Flexural Performance of an Innovative Girder-to-Pier Joint for Composite Bridges with Integral Piers: Full-Scale Test

Abstract

1. Introduction

1.1. Girder-to-Pier/Abutment Joint

1.2. Measures to Mitigate the Cracking of Concrete Slabs in the Hogging Moment Zone

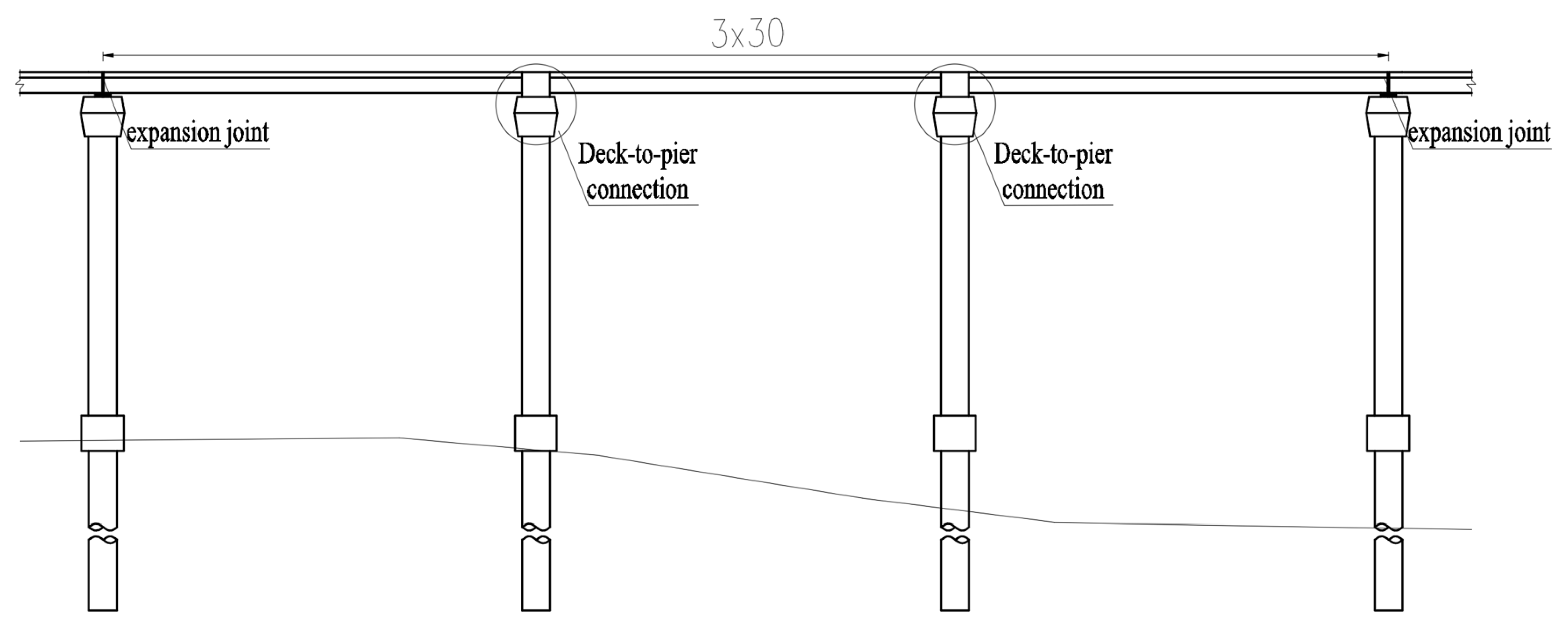

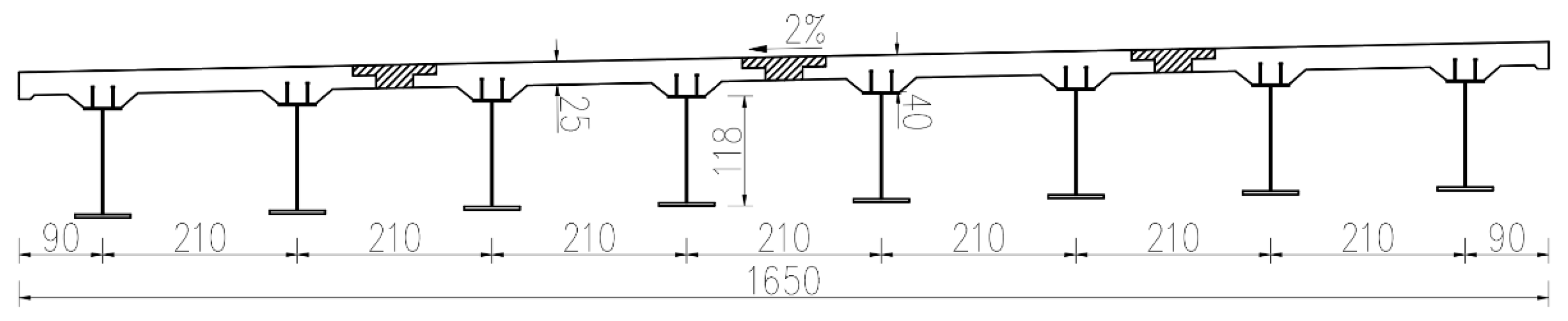

2. Reference Engineering

2.1. Bridge Layout

2.2. Finite Element Analysis

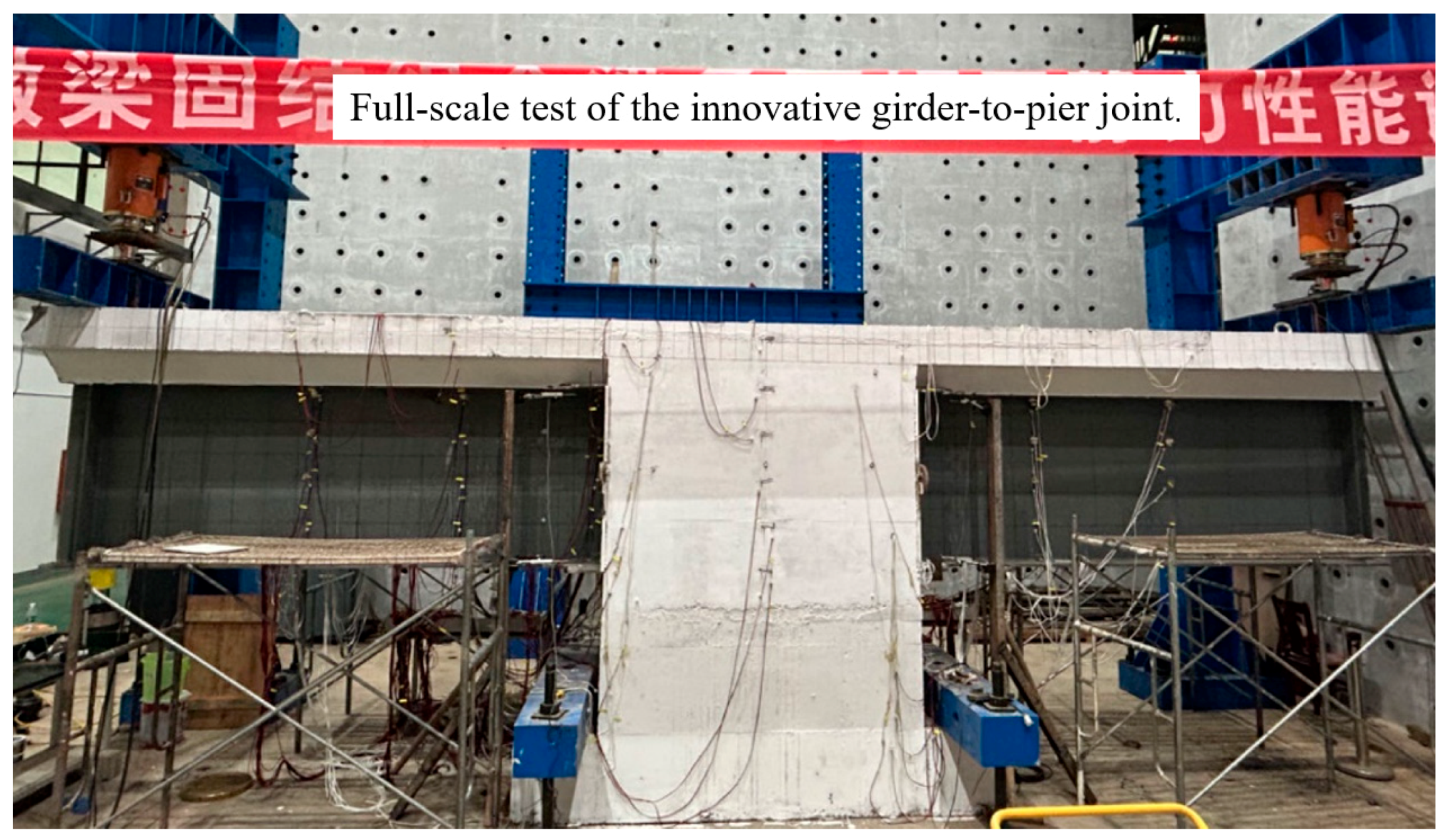

