Creep Mechanism and Microstructure Evolution of a Directionally Solidified Ni-Based Superalloy with Different Orientations at 850 °C

Abstract

1. Introduction

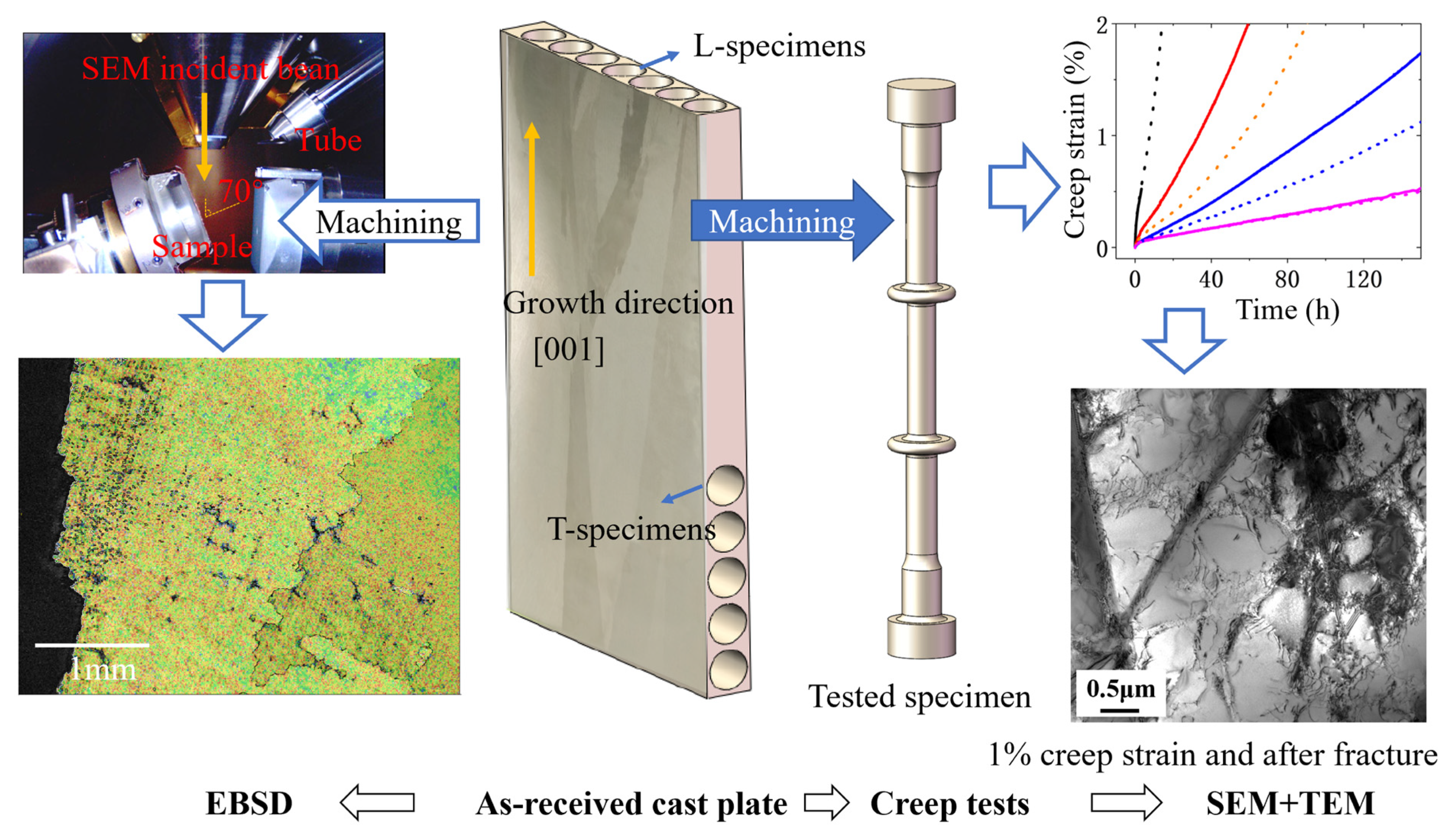

2. Materials and Methods

3. Results

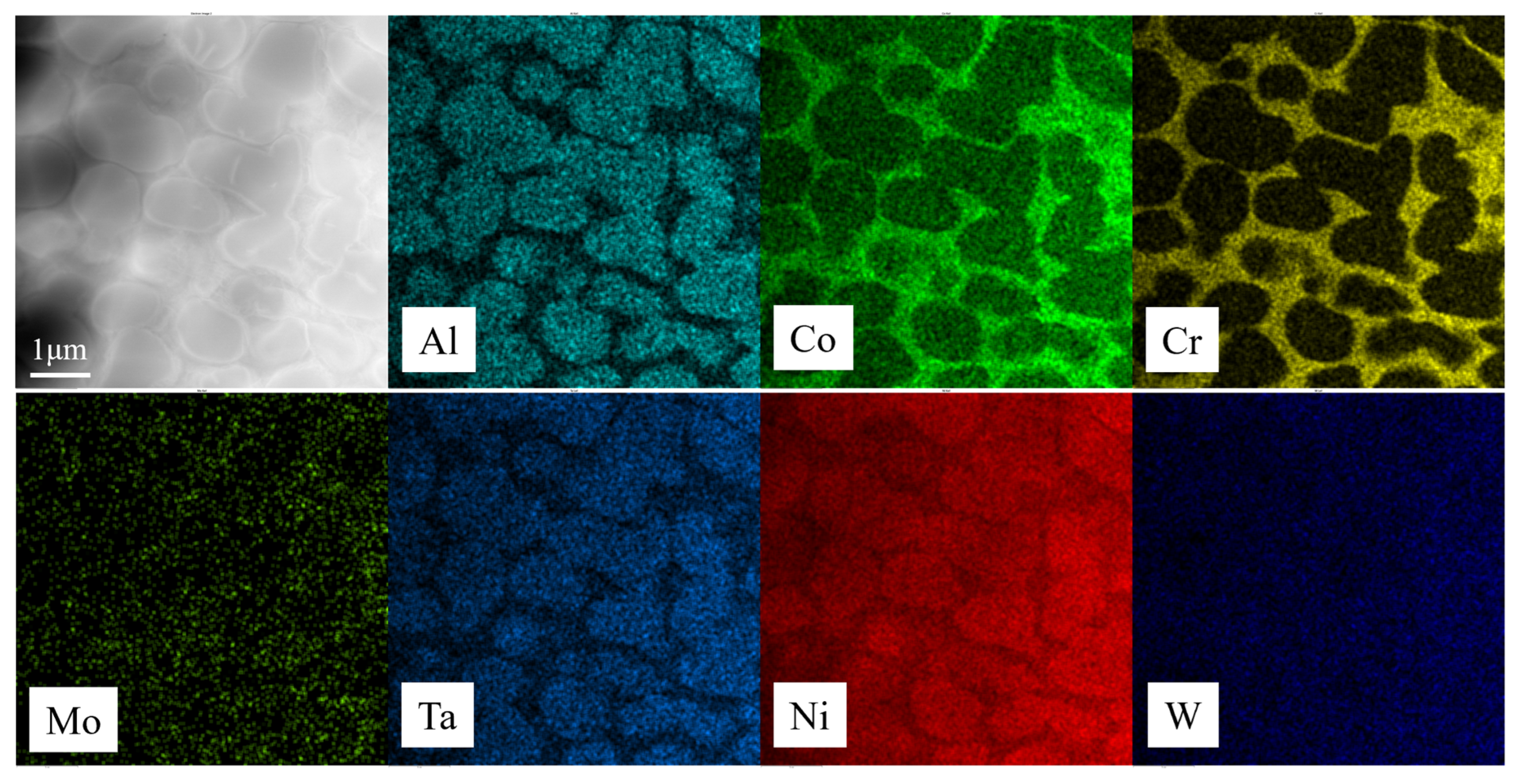

3.1. Microstructure After Heat Treatment

