Effect of Additive Friction Stir Deposition Processing on the Microstructure and Mechanical Properties of 1045 Steel

Abstract

:1. Introduction

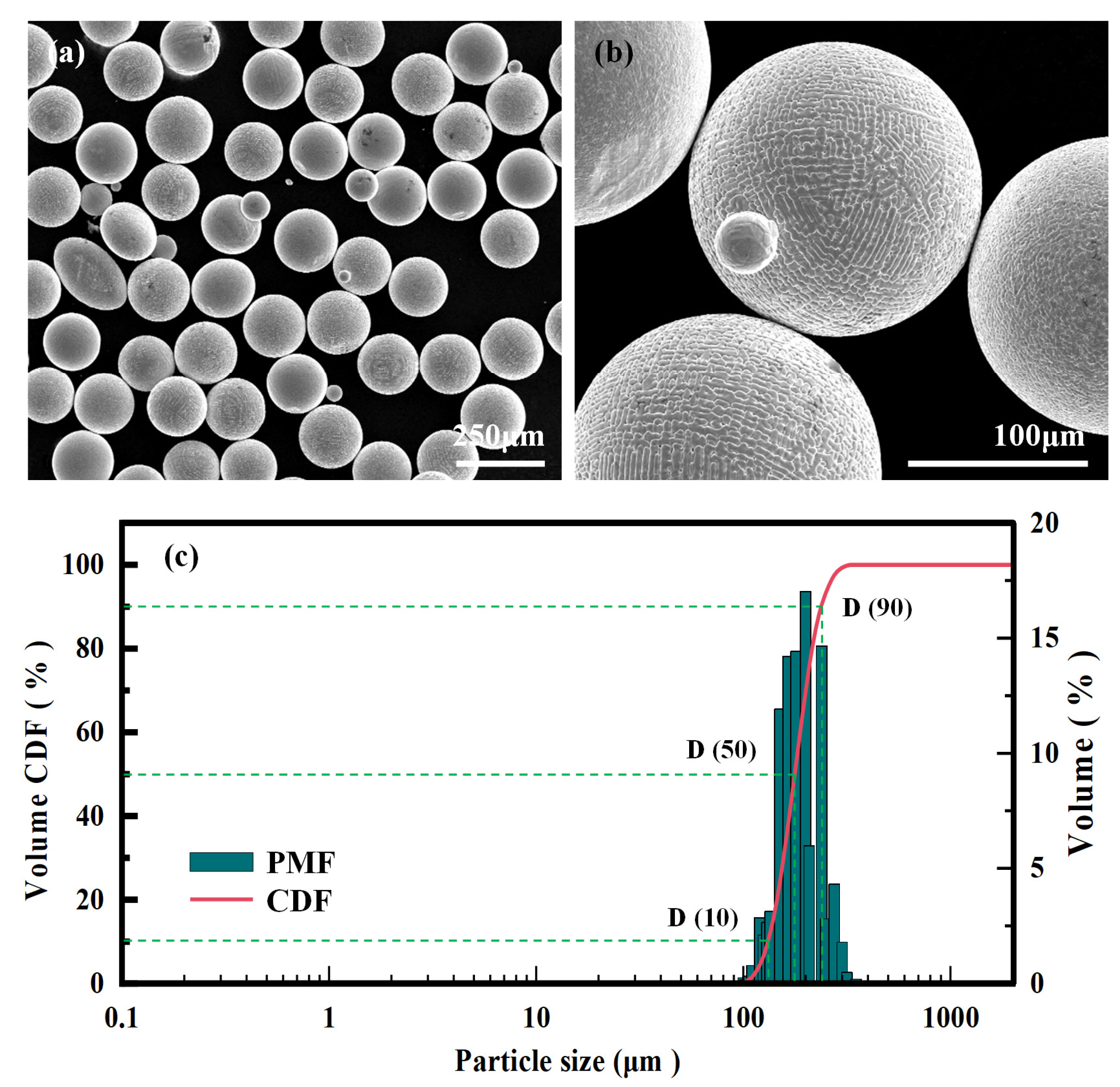

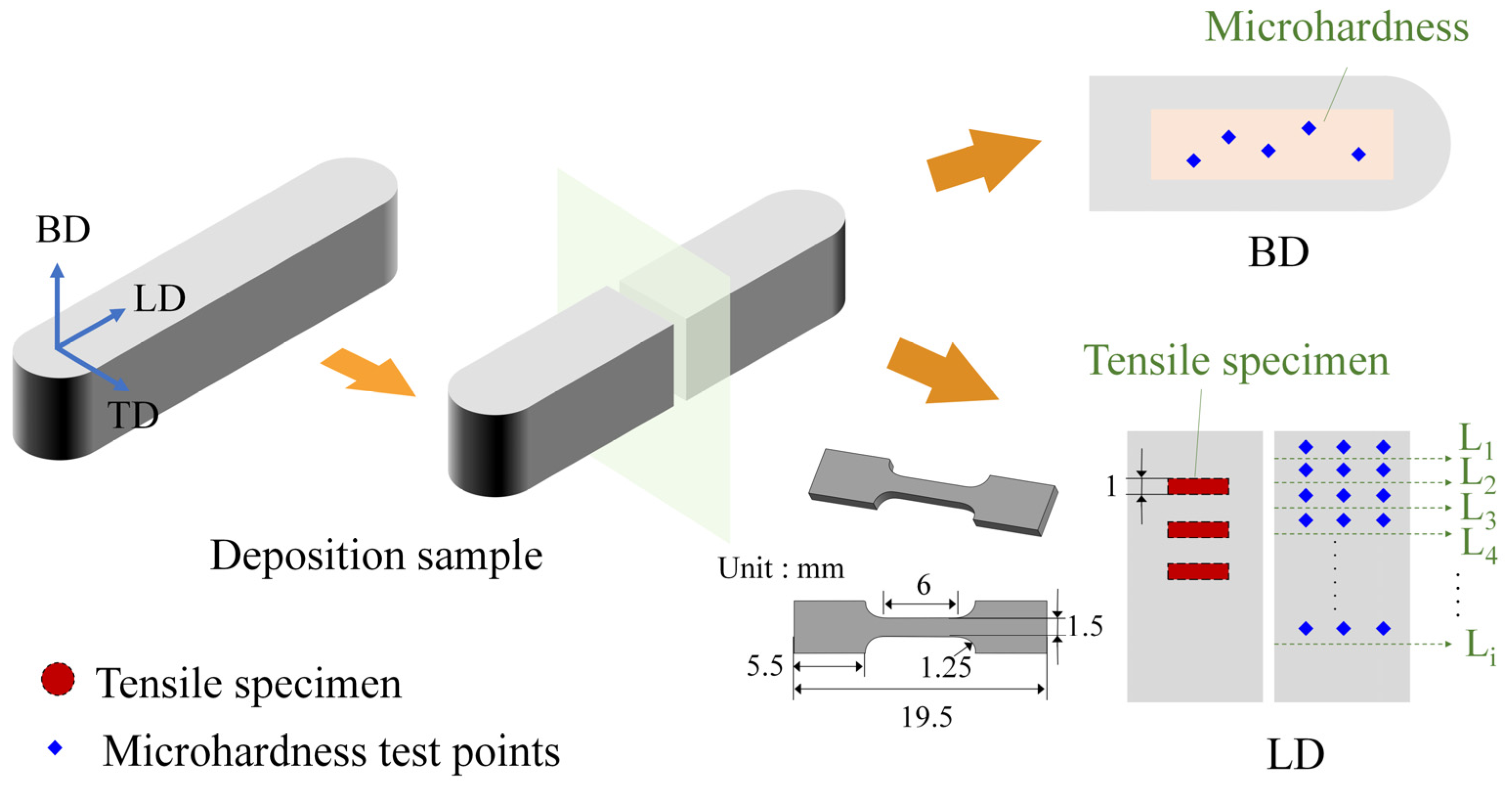

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure Analysis

