Preparation of Laminated Titanium Matrix Composites with High Strength and Plasticity via Regulating Heat Treatment Processes

Abstract

1. Introduction

2. Experimental Procedures

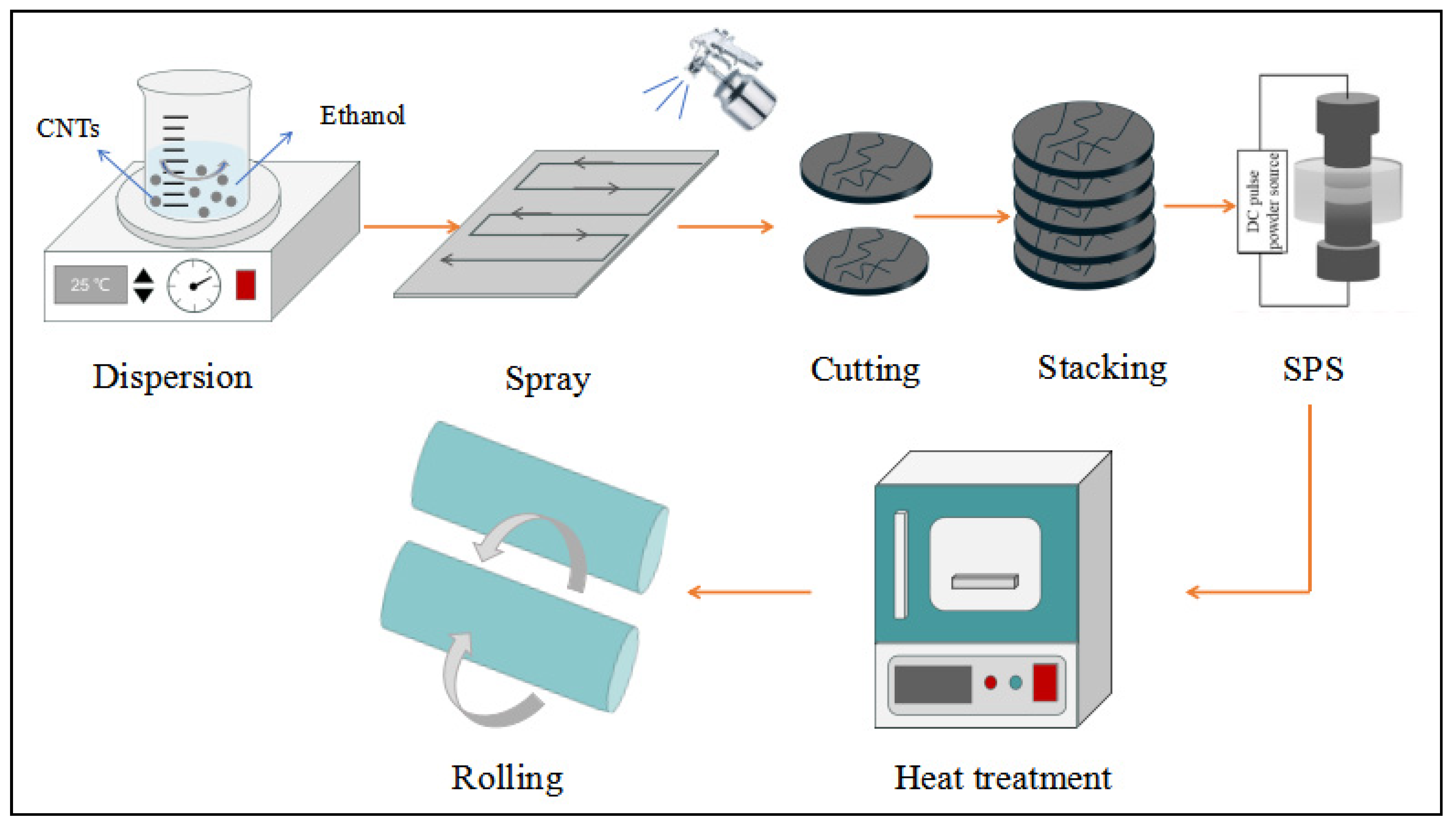

2.1. Preparation of Laminated Composites

2.2. Characterization

3. Results and Discussion

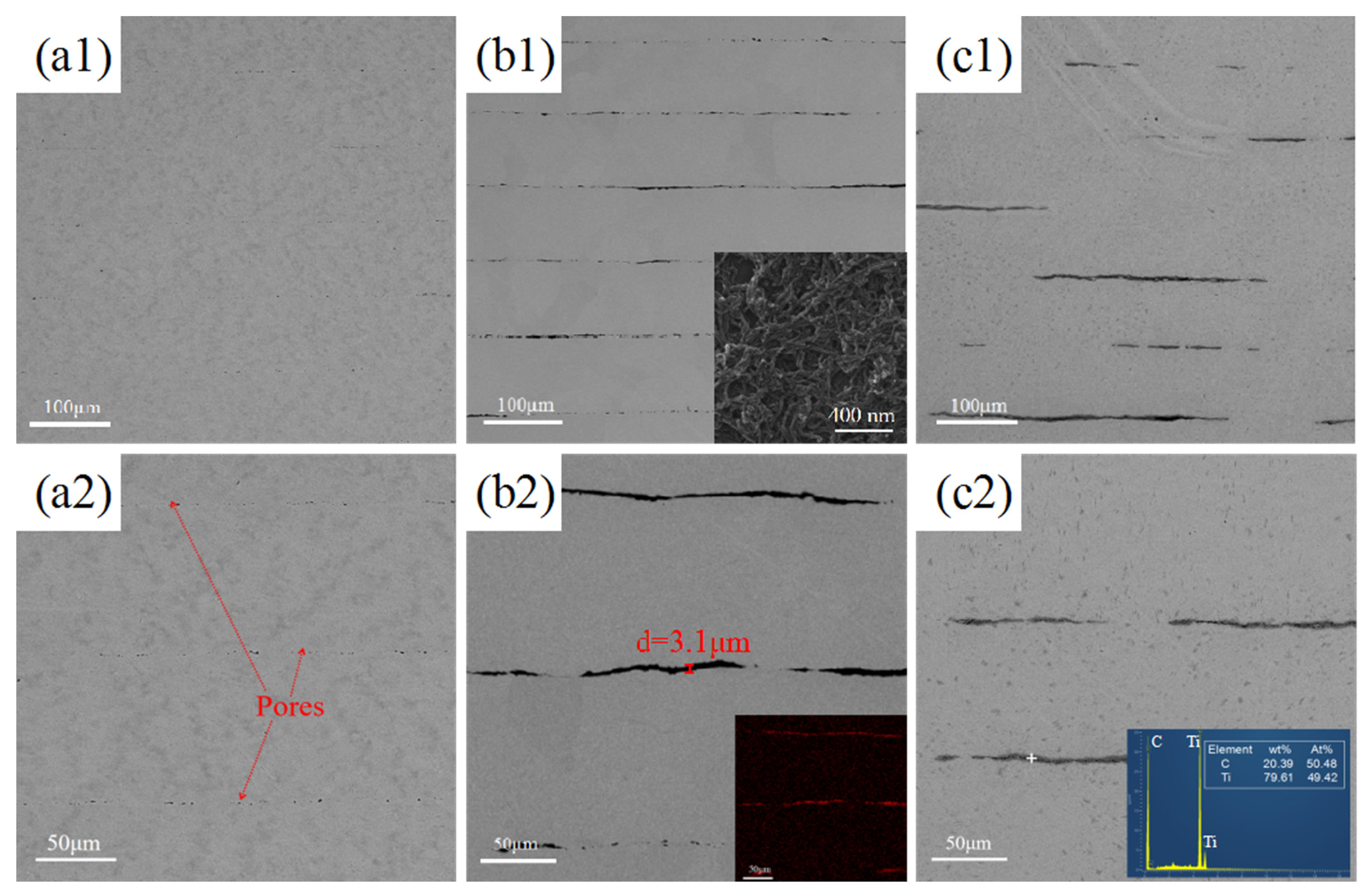

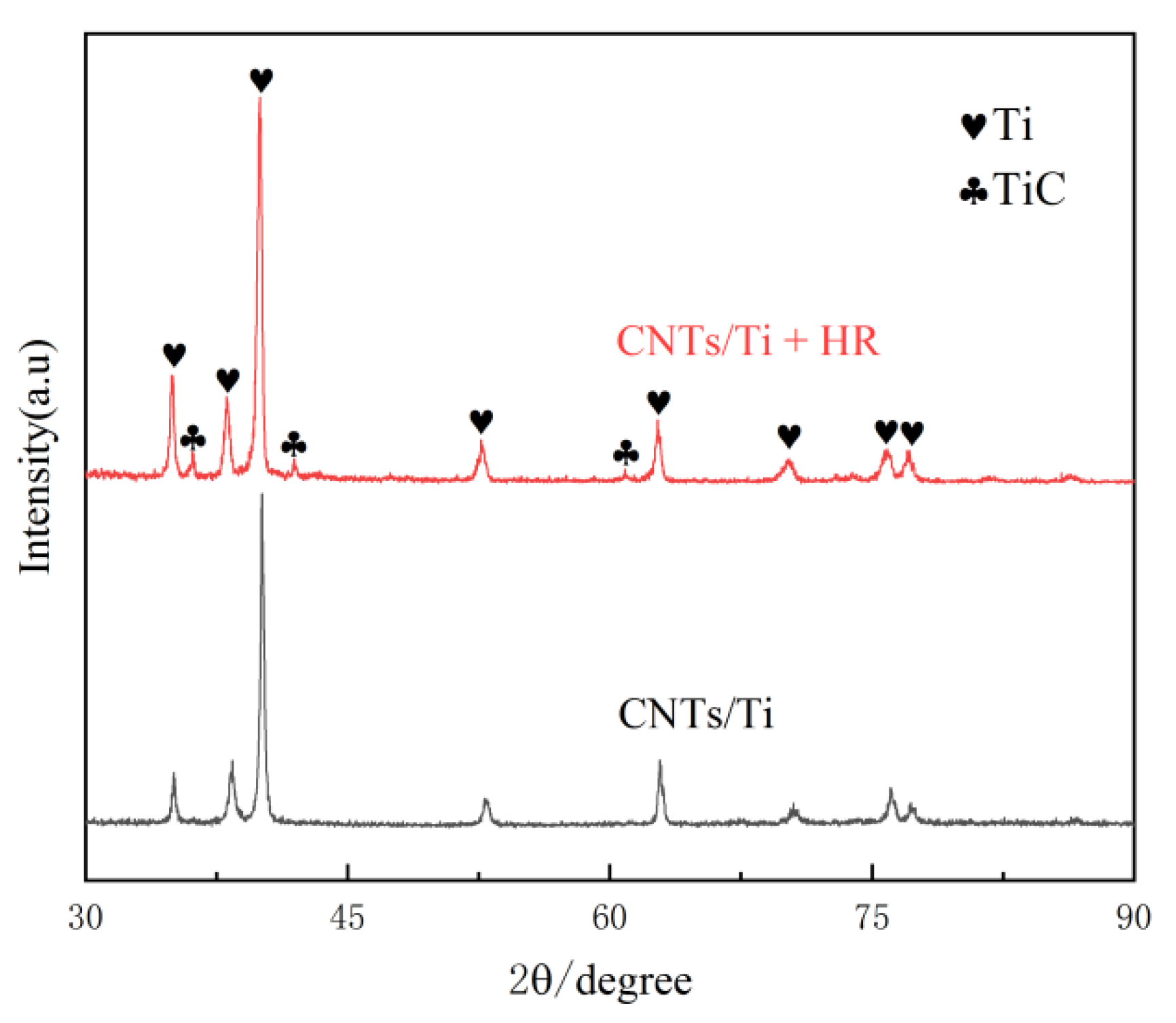

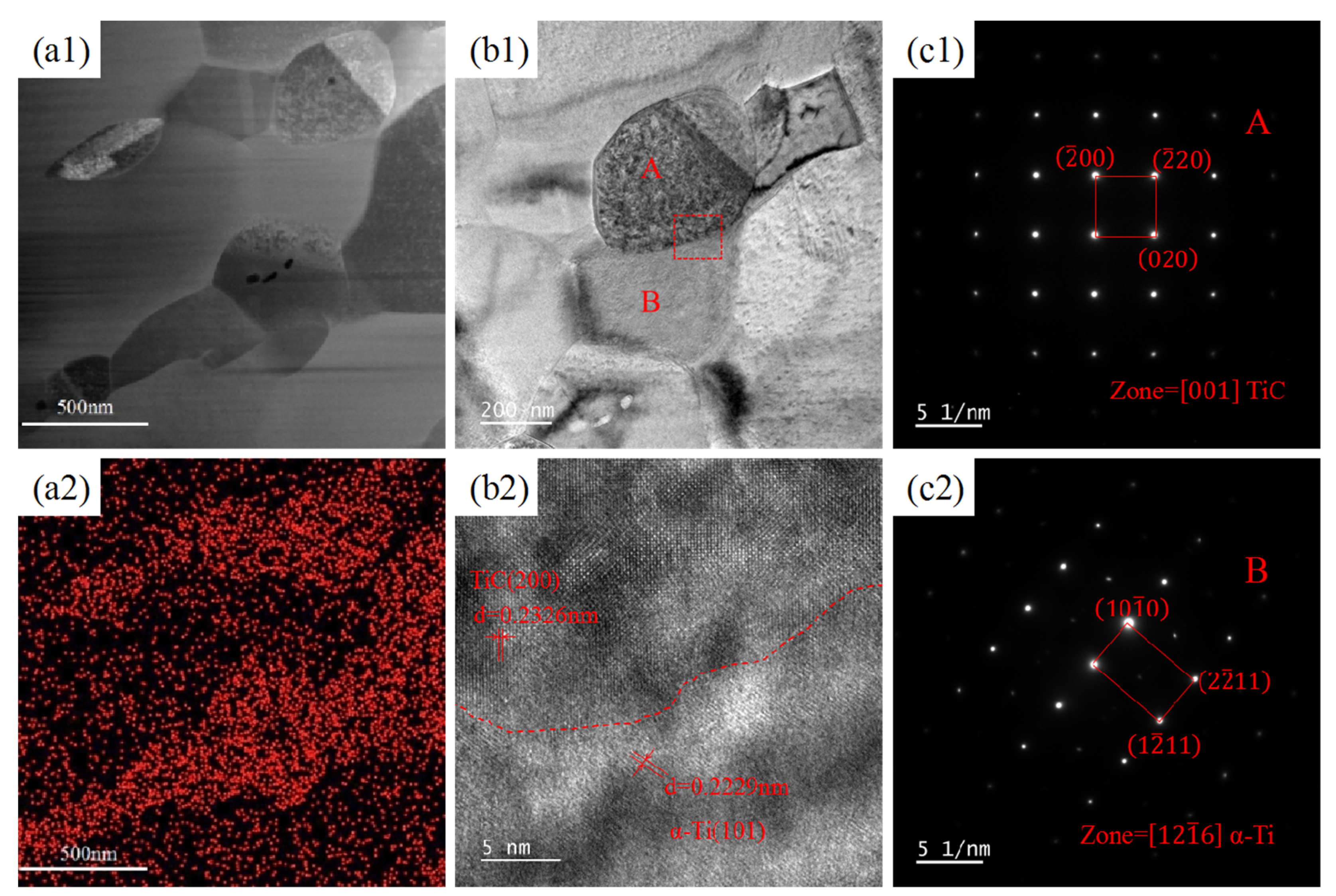

3.1. Microstructure

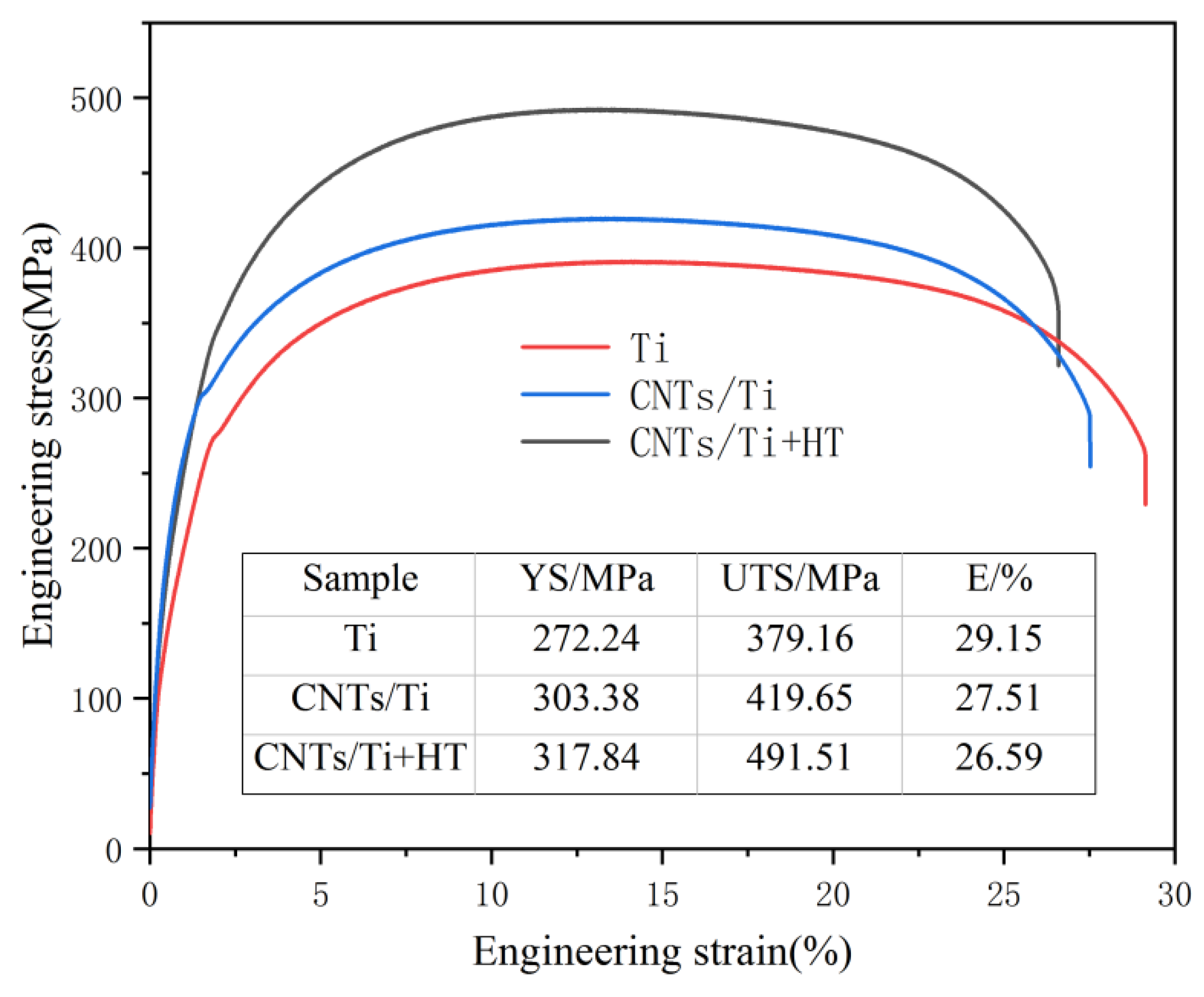

3.2. Mechanical Properties

