.J.; Teng, D.; Engler, A.J.; Chien, S.; Jin, S. Stem Cell Fate Dictated Solely by Altered Nanotube Dimension. Proc. Natl. Acad. Sci. USA 2009, 106, 2130–2135. [Google Scholar] [CrossRef] [PubMed]

- Mori, H.; Ogura, Y.; Enomoto, K.; Hara, M.; Maurstad, G.; Stokke, B.T.; Kitamura, S. Dense Carbon-Nanotube Coating Scaffolds Stimulate Osteogenic Differentiation of Mesenchymal Stem Cells. PLoS ONE 2020, 15, e0225589. [Google Scholar] [CrossRef]

- Chen, C.S. Mechanotransduction—A Field Pulling Together? J. Cell Sci. 2008, 121, 3285–3292. [Google Scholar] [CrossRef]

- Orr, A.W.; Helmke, B.P.; Blackman, B.R.; Schwartz, M.A. Mechanisms of Mechanotransduction. Dev. Cell 2006, 10, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Han, M.K.L.; de Rooij, J. Converging and Unique Mechanisms of Mechanotransduction at Adhesion Sites. Trends Cell Biol. 2016, 26, 612–623. [Google Scholar] [CrossRef]

- Vitkov, L.; Hartl, D.; Hannig, M. Is Osseointegration Inflammation-Triggered? Med. Hypotheses 2016, 93, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Luu, T.U.; Gott, S.C.; Woo, B.W.K.; Rao, M.P.; Liu, W.F. Micro- and Nanopatterned Topographical Cues for Regulating Macrophage Cell Shape and Phenotype. ACS Appl. Mater. Interfaces 2015, 7, 28665–28672. [Google Scholar] [CrossRef] [PubMed]

- Östberg, A.K.; Dahlgren, U.; Sul, Y.T.; Johansson, C.B. Inflammatory Cytokine Release Is Affected by Surface Morphology and Chemistry of Titanium Implants. J. Mater. Sci. Mater. Med. 2015, 26, 155. [Google Scholar] [CrossRef] [PubMed]

- Neacsu, P.; Mazare, A.; Schmuki, P.; Cimpean, A. Attenuation of the Macrophage Inflammatory Activity by TiO2 Nanotubes via Inhibition of MAPK and NF-ΚB Pathways. Int. J. Nanomed. 2015, 10, 6455–6467. [Google Scholar] [CrossRef]

- Ma, Q.L.; Fang, L.; Jiang, N.; Zhang, L.; Wang, Y.; Zhang, Y.M.; Chen, L.H. Bone Mesenchymal Stem Cell Secretion of SRANKL/OPG/M-CSF in Response to Macrophage-Mediated Inflammatory Response Influences Osteogenesis on Nanostructured Ti Surfaces. Biomaterials 2018, 154, 234–247. [Google Scholar] [CrossRef]

- Yao, S.; Feng, X.; Li, W.; Wang, L.N.; Wang, X. Regulation of RAW 264.7 Macrophages Behavior on Anodic TiO2 Nanotubular Arrays. Front. Mater. Sci. 2017, 11, 318–327. [Google Scholar] [CrossRef]

- Hotchkiss, K.M.; Reddy, G.B.; Hyzy, S.L.; Schwartz, Z.; Boyan, B.D.; Olivares-Navarrete, R. Titanium Surface Characteristics, Including Topography and Wettability, Alter Macrophage Activation. Acta Biomater. 2016, 31, 425–434. [Google Scholar] [CrossRef] [PubMed]

- Prasopthum, A.; Cooper, M.; Shakesheff, K.M.; Yang, J. Three-Dimensional Printed Scaffolds with Controlled Micro-/Nanoporous Surface Topography Direct Chondrogenic and Osteogenic Differentiation of Mesenchymal Stem Cells. ACS Appl. Mater. Interfaces 2019, 11, 18896–18906. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Bauer, S.; Schlegel, K.A.; Neukam, F.W.; der Von Mark, K.; Schmuki, P. TiO2 Nanotube Surfaces: 15 Nm—An Optimal Length Scale of Surface Topography for Cell Adhesion and Differentiation. Small 2009, 5, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Dulgar-Tulloch, A.J.; Bizios, R.; Siegel, R.W. Human Mesenchymal Stem Cell Adhesion and Proliferation in Response to Ceramic Chemistry and Nanoscale Topography. J. Biomed. Mater. Res. Part A 2009, 90A, 586–594. [Google Scholar] [CrossRef]

- Bauer, S.; Park, J.; von der Mark, K.; Schmuki, P. Improved Attachment of Mesenchymal Stem Cells on Super-Hydrophobic TiO2 Nanotubes. Acta Biomater. 2008, 4, 1576–1582. [Google Scholar] [CrossRef]

- Bauer, S.; Park, J.; Pittrof, A.; Song, Y.Y.; Von Der Mark, K.; Schmuki, P. Covalent Functionalization of TiO2 Nanotube Arrays with EGF and BMP-2 for Modified Behavior towards Mesenchymal Stem Cells. Integr. Biol. 2011, 3, 927–936. [Google Scholar] [CrossRef] [PubMed]

- Kodama, A.; Bauer, S.; Komatsu, A.; Asoh, H.; Ono, S.; Schmuki, P. Bioactivation of Titanium Surfaces Using Coatings of TiO2 Nanotubes Rapidly Pre-Loaded with Synthetic Hydroxyapatite. Acta Biomater. 2009, 5, 2322–2330. [Google Scholar] [CrossRef] [PubMed]

- Brammer, K.S.; Choi, C.; Frandsen, C.J.; Oh, S.; Johnston, G.; Jin, S. Comparative Cell Behavior on Carbon-Coated TiO2 Nanotube Surfaces for Osteoblasts vs. Osteo-Progenitor Cells. Acta Biomater. 2011, 7, 2697–2703. [Google Scholar] [CrossRef]

- Bauer, S.; Park, J.; Faltenbacher, J.; Berger, S.; Von Der Mark, K.; Schmuki, P. Size Selective Behavior of Mesenchymal Stem Cells on ZrO2 and TiO2 Nanotube Arrays. Integr. Biol. 2009, 1, 525–532. [Google Scholar] [CrossRef]

- Berger, S.; Faltenbacher, J.; Bauer, S.; Schmuki, P. Enhanced Self-Ordering of Anodic ZrO2 Nanotubes in Inorganic and Organic Electrolytes Using Two-Step Anodization. Phys. Status Solidi–Rapid Res. Lett. 2008, 2, 102–104. [Google Scholar] [CrossRef]

- Oliveira, N.T.C.; Biaggio, S.R.; Rocha-Filho, R.C.; Bocchi, N. Electrochemical Studies on Zirconium and Its Biocompatible Alloys Ti-50Zr at.% and Zr-2.5Nb Wt.% in Simulated Physiologic Media. J. Biomed. Mater. Res. Part A 2005, 74A, 397–407. [Google Scholar] [CrossRef] [PubMed]

- Lischer, S.; Körner, E.; Balazs, D.J.; Shen, D.; Wick, P.; Grieder, K.; Haas, D.; Heuberger, M.; Hegemann, D. Antibacterial Burst-Release from Minimal Ag-Containing Plasma Polymer Coatings. J. R. Soc. Interface 2011, 8, 1019–1030. [Google Scholar] [CrossRef]

- Li, X.; Qi, M.; Sun, X.; Weir, M.D.; Tay, F.R.; Oates, T.W.; Dong, B.; Zhou, Y.; Wang, L.; Xu, H.H.K. Surface Treatments on Titanium Implants via Nanostructured Ceria for Antibacterial and Anti-Inflammatory Capabilities. Acta Biomater. 2019, 94, 627–643. [Google Scholar] [CrossRef]

- Wang, M.; Tang, T. Surface Treatment Strategies to Combat Implant-Related Infection from the Beginning. J. Orthop. Transl. 2019, 17, 42. [Google Scholar] [CrossRef]

- Wang, Y.; Subbiahdoss, G.; Swartjes, J.; Van Der Mei, H.C.; Busscher, H.J.; Libera, M. Length-Scale Mediated Differential Adhesion of Mammalian Cells and Microbes. Adv. Funct. Mater. 2011, 21, 3916–3923. [Google Scholar] [CrossRef]

- Narendrakumar, K.; Kulkarni, M.; Addison, O.; Mazare, A.; Junkar, I.; Schmuki, P.; Sammons, R.; Iglič, A. Adherence of Oral Streptococci to Nanostructured Titanium Surfaces. Dent. Mater. 2015, 31, 1460–1468. [Google Scholar] [CrossRef] [PubMed]

- Ercan, B.; Taylor, E.; Alpaslan, E.; Webster, T.J. Diameter of Titanium Nanotubes Influences Anti-Bacterial Efficacy. Nanotechnology 2011, 22, 295102. [Google Scholar] [CrossRef]

- Kavathekar, R.S.; English, N.J.; MacElroy, J.M.D. Spatial Distribution of Adsorbed Water Layers at the TiO2 Rutile and Anatase Interfaces. Chem. Phys. Lett. 2012, 554, 102–106. [Google Scholar] [CrossRef]