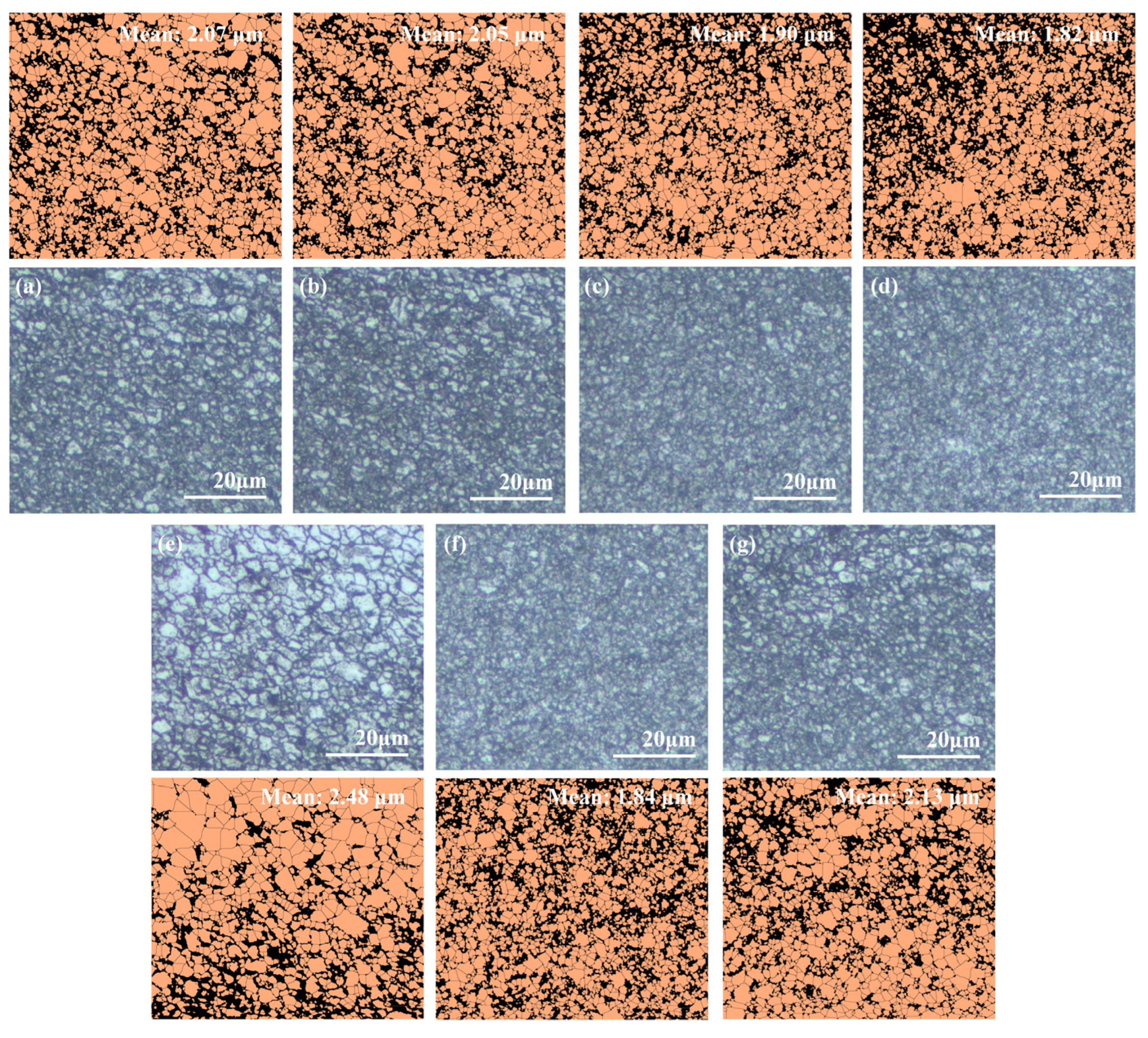

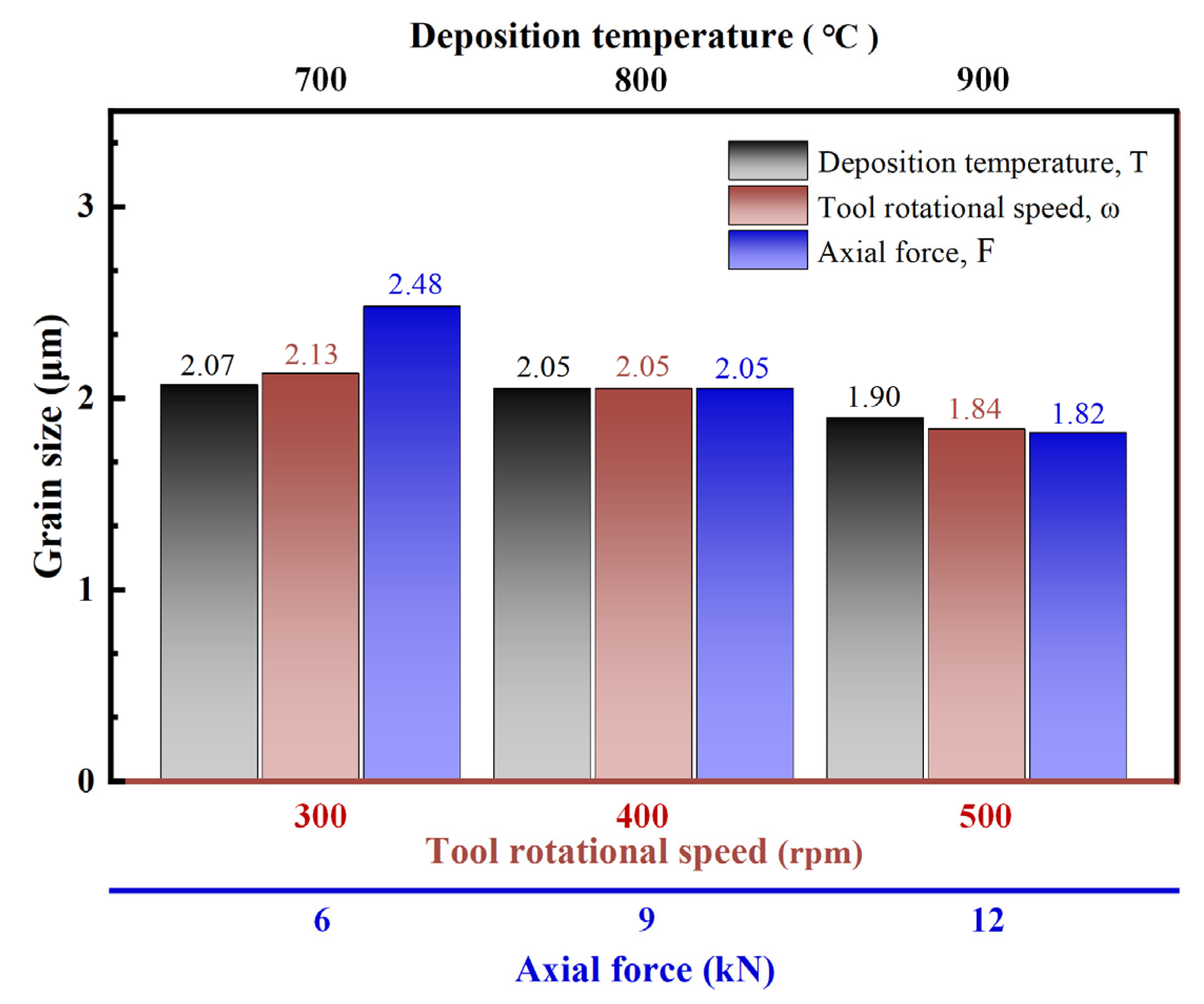

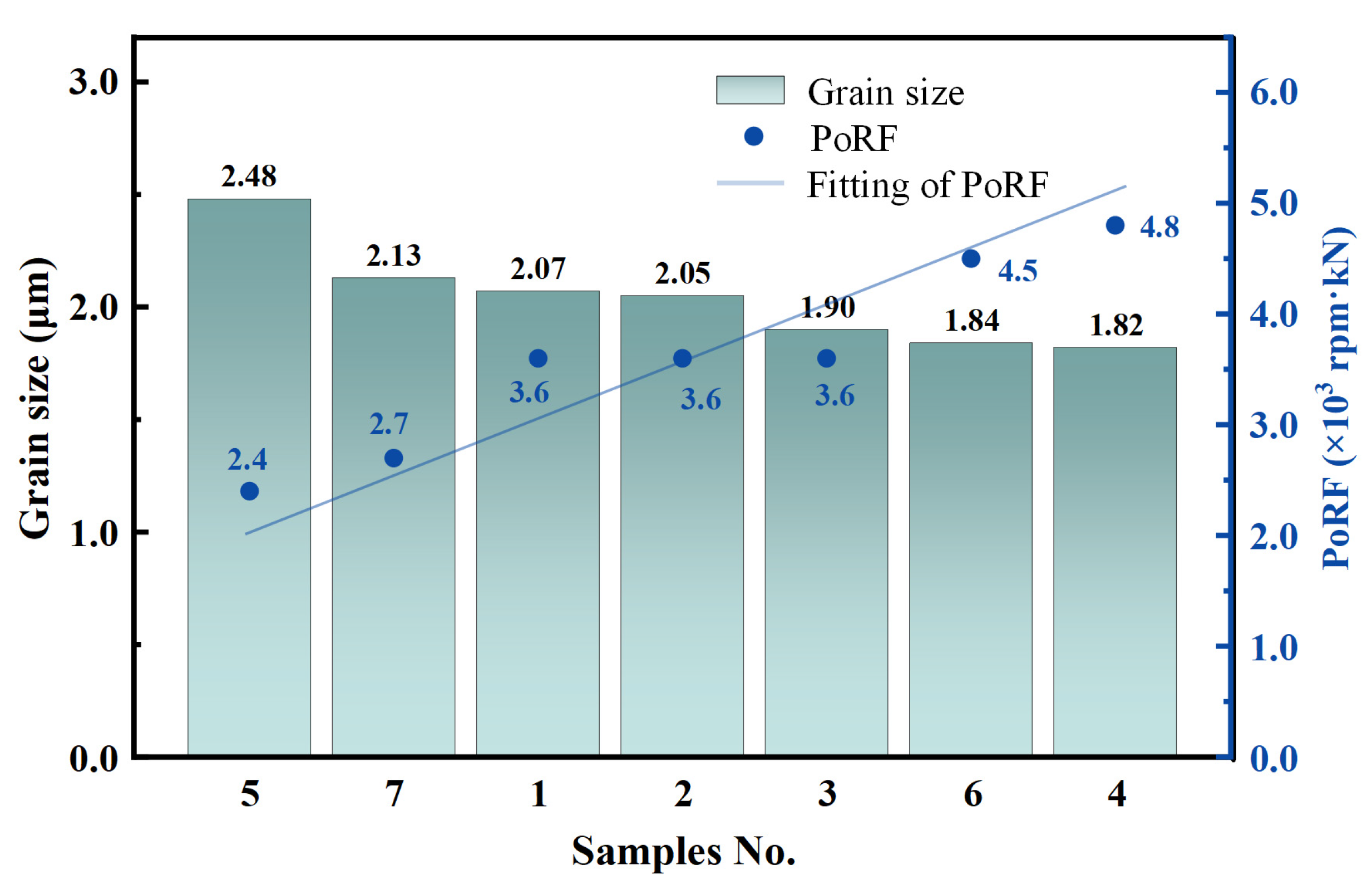

3.1.1. Grain Size

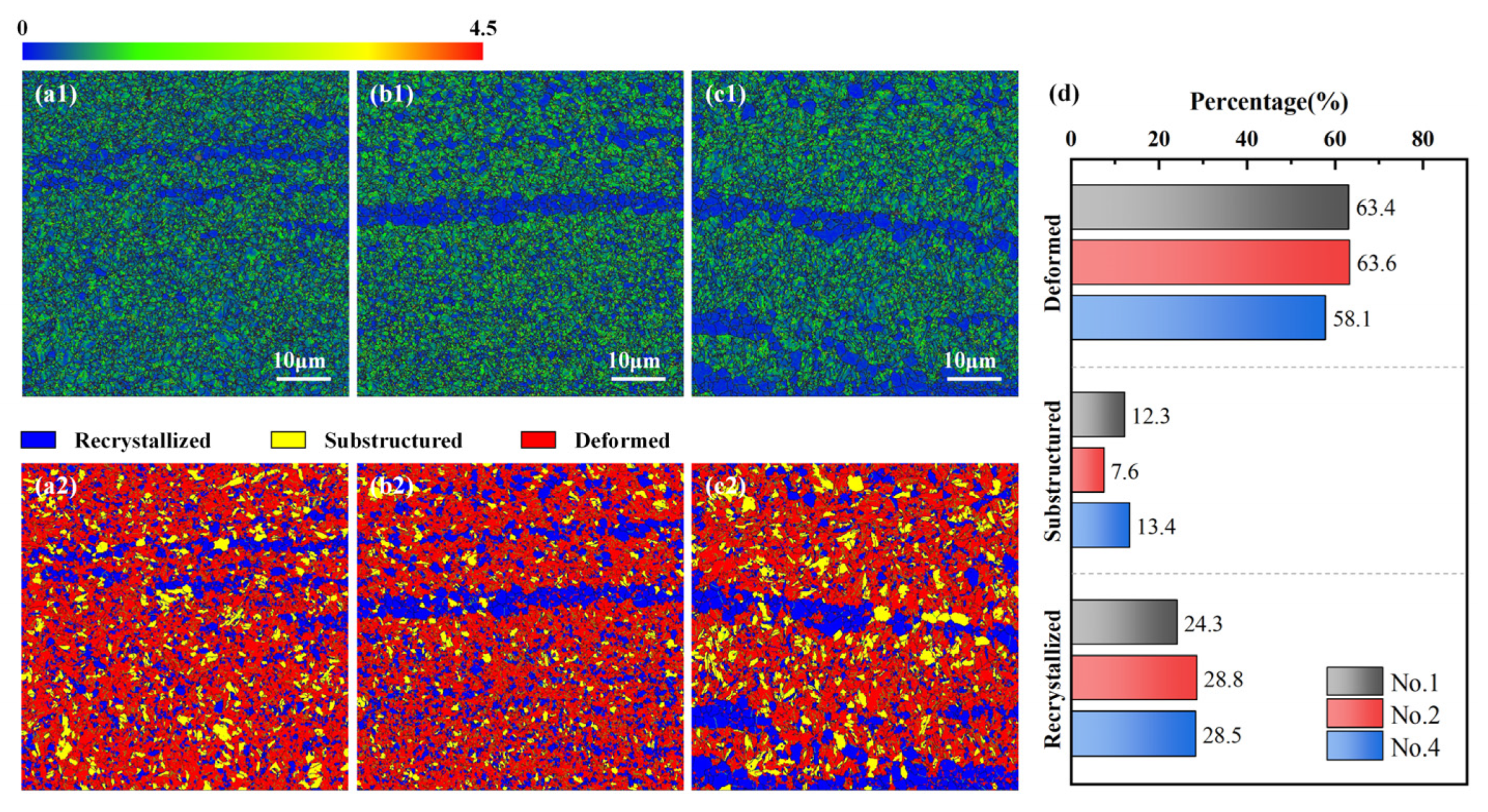

3.1.2. Recrystallization Characteristics

3.2. Mechanical Properties

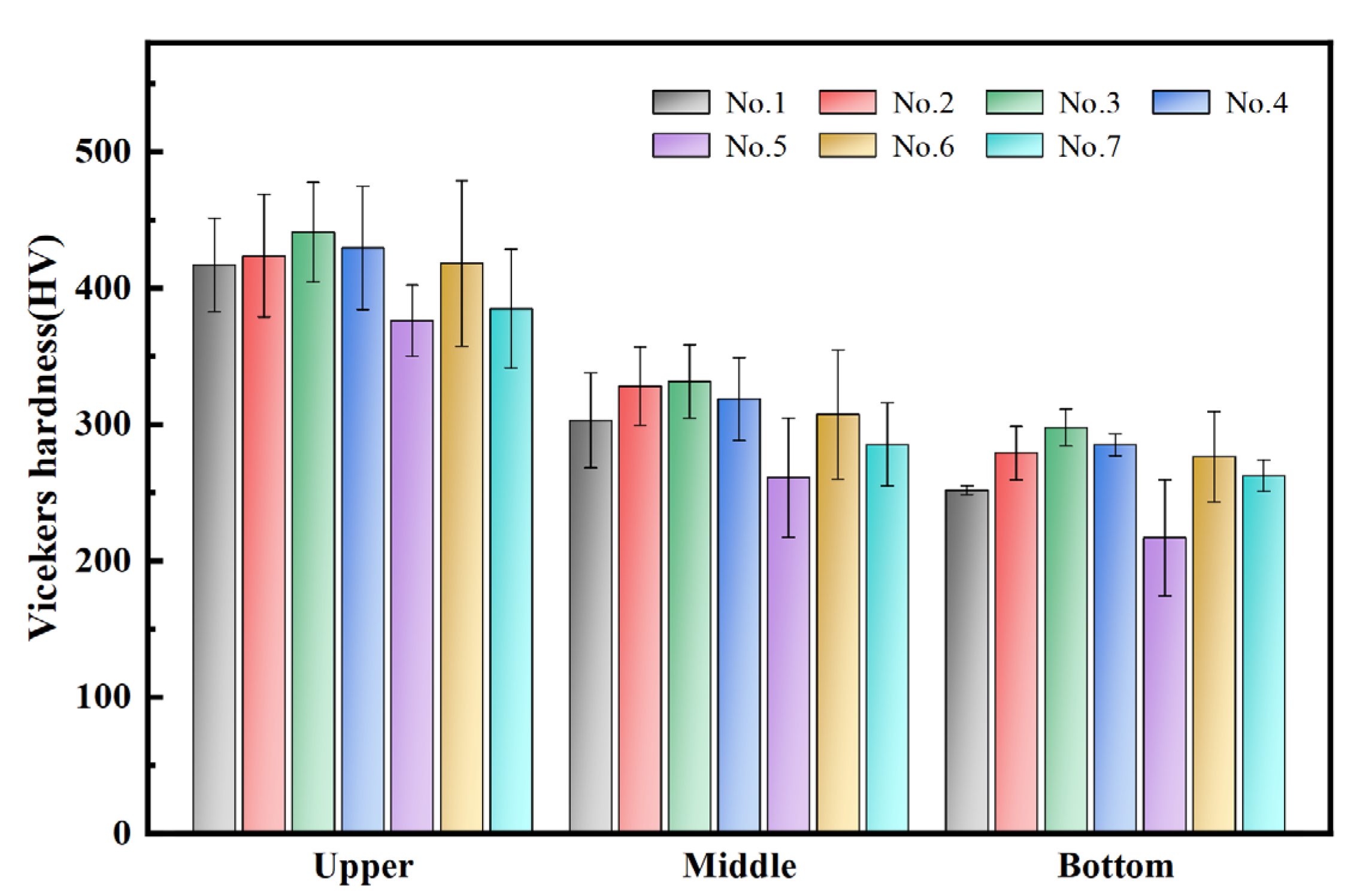

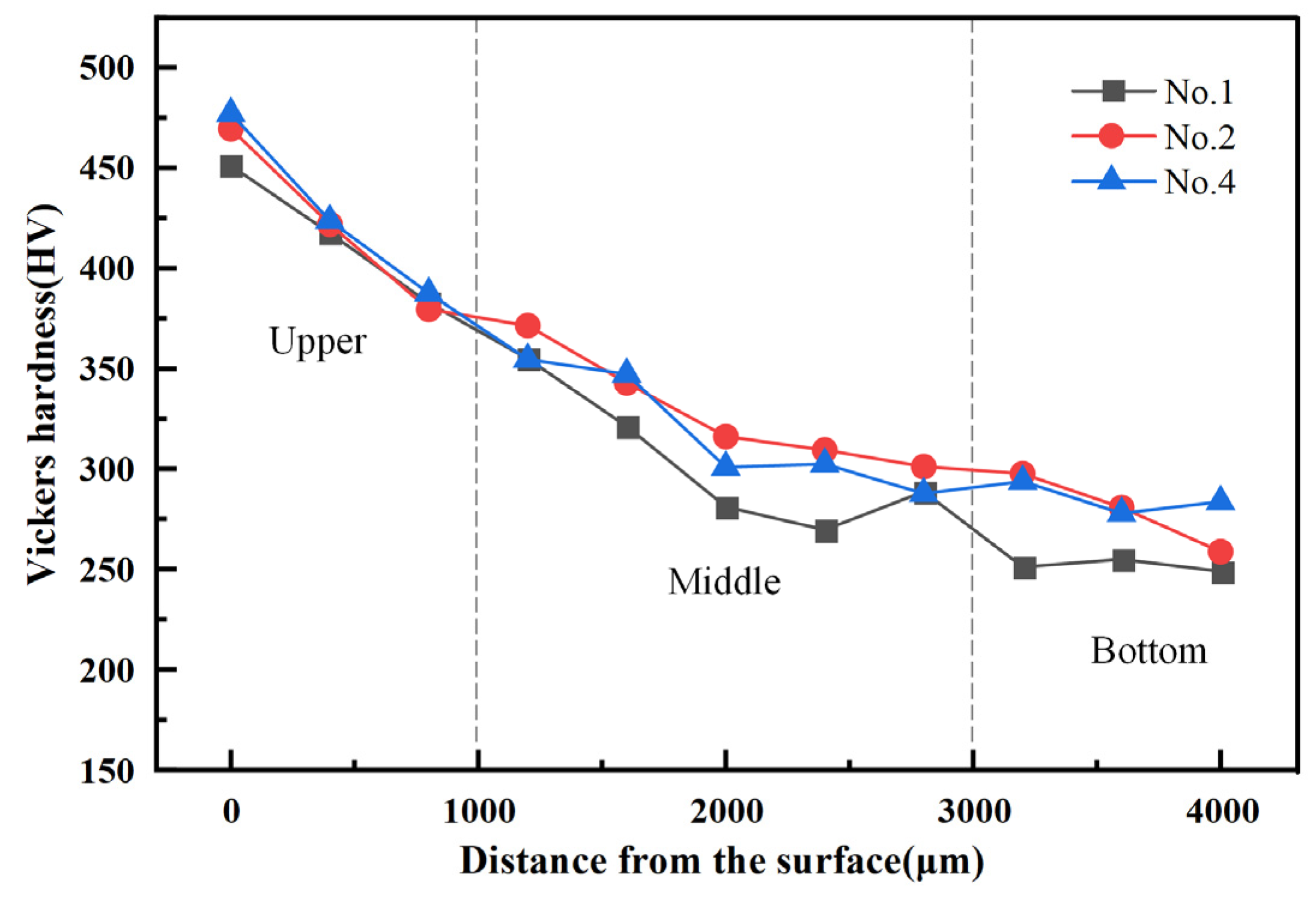

