Effects of Multi-Fluorinated Liquid Crystals with High Refractive Index on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystals

Abstract

:1. Introduction

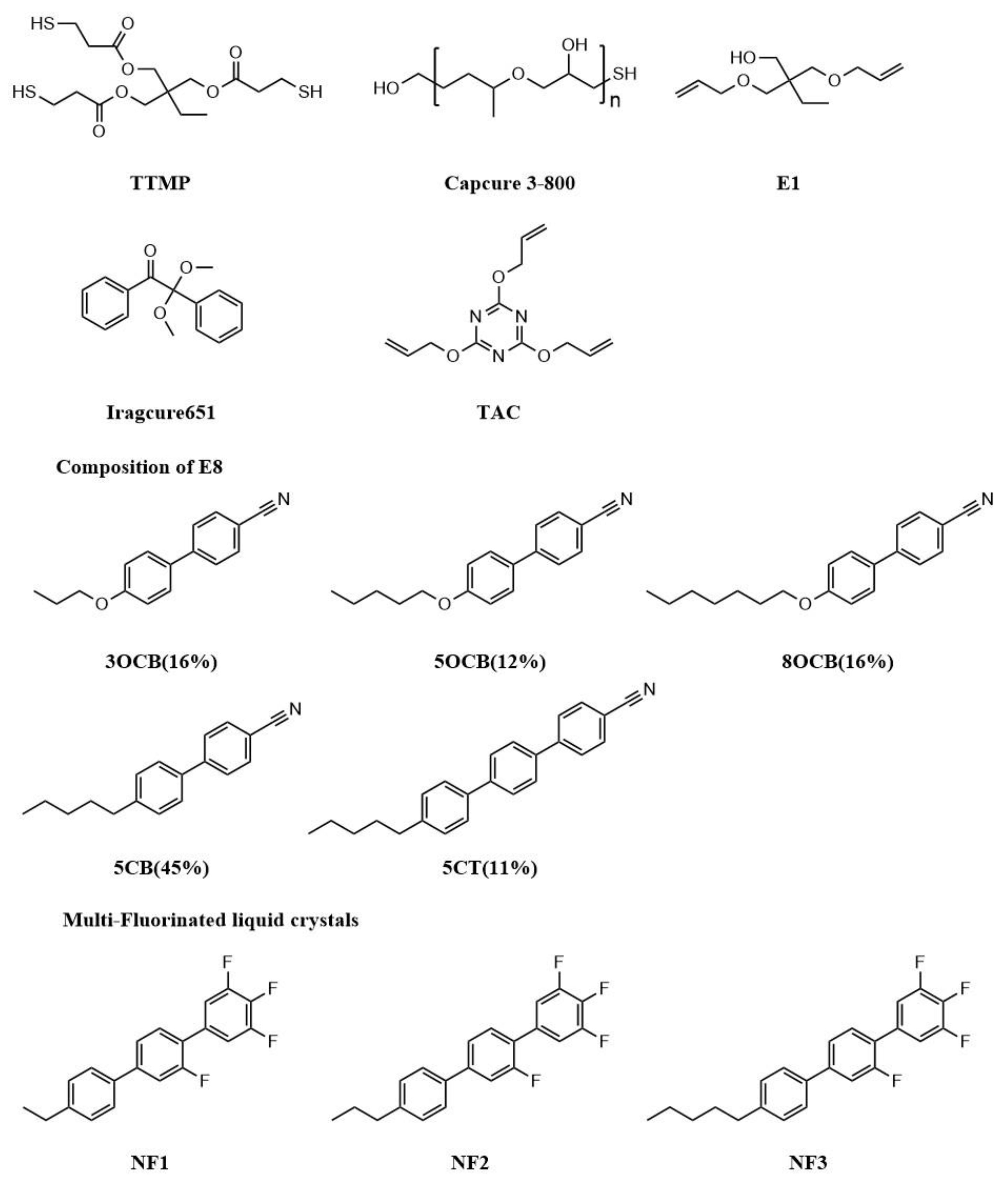

2. Materials and Methods

3. Results

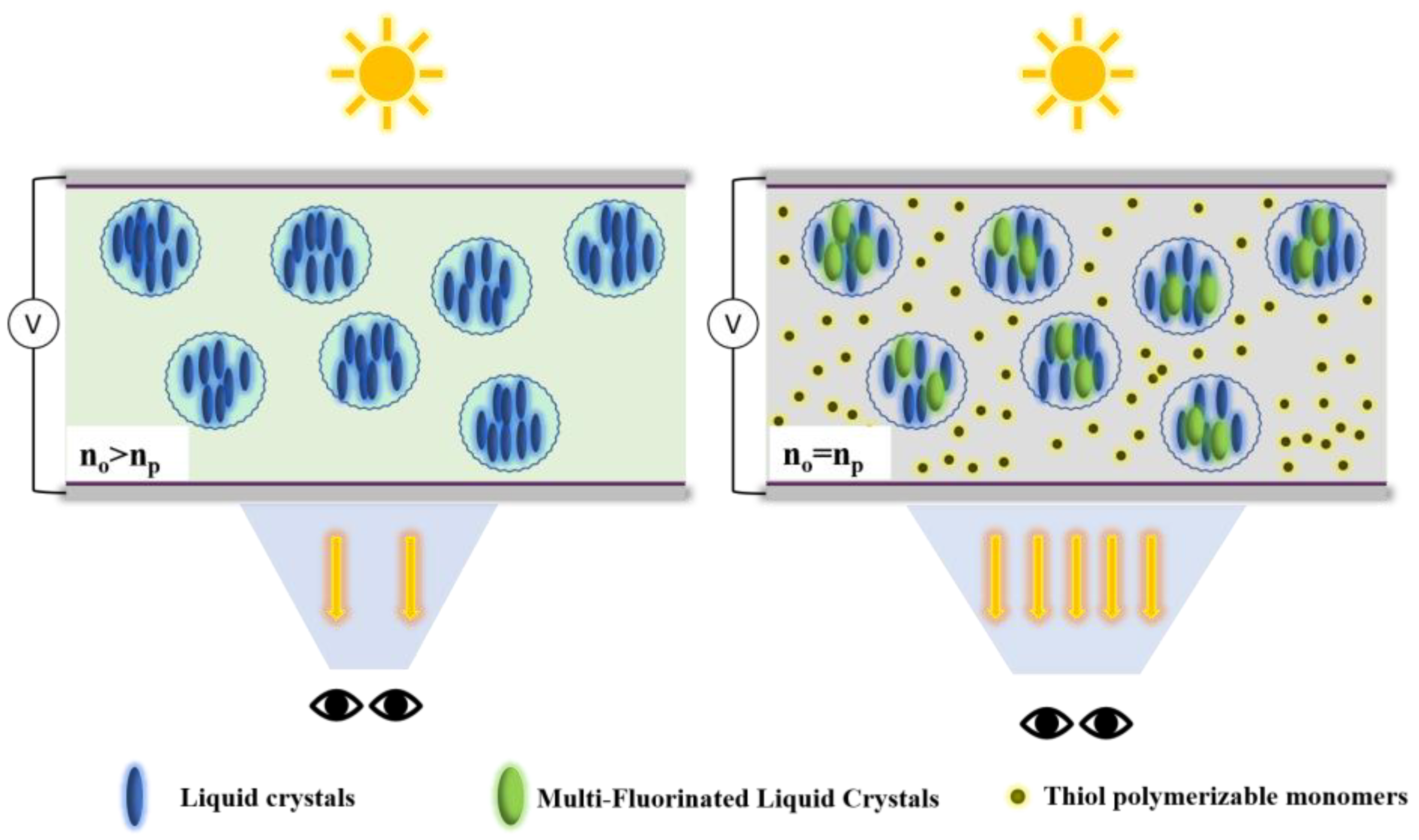