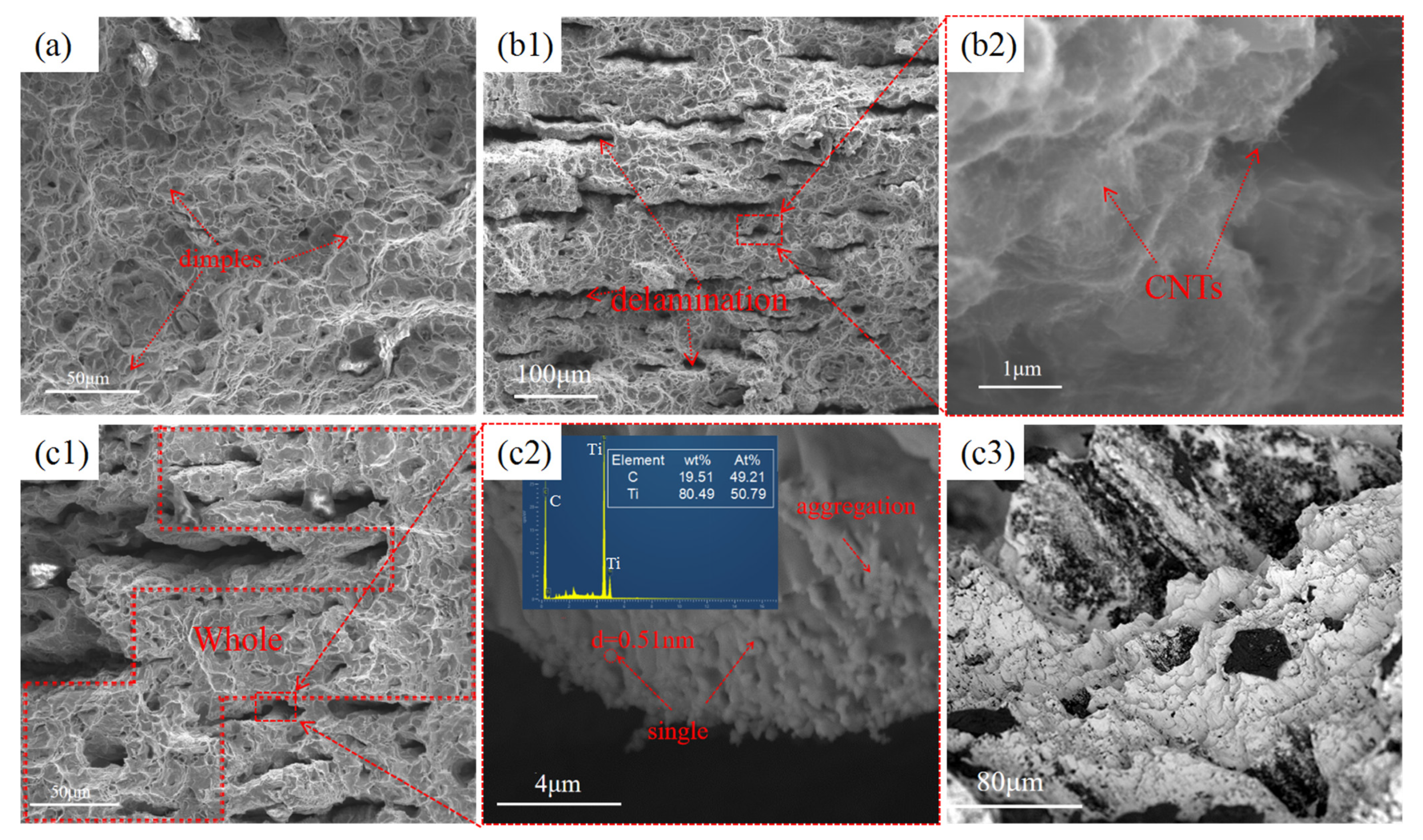

3.3. Fracture Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lei, C.; Du, Y.; Zhu, M.; Huo, W.; Wu, H.; Zhang, Y. Microstructure and mechanical properties of in situ TiC/Ti composites with a laminated structure synthesized by spark plasma sintering. Mater. Sci. Eng. A 2021, 812, 141136. [Google Scholar] [CrossRef]

- Shang, C.; Zhang, F.; Xiong, Y.; Wan, Q.; Chen, F. Spark plasma forging and network size effect on strength-ductility trade-off in graphene reinforced Ti6Al4V matrix nanocomposites. Mater. Sci. Eng. A 2023, 862, 144480. [Google Scholar] [CrossRef]

