Experimental and Model Calculation Research on Shrinkage of Hybrid Fiber-Reinforced Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Concrete Mixture Proportion

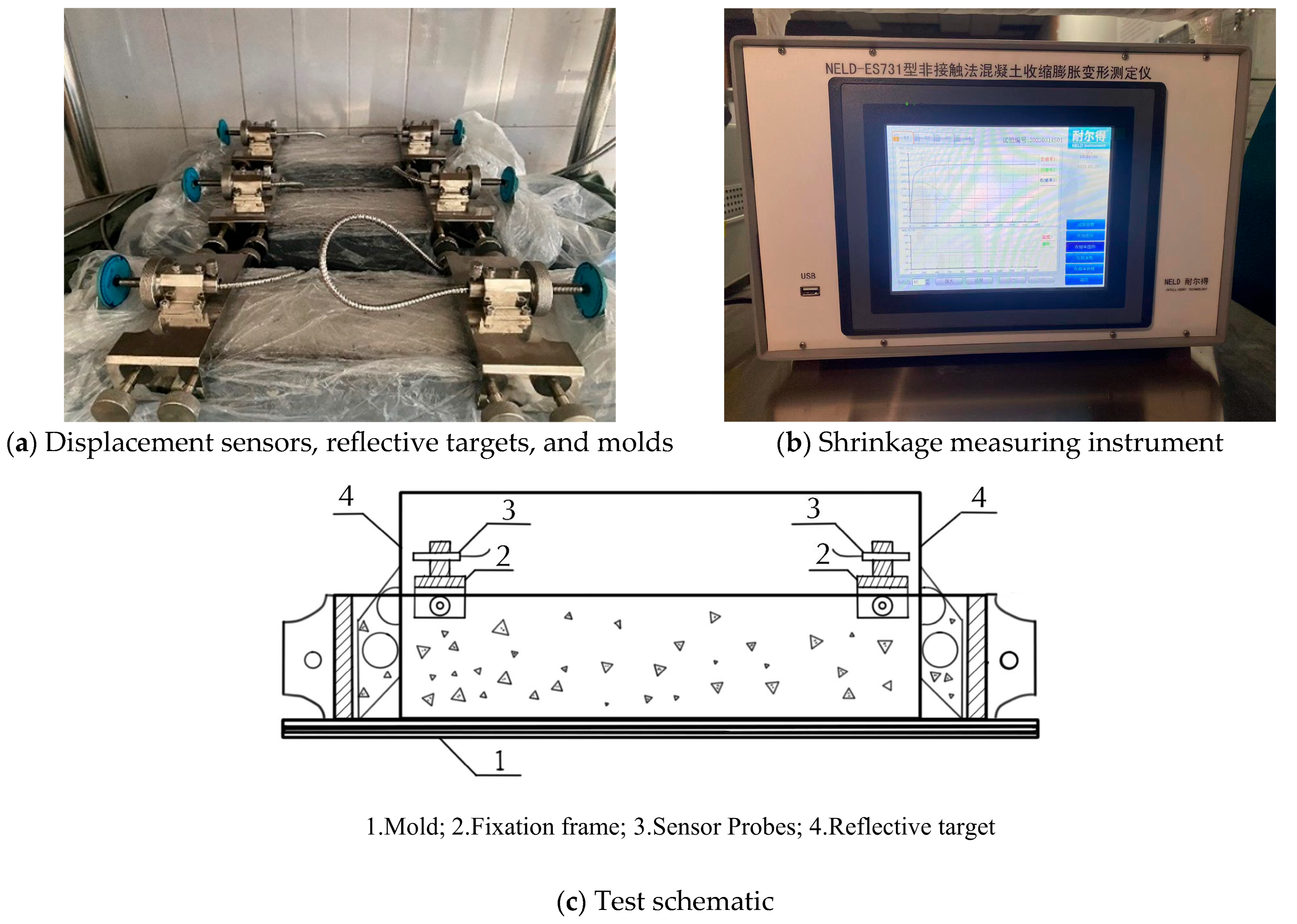

2.3. Experiment and Methodology

2.4. Experimental Data Processing

3. Test Results and Discussion

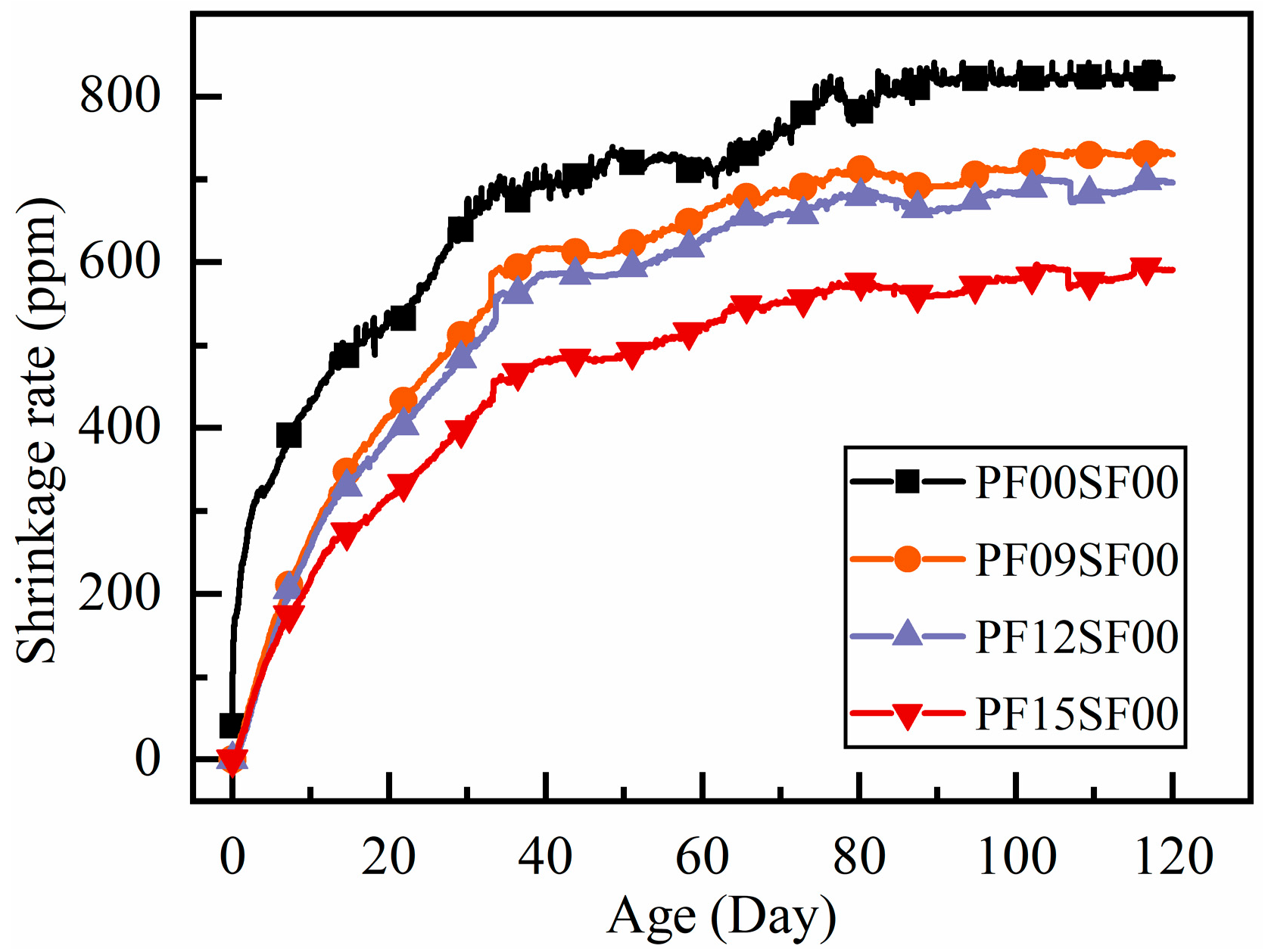

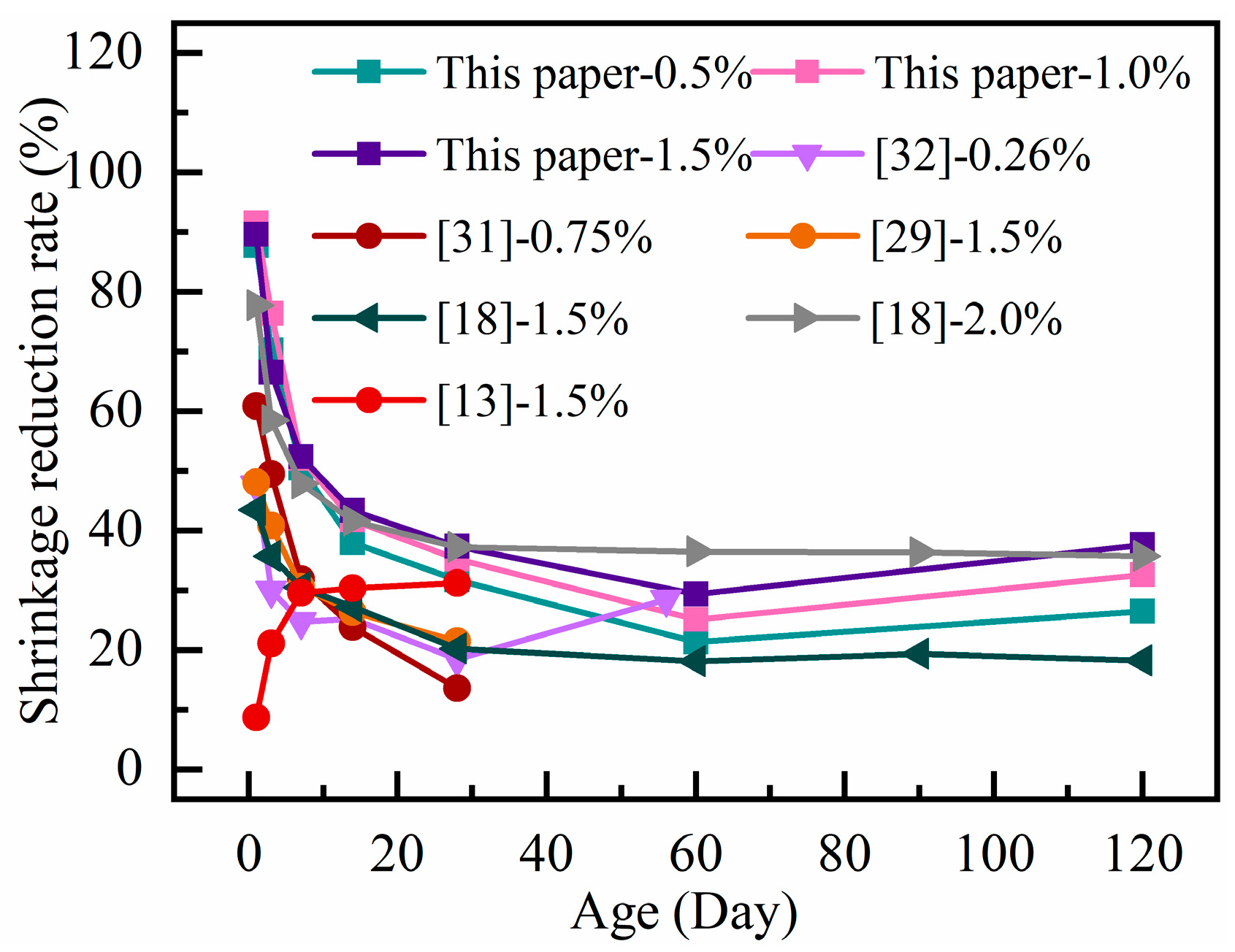

3.1. Influence of Polypropylene Fiber

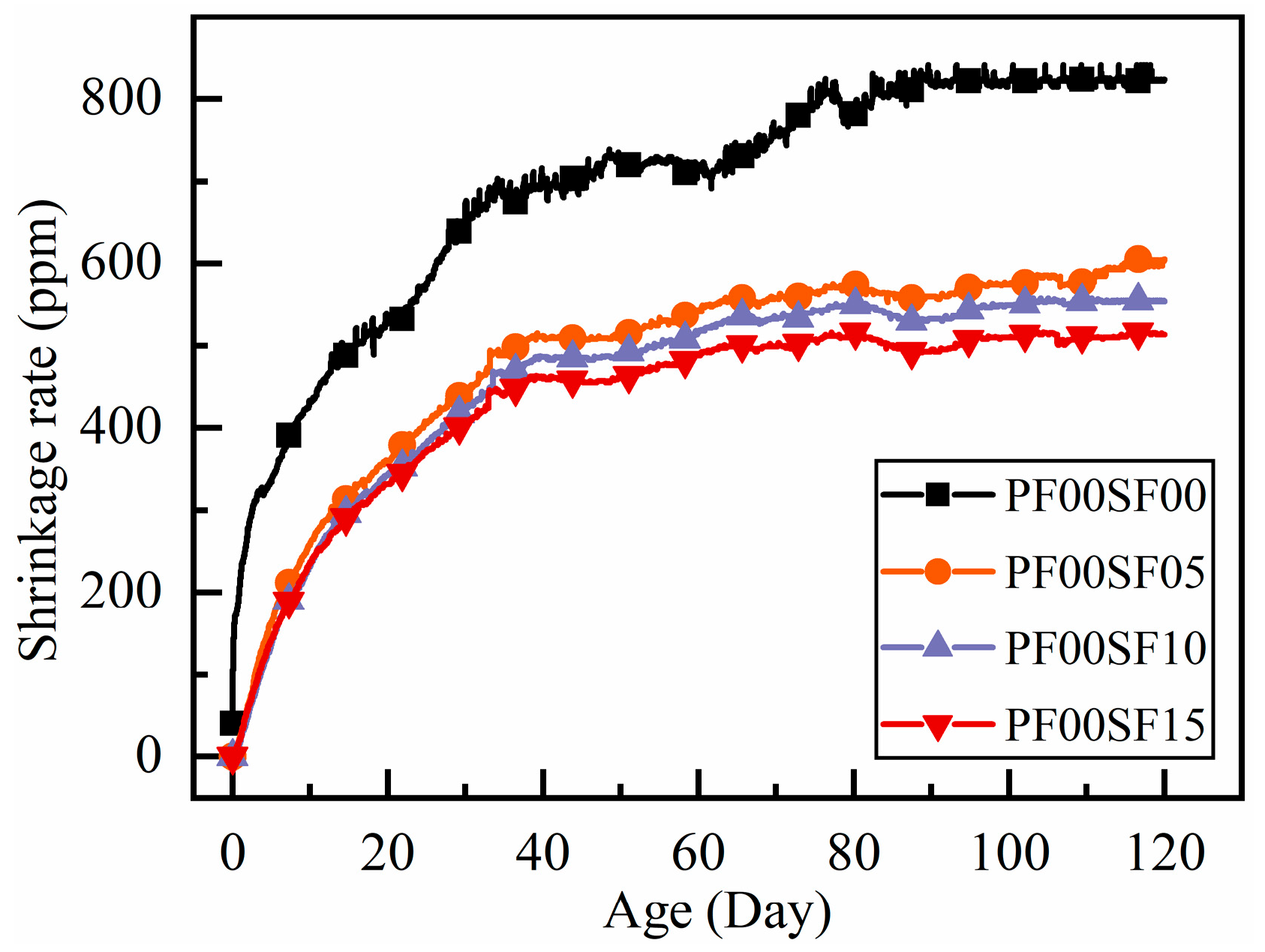

3.2. Influence of Steel Fiber

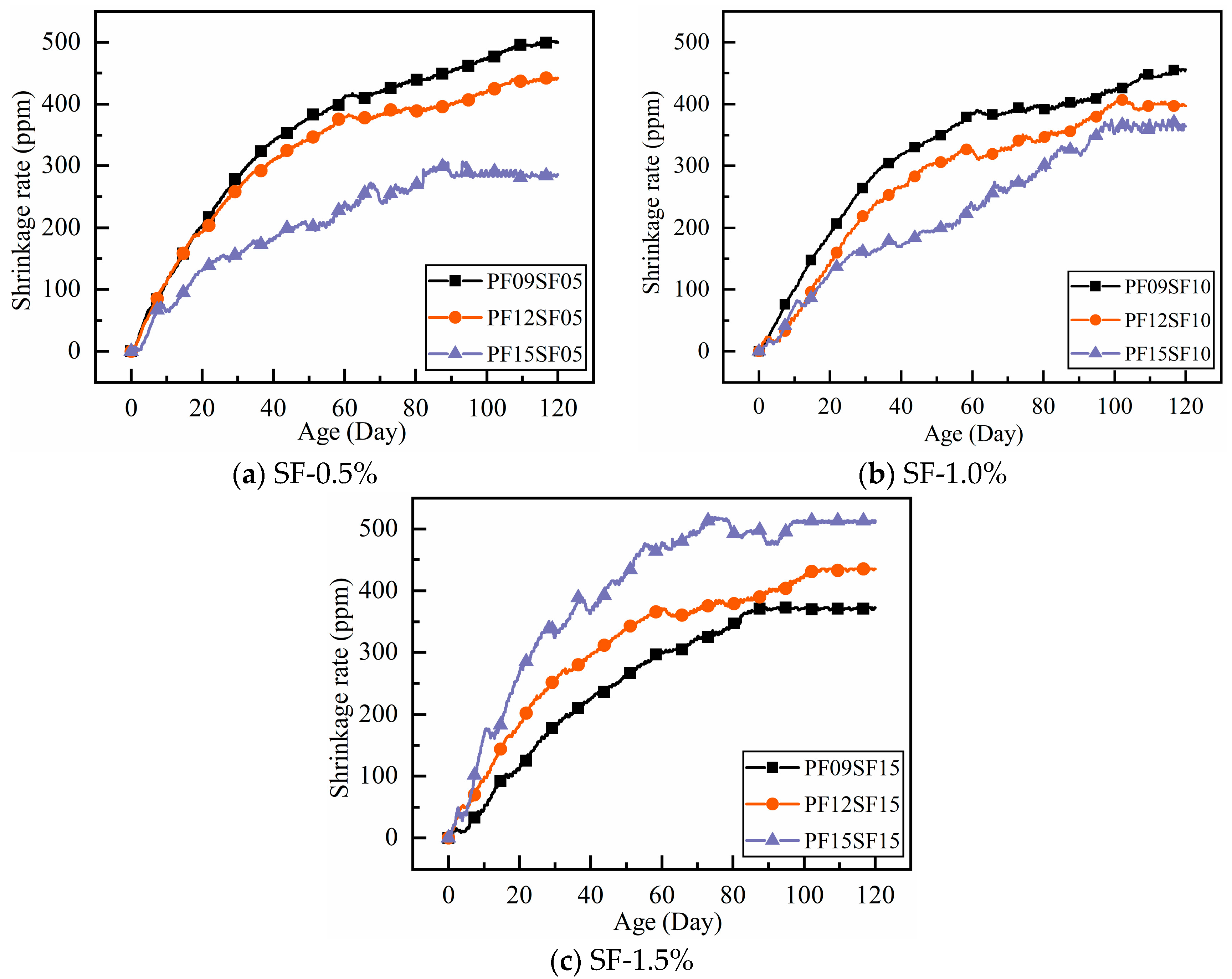

3.3. Influence of Hybrid Fiber

