Comparative Analysis of Energy Viability of Crop Residue from Different Corn Varieties

Abstract

:1. Introduction

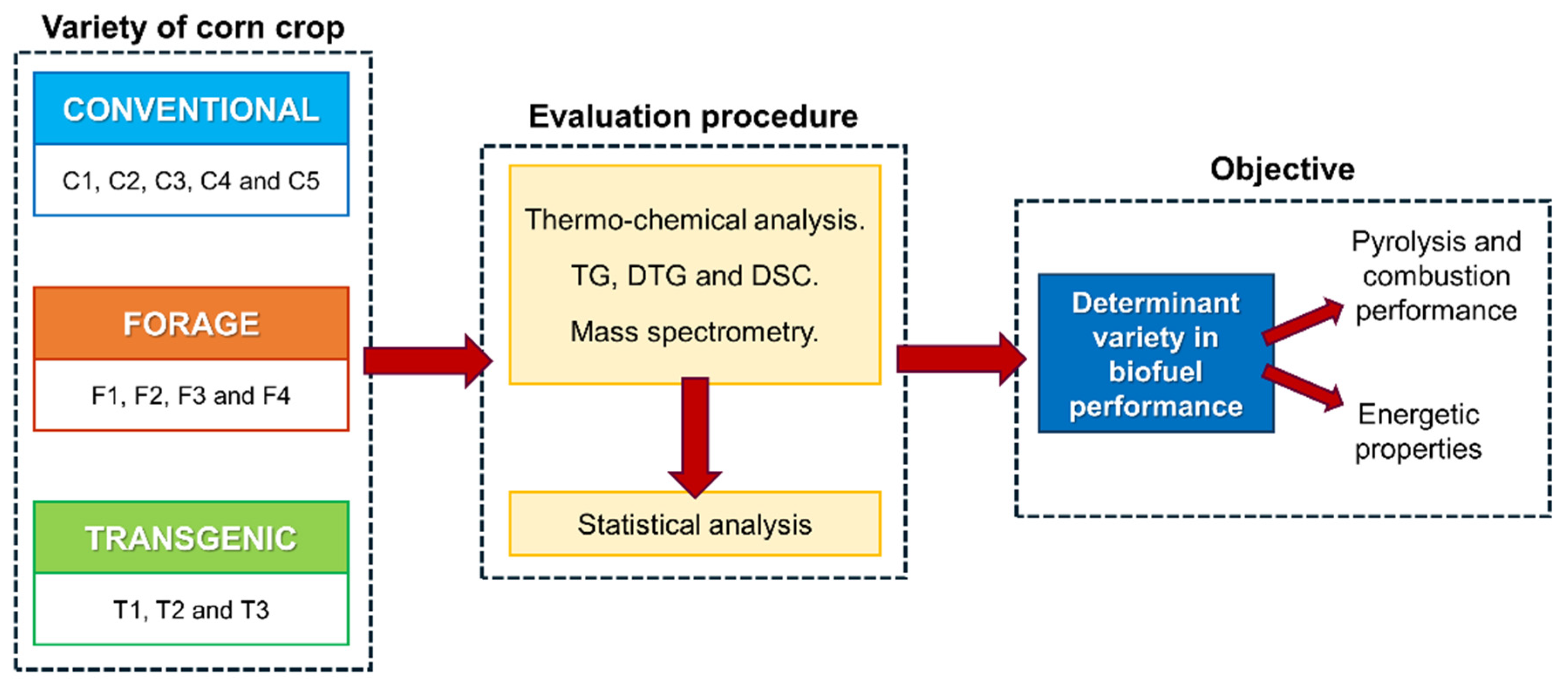

2. Materials and Methods

2.1. Sample Collection and Preparation

2.2. Thermo-Chemical Analysis

2.3. Thermogravimetric and Differential Scanning Calorimetry Analyses

2.4. Mass Spectrometry

2.5. Methodology for Statistical Analysis

- Stage 1: Normality test

- Stage 2: Levene’s F-test

- Stage 3: Hypothesis setting

- Stage 4. ANOVA and Kruskal-Wallis test

2.6. Methodology for Comparative Analysis of Differential Factors Among Corn Varieties

3. Results and Discussion

3.1. Ultimate and Proximate Analyses and Higher Heating Value

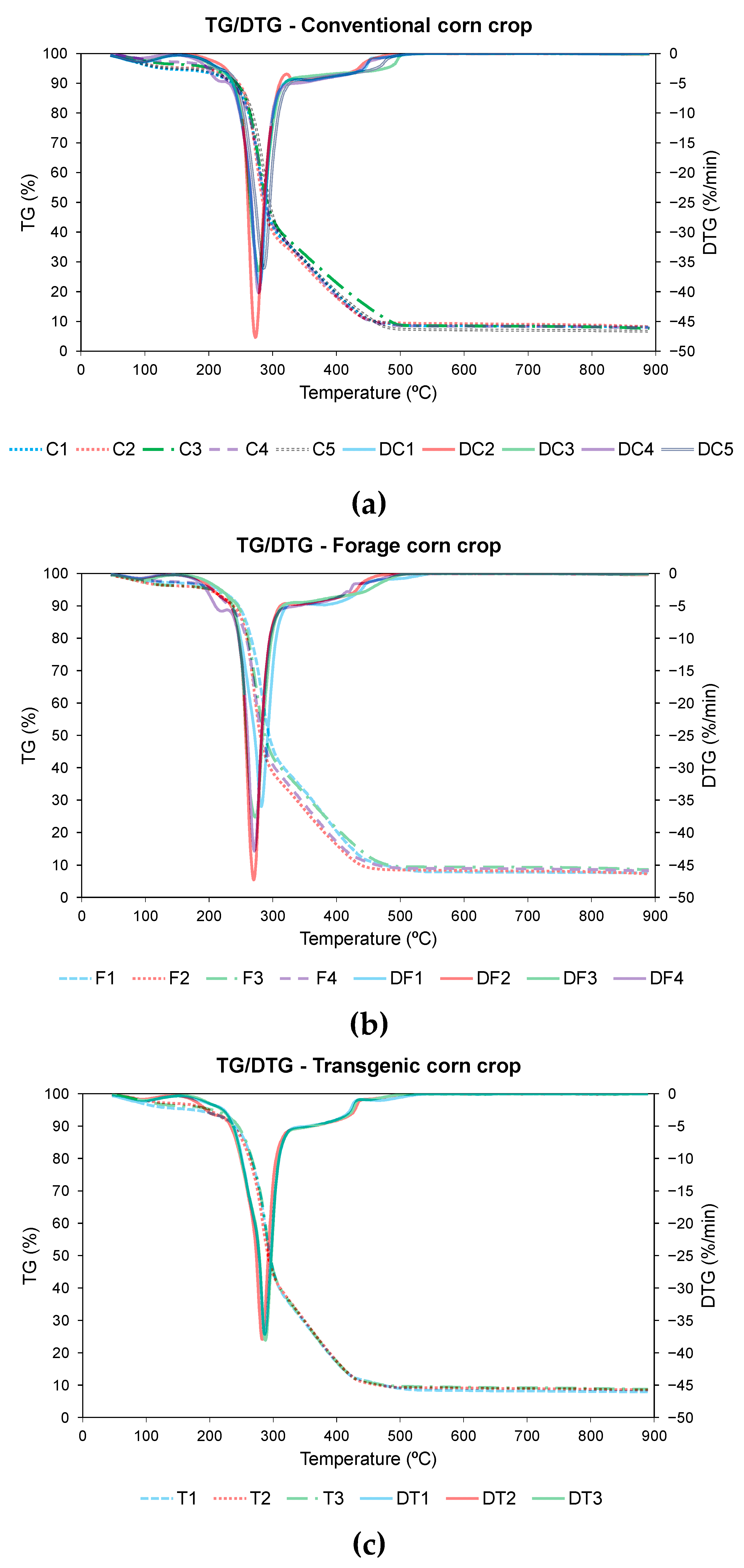

3.2. Thermogravimetric Analysis

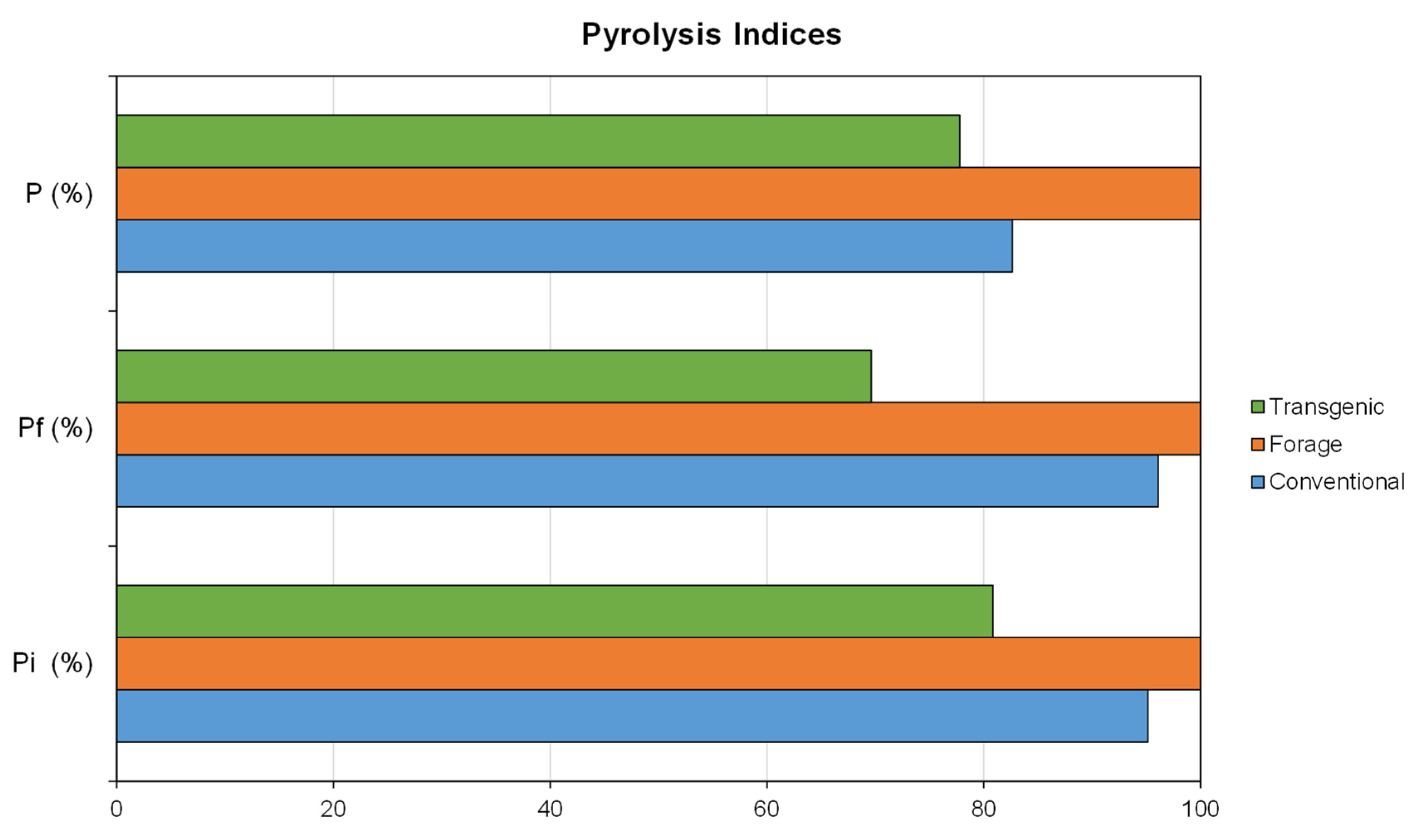

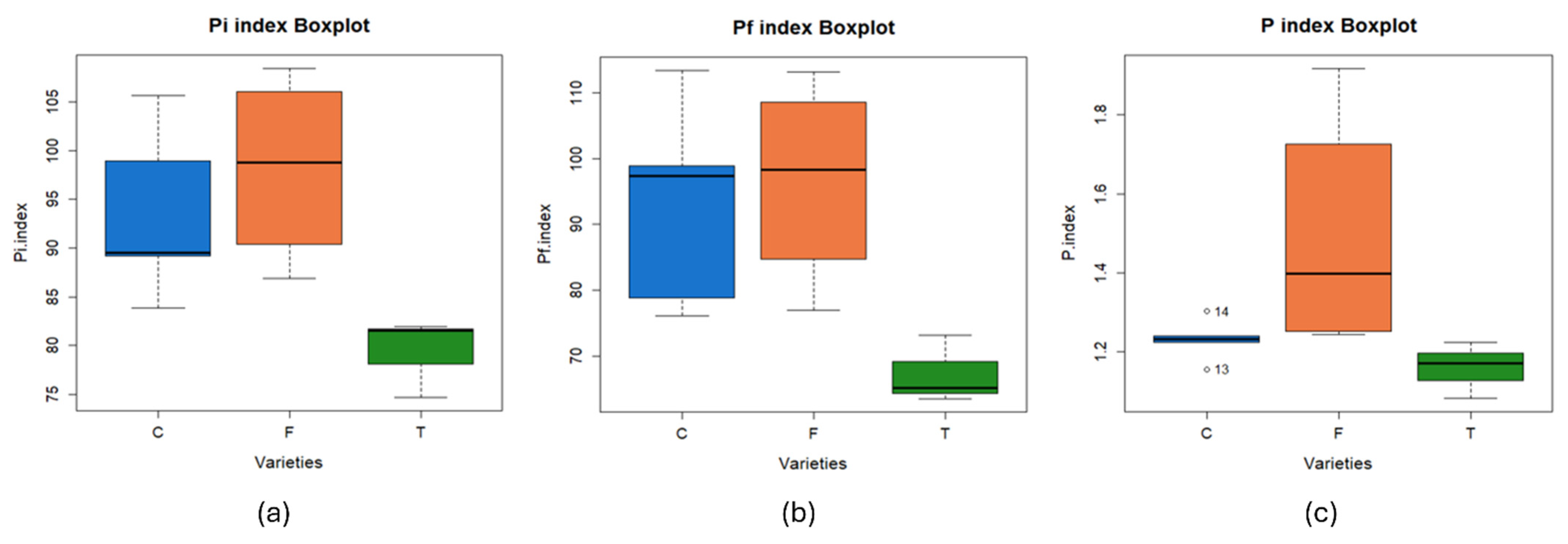

3.2.1. Pyrolysis

3.2.2. Combustion

3.3. Differential Scanning Calorimetry Analysis

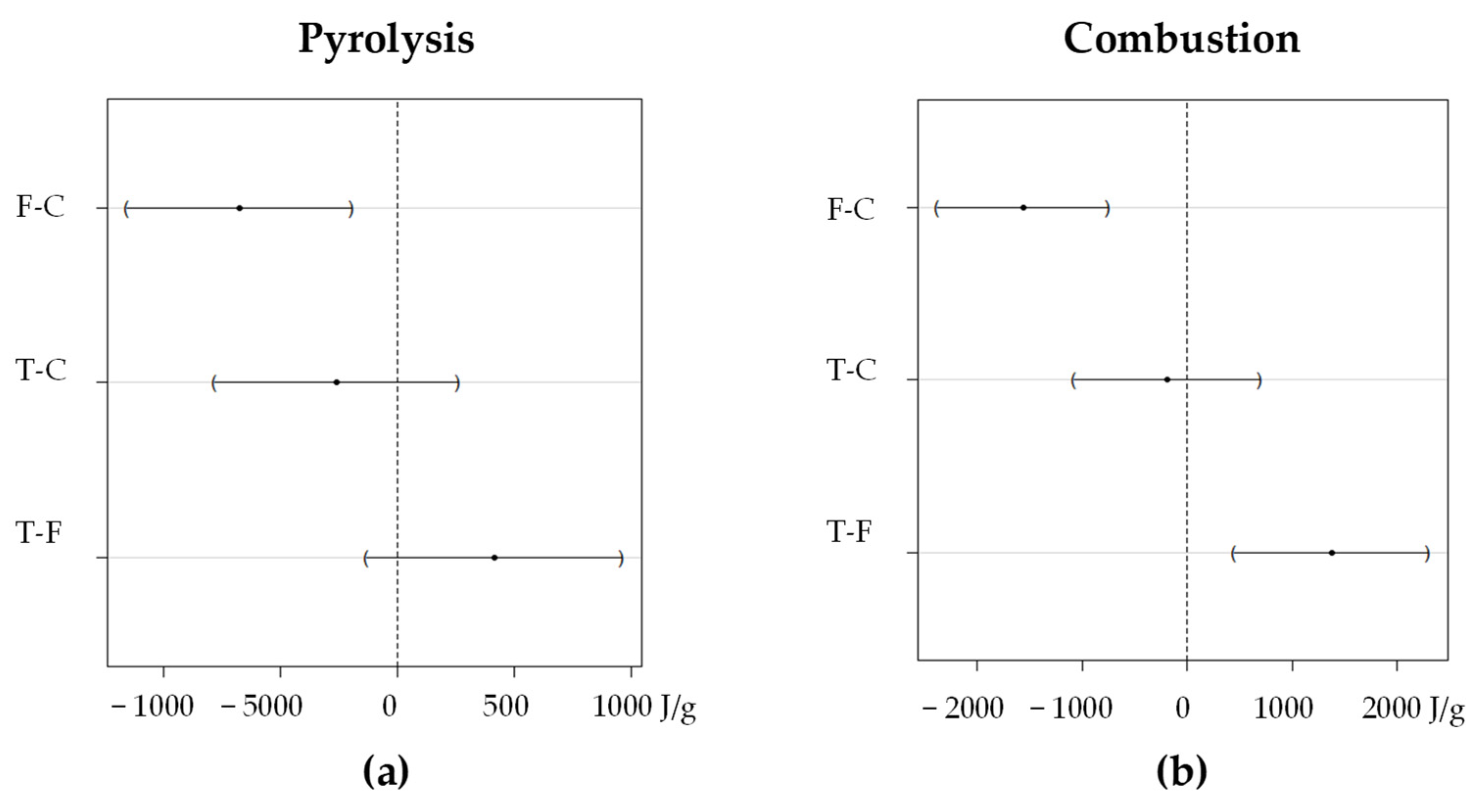

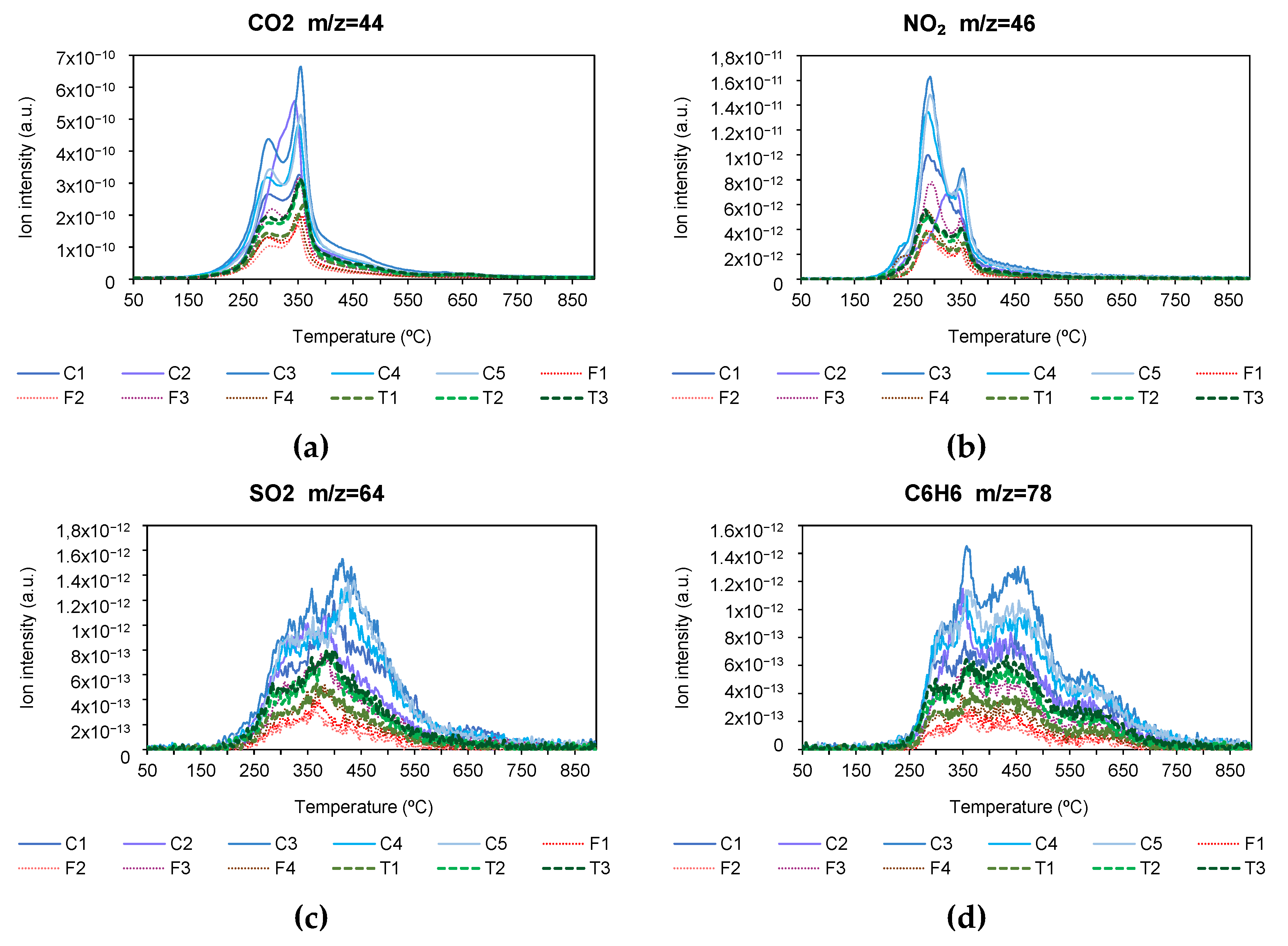

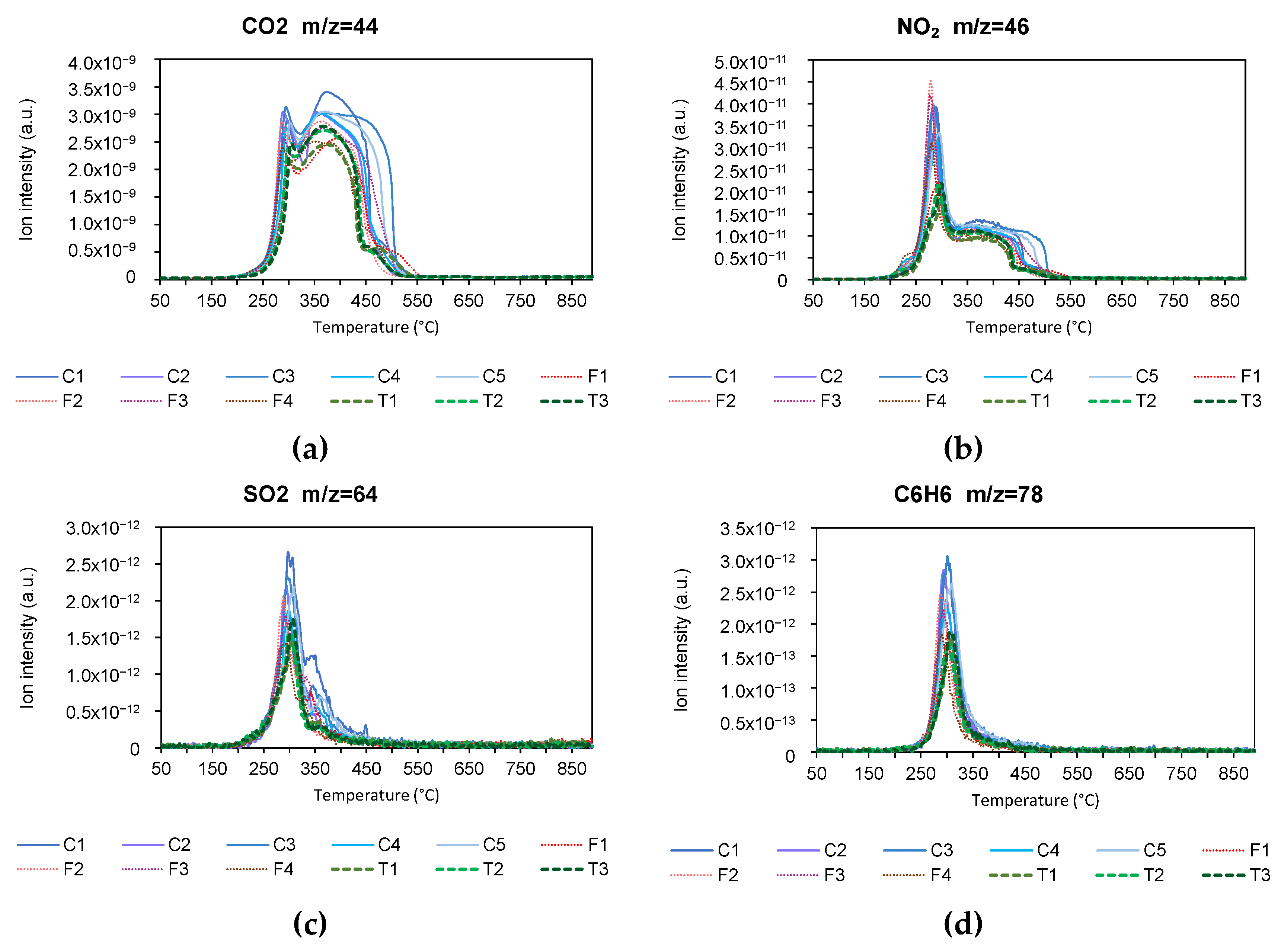

3.4. Mass Spectrometry Analysis