- Yu, Z.; Chen, Z.; Ren, X.; Chen, J.; Zhang, B.; Zhao, W.; Zhao, Y.; Ren, S.; Qu, X. Thermal conductivity and microstructure of graphite flakes reinforced titanium matrix composites fabricated by spark plasma sintering. J. Alloys Compd. 2023, 937, 168423. [Google Scholar] [CrossRef]

- Zhuang, W.; Qin, L.; Jia, J.; Li, J.; Cao, Q.; Meng, C.; Liu, J. Microstructure and mechanical properties of network/point cluster structured TiC/6061 composites prepared by in-situ synthesis. Mater. Lett. 2024, 365, 136446. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, G.; Bi, Y.; He, J.; Qin, Y.; Yin, F.; Zhao, H. Plasma sprayed TiC–Ti5Si3–Ti3SiC2–SiC composite coatings using annealed Ti–SiC composite powders based on SiC content. Ceram. Int. 2023, 49, 11433–11441. [Google Scholar] [CrossRef]

- Xie, L.; Wu, Y.; Yao, Y.; Hua, L.; Wang, L.; Zhang, L.-C.; Lu, W. Refinement of TiB reinforcements in TiB/Ti-2Al-6Sn titanium matrix composite via electroshock treatment. Mater. Charact. 2021, 180, 111395. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Z.