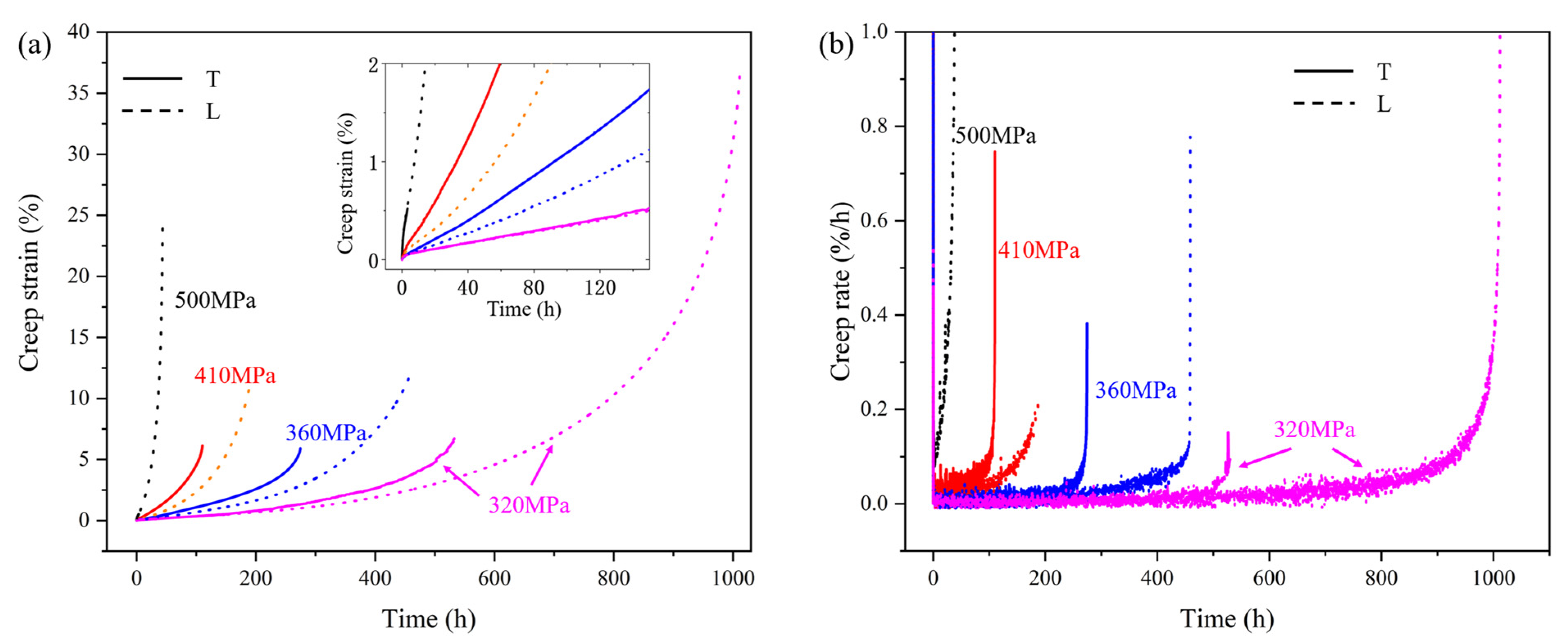

3.2. Creep Behavior at 850 °C

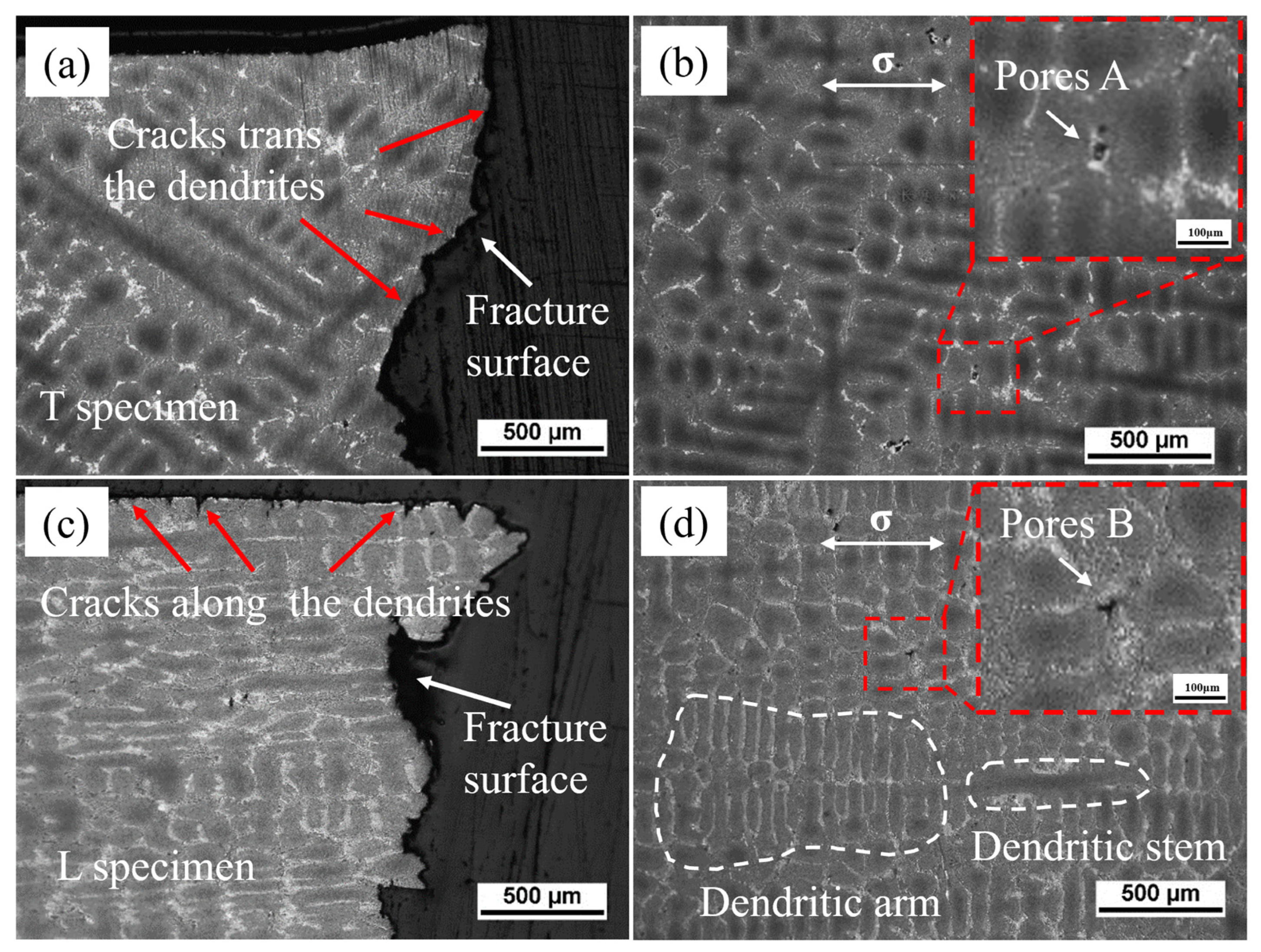

3.3. Fracture Microstructure After Creep at 850 °C/320 MPa

4. Discussion

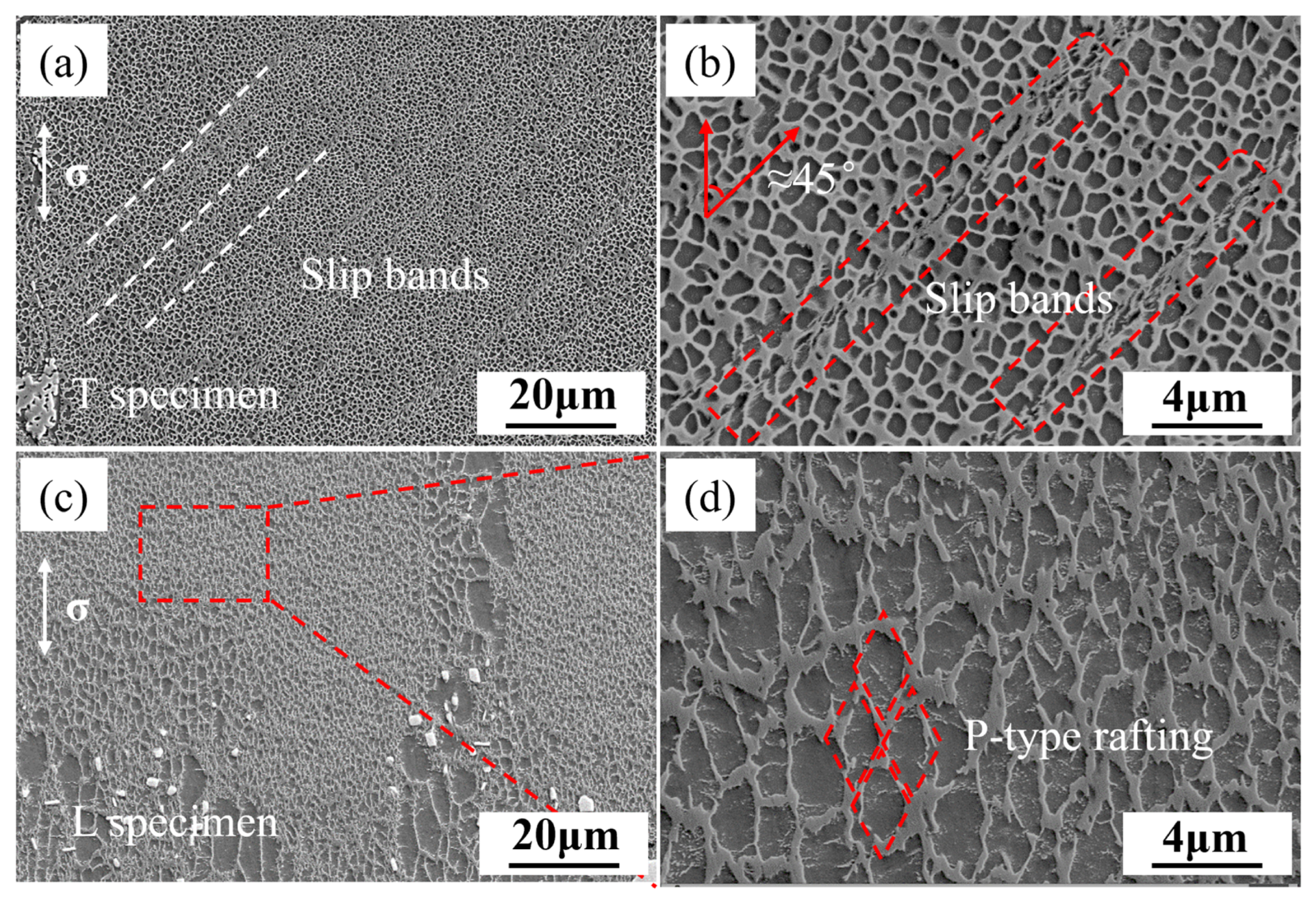

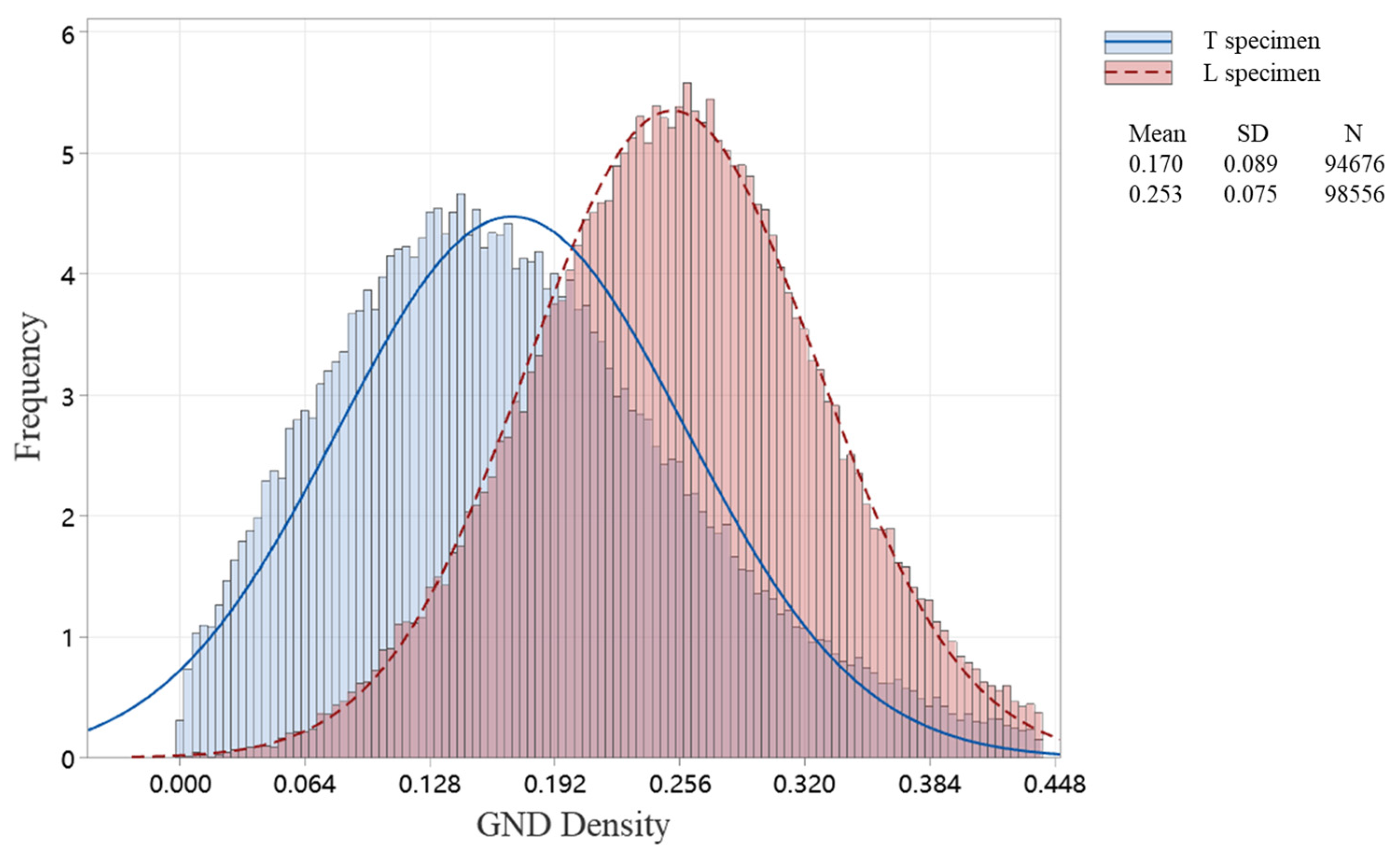

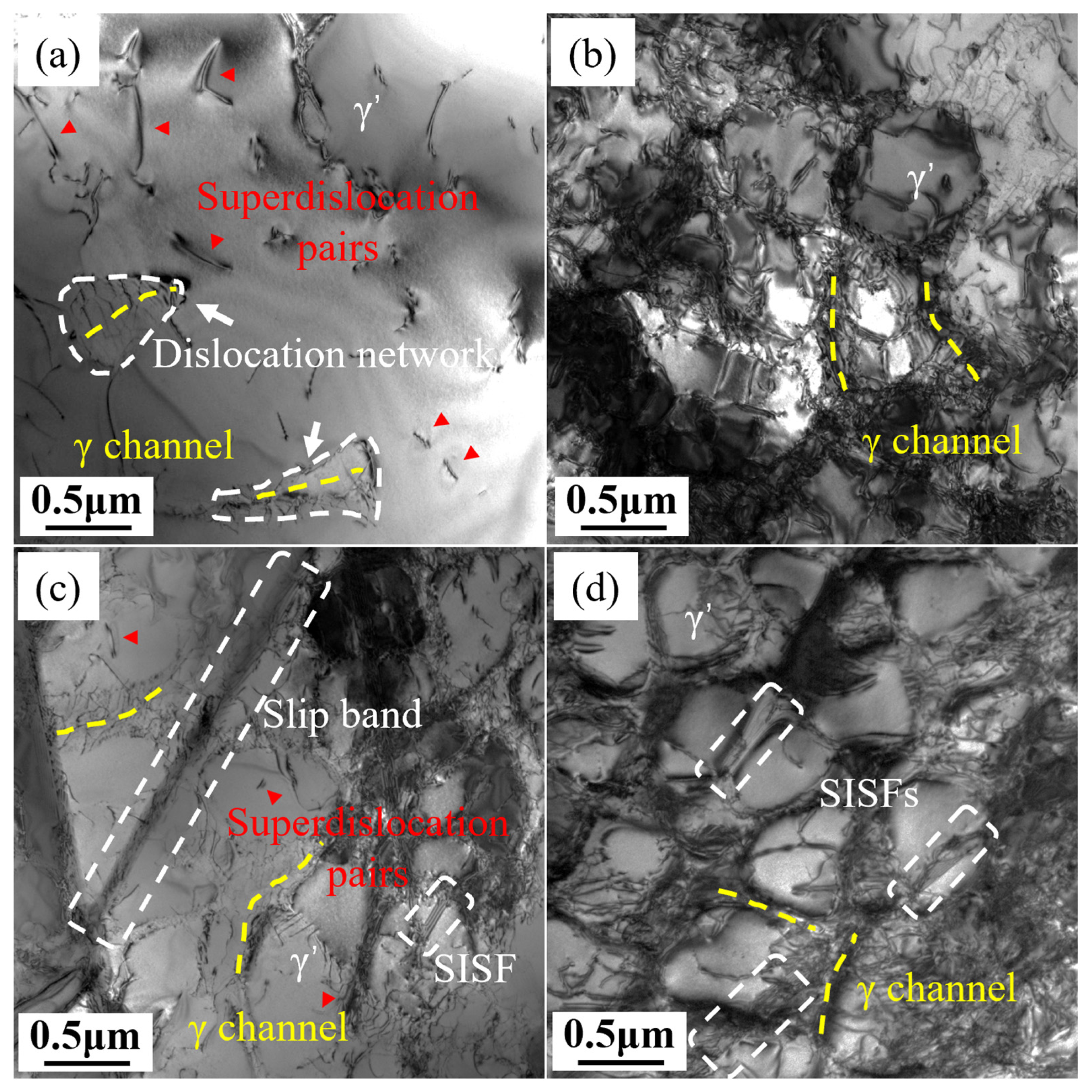