3.5. Comparative Analysis of Differential Factors Among Corn Varieties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naddeo, V.; Taherzadeh, M.J. Biomass valorization and bioenergy in the blue circular economy. Biomass Bioenergy 2021, 149, 106069. [Google Scholar] [CrossRef]

- Olugbenga, O.S.; Adeleye, P.G.; Oladipupo, S.B.; Adeleye, A.T.; John, K.I. Biomass-derived biochar in wastewater treatment—A circular economy approach. Waste Manag. Bull. 2024, 1, 1–14. [Google Scholar] [CrossRef]

- Wani, A.K.; Rahayu, F.; Yustina, I.; Fatah, G.S.A.; Kariada, I.K.; Antarlina, S.S.; Jufri, A.; Pamungkas, D. Contribution of yeast and its biomass for the preparation of industrially essential materials: A boon to circular economy. Bioresour. Technol. Rep. 2023, 23, 101508. [Google Scholar] [CrossRef]

- Osman, A.I.; Abdelkader, A.; Farrell, C.; Rooney, D.; Morgan, K. Reusing, recycling and up-cycling of biomass: A review of practical and kinetic modelling approaches. Fuel Process. Technol. 2019, 192, 179–202. [Google Scholar] [CrossRef]

- Viotti, P.; Marzeddu, S.; Antonucci, A.; Décima, M.A.; Lovascio, P.; Tatti, F.; Boni, M.R. Biochar as Alternative Material for Heavy Metal Adsorption from Groundwaters: Lab-Scale (Column) Experiment Review. Materials 2024, 17, 809. [Google Scholar] [CrossRef]

- Mujtaba, M.; Fraceto, L.F.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; Pereira, A.D.E.S.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Chan, Y.H.; Lock, S.S.M.; Chin, B.L.F.; Wong, M.K.; Loy, A.C.M.; Foong, S.Y.; Yiin, C.L.; Lam, S.S. Progress in thermochemical co-processing of biomass and sludge for sustainable energy, value-added products and circular economy. Bioresour. Technol. 2023, 380, 129061. [Google Scholar] [CrossRef]

- Paniagua, S.; Escudero, L.; Coimbra, R.N.; Escapa, C.; Otero, M.; Calvo, L.F. Effect of Applying Organic Amendments on the Pyrolytic Behavior of a Poplar Energy Crop. Waste Biomass Valorization 2018, 9, 1435–1449. [Google Scholar] [CrossRef]

- Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652, DOUE 2413 (2023). Available online: https://eur-lex.europa.eu/eli/dir/2023/2413/oj/eng (accessed on 30 March 2025).