-H.; Liu, L.-J.; Jia, X.-T.; He, Y.-Y.; Sun, Y.-H.; Cheng, X.-W. Fabrication of TiB-reinforced titanium matrix composite via spark plasma sintering and vertical bidirectional reactive hot rolling. Mater. Charact. 2023, 206, 113450. [Google Scholar] [CrossRef]

- Shi, S.; Cho, S.; Goto, T.; Sekino, T. The effects of sintering temperature on mechanical and electrical properties of Al2O3/Ti composites. Mater. Today Commun. 2020, 25, 101522. [Google Scholar] [CrossRef]

- Wang, S.; Huang, L.; Geng, L.; Sun, Y.; Peng, H.-X.; Qu, S. Microstructure evolution and damage mechanism of layered titanium matrix composites under tensile loading. Mater. Sci. Eng. A 2020, 777, 139067. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Yang, F.Y.; Peng, H.X. In situ TiBw/Ti–6Al–4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 60, 996–999. [Google Scholar] [CrossRef]

- Ni, D.R.; Geng, L.; Zhang, J.; Zheng, Z.Z. Effect of B4C particle size on microstructure of in situ titanium matrix composites prepared by reactive processing of Ti–B4C system. Scr. Mater. 2006, 55, 429–432. [Google Scholar] [CrossRef]