4. Shrinkage Calculation Model

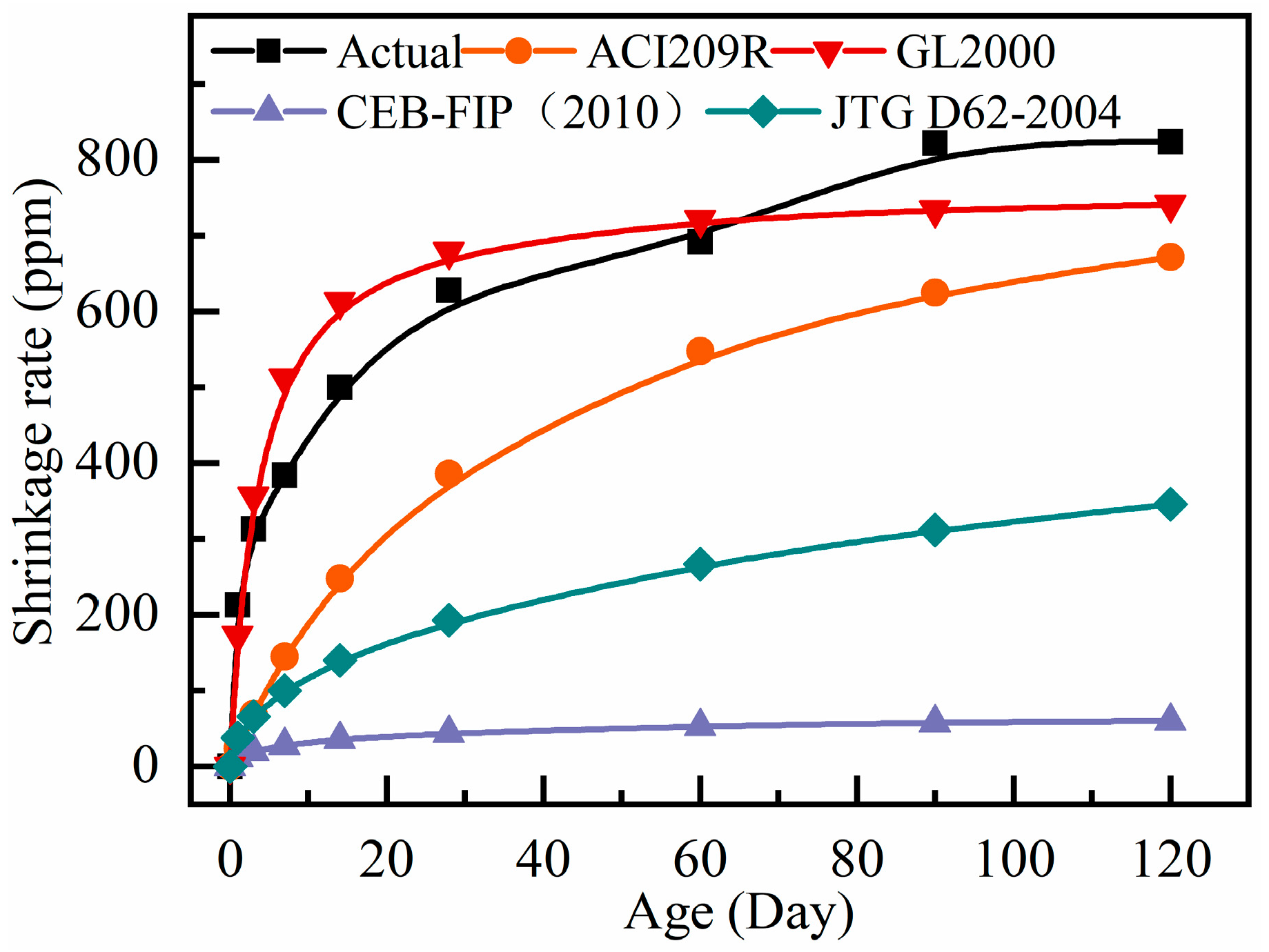

4.1. Comparison of Existing Calculation Model

4.2. Modified Prediction Model

4.2.1. Correction Based on GL2000 Model

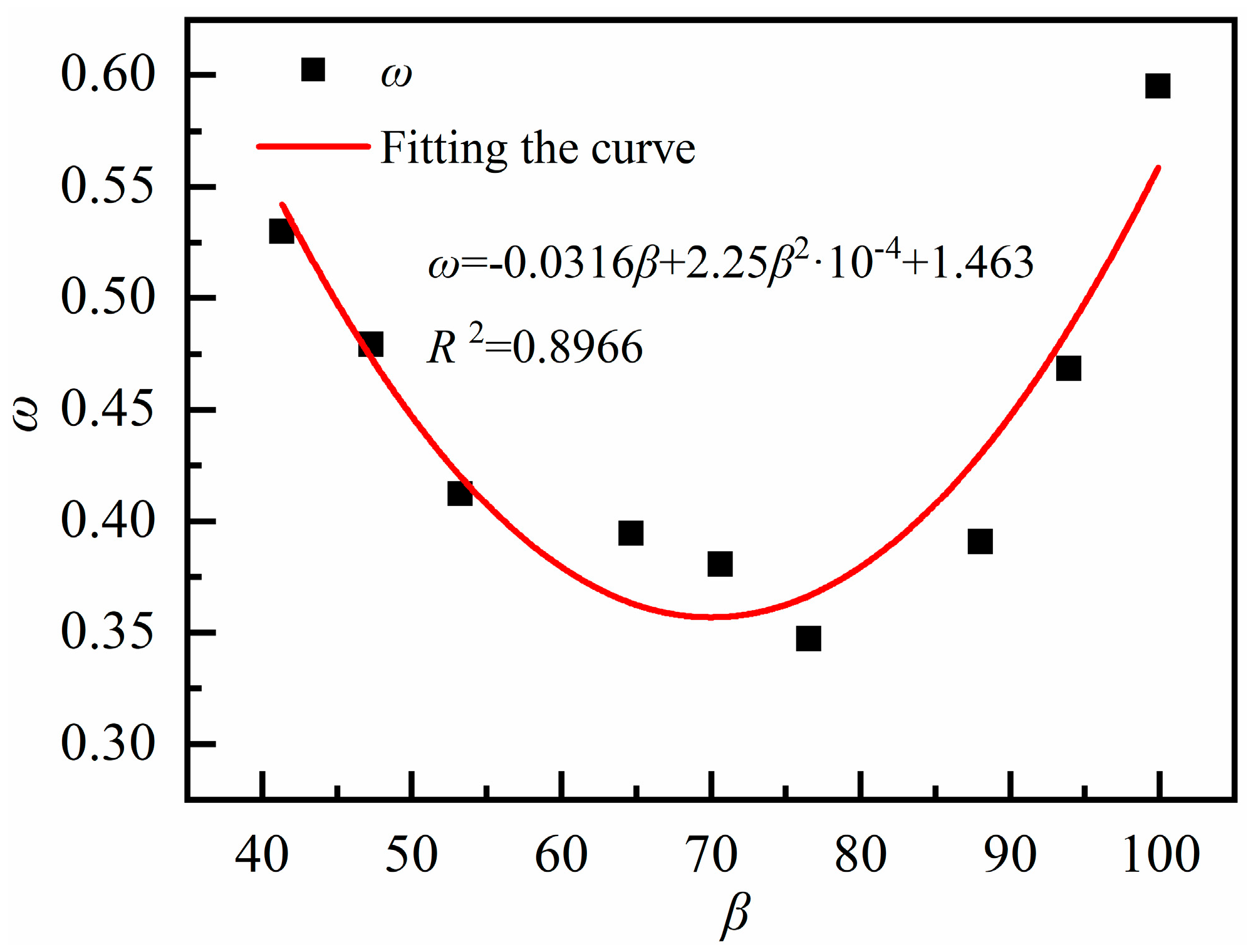

4.2.2. Shrinkage Prediction Model Considering Fiber Impact

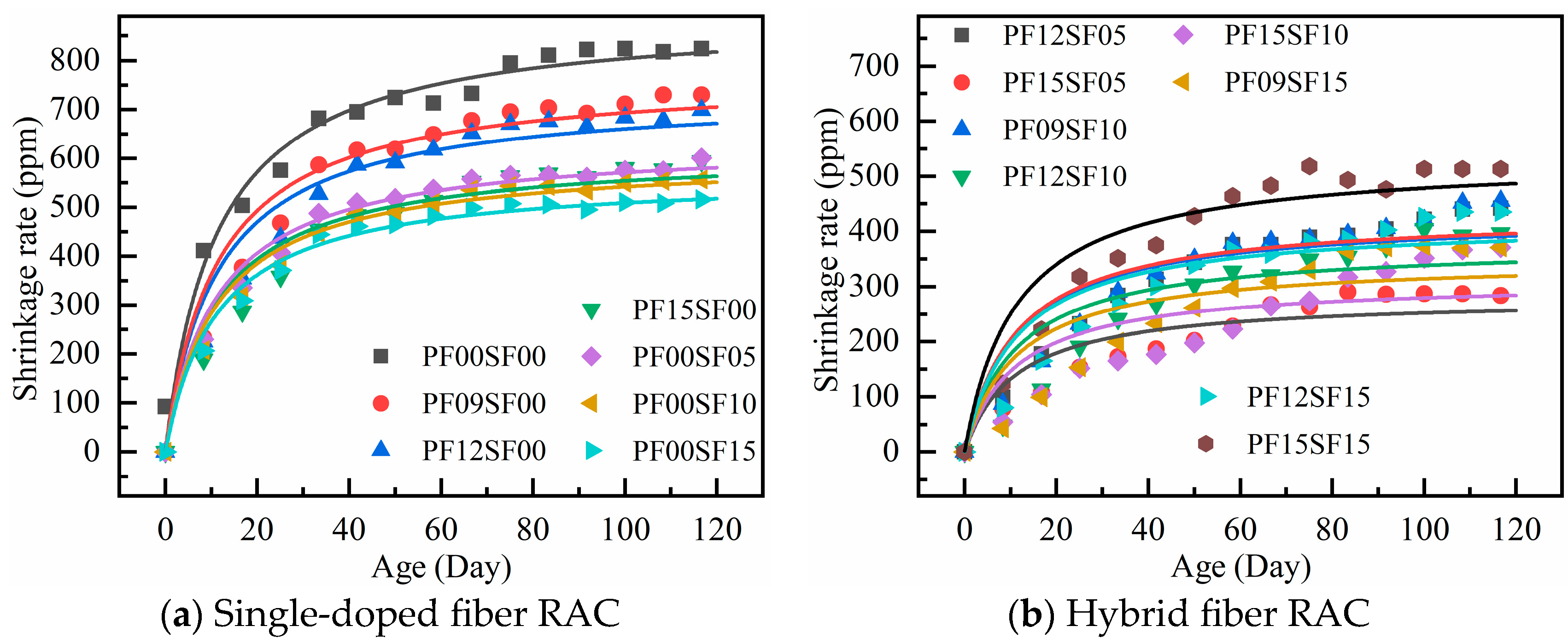

- Single-mixed fiber RAC shrinkage prediction model

- 2.

- RAC shrinkage prediction model for hybrid fibers

- 3.

- Shrinkage prediction model validation

5. Conclusions