- Nordin, I.; Elofsson, K.; Jansson, T. Cost-effective reductions in greenhouse gas emissions: Reducing fuel consumption or replacing fossil fuels with biofuels. Energy Policy 2024, 190, 114138. [Google Scholar] [CrossRef]

- Kamran, M.; Sajid, J.; Sajid, M.N.; Ahmad, M.M.; Ismail, M.A.; Sajid, M.B. Energy efficiency and greenhouse gas emission reduction potential of solar PV and biomass-based systems for a food processing plant. Case Stud. Therm. Eng. 2024, 60, 104674. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, F.; Gao, C.; Mangi, E.; Ali, C. The potential for bioenergy generated on marginal land to offset agricultural greenhouse gas emissions in China. Renew. Sustain. Energy Rev. 2024, 189, 113924. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAOSTAT. Available online: http://fao.org/faostat/en/#data (accessed on 1 September 2020).

- Aghaei, S.; Alavijeh, M.K.; Shafiei, M.; Karimi, K. A comprehensive review on bioethanol production from corn stover: Worldwide potential, environmental importance, and perspectives. Biomass Bioenergy 2022, 161, 106447. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Turhollow, A.; Cushman, J.; Cundiff, J. Engineering aspects of collecting corn stover for bioenergy. Biomass Bioenergy 2002, 23, 347–355. [Google Scholar] [CrossRef]

- Azuara, M.; Baguer, B.; Villacampa, J.I.; Hedin, N.; Manyà, J.J. Influence of pressure and temperature on key physicochemical properties of corn stover-derived biochar. Fuel 2016, 186, 525–533. [Google Scholar] [CrossRef]

- Zheng, J.; Choo, K.; Bradt, C.; Lehoux, R.; Rehmann, L. Enzymatic hydrolysis of steam exploded corncob residues after pretreatment in a twin-screw extruder. Biotechnol. Rep. 2014, 3, 99–107. [Google Scholar] [CrossRef]

- Miranda, M.T.; García-Mateos, R.; Arranz, J.I.; Sepúlveda, F.J.; Romero, P.; Botet-Jiménez, A. Selective use of corn crop residues: Energy viability. Appl. Sci. 2021, 11, 3284. [Google Scholar] [CrossRef]

- Gao, C.Q.; Ma, Q.G.; Ji, C.; Luo, X.G.; Tang, H.F.; Wei, Y.M. Evaluation of the compositional and nutritional values of phytase transgenic corn to conventional corn in roosters. Poult. Sci. 2012, 91, 1142–1148. [Google Scholar] [CrossRef]

- SDib, S.R.; Silva, T.V.; Neto, J.A.G.; Guimarães, L.J.M.; Ferreira, E.J.; Ferreira, E.C. Raman spectroscopy for discriminating transgenic corns. Vib. Spectrosc. 2021, 112, 103183. [Google Scholar] [CrossRef]

- Zinla, D.; Gbaha, P.; Koffi, P.M.E.; Koua, B.K. Characterization of rice, coffee and cocoa crops residues as fuel of thermal power plant in Côte d’Ivoire. Fuel 2021, 283, 119250. [Google Scholar] [CrossRef]

- Yoon, S.J.; Son, Y.-I.; Kim, Y.-K.; Lee, J.-G. Gasification and power generation characteristics of rice husk and rice husk pellet using a downdraft fixed-bed gasifier. Renew Energy 2012, 42, 163–167. [Google Scholar] [CrossRef]

- Wang, M.J.; Huang, Y.F.; Chiueh, P.T.; Kuan, W.H.; Lo, S.L. Microwave-induced torrefaction of rice husk and sugarcane residues. Energy 2012, 37, 177–184. [Google Scholar] [CrossRef]

- Lu, J.J.; Chen, W.H. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl. Energy 2015, 160, 49–57. [Google Scholar] [CrossRef]

- Ferreira, R.A.d.R.; Meireles, C.d.S.; Assunção, R.M.N.; Barrozo, M.A.S.; Soares, R.R. Optimization of the oxidative fast pyrolysis process of sugarcane straw by TGA and DSC analyses. Biomass Bioenergy 2020, 134, 105456. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Ivanovski, M.; Petrovic, A.; Ban, I.; Goricanec, D.; Urbancl, D. Determination of the kinetics and thermodynamic parameters of lignocellulosic biomass subjected to the torrefaction process. Materials 2021, 14, 7877. [Google Scholar] [CrossRef]

- Amado-Fierro, Á.; Centeno, T.A.; Diez, M.A. Exploring Hydrochars from Lignocellulosic Wastes as Secondary Carbon Fuels for Sustainable Steel Production. Materials 2023, 16, 6563. [Google Scholar] [CrossRef]

- Mishra, A.; Mishra, T.K.; Nanda, S.; Jena, P.K.; Dwibedi, S.K.; Jena, B.; Samantaray, S.; Samantaray, D.; Mohanty, M.K.; Yama, M.; et al. Bioenergy potential of different varieties of paddy straw biomass. Bioresour. Technol. Rep. 2022, 20, 101229. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Niksa, D.; Krzyżaniak, M. Elemental composition of willow short rotation crops biomass depending on variety and harvest cycle. Biomass Bioenergy 2017, 105, 342–350. [Google Scholar] [CrossRef]

- Colauzzi, M.; Serra, P.; Amaducci, S. Variety earliness effect on field drying of biomass sorghum. Biomass Bioenergy 2018, 115, 160–173. [Google Scholar] [CrossRef]

- Oslaj, M.; Mursec, B.; Vindis, P. Biogas production from maize hybrids. Biomass Bioenergy 2010, 34, 1538–1545. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Nyashina, G.S.; Anand, R.; Strizhak, P.A. Composition of gas produced from the direct combustion and pyrolysis of biomass. Process Saf. Environ. Prot. 2021, 156, 43–56. [Google Scholar] [CrossRef]

- ISO 18134-2:2017; Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Part 2: Total Moisture. Simplified Method. ISO: Geneva, Switzerland, 2017.

- ISO 16948:2015; Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- ISO 16994:2016; Solid Biofuels. Determination of Content of Sulfur and Chlorine. ISO: Geneva, Switzerland, 2017.

- ISO 18123:2016; Solid Biofuels. Determination of the Content of Volatile Matter. ISO: Geneva, Switzerland, 2015.

- ISO 18122:2015; Solid Biofuels. Determination of Ash Content. ISO: Geneva, Switzerland, 2015.

- Racero-Galaraga, D.; Rhenals-Julio, J.D.; Sofan-German, S.; Mendoza, J.M.; Bula-Silvera, A. Proximate analysis in biomass: Standards, applications and key characteristics. Results Chem. 2024, 12, 101886. [Google Scholar] [CrossRef]

- Nanda, S.; Mishra, A.; Priyadarsini, A.; Barpanda, T.; Baral, A.K.; Jena, S.; Jena, P.K.; Mallick, B.; Dash, M.; Swain, N.; et al. A comparative thermo-chemical characterization of oilseed, millet and pulse stem biomass for bioethanol production. Heliyon 2024, 10, e36946. [Google Scholar] [CrossRef]

- ISO 18125:2018; Solid Biofuels—Determination of Calorific Value. ISO: Geneva, Switzerland, 2018.

- Chen, C.; Qu, B.; Wang, W.; Wang, W.; Ji, G.; Li, A. Rice husk and rice straw torrefaction: Properties and pyrolysis kinetics of raw and torrefied biomass. Environ. Technol. Innov. 2021, 24, 101872. [Google Scholar] [CrossRef]

- Lopes, F.C.R.; Tannous, K. Coconut fiber pyrolysis: Specific heat capacity and enthalpy of reaction through thermogravimetry and differential scanning calorimetry. Thermochim. Acta 2022, 707, 504527. [Google Scholar] [CrossRef]

- Barneto, A.G.; Carmona, J.A.; Alfonso, J.E.M.; Serrano, R.S. Simulation of the thermogravimetry analysis of three non-wood pulps. Bioresour. Technol. 2010, 101, 3220–3229. [Google Scholar] [CrossRef]

- Mishra, A.; Nanda, S.; Parida, M.R.; Jena, P.K.; Dwibedi, S.K.; Samantaray, S.M.; Samantaray, D.; Mohanty, M.K.; Dash, M. A comparative study on pyrolysis kinetics and thermodynamic parameters of little millet and sunflower stems biomass using thermogravimetric analysis. Bioresour. Technol. 2023, 367, 128231. [Google Scholar] [CrossRef]

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Sepúlveda, F.J. Thermal study and emission characteristics of rice husk using tg-ms. Materials 2021, 14, 6203. [Google Scholar] [CrossRef]