- Barthelat, F.; Tang, H.; Zavattieri, P.D.; Li, C.M.; Espinosa, H.D. On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure. J. Mech. Phys. Solids 2007, 55, 306–337. [Google Scholar] [CrossRef]

- Taotao, A.; Zhifeng, D.; Wenhu, L.; Hongfeng, D.; Ran, J.J.M.L. Bioinspired Design and Toughening Mechanism of the TC4-(γ-TiAl/α2-Ti3Al) Laminated Composite Fabricated by Spark Plasma Sintering. Mater. Lett. 2020, 273, 127965. [Google Scholar] [CrossRef]

- Wang, S.; An, Q.; Liu, W.; Zhang, R.; Ma, Z.; Huang, L.; Geng, L. Towards strength-ductility enhancement of titanium matrix composites through heterogeneous grain structured Ti matrix design. J. Alloys Compd. 2022, 927, 167022. [Google Scholar] [CrossRef]

- Meng, L.; Wang, X.; Hu, X.; Shi, H.; Wu, K. Role of structural parameters on strength-ductility combination of laminated carbon nanotubes/copper composites. Compos. Part A Appl. Sci. Manuf. 2019, 116, 138–146. [Google Scholar] [CrossRef]

- Duan, H.; Han, Y.; Lu, W.; Wang, L.; Mao, J.; Zhang, D. Materials, Design, Configuration design and fabrication of laminated titanium matrix composites. Mater. Des. 2016, 99, 219–224. [Google Scholar] [CrossRef]

- Ding, H.; Cui, X.; Zhang, Y.; Wang, Z.; Gao, N.; Zhang, T.; Luo, J.; Zhai, X.; Chen, J.; Geng, L.; et al. Overcoming strength-ductility trade-off by building a micro-nano laminated structure based on an ultralow amount of single-dispersed carbon nanotubes. Int. J. Plast. 2023, 171, 103805. [Google Scholar] [CrossRef]

- Tan, Y.; Cai, H.; Cheng, X.; Ma, Z.; Xu, Z.; Zhou, Z. Microstructural and mechanical properties of in-situ micro-laminated TiC/Ti composite synthesised. Mater. Lett. 2018, 228, 1–4. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, C.; Yan, J.; Meng, Z.; Chen, L.; Zhao, G. Achieving the strength-ductility synergy in ultra-fined grained CNT/2024Al composites via a low-temperature aging strategy. Compos. Part B Eng. 2024, 281, 111552. [Google Scholar] [CrossRef]

- Nazari, M.; Shakeri, E.; Mohammadi, M. Fabrication and optimization process of mechanical properties of MoSi2 composites reinforced by carbon nanotubes (CNT) using Taguchi method. Ceram. Int. 2024, 50, 25568–25577. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Wang, J.; Li, B.; Liu, L.; Hou, X.; Li, S.; Ji, X.; Gao, L.; Li, S. Stimulating adequate strengthening effect through alloying regulation for powder metallurgy CNTs reinforced aluminum matrix composites. J. Mater. Res. Technol. 2024, 28, 1725–1733. [Google Scholar] [CrossRef]

- Li, R.; Yue, H.; Luo, S.; Zhang, F.; Sun, B. Microstructure and mechanical properties of in situ synthesized (TiB+TiC)-reinforced Ti6Al4V composites produced by directed energy deposition of Ti and B4C powders. Mater. Sci. Eng. A 2023, 864, 144466. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, L.; Liang, Z.; Wang, X.; Chi, D.; Xiao, S.; Xue, X.; Tian, J.; Chen, Y. Constructing tri-modal microstructure via new three-step heat treatments for improved tensile strength and creep resistance in (TiB+TiC+Y2O3)/α-Ti composite. Mater. Sci. Eng. A 2023, 888, 145808. [Google Scholar] [CrossRef]

- Mu, X.N.; Zhang, H.M.; Chen, P.W.; Cheng, X.W.; Liu, L.; Ge, Y.X.; Xiong, N.; Zheng, Y.C. Achieving high performance in graphite nano-flakes reinforced titanium matrix composites through a novel reaction interface design. Carbon 2021, 175, 334–351. [Google Scholar] [CrossRef]

- Choi, Y.; Rhee, S.W. Equilibrium in the reaction of Ti and C to form substoichiometric TiCx. J. Mater. Sci. Lett. 1994, 13, 323–325. [Google Scholar] [CrossRef]