- The shrinkage deformation of RAC increases with age, with the fastest rate of increase occurring during the first 14 days. After 40 days, the increase in shrinkage deformation gradually levels off, and after 60 days the increase becomes minimal. The shrinkage deformation value at 120 days is not significantly different from that at later ages.

- The shrinkage rate of the fiber-reinforced groups is much smaller than that of ordinary recycled concrete. When a single type of fiber is used, the shrinkage rate decreases with the increase in fiber content at different ages. The shrinkage performance of steel fiber-reinforced RAC is better than that of polypropylene fiber-reinforced RAC. At 120 days, PF09, PF12, and PF15 showed reductions of 11.4%, 15.5%, and 28.3%, respectively, compared to ordinary RAC. At 120 days, SF05, SF10, and SF15 showed reductions of 26.5%, 32.6%, and 37.6%, respectively, compared to ordinary RAC.

- The hybrid fiber group exhibits less shrinkage deformation compared to the single fiber group. The optimal reduction in shrinkage deformation occurs when the volume fraction of steel fiber is 0.5% and the polypropylene fiber content is 1.5 kg/m3. At 120 days, PF15SF05 showed a maximal shrinkage reduction of 52.8% compared to PF00SF05. The shrinkage progressively decreases with an increase in polypropylene fiber when the volume fraction of steel fiber in the hybrid group is between 0.5% and 1.0%, while the trend is exactly the opposite when the steel fiber content is 1.5%.

- Four shrinkage prediction models were compared with the measured values, among which the GL2000 shrinkage prediction model was the closest to the measured values. The autogenous shrinkage prediction model for hybrid fiber-reinforced RAC was established by modifying the GL2000 model and considering the effect of the fiber.