3. Experimental Program

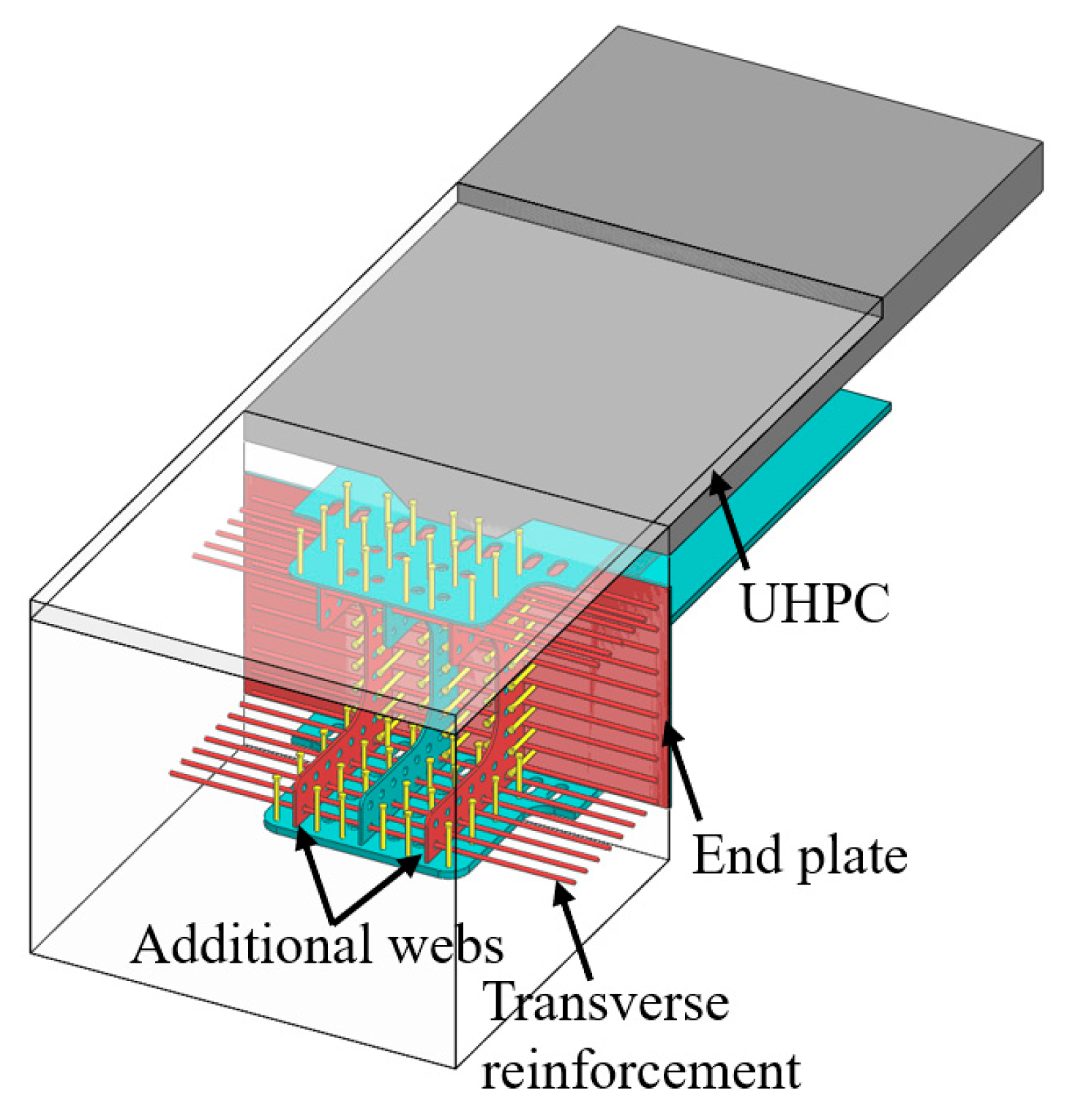

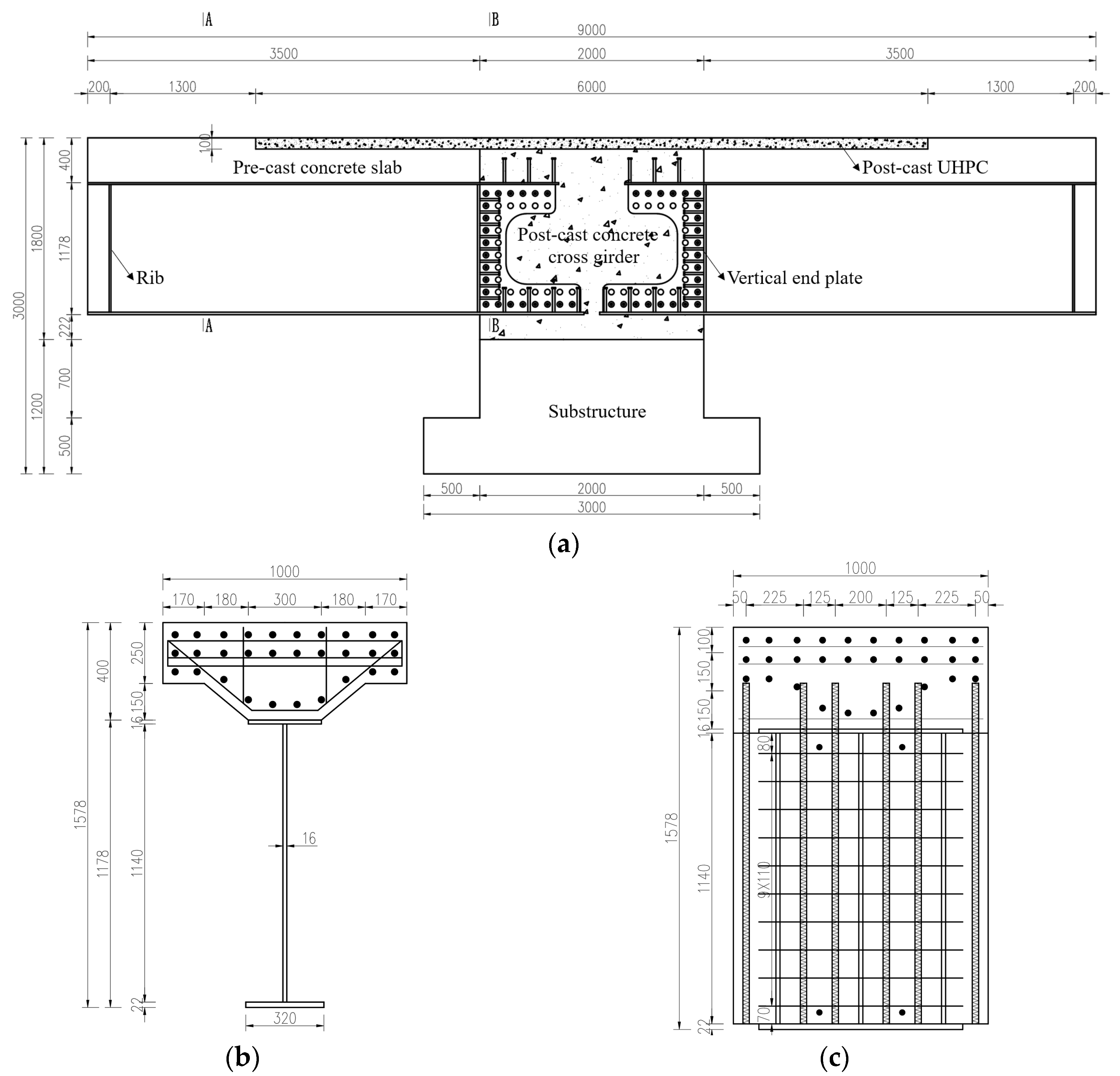

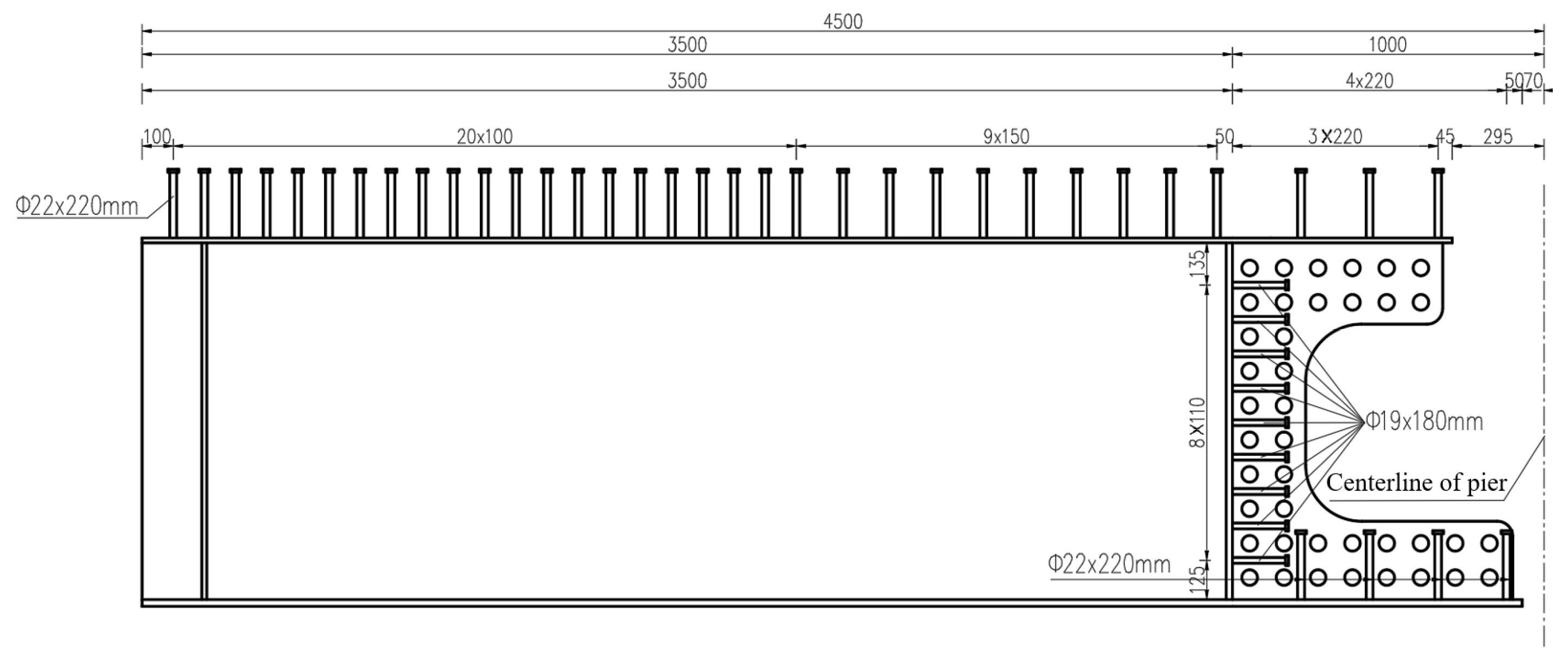

3.1. Specimen Design and Manufacture Process

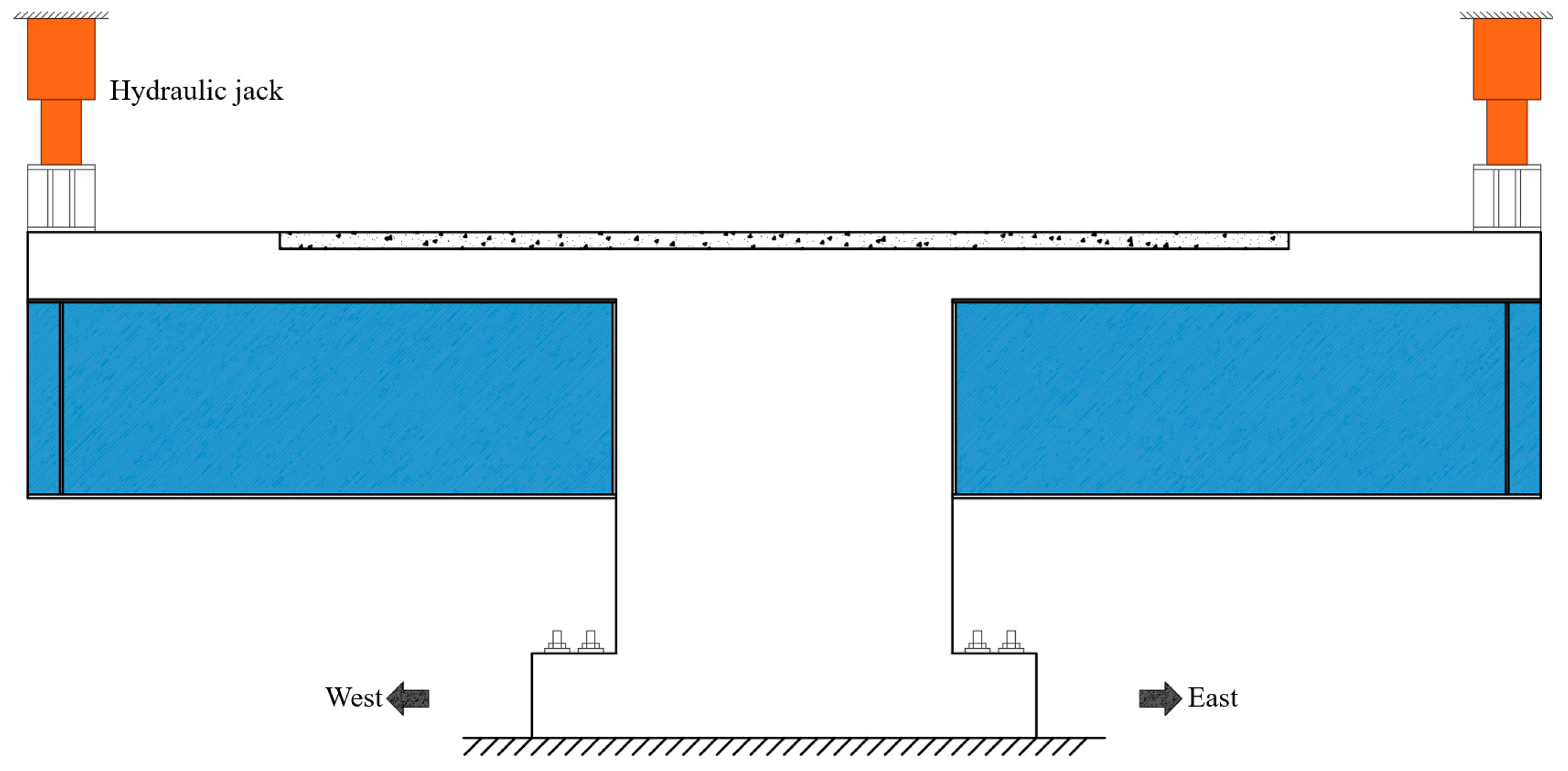