3.2.1. Vickers Hardness

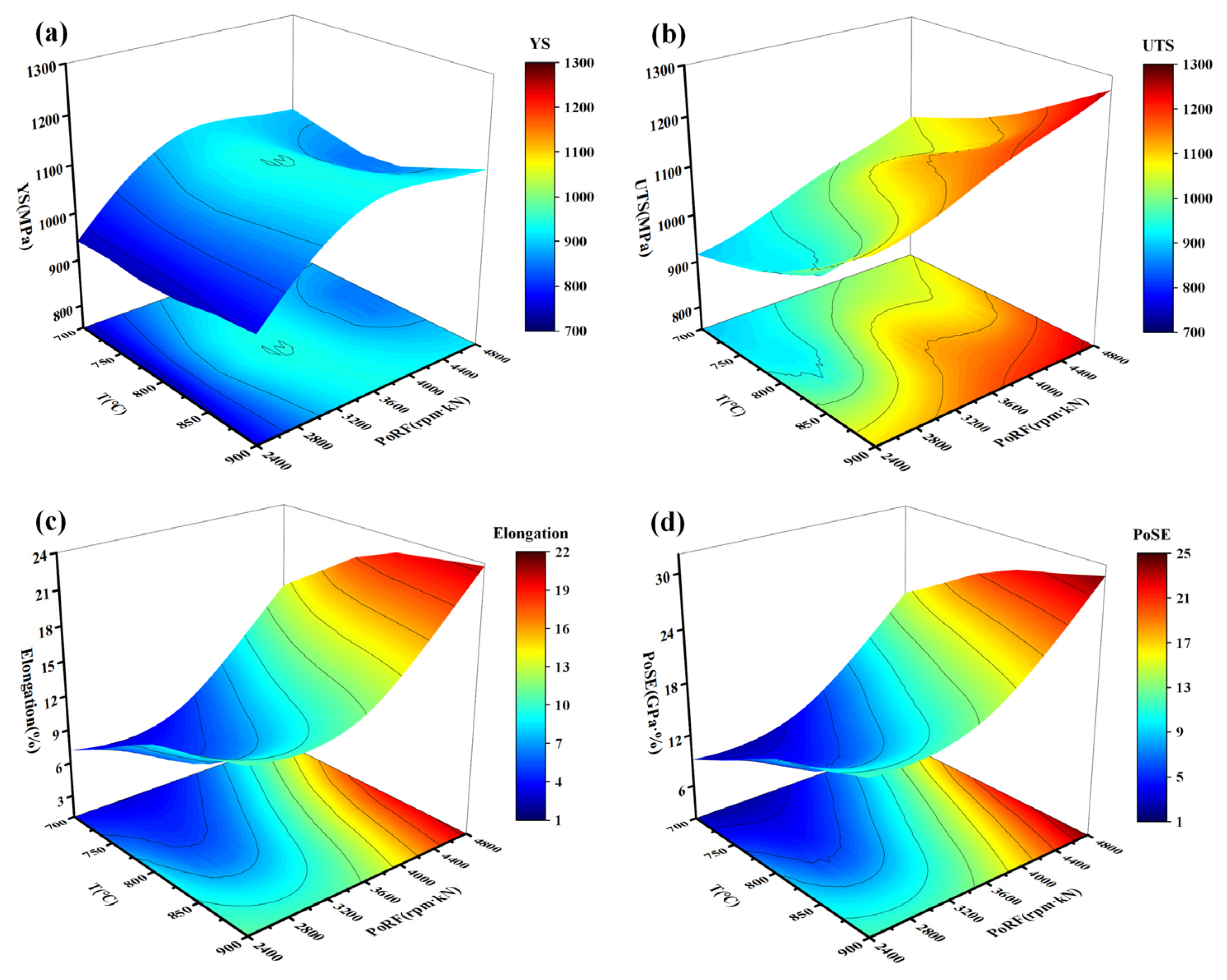

3.2.2. Tensile Properties

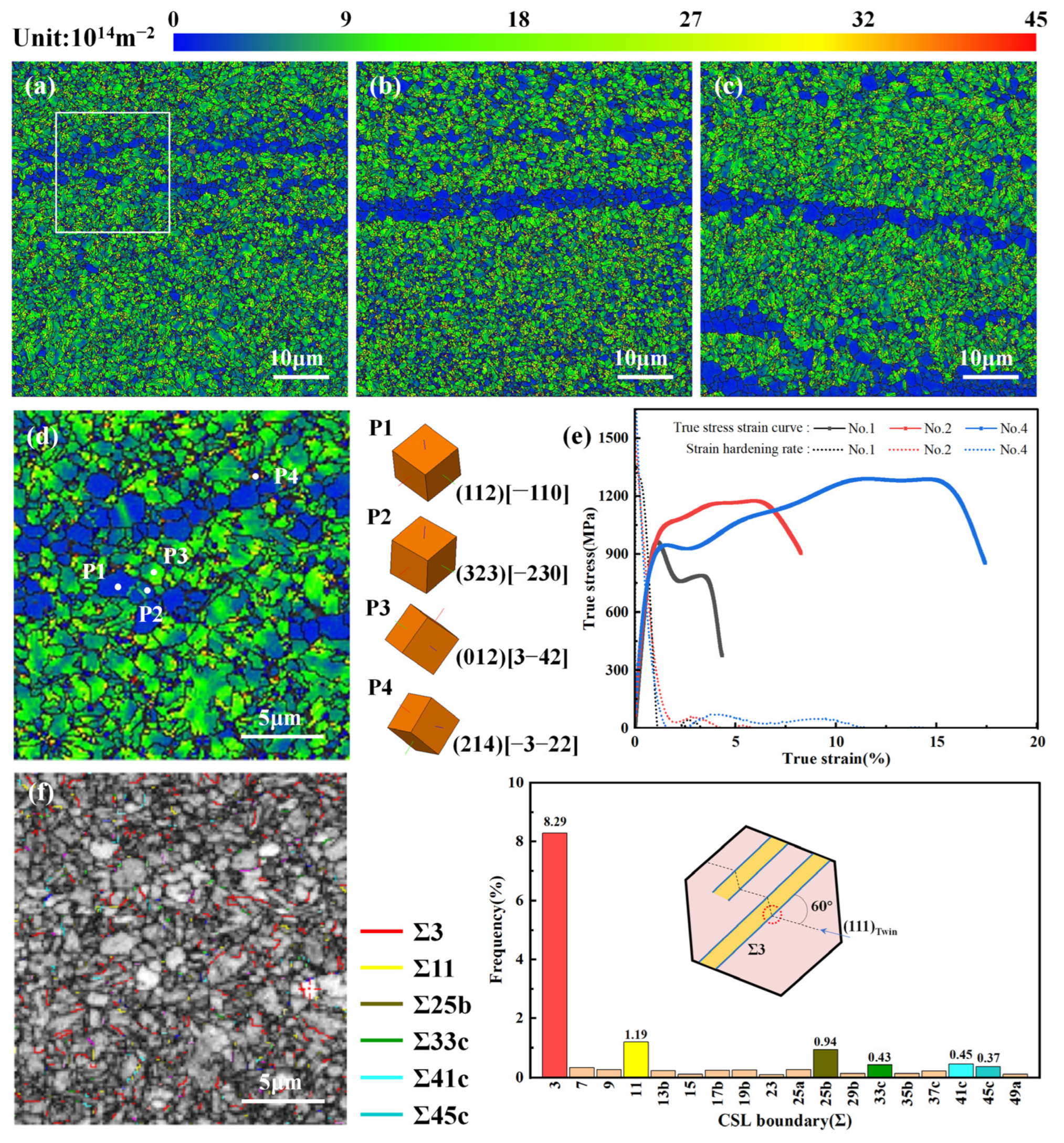

3.3. Strengthening Mechanism

4. Conclusions

- The AFSD 1045 steel exhibits equiaxed grains with an average size of 1–3 μm, and high tool rotational speed (ω) and axial force (F) are more likely to cause the grain refinement. Additionally, there is a notable proportion of low-angle grain boundaries (56.8–60.7%) and deformed grains (58.1–63.6%), accompanied by dynamic recrystallization.

- Compared to other forming processes, AFSD 1045 steel demonstrates an excellent balance of strength and plasticity, with an ultimate tensile strength (UTS) of 1061.9–1172.3 MPa and elongation 8.6–19.0%. The product of strength and plasticity (PoSE) indicates an optimal AFSD process window with a deposition temperature (T) 850–900 °C and the product of rotational speed and force (PoRF) 4400–4800 rpm·kN.

