Impact of Heat Treatment Parameters on the Plastic Properties of 6061 Aluminum Alloy

Abstract

1. Introduction

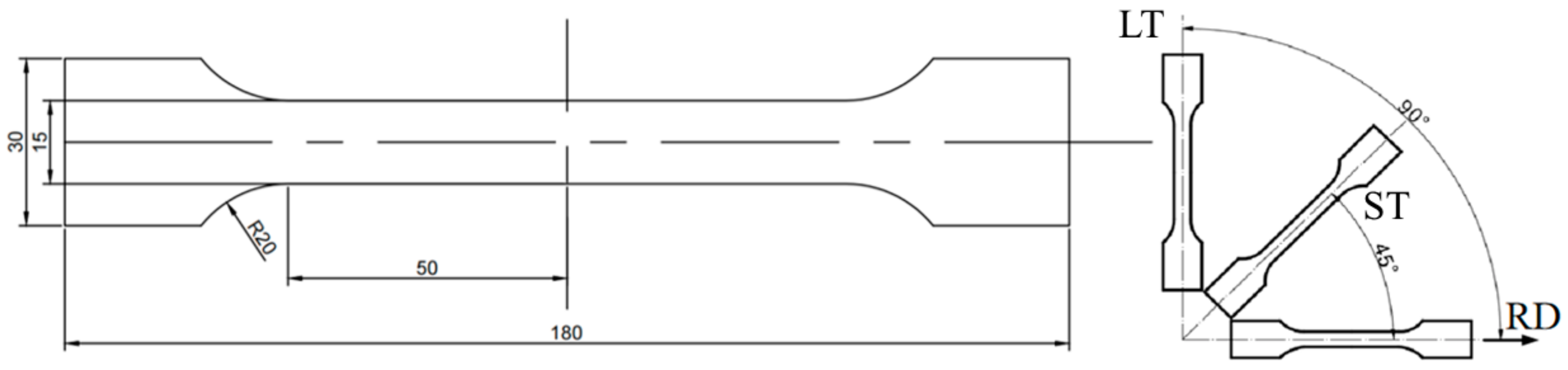