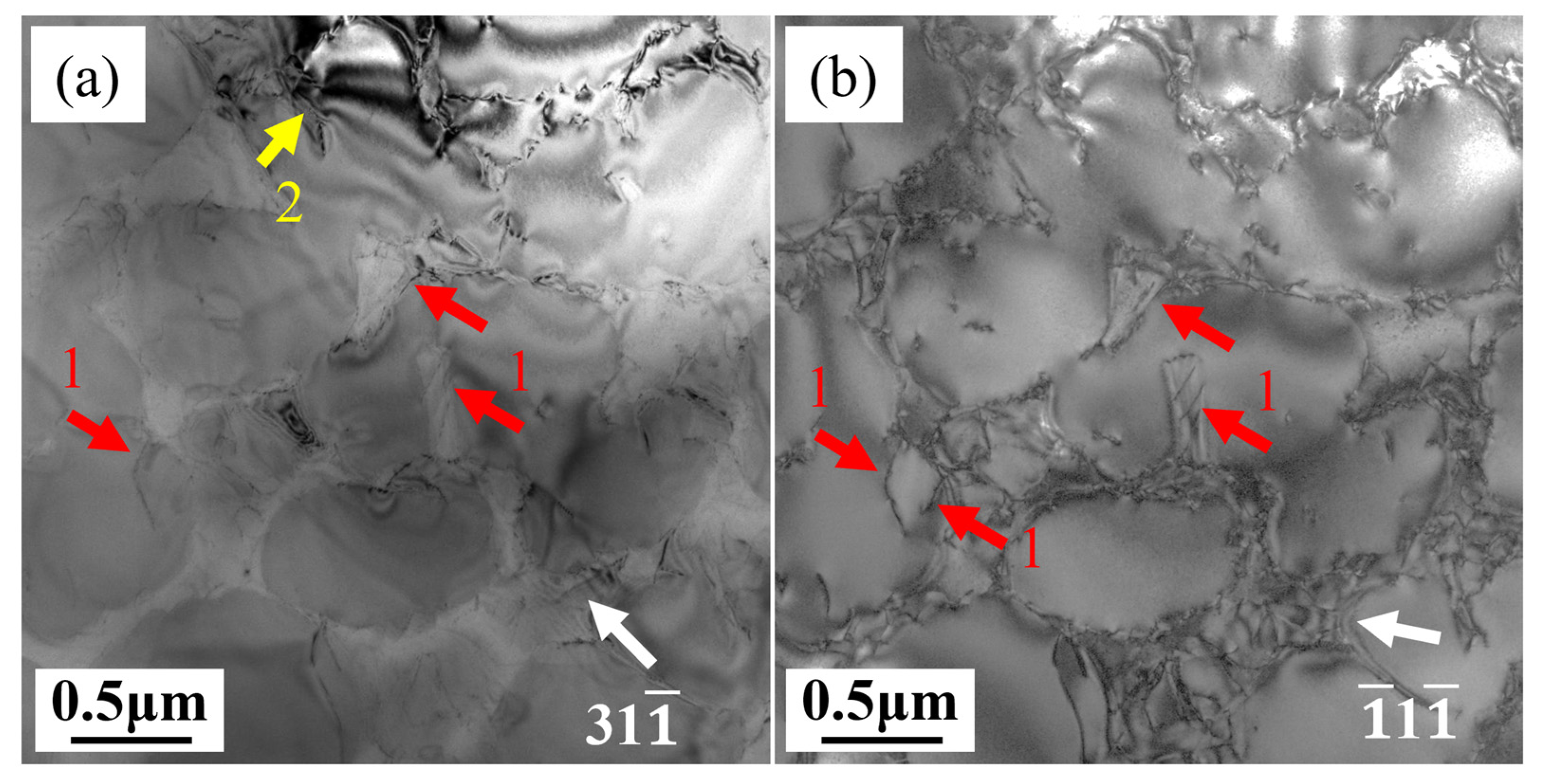

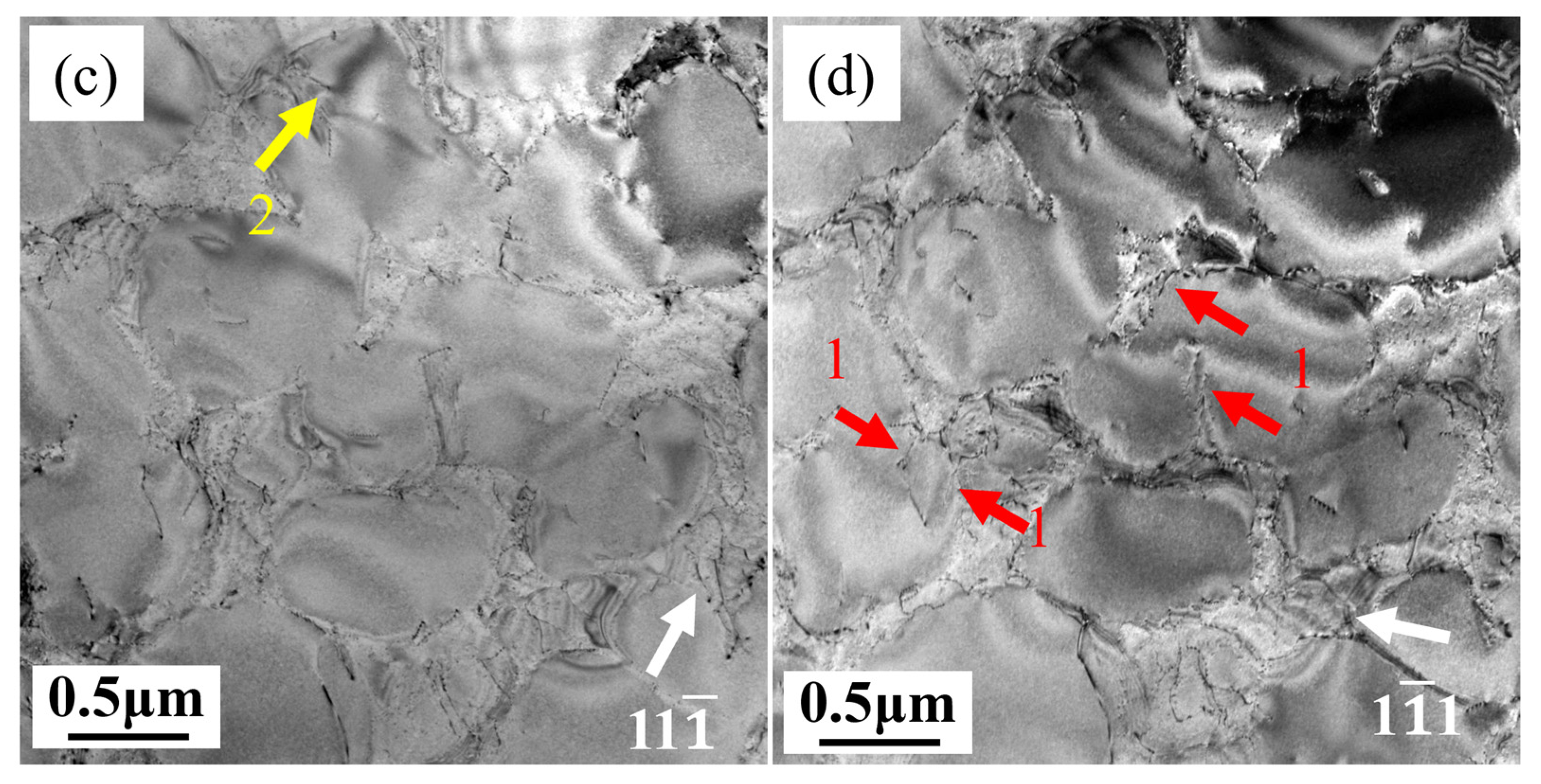

4.1. Deformation Mechanisms

4.2. Creep Microstructural Evolution

5. Conclusions

- The longitudinal specimens demonstrated superior creep resistance compared to the transverse specimens under varying stress