Enhancing the Thermoelectric Performance of n-Type PbTe via Mn Doping

Abstract

1. Introduction

2. Materials and Methods

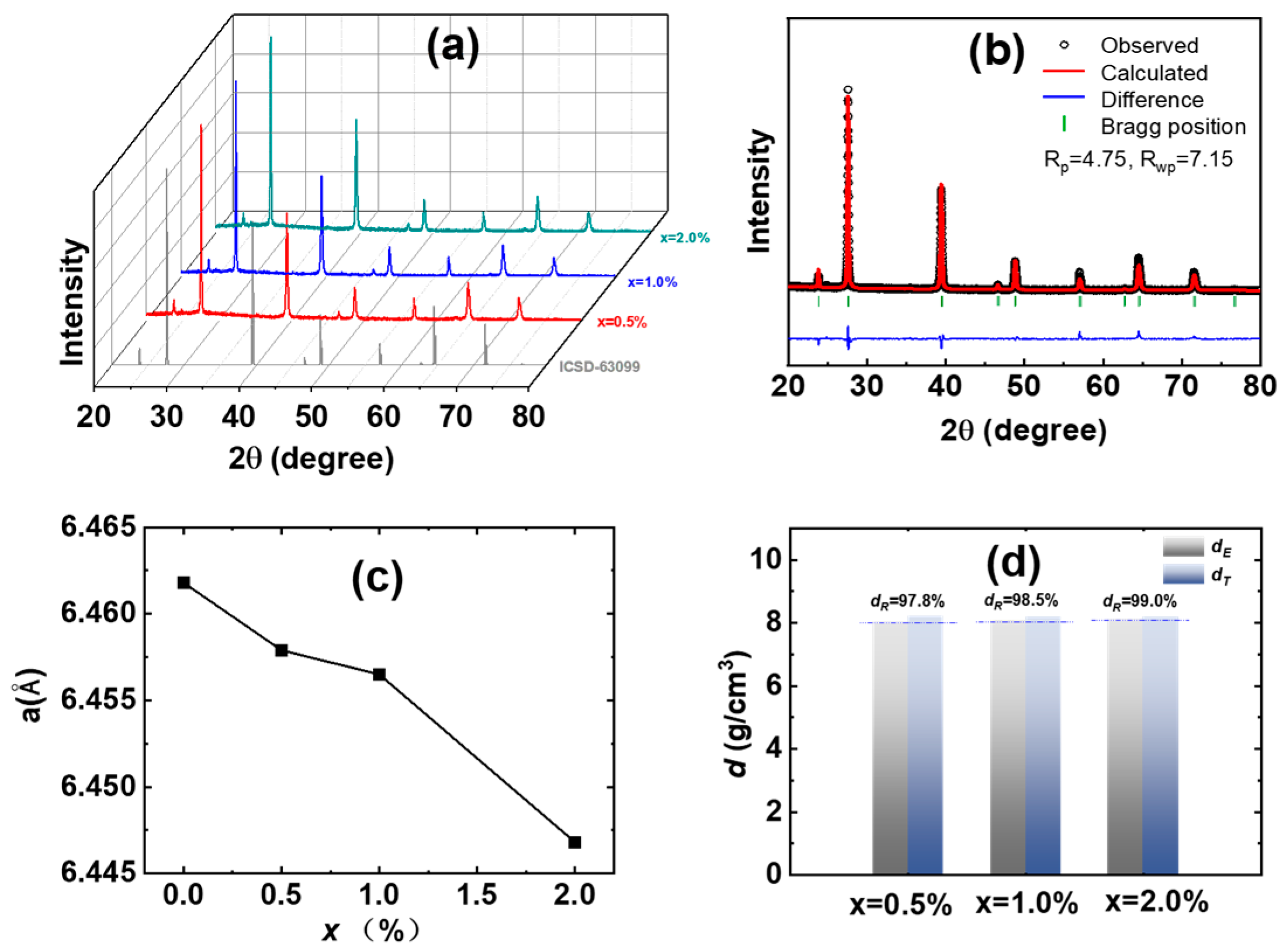