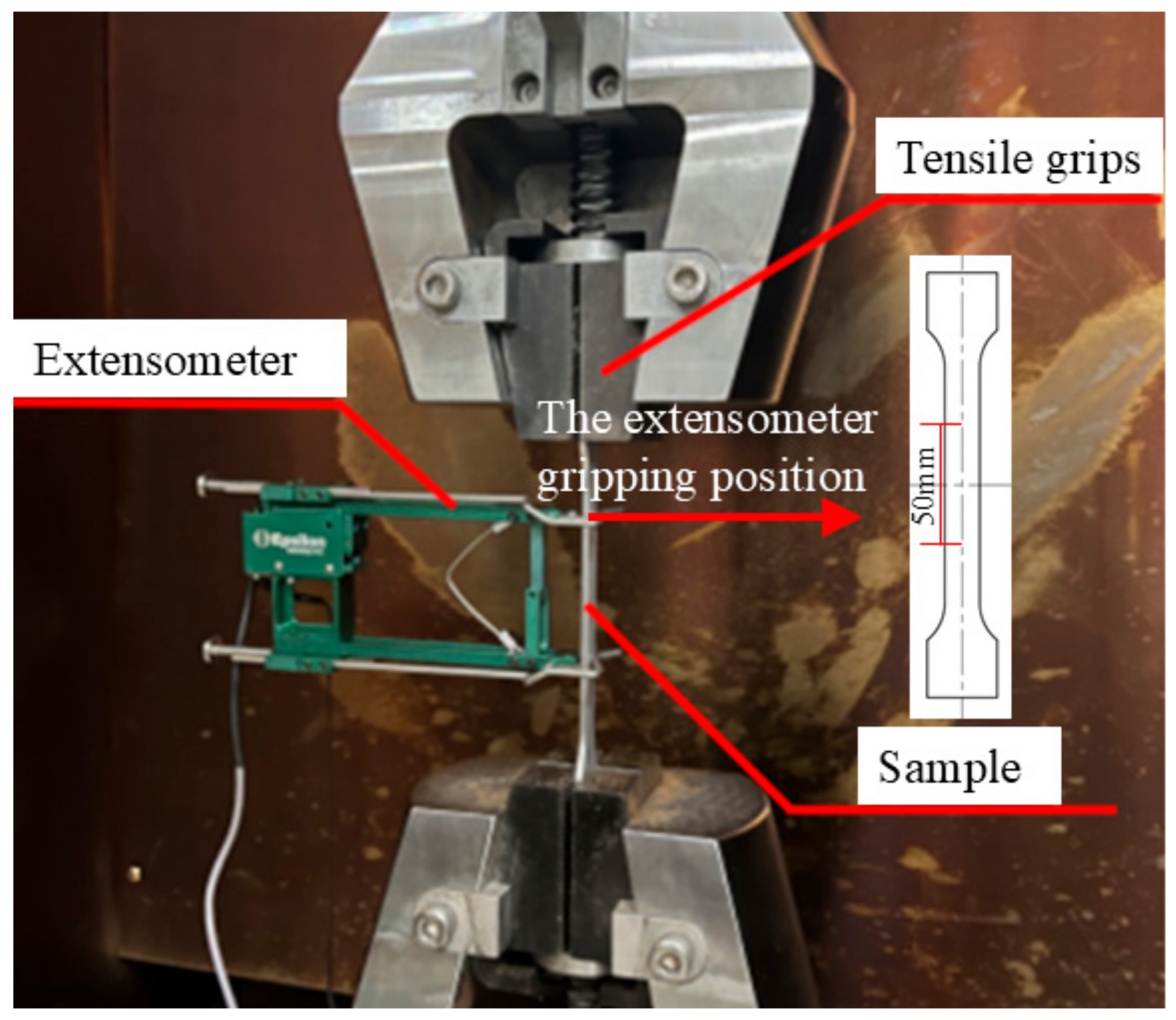

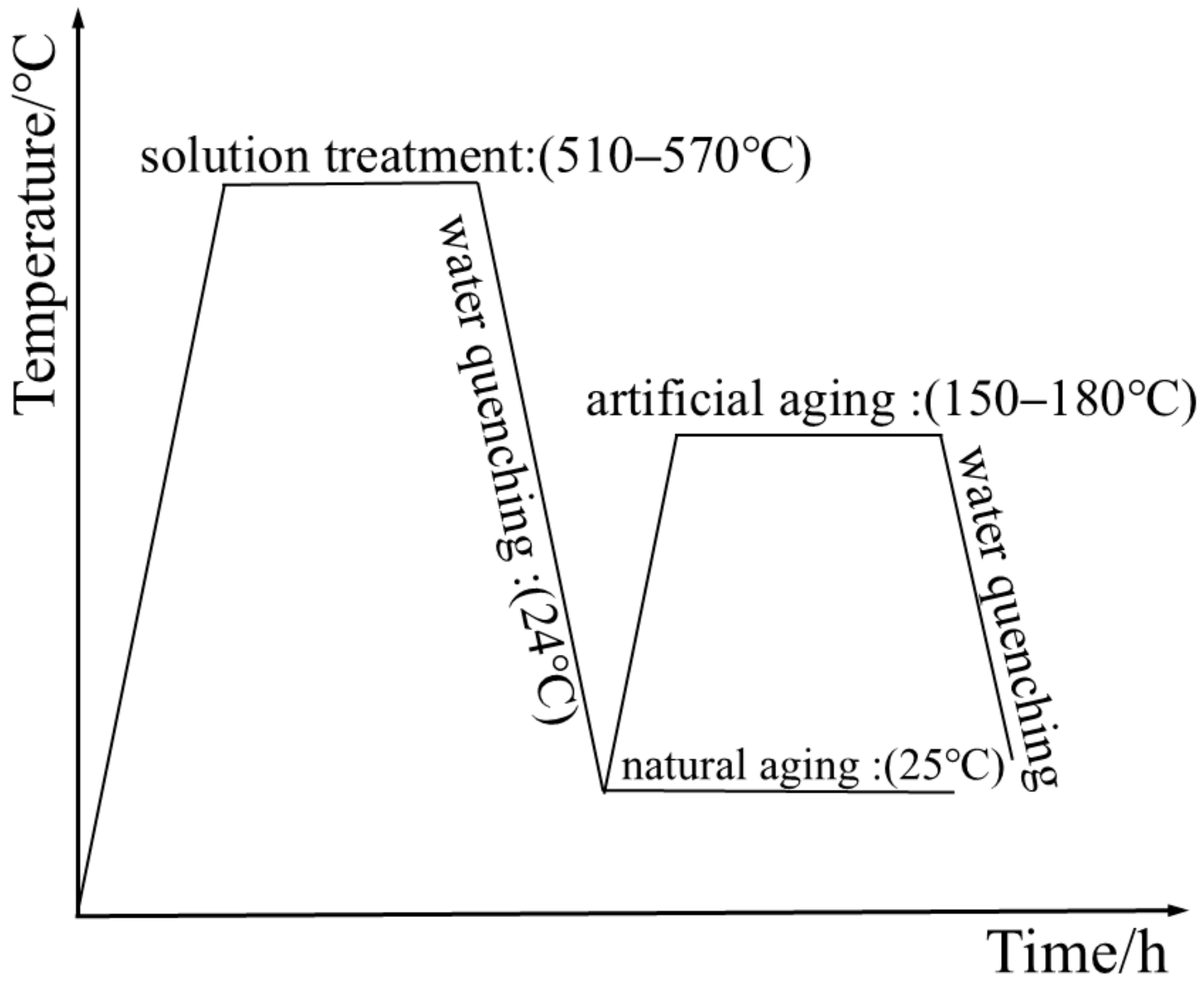