3.2. Experimental Setup

3.3. Material Properties

4. Experimental Results

4.1. Failure Process

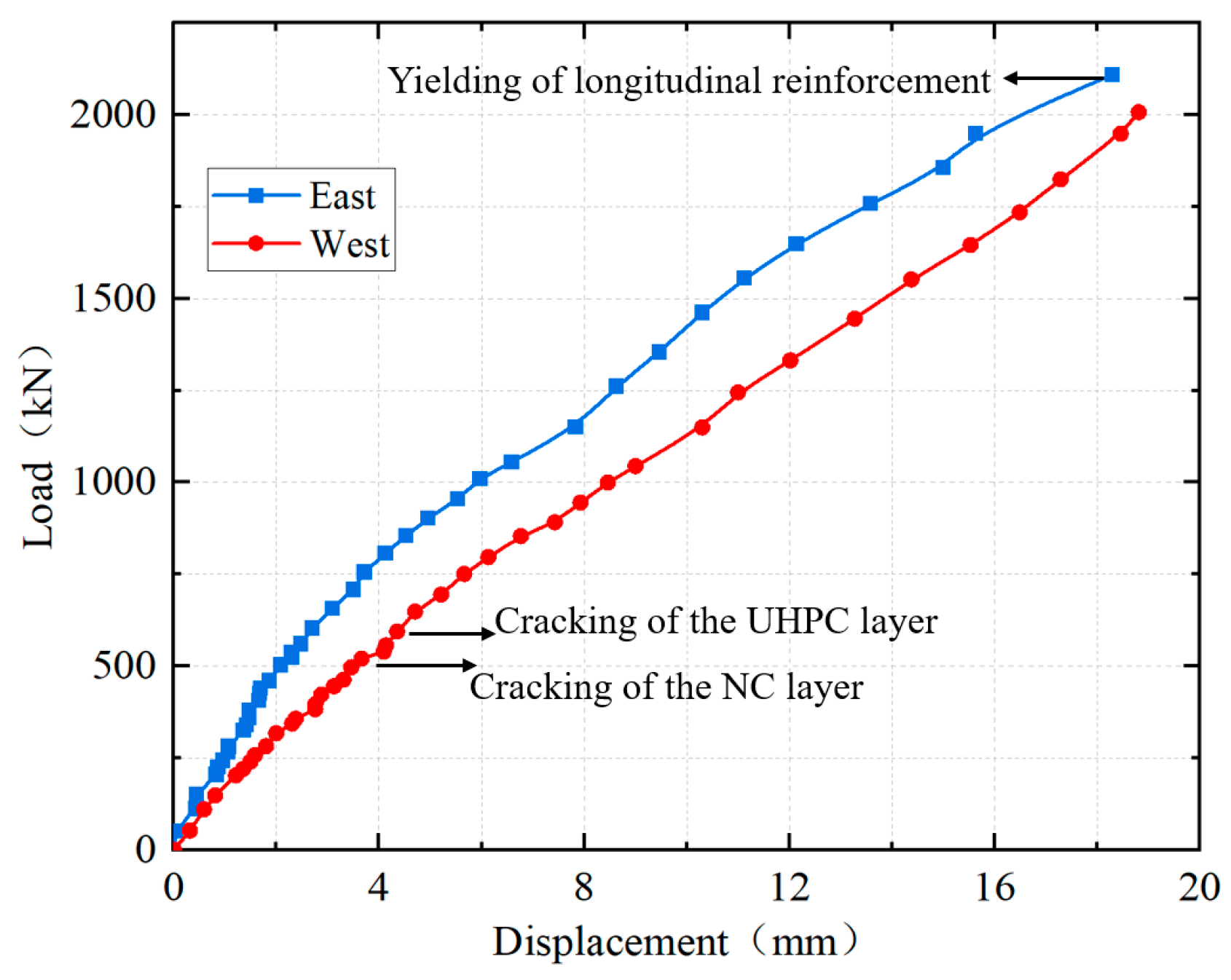

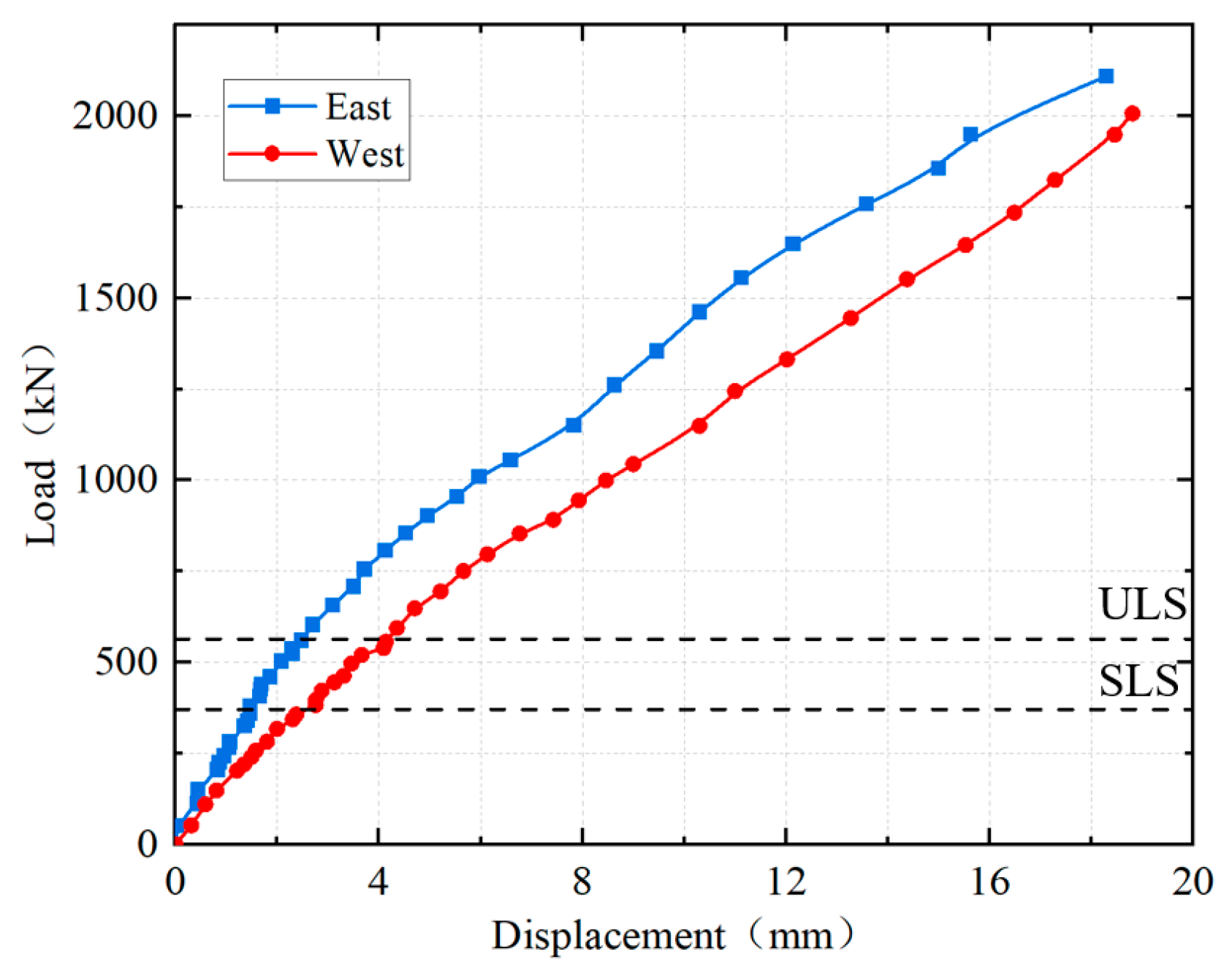

4.2. Load–Displacement Curve