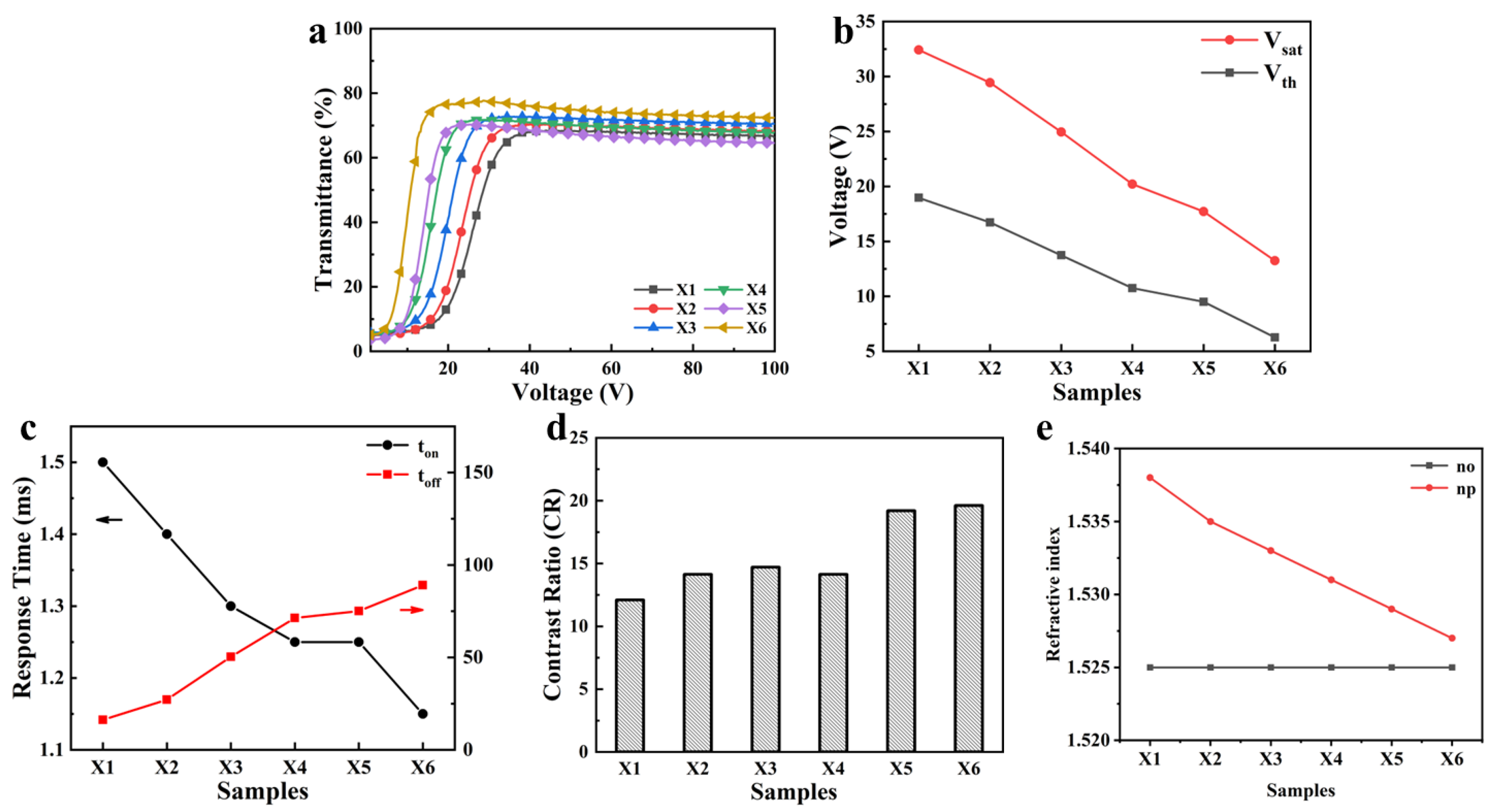

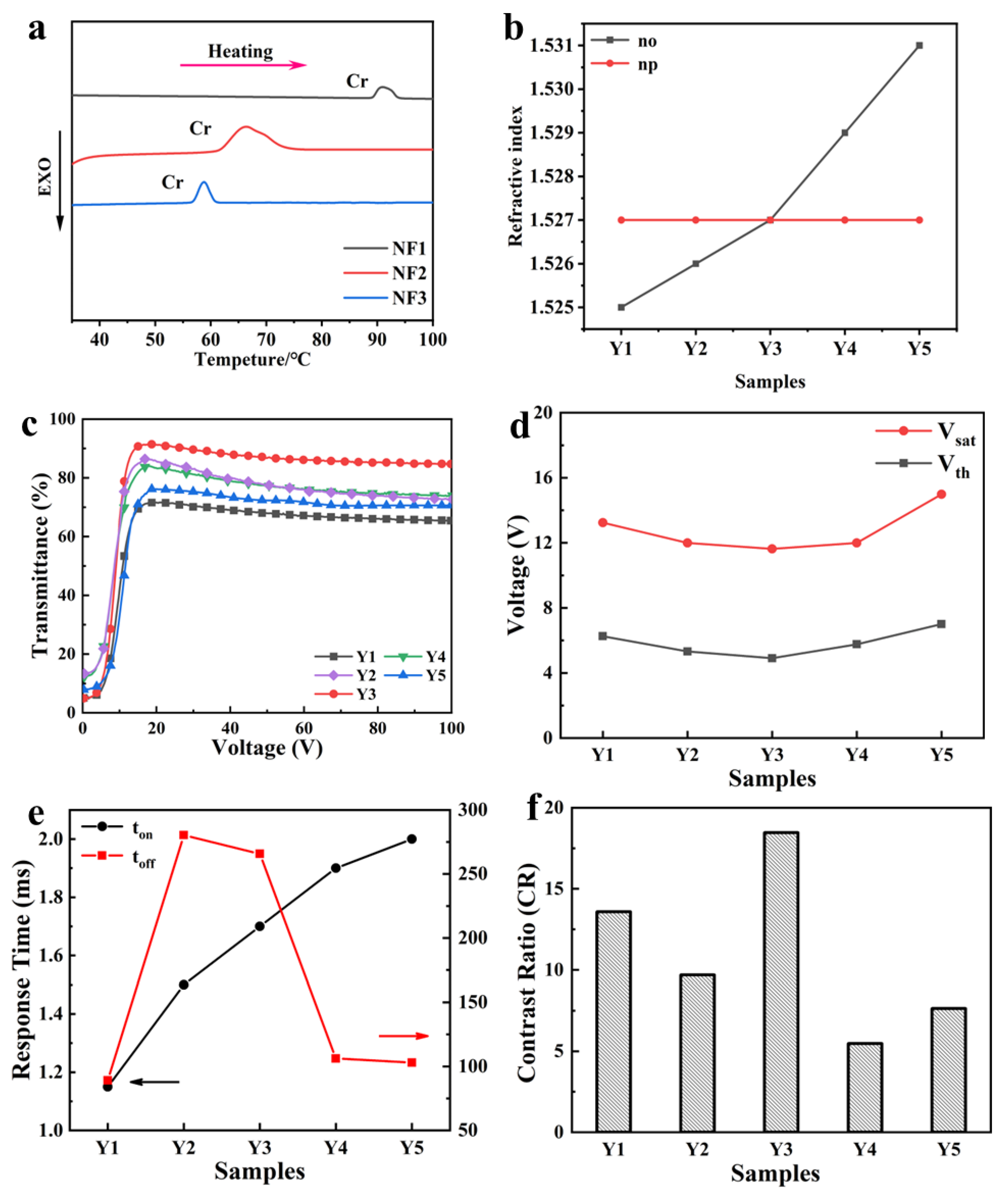

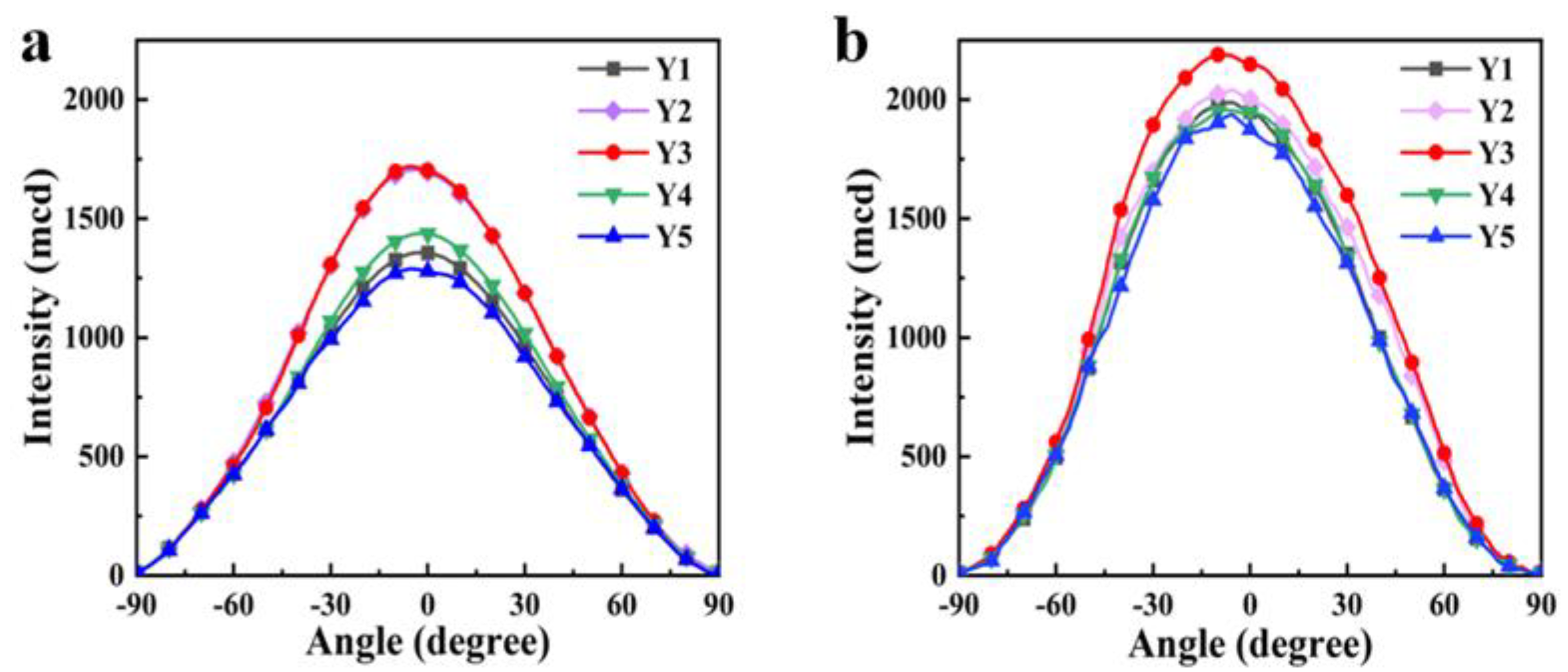

3.1. Effects of Polymer Refractive