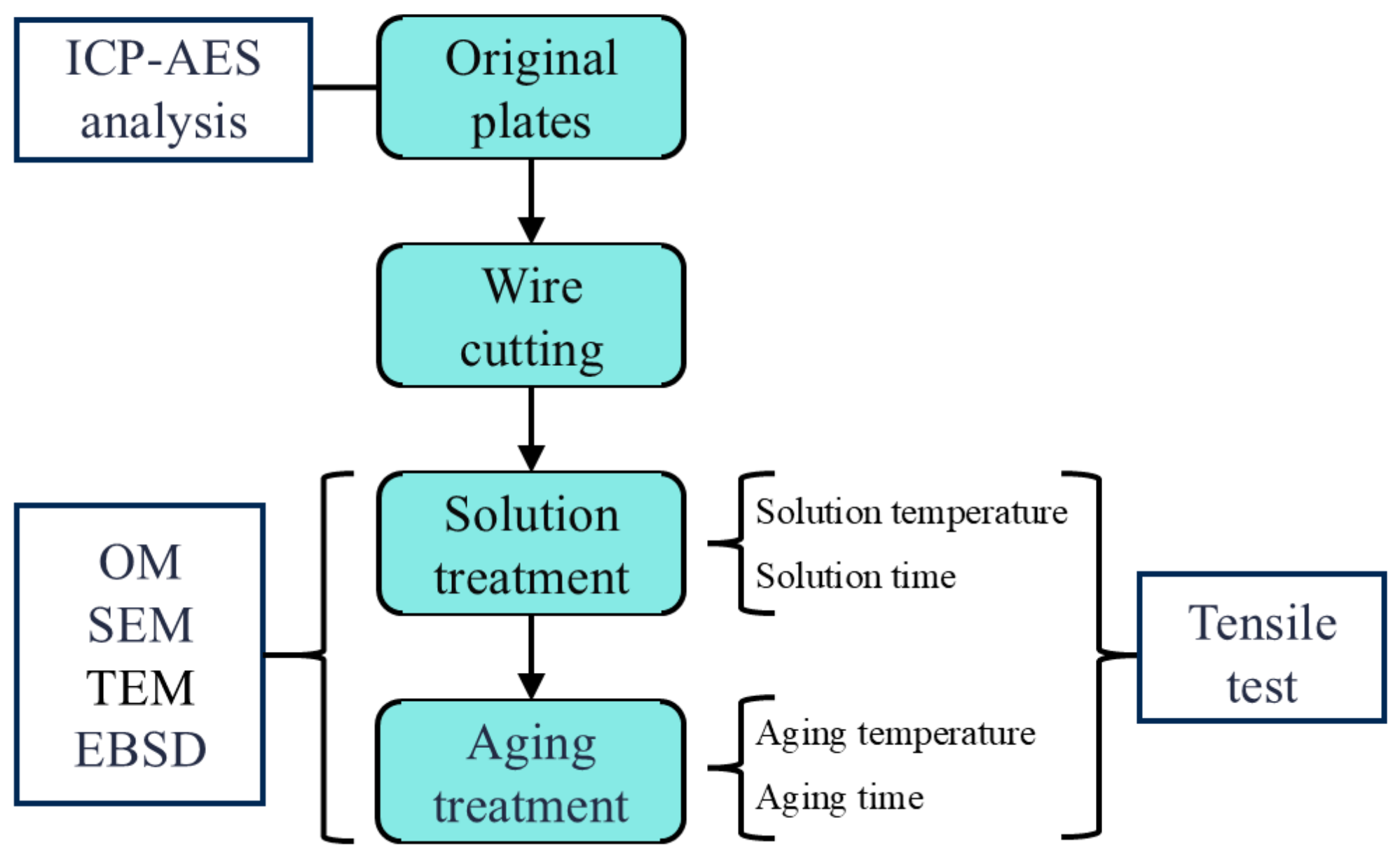

2. Materials and Methods

3. Results and Discussion