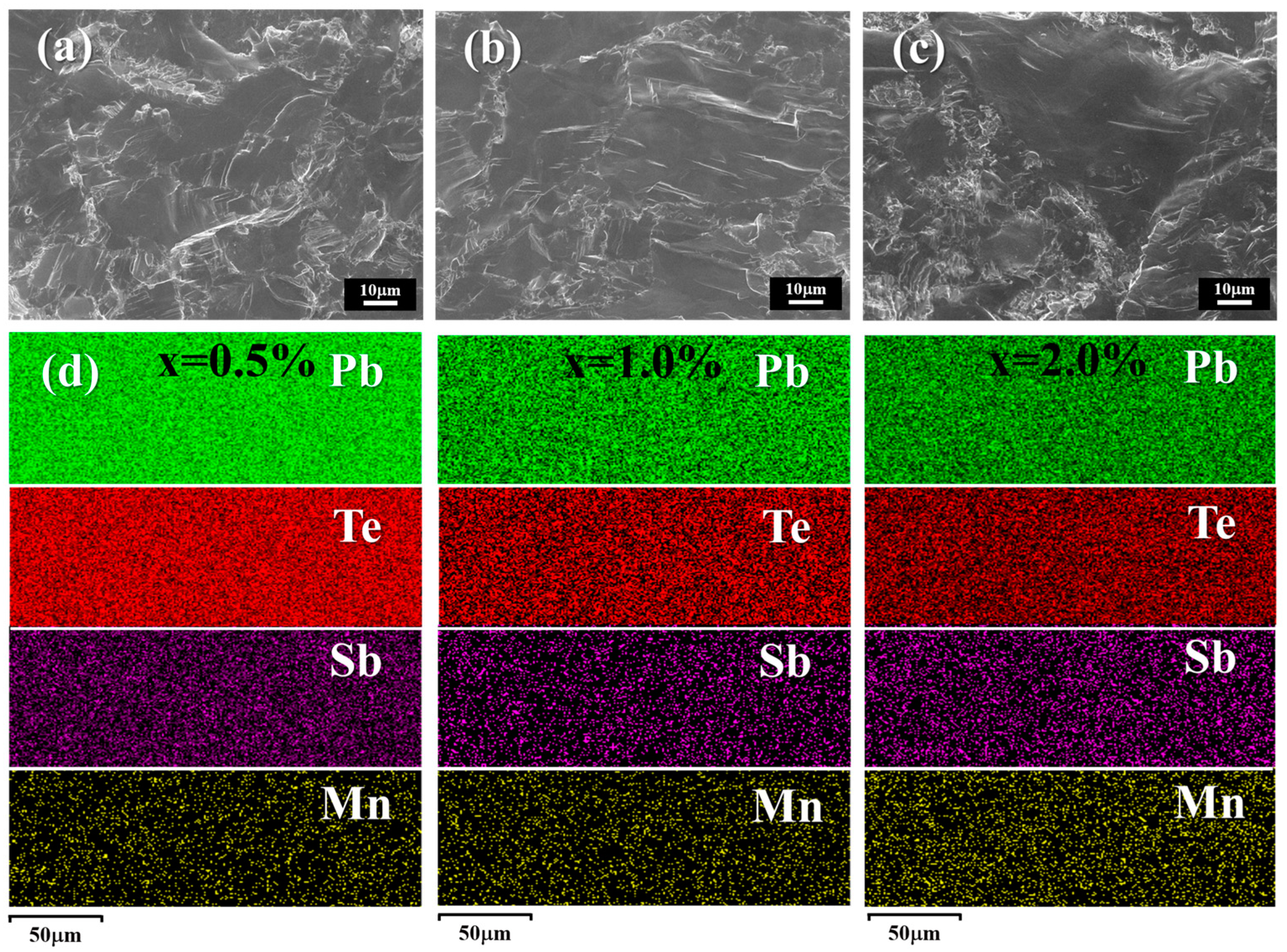

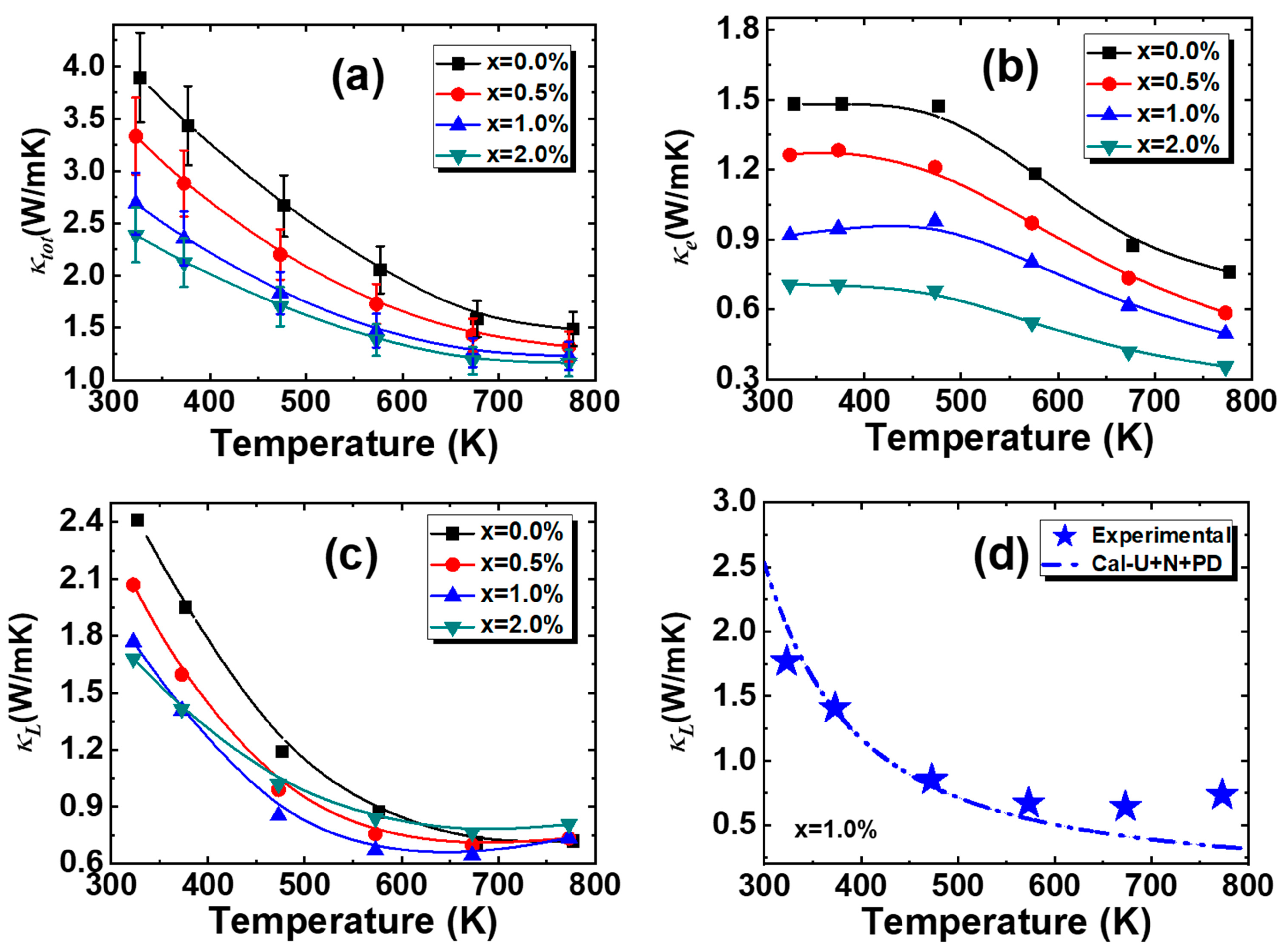

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Shi, X.-L.; Li, M.; Liu, T.; Mao, Y.; Liu, Q.; Dargusch, M.; Zou, J.; Lu, G.Q.; Chen, Z.-G. Nanobinders advance screen-printed flexible thermoelectrics. Science 2024, 386, 1265–1271. [Google Scholar] [CrossRef] [PubMed]