- Xu, Q.; Li, X.; Jin, Y.; Sun, L.; Ding, X.; Liang, L.; Wang, L.; Nan, K.; Ji, J.; Chen, H.; et al. Bacterial self-defense antibiotics release from organic–inorganic hybrid multilayer films for long-term anti-adhesion and biofilm inhibition properties. Nanoscale 2017, 9, 19245–19254. [Google Scholar] [CrossRef]

- Bakhshandeh, S.; Gorgin Karaji, Z.; Lietaert, K.; Fluit, A.C.; Boel, C.H.E.; Vogely, H.C.; Vermonden, T.; Hennink, W.E.; Weinans, H.; Zadpoor, A.A.; et al. Simultaneous Delivery of Multiple Antibacterial Agents from Additively Manufactured Porous Biomaterials to Fully Eradicate Planktonic and Adherent Staphylococcus aureus. ACS Appl. Mater. Interfaces 2017, 9, 25691–25699. [Google Scholar] [CrossRef] [PubMed]

- Necula, B.S.; Van Leeuwen, J.P.T.M.; Fratila-Apachitei, L.E.; Zaat, S.A.J.; Apachitei, I.; Duszczyk, J. In Vitro Cytotoxicity Evaluation of Porous TiO2-Ag Antibacterial Coatings for Human Fetal Osteoblasts. Acta Biomater. 2012, 8, 4191–4197. [Google Scholar] [CrossRef]

- Jia, Z.; Xiu, P.; Xiong, P.; Zhou, W.; Cheng, Y.; Wei, S.; Zheng, Y.; Xi, T.; Cai, H.; Liu, Z.; et al. Additively Manufactured Macroporous Titanium with Silver-Releasing Micro-/Nanoporous Surface for Multipurpose Infection Control and Bone Repair—A Proof of Concept. ACS Appl. Mater. Interfaces 2016, 8, 28495–28510. [Google Scholar] [CrossRef] [PubMed]

- van Hengel, I.A.J.; Riool, M.; Fratila-Apachitei, L.E.; Witte-Bouma, J.; Farrell, E.; Zadpoor, A.A.; Zaat, S.A.J.; Apachitei, I. Selective Laser Melting Porous Metallic Implants with Immobilized Silver Nanoparticles Kill and Prevent Biofilm Formation by Methicillin-Resistant Staphylococcus aureus. Biomaterials 2017, 140, 1–15. [Google Scholar] [CrossRef]

- Amin Yavari, S.; Loozen, L.; Paganelli, F.L.; Bakhshandeh, S.; Lietaert, K.; Groot, J.A.; Fluit, A.C.; Boel, C.H.E.; Alblas, J.; Vogely, H.C.; et al. Antibacterial Behavior of Additively Manufactured Porous Titanium with Nanotubular Surfaces Releasing Silver Ions. ACS Appl. Mater. Interfaces 2016, 8, 17080–17089. [Google Scholar] [CrossRef] [PubMed]

- Gallardo-Godoy, A.; Muldoon, C.; Becker, B.; Elliott, A.G.; Lash, L.H.; Huang, J.X.; Butler, M.S.; Pelingon, R.; Kavanagh, A.M.; Ramu, S.; et al. Activity and Predicted Nephrotoxicity of Synthetic Antibiotics Based on Polymyxin B. J. Med. Chem. 2016, 59, 1068–1077. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.Q.; Fang, L.; Ling, J.; Ding, C.Z.; Kang, B.; Huang, C.Z. Nanotoxicity of Silver Nanoparticles to Red Blood Cells: Size Dependent Adsorption, Uptake, and Hemolytic Activity. Chem. Res. Toxicol. 2015, 28, 501–509. [Google Scholar] [CrossRef]

- Singh, R.P.; Ramarao, P. Cellular Uptake, Intracellular Trafficking and Cytotoxicity of Silver Nanoparticles. Toxicol. Lett. 2012, 213, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Panáček, A.; Kvítek, L.; Smékalová, M.; Večeřová, R.; Kolář, M.; Röderová, M.; Dyčka, F.; Šebela, M.; Prucek, R.; Tomanec, O.; et al. Bacterial Resistance to Silver Nanoparticles and How to Overcome It. Nat. Nanotechnol. 2017, 13, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Elbourne, A.; Crawford, R.J.; Ivanova, E.P. Nano-Structured Antimicrobial Surfaces: From Nature to Synthetic Analogues. J. Colloid Interface Sci. 2017, 508, 603–616. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Chen, A.; Song, X.; Brasch, M.E.; Henderson, J.H.; Ren, D. How Escherichia coli Lands and Forms Cell Clusters on a Surface: A New Role of Surface Topography. Sci. Rep. 2016, 6, 29516. [Google Scholar] [CrossRef]

- Crawford, R.J.; Webb, H.K.; Truong, V.K.; Hasan, J.; Ivanova, E.P. Surface Topographical Factors Influencing Bacterial Attachment. Adv. Colloid Interface Sci. 2012, 179–182, 142–149. [Google Scholar] [CrossRef]

- Song, F.; Brasch, M.E.; Wang, H.; Henderson, J.H.; Sauer, K.; Ren, D. How Bacteria Respond to Material Stiffness during Attachment: A Role of Escherichia coli Flagellar Motility. ACS Appl. Mater. Interfaces 2017, 9, 22176–22184. [Google Scholar] [CrossRef]

- Anselme, K.; Davidson, P.; Popa, A.M.; Giazzon, M.; Liley, M.; Ploux, L. The Interaction of Cells and Bacteria with Surfaces Structured at the Nanometre Scale. Acta Biomater. 2010, 6, 3824–3846. [Google Scholar] [CrossRef]

- Dobbenga, S.; Fratila-Apachitei, L.E.; Zadpoor, A.A. Nanopattern-Induced Osteogenic Differentiation of Stem Cells—A Systematic Review. Acta Biomater. 2016, 46, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Busscher, H.J.; Van Der Mei, H.C.; Subbiahdoss, G.; Jutte, P.C.; Van Den Dungen, J.J.A.M.; Zaat, S.A.J.; Schultz, M.J.; Grainger, D.W. Biomaterial-Associated Infection: Locating the Finish Line in the Race for the Surface. Sci. Transl. Med. 2012, 4, 153rv10. [Google Scholar] [CrossRef] [PubMed]

- Pham, V.T.H.; Truong, V.K.; Orlowska, A.; Ghanaati, S.; Barbeck, M.; Booms, P.; Fulcher, A.J.; Bhadra, C.M.; Buividas, R.; Baulin, V.; et al. Race for the Surface: Eukaryotic Cells Can Win. ACS Appl. Mater. Interfaces 2016, 8, 22025–22031. [Google Scholar] [CrossRef]

- Persat, A. Bacterial Mechanotransduction. Curr. Opin. Microbiol. 2017, 36, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Vorobyev, A.Y.; Guo, C. Femtosecond Laser Blackening of Platinum. J. Appl. Phys. 2008, 104, 053516. [Google Scholar] [CrossRef]

- Ardron, M.; Weston, N.; Hand, D. A Practical Technique for the Generation of Highly Uniform LIPSS. Appl. Surf. Sci. 2014, 313, 123–131. [Google Scholar] [CrossRef]

- Birnbaum, M. Semiconductor Surface Damage Produced by Ruby Lasers. J. Appl. Phys. 1965, 36, 3688–3689. [Google Scholar] [CrossRef]

- Baudach, S.; Bonse, J.; Kautek, W. Ablation Experiments on Polyimide with Femtosecond Laser Pulses. Appl. Phys. A Mater. Sci. Process. 1999, 69, S395–S398. [Google Scholar] [CrossRef]

- Bonse, J.; Sturm, H.; Schmidt, D.; Kautek, W. Chemical, Morphological and Accumulation Phenomena in Ultrashort-Pulse Laser Ablation of TiN in Air. Appl. Phys. A Mater. Sci. Process. 2000, 71, 657–665. [Google Scholar] [CrossRef]

- Simova, E.; Hnatovsky, C.; Taylor, R.S.; Rayner, D.M.; Corkum, P.B. Femtosecond Laser-Induced Long-Range Self-Organized Periodic Planar Nanocracks for Applications in Biophotonics. Photon Process. Microelectron. Photonics VI 2007, 6458, 317–330. [Google Scholar] [CrossRef]

- Shen, M.; Carey, J.E.; Crouch, C.H.; Kandyla, M.; Stone, H.A.; Mazur, E. High-Density Regular Arrays of Nanometer-Scale Rods Formed on Silicon Surfaces via Femtosecond Laser Irradiation in Water. Nano Lett. 2008, 8, 2087–2091. [Google Scholar] [CrossRef] [PubMed]

- Vorobyev, A.Y.; Makin, V.S.; Guo, C. Brighter Light Sources from Black Metal: Significant Increase in Emission Efficiency of Incandescent Light Sources. Phys. Rev. Lett. 2009, 102, 234301. [Google Scholar] [CrossRef]

- Wong, M.; Eulenberger, J.; Schenk, R.; Hunziker, E. Effect of Surface Topology on the Osseointegration of Implant Materials in Trabecular Bone. J. Biomed. Mater. Res. 1995, 29, 1567–1575. [Google Scholar] [CrossRef] [PubMed]