- After the computed theoretical values were verified, the findings demonstrated limited dispersion and good agreement with the experimental values. This indicates good practical applicability and can provide valuable reference for the structural design of hybrid fiber-reinforced RAC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al Shouny, A.; Issa, U.H.; Miky, Y.; Sharaky, I.A. Evaluating and selecting the best sustainable concrete mixes based on recycled waste materials. Case Stud. Constr. Mater. 2023, 19, e2382. [Google Scholar] [CrossRef]

- Dacić, A.; Mester-Szabó, E.; Fenyvesi, O.; Szalay, Z. Life cycle assessment of concrete incorporating all concrete recycling products. Case Stud. Constr. Mater. 2024, 21, e3910. [Google Scholar] [CrossRef]

- Prasad, D.; Singh, B.; Suman, S.K. Utilization of recycled concrete aggregate in bituminous mixtures: A comprehensive review. Constr. Build. Mater. 2022, 326, 126859. [Google Scholar] [CrossRef]

- Ouyang, K.; Liu, J.; Liu, S.; Song, B.; Guo, H.; Li, G.; Shi, C. Influence of pre-treatment methods for recycled concrete aggregate on the performance of recycled concrete: A review. Resour. Conserv. Recycl. 2023, 188, 106717. [Google Scholar] [CrossRef]

- Ouyang, K.; Shi, C.; Chu, H.; Guo, H.; Song, B.; Ding, Y.; Guan, X.; Zhu, J.; Zhang, H.; Wang, Y.; et al. An overview on the efficiency of different pretreatment techniques for recycled concrete aggregate. J. Clean. Prod. 2020, 263, 121264. [Google Scholar] [CrossRef]

- Wang, D.; Lu, C.; Zhu, Z.; Zhang, Z.; Liu, S.; Ji, Y.; Xing, Z. Mechanical performance of recycled aggregate concrete in green civil engineering: Review. Case Stud. Constr. Mater. 2023, 19, e2384. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Jian, S.; Wu, B. Compressive behavior of compound concrete containing demolished concrete lumps and recycled aggregate concrete. Constr. Build. Mater. 2021, 272, 121624. [Google Scholar] [CrossRef]

- Lv, Z.; Liu, C.; Zhu, C.; Bai, G.; Qi, H. Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete. Appl. Sci. 2019, 9, 4322. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Production of sustainable and structural fiber reinforced recycled aggregate concrete with improved fracture properties: A review. J. Clean. Prod. 2021, 279, 123832. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M. Mechanical behavior of recycled coarse aggregate concrete reinforced with steel fibers under direct shear. Cem. Concr. Compos. 2017, 79, 1–8. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Chen, W.; Xie, Y.; Li, B.; Li, B.; Wang, J.; Thom, N. Role of aggregate and fibre in strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2021, 299, 124002. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, J.; Kang, T.; Wang, F.; Ding, X.; Wang, S. Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete. Materials 2019, 12, 1196. [Google Scholar] [CrossRef]

- Zaid, O.; Martínez-García, R.; Abadel, A.A.; Fraile-Fernández, F.J.; Alshaikh, I.M.H.; Palencia-Coto, C. To determine the performance of metakaolin-based fiber-reinforced geopolymer concrete with recycled aggregates. Arch. Civ. Mech. Eng. 2022, 22, 114. [Google Scholar] [CrossRef]

- Aghaee, K.; Khayat, K.H. Design and performance of fiber-reinforced shrinkage compensating eco-friendly concrete. Constr. Build. Mater. 2023, 408, 133803. [Google Scholar] [CrossRef]

- Dong, W.; Yuan, W.; Zhou, X.; Zhao, X. Influence of specimen geometries and drying conditions on concrete cracking in restrained elliptical ring tests. Constr. Build. Mater. 2019, 207, 273–283. [Google Scholar] [CrossRef]

- Fang, C.; Ali, M.; Xie, T.; Visintin, P.; Sheikh, A.H. The influence of steel fibre properties on the shrinkage of ultra-high performance fibre reinforced concrete. Constr. Build. Mater. 2020, 242, 117993. [Google Scholar] [CrossRef]

- Hassan, A.; ElNemr, A.; Goebel, L.; Koenke, C. Effect of hybrid polypropylene fibers on mechanical and shrinkage behavior of alkali-activated slag concrete. Constr. Build. Mater. 2024, 411, 134485. [Google Scholar] [CrossRef]

- Ma, R.; Guo, L.; Ye, S.; Sun, W.; Liu, J. Influence of Hybrid Fiber Reinforcement on Mechanical Properties and Autogenous Shrinkage of an Ecological UHPFRCC. J. Mater. Civ. Eng. 2019, 31, 04019032. [Google Scholar] [CrossRef]

- GB 175-2023; Common Portland Cement. Standards Press of China: Beijing, China, 2023.

- GB/T 1596-2017; Fly Ash Used for Cement and Concrete. Standards Press of China: Beijing, China, 2017.

- GB/T 25177-2010; Recycled Coarse Aggregate for Concrete. China Architecture & Building Press: Beijing, China, 2010.

- GB/T 25176-2010; Recycled Fine Aggregate for Concrete an Mortar. Standards Press of China: Beijing, China, 2010.

- GB 8076-2008; Concrete Admixtures. Standards Press of China: Beijing, China, 2008.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Standards Press of China: Beijing, China, 2009.

- Matalkah, F.; Ababneh, A.; Aqel, R. Effect of fiber type and content on the mechanical properties and shrinkage characteristics of alkali-activated kaolin. Struct. Concr. J. FIB 2022, 23, 300–310. [Google Scholar] [CrossRef]

- Ding, D.; Zhang, L.; Zhao, J.; Li, C.; Wang, Z. Effects of air-entraining agent and polypropylene fiber on the mechanical properties, autogenous shrinkage, and fracture properties of fully recycled aggregate concrete. Front. Mater. 2022, 9, 1049304. [Google Scholar] [CrossRef]

- Vafaei, D.; Ma, X.; Hassanli, R.; Duan, J.; Zhuge, Y. Microstructural behaviour and shrinkage properties of high-strength fiber-reinforced seawater sea-sand concrete. Constr. Build. Mater. 2022, 320, 126222. [Google Scholar] [CrossRef]

- Statkauskas, M.; Grinys, A.; Vaičiukynienė, D. Investigation of Concrete Shrinkage Reducing Additives. Materials 2022, 15, 3407. [Google Scholar] [CrossRef]

- Roberti, F.; Cesari, V.F.; de Matos, P.R.; Pelisser, F.; Pilar, R. High- and ultra-high-performance concrete produced with sulfate-resisting cement and steel microfiber: Autogenous shrinkage, fresh-state, mechanical properties and microstructure characterization. Constr. Build. Mater. 2021, 268, 121092. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.; Choi, W. Characteristics of Restrained Drying Shrinkage on Arched Steel Fiber-Reinforced Concrete. Appl. Sci. 2021, 11, 7537. [Google Scholar] [CrossRef]

- ACI PRC-209.2-08; Guide for Modeling and Calculating Shrinkage and Creep in Hardened Concrete. American Concrete Institute: Indianapolis, IN, USA, 2008.