Index on Electro-Optical Properties and Viewing Angle of PDLC Films

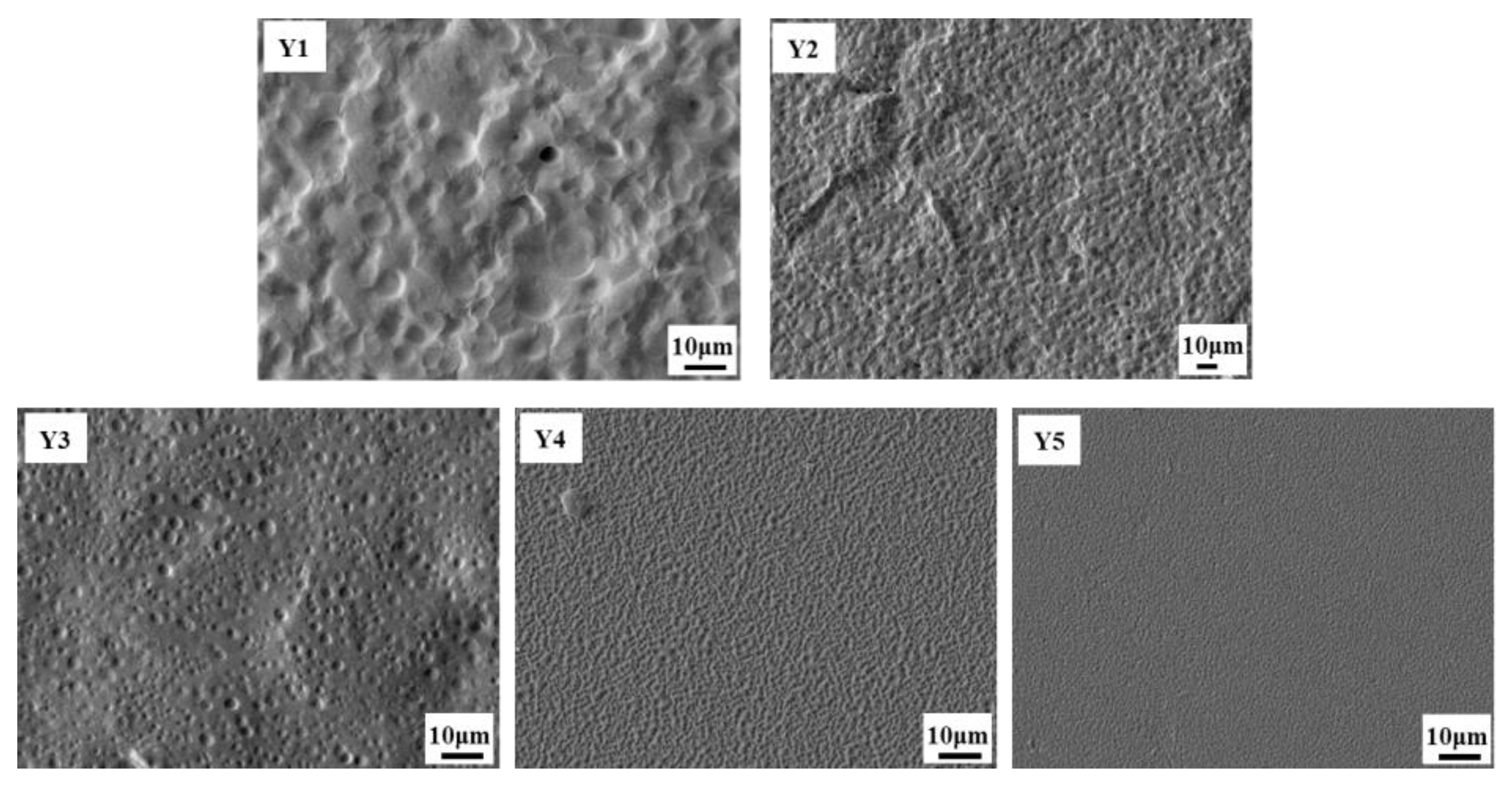

3.2. Effects of LC Refractive Index on Electro-Optical Properties and Viewing Angle of PDLC Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PDLC | Polymer-Dispersed Liquid Crystal |