- Gotfredson, K.; Wennerberg, A.; Johansson, C.; Skovgaard, L.T.; Hjørting-Hansen, E. Anchorage of TiO2-Blasted, HA-Coated, and Machined Implants: An Experimental Study with Rabbits. J. Biomed. Mater. Res. 1995, 29, 1223–1231. [Google Scholar] [CrossRef]

- Gottlander, M.; Johansson, C.B.; Wennerberg, A.; Albrektsson, T.; Radin, S.; Ducheyne, P. Bone Tissue Reactions to an Electrophoretically Applied Calcium Phosphate Coating. Biomaterials 1997, 18, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Vercaigne, S.; Wolke, J.G.C.; Naert, I.; Jansen, J.A. Bone Healing Capacity of Titanium Plasma-Sprayed and Hydroxylapatite-Coated Oral Implants. Clin. Oral Implants Res. 1998, 9, 261–271. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Behaviour of Titanium and Titania-Based Ceramics In Vitro and In Vivo. Biomaterials 1993, 14, 229–232. [Google Scholar] [CrossRef] [PubMed]

- Yeo, I.S.; Han, J.S.; Yang, J.H. Biomechanical and Histomorphometric Study of Dental Implants with Different Surface Characteristics. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 87B, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Vercaigne, S.; Wolke, J.G.C.; Naert, I.; Jansen, J.A. A Histological Evaluation of TiO2-Gritblasted and Ca-P Magnetron Sputter Coated Implants Placed into the Trabecular Bone of the Goat: Part 2. Clin. Oral Implants Res. 2000, 11, 314–324. [Google Scholar] [CrossRef]

- Borsari, V.; Fini, M.; Giavaresi, G.; Rimodini, L.; Consolo, U.; Chiusoli, L.; Salito, A.; Volpert, A.; Chiesa, R.; Giardino, R. Osteointegration of Titanium and Hydroxyapatite Rough Surfaces in Healthy and Compromised Cortical and Trabecular Bone: In Vivo Comparative Study on Young, Aged, and Estrogen-Deficient Sheep. J. Orthop. Res. 2007, 25, 1250–1260. [Google Scholar] [CrossRef]

- Savarino, L.; Fini, M.; Ciapetti, G.; Cenni, E.; Granchi, D.; Baldini, N.; Greco, M.; Rizzi, G.; Giardino, R.; Giunti, A. Biologic Effects of Surface Roughness and Fluorhydroxyapatite Coating on Osteointegration in External Fixation Systems: An In Vivo Experimental Study. J. Biomed. Mater. Res. A 2003, 66, 652–661. [Google Scholar] [CrossRef] [PubMed]

- Mendes, V.C.; Moineddin, R.; Davies, J.E. The Effect of Discrete Calcium Phosphate Nanocrystals on Bone-Bonding to Titanium Surfaces. Biomaterials 2007, 28, 4748–4755. [Google Scholar] [CrossRef] [PubMed]

- Meirelles, L.; Currie, F.; Jacobsson, C.M.; Albrektsson, T.; Wennerberg, A. The Effect of Chemical and Nano Topographical Modifications on Early Stage of Osseointegration. Int. J. Oral Maxillofac. Implant. 2008, 23, 641–647. [Google Scholar]

- Schliephake, H.; Aref, A.; Scharnweber, D.; Rößler, S.; Sewing, A. Effect of Modifications of Dual Acid-Etched Implant Surfaces on Periimplant Bone Formation. Part II: Calcium Phosphate Coatings. Clin. Oral Implants Res. 2009, 20, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Wennerberg, A.; Albrektsson, T. Effects of Titanium Surface Topography on Bone Integration: A Systematic Review. Clin. Oral Implants Res. 2009, 20 (Suppl. S4), 172–184. [Google Scholar] [CrossRef]

- Cardoso, G.C.; Grandini, C.R.; Rau, J. V Comprehensive review of PEO coatings on titanium alloys for biomedical implants. J. Mater. Res. Technol. 2024, 31, 311–328. [Google Scholar] [CrossRef]

- Grizon, F.; Aguado, E.; Huré, G.; Baslé, M.F.; Chappard, D. Enhanced Bone Integration of Implants with Increased Surface Roughness: A Long Term Study in the Sheep. J. Dent. 2002, 30, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Becker, W.; Becker, B.E.; Ricci, A.; Bahat, O.; Rosenberg, E.; Rose, L.F.; Handelsman, M.; Israelson, H. A Prospective Multicenter Clinical Trial Comparing One- and Two-Stage Titanium Screw-Shaped Fixtures with One-Stage Plasma-Sprayed Solid-Screw Fixtures. Clin. Implant Dent. Relat. Res. 2000, 2, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Wennerberg, A.; Albrektsson, T.; Andersson, B.; Krol, J.J. A Histomorphometric and Removal Torque Study of Screw-Shaped Titanium Implants with Three Different Surface Topographies. Clin. Oral Implants Res. 1995, 6, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Roi, A.; Ardelean, L.C.; Roi, C.I.; Boia, E.R.; Boia, S.; Rusu, L.C. Oral Bone Tissue Engineering: Advanced Biomaterials for Cell Adhesion, Proliferation and Differentiation. Materials 2019, 12, 2296. [Google Scholar] [CrossRef] [PubMed]

- Cochran, D.L.; Schenk, R.K.; Lussi, A.; Higginbottom, F.L.; Buser, D. Bone Response to Unloaded and Loaded Titanium Implants with a Sandblasted and Acid-Etched Surface: A Histometric Study in the Canine Mandible. J. Biomed. Mater. Res. 1998, 40, 1–11. [Google Scholar] [CrossRef]

- López-valverde, N.; Flores-fraile, J.; Ramírez, J.M.; de Sousa, B.M.; Herrero-hernández, S.; López-valverde, A. Bioactive Surfaces vs. Conventional Surfaces in Titanium Dental Implants: A Comparative Systematic Review. J. Clin. Med. 2020, 9, 2047. [Google Scholar] [CrossRef] [PubMed]

- Beutner, R.; Michael, J.; Schwenzer, B.; Scharnweber, D. Biological nano-functionalization of titanium-based biomaterial surfaces: A flexible toolbox. J. R. Soc. Interface 2009, 7 (Suppl. S1), S93–S105. [Google Scholar] [CrossRef] [PubMed]

- Rai, M.; Yadav, A.; Gade, A. Silver Nanoparticles as a New Generation of Antimicrobials. Biotechnol. Adv. 2009, 27, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Alla, R.K.; Ginjupalli, K.; Upadhya, N.; Shammas, M.; Ravi, R.K.; Sekhar, R. Surface Roughness of Implants: A Review. Trends Biomater. Artif. Organs 2011, 25, 112–118. [Google Scholar]

- Gittens, R.A.; McLachlan, T.; Olivares-Navarrete, R.; Cai, Y.; Berner, S.; Tannenbaum, R.; Schwartz, Z.; Sandhage, K.H.; Boyan, B.D. The Effects of Combined Micron-/Submicron-Scale Surface Roughness and Nanoscale Features on Cell Proliferation and Differentiation. Biomaterials 2011, 32, 3395–3403. [Google Scholar] [CrossRef]

- Gittens, R.A.; Olivares-Navarrete, R.; McLachlan, T.; Cai, Y.; Hyzy, S.L.; Schneider, J.M.; Schwartz, Z.; Sandhage, K.H.; Boyan, B.D. Differential Responses of Osteoblast Lineage Cells to Nanotopographically-Modified, Microroughened Titanium–Aluminum–Vanadium Alloy Surfaces. Biomaterials 2012, 33, 8986–8994. [Google Scholar] [CrossRef] [PubMed]

- Gittens, R.A.; Olivares-Navarrete, R.; Cheng, A.; Anderson, D.M.; McLachlan, T.; Stephan, I.; Geis-Gerstorfer, J.; Sandhage, K.H.; Fedorov, A.G.; Rupp, F.; et al. The Roles of Titanium Surface Micro/Nanotopography and Wettability on the Differential Response of Human Osteoblast Lineage Cells. Acta Biomater. 2013, 9, 6268–6277. [Google Scholar] [CrossRef]

- Browne, M.; Gregson, P.J. Effect of Mechanical Surface Pretreatment on Metal Ion Release. Biomaterials 2000, 21, 385–392. [Google Scholar] [CrossRef] [PubMed]

- Song, W.W.; Heo, J.H.; Lee, J.H.; Park, Y.M.; Kim, Y.D. Osseointegration of Magnesium-Incorporated Sand-Blasted Acid-Etched Implant in the Dog Mandible: Resonance Frequency Measurements and Histomorphometric Analysis. Tissue Eng. Regen. Med. 2016, 13, 191–199. [Google Scholar] [CrossRef] [PubMed]

- Roy, M.; Bandyopadhyay, A.; Bose, S. Induction Plasma Sprayed Nano Hydroxyapatite Coatings on Titanium for Orthopaedic and Dental Implants. Surf. Coat. Technol. 2011, 205, 2785–2792. [Google Scholar] [CrossRef]