- Miranda, M.; Sepúlveda, F.; Arranz, J.; Montero, I.; Rojas, C. Physical-energy characterization of microalgae Scenedesmus and experimental pellets. Fuel 2018, 226, 121–126. [Google Scholar] [CrossRef]

- Senneca, O. Kinetics of pyrolysis, combustion and gasification of three biomass fuels. Fuel Process. Technol. 2006, 88, 87–97. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Y.; Xue, Y.; Chen, S.; Liu, J.; Mei, M.; Li, J.; Ren, L.; Wang, T. Study on the effect of biomass on sulfur release behavior from dyeing sludge incineration: Focusing on in-situ sulfur fixation mechanism based on model compounds. Sci. Total. Environ. 2023, 875, 162544. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Liao, L.; Liu, R.; Li, C.; Zhang, Y. A rational and feasible approach to the co-management of condensates from biomass torrefaction and carbon-rich fly ash from fluidized-bed coal gasification. Waste Manag. 2022, 154, 312–319. [Google Scholar] [CrossRef] [PubMed]

- Manić, N.; Janković, B.; Stojiljković, D.; Radojević, M.; Somoza, B.C.; Medić, L. Self-ignition potential assessment for different biomass feedstocks based on the dynamic thermal analysis. Clean. Eng. Technol. 2021, 2, 100040. [Google Scholar] [CrossRef]

- Paniagua Bermejo, S.; Prado-Guerra, A.; Pérez, A.I.G.; Prieto, L.F.C. Study of quinoa plant residues as a way to produce energy through thermogravimetric analysis and indexes estimation. Renew. Energy 2020, 146, 2224–2233. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Jiang, X.; Li, F.; Lei, Y.; Lin, Q. The thermal behavior and kinetics of co-combustion between sewage sludge and wheat straw. Fuel Process. Technol. 2019, 189, 1–14. [Google Scholar] [CrossRef]

- Moon, C.; Sung, Y.; Ahn, S.; Kim, T.; Choi, G.; Kim, D. Effect of blending ratio on combustion performance in blends of biomass and coals of different ranks. Exp. Therm. Fluid Sci. 2013, 47, 232–240. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef]

- Aboudaoud, S.; El Hallaoui, Z.; Abderafi, S. Specific heat measurements and thermal behaviour analysis of argan residues for pyrolysis applications. Renew. Energy 2025, 243, 122523. [Google Scholar] [CrossRef]

- Šumić, Z.; Vakula, A.; Tepić, A.; Čakarević, J.; Vitas, J.; Pavlić, B. Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chem. 2016, 203, 465–475. [Google Scholar] [CrossRef]

- Colpani, D.; Santos, V.O.; Araujo, R.O.; Lima, V.M.; Tenório, J.A.; Coleti, J.; Chaar, J.S.; de Souza, L.K. Bioenergy potential analysis of Brazil nut biomass residues through pyrolysis: Gas emission, kinetics, and thermodynamic parameters. Clean. Chem. Eng. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Sullivan, L.M.; Weinberg, J.; Keaney, J.F. Common statistical pitfalls in basic science research. J. Am. Heart Assoc. 2016, 5, e004142. [Google Scholar] [CrossRef] [PubMed]

- ISO 17225-6:2021; Solid Biofuels. Fuel Specifications and Classes. Part 6: Graded Non-Woody Pellets. ISO: Geneva, Switzerland, 2022.

- Wang, S.; Zou, C.; Yang, H.; Lou, C.; Cheng, S.; Peng, C.; Wang, C.; Zou, H. Effects of cellulose, hemicellulose, and lignin on the combustion behaviours of biomass under various oxygen concentrations. Bioresour. Technol. 2021, 320, 124375. [Google Scholar] [CrossRef]

- Gani, A.; Reza, M.; Desvita, H. Proximate and ultimate analysis of corncob biomass waste as raw material for biocoke fuel production. Case Stud. Chem. Environ. Eng. 2023, 8, 100525. [Google Scholar] [CrossRef]

- Siyal, A.A.; Yang, L.; Ali, B.; Hassan, M.; Zhou, C.; Li, X.; Ahmed, I.; Soomro, A.; Liu, G.; Dai, J. Characterization and quality analysis of biomass pellets prepared from furfural residue, sawdust, corn stalk and sewage sludge. Fuel Process. Technol. 2023, 241, 107620. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, Y.; Li, X.; Liu, H.; Yan, W.; Sui, R.; Lu, Q. Temperature and emissivity measurements from combustion of pine wood, rice husk and fir wood using flame emission spectrum. Fuel Process. Technol. 2020, 204, 106423. [Google Scholar] [CrossRef]

- Rabea, K.; Michailos, S.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. An improved kinetic modelling of woody biomass gasification in a downdraft reactor based on the pyrolysis gas evolution. Energy Convers. Manag. 2022, 258, 115495. [Google Scholar] [CrossRef]

- Sun, Z.; Mao, Y.; Liu, S.; Zhang, H.; Xu, Y.; Geng, R.; Lu, J.; Huang, S.; Yuan, Q.; Zhang, S.; et al. Effect of pretreatment with Phanerochaete chrysosporium on physicochemical properties and pyrolysis behaviors of corn stover. Bioresour. Technol. 2022, 361, 127687. [Google Scholar] [CrossRef]

- Wang, L.; Shahbazi, A.; Hanna, M.A. Characterization of corn stover, distiller grains and cattle manure for thermochemical conversion. Biomass Bioenergy 2011, 35, 171–178. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F.; Yang, Q.; Liang, R. Thermogravimetric studies of the behavior of wheat straw with added coal during combustion. Biomass Bioenergy 2009, 33, 50–56. [Google Scholar] [CrossRef]

- Dias, A.P.S.; Rijo, B.; Ramos, M.; Casquilho, M.; Rodrigues, A.; Viana, H.; Rosa, F. Pyrolysis of burnt maritime pine biomass from forest fires. Biomass Bioenergy 2022, 163, 106535. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, B.; Rony, A.H.; Toan, S.; Chen, S.; Gasem, K.A.M.; Adidharma, H.; Fan, M.; Xiang, W. Thermogravimetric and kinetics investigation of pine wood pyrolysis catalyzed with alkali-treated CaO/ZSM-5. Energy Convers. Manag. 2017, 146, 182–194. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Chai, M.; Li, C.; Nishu; Yellezuome, D.; Liu, R. Pyrolysis kinetics and thermodynamic parameters of bamboo residues and its three main components using thermogravimetric analysis. Biomass Bioenergy 2023, 170, 106705. [Google Scholar] [CrossRef]

- Aboyade, A.O.; Hugo, T.J.; Carrier, M.; Meyer, E.L.; Stahl, R.; Knoetze, J.H.; Görgens, J.F. Non-isothermal kinetic analysis of the devolatilization of corn cobs and sugar cane bagasse in an inert atmosphere. Thermochim. Acta 2011, 517, 81–89. [Google Scholar] [CrossRef]

- Rodríguez, J.L.; Álvarez, X.; Valero, E.; Ortiz, L.; de la Torre-Rodríguez, N.; Acuña-Alonso, C. Influence of ashes in the use of forest biomass as source of energy. Fuel 2021, 283, 119256. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, W.; Meng, B.; Liu, C.; Zhu, Q.; Zhao, G. Kinetic study of corn straw pyrolysis: Comparison of two different three-pseudocomponent models. Bioresour. Technol. 2008, 99, 7616–7622. [Google Scholar] [CrossRef]

- Bongomin, O.; Nzila, C.; Mwasiagi, J.I.; Maube, O. Comprehensive thermal properties, kinetic, and thermodynamic analyses of biomass wastes pyrolysis via TGA and Coats-Redfern methodologies. Energy Convers. Manag. X 2024, 24, 100723. [Google Scholar] [CrossRef]

- Rueda-Ordóñez, Y.J.; Arias-Hernández, C.J.; Manrique-Pinto, J.F.; Gauthier-Maradei, P.; Bizzo, W.A. Assessment of the thermal decomposition kinetics of empty fruit bunch, kernel shell and their blend. Bioresour. Technol. 2019, 292, 121923. [Google Scholar] [CrossRef]

- Kumar, A.; Wang, L.; Dzenis, Y.A.; Jones, D.D.; Hanna, M.A. Thermogravimetric characterization of corn stover as gasification and pyrolysis feedstock. Biomass Bioenergy 2008, 32, 460–467. [Google Scholar] [CrossRef]

- Janković, B.; Manić, N.; Popović, M.; Cvetković, S.; Dželetović, Ž.; Stojiljković, D. Kinetic and thermodynamic compensation phenomena in C3 and C4 energy crops pyrolysis: Implications on reaction mechanisms and product distributions. Ind. Crop. Prod. 2023, 194, 116275. [Google Scholar] [CrossRef]

- Bi, H.; Wang, C.; Lin, Q.; Jiang, X.; Jiang, C.; Bao, L. Combustion behavior, kinetics, gas emission characteristics and artificial neural network modeling of coal gangue and biomass via TG-FTIR. Energy 2020, 213, 118790. [Google Scholar] [CrossRef]

- Paniagua, S.; García-Pérez, A.I.; Calvo, L.F. Biofuel consisting of wheat straw–poplar wood blends: Thermogravimetric studies and combustion characteristic indexes estimation. Biomass Convers. Biorefinery 2018, 9, 433–443. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, S.; Liu, L.; Li, X.; Chen, H.; Yang, H.; Wang, X. Combustion behaviours of tobacco stem in a thermogravimetric analyser and a pilot-scale fluidized bed reactor. Bioresour. Technol. 2012, 110, 595–602. [Google Scholar] [CrossRef]