conditions at 850 °C. This was evidenced by their lower steady-state creep rates and greater elongation at fracture.

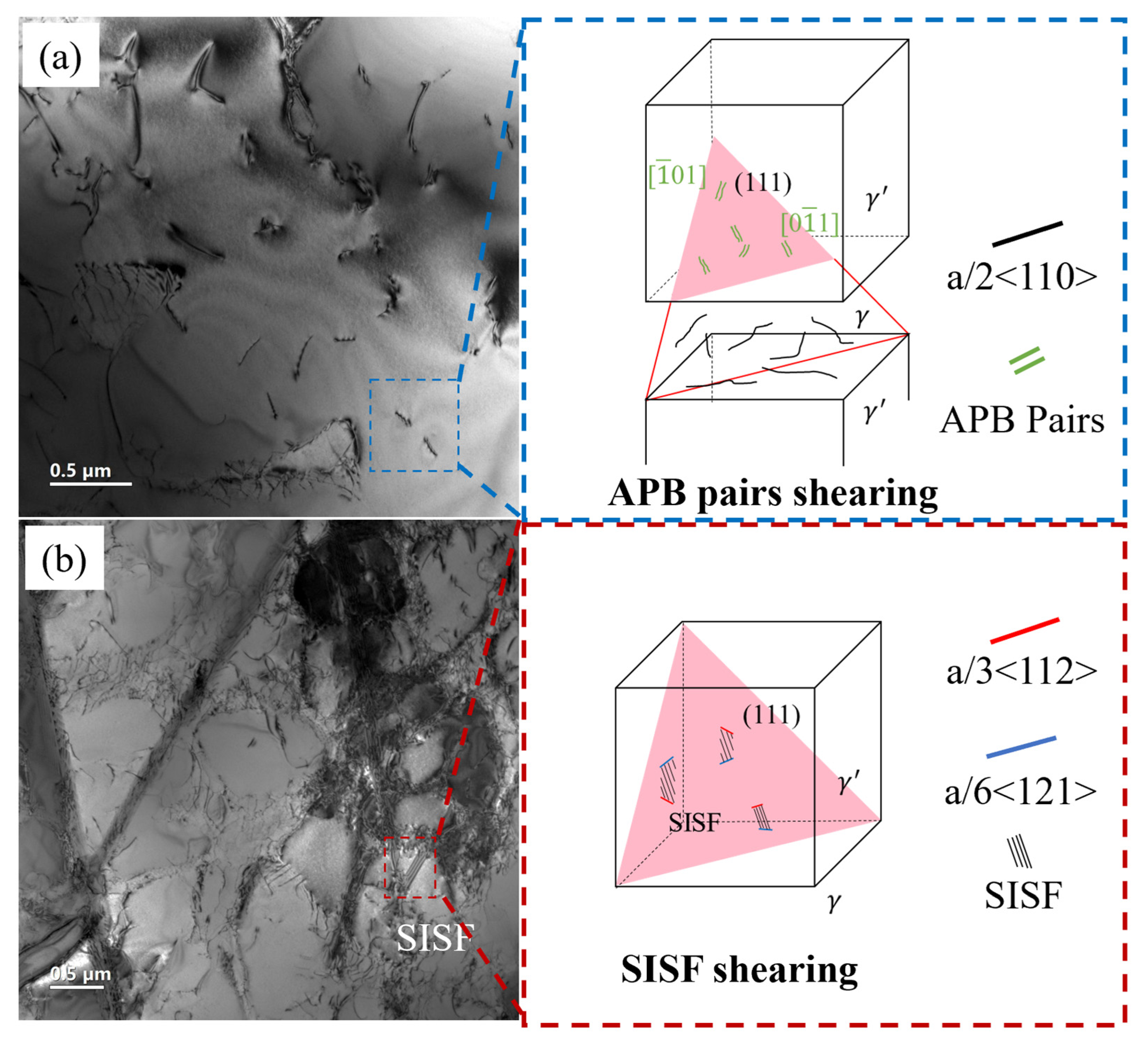

- The creep mechanism in the longitudinal direction involved the activation of multiple {111}<110> slip systems, with dislocations shearing the γ′ precipitates through antiphase boundaries (APBs). In contrast, the creep mechanism in the transverse direction involved the activation of a few {111}<112> slip systems, with dislocations shearing the γ′ precipitates through stacking fault energy (SISF) and forming slip bands at a certain angle to the applied stress axis.