- Pan, Z.; Zhang, H.; Zeng, B.; Wang, Y. Statistical Evaluation of CEB-FIP 2010 Model for Concrete Creep and Shrinkage. Materials 2023, 16, 1576. [Google Scholar] [CrossRef]

- Delsaute, B.; Torrenti, J.M.; Nedjar, B.; Staquet, S.; Bourchy, A.; Briffaut, M. Modeling compressive basic creep of concrete at early age. Mech. Time-Depend. Mater. 2024, 28, 143–162. [Google Scholar] [CrossRef]

- JTG 3362-2018; Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridged and Culverts. China Communications Press: Beijing, China, 2018.

| Index | Units | Standard Values | Test Value | Index | Units | Standard Values | Test Value |

|---|---|---|---|---|---|---|---|

| Compressive strength (3 d) | MPa | ≥17.0 | 23.5 | Specific surface area | m2/kg | ≥300 | 345 |

| Flexural strength (3 d) | MPa | ≥3.5 | 5.6 | Initial setting time | Min | ≥45 | 230 |

| Compressive strength (28 d) | MPa | ≥42.5 | 44.8 | Final setting time | Min | ≤600 | 280 |

| Flexural strength (28 d) | MPa | ≥6.5 | 8.5 | Loss on ignition | % | ≤5.00 | 2.81 |

| Index | Fineness Modulus | Bulk Density (kg/m3) | Moisture Content/% | SO3/% | Water Demand Ratio |

|---|---|---|---|---|---|

| Standard values | 12.00 | — | 1.0 | 3.0 | 95 |

| Test result | 5.692 | 1120 | 0.10 | 0.933 | 92 |

| Sieve Size | 4.75 mm | 2.36 mm | 1.18 mm | 0.6 mm | 0.3 mm | 0.15 mm |

|---|---|---|---|---|---|---|

| Standard values | 10~0 | 35~5 | 65~35 | 85~71 | 95~80 | 100~85 |

| Residual of sieve | 2 | 35 | 54 | 71 | 81 | 92 |

| Sieve Size | 2.36 mm | 4.75 mm | 9.5 mm | 16 mm | 19 mm | 26.5 mm |

|---|---|---|---|---|---|---|

| Standard values | 95~100 | 90~100 | 40~80 | — | 0~10 | 0 |

| Accumulated screening rate (%) | 98.42 | 95.57 | 69.14 | 49.31 | 9.875 | 0 |

| Category | Apparent Density (kg/m3) | Crushing Index/% | Water Absorption Rate/% | Mud Content/% |

|---|---|---|---|---|

| Standard values | >2450 | ≤20.0 | ≤8.0 | ≤5.0 |

| Test result | 2612 | 16.4 | 6.95 | 0.4 |

| Specimen Number | Mixture Proportions (kg/m3) | Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| W | OPC | FA | RFA | RCA | WRA | PF | SF | ||