- Dong, L.L.; Xiao, B.; Liu, Y.; Li, Y.L.; Fu, Y.Q.; Zhao, Y.Q.; Zhang, Y.S. Sintering effect on microstructural evolution and mechanical properties of spark plasma sintered Ti matrix composites reinforced by reduced graphene oxides. Ceram. Int. 2018, 44, 17835–17844. [Google Scholar] [CrossRef]

- Duan, Y.; Wang, X.; Liu, D.; Bao, W.; Li, P.; Peng, M. Characteristics, wear and corrosion properties of borided pure titanium by pack boriding near α → β phase transition temperature. Ceram. Int. 2020, 46 Pt B, 16380–16387. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Q.; Han, Y.; Zhao, L.; An, D.; Wu, H.; Li, X.; Chen, J. Two kinds of α/β phase transformations and enhanced strengths of the bonded interface in laminated Ti alloys. Mater. Sci. Eng. A 2023, 869, 144811. [Google Scholar] [CrossRef]

- Liu, B.X.; Huang, L.J.; Geng, L.; Kaveendran, B.; Wang, B.; Song, X.Q.; Cui, X.P. Gradient grain distribution and enhanced properties of novel laminated Ti–TiBw/Ti composites by reaction hot-pressing. Mater. Sci. Eng. A 2014, 595, 257–265. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, B.; You, C.; Zhang, W.; Li, Y.; Zhang, Y. Strengthening and toughening mechanisms of titanium-nitrogen alloy with a laminated structure fabricated by spark plasma sintering. Mater. Sci. Eng. A 2020, 769, 138492. [Google Scholar] [CrossRef]

- Dong, L.L.; Lu, J.W.; Fu, Y.Q.; Huo, W.T.; Liu, Y.; Li, D.D.; Zhang, Y.S. Carbonaceous nanomaterial reinforced Ti-6Al-4V matrix composites: Properties, interfacial structures and strengthening mechanisms. Carbon 2020, 164, 272–286. [Google Scholar] [CrossRef]

- Ghasali, E.; Shahedi Asl, M. Microstructural development during spark plasma sintering of ZrB2–SiC–Ti composite. Ceram. Int. 2018, 44, 18078–18083. [Google Scholar] [CrossRef]

- Lei, C.; Pan, Y.; Kuang, F.; Huo, W.; Zhu, M.; Lu, X. A novel configuration design of strong and ductile (TiC + Ti5Si3)/Ti laminated composites. Mater. Sci. Eng. A 2024, 892, 145961. [Google Scholar] [CrossRef]

- Wang, F.-C.; Zhang, Z.-H.; Sun, Y.-J.; Liu, Y.; Hu, Z.-Y.; Wang, H.; Korznikov, A.V.; Korznikova, E.; Liu, Z.-F.; Osamu, S. Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon 2015, 95, 396–407. [Google Scholar] [CrossRef]

- Wei, Z.; Han, Y.; Li, S.; Zong, N.; Le, J.; Zhang, S.; Chen, J.; Zhong, S.; Huang, G.; Lu, W. Interfacial modification strategy to break through the strength and ductility trade-off in multi-walled carbon nanotubes reinforced titanium matrix composites. Mater. Sci. Eng. A 2023, 880, 145284. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Yang, Y.; Liu, J.; Sun, T.; Zhang, F. Preparation of Laminated Titanium Matrix Composites with High Strength and Plasticity via Regulating Heat Treatment Processes. Materials 2025, 18, 1429. https://doi.org/10.3390/ma18071429

Zou X, Yang Y, Liu J, Sun T, Zhang F. Preparation of Laminated Titanium Matrix Composites with High Strength and Plasticity via Regulating Heat Treatment Processes. Materials. 2025; 18(7):1429. https://doi.org/10.3390/ma18071429

Chicago/Turabian StyleZou, Xiong, Yu Yang, Junliang Liu, Tingting Sun, and Fuqin Zhang. 2025. "Preparation of Laminated Titanium Matrix Composites with High Strength and Plasticity via Regulating Heat Treatment Processes" Materials 18, no. 7: 1429. https://doi.org/10.3390/ma18071429

APA StyleZou, X., Yang, Y., Liu, J., Sun, T., & Zhang, F. (2025). Preparation of Laminated Titanium Matrix Composites with High Strength and Plasticity via Regulating Heat Treatment Processes. Materials, 18(7), 1429. https://doi.org/10.3390/ma18071429