- Liao, H.; Fartash, B.; Li, J. Stability of Hydroxyapatite-Coatings on Titanium Oral Implants (IMZ). Clin. Oral Implants Res. 1997, 8, 68–72. [Google Scholar] [CrossRef]

- Peltola, T.; Patsi, M.; Rahiala, H.; Kangasniemi, I.; Yli-Urpo, A. Calcium Phosphate Induction by Sol-Gel-Derived Titania Coatings on Titanium Substratesin Vitro. J. Biomed. Mater. Res. 1998, 41, 504–510. [Google Scholar] [CrossRef]

- Mustafa, K.; Wennerberg, A.; Wroblewski, J.; Hultenby, K.; Lopez, B.S.; Arvidson, K. Determining Optimal Surface Roughness of TiO2 Blasted Titanium Implant Material for Attachment, Proliferation and Differentiation of Cells Derived from Human Mandibular Alveolar Bone. Clin. Oral Implants Res. 2001, 12, 515–525. [Google Scholar] [CrossRef] [PubMed]

- Hou, F.; Gorthy, R.; Mardon, I.; Tang, D.; Goode, C. Protecting Light Metal Alloys Using a Sustainable Plasma Electrolytic Oxidation Process. ACS Omega 2022, 7, 8570–8580. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liang, J.; Wang, Q. Plasma Electrolytic Oxidation Coatings on Lightweight Metals. Mod. Surf. Eng. Treat. 2013, 4, 75–99. [Google Scholar] [CrossRef]

- Wu, J.; Wu, L.; Yao, W.; Chen, Y.; Chen, Y.; Yuan, Y.; Wang, J.; Atrens, A.; Pan, F. Effect of Electrolyte Systems on Plasma Electrolytic Oxidation Coatings Characteristics on LPSO Mg-Gd-Y-Zn Alloy. Surf. Coat. Technol. 2023, 454, 129192. [Google Scholar] [CrossRef]

- Oh, G.H.; Yoon, J.K.; Huh, J.Y.; Doh, J.M. Effect of Frequency of Plasma Electrolytic Oxidation on the Microstructure and Corrosion Resistance of 6061 Aluminium Alloy. Surf. Coat. Technol. 2023, 471, 129861. [Google Scholar] [CrossRef]

- Nominé, A.; Nominé, A.V.; Braithwaite, N.S.J.; Belmonte, T.; Henrion, G. High-Frequency-Induced Cathodic Breakdown during Plasma Electrolytic Oxidation. Phys. Rev. Appl. 2017, 8, 031001. [Google Scholar] [CrossRef]

- Dehnavi, V.; Luan, B.L.; Shoesmith, D.W.; Liu, X.Y.; Rohani, S. Effect of Duty Cycle and Applied Current Frequency on Plasma Electrolytic Oxidation (PEO) Coating Growth Behavior. Surf. Coat. Technol. 2013, 226, 100–107. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X.; Yin, X.; Du, N. Influence of Electrolyte Components on the Microstructure and Growth Mechanism of Plasma Electrolytic Oxidation Coatings on 1060 Aluminum Alloy. Surf. Coat. Technol. 2020, 381, 125214. [Google Scholar] [CrossRef]

- Luo, S.; Wang, Q.; Ye, R.; Ramachandran, C.S. Effects of Electrolyte Concentration on the Microstructure and Properties of Plasma Electrolytic Oxidation Coatings on Ti-6Al-4V Alloy. Surf. Coat. Technol. 2019, 375, 864–876. [Google Scholar] [CrossRef]

- Attarzadeh, N.; Ramana, C.V. Plasma Electrolytic Oxidation Ceramic Coatings on Zirconium (Zr) and ZrAlloys: Part I—Growth Mechanisms, Microstructure, and Chemical Composition. Coatings 2021, 11, 634. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Wang, R.Q.; Zhang, H.; Shen, X.J.; Zhang, X.Z.; He, Y.; Huang, C.; Shen, D.J.; Li, D.L. Effect of Nanosized Silicon Dioxide Additive on Plasma Electrolytic Oxidation Coatings Fabricated on Aluminium. Int. J. Electrochem. Sci. 2020, 15, 11191–11202. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Skeldon, P.; Thompson, G.E. Incorporation of Zirconia Particles into Coatings Formed on Magnesium by Plasma Electrolytic Oxidation. J. Mater. Sci. 2008, 43, 1532–1538. [Google Scholar] [CrossRef]

- Savushkina, S.; Gerasimov, M.; Apelfeld, A.; Suminov, I. Study of Coatings Formed on Zirconium Alloy by Plasma Electrolytic Oxidation in Electrolyte with Submicron Yttria Powder Additives. Metals 2021, 11, 1392. [Google Scholar] [CrossRef]

- Li, W.; Zhu, L.; Li, Y. Electrochemical oxidation characteristic of AZ91D magnesium alloy under the action of silica sol. Surf. Coat. Technol. 2006, 201, 1085–1092. [Google Scholar] [CrossRef]

- Li, W.; Zhu, L.; Liu, H. Preparation of Hydrophobic Anodic Film on AZ91D Magnesium Alloy in Silicate Solution Containing Silica Sol. Surf. Coat. Technol. 2006, 201, 2573–2577. [Google Scholar] [CrossRef]

- Tang, M.; Li, W.; Liu, H.; Zhu, L. Influence of Titania Sol in the Electrolyte on Characteristics of the Microarc Oxidation Coating Formed on 2A70 Aluminum Alloy. Surf. Coat. Technol. 2011, 205, 4135–4140. [Google Scholar] [CrossRef]

- Laleh, M.; Rouhaghdam, A.S.; Shahrabi, T.; Shanghi, A. Effect of Alumina Sol Addition to Micro-Arc Oxidation Electrolyte on the Properties of MAO Coatings Formed on Magnesium Alloy AZ91D. J. Alloys Compd. 2010, 496, 548–552. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Huang, Y.; Ovri, H.; Zheludkevich, M.L.; Kainer, K.U. Plasma Electrolytic Oxidation Coatings on Mg Alloy with Addition of SiO2 Particles. Electrochim. Acta 2016, 187, 20–33. [Google Scholar] [CrossRef]

- Lu, X.; Mohedano, M.; Blawert, C.; Matykina, E.; Arrabal, R.; Kainer, K.U.; Zheludkevich, M.L. Plasma electrolytic oxidation coatings with particle additions—A review. Surf. Coat. Technol. 2016, 307, 1165–1182. [Google Scholar] [CrossRef]

- Lederer, S.; Sankaran, S.; Smith, T.; Fürbeth, W. Formation of Bioactive Hydroxyapatite-Containing Titania Coatings on CP-Ti 4+ Alloy Generated by Plasma Electrolytic Oxidation. Surf. Coat. Technol. 2019, 363, 66–74. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Viejo, F.; Skeldon, P.; Thompson, G.E.; Merino, M.C. AC Plasma Electrolytic Oxidation of Magnesium with Zirconia Nanoparticles. Appl. Surf. Sci. 2008, 254, 6937–6942. [Google Scholar] [CrossRef]

- Gowtham, S.; Hariprasad, S.; Arunnellaiappan, T.; Rameshbabu, N. An Investigation on ZrO2 Nano-Particle Incorporation, Surface Properties and Electrochemical Corrosion Behaviour of PEO Coating Formed on Cp-Ti. Surf. Coat. Technol. 2017, 313, 263–273. [Google Scholar] [CrossRef]

- Rapheal, G.; Kumar, S.; Scharnagl, N.; Blawert, C. Effect of Current Density on the Microstructure and Corrosion Properties of Plasma Electrolytic Oxidation (PEO) Coatings on AM50 Mg Alloy Produced in an Electrolyte Containing Clay Additives. Surf. Coat. Technol. 2016, 289, 150–164. [Google Scholar] [CrossRef]

- Blawert, C.; Sah, S.P.; Liang, J.; Huang, Y.; Höche, D. Role of Sintering and Clay Particle Additions on Coating Formation during PEO Processing of AM50 Magnesium Alloy. Surf. Coat. Technol. 2012, 213, 48–58. [Google Scholar] [CrossRef]

- Polunin, A.V.; Borgardt, E.D.; Shafeev, M.R.; Katsman, A.V.; Krishtal, M.M. Effects of Different Nanoparticles Additions on Composition and Properties of Oxide Layers Formed by Plasma Electrolytic Oxidation on Cast Al-Si Alloy. J. Phys. Conf. Ser. 2020, 1713, 012035. [Google Scholar] [CrossRef]

- Ceriani, F.; Casanova, L.; Massimini, L.; Brenna, A.; Ormellese, M. TiO2 Microparticles Incorporation in Coatings Produced by Plasma Electrolytic Oxidation (PEO) on Titanium. Coatings 2023, 13, 1718. [Google Scholar] [CrossRef]

- Rizwan, M.; Alias, R.; Zaidi, U.Z.; Mahmoodian, R.; Hamdi, M. Surface Modification of Valve Metals Using Plasma Electrolytic Oxidation for Antibacterial Applications: A Review. J. Biomed. Mater. Res. Part A 2018, 106, 590–605. [Google Scholar] [CrossRef] [PubMed]