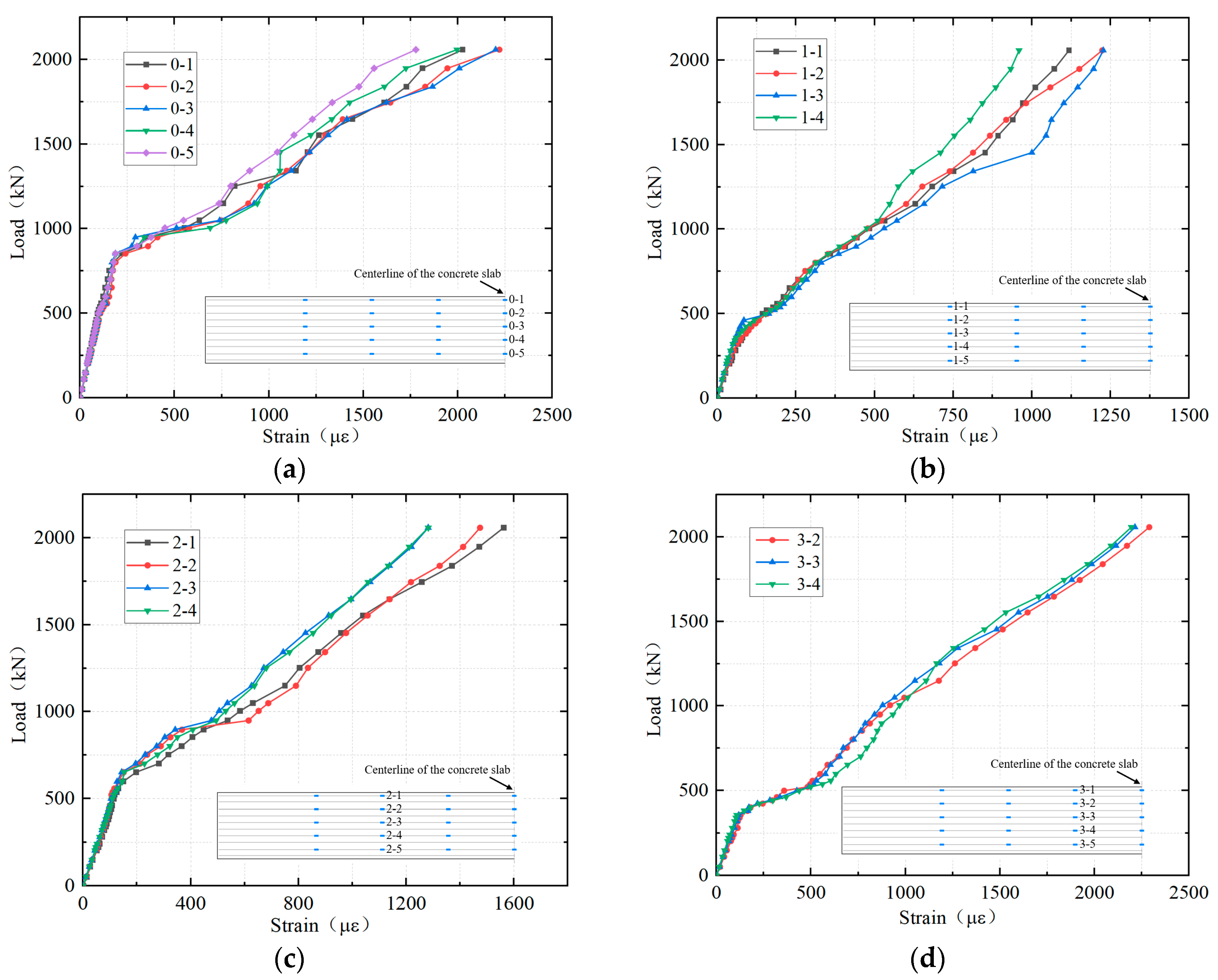

4.3. Strains of Longitudinal Reinforcement

4.4. Strains of Steel Plates

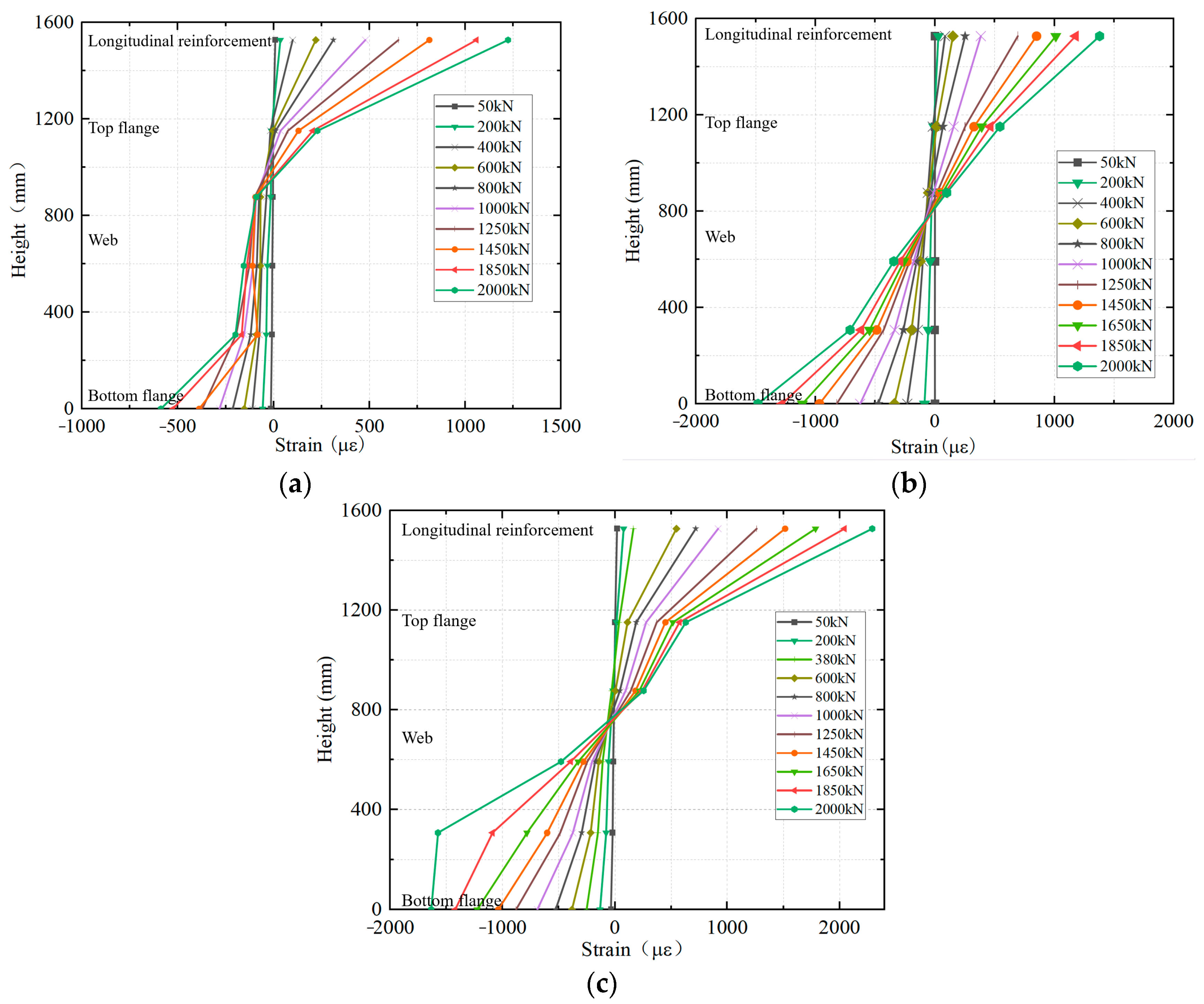

4.5. Cross-Section Strain Distribution

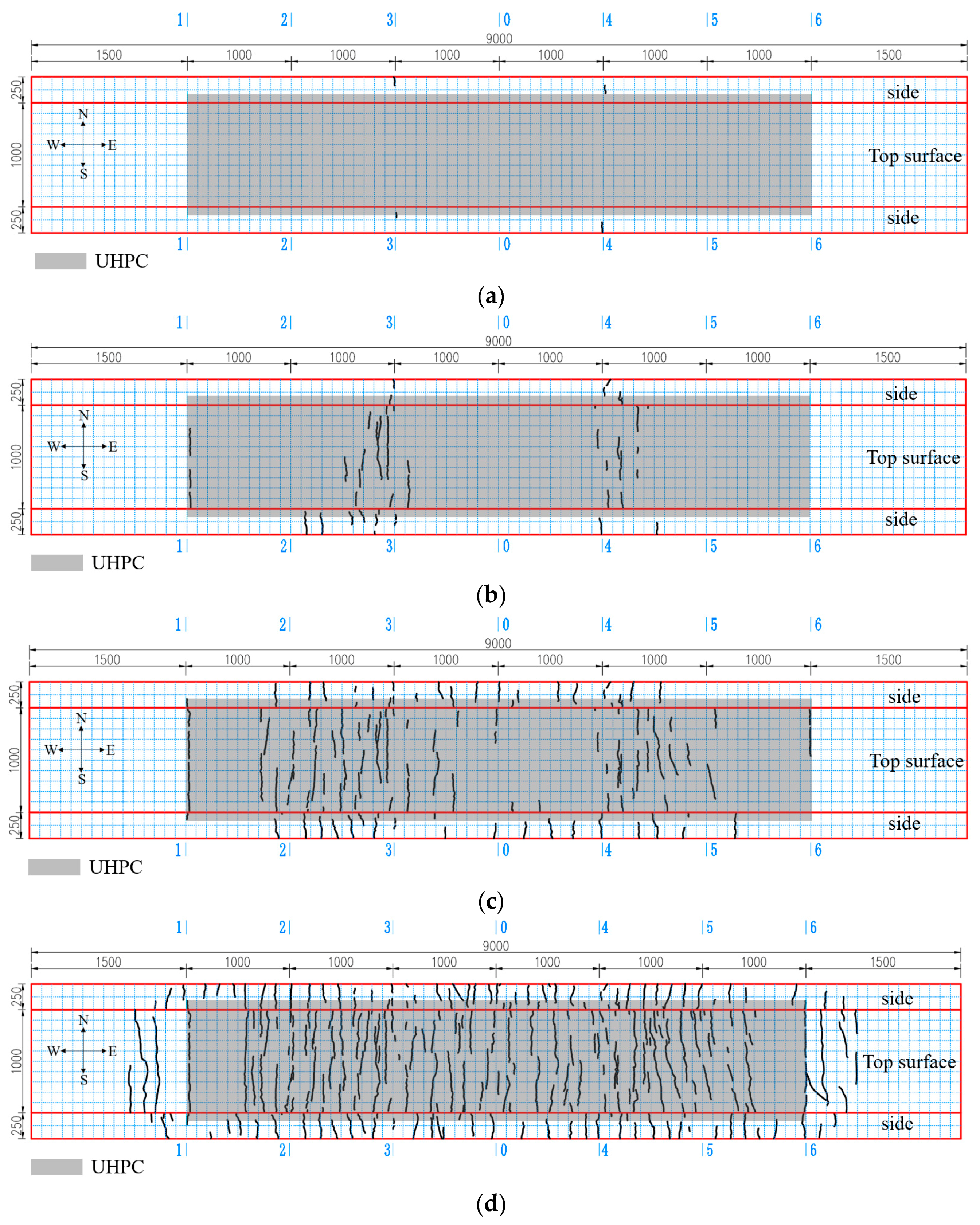