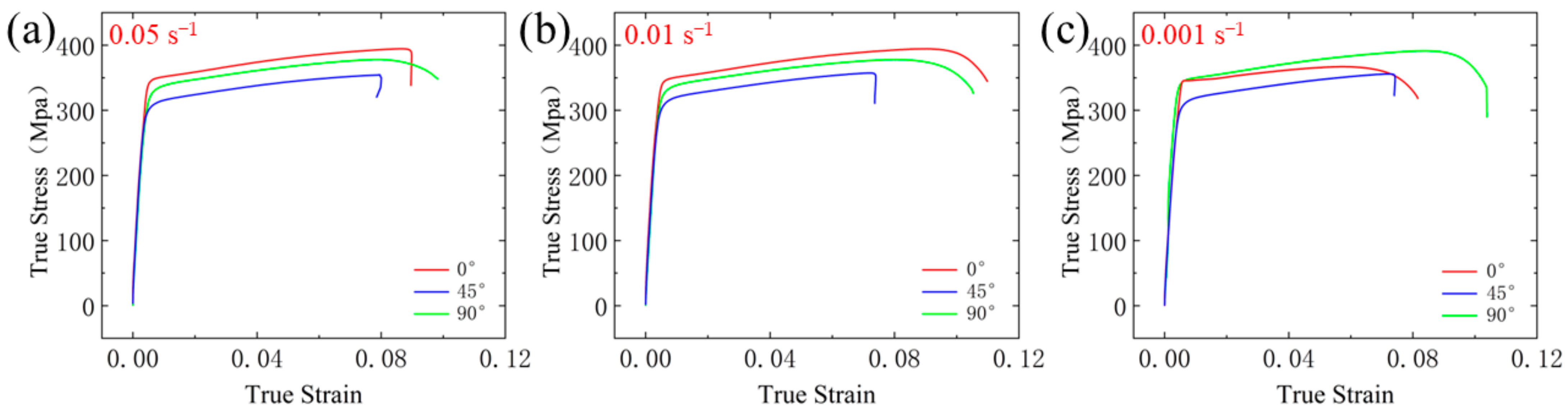

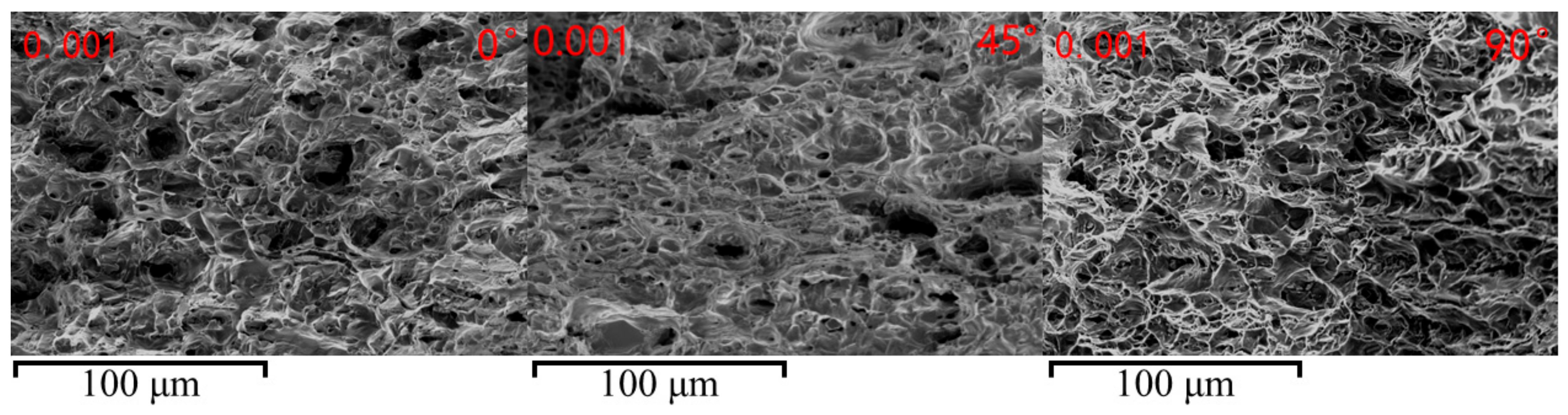