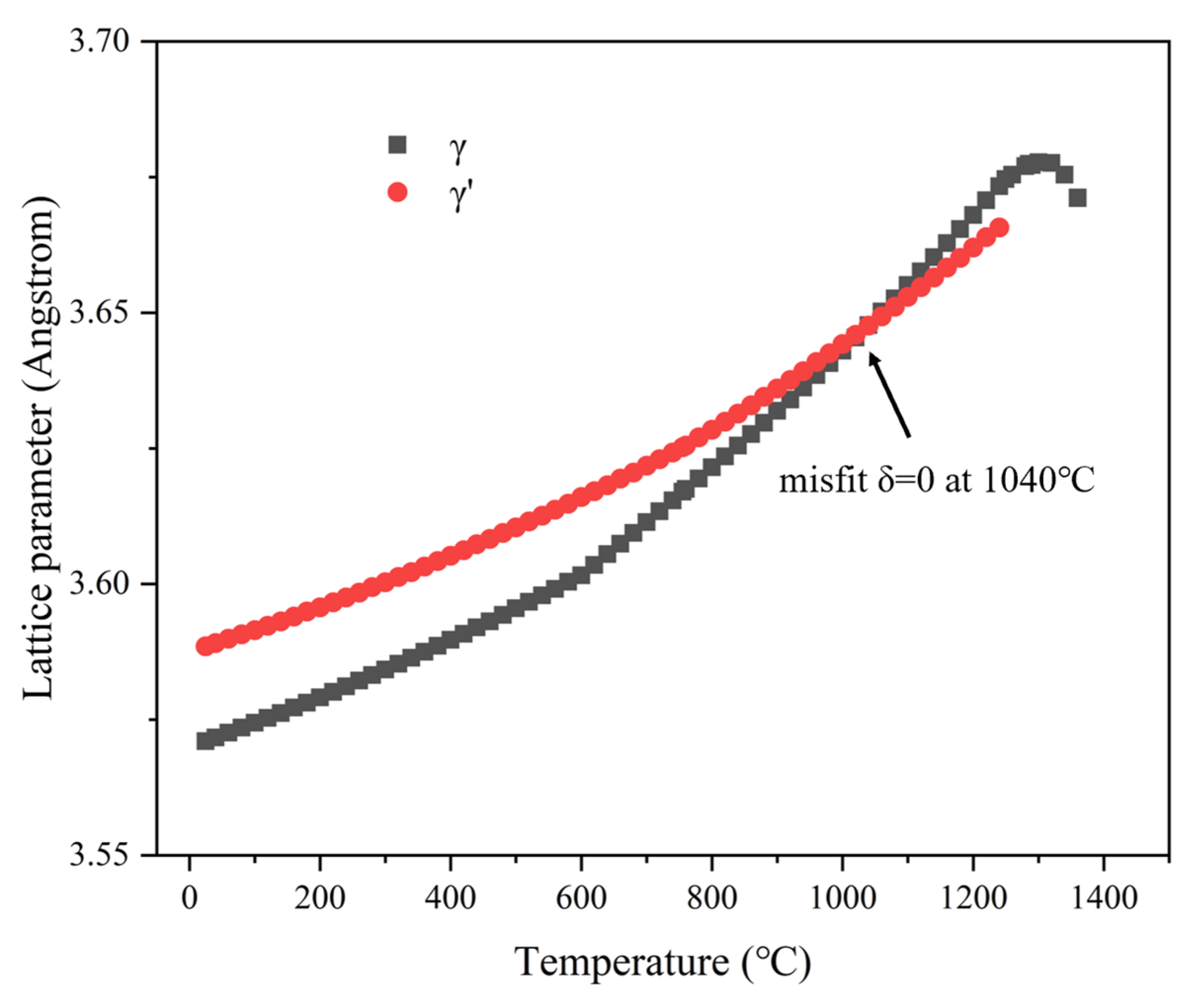

- Al is the controlling element for the rafting of the γ′ precipitates. The longitudinal specimens, with more activated slip systems and sufficient plastic strain flow due to dislocation motion, underwent P-type rafting. In contrast, the transverse specimens, with limited slip systems, showed almost no rafting of the γ′ precipitates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sajjadi, S.A.; Nategh, S. A high temperature deformation mechanism map for the high performance Ni-base superalloy GTD-111. Mater. Sci. Eng. A 2001, 307, 158–164. [Google Scholar] [CrossRef]

- Wang, C.S.; Zhang, J.; Liu, L.; Fu, H.Z. Microstructure evolution of directionally solidified DZ125 superalloy with melt superheating treatment. J. Alloys Compd. 2010, 508, 440–445. [Google Scholar] [CrossRef]

- Gao, G.D.; Duan, S.L.; Zhang, W.X. A study of high temperature low cycle fatigue life prediction for two superalloys. J. Eng. Res. 2015, 3, 1–14. [Google Scholar] [CrossRef]

- Zhang, H.J.; Wen, W.D.; Cui, H.T. An experimental study on constitutive equations of alloy IC10 over a wide range of temperatures and strain rates. Mater. Des. 2012, 36, 130–135. [Google Scholar] [CrossRef]

- Chiou, M.S.; Jian, S.R.; Yeh, A.C.; Kuo, C.M.; Juang, J.Y. High temperature creep properties of directionally solidified CM-247LC Ni-based superalloy. Mater. Sci. Eng. A 2016, 655, 237–243. [Google Scholar] [CrossRef]

- Xia, W.S.; Zhao, X.B.; Yue, L.; Zhang, Z. Microstructural evolution and creep mechanisms in Ni-based single crystal superalloys: A review. J. Alloys Compd. 2020, 819, 152954. [Google Scholar] [CrossRef]

- Sharma, A.; Mondal, C.; Makineni, S.K.; Chattopadhyay, K.; Banerjee, D. Exploring the correlation between microscopic mechanisms and macroscopic behaviour in creep of a directionally solidified tungsten-free γ/γ′ CoNi-base superalloy. Acta Mater. 2022, 228, 117738. [Google Scholar] [CrossRef]

- Li, J.C.; Tian, N.; Zhang, P.; Yu, F.; Zhao, G.Q.; Zhang, P. Creep damage and deformation mechanism of a directionally solidified alloy during moderate-temperature creep. Crystals 2021, 11, 646. [Google Scholar] [CrossRef]

- Li, Q.Y.; Tian, S.G.; Yu, H.C.; Tian, N.; Su, Y.; Li, Y. Effects of carbides and its evolution on creep properties of a directionally solidified nickel-based superalloy. Mater. Sci. Eng. A 2015, 633, 20–27. [Google Scholar] [CrossRef]

- D’Souza, N.; Kelleher, J.; Qiu, C.; Zhang, S.Y.; Gardner, S.; Jones, R.E.; Putman, D.; Panwisawas, C. The role of stress relaxation and creep during high temperature deformation in Ni-base single crystal superalloys–implications to strain build-up during directional solidification. Acta Mater. 2016, 106, 322–332. [Google Scholar] [CrossRef]

- Zhang, P.; Li, J.; Gong, X.F.; Yuan, Y.; Gu, Y.F.; Wang, J.C.; Yan, J.B.; Yin, H.F. Creep behavior and deformation mechanisms of a novel directionally solidified Ni-base superalloy at 900 C. Mater. Charact. 2019, 148, 201–207. [Google Scholar] [CrossRef]

- Guo, J.T.; Yuan, C.; Yang, H.C.; Lupinc, V.; Maldini, M. Creep-rupture behavior of a directionally solidified nickel-base superalloy. Metall. Mater. Trans. A 2001, 32, 1103–1110. [Google Scholar] [CrossRef]

- Ichitsubo, T.; Koumoto, D.; Hirao, M.; Tanaka, K.; Osawa, M.; Yokokawa, T.; Harada, H. Rafting mechanism for Ni-base superalloy under external stress: Elastic or elastic–plastic phenomena? Acta Mater. 2003, 51, 4033–4044. [Google Scholar] [CrossRef]

- Cao, L.; Wollgramm, P.; Bürger, D.; Kostka, A.; Cailletaud, G.; Eggeler, G. How evolving multiaxial stress states affect the kinetics of rafting during creep of single crystal Ni-base superalloys. Acta Mater. 2018, 158, 381–392. [Google Scholar] [CrossRef]

- Tan, Y.G.; Zhang, W.W.; Gao, N.; Reed, P. The finding of anisotropic compatibility of grain boundaries in a directionally solidified superalloy. J. Mater. Sci. 2024, 59, 11533–11545. [Google Scholar] [CrossRef]

- Fernandez-Zelaia, P.; Lee, Y.; Dryepondt, S.; Kirka, M.M. Creep anisotropy modeling and uncertainty quantification of an additively manufactured Ni-based superalloy. Int. J. Plast. 2022, 151, 103177. [Google Scholar] [CrossRef]

- Qu, P.F.; Yang, W.C.; Liu, C.; Qin, J.R.; Wang, Q.; Zhang, J.; Liu, L. Creep anisotropy dominated by orientation rotation in Ni-based single crystal superalloys at 750 °C/750 MPa. J. Mater. Sci. Technol. 2024, 186, 91–103. [Google Scholar] [CrossRef]