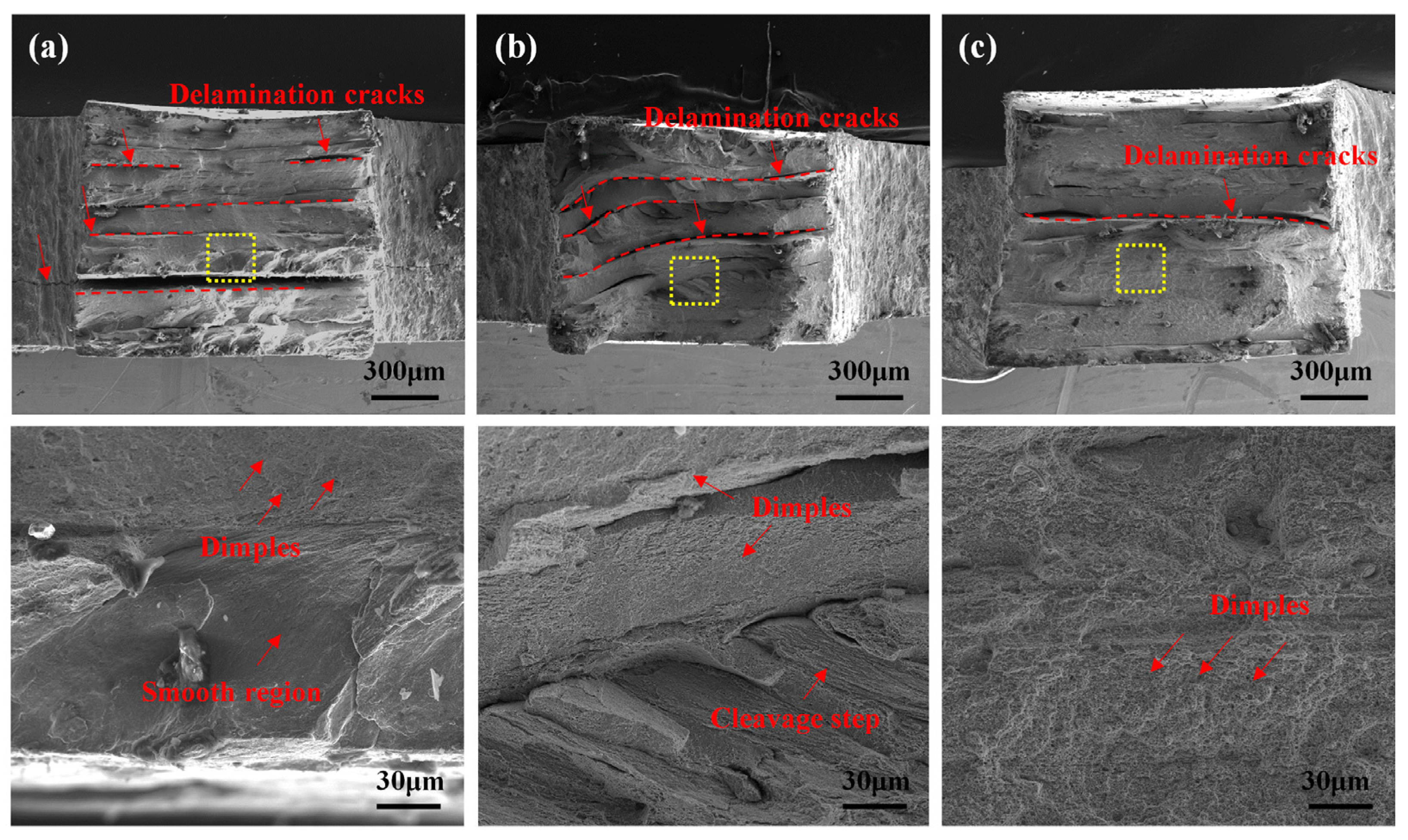

- The remarkable plasticity of AFSD 1045 steel can be attributed to (i) the generation of delamination bifurcation cracks within the material to reduce the local stress concentration; (ii) the crack shielding effect of pile-up dislocations; and (iii) the deflection of crack propagation paths by precipitated phases. Furthermore, the combination of strengthening mechanisms, including grain boundary strengthening, dislocation strengthening, twin boundary strengthening, solid solution strengthening, and precipitation strengthening, attribute excellent overall mechanical properties to AFSD 1045 steel.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hodonou, C.; Balazinski, M.; Brochu, M.; Mascle, C. Material-design-process selection methodology for aircraft structural components: Application to additive vs subtractive manufacturing processes. Int. J. Adv. Manuf. Technol. 2019, 103, 1509–1517. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Godina, R. A LCA and LCC analysis of pure subtractive manufacturing, wire arc additive manufacturing, and selective laser melting approaches. J. Manuf. Process. 2023, 101, 67–85. [Google Scholar] [CrossRef]

- Newman, S.T.; Zhu, Z.; Dhokia, V.; Shokrani, A. Process planning for additive and subtractive manufacturing technologies. CIRP Ann. 2015, 64, 467–470. [Google Scholar] [CrossRef]

- Dong, X.; Zhou, M.; Geng, Y.; Han, Y.; Lei, Z.; Chen, G.; Shi, Q. Recent Advances in Additive Friction Stir Deposition: A Critical Review. Materials 2024, 17, 5205. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M.; Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet lamination. In Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; pp. 253–283. [Google Scholar]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Gnster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Heigel, J.C.; Michaleris, P.; Reutzel, E.W. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti--6Al--4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Grtner, F.; Klassen, T.J.A.M. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Grtner, F.; Stoltenhoff, T.; Voyer, J.; Kreye, H.; Riekehr, S.; Koak, M. Mechanical properties of cold-sprayed and thermally sprayed copper coatings. Surf. Coat. Technol. 2006, 200, 6770–6782. [Google Scholar] [CrossRef]

- Klassen, T.; Grtner, F.; Assadi, H. Process science of cold spray. In High Pressure Cold Spray: Principles and Applications; ASM International: Ohio, USA, 2016; pp. 17–65. [Google Scholar]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Hang, Z.Y. Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition. Addit. Manuf. 2020, 35, 101293. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Brewer, L.N.; Rodriguez, O.L.; Jordon, J.B.; Liu, T.; Whittington, W.R.; Martens, R.L.; McClelland, Z.; Mason, C.J.T.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Hang, Z.Y.; Jones, M.E.; Brady, G.W.; Griffiths, R.J.; Garcia, D.; Rauch, H.A.; Cox, C.D.; Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scr. Mater. 2018, 153, 122–130. [Google Scholar]

- Gopan, V.; Leo Dev Wins, K.; Surendran, A. Innovative potential of additive friction stir deposition among current laser based metal additive manufacturing processes: A review. CIRP J. Manuf. Sci. Technol. 2021, 32, 228–248. [Google Scholar] [CrossRef]

- Shao, J.; Samaei, A.; Xue, T.; Xie, X.; Guo, S.; Cao, J.; MacDonald, E.; Gan, Z. Additive friction stir deposition of metallic materials: Process, structure and properties. Mater. Des. 2023, 234, 112356. [Google Scholar] [CrossRef]