- Deng, T.; Gao, Z.; Li, Z.; Qiu, P.; Li, Z.; Yuan, X.; Ming, C.; Wei, T.-R.; Chen, L.; Shi, X. Room-temperature exceptional plasticity in defective Bi2Te3-based bulk thermoelectric crystals. Science 2024, 386, 1112–1117. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Yu, Y.; Cui, J.; Liu, X.; Xie, L.; Liao, J.; Zhang, Q.; Huang, Y.; Ning, S.; Jia, B.; et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 2021, 371, 830–834. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Liu, Z.; Sun, Z.; Zhang, Q.; Wei, P.; Mu, X.; Zhou, H.; Li, C.; Ma, S.; He, D.; et al. Superparamagnetic enhancement of thermoelectric performance. Nature 2017, 549, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Wang, D.; Wang, S.; Qin, B.; Wang, Y.; Qin, Y.; Jin, Y.; Chang, C.; Zhao, L.-D. High thermoelectric performance realized through manipulating layered phonon-electron decoupling. Science 2022, 375, 1385–1389. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zhang, K.; Wang, H.; Su, W.; Mehmood, F.; Wang, T.; Zhai, J.; Wang, X.; Huo, T.; Wang, C. The high thermoelectric performance of slightly Sb doped PbTe alloys. J. Mater. Chem. C 2020, 8, 1679–1685. [Google Scholar] [CrossRef]

- Chen, T.; Wang, H.; Su, W.; Wang, X.; Mehmood, F.; Zhang, K.; Huo, T.; Wang, C. Thermoelectric performance of Dy/Y co-doped SrTiO3 ceramic composites with submicron A2Ti2O7 (A = Dy, Y) pyrochlore. J. Phys. D Appl. Phys. 2021, 54, 155501. [Google Scholar] [CrossRef]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Zhong, Y.; Tang, J.; Liu, H.; Chen, Z.; Lin, L.; Ren, D.; Liu, B.; Ang, R. Optimized strategies for advancing n-Type PbTe thermoelectrics: A review. ACS Appl. Mater. Interfaces 2020, 12, 49323–49334. [Google Scholar] [CrossRef] [PubMed]

- Pei, Y.; Shi, X.; LaLonde, A.; Wang, H.; Chen, L.; Snyder, G.J. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 2011, 473, 66–69. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Wang, H.; Bahk, J.H.; Kang, C.; Hwang, J.; Kim, K.; Kim, J.; Burke, P.; Bowers, J.E.; Gossard, A.C.; Shakouri, A.; et al. Right sizes of nano- and microstructures for high-performance and rigid bulk thermoelectrics. Proc. Natl. Acad. Sci. USA 2014, 111, 10949–10954. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Wu, H.; Wang, D.; Niu, C.; Pei, Y.; Zhang, Y.; Spanopoulos, I.; Witting, I.T.; Li, X.; Pennycook, S.J.; et al. Amphoteric indium enables carrier engineering to enhance the power factor and thermoelectric performance in n-Type AgnPb100InnTe100+2n(LIST). Adv. Energy Mater. 2019, 9, 1900414. [Google Scholar] [CrossRef]

- Jia, B.; Huang, Y.; Wang, Y.; Zhou, Y.; Zhao, X.; Ning, S.; Xu, X.; Lin, P.; Chen, Z.; Jiang, B.; et al. Realizing high thermoelectric performance in non-nanostructured n-type PbTe. Energy Environ. Sci. 2022, 5, 1920–1929. [Google Scholar] [CrossRef]