4.6. Cracking Patterns

4.7. Assessment of Experimental Results

4.7.1. Structural Safety Factor

4.7.2. Nominal Cracking Stress

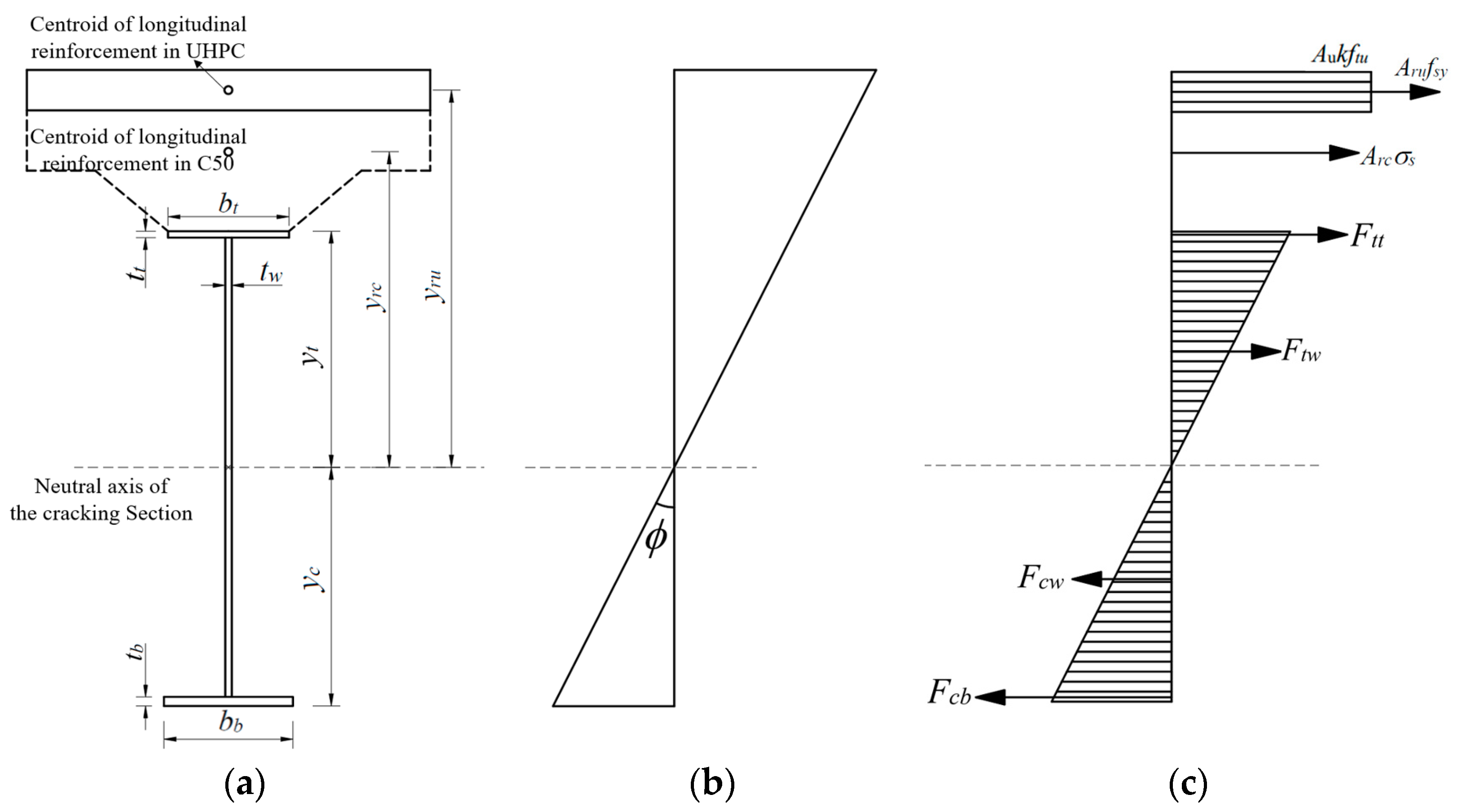

5. Calculation of Elastic Flexural Capacity

- (1)