- Paniagua, S.; Reyes, S.; Lima, F.; Pilipenko, N.; Calvo, L.F. Combustion of avocado crop residues: Effect of crop variety and nature of nutrients. Fuel 2021, 291, 119660. [Google Scholar] [CrossRef]

- Dorokhov, V.; Nyashina, G.; Romanov, D.; Strizhak, P. Combustion and mechanical properties of pellets from biomass and industrial waste. Renew. Energy 2024, 228, 120625. [Google Scholar] [CrossRef]

- López-González, D.; Fernandez-Lopez, M.; Valverde, J.L.; Sanchez-Silva, L. Thermogravimetric-mass spectrometric analysis on combustion of lignocellulosic biomass. Bioresour. Technol. 2013, 143, 562–574. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Yang, W.; Zhao, Q.; Dai, Y. Evaluation of combustion properties and pollutant emission characteristics of blends of sewage sludge and biomass. Sci. Total. Environ. 2020, 720, 137365. [Google Scholar] [CrossRef]

- Mureddu, M.; Dessì, F.; Orsini, A.; Ferrara, F.; Pettinau, A. Air- and oxygen-blown characterization of coal and biomass by thermogravimetric analysis. Fuel 2018, 212, 626–637. [Google Scholar] [CrossRef]

- Paredes, R.; Amez, I.; León, D.; Castells, B. Biomass minimum ignition temperature prediction through differential study of thermogravimetric analysis. J. Loss Prev. Process. Ind. 2024, 92, 105486. [Google Scholar] [CrossRef]

- Varol, M.; Atimtay, A.; Bay, B.; Olgun, H. Investigation of co-combustion characteristics of low quality lignite coals and biomass with thermogravimetric analysis. Thermochim. Acta 2010, 510, 195–201. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Yang, H.; Zhang, H.; Zhang, S.; Chen, H. Influence of interaction between biomass inorganic components and volatiles on corncob pyrolysis and char structure. Fuel Process. Technol. 2022, 235, 107360. [Google Scholar] [CrossRef]

- Mythili, R.; Venkatachalam, P.; Subramanian, P.; Uma, D. Characterization of bioresidues for biooil production through pyrolysis. Bioresour. Technol. 2013, 138, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Kijo-Kleczkowska, A.; Szumera, M.; Gnatowski, A.; Sadkowski, D. Comparative thermal analysis of coal fuels, biomass, fly ash and polyamide. Energy 2022, 258, 124840. [Google Scholar] [CrossRef]

- Mohalik, N.K.; Mandal, S.; Ray, S.K.; Khan, A.M.; Mishra, D.; Pandey, J.K. TGA/DSC study to characterise and classify coal seams conforming to susceptibility towards spontaneous combustion. Int. J. Min. Sci. Technol. 2022, 32, 75–88. [Google Scholar] [CrossRef]

- Kok, M.V.; Özgür, E. Thermal analysis and kinetics of biomass samples. Fuel Process. Technol. 2013, 106, 739–743. [Google Scholar] [CrossRef]

- Tang, S.; Tan, G.; Liang, J.; Li, O.; Xuan, W.; Li, Z. Key element course-tracked copyrolysis of sewage sludge and biomass for resource recovery and pollution control through kinetic and thermodynamic insights. Energy Convers. Manag. 2023, 280, 116830. [Google Scholar] [CrossRef]

- Maurya, R.; Ghosh, T.; Saravaia, H.; Paliwal, C.; Ghosh, A.; Mishra, S. Non-isothermal pyrolysis of de-oiled microalgal biomass: Kinetics and evolved gas analysis. Bioresour. Technol. 2016, 221, 251–261. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M. Thermogravimetric study of biomass, sewage sludge and coal combustion. Energy Convers. Manag. 2013, 75, 425–430. [Google Scholar] [CrossRef]

| Term | |

|---|---|

| DTGmax (%/min) | maximum pyrolysis rate |

| DTGmean (%/min) | mean pyrolysis rate |

| Tm (°C) | starting temperature |

| Tf (°C) | end temperature |

| tm (min) | corresponding time of the starting temperature |

| tp (min) | corresponding time of the maximum pyrolysis rate |

| tf (min) | corresponding time of the end temperature |

| Δt_(1/2) (min) | time range that corresponds to DTG/DTGmax = ½ |

| Term | |

|---|---|

| DTGmax (%/min) | maximum combustion rate |

| DTGmean (%/min) | mean combustion rate |

| Ti (°C) | ignition temperature |

| Tp (°C) | peak temperature |

| Tf (°C) | burnout temperature |

| ΔT (°C) | difference between Tp and Ti |

| ti (min) | ignition time |

| tp (min) | corresponding time of the maximum combustion rate |

| tf (min) | burnout time |

| Δt_(1/2) (min) | time range that corresponds to DTG/DTGmax = ½ |

| Variety | Moisture (% wb) | Ultimate Analysis (% db) | Proximate Analysis (% db) | HHV (MJ/kg db) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | S | O | Ash | Volatile Matter | Fixed Carbon | |||

| C1 | 8.03 | 44.70 ± 0.32 | 5.19 ± 0.10 | 0.27 ± 0.03 | 0.08 ± 0.02 | 49.76 | 6.12 ± 0.20 | 73.94 ± 0.24 | 19.94 | 17.38 ± 0.30 |

| C2 | 9.29 | 44.10 ± 0.04 | 5.29 ± 0.02 | 0.22 ± 0.03 | 0.1 ± 0.02 | 50.29 | 6.67 ± 0.66 | 74.36 ± 0.45 | 18.97 | 17.09 ± 0.35 |

| C3 | 8.67 | 43.90 ± 0.63 | 5.04 ± 0.16 | 0.65 ± 0.28 | 0.07 ± 0.01 | 50.34 | 7.14 ± 0.40 | 71.49 ± 0.19 | 21.37 | 17.65 ± 0.08 |

| C4 | 8.88 | 45.20 ± 0.57 | 5.07 ± 0.07 | 0.52 ± 0.50 | 0.1 ± 0.01 | 49.11 | 7.61 ± 0.61 | 71.01 ± 0.38 | 21.38 | 17.66 ± 0.06 |

| C5 | 9.13 | 44.70 ± 0.03 | 5.15 ± 0.09 | 0.47 ± 0.08 | 0.15 ± 0.08 | 49.53 | 7.51 ± 0.39 | 72.74 ± 0.44 | 19.75 | 17.37 ± 0.51 |

| F1 | 7.96 | 45.30 ± 0.33 | 5.49 ± 0.03 | 0.81 ± 0.10 | 0.15 ± 0.02 | 48.25 | 7.49 ± 0.32 | 72.16 ± 0.12 | 20.35 | 17.93 ± 0.10 |

| F2 | 7.95 | 44.30 ± 0.30 | 5.46 ± 0.17 | 0.56 ± 0.07 | 0.11 ± 0.01 | 49.57 | 8.40 ± 0.46 | 72.72 ± 0.44 | 18.88 | 17.56 ± 0.02 |

| F3 | 10.39 | 44.20 ± 0.26 | 5.37 ± 0.16 | 0.81 ± 0.02 | 0.19 ± 0.02 | 49.43 | 8.42 ± 0.27 | 71.71 ± 0.04 | 19.87 | 17.06 ± 0.57 |

| F4 | 8.14 | 44.70 ± 0.42 | 5.39 ± 0.13 | 0.34 ± 0.05 | 0.12 ± 0.01 | 49.45 | 5.95 ± 0.38 | 73.31 ± 0.35 | 20.74 | 17.60 ± 0.06 |

| T1 | 10.75 | 45.20 ± 0.15 | 5.42 ± 0.01 | 0.61 ± 0.05 | 0.05 ± 0.01 | 48.72 | 8.27 ± 0.62 | 72.14 ± 0.30 | 19.59 | 17.80 ± 0.15 |

| T2 | 10.16 | 45.00 ± 0.08 | 5.49 ± 0.03 | 0.49 ± 0.23 | 0.27 ± 0.04 | 48.75 | 5.55 ± 0.25 | 72.29 ± 0.22 | 22.16 | 17.56 ± 0.23 |

| T3 | 10.81 | 45.00 ± 0.20 | 5.52 ± 0.04 | 0.32 ± 0.21 | 0.08 ± 0.02 | 49.08 | 7.17 ± 0.12 | 74.85 ± 5.71 | 17.98 | 17.25 ± 0.26 |

| Variety | Ultimate Analysis (% db) | Proximate Analysis (% db) | HHV | ||

|---|---|---|---|---|---|

| C | H | Ash | Volatile Matter | (MJ/kg db) | |

| C1 | 0.72 | 1.93 | 3.29 | 0.33 | 1.71 |

| C2 | 0.09 | 0.38 | 9.82 | 0.61 | 2.05 |

| C3 | 1.44 | 3.17 | 5.61 | 0.26 | 0.45 |

| C4 | 1.26 | 1.38 | 8.08 | 0.53 | 0.31 |

| C5 | 0.07 | 1.75 | 5.14 | 0.61 | 2.92 |

| F1 | 0.73 | 0.55 | 4.21 | 0.17 | 0.54 |

| F2 | 0.68 | 3.11 | 5.47 | 0.60 | 0.11 |

| F3 | 0.59 | 2.98 | 3.22 | 0.05 | 3.35 |

| F4 | 0.94 | 2.41 | 6.37 | 0.48 | 0.32 |

| T1 | 0.33 | 0.00 | 7.49 | 0.41 | 0.85 |

| T2 | 0.18 | 0.55 | 4.42 | 0.30 | 1.31 |

| T3 | 0.44 | 0.72 | 1.70 | 7.62 | 1.52 |

| Parameter | Shapiro-Wilk | Levene’s | Test | p-Value | Conclusion |

|---|---|---|---|---|---|

| % Moisture | Non-normal | Equal | Kruskal-Wallis | 0.056 | Retain the null hypothesis |