| LC | Liquid Crystal |

| PIPS | Polymerization-Induced Phase Separation |

References

- Zhang, X.; Fan, F.; Zhang, C.-Y.; Ji, Y.-Y.; Wang, X.-H.; Chang, S.-J. Tunable terahertz phase shifter based on dielectric artificial birefringence grating filled with polymer dispersed liquid crystal. Opt. Mater. Express 2020, 10, 282–292. [Google Scholar] [CrossRef]

- Huh, J.-W.; Seo, J.-H.; Oh, S.-W.; Kim, S.-H.; Yoon, T.-H. Tristate switching of a liquid-crystal cell among initial transparent, haze-free dark, and high-haze dark states. J. Mol. Liq. 2019, 281, 81–85. [Google Scholar] [CrossRef]

- Murray, J.; Ma, D.K.; Munday, J.N. Electrically Controllable Light Trapping for Self-Powered Switchable Solar Windows. ACS Photonics 2017, 4, 1–7. [Google Scholar] [CrossRef]

- Kumari, A.; Sinha, A. Role of BaTiO3 nanoparticles on electro-optic performance of epoxy-resin-based PDLC devices. Liq. Cryst. 2021, 48, 23–34. [Google Scholar] [CrossRef]

- Saeed, M.H.; Gao, Y.Z.; Zhou, L.; Zhong, T.J.; Zhang, S.F.; Li, C.Y.; Zhang, L.Y.; Yang, H. Effects of multifunctional acrylates and thiols on the morphology and electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2021, 48, 1457–1466. [Google Scholar] [CrossRef]

- Park, S.; Hong, J.W. Polymer dispersed liquid crystal film for variable-transparency glazing. Thin Solid. Film. 2009, 517, 3183–3186. [Google Scholar] [CrossRef]

- Yao, W.; Zhao, J.; Liu, L.; Wang, Y.; Ma, Z.; Ma, A.; He, Z.; Miao, Z. The effect of doping sulphhydryl-functionalised silica with different diameters on the electro-optical properties of PDLC. Liq. Cryst. 2024, 51, 1247–1255. [Google Scholar] [CrossRef]

- Zhang, H.; Zhong, T.; Chen, M.; Zhang, L.; Liu, X.; Cao, H.; Yang, H.; Zhu, S. The physical properties of alkene-terminated liquid crystal molecules/E8 mixture and the electro-optical properties as they doped in polymer-dispersed liquid crystal systems. Liq. Cryst. 2018, 45, 1118–1128. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Chen, G.; Li, C.; Zhang, L.; Yang, Z.; Yang, H. A facile route towards controllable electric-optical performance of polymer-dispersed liquid crystal via the implantation of liquid crystalline epoxy network in conventional resin. Polymer 2019, 167, 67–77. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Chen, G.; Li, C.; Han, C.; Zhang, J.; Zhang, J.; Zhang, L.; Yang, H. Effects of polymer micro-structures on the thermo-optical properties of a flexible soft-mater film based on liquid crystals/polymer composite. Polymer 2018, 146, 161–168. [Google Scholar] [CrossRef]

- Guo, S.M.; Liang, X.; Zhang, C.H.; Chen, M.; Shen, C.; Zhang, L.Y.; Yuan, X.; He, B.F.; Yang, H. Preparation of a Thermally Light-Transmittance-Controllable Film from a Coexistent System of Polymer-Dispersed and Polymer-Stabilized Liquid Crystals. ACS Appl. Mater. Interfaces 2017, 9, 2942–2947. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, J.; Ayarza, J.; Steeves, T.; Hu, Z.; Manna, S.; Esser-Kahn, A.P. Bio-inspired mechanically adaptive materials through vibration-induced crosslinking. Nat. Mater. 2021, 20, 869–874. [Google Scholar] [CrossRef] [PubMed]

- Boutureira, O.; Bernardes, G.J. Advances in chemical protein modification. Chem. Rev. 2015, 115, 2174–2195. [Google Scholar] [CrossRef] [PubMed]