- The cross-section of the composite girders conforms to the plane section assumption at all stages;

- (2)

- The tensile strength of the normal concrete is ignored;

- (3)

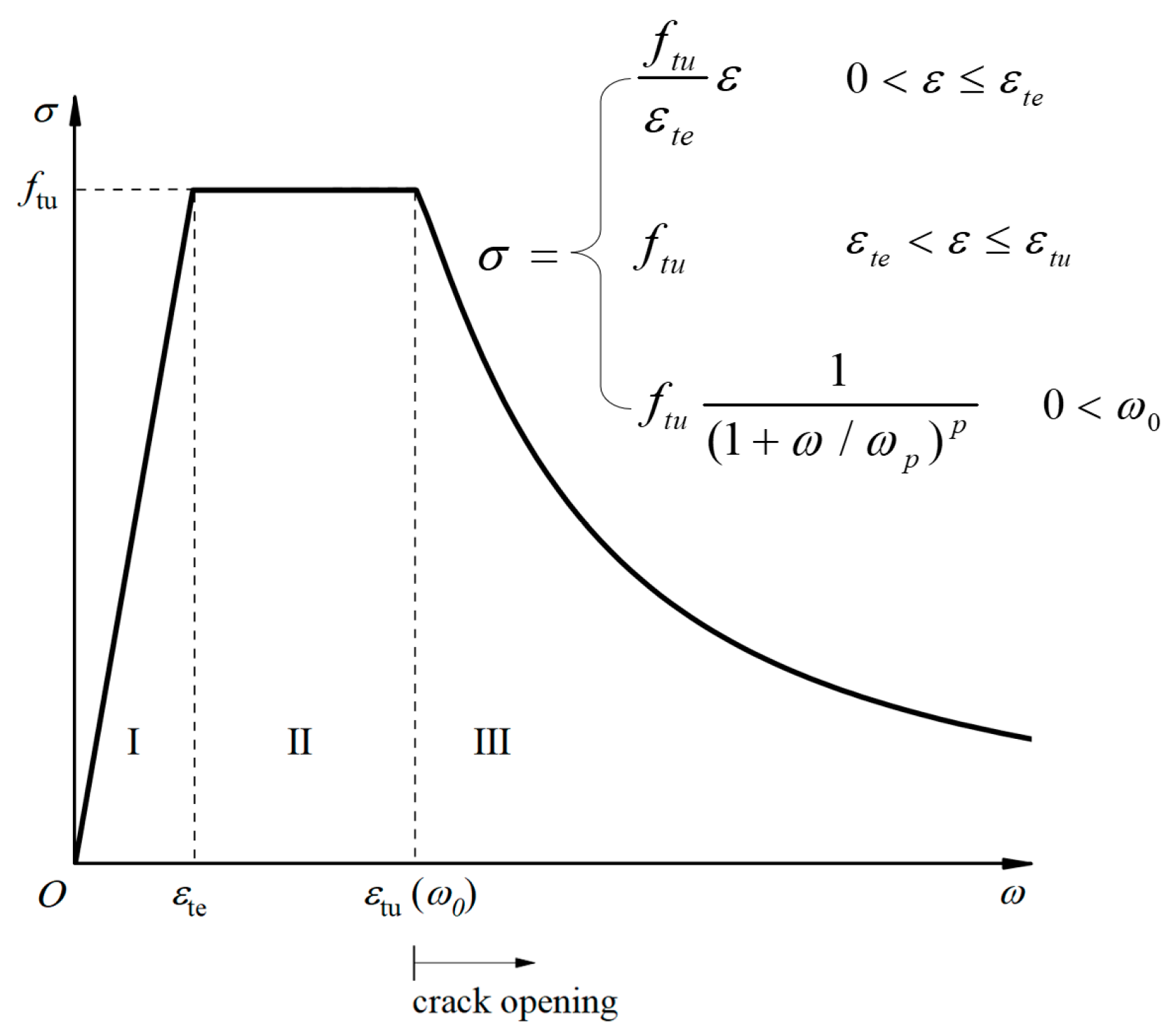

- The bridging effect of the steel fibers after UHPC cracking is considered, i.e., the contribution of the tensile strength of the UHPC is incorporated;

- (4)

- The contribution of the stud connectors to the moment of inertia of the cross-section is ignored.

6. Conclusions

- (1)

- The safety factors of this proposed joint at the serviceability and ultimate limit state were 2.8 and 3.6, respectively. Compared with the calculated equivalent safety factor of this bridge, the flexural capacity of the girder-to-pier joint can be verified.

- (2)

- During the loading process, first cracks initiated on the side of the NC layer beneath the UHPC layer. Subsequently, the cracks were observed on the top surface of the UHPC layer, at the interface of UHPC-NC, and at the central plane of the girder-to-pier joint in sequence. At the terminal stage of loading, the cracks within the girder-to-pier joint propagated more rapidly. The final crack distribution was characterized by numerous and dense crack patterns.

- (3)

- This paper also proposes a calculation method for the elastic flexural capacity of the girder-to-pier joint incorporating the tensile strength of UHPC, and the ratio of the test value to the calculated value was 1.02.

- (4)

- The application of UHPC can enhance the flexural capacity of this joint, with an increase of 8.5%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Xu, H.; Li, A.; Zhang, Y. Review on operating disease and effects of bridge plate rubber bearing. Earthq. Resist. Eng. Retrofit. 2021, 43, 104–113+95. [Google Scholar]

- Cazzador, E.; Fassin, M.; Bursi, O.S.; Paolacci, F.; Hechler, O. Performance Based Earth-quake Engineering applied to composite bridges with short and medium spans and CCBs. In Proceedings of the 8th International Symposium on Steel Bridges: Innovation & New Challenges 2015 (SBIC-2015), Istanbul, Turkey, 14–16 September 2015. [Google Scholar]

- Nie, J. Steel-Concrete Composite Bridges; People’s Communications Press: Beijing, China, 2011. [Google Scholar]

- VTrans Integral Abutment Committee. Integral Abutment Bridge Design Guidelines; Vermont Agency of Transportation: Montpelier, VT, USA, 2008. [Google Scholar]

- Kunin, J.; Alampalli, S. Integral abutment bridges: Current practice in UnitedStates and Canada. J. Perform. Constr. Facil. 2000, 14, 104–111. [Google Scholar] [CrossRef]

- AISl. Integral Abutments for Steel Bridges. In Highway Structures Design Handbook; American lron and Steel Institute: Washington, DC, USA, 1996. [Google Scholar]

- Way, J.A.; Yandzio, E. Integral Steel Bridges: Design of a Single-Span BridgeWorked Example; The Steel Construction Institute: Ascot, UK, 1997. [Google Scholar]

- Feldmann, M.; Naumes, J.; Pak, D.; Veljkovic, M.; Eriksen, J. Economic and Durable Design of Composite Bridges with Integral Abutments (INTAB+); European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Kim, S.H.; Yoon, J.H.; Kim, J.H.; Choi, W.J.; Ahn, J.H. Structural details of steel girder-abutment joints in integral bridges: An experimental study. J. Constr. Steel Res. 2012, 70, 190–212. [Google Scholar] [CrossRef]

- Lampe, N.; Mossahebi, N.; Yakel, A.; Farimani, R.; Azizinamini, A. Development and experimental testing of connections for the simple for dead load-continuous for live load steel bridge system. Eng. J. 2014, 51, 83–108. [Google Scholar] [CrossRef]