- Pezzato, L.; Settimi, A.G.; Fanchin, D.; Moschin, E.; Moro, I.; Dabalà, M. Effect of Cu Addition on the Corrosion and Antifouling Properties of PEO Coated Zinc-Aluminized Steel. Materials 2022, 15, 7895. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.M.; Lee, B.U.; Yoon, S.I.; Lee, E.S.; Yoo, B.; Shin, D.H. Evaluation of Plasma Temperature during Plasma Oxidation Processing of AZ91 Mg Alloy through Analysis of the Melting Behavior of Incorporated Particles. Electrochim. Acta 2012, 67, 6–11. [Google Scholar] [CrossRef]

- Guo, J.; Wang, L.; Wang, S.C.; Liang, J.; Xue, Q.; Yan, F. Preparation and Performance of a Novel Multifunctional Plasma Electrolytic Oxidation Composite Coating Formed on Magnesium Alloy. J. Mater. Sci. 2009, 44, 1998–2006. [Google Scholar] [CrossRef]

- Balaji, R.; Pushpavanam, M.; Kumar, K.Y.; Subramanian, K. Electrodeposition of Bronze–PTFE Composite Coatings and Study on Their Tribological Characteristics. Surf. Coat. Technol. 2006, 201, 3205–3211. [Google Scholar] [CrossRef]

- Atiyeh, B.S.; Costagliola, M.; Hayek, S.N.; Dibo, S.A. Effect of Silver on Burn Wound Infection Control and Healing: Review of the Literature. Burns 2007, 33, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Burg, K.J.L.; Porter, S.; Kellam, J.F. Biomaterial Developments for Bone Tissue Engineering. Biomaterials 2000, 21, 2347–2359. [Google Scholar] [CrossRef] [PubMed]

- Mu, M.; Liang, J.; Zhou, X.; Xiao, Q. One-Step Preparation of TiO2/MoS2 Composite Coating on Ti6Al4V Alloy by Plasma Electrolytic Oxidation and Its Tribological Properties. Surf. Coat. Technol. 2013, 214, 124–130. [Google Scholar] [CrossRef]

- Hannink, R.H.J. Microstructural Development of Sub-Eutectoid Aged MgO-ZrO2 Alloys. J. Mater. Sci. 1983, 18, 457–470. [Google Scholar] [CrossRef]

- Fukumasa, O.; Tagashira, R.; Tachino, K.; Mukunoki, H. Spraying of MgO Films with a Well-Controlled Plasma Jet. Surf. Coat. Technol. 2003, 169–170, 579–582. [Google Scholar] [CrossRef]

- Galliano, P.; De Damborenea, J.J.; Pascual, M.J.; Durán, A. Sol-Gel Coatings on 316L Steel for Clinical Applications. J. Sol-Gel Sci. Technol. 1998, 13, 723–727. [Google Scholar] [CrossRef]

- Vasconcelos, D.C.L.; Carvalho, J.A.N.; Mantel, M.; Vasconcelos, W.L. Corrosion Resistance of Stainless Steel Coated with Sol–Gel Silica. J. Non. Cryst. Solids 2000, 273, 135–139. [Google Scholar] [CrossRef]

- Wang, D.; Bierwagen, G.P. Sol–Gel Coatings on Metals for Corrosion Protection. Prog. Org. Coat. 2009, 64, 327–338. [Google Scholar] [CrossRef]

- Khazrayie, M.A.; Aghdam, A.R.S. Si3N4/Ni Nanocomposite Formed by Electroplating: Effect of Average Size of Nanoparticulates. Trans. Nonferrous Met. Soc. China 2010, 20, 1017–1023. [Google Scholar] [CrossRef]

- Pepe, A.; Aparicio, M.; Durán, A.; Ceré, S. Cerium Hybrid Silica Coatings on Stainless Steel AISI 304 Substrate. J. Sol-Gel Sci. Technol. 2006, 39, 131–138. [Google Scholar] [CrossRef]

- Schem, M.; Schmidt, T.; Gerwann, J.; Wittmar, M.; Veith, M.; Thompson, G.E.; Molchan, I.S.; Hashimoto, T.; Skeldon, P.; Phani, A.R.; et al. CeO2-Filled Sol–Gel Coatings for Corrosion Protection of AA2024-T3 Aluminium Alloy. Corros. Sci. 2009, 51, 2304–2315. [Google Scholar] [CrossRef]

- Czosnek, C.; Bućko, M.M.; Janik, J.F.; Olejniczak, Z.; Bystrzejewski, M.; Łabędź, O.; Huczko, A. Preparation of Silicon Carbide SiC-Based Nanopowders by the Aerosol-Assisted Synthesis and the DC Thermal Plasma Synthesis Methods. Mater. Res. Bull. 2015, 63, 164–172. [Google Scholar] [CrossRef]

- Bhatt, R.T.; Choi, S.R.; Cosgriff, L.M.; Fox, D.S.; Lee, K.N. Impact Resistance of Environmental Barrier Coated SiC/SiC Composites. Mater. Sci. Eng. A 2008, 476, 8–19. [Google Scholar] [CrossRef]

- Hou, Y.Q.; Zhuang, D.M.; Zhang, G.; Wu, M.S.; Liu, J.J. Tribological Performances of Diamond Film and Graphite/Diamond Composite Film. Wear 2002, 253, 711–719. [Google Scholar] [CrossRef]

- Jones, D.W.; Smith, J.A.S. Hydrogen Bonding in Calcium Orthophosphates. Natute 1962, 195, 1090–1091. [Google Scholar] [CrossRef]

- Soejima, T.; Yagyu, H.; Ito, S. One-Pot Synthesis and Photocatalytic Activity of Fe-Doped TiO2 Films with Anatase-Rutile Nanojunction Prepared by Plasma Electrolytic Oxidation. J. Mater. Sci. 2011, 46, 5378–5384. [Google Scholar] [CrossRef]

- Rudnev, V.S.; Lukiyanchuk, I.V.; Adigamova, M.V.; Morozova, V.P.; Tkachenko, I.A. The effect of nanocrystallites in the pores of PEO coatings on their magnetic properties. Surf. Coat. Technol. 2015, 269, 23–29. [Google Scholar] [CrossRef]

- Hang, R.; Gao, A.; Huang, X.; Wang, X.; Zhang, X.; Qin, L.; Tang, B. Antibacterial Activity and Cytocompatibility of Cu–Ti–O Nanotubes. J. Biomed. Mater. Res. Part A 2014, 102, 1850–1858. [Google Scholar] [CrossRef]

- Vasilyeva, M.S.; Rudnev, V.S.; Korotenko, I.A.; Nedozorov, P.M. Producing and Studying Oxide Coatings Containing Manganese and Nickel Compounds on Titanium from Electrolyte Suspensions. Prot. Met. Phys. Chem. Surf. 2012, 48, 106–115. [Google Scholar] [CrossRef]

- Mohedano, M.; Matykina, E.; Arrabal, R.; Pardo, A.; Merino, M.C. Metal Release from Ceramic Coatings for Dental Implants. Dent. Mater. 2014, 30, e28–e40. [Google Scholar] [CrossRef]

- Matykina, E.; Montuori, M.; Gough, J.; Monfort, F.; Berkani, A.; Skeldon, P.; Thompson, G.E.; Habazaki, H. Spark Anodising of Titanium for Biomedical Applications. Trans. IMF 2006, 84, 125–133. [Google Scholar] [CrossRef]

- Whiteside, P.; Matykina, E.; Gough, J.E.; Skeldon, P.; Thompson, G.E. In Vitro Evaluation of Cell Proliferation and Collagen Synthesis on Titanium Following Plasma Electrolytic Oxidation. J. Biomed. Mater. Res. Part A 2010, 94A, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Mohedano, M.; Guzman, R.; Arrabal, R.; Lõpez Lacomba, J.L.; Matykina, E. Bioactive Plasma Electrolytic Oxidation Coatings—The Role of the Composition, Microstructure, and Electrochemical Stability. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 1524–1537. [Google Scholar] [CrossRef]

- Cimenoglu, H.; Gunyuz, M.; Kose, G.T.; Baydogan, M.; Uǧurlu, F.; Sener, C. Micro-Arc Oxidation of Ti6Al4V and Ti6Al7Nb Alloys for Biomedical Applications. Mater. Charact. 2011, 62, 304–311. [Google Scholar] [CrossRef]

- Li, W.; Tang, M.; Zhu, L.; Liu, H. Formation of Microarc Oxidation Coatings on Magnesium Alloy with Photocatalytic Performance. Appl. Surf. Sci. 2012, 258, 10017–10021. [Google Scholar] [CrossRef]

- Lim, T.S.; Ryu, H.S.; Hong, S.H. Electrochemical Corrosion Properties of CeO2-Containing Coatings on AZ31 Magnesium Alloys Prepared by Plasma Electrolytic Oxidation. Corros. Sci. 2012, 62, 104–111. [Google Scholar] [CrossRef]

- Liang, J.; Hu, L.; Hao, J. Preparation and Characterization of Oxide Films Containing Crystalline TiO2 on Magnesium Alloy by Plasma Electrolytic Oxidation. Electrochim. Acta 2007, 52, 4836–4840. [Google Scholar] [CrossRef]

- Tang, M.; Liu, H.; Li, W.; Zhu, L. Effect of Zirconia Sol in Electrolyte on the Characteristics of Microarc Oxidation Coating on AZ91D Magnesium. Mater. Lett. 2011, 65, 413–415. [Google Scholar] [CrossRef]

- Liu, J.; Lu, Y.; Jing, X.; Yuan, Y.; Zhang, M. Characterization of Plasma Electrolytic Oxidation Coatings Formed on Mg–Li Alloy in an Alkaline Silicate Electrolyte Containing Silica Sol. Mater. Corros. 2009, 60, 865–870. [Google Scholar] [CrossRef]

- Mohedano, M.; Blawert, C.; Zheludkevich, M.L. Silicate-Based Plasma Electrolytic Oxidation (PEO) Coatings with Incorporated CeO2 Particles on AM50 Magnesium Alloy. Mater. Des. 2015, 86, 735–744. [Google Scholar] [CrossRef]

- Mingo, B.; Guo, Y.; Němcová, A.; Gholinia, A.; Mohedano, M.; Sun, M.; Matthews, A.; Yerokhin, A. Incorporation of Halloysite Nanotubes into Forsterite Surface Layer during Plasma Electrolytic Oxidation of AM50 Mg Alloy. Electrochim. Acta 2019, 299, 772–788. [Google Scholar] [CrossRef]

- Seyfoori, A.; Mirdamadi, S.; Seyedraoufi, Z.S.; Khavandi, A.; Aliofkhazraei, M. Synthesis of Biphasic Calcium Phosphate Containing Nanostructured Films by Micro Arc Oxidation on Magnesium Alloy. Mater. Chem. Phys. 2013, 142, 87–94. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Scharnagl, N.; Kainer, K.U. Influence of Incorporating Si3N4 Particles into the Oxide Layer Produced by Plasma Electrolytic Oxidation on AM50 Mg Alloy on Coating Morphology and Corrosion Properties. J. Magnes. Alloy. 2013, 1, 267–274. [Google Scholar] [CrossRef]

- Zoubi, W.A.; Kamil, M.P.; Ko, Y.G. Synergistic Influence of Inorganic Oxides (ZrO2 and SiO2) with N2H4 to Protect Composite Coatings Obtained via Plasma Electrolyte Oxidation on Mg Alloy. Phys. Chem. Chem. Phys. 2017, 19, 2372–2382. [Google Scholar] [CrossRef]

- Wang, Y.M.; Wang, F.H.; Xu, M.J.; Zhao, B.; Guo, L.X.; Ouyang, J.H. Microstructure and Corrosion Behavior of Coated AZ91 Alloy by Microarc Oxidation for Biomedical Application. Appl. Surf. Sci. 2009, 255, 9124–9131. [Google Scholar] [CrossRef]

- Peng, Z.X.; Wang, L.; Du, L.; Guo, S.R.; Wang, X.Q.; Tang, T.T. Adjustment of the Antibacterial Activity and Biocompatibility of Hydroxypropyltrimethyl Ammonium Chloride Chitosan by Varying the Degree of Substitution of Quaternary Ammonium. Carbohydr. Polym. 2010, 81, 275–283. [Google Scholar] [CrossRef]

- Shishir, R.; Lokeshkumar, E.; Manojkumar, P.; Nasiruddin, U.; Premchand, C.; Ponnilavan, V.; Rameshbabu, N. Development of Biocompatible and Corrosion-Resistant Plasma Electrolytic Oxidation Coating over Zinc for Orthopedic Implant Applications. Surf. Coat. Technol. 2022, 450, 128990. [Google Scholar] [CrossRef]

- Francisca, F.G.S.; Vitoriano, J.D.O.; Alves-Junior, C. Controlling Plasma Electrolytic Oxidation of Titanium Using Current Pulses Compatible with the Duration of Microdischarges. Results Mater. 2022, 15, 100310. [Google Scholar] [CrossRef]

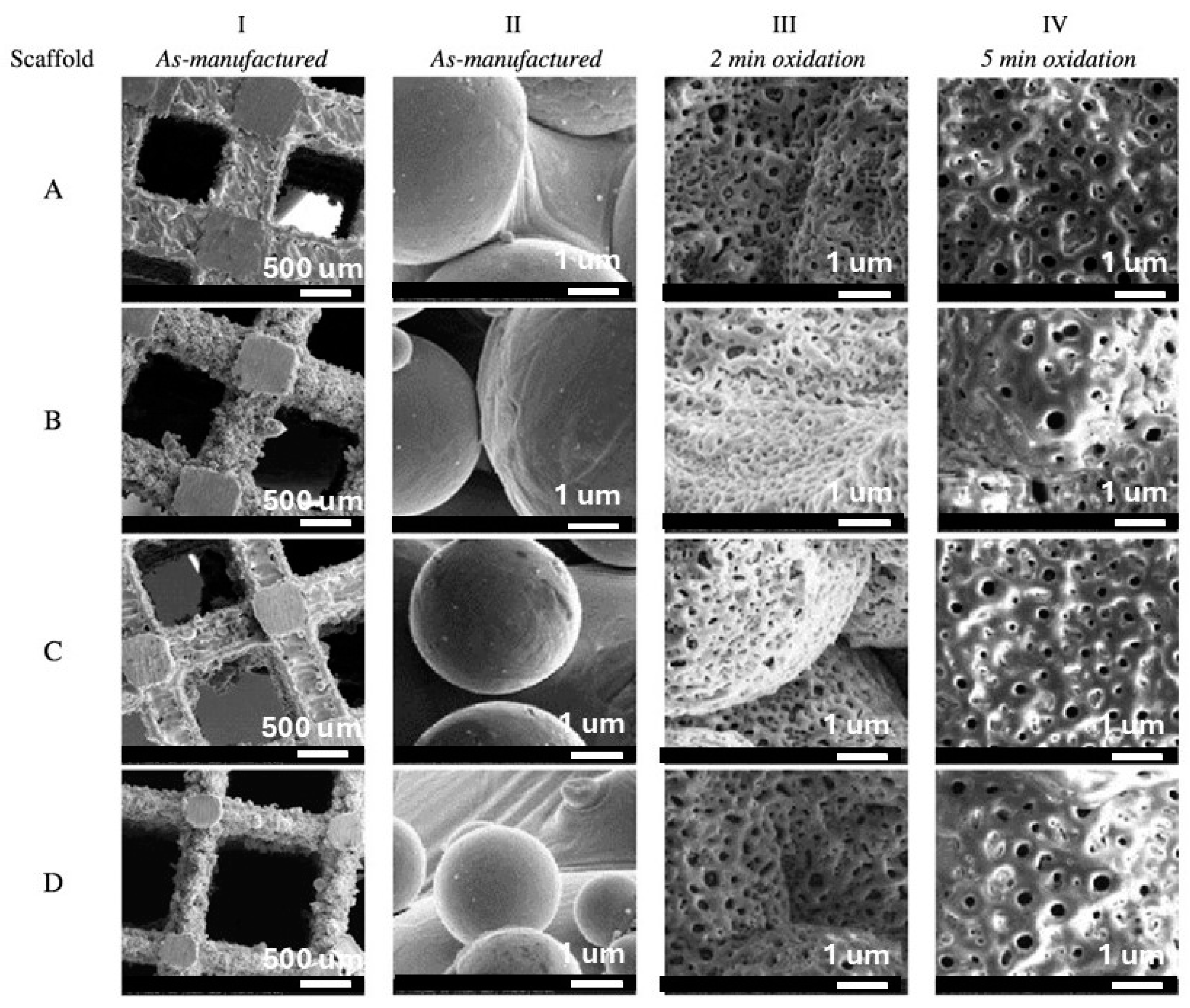

- Gorgin Karaji, Z.; Hedayati, R.; Pouran, B.; Apachitei, I.; Zadpoor, A.A. Effects of Plasma Electrolytic Oxidation Process on the Mechanical Properties of Additively Manufactured Porous Biomaterials. Mater. Sci. Eng. C 2017, 76, 406–416. [Google Scholar] [CrossRef]

- van Hengel, I.A.J.; Tierolf, M.W.A.M.; Fratila-apachitei, L.E.; Apachitei, I.; Zadpoor, A.A. Antibacterial Titanium Implants Biofunctionalized by Plasma Electrolytic Oxidation with Silver, Zinc, and Copper: A Systematic Review. Int. J. Mol. Sci. 2021, 22, 3800. [Google Scholar] [CrossRef]

- Hou, F.; Gorthy, R.; Mardon, I.; Tang, D.; Goode, C. Low Voltage Environmentally Friendly Plasma Electrolytic Oxidation Process for Titanium Alloys. Sci. Rep. 2022, 12, 6037. [Google Scholar] [CrossRef]

- Polizzi, G.; Gualini, F.; Friberg, B. A Two-Center Retrospective Analysis of Long-Term Clinical and Radiologic Data of TiUnite and Turned Implants Placed in the Same Mouth. Int. J. Prosthodont. 2013, 26, 350–358. [Google Scholar] [CrossRef][Green Version]

- Szymonowicz, M.; Kazek-Kęsik, A.; Sowa, M.; Żywicka, B.; Rybak, Z.; Simka, W. On Influence of Anodic Oxidation on Thrombogenicity and Bioactivity of the Ti-13Nb- 13Zr Alloy. Acta Bioeng. Biomech. 2017, 19, 41–50. [Google Scholar]

- Imburgia, M.; Fabbro, M. Del Long-Term Retrospective Clinical and Radiographic Follow-up of 205 Brånemark System Mk III TiUnite Implants Submitted to Either Immediate or Delayed Loading. Implant Dent. 2015, 24, 533–540. [Google Scholar] [CrossRef]

- Sowa, M.; Simka, W. Effect of DC Plasma Electrolytic Oxidation on Surface Characteristics and Corrosion Resistance of Zirconium. Materials 2018, 11, 723. [Google Scholar] [CrossRef]

- Duarte, L.T.; Biaggio, S.R.; Rocha-Filho, R.C.; Bocchi, N. Preparation and Characterization of Biomimetically and Electrochemically Deposited Hydroxyapatite Coatings on Micro-Arc Oxidized Ti-13Nb-13Zr. J. Mater. Sci. Mater. Med. 2011, 22, 1663–1670. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.S.; Zeng, X.T.; Khor, K.A.; Weng, W.; Sun, D.E. Evaluation of Adhesion Strength and Toughness of Fluoridated Hydroxyapatite Coatings. Thin Solid Films 2008, 516, 5162–5167. [Google Scholar] [CrossRef]

- Lugovskoy, A.; Lugovskoy, S. Production of Hydroxyapatite Layers on the Plasma Electrolytically Oxidized Surface of Titanium Alloys. Mater. Sci. Eng. C 2014, 43, 527–532. [Google Scholar] [CrossRef]

- Santos-Coquillat, A.; Mohedano, M.; Martinez-Campos, E.; Arrabal, R.; Pardo, A.; Matykina, E. Bioactive Multi-Elemental PEO-Coatings on Titanium for Dental Implant Applications. Mater. Sci. Eng. C 2019, 97, 738–752. [Google Scholar] [CrossRef]

- Zhou, K.; Xie, F.; Wu, X.; Wang, S. Fabrication of High Temperature Oxidation Resistance Nanocomposite Coatings on PEO Treated TC21 Alloy. Materials 2019, 13, 11. [Google Scholar] [CrossRef]

- Sandhyarani, M.; Ashfaq, M.; Arunnellaiappan, T.; Selvan, M.P.; Subramanian, S.; Rameshbabu, N. Effect of Electrical Parameters on Morphology and In-Vitro Corrosion Resistance of Plasma Electrolytic Oxidized Films Formed on Zirconium. Surf. Coat. Technol. 2015, 269, 286–294. [Google Scholar] [CrossRef]

- Nikoomanzari, E.; Fattah-alhosseini, A.; Pajohi Alamoti, M.R.; Keshavarz, M.K. Effect of ZrO2 Nanoparticles Addition to PEO Coatings on Ti–6Al–4V Substrate: Microstructural Analysis, Corrosion Behavior and Antibacterial Effect of Coatings in Hank’s Physiological Solution. Ceram. Int. 2020, 46, 13114–13124. [Google Scholar] [CrossRef]

- Junker, R.; Manders, P.J.D.; Wolke, J.; Borisov, Y.; Braceras, I.; Jansen, J.A. Bone Reaction Adjacent to Microplasma-Sprayed Calcium Phosphate-Coated Oral Implants Subjected to an Occlusal Load, an Experimental Study in the Dog. Clin. Oral Implants Res. 2011, 22, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, A.; Kossenko, A.; Zinigrad, M.; Gofer, Y.; Borodianskiy, K.; Sobolev, A. Hydroxyapatite Coating on Ti-6Al-7Nb Alloy by Plasma Electrolytic Oxidation in Salt-Based Electrolyte. Materials 2022, 15, 7374. [Google Scholar] [CrossRef] [PubMed]

- Momesso, G.A.C.; de Souza Santos, A.M.; Fonseca e Santos, J.M.; da Cruz, N.C.; Okamoto, R.; Ricardo Barão, V.A.; Siroma, R.S.; Shibli, J.A.; Faverani, L.P. Comparison between Plasma Electrolytic Oxidation Coating and Sandblasted Acid-Etched Surface Treatment: Histometric, Tomographic, and Expression Levels of Osteoclastogenic Factors in Osteoporotic Rats. Materials 2020, 13, 1604. [Google Scholar] [CrossRef] [PubMed]

- Ishizawa, H.; Ogino, M. Formation and Characterization of Anodic Titanium Oxide Films Containing Ca and P. J. Biomed. Mater. Res. 1995, 29, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Blawert, C.; Serdechnova, M.; Karlova, P.; Dovzhenko, G.; Florian Wieland, D.C.; Stojadinovic, S.; Vasilic, R.; Mojsilovic, K.; Zheludkevich, M.L. Formation of Plasma Electrolytic Oxidation Coatings on Pure Niobium in Different Electrolytes. Appl. Surf. Sci. 2022, 573, 151629. [Google Scholar] [CrossRef]

- Stevens, H.Y.; Meays, D.R.; Yeh, J.; Bjursten, L.M.; Frangos, J.A. COX-2 Is Necessary for Venous Ligation-Mediated Bone Adaptation in Mice. Bone 2006, 38, 93–104. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zheng, W.; Li, X.; Li, A.; Ye, N.; Zhang, L.; Liu, Y.; Liu, X.; Zhang, R.; Wang, M.; et al. Investigating the Effect of Ti3C2 (MXene) Nanosheet on Human Umbilical Vein Endothelial Cells via a Combined Untargeted and Targeted Metabolomics Approach. Carbon 2021, 178, 810–821. [Google Scholar] [CrossRef]

- Liu, Q.; Meng, Q.; Guo, S.; Zhao, X. A′ Type Ti–Nb–Zr Alloys with Ultra-Low Young’s Modulus and High Strength. Prog. Nat. Sci. Mater. Int. 2013, 23, 562–565. [Google Scholar] [CrossRef]

- Nie, L.; Zhan, Y.; Liu, H.; Tang, C. Novel β-Type Zr–Mo–Ti Alloys for Biological Hard Tissue Replacements. Mater. Des. 2014, 53, 8–12. [Google Scholar] [CrossRef]

- Shin, K.R.; Ko, Y.G.; Shin, D.H. Surface Characteristics of ZrO2-Containing Oxide Layer in Titanium by Plasma Electrolytic Oxidation in K4P2O7 Electrolyte. J. Alloys Compd. 2012, 536, S226–S230. [Google Scholar] [CrossRef]

- Komasa, S.; Nishizaki, M.; Zhang, H.; Takao, S.; Yin, D.; Terada, C.; Kobayashi, Y.; Kusumoto, T.; Yoshimine, S.; Nishizaki, H.; et al. Osseointegration of Alkali-Modified NANOZR Implants: An In Vivo Study. Int. J. Mol. Sci. 2019, 20, 842. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Z.; Li, C.; Yin, K.; Hao, D.; Lan, J. Application of Plasma-Sprayed Zirconia Coating in Dental Implants: Study in Implants. J. Oral Implantol. 2018, 53, 102–108. [Google Scholar] [CrossRef] [PubMed]

- Gomez Sanchez, A.; Ballarre, J.; Orellano, J.C.; Duffó, G.; Ceré, S. Surface Modification of Zirconium by Anodisation as Material for Permanent Implants: In Vitro and In Vivo Study. J. Mater. Sci. Mater. Med. 2013, 24, 81. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kang, I.G.; Cheon, K.H.; Lee, S.; Park, S.; Kim, H.E.; Han, C.M. Stable Sol-Gel Hydroxyapatite Coating on Zirconia Dental Implant for Improved Osseointegration. J. Mater. Sci. Mater. Med. 2021, 32, 161–169. [Google Scholar] [CrossRef]

- Attarzadeh, N.; Ramana, C.V. Plasma Electrolytic Oxidation Ceramic Coatings on Zirconium (Zr) and Zr-Alloys: Part-II: Properties and Applications. Coatings 2021, 11, 620. [Google Scholar] [CrossRef]

- Peng, F.; Wang, D.; Tian, Y.; Cao, H.; Qiao, Y.; Liu, X. Sealing the Pores of PEO Coating with Mg-Al Layered Double Hydroxide: Enhanced Corrosion Resistance, Cytocompatibility and Drug Delivery Ability. Sci. Rep. 2017, 7, 620. [Google Scholar] [CrossRef] [PubMed]

- Katić, J.; Šarić, A.; Despotović, I.; Matijaković, N.; Petković, M.; Petrović, Ž. Bioactive Coating on Titanium Dental Implants for Improved Anticorrosion Protection: A Combined Experimental and Theoretical Study. Coatings 2019, 9, 8167. [Google Scholar] [CrossRef]

- Bai, L.; Du, Z.; Du, J.; Yao, W.; Zhang, J.; Weng, Z.; Liu, S.; Zhao, Y.; Liu, Y.; Zhang, X.; et al. A Multifaceted Coating on Titanium Dictates Osteoimmunomodulation and Osteo/Angio-Genesis towards Ameliorative Osseointegration. Biomaterials 2018, 162, 154–169. [Google Scholar] [CrossRef]

- Ha, S.W.; Jang, H.L.; Nam, K.T.; Beck, G.R. Nano-Hydroxyapatite Modulates Osteoblast Lineage Commitment by Stimulation of DNA Methylation and Regulation of Gene Expression. Biomaterials 2015, 65, 32. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.H.; Hong, S.J.; Kim, C.H.; Kim, E.C.; Jang, J.H.; Shin, H.I.; Kim, H.W. Preparation of Hydroxyapatite Spheres with an Internal Cavity as a Scaffold for Hard Tissue Regeneration. J. Mater. Sci. Mater. Med. 2008, 19, 3029–3034. [Google Scholar] [CrossRef] [PubMed]

- Yeung, W.K.; Reilly, G.C.; Matthews, A.; Yerokhin, A. In Vitro Biological Response of Plasma Electrolytically Oxidized and Plasma-Sprayed Hydroxyapatite Coatings on Ti-6Al-4V Alloy. J. Biomed. Mater. Res. B. Appl. Biomater. 2013, 101, 939–949. [Google Scholar] [CrossRef] [PubMed]

- Thomas, K.A. Hydroxyapatite Coatings. Orthopedics 1994, 17, 267–278. [Google Scholar] [CrossRef]

- Yazdani, J.; Ahmadian, E.; Sharifi, S.; Shahi, S.; Maleki Dizaj, S. A Short View on Nanohydroxyapatite as Coating of Dental Implants. Biomed. Pharmacother. 2018, 105, 553–557. [Google Scholar] [CrossRef] [PubMed]

- Harun, W.S.W.; Asri, R.I.M.; Sulong, A.B.; Ghani, S.A.C.; Ghazalli, Z.; Harun, W.S.W.; Asri, R.I.M.; Sulong, A.B.; Ghani, S.A.C.; Ghazalli, Z. Hydroxyapatite-Based Coating on Biomedical Implant. Hydroxyapatite Adv. Compos. Nanomater. Biomed. Appl. Technol. Facets 2018. [Google Scholar] [CrossRef]

- Takahashi, N.; Maeda, K.; Ishihara, A.; Uehara, S.; Kobayashi, Y. Regulatory Mechanism of Osteoclastogenesis by RANKL and Wnt Signals. Front. Biosci. (Landmark Ed.) 2011, 16, 21–30. [Google Scholar] [CrossRef]

- Cao, J.; Lian, R.; Jiang, X. Magnesium and Fluoride Doped Hydroxyapatite Coatings Grown by Pulsed Laser Deposition for Promoting Titanium Implant Cytocompatibility. Appl. Surf. Sci. 2020, 515, 146069. [Google Scholar] [CrossRef]

- Zhao, Q.M.; Li, X.; Guo, S.; Wang, N.; Liu, W.W.; Shi, L.; Guo, Z. Osteogenic Activity of a Titanium Surface Modified with Silicon-Doped Titanium Dioxide. Mater. Sci. Eng. C 2020, 110, 110682. [Google Scholar] [CrossRef] [PubMed]

- Michalska, J.; Sowa, M.; Piotrowska, M.; Widziołek, M.; Tylko, G.; Dercz, G.; Socha, R.P.; Osyczka, A.M.; Simka, W. Incorporation of Ca Ions into Anodic Oxide Coatings on the Ti-13Nb-13Zr Alloy by Plasma Electrolytic Oxidation. Mater. Sci. Eng. C 2019, 104, 109957. [Google Scholar] [CrossRef] [PubMed]

- van Oirschot, B.A.J.A.; Bronkhorst, E.M.; van den Beucken, J.J.J.P.; Meijer, G.J.; Jansen, J.A.; Junker, R. Long-Term Survival of Calcium Phosphate-Coated Dental Implants: A Meta-Analytical Approach to the Clinical Literature. Clin. Oral Implants Res. 2013, 24, 355–362. [Google Scholar] [CrossRef] [PubMed]

- Sandhyarani, M.; Rameshbabu, N.; Venkateswarlu, K.; Rama Krishna, L. Fabrication, Characterization and in-Vitro Evaluation of Nanostructured Zirconia/Hydroxyapatite Composite Film on Zirconium. Surf. Coat. Technol. 2014, 238, 58–67. [Google Scholar] [CrossRef]

- Abbasi, S.; Golestani-Fard, F.; Rezaie, H.R.; Mirhosseini, S.M.M. MAO-Derived Hydroxyapatite/TiO2 Nanostructured Multi-Layer Coatings on Titanium Substrate. Appl. Surf. Sci. 2012, 261, 37–42. [Google Scholar] [CrossRef]

- Durdu, S.; Bayramoglu, S.; Demirtaş, A.; Usta, M.; Üçşk, A.H. Characterization of AZ31 Mg Alloy Coated by Plasma Electrolytic Oxidation. Vacuum 2013, 88, 130–133. [Google Scholar] [CrossRef]

- Shi, W.; Dong, L.; Li, Q.; Wang, C.; Liang, T.; Tian, J. One-Step Approach for the Fabrication and Characterization of Hydroxyapatite/TiO2 Composite Ceramic Coatings by Micro-Arc Oxidation in Situ on the Surface of Pure Titanium. Key Eng. Mater. 2013, 602–603, 598–601. [Google Scholar] [CrossRef]

- Khan, R.H.U.; Yerokhin, A.L.; Li, X.; Dong, H.; Matthews, A. Influence of Current Density and Electrolyte Concentration on DC PEO Titania Coatings. Surf. Eng. 2014, 30, 102–108. [Google Scholar] [CrossRef]

- Aliasghari, S.; Skeleton, P.; Thompson, G.E. Plasma Electrolytic Oxidation of Titanium in a Phosphate/Silicate Electrolyte and Tribological Performance of the Coatings. Appl. Surf. Sci. 2014, 316, 463–476. [Google Scholar] [CrossRef]

- Durdu, S.; Deniz, Ö.F.; Kutbay, I.; Usta, M. Characterization and Formation of Hydroxyapatite on Ti6Al4V Coated by Plasma Electrolytic Oxidation. J. Alloys Compd. 2013, 551, 422–429. [Google Scholar] [CrossRef]

- Kim, M.S.; Ryu, J.J.; Sung, Y.M. One-Step Approach for Nano-Crystalline Hydroxyapatite Coating on Titanium via Micro-Arc Oxidation. Electrochem. Commun. 2007, 9, 1886–1891. [Google Scholar] [CrossRef]

- Langstaff, S.; Sayer, M.; Smith, T.J.N.; Pugh, S.M. Resorbable Bioceramics Based on Stabilized Calcium Phosphates. Part II: Evaluation of Biological Response. Biomaterials 2001, 22, 135–150. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.H.; Lee, D.H.; Kim, K.M.; Lee, Y.K. Study on Bioactivity and Bonding Strength between Ti Alloy Substrate and TiO2 Film by Micro-Arc Oxidation. Thin Solid Films 2011, 519, 7065–7070. [Google Scholar] [CrossRef]

- Jaspard-Mécuson, F.; Czerwiec, T.; Henrion, G.; Belmonte, T.; Dujardin, L.; Viola, A.; Beauvir, J. Tailored Aluminium Oxide Layers by Bipolar Current Adjustment in the Plasma Electrolytic Oxidation (PEO) Process. Surf. Coat. Technol. 2007, 201, 8677–8682. [Google Scholar] [CrossRef]

- Kaluđerović, M.R.; Schreckenbach, J.P.; Graf, H.L. Titanium Dental Implant Surfaces Obtained by Anodic Spark Deposition—From the Past to the Future. Mater. Sci. Eng. C 2016, 69, 1429–1441. [Google Scholar] [CrossRef]

- Huang, T.; Wang, H.; Zhang, Z.; Feng, K.; Xiang, L. Incorporation of Inorganic Elements onto Titanium-Based Implant Surfaces by One-Step Plasma Electrolytic Oxidation: An Efficient Method to Enhance Osteogenesis. Biomater. Sci. 2022, 10, 6656–6674. [Google Scholar] [CrossRef] [PubMed]

- Kaluderović, M.R.; Schreckenbach, J.P.; Graf, H.L. Plasma-Electrochemical Deposition of Porous Zirconia on Titanium-Based Dental Material and in Vitro Interactions with Primary Osteoblasts Cells. J. Biomater. Appl. 2016, 30, 711–721. [Google Scholar] [CrossRef]

- Schreckenbach, J.; Schlottig, F.; Marx, G.; Kriven, W.M.; Popoola, O.O.; Jilavi, M.H.; Brown, S.D. Preparation and Microstructure Characterization of Anodic Spark Deposited Barium Titanate Conversion Layers. J. Mater. Res. 1999, 14, 1437–1443. [Google Scholar] [CrossRef]