- Li, Y.M.; Tan, Z.H.; Guo, H.Y.; Wang, X.G.; Li, J.G.; Zhou, Y.Z.; Sun, X.F. Enhancing Economic Affordability of Aircraft Engines: Development of a Low-Cost Single Crystal Superalloy DD93 Containing 3 Wt.% Re, Designed to Meet Third-Generation Superalloys Properties. In Superalloys; Springer: Cham, Switzerland, 2024; pp. 176–185. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.W.; Gao, Y.H.; Ru, Y.; Zhao, W.Y.; Jia, J.H.; Gan, B.; Li, S.; Pei, Y.L.; Li, S.S. Multi-scale influences of as-cast microstructure heritability on intermediate/high temperature stress rupture behaviors of [111]-oriented Ni-based single crystal superalloy. Mater. Des. 2024, 247, 113425. [Google Scholar] [CrossRef]

- Godha, A.; Das, D.; Ghosal, P.; Makineni, S.K. New insights on the interaction of solutes with the defects during creep deformation of CMSX4 Ni-based single crystal superalloy. Acta Mater. 2024, 281, 120360. [Google Scholar] [CrossRef]

- Wang, G.Y.; Zhang, S.; Tian, S.G.; Tian, N.; Zhao, G.Q.; Yan, H.J. Microstructure evolution and deformation mechanism of a [111]-oriented nickel-based single-crystal superalloy during high-temperature creep. J. Mater. Res. Technol. 2022, 16, 495–504. [Google Scholar] [CrossRef]

- Sass, V.; Glatzel, U.; Feller-Kniepmeier, M. Anisotropic creep properties of the nickel-base superalloy CMSX-4. Acta Mater. 1996, 44, 1967–1977. [Google Scholar] [CrossRef]

- Xia, W.S.; Zhao, X.B.; Yue, Q.Z.; Xuan, W.D.; Pan, Q.H.; Wang, J.W.; Ding, Q.Q.; Bei, H.B.; Zhang, Z. Competitive deformation induced by TCP precipitation and creep inconsistency on dendritic structures in a nickel-based single crystal superalloy crept at high temperatures. Mater. Charact. 2022, 187, 111855. [Google Scholar] [CrossRef]

- Qiu, Z.J.; Zhu, H.L.; Wang, Z.Y.; Muránsky, O.; Wei, T.; Budzakoska-Testone, E.; Davis, J.; Studer, A.; Gu, Q.F.; Garbe, U. Crystallographic texture and multiscale boundaries mediated creep anisotropy in additively manufactured Ni-based Hastelloy C276 superalloy. Addit. Manuf. 2024, 83, 104069. [Google Scholar] [CrossRef]

- Ali, M.A.; López-Galilea, I.; Gao, S.; Ruttert, B.; Amin, W.; Shchyglo, O.; Hartmaier, A.; Theisen, W.; Steinbach, I. Effect of γ′ precipitate size on hardness and creep properties of Ni-base single crystal superalloys: Experiment and simulation. Materialia 2020, 12, 100692. [Google Scholar] [CrossRef]

- Harte, A.; Atkinson, M.; Preuss, M.; Da Fonseca, J.Q. A statistical study of the relationship between plastic strain and lattice misorientation on the surface of a deformed Ni-based superalloy. Acta Mater. 2020, 195, 555–570. [Google Scholar] [CrossRef]

- Rui, S.S.; Shang, Y.B.; Fan, Y.N.; Han, Q.N.; Niu, L.S.; Shi, H.J.; Hashimoto, K.; Komai, N. EBSD analysis of creep deformation induced grain lattice distortion: A new method for creep damage evaluation of austenitic stainless steels. Mater. Sci. Eng. A 2018, 733, 329–337. [Google Scholar] [CrossRef]

- Long, H.B.; Liu, Y.N.; Kong, D.L.; Wei, H.; Chen, Y.H.; Mao, S.C. Shearing mechanisms of stacking fault and anti-phase-boundary forming dislocation pairs in the γ′ phase in Ni-based single crystal superalloy. J. Alloys Compd. 2017, 724, 287–295. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Titus, M.S.; Suzuki, A.; Pollock, T.M. Creep deformation-induced antiphase boundaries in L12-containing single-crystal cobalt-base superalloys. Acta Mater. 2014, 77, 352–359. [Google Scholar] [CrossRef]

- Rai, R.K.; Sahu, J.K. Strength-ductility paradox in a directionally solidified nickel base superalloy. Mater. Lett. 2018, 220, 90–93. [Google Scholar] [CrossRef]

- Qu, P.F.; Yang, W.C.; Qin, J.R.; Cao, K.L.; Liu, C.; Zhang, J.; Liu, L. Reveal the stacking fault shearing mechanism by its annihilation process in Ni-based single crystal superalloys. Mater. Charact. 2021, 180, 111419. [Google Scholar] [CrossRef]

- Shi, S.J.; Li, Y.S.; Yan, Z.W.; Yang, S.G.; Ju, Y.F. Crystal plasticity phase-field simulation of slip system anisotropy during creep of Co-Al-V monocrystal alloy under multidirectional strain. Int. J. Mech. Sci. 2022, 227, 107436. [Google Scholar] [CrossRef]

- Heep, L.; Bürger, D.; Bonnekoh, C.; Wollgramm, P.; Dlouhy, A.; Eggeler, G. The effect of deviations from precise [001] tensile direction on creep of Ni-base single crystal superalloys. Scr. Mater. 2022, 207, 114274. [Google Scholar] [CrossRef]

- Wu, X.; Wollgramm, P.; Somsen, C.; Dlouhy, A.; Kostka, A.; Eggeler, G. Double minimum creep of single crystal Ni-base superalloys. Acta Mater. 2016, 112, 242–260. [Google Scholar] [CrossRef]

- Bürger, D.; Dlouhý, A.; Yoshimi, K.; Eggeler, G. How nanoscale dislocation reactions govern low-temperature and high-stress creep of Ni-base single crystal superalloys. Crystals 2020, 10, 134. [Google Scholar] [CrossRef]

- Koehler, J.S. The nature of work-hardening. Phys. Rev. 1952, 86, 52. [Google Scholar] [CrossRef]

- Déprés, C.; Robertson, C.F.; Fivel, M.C. Crack initiation in fatigue: Experiments and three-dimensional dislocation simulations. Mater. Sci. Eng. A 2004, 387, 288–291. [Google Scholar] [CrossRef]

- Messerschmidt, U.; Bartsch, M. Generation of dislocations during plastic deformation. Mater. Chem. Phys. 2003, 81, 518–523. [Google Scholar] [CrossRef]

- Déprés, C.; Robertson, C.F.; Fivel, M.C. Low-strain fatigue in AISI 316L steel surface grains: A three-dimensional discrete dislocation dynamics modelling of the early cycles I. Dislocation microstructures and mechanical behaviour. Philos. Mag. 2004, 84, 2257–2275. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Beyerlein, I.J.; LeSar, R. Slip band formation and mobile dislocation density generation in high rate deformation of single fcc crystals. Philos. Mag. 2008, 88, 1321–1343. [Google Scholar] [CrossRef]

- Stoltz, R.E.; Pineau, A.G. Dislocation-precipitate interaction and cyclic stress-strain behavior of a γ′ strengthened superalloy. Mater. Sci. Eng. 1978, 34, 275–284. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T.; Brückner, U.; Portella, P.D. Kinetics of the topological inversion of the γ/γ′-microstructure during creep of a nickel-based superalloy. Acta Mater. 2001, 49, 4017–4023. [Google Scholar] [CrossRef]

- Harikrishnan, R.; Le Graverend, J.B. A creep-damage phase-field model: Predicting topological inversion in Ni-based single crystal superalloys. Mater. Des. 2018, 160, 405–416. [Google Scholar] [CrossRef]

- Nabarro, F.; Cress, C.M.; Kotschy, P. The thermodynamic driving force for rafting in superalloys. Acta Mater. 1996, 44, 3189–3198. [Google Scholar] [CrossRef]

- Li, S.C.; Liang, H.Y.; Li, C.; Liu, Y.C. Lattice mismatch in Ni3Al-based alloy for efficient oxygen evolution. J. Mater. Sci. Technol. 2022, 106, 19–27. [Google Scholar] [CrossRef]