- Yu, H.Z.; Mishra, R.S. Additive friction stir deposition: A deformation processing route to metal additive manufacturing. Mater. Res. Lett. 2020, 9, 71–83. [Google Scholar] [CrossRef]

- Arora, A.; Zhang, Z.; De, A.; DebRoy, T. Strains and strain rates during friction stir welding. Scr. Mater. 2009, 61, 863–866. [Google Scholar] [CrossRef]

- Kumar, R.; Pancholi, V.; Bharti, R.P. Material flow visualization and determination of strain rate during friction stir welding. J. Mater. Process. Technol. 2018, 255, 470–476. [Google Scholar] [CrossRef]

- Peng, Y.; Huang, B.; Zhong, Y.; Su, C.; Tao, Z.; Rong, X.; Li, Z.; Tang, H. Electrochemical corrosion behavior of 6061 Al alloy under high rotating speed submerged friction stir processing. Corros. Sci. 2023, 215, 111029. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, R.; Wang, L.; Liu, M.; Li, S. Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals 2024, 14, 581. [Google Scholar] [CrossRef]

- Ma, T.J.; Li, W.-Y.; Xu, Q.Z.; Zhang, Y.; Li, J.L.; Yang, S.Q.; Liao, H.L. Microstructure evolution and mechanical properties of linear friction welded 45 steel joint. Adv. Eng. Mater. 2007, 9, 703–707. [Google Scholar] [CrossRef]

- Liu, B.X.; Fan, K.Y.; Yin, F.X.; Feng, J.H.; Ji, P.G. Effect of caliber rolling reduction ratios on the microstructure and mechanical properties of 45 medium carbon steel. Mater. Sci. Eng. A 2020, 774, 138954. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Wang, Y.; Wei, Y.; Han, L.; Zhi, H.; Yang, X. Effects of process parameters on the microstructure and mechanical properties of AISI 1045 steel prepared by selective laser melting. Mater. Today Commun. 2023, 37, 107287. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Zhi, H.; Yang, X.; Zhang, J.; Wang, Y. In-situ generation of high-strength AISI 1045 steel with SiO2 nano-precipitation by selective laser melting (SLM). J. Manuf. Process. 2023, 94, 374–386. [Google Scholar] [CrossRef]

- Zhang, L.; Song, Y.; Wang, X.; Zhou, S.; Ding, Z.; Jin, W.; Gao, Z.; Jiang, Y. A study of fatigue property enhancement of 1045 steel processed by surface mechanical rolling treatment with an emphasis on residual stress influence. Int. J. Fatigue 2024, 189, 108560. [Google Scholar] [CrossRef]

- Li, Z.; La, P.; Sheng, J.; Shi, Y.; Zhou, X.; Meng, Q. Outstanding synergy of superior strength and ductility in heterogeneous structural 1045 carbon steel. Met. Mater. Int. 2021, 27, 2562–2574. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, H.; Zhou, F. Improvement in geometrical accuracy and mechanical property for arc-based additive manufacturing using metamorphic rolling mechanism. J. Manuf. Sci. Eng. 2016, 138, 111002. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Chalasani, D.; Hadadzadeh, A.; Amirkhiz, B.S.; Odeshi, A.; Mohammadi, M. Dynamic compressive response of electron beam melted Ti--6Al--4V under elevated strain rates: Microstructure and constitutive models. Addit. Manuf. 2020, 35, 101347. [Google Scholar] [CrossRef]

- Alam, M.E.; Pal, S.; Maloy, S.A.; Odette, G.R. On delamination toughening of a 14YWT nanostructured ferritic alloy. Acta Mater. 2017, 136, 61–73. [Google Scholar] [CrossRef]

- Gao, K.; Zhang, X.; Liu, B.; He, J.; Feng, J.; Ji, P.; Fang, W.; Yin, F. The deformation characteristics, fracture behavior and strengthening-toughening mechanisms of laminated metal composites: A review. Metals 2019, 10, 4. [Google Scholar] [CrossRef]