- Kempe, K.; Krieg, A.; Becer, C.R.; Schubert, U.S. “Clicking” on/with polymers: A rapidly expanding field for the straightforward preparation of novel macromolecular architectures. Chem. Soc. Rev. 2012, 41, 176–191. [Google Scholar] [CrossRef]

- Xi, W.; Scott, T.F.; Kloxin, C.J.; Bowman, C.N. Click Chemistry in Materials Science. Adv. Funct. Mater. 2014, 24, 2572–2590. [Google Scholar] [CrossRef]

- Northrop, B.H.; Coffey, R.N. Thiol-ene click chemistry: Computational and kinetic analysis of the influence of alkene functionality. J. Am. Chem. Soc. 2012, 134, 13804–13817. [Google Scholar] [CrossRef]

- Hu, W.; Chen, M.; Wang, Q.; Zhang, L.; Yuan, X.; Chen, F.; Yang, H. Broadband Reflection in Polymer-Stabilized Cholesteric Liquid Crystals via Thiol-Acrylate Chemistry. Angew. Chem. Int. Ed. Engl. 2019, 58, 6698–6702. [Google Scholar] [CrossRef]

- Zhong, T.; Mandle, R.J.; Goodby, J.W.; Zhang, C.; Zhang, L. Thiol-ene reaction based polymer dispersed liquid crystal composite films with low driving voltage and high contrast ratio. Liq. Cryst. 2019, 47, 2171–2183. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Y.; Wang, Y. Effects of thiol monomers on the electro-optical properties of polymer-dispersed liquid crystal films prepared by nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2018, 45, 1746–1752. [Google Scholar] [CrossRef]

- Ren, Y.; Hu, W.; Sun, C.; Huang, J.; Hu, J.; Shen, J.; He, W.; Zhang, L.; Yuan, X.; Yu, M.; et al. Study on electro-optical and adhesion properties of polymer dispersed liquid crystal films from thiol-ene click reaction. Liq. Cryst. 2021, 48, 2188–2199. [Google Scholar] [CrossRef]

- Papež, N.; Pisarenko, T.; Ščasnovič, E.; Sobola, D.; Ţălu, Ş.; Dallaev, R.; Částková, K.; Sedlák, P. A Brief Introduction and Current State of Polyvinylidene Fluoride as an Energy Harvester. Coatings 2022, 12, 1429. [Google Scholar] [CrossRef]

- Saxena, P.; Shukla, P. A comprehensive review on fundamental properties and applications of poly(vinylidene fluoride) (PVDF). Adv. Compos. Hybrid. Mater. 2021, 4, 8–26. [Google Scholar] [CrossRef]

- Aphonin, O.A.; Panina, Y.V.; Pravdin, A.B.; Yakovlev, D.A. Optical properties of stretched polymer dispersed liquid crystal films. Liq. Cryst. 2006, 15, 395–407. [Google Scholar] [CrossRef]

- He, Z.; Yin, K.; Wu, S.T. Passive polymer-dispersed liquid crystal enabled multi-focal plane displays. Opt. Express 2020, 28, 15294–15299. [Google Scholar] [CrossRef]

- Kitzerow, H.-S. Polymer-dispersed liquid crystals From the nematic curvilinear aligned phase to ferroelectric films. Liq. Cryst. 1994, 16, 1–31. [Google Scholar] [CrossRef]

- Wu, B.G.; West, J.L.; Doane, J.W. Angular discrimination of light transmission through polymer-dispersed liquid-crystal films. J. Appl. Phys. 1987, 62, 3925–3931. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, M.; Jiang, T.; Chen, H.; Zhang, D.; Sun, Y.; Zhang, L.; Zhu, S.; Yang, H. Cyano terminated tolane compounds for polymer dispersed liquid crystal application: Relationship between cyano terminated tolane based molecular structures and electro-optical properties. Liq. Cryst. 2018, 45, 1771–1782. [Google Scholar] [CrossRef]

- Vaz, N.A.; Montgomery, G.P. Dual frequency addressing of polymer-dispersed liquid-crystal films. J. Appl. Phys. 1989, 65, 5043–5050. [Google Scholar] [CrossRef]

- Gdovinová, V.; Tomašovičová, N.; Jeng, S.-C.; Zakutanská, K.; Kula, P.; Kopčanský, P. Memory effect in nematic phase of liquid crystal doped with magnetic and non-magnetic nanoparticles. J. Mol. Liq. 2019, 282, 286–291. [Google Scholar] [CrossRef]

- Zhou, L.; Han, C.; Saeed, M.H.; Zhang, C.; Zhang, L. A switchable optical diffuser based on a polymer/nematic liquid crystal composite film with transient polymer balls-networks microstructure. Liq. Cryst. 2019, 46, 2213–2222. [Google Scholar] [CrossRef]