| PF00SF00 | 200 | 457 | 114 | 628 | 942 | 5.484 | 0 | 0 | 38.87 |

| PF09SF00 | 200 | 457 | 114 | 628 | 942 | 5.484 | 0.9 | 0 | 46.76 |

| PF12SF00 | 200 | 457 | 114 | 628 | 942 | 5.484 | 1.2 | 0 | 49.49 |

| PF15SF00 | 200 | 457 | 114 | 628 | 942 | 5.484 | 1.5 | 0 | 48.91 |

| PF00SF05 | 200 | 457 | 114 | 623 | 935 | 5.484 | 0 | 39 | 52.70 |

| PF00SF10 | 200 | 457 | 114 | 618 | 927 | 5.484 | 0 | 78 | 54.50 |

| PF00SF15 | 200 | 457 | 114 | 613 | 920 | 5.484 | 0 | 117 | 54.63 |

| PF09SF05 | 200 | 457 | 114 | 623 | 935 | 5.484 | 0.9 | 39 | 52.01 |

| PF12SF05 | 200 | 457 | 114 | 623 | 935 | 5.484 | 1.2 | 39 | 60.98 |

| PF15SF05 | 200 | 457 | 114 | 623 | 935 | 5.484 | 1.5 | 39 | 59.78 |

| PF09SF10 | 200 | 457 | 114 | 618 | 927 | 5.484 | 0.9 | 78 | 63.36 |

| PF12SF10 | 200 | 457 | 114 | 618 | 927 | 5.484 | 1.2 | 78 | 59.47 |

| PF15SF10 | 200 | 457 | 114 | 618 | 927 | 5.484 | 1.5 | 78 | 56.52 |

| PF09SF15 | 200 | 457 | 114 | 613 | 920 | 5.484 | 0.9 | 117 | 51.05 |

| PF12SF15 | 200 | 457 | 114 | 613 | 920 | 5.484 | 1.2 | 117 | 57.05 |

| PF15SF15 | 200 | 457 | 114 | 613 | 920 | 5.484 | 1.5 | 117 | 56.34 |

| Test Number | Maximum Shrinkage Rate (ppm) | ||||||

|---|---|---|---|---|---|---|---|

| 1 d | 3 d | 7 d | 14 d | 28 d | 60 d | 120 d | |

| PF00SF00 | 213 | 313 | 384 | 500 | 628 | 692 | 824 |

| PF09SF00 | 23 | 94 | 205 | 339 | 501 | 658 | 730 |

| PF12SF00 | 17 | 78 | 194 | 322 | 469 | 628 | 696 |

| PF15SF00 | 16 | 75 | 170 | 269 | 390 | 523 | 591 |

| PF00SF05 | 26 | 93 | 190 | 310 | 429 | 544 | 606 |

| PF00SF10 | 18 | 74 | 184 | 291 | 407 | 518 | 555 |

| PF00SF15 | 22 | 105 | 183 | 283 | 393 | 489 | 514 |

| PF09SF05 | 8 | 80 | 84 | 151 | 268 | 411 | 500 |

| PF12SF05 | 4 | 90 | 82 | 153 | 251 | 379 | 442 |

| PF15SF05 | 6 | 10 | 62 | 90 | 151 | 243 | 286 |

| PF09SF10 | 3 | 26 | 70 | 141 | 256 | 384 | 456 |

| PF12SF10 | 13 | 23 | 31 | 89 | 209 | 324 | 397 |

| PF15SF10 | 1 | 16 | 36 | 78 | 164 | 236 | 364 |

| PF09SF15 | 10 | 11 | 30 | 87 | 170 | 301 | 373 |

| PF12SF15 | 7 | 44 | 70 | 137 | 243 | 371 | 435 |

| PF15SF15 | 6 | 37 | 88 | 171 | 348 | 476 | 513 |

| Age (d) | Maximum Shrinkage Rate (ppm) | ||||

|---|---|---|---|---|---|

| Measured Value | ACI209R | CEB-FIP | GL2000 | JTG D62-2004 | |

| 1 | 213 | 24.12 | 12.30 | 172.51 | 38.41 |

| 3 | 313 | 68.55 | 19.86 | 356.25 | 66.26 |

| 7 | 384 | 144.70 | 27.87 | 512.10 | 100.41 |

| 14 | 500 | 248.06 | 35.74 | 612.59 | 140.08 |

| 28 | 628 | 385.87 | 44.29 | 679.247 | 192.96 |

| 60 | 692 | 548.33 | 53.42 | 721.08 | 267.26 |

| 90 | 822 | 625.10 | 57.66 | 734.27 | 312.35 |

| 120 | 824 | 672.15 | 60.25 | 741.05 | 345.54 |

| 0 | 0.476 | 0.931 | 0.053 | 0.697 | |

| Test Number | R2 | Test Number | R2 | ||

|---|---|---|---|---|---|

| PF00SF00 | 1 | 0.979 | PF12SF05 | 0.479 | 0.851 |

| PF09SF00 | 0.862 | 0.940 | PF15SF05 | 0.412 | 0.807 |

| PF12SF00 | 0.821 | 0.935 | PF09SF10 | 0.394 | 0.835 |

| PF15SF00 | 0.689 | 0.928 | PF12SF10 | 0.381 | 0.782 |

| PF00SF05 | 0.710 | 0.975 | PF15SF10 | 0.348 | 0.750 |

| PF00SF10 | 0.674 | 0.968 | PF09SF15 | 0.391 | 0.790 |

| PF00SF15 | 0.633 | 0.979 | PF12SF15 | 0.469 | 0.826 |

| PF09SF05 | 0.530 | 0.818 | PF15SF15 | 0.595 | 0.817 |

| R2 Average | 0.877 | ||||

| Test Number | PF09SF05 | PF12SF05 | PF15SF05 | PF09SF10 | PF12SF10 | PF15SF10 | PF09SF15 | PF12SF15 |

|---|---|---|---|---|---|---|---|---|

| 41.335 | 47.275 | 53.215 | 64.670 | 70.610 | 76.550 | 88.005 | 93.945 |

| Test Number | 1 d | 3 d | 7 d | 14 d | 28 d | 60 d | 120 d |

|---|---|---|---|---|---|---|---|

| PF00SF00 | 1.128 | 1.044 | 0.956 | 0.988 | 0.979 | 0.985 | 0.942 |

| PF09SF00 | 1.276 | 1.152 | 1.064 | 1.08 | 1.014 | 1.057 | 0.980 |

| PF12SF00 | 1.110 | 1.973 | 1.145 | 1.159 | 1.012 | 1.035 | 0.961 |

| PF15SF00 | 1.068 | 0.908 | 1.034 | 1.002 | 1.044 | 1.156 | 1.052 |

| PF00SF05 | 1.032 | 1.033 | 0.921 | 0.816 | 0.859 | 0.846 | 0.989 |

| PF00SF10 | 1.389 | 1.161 | 1.144 | 1.046 | 0.962 | 0.942 | 0.905 |

| PF00SF15 | 1.097 | 1.173 | 0.85 | 0.836 | 1.016 | 1.018 | 1.086 |

| PF09SF05 | 1.236 | 1.073 | 1.109 | 0.977 | 1.088 | 1.047 | 0.885 |

| PF12SF05 | 1.108 | 1.987 | 1.074 | 1.029 | 1.100 | 0.99 | 0.873 |

| PF15SF05 | 1.090 | 0.876 | 1.115 | 1.106 | 1.168 | 1.070 | 1.097 |

| PF09SF10 | 1.165 | 1.109 | 1.066 | 1.067 | 0.898 | 0.846 | 0.846 |

| PF12SF10 | 0.984 | 1.892 | 0.910 | 0.969 | 1.079 | 0.868 | 0.728 |

| PF15SF10 | 1.147 | 1.263 | 1.053 | 1.104 | 1.010 | 1.021 | 0.814 |

| PF09SF15 | 1.298 | 1.064 | 1.055 | 1.020 | 1.194 | 1.122 | 0.931 |

| PF12SF15 | 1.204 | 1.053 | 1.152 | 1.037 | 1.060 | 1.029 | 0.903 |

| PF15SF15 | 1.105 | 0.805 | 1.149 | 1.199 | 1.011 | 0.921 | 0.879 |

| Test Number | Mean | Mean Square Error | Coefficient of Variation |

|---|---|---|---|

| PF00SF00 | 1.003 | 0.059 | 0.059 |

| PF09SF00 | 1.089 | 0.091 | 0.084 |

| PF12SF00 | 1.199 | 0.323 | 0.269 |

| PF15SF00 | 1.037 | 0.069 | 0.066 |

| PF00SF05 | 0.928 | 0.084 | 0.091 |

| PF00SF10 | 1.078 | 0.156 | 0.145 |

| PF00SF15 | 1.010 | 0.117 | 0.116 |

| PF09SF05 | 1.059 | 0.101 | 0.096 |

| PF12SF05 | 1.165 | 0.343 | 0.295 |

| PF15SF05 | 1.074 | 0.085 | 0.080 |

| PF09SF10 | 0.999 | 0.123 | 0.123 |

| PF12SF10 | 1.061 | 0.353 | 0.333 |

| PF15SF10 | 1.058 | 0.128 | 0.121 |

| PF09SF15 | 1.097 | 0.111 | 0.101 |

| PF12SF15 | 1.06 | 0.089 | 0.084 |

| PF15SF15 | 1.009 | 0.137 | 0.136 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; He, M.; Li, X.; Li, C.; Zhao, J.; Wang, H.-C. Experimental and Model Calculation Research on Shrinkage of Hybrid Fiber-Reinforced Recycled Aggregate Concrete. Materials 2025, 18, 1183. https://doi.org/10.3390/ma18051183

Zhang L, He M, Li X, Li C, Zhao J, Wang H-C. Experimental and Model Calculation Research on Shrinkage of Hybrid Fiber-Reinforced Recycled Aggregate Concrete. Materials. 2025; 18(5):1183. https://doi.org/10.3390/ma18051183

Chicago/Turabian StyleZhang, Lijuan, Meng He, Xinzhe Li, Changbin Li, Jun Zhao, and Hai-Cui Wang. 2025. "Experimental and Model Calculation Research on Shrinkage of Hybrid Fiber-Reinforced Recycled Aggregate Concrete" Materials 18, no. 5: 1183. https://doi.org/10.3390/ma18051183

APA StyleZhang, L., He, M., Li, X., Li, C., Zhao, J., & Wang, H.-C. (2025). Experimental and Model Calculation Research on Shrinkage of Hybrid Fiber-Reinforced Recycled Aggregate Concrete. Materials, 18(5), 1183. https://doi.org/10.3390/ma18051183