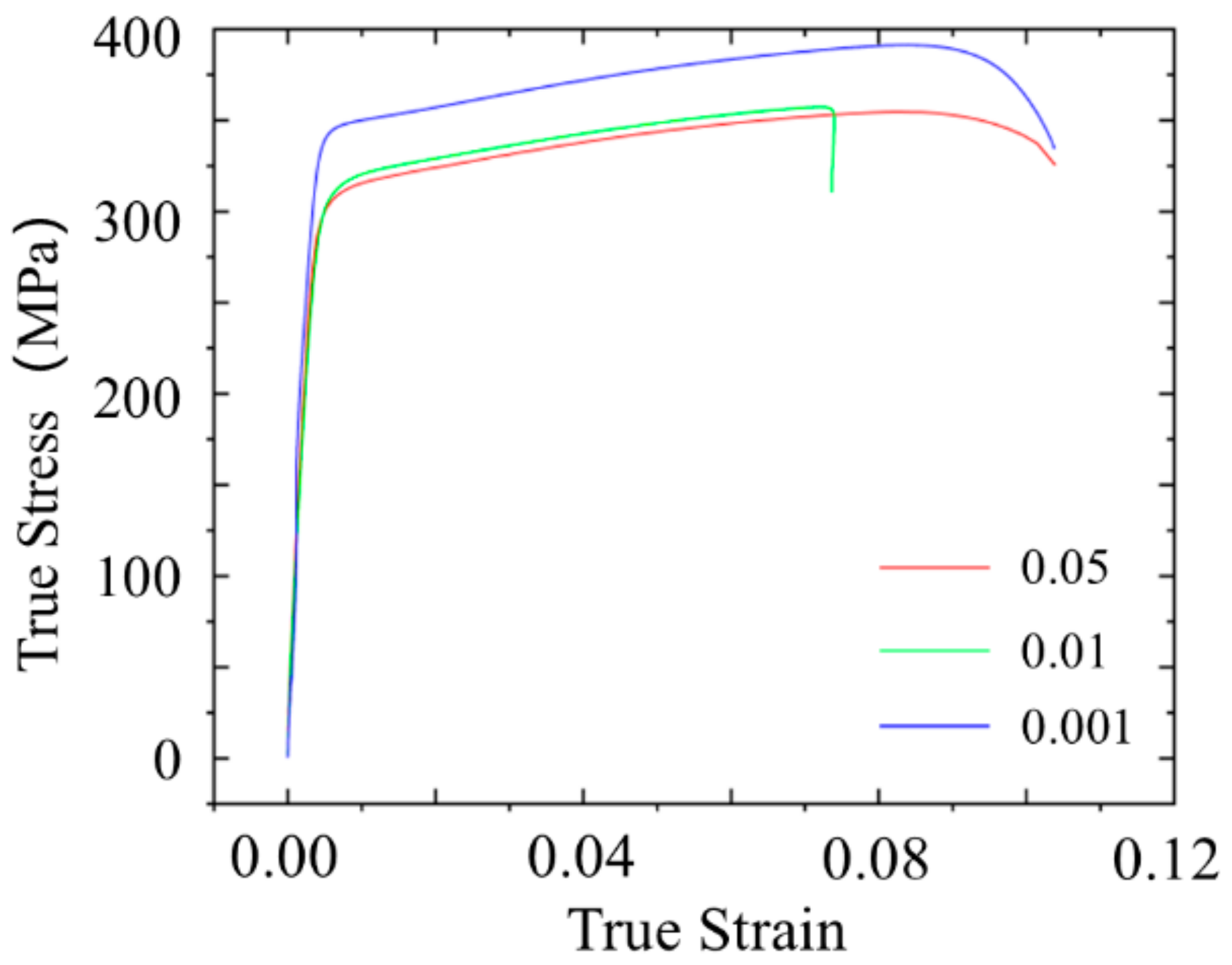

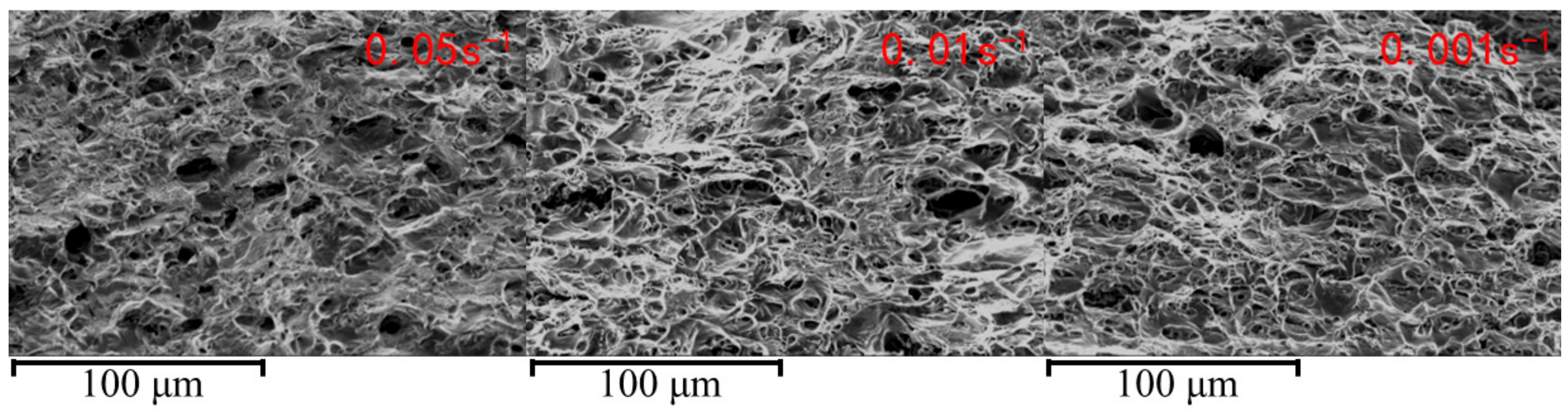