- He, Z.; Yin, K.; Hsiang, E.-L.; Wu, S.-T. Volumetric light-shaping polymer-dispersed liquid crystal films for mini-LED backlights. Liq. Cryst. 2020, 47, 1458–1463. [Google Scholar] [CrossRef]

- Han, C.; Zhou, L.E.; Ma, H.; Li, C.; Zhang, S.; Cao, H.; Zhang, L.; Yang, H. Fabrication of a controllable anti-peeping device with a laminated structure of microlouver and polymer dispersed liquid crystals film. Liq. Cryst. 2019, 46, 2235–2244. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, L.; Han, C.; Zhang, C.; Zhang, L. The fabrication of novel optical diffusers based on UV-cured polymer dispersed liquid crystals. Liq. Cryst. 2018, 46, 138–144. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, H.; Han, C.; Hu, W.; Zhang, S.; Zhang, L.; Yang, H. A novel light diffuser based on the combined morphology of polymer networks and polymer balls in a polymer dispersed liquid crystals film. RSC Adv. 2018, 8, 21690–21698. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Han, C.; Zhang, C.; Zhang, L. A novel optical diffuser based on polymer micro-balls-filled nematic liquid crystal composite film. RSC Adv. 2018, 8, 40347–40357. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, P.; Chinky; Malik, P.; Raina, K.K. Preparation and electrooptic study of reverse mode polymer dispersed liquid crystal: Performance augmentation with the doping of nanoparticles and dichroic dye. J. Appl. Polym. Sci. 2019, 137, 48745. [Google Scholar] [CrossRef]

- Zhou, L.; He, Z.; Han, C.; Zhang, L.; Yang, H. Switchable anti-peeping film for liquid crystal displays from polymer dispersed liquid crystals. Liq. Cryst. 2018, 46, 718–724. [Google Scholar] [CrossRef]

- Hu, J.; Hu, W.; Zhang, S.; Sun, C.; Lan, R.; Cao, Y.; Ren, Y.; Xu, J.; Wang, X.; Saeed, M.H.; et al. Combined effect of hydroxylated and fluorinated acrylate monomers on improving the electro-optical and mechanical performances of PDLC-films. Liq. Cryst. 2021, 49, 769–779. [Google Scholar] [CrossRef]

| Sample ID | TTMP/Capcure 3–800/TAC/E1 (wt%) | E8/NF | no | Δn | np | η (mPa·s) |

|---|---|---|---|---|---|---|

| X1 | 27.50/0/13.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.538 | 49.50 |

| X2 | 24.75/2.75/13.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.535 | 49.50 |

| X3 | 22.00/5.50/13.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.533 | 49.50 |

| X4 | 19.25/8.25/13.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.531 | 49.50 |

| X5 | 16.50/11.0013.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.529 | 49.50 |

| X6 | 13.75/13.7513.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.527 | 49.50 |

| Y1 | 13.75/13.7513.25/13.25 | 45.00/0 | 1.525 | 0.248 | 1.527 | 49.50 |

| Y2 | 13.75/13.7513.25/13.25 | 40.50/4.50 | 1.526 | 0.210 | 1.527 | 50.00 |

| Y3 | 13.75/13.7513.25/13.25 | 36.00/9.00 | 1.527 | 0.208 | 1.527 | 54.60 |

| Y4 | 13.75/13.7513.25/13.25 | 31.50/13.50 | 1.529 | 0.203 | 1.527 | 57.60 |

| Y5 | 13.75/13.7513.25/13.25 | 27.00/18.00 | 1.531 | 0.200 | 1.527 | 63.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Hu, W. Effects of Multi-Fluorinated Liquid Crystals with High Refractive Index on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystals. Materials 2025, 18, 1406. https://doi.org/10.3390/ma18071406

Ren Y, Hu W. Effects of Multi-Fluorinated Liquid Crystals with High Refractive Index on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystals. Materials. 2025; 18(7):1406. https://doi.org/10.3390/ma18071406

Chicago/Turabian StyleRen, Yunxiao, and Wei Hu. 2025. "Effects of Multi-Fluorinated Liquid Crystals with High Refractive Index on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystals" Materials 18, no. 7: 1406. https://doi.org/10.3390/ma18071406

APA StyleRen, Y., & Hu, W. (2025). Effects of Multi-Fluorinated Liquid Crystals with High Refractive Index on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystals. Materials, 18(7), 1406. https://doi.org/10.3390/ma18071406