- Briseghella, B.; Zordan, T. An innovative steel-concrete joint for integral abutment bridges. J. Traffic Transp. Eng. 2015, 2, 209–222. [Google Scholar] [CrossRef]

- Abbiati, G.; Cazzador, E.; Alessandri, S.; Bursi, O.S.; Paolacci, F.; De Santis, S. Experimental characterization and component-based modeling of deck-to-pier connections for composite bridges. J. Constr. Steel Res. 2018, 150, 31–50. [Google Scholar] [CrossRef]

- Liang, C.; Liu, Y.; Zhao, C.; Lei, B.; Wu, J. Experimental and numerical study on an innovative girder-abutment joint in composite bridges with integral abutments. Constr. Build. Mater. 2018, 186, 709–730. [Google Scholar] [CrossRef]

- Fan, H.; Zheng, S.; Li, H.; Chen, M.; Shu, P. Stress Mechanism Analysis of the Joint Between Integral Abutment and Composite Beam. Progress. Steel Build. Struct. 2023, 25, 85–94. [Google Scholar]

- Tuutti, K. Corrosion of Steel in Concrete; Cementoch Betonginst: Stockholm, Sweden, 1982. [Google Scholar]

- Shevtsov, D.; Cao, N.L.; Nguyen, V.C.; Nong, Q.Q.; Le, H.Q.; Nguyen, D.A.; Zartsyn, I.; Kozaderov, O. Progress in Sensors for Monitoring Reinforcement Corrosion in Reinforced Concrete Structures—A Review. Sensors 2022, 22, 3421. [Google Scholar] [CrossRef] [PubMed]

- Kwak, H.G.; Seo, Y.J.; Jung, C.M. Effects of the Slab Casting Sequences and the Drying Shrinkage of Concrete Slabs on the Short-term and Long term Behavior of Composite Steel Box Girder: Part 1. Eng. Struct. 2000, 23, 1453–1466. [Google Scholar] [CrossRef]

- Zhao, W.D. The Design and Construction of Continuous Girder Bridge Transformed from Simply-Supported Structure. Master’s Thesis, Jilin University, Changchun, China, 2005. [Google Scholar]

- Zhao, Q. Steel Bridge—Steel Structure and Composite Structure Bridges; People’s Transportation Publishing House: Beijing, China, 2017. [Google Scholar]

- Nan, S. Technical Research on Prefabricated Steel Plate-Concrete Composite Beam Bridges. Ph.D. Thesis, Jilin University, Changchun, China, 2020. [Google Scholar]

- Zhang, L.Z. Study on Construction Technology of Panel Concrete Deck Steel-Concrete Composite Box Girder Bridge. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. [Google Scholar]

- Hassan, R.F.; Jaber, M.H.; Al-Salim, N.H.; Hussein, H.H. Experimental research on torsional strength of synthetic/steel fiber-reinforced hollow concrete beam. Eng. Struct. 2020, 220, 110948. [Google Scholar] [CrossRef]

- Dogu, M.; Menkulasi, F. A flexural design methodology for UHPC beams posttensioned with unbonded tendons. Eng. Struct. 2020, 207, 110193. [Google Scholar] [CrossRef]

- Wu, T.; Sun, Y.; Liu, X.; Cao, Y. Comparative study of the flexural behavior of steel fiber-reinforced lightweight aggregate concrete beams reinforced and prestressed with CFRP tendons. Eng. Struct. 2021, 233, 111901. [Google Scholar] [CrossRef]

- Lin, W.; Yoda, T.; Taniguchi, N. Application of SFRC in steel-concrete compositebeams subjected to hogging moment. J. Constr. Steel Res. 2014, 101, 175–183. [Google Scholar] [CrossRef]

- Graybeal, B.A.; Tanesi, J. Durability of an ultrahigh-performance concrete. J. Mater. Civil. Eng. 2007, 19, 848–854. [Google Scholar] [CrossRef]

- JTGD60-2015; General Specification for the Design of Highway Bridges and Culverts. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Liu, Y.; Zhang, G.; Zhou, X. Discussion on the value of the safety factor for the bridge structure. China J. Highw. Transp. 2022, 35, 116–132. [Google Scholar]

- Rafiee, A. Computer Modeling and Investigation on the Steel Corrosion in Cracked Ultra High Performance Concrete; University of Kassel: Kassel, Germany, 2012. [Google Scholar]

- Makita, T.; Bruhwiler, E. Tensile fatigue behaviour of ultra-high performance fibre reinforced concrete (UHPFRC). Mater. Struct. 2014, 47, 475–491. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, X.-D.; Li, W.-G.; Zhu, P.; Chen, H. Axial tensile behavior test of ultra high performance concrete. China Joual Highw. Transp. 2015, 28, 50–58. [Google Scholar]

- Citroni, R.; Di Paolo, F.; Livreri, P. Evaluation of an optical energy harvester for SHM application. Int. J. Electron. Commun. 2019, 111, 152918. [Google Scholar] [CrossRef]

| Section | Serviceability Limit State (SLS) | Ultimate Limit State (ULS) | ||

|---|---|---|---|---|

| Moment (kN·m) | Tensile Stress (MPa) | Moment (kN·m) | Tensile Stress (MPa) | |

| Section I | 4157.7 | 3.8 | 6454.5 | 4.6 |

| Section II | 5139.8 | 7.5 | 7819.3 | 9.3 |

| Material | Diameter/Thickness (mm) | fy (MPa) | fu (MPa) |

|---|---|---|---|

| reinforcement | 20 | 460 | 642 |

| 25 | 415 | 622 | |

| steel plate | 16 | 428 | 532 |

| 22 | 433 | 543 |

| Material | ftu (MPa) | fc (MPa) | Ec (GPa) |

|---|---|---|---|

| UHPC | 7.81 | 121.3 | 45.1 |

| C50 | / | 52.7 | 34.2 |

| Cement | Fly Ash | Silica Fume | Quartz Sand | Water | Steel Fiber | Water-Reducing Admixture |

|---|---|---|---|---|---|---|

| 600 | 150 | 100 | 1275 | 207 | 188 | 26 |

| Section | Pcr (kN) | σcr (MPa) | Design Stress (MPa) |

|---|---|---|---|

| Section 1 | 850 | 4.2 | 3.8 |

| Section 3 | 600 | 7.6 | 7.5 |

| yc (mm) | Flexural Capacity (kN·m) | Calculated Load (kN) | Test Load (kN) | Test Load/Calculated Load |

|---|---|---|---|---|

| 766.2 | 6661.5 | 2018.6 | 2058.7 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, W.; Zhang, B.; Yu, L.; Su, Q.; Matanmi, F.O. Flexural Performance of an Innovative Girder-to-Pier Joint for Composite Bridges with Integral Piers: Full-Scale Test. Materials 2025, 18, 1157. https://doi.org/10.3390/ma18051157

Xie W, Zhang B, Yu L, Su Q, Matanmi FO. Flexural Performance of an Innovative Girder-to-Pier Joint for Composite Bridges with Integral Piers: Full-Scale Test. Materials. 2025; 18(5):1157. https://doi.org/10.3390/ma18051157

Chicago/Turabian StyleXie, Wei, Binju Zhang, Litao Yu, Qingtian Su, and Fawas O. Matanmi. 2025. "Flexural Performance of an Innovative Girder-to-Pier Joint for Composite Bridges with Integral Piers: Full-Scale Test" Materials 18, no. 5: 1157. https://doi.org/10.3390/ma18051157

APA StyleXie, W., Zhang, B., Yu, L., Su, Q., & Matanmi, F. O. (2025). Flexural Performance of an Innovative Girder-to-Pier Joint for Composite Bridges with Integral Piers: Full-Scale Test. Materials, 18(5), 1157. https://doi.org/10.3390/ma18051157