| % C | Non-normal | Equal | Kruskal-Wallis | 0.291 | Retain the null hypothesis |

| % N | Normal | Equal | ANOVA | 0.309 | Retain the null hypothesis |

| % S | Normal | Unequal | ANOVA | 0.316 | Retain the null hypothesis |

| % Ash | Normal | Equal | ANOVA | 0.679 | Retain the null hypothesis |

| % Volatile matter | Normal | Equal | ANOVA | 0.821 | Retain the null hypothesis |

| % CF | Normal | Equal | ANOVA | 0.904 | Retain the null hypothesis |

| PCS (MJ/kg) | Normal | Equal | ANOVA | 0.824 | Retain the null hypothesis |

| Main Pyrolysis Parameters | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| Pyrolysis initial Tm (°C) | 239.0 ± 0.7 | 274.0 ± 0.2 | 247.9 ± 0.3 | 235.8 ± 0.1 | 248.2 ± 3.1 | 244.3 ± 0.2 | 245.6 ± 1.8 | 259.0 ± 1.7 | 207.3 ± 1.8 | 245.8 ± 1.2 | 235.5 ± 0.6 | 241.6 ± 2.6 |

| Peak temperature Tp (°C) | 276.0 ± 0.4 | 330.7 ± 0.6 | 342.8 ± 0.6 | 338.3 ± 0.4 | 343.1 ± 0.6 | 345.2 ± 1.6 | 338.0 ± 0.6 | 339.7 ± 0.5 | 336.9 ± 0.2 | 347.7 ± 0.2 | 343.9 ± 0.7 | 342.9 ± 0.1 |

| Shoulder peak Ts (°C) | 339.8 ± 0.3 | 311.2 ± 2.0 | 280.1 ± 0.8 | 276.1 ± 0.1 | 283.1 ± 1.1 | 277.2 ± 0.6 | 286.9 ± 3.8 | 288.3 ± 2.1 | 283.3 ± 0.4 | 274.2 ± 0.2 | 273.0 ± 2.1 | 271.6 ± 1.2 |

| Pyrolysis finish Tf (°C) | 382.6 ± 1.2 | 366.2 ± 0.6 | 376.7 ± 0.7 | 378.6 ± 1.2 | 380.9 ± 1.8 | 383.5 ± 1.5 | 369.5 ± 1.4 | 373.4 ± 1.9 | 372.4 ± 2.6 | 387.3 ± 1.1 | 383.1 ± 1.4 | 384.4 ± 1.9 |

| DTG peak max (%/min) | 12.8 ± 0.2 | 18.4 ± 0.3 | 14.7 ± 0.1 | 13.1 ± 0.1 | 14.7 ± 0.2 | 14.4 ± 0.3 | 16.9 ± 0.3 | 16.0 ± 0.2 | 15.4 ± 0.4 | 13.4 ± 0.3 | 13.1 ± 0.1 | 12.1 ± 0.2 |

| DTG shoulder (%/min) | 11.1 ± 0.3 | 15.9 ± 0.5 | 11.1 ± 0.2 | 10.9 ± 0.2 | 11.9 ± 0.3 | 11.9 ± 0.2 | 11.1 ± 0.4 | 11.6 ± 0.5 | 10.4 ± 0.1 | 11.8 ± 0.1 | 10.6 ± 0.2 | 12.1 ± 0.2 |

| DTG mean (%/min) | 2.0 | 1.9 | 1.9 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | |||

| Pyrolysis initial tm (min) | 10.7 ± 0.0 | 12.1 ± 0.2 | 11.0 ± 0.1 | 10.6 ± 0.1 | 11.0 ± 0.1 | 11.0 ± 0.0 | 11.0 ± 0.2 | 11.5 ± 0.1 | 9.7 ± 0.1 | 10.8 ± 0.0 | 10.7 ± 0.0 | 10.8 ± 0.1 |

| Peak time tp (min) | 12.1 ± 0.0 | 14.4 ± 0.1 | 14.9 ± 0.0 | 14.7 ± 0.1 | 15.0 ± 0.0 | 15.1 ± 0.2 | 14.8 ± 0.1 | 14.8 ± 0.0 | 14.7 ± 0.0 | 15.0 ± 0.1 | 15.0 ± 0.1 | 15.0 ± 0.0 |

| Pyrolysis finish tf (min) | 16.8 ± 0.1 | 16.1 ± 0.1 | 16.6 ± 0.6 | 16.7 ± 0.1 | 16.8 ± 0.1 | 17.0 ± 0.1 | 16.3 ± 0.1 | 16.5 ± 0.1 | 16.4 ± 0.1 | 17.1 ± 0.1 | 17.0 ± 0.1 | 17.0 ± 0.1 |

| Pi (%/min3 × 10−3) | 98.94 | 105.60 | 89.51 | 83.88 | 89.21 | 86.87 | 103.65 | 93.90 | 108.40 | 81.94 | 81.53 | 74.71 |

| Pf (%/min4 × 10−3) | 78.77 | 113.38 | 98.85 | 76.06 | 97.35 | 76.92 | 113.18 | 104.05 | 92.52 | 63.53 | 73.18 | 65.18 |

| P (%2/°C3 × 10−6) | 1.15 | 1.30 | 1.23 | 1.22 | 1.24 | 1.26 | 1.54 | 1.24 | 1.92 | 1.17 | 1.22 | 1.08 |

| Residual mass (%) | 27.3 ± 0.6 | 27.5 ± 1.2 | 27.6 ± 0.1 | 27.4 ± 0.2 | 25.8 ± 0.1 | 26.7 ± 0.7 | 27.7 ± 0.2 | 28.1 ± 0.8 | 28.2 ± 0.4 | 24.7 ± 0.8 | 27.8 ± 0.4 | 26.5 ± 0.3 |

| Main Pyrolysis Parameters | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| Pyrolysis initial Tm (°C) | 0.28 | 0.07 | 0.10 | 0.05 | 1.23 | 0.09 | 0.34 | 0.64 | 0.88 | 0.47 | 0.26 | 1.05 |

| Peak temperature Tp (°C) | 015 | 0.18 | 0.17 | 0.10 | 0.16 | 0.48 | 0.19 | 0.13 | 0.06 | 0.04 | 0.19 | 0.02 |

| Shoulder peak Ts (°C) | 0.08 | 0.65 | 0.29 | 0.02 | 0.39 | 0.21 | 1.33 | 0.73 | 0.14 | 0.06 | 0.74 | 0.43 |

| Pyrolysis finish Tf (°C) | 0.30 | 0.17 | 0.18 | 0.30 | 0.48 | 0.39 | 0.37 | 0.51 | 0.71 | 0.29 | 0.36 | 0.48 |

| DTG peak max (%/min) | 1.34 | 1.40 | 0.92 | 0.92 | 1.53 | 2.32 | 1.95 | 1.02 | 2.53 | 2.02 | 0.62 | 1.51 |

| DTG shoulder (%/min) | 2.17 | 2.87 | 2.14 | 2.11 | 2.15 | 1.94 | 3.18 | 3.79 | 1.02 | 0.89 | 1.99 | 1.79 |

| Pyrolysis initial tm (min) | 0.00 | 1.28 | 0.52 | 0.54 | 0.90 | 0.37 | 1.42 | 0.48 | 0.77 | 0.32 | 0.27 | 0.74 |

| Peak time tp (min) | 0.00 | 0.81 | 0.00 | 0.39 | 0.00 | 1.12 | 0.55 | 0.08 | 0.04 | 0.65 | 0.34 | 0.04 |

| Pyrolysis finish tf (min) | 0.34 | 0.63 | 3.91 | 0.35 | 0.60 | 0.81 | 0.89 | 0.56 | 0.78 | 0.29 | 0.45 | 0.65 |

| Residual mass (%) | 2.28 | 4.55 | 0.31 | 0.60 | 0.43 | 2.58 | 4.44 | 0.25 | 1.34 | 3.29 | 1.59 | 0.93 |

| Parameter | Shapiro-Wilk | Levene’s | Test | p-Value | Conclusion |

|---|---|---|---|---|---|

| Pi | Normal | Equal | ANOVA | 0.041 | Reject the null hypothesis |

| Pf | Normal | Equal | ANOVA | 0.047 | Reject the null hypothesis |

| P | Normal | Unequal | Welch’s ANOVA | 0.210 | Retain the null hypothesis |

| Main Combustion Parameters | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| T 5% weigh loss (°C) | 127.0 | 182.0 | 203.0 | 204.0 | 152.0 | 213.0 | 199.0 | 206.0 | 206.0 | 176.0 | 199.0 | 205.0 |