- Kalcska, S.; Ast, J.; Ispnovity, P.D.; Michler, J.; Maeder, X. 3D HR-EBSD Characterization of the plastic zone around crack tips in tungsten single crystals at the micron scale. Acta Mater. 2020, 200, 211–222. [Google Scholar] [CrossRef]

- Pande, C.S.; Goswami, R. Dislocation emission and crack dislocation interactions. Metals 2020, 10, 473. [Google Scholar] [CrossRef]

- Kujawski, D.; Vasudevan, A.K. Unusual Fatigue Crack Growth Behavior of Long Cracks at Low Stress Intensity Factor Ranges. Materials 2024, 17, 792. [Google Scholar] [CrossRef]

- Mao, H.; Shen, F.; Zhang, Y.; Wang, J.; Cui, K.; Wang, H.; Lv, T.; Fu, T.; Tan, T. Microstructure and mechanical properties of carbide reinforced TiC-based ultra-high temperature ceramics: A Review. Coatings 2021, 11, 1444. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, W.; Zhou, S.; Hu, F.; Yershov, S.; Wu, K. Investigation of microstructural evolution and crack extension in a quenching and partitioning (Q & P) steel at different strain rates. J. Mater. Res. Technol. 2023, 24, 2385–2402. [Google Scholar]

- Mohapatra, S.; Baek, K.-C.; Oh, M.-S. Intercritically Annealed Medium-Manganese Steel: Insights into Microstructural and Microtextural Evolution, Strain Distribution, and Grain Boundary Characteristics. Materials 2024, 17, 2757. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Chang, Y.T.; Charpagne, M.A. Origins of twin boundaries in additive manufactured stainless steels. Acta Mater. 2024, 275, 120035. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; He, Y.; Wang, C.; Zhong, L.; Mao, S.X. Unstable twin in body-centered cubic tungsten nanocrystals. Nat. Commun. 2020, 11, 2497. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhao, Q.; Tian, Y.; Wang, Q.; Fan, J.; Song, K.; Zhou, H.; Wang, J. Phase transformation induced transitional twin boundary in body-centered cubic metals. Acta Mater. 2023, 249, 118815. [Google Scholar] [CrossRef]

- Veerababu, J.; Nagesha, A.; Shankar, V. Atomistic study on the deformation behavior of CSL low angle tilt grain boundaries in BCC iron. Mater. Today Commun. 2024, 40, 110111. [Google Scholar] [CrossRef]

- Rath, D.; Setia, P.; Tripathi, N.; Shekhar, S. Outstanding improvement in the CSL distribution in interstitial free (IF) steel via strain annealing route. Mater. Charact. 2022, 186, 111817. [Google Scholar] [CrossRef]

- Brckner, G.; Pospiech, J.; Seidl, I.; Gottstein, G. Orientation correlation during diffusional $$→ $$ phase transformation in a ferritic low carbon steel. Scr. Mater. 2001, 44, 2635–2640. [Google Scholar] [CrossRef]

- Zhu, H.-w.; Xu, K.; Qin, S.; Xiao, F.-r.; Liao, B. Effect of heat treatment on microstructure and properties of 1045 steel modified with (NbTi) C nanoparticles. Mater. Sci. Eng. A 2018, 728, 175–182. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, M.; Fan, Z.; Huang, S.; Huang, H. Laser deposition of wear-resistant titanium oxynitride/titanium composite coatings on Ti-6Al-4V alloy. Appl. Surf. Sci. 2020, 531, 147212. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Safyari, M.; Kuramoto, S.; Hojo, T. Unraveling the effect of dislocations and deformation-induced boundaries on environmental hydrogen embrittlement behavior of a cold-rolled Al–Zn–Mg–Cu alloy. Int. J. Hydrogen Energy 2021, 46, 8285–8299. [Google Scholar] [CrossRef]

- Kim, J.G.; Enikeev, N.A.; Seol, J.B.; Abramova, M.M.; Karavaeva, M.V.; Valiev, R.Z.; Park, C.G.; Kim, H.S. Superior strength and multiple strengthening mechanisms in nanocrystalline TWIP steel. Sci. Rep. 2018, 8, 11200. [Google Scholar] [CrossRef]

- Zheng, T.; Hu, X.; He, F.; Wu, Q.; Han, B.; Chen, D.; Li, J.; Wang, Z.; Wang, J.; Kai, J.-j.; et al. Tailoring nanoprecipitates for ultra-strong high-entropy alloys via machine learning and prestrain aging. J. Mater. Sci. Technol. 2021, 69, 156–167. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Content/% | 0.460 | 0.230 | 0.720 | 0.170 | 0.180 | 0.08 | Bal. |

| Samples No. | T/°C | ω/rpm | F/kN |

|---|---|---|---|

| 1 | 700 | 400 | 9 |

| 2 | 800 | 400 | 9 |

| 3 | 900 | 400 | 9 |

| 4 | 800 | 400 | 12 |

| 5 | 800 | 400 | 6 |

| 6 | 800 | 500 | 9 |

| 7 | 800 | 300 | 9 |

| Samples No. | YS/MPa | UTS/MPa | Elongation/% | PoSE/GPa·% |

|---|---|---|---|---|

| 1 | 910.4 | 976.7 | 4.4 | 4.3 |

| 2 | 942.4 | 1116.6 | 8.6 | 9.6 |

| 3 | 934.2 | 1172.3 | 11.6 | 13.6 |

| 4 | 853.1 | 1144.2 | 19.0 | 21.7 |

| 5 | 714.4 | 976.2 | 9.2 | 9.0 |

| 6 | 838.6 | 1061.9 | 15.8 | 16.8 |

| 7 | 860.8 | 893.9 | 5.0 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, W.; Ran, X.; Wang, Q.; Wu, Y.; Sun, J.; Zhang, F.; Huang, S.; Xiang, L.; Tao, J.; Chen, Q. Effect of Additive Friction Stir Deposition Processing on the Microstructure and Mechanical Properties of 1045 Steel. Materials 2025, 18, 1257. https://doi.org/10.3390/ma18061257

Lei W, Ran X, Wang Q, Wu Y, Sun J, Zhang F, Huang S, Xiang L, Tao J, Chen Q. Effect of Additive Friction Stir Deposition Processing on the Microstructure and Mechanical Properties of 1045 Steel. Materials. 2025; 18(6):1257. https://doi.org/10.3390/ma18061257

Chicago/Turabian StyleLei, Wei, Xudong Ran, Qi Wang, Yang Wu, Jipeng Sun, Feiyue Zhang, Shuhai Huang, Lin Xiang, Jianquan Tao, and Qiang Chen. 2025. "Effect of Additive Friction Stir Deposition Processing on the Microstructure and Mechanical Properties of 1045 Steel" Materials 18, no. 6: 1257. https://doi.org/10.3390/ma18061257

APA StyleLei, W., Ran, X., Wang, Q., Wu, Y., Sun, J., Zhang, F., Huang, S., Xiang, L., Tao, J., & Chen, Q. (2025). Effect of Additive Friction Stir Deposition Processing on the Microstructure and Mechanical Properties of 1045 Steel. Materials, 18(6), 1257. https://doi.org/10.3390/ma18061257