- Luo, Z.-Z.; Cai, S.; Hao, S.; Bailey, T.P.; Luo, Y.; Luo, W.; Yu, Y.; Uher, C.; Wolverton, C.; Dravid, V.P.; et al. Extraordinary role of Zn in enhancing thermoelectric performance of Ga-doped n-type PbTe. Energy Environ. Sci. 2022, 1, 368–375. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, D.; He, D.; Feng, D.; Yin, M.; Qin, X.; He, J. Extraordinary thermoelectric performance realized in n-Type PbTe through multiphase nanostructure engineering. Adv. Mater. 2017, 29, 1703148. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Yin, M.; Wu, D.; Li, W.; Feng, D.; Huang, L.; He, J. Large enhancement of thermoelectric properties in n-type PbTe via dual-site point defects. Energy Environ. Sci. 2017, 10, 2030–2040. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, L.-D. Charge and phonon transport in PbTe-based thermoelectric materials. NPJ Quantum Mater. 2018, 3, 55. [Google Scholar] [CrossRef]

- Lee, K.H.; Oh, M.-W.; Kim, H.-S.; Shin, W.H.; Lee, K.; Lim, J.-H.; Kim, J.-I.; Kim, S.-I. Enhanced thermoelectric transport properties of n-type InSe due to the emergence of the flat band by Si doping. Inorg. Chem. Front. 2019, 6, 1475–1481. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Li, J.; Bu, Z.; Meng, X.; Ang, R.; Li, W. Band and phonon engineering for thermoelectric enhancements of rhombohedral GeTe. ACS Appl. Mater. Interfaces 2019, 11, 30756–30762. [Google Scholar] [CrossRef] [PubMed]

- Dutta, M.; Biswas, R.K.; Pati, S.K.; Biswas, K. Discordant Gd and electronic band flattening synergistically induce high thermoelectric performance in n-type PbTe. ACS Energy Lett. 2021, 6, 1625–1632. [Google Scholar] [CrossRef]

- Hong, T.; Wang, D.; Qin, B.; Zhang, X.; Chen, Y.; Gao, X.; Zhao, L.-D. Band convergence and nanostructure modulations lead to high thermoelectric performance in SnPb0.04Te-y% AgSbTe2. Mater. Today Phys. 2021, 21, 100505. [Google Scholar] [CrossRef]

- Wang, H.; Hu, H.; Man, N.; Xiong, C.; Xiao, Y.; Tan, X.; Liu, G.; Jiang, J. Band flattening and phonon-defect scattering in cubic SnSe-AgSbTe2 alloy for thermoelectric enhancement. Mater. Today Phys. 2021, 16, 100298. [Google Scholar] [CrossRef]

- Zhi, S.; Li, J.; Hu, L.; Li, J.; Li, N.; Wu, H.; Liu, F.; Zhang, C.; Ao, W.; Xie, H.; et al. Medium entropy-enabled high performance cubic gete thermoelectrics. Adv. Sci. 2021, 8, 2100220. [Google Scholar] [CrossRef]

- Zeng, X.; Ma, Z.; Li, W.; Yang, B.; Qian, Y.; Luo, Y.; Yang, J.; Liu, Y.; Jiang, Q. Entropy engineering for superior performance in BiCuSeO by band flattening and all-scale hierarchical microstructures. Chem. Eng. J. 2023, 474, 145663. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Cui, J.; Wang, D.; Fu, L.; Zhang, Y.; Chen, Y.; He, J.; Pennycook, S.J.; Zhao, L.-D. Realizing high performance n-type PbTe by synergistically optimizing effective mass and carrier mobility and suppressing bipolar thermal conductivity. Energy Environ. Sci. 2018, 11, 2486–2495. [Google Scholar] [CrossRef]

- Tan, G.; Stoumpos, C.C.; Wang, S.; Bailey, T.P.; Zhao, L.-D.; Uher, C.; Kanatzidis, M.G. Subtle roles of Sb and S in regulating the thermoelectric properties of N-Type PbTe to high performance. Adv. Energy Mater. 2017, 7, 1700099. [Google Scholar] [CrossRef]

- Blachnik, R.; Igel, R. Thermodynamic properties of IV-VI-compounds: Leadchalcogenides. Z. Für Naturforschung B 1974, 29, 625–629. [Google Scholar] [CrossRef]