| Ignition temp. Ti (°C) | 253.2 ± 0.5 | 254.7 ± 2.2 | 250.9 ± 2.4 | 248.3 ± 2.0 | 258.4 ± 2.8 | 252.8 ± 1.9 | 248.1 ± 2.7 | 251.0 ± 1.1 | 239.9 ± 6.6 | 249.7 ± 0.4 | 246.1 ± 1.4 | 250.7 ± 3.2 |

| Peak temp. Tp (°C) | 280.1 ± 0.8 | 273.2 ± 1.2 | 278.8 ± 1.3 | 278.6 ± 2.2 | 286.5 ± 1.8 | 281.3 ± 4.3 | 270.6 ± 1.1 | 273.7 ± 0.5 | 270.5 ± 1.6 | 286.1 ± 0.3 | 282.0 ± 0.6 | 287.1 ± 1.6 |

| Burnout temp. Tf (°C) | 468.6 ± 7.3 | 471.0 ± 29.7 | 482.0 ± 2.6 | 474.0 ± 12.2 | 475.0 ± 6.0 | 504.0 ± 20.1 | 473.0 ± 7.1 | 486.0 ± 44.3 | 479.0 ± 5.4 | 485.0 ± 5.8 | 478.0 ± 9.0 | 510.0 ± 20.7 |

| DTGmax (%/min) | 40.7 ± 1.0 | 50.1 ± 4.1 | 38.0 ± 1.7 | 42.5 ± 6.0 | 37.5 ± 3.4 | 38.9 ± 2.3 | 50.4 ± 1.7 | 38.7 ± 3.3 | 45.5 ± 5.7 | 40.3 ± 1.9 | 41.1 ± 1.2 | 41.2 ± 2.5 |

| DTGmean (%/min) | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.6 | 2.7 | 2.6 |

| Ignition time ti (min) | 11.2 ± 0.1 | 11.2 ± 0.1 | 11.2 ± 0.1 | 11.1 ± 0.1 | 11.4 ± 0.1 | 11.2 ± 0.1 | 11.0 ± 0.1 | 11.2 ± 0.0 | 11.2 ± 0.2 | 11.2 ± 0.1 | 11.0 ± 0.1 | 11.2 ± 0.1 |

| Peak time tp (min) | 12.2 ± 0.0 | 11.9 ± 0.1 | 12.1 ± 0.1 | 12.2 ± 0.1 | 12.4 ± 0.1 | 12.3 ± 0.1 | 11.8 ± 0.1 | 11.9 ± 0.0 | 11.9 ± 0.1 | 12.4 ± 0.1 | 12.3 ± 0.1 | 12.5 ± 0.1 |

| Burnout time tf (min) | 21.5 ± 0.4 | 21.6 ± 1.6 | 22.0 ± 0.1 | 21.7 ± 0.6 | 21.7 ± 0.3 | 23.2 ± 1.0 | 21.7 ± 0.4 | 22.3 ± 0.1 | 22.0 ± 0.3 | 22.3 ± 0.3 | 21.9 ± 0.4 | 23.5 ± 1.1 |

| Di (%/min3 × 10−3) | 297.64 | 376.13 | 280.62 | 313.84 | 265.56 | 282.08 | 388.29 | 290.29 | 341.54 | 290.18 | 303.47 | 294.07 |

| S (%2/°C3 × 10−7) | 35.85 | 44.24 | 33.52 | 39.16 | 31.46 | 31.94 | 47.34 | 33.51 | 44.74 | 35.12 | 37.70 | 33.80 |

| D (%/°C2 × 10−3) | 5.40 | 9.92 | 4.89 | 5.03 | 4.66 | 4.85 | 8.28 | 6.23 | 5.50 | 3.87 | 4.06 | 3.94 |

| Df (%/min4 × 10−3) | 387.63 | 390.06 | 238.10 | 401.34 | 232.52 | 194.54 | 393.66 | 242.99 | 347.75 | 242.90 | 304.86 | 280.31 |

| Residual mass (%) | 8.1 ± 0.1 | 8.1 ± 0.8 | 7.6 ± 0.1 | 7.9 ± 0.3 | 6.7 ± 0.3 | 7.6 ± 0.7 | 7.3 ± 0.7 | 8.5 ± 0.2 | 8.4 ± 0.9 | 7.9 ± 0.8 | 8.6 ± 0.3 | 8.8 ± 0.7 |

| Main Combustion Parameters | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| Ignition temp. Ti (°C) | 0.18 | 0.84 | 0.95 | 0.81 | 1.09 | 0.76 | 1.06 | 0.42 | 2.67 | 0.16 | 0.57 | 1.24 |

| Peak temp. Tp (°C) | 0.28 | 0.42 | 0.45 | 0.79 | 0.62 | 1.53 | 0.39 | 0.19 | 0.59 | 0.10 | 0.20 | 0.56 |

| Burnout temp. Tf (°C) | 1.56 | 6.79 | 0.55 | 2.63 | 1.27 | 4.17 | 1.53 | 9.63 | 1.15 | 1.20 | 1.92 | 4.24 |

| DTGmax (%/min) | 2.47 | 8.16 | 4.32 | 14.05 | 8.41 | 5.92 | 3.38 | 7.88 | 12.01 | 4.70 | 3.05 | 6.54 |

| Ignition time ti (min) | 0.51 | 0.88 | 0.51 | 0.90 | 1.00 | 1.02 | 0.9 | 0.00 | 1.89 | 1.05 | 0.52 | 0.51 |

| Peak time tp (min) | 0.00 | 0.49 | 0.48 | 0.47 | 0.47 | 0.47 | 0.49 | 0.00 | 0.84 | 0.81 | 0.47 | 0.81 |

| Burnout time tf (min) | 1.77 | 8.21 | 0.53 | 2.86 | 1.24 | 4.36 | 1.65 | 0.52 | 1.22 | 1.46 | 1.88 | 4.74 |

| Residual mass (%) | 1.28 | 9.96 | 1.55 | 4.11 | 4.63 | 9.97 | 8.51 | 1.79 | 9.99 | 9.92 | 3.38 | 8.14 |

| Parameter | Shapiro-Wilk | Levene’s | Test | p-Value | Conclusion |

|---|---|---|---|---|---|

| Di | Normal | Equal | ANOVA | 0.626 | Retain the null hypothesis |

| Df | Non-normal | Unequal | Kruskal-Wallis | 0.832 | Retain the null hypothesis |

| D | Non-normal | Unequal | Kruskal-Wallis | 0.038 | Reject the null hypothesis |

| S | Normal | Unequal | Welch’s ANOVA | 0.648 | Retain the null hypothesis |

| Area DSC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| Pyrolysis Area (J/g) | −636 ± 40 | −1248 ± 121 | −910 ± 86 | −931 ± 77 | −981 ± 52 | −1932 ± 127 | −1784 ± 152 | −1176 ± 22 | −1583 ± 95 | −1355 ± 103 | −980 ± 93 | −1275 ± 99 |

| Combustion Area (J/g) | −7314 ± 275 | −8317 ± 239 | −8042 ± 159 | −8126 ± 10 | −7715 ± 105 | −9470 ± 142 | −8707 ± 112 | −9597 ± 538 | −10,100 ± 339 | −8131 ± 119 | −8270 ± 48 | −7873 ± 316 |

| Area DSC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conventional | Forage | Transgenic | ||||||||||

| C1 | C2 | C3 | C4 | C5 | F1 | F2 | F3 | F4 | T1 | T2 | T3 | |

| Pyrolysis | 6.15 | 8.81 | 8.71 | 8.57 | 5.35 | 6.58 | 9.47 | 1.87 | 6.46 | 8.29 | 8.67 | 836 |

| Combustion | 3.67 | 2.79 | 1.99 | 0.13 | 1.36 | 1.52 | 1.31 | 5.94 | 3.39 | 1.49 | 0.58 | 4.21 |

| Parameter | Shapiro-Wilk | Levene’s | Test | p-Value | Conclusion |

|---|---|---|---|---|---|

| Pyrolysis Area | Normal | Equal | ANOVA | 0.002 | Reject the null hypothesis |

| Combustion Area | Normal | Equal | ANOVA | 0.020 | Reject the null hypothesis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Mateos, R.; Miranda, M.T.; Arranz, J.I.; Romero, P.; Sepúlveda, F.J.; Cuellar-Borrego, S. Comparative Analysis of Energy Viability of Crop Residue from Different Corn Varieties. Materials 2025, 18, 1683. https://doi.org/10.3390/ma18071683

García-Mateos R, Miranda MT, Arranz JI, Romero P, Sepúlveda FJ, Cuellar-Borrego S. Comparative Analysis of Energy Viability of Crop Residue from Different Corn Varieties. Materials. 2025; 18(7):1683. https://doi.org/10.3390/ma18071683

Chicago/Turabian StyleGarcía-Mateos, Raquel, María Teresa Miranda, José Ignacio Arranz, Pilar Romero, Francisco José Sepúlveda, and Santiago Cuellar-Borrego. 2025. "Comparative Analysis of Energy Viability of Crop Residue from Different Corn Varieties" Materials 18, no. 7: 1683. https://doi.org/10.3390/ma18071683

APA StyleGarcía-Mateos, R., Miranda, M. T., Arranz, J. I., Romero, P., Sepúlveda, F. J., & Cuellar-Borrego, S. (2025). Comparative Analysis of Energy Viability of Crop Residue from Different Corn Varieties. Materials, 18(7), 1683. https://doi.org/10.3390/ma18071683