- Gao, Q.Z.; Jiang, Y.J.; Liu, Z.Y.; Zhang, H.L.; Jiang, C.C.; Zhang, X.; Li, H.J. Effects of alloying elements on microstructure and mechanical properties of Co–Ni–Al–Ti superalloy. Mater. Sci. Eng. A 2020, 779, 139139. [Google Scholar] [CrossRef]

| C | Cr | Co | W | Al | Ta | Mo | Hf | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.09 | 7.0 | 12.0 | 4.95 | 5.9 | 7.0 | 1.5 | 1.5 | 0.015 | ≤0.1 | Bal. |

| Specimens | 320 MPa | 360 MPa | 410 MPa | 500 MPa | |

|---|---|---|---|---|---|

| T | Creep life, h | 533 ± 6 | 275 ± 4 | 110 ± 8 | 4.2 ± 0.8 |

| steady-state creep rates, %/h | 0.0055 | 0.0224 | 0.0416 | 0.1104 | |

| L | Creep life, h | 1012 ± 59 | 459 ± 26 | 191 ± 4 | 43.6 ± 3 |

| steady-state creep rates, %/h | 0.0042 | 0.0055 | 0.0262 | 0.0988 |

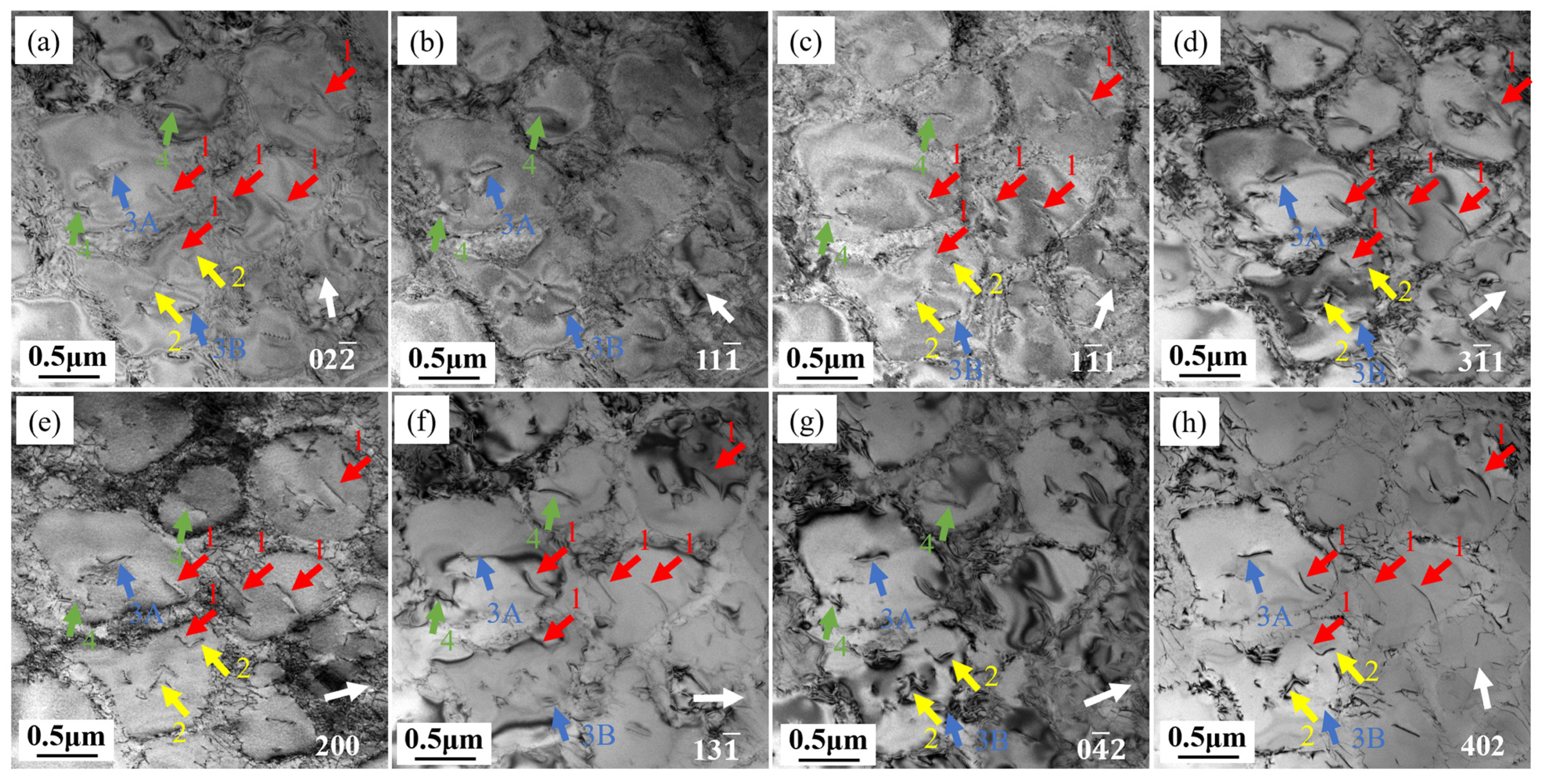

| Beam | g | 1 | 2 |

|---|---|---|---|

| [011] | √ | √ | |

| √ | × | ||

| × | √ | ||

| 12] | 1 | √ | × |

| Burgers vectors b | data |

| Beam | g | 1 | 2 | 3A | 3B | 4 |

|---|---|---|---|---|---|---|

| [011] | × | × | √ | √ | √ | |

| √ | √ | √ | √ | √ | ||

| 1 | √ | √ | × | √ | √ | |

| √ | √ | √ | √ | × | ||

| 200 | √ | √ | √ | × | √ | |

| 12] | √ | × | √ | √ | √ | |

| 02 | × | √ | √ | √ | √ | |

| 402 | √ | √ | √ | √ | × | |

| Burgers vectors b |

| Phase | Cr | Co | W | Al | Ta | Mo |

|---|---|---|---|---|---|---|

| γ | 17.39 ± 0.11 | 19.91 ± 0.13 | 2.07 ± 0.20 | 5.74 ± 0.06 | 0.81 ± 0.20 | 1.70 ± 0.14 |

| 3.37 ± 0.06 | 10.76 ± 0.11 | 2.02 ± 0.23 | 14.44 ± 0.09 | 3.54 ± 0.26 | 0.57 ± 0.13 | |

| 0.19 | 0.54 | 0.98 | 2.50 | 4.35 | 0.34 |

| Elements | Cr | Co | W | Al | Ta | Mo |

|---|---|---|---|---|---|---|

| Mobility | 1.80 × 10−5 | 4.37 × 10−6 | 1.05 × 10−4 | 4.00 × 10−4 | 3.13 × 10−4 | 5.48 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, A.; Xiong, J.; Wei, B.; Zhang, G.; Feng, G.; Guo, J.; Liu, R. Creep Mechanism and Microstructure Evolution of a Directionally Solidified Ni-Based Superalloy with Different Orientations at 850 °C. Materials 2025, 18, 1540. https://doi.org/10.3390/ma18071540

Long A, Xiong J, Wei B, Zhang G, Feng G, Guo J, Liu R. Creep Mechanism and Microstructure Evolution of a Directionally Solidified Ni-Based Superalloy with Different Orientations at 850 °C. Materials. 2025; 18(7):1540. https://doi.org/10.3390/ma18071540

Chicago/Turabian StyleLong, Anping, Jiangying Xiong, Bing Wei, Gaoxiang Zhang, Ganjiang Feng, Jianzheng Guo, and Rutie Liu. 2025. "Creep Mechanism and Microstructure Evolution of a Directionally Solidified Ni-Based Superalloy with Different Orientations at 850 °C" Materials 18, no. 7: 1540. https://doi.org/10.3390/ma18071540

APA StyleLong, A., Xiong, J., Wei, B., Zhang, G., Feng, G., Guo, J., & Liu, R. (2025). Creep Mechanism and Microstructure Evolution of a Directionally Solidified Ni-Based Superalloy with Different Orientations at 850 °C. Materials, 18(7), 1540. https://doi.org/10.3390/ma18071540