- Heremans, J.P.; Martin, J. Thermoelectric measurements. Nat. Mater. 2024, 23, 18–19. [Google Scholar] [CrossRef] [PubMed]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Chen, S.; Zhong, Y.; Cai, J.; Zhang, Z.; Gao, F.; Huo, S.; Wu, J.; Cui, C.; Tan, X.; Liu, G.; et al. High thermoelectric performance of GeTe-MnTe alloy driven by spin degree of freedom. Mater. Today Phys. 2024, 43, 101393. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, H.; Su, W.; Wang, T.; Wang, X.; Chen, T.; Huo, T.; Dang, F.; Dong, M.; Wang, C.; et al. Trace bismuth and iodine co-doping enhanced thermoelectric performance of PbTe alloys. J. Phys. D Appl. Phys. 2020, 53, 245501. [Google Scholar] [CrossRef]

- Wang, H.; Charoenphakdee, A.; Kurosaki, K.; Yamanaka, S.; Snyder, G.J. Reduction of thermal conductivity in PbTe:Tl by alloying withTlSbTe2. Phys. Rev. B 2011, 83, 024303. [Google Scholar] [CrossRef]

- He, H.; Song, J.; Liang, R.; Yan, G.; Geng, Y.; Hu, L.; Liu, F.; Ao, W.; Zhang, C. Multicomponent synergistic doping enables high-efficiency n-type pbte thermoelectric devices. Small 2024, 21, 2408864. [Google Scholar] [CrossRef] [PubMed]

- Jood, P.; Ohta, M.; Kunii, M.; Hu, X.; Nishiate, H.; Yamamoto, A.; Kanatzidis, M.G. Enhanced average thermoelectric figure of merit of n-type PbTe1−xIx—MgTe. J. Mater. Chem. C 2015, 3, 10401–10408. [Google Scholar] [CrossRef]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

- Gao, F.; Cai, J.; Li, M.; Chen, Z.; Wang, Y.; Zhang, Z.; Chen, L.; Hu, D.; Tan, X.; Wu, J.; et al. Thermoelectric performance optimization of n-type PbTe by In and Cu2Te co-doping and anomalous temperature-dependent transport. J. Mater. Chem. A 2024, 12, 11875–11882. [Google Scholar] [CrossRef]

- Chen, Z.; Li, M.; Chen, Z.; Wang, Y.; Zhou, D.; Huang, X.; Zhang, X.; Guo, R.; Liu, X.; Wang, Z. Enhancing n-type PbTe thermoelectric performance through Cd alloying and strategic defects management. J. Alloys Compd. 2024, 1002, 175183. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Shi, H.; Xu, L.; Zhu, Y.; Qin, Y.; Peng, G.; Zhang, Y.; Ge, Z.-H.; Ding, X.; et al. High-ranged ZT value promotes thermoelectric cooling and power generation in n-Type PbTe. Adv. Energy Mater. 2022, 12, 2200204. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Shao, Y.; Feng, R.; Zhang, J.; Wang, Q.; Dong, Y.; Ma, H.; Sun, B.; Ao, D. Enhancing the Thermoelectric Performance of n-Type PbTe via Mn Doping. Materials 2025, 18, 1029. https://doi.org/10.3390/ma18051029

Chen T, Shao Y, Feng R, Zhang J, Wang Q, Dong Y, Ma H, Sun B, Ao D. Enhancing the Thermoelectric Performance of n-Type PbTe via Mn Doping. Materials. 2025; 18(5):1029. https://doi.org/10.3390/ma18051029

Chicago/Turabian StyleChen, Tingting, Yaqi Shao, Ruilin Feng, Junxiang Zhang, Qidong Wang, Yanan Dong, Hongan Ma, Bing Sun, and Dongwei Ao. 2025. "Enhancing the Thermoelectric Performance of n-Type PbTe via Mn Doping" Materials 18, no. 5: 1029. https://doi.org/10.3390/ma18051029

APA StyleChen, T., Shao, Y., Feng, R., Zhang, J., Wang, Q., Dong, Y., Ma, H., Sun, B., & Ao, D. (2025). Enhancing the Thermoelectric Performance of n-Type PbTe via Mn Doping. Materials, 18(5), 1029. https://doi.org/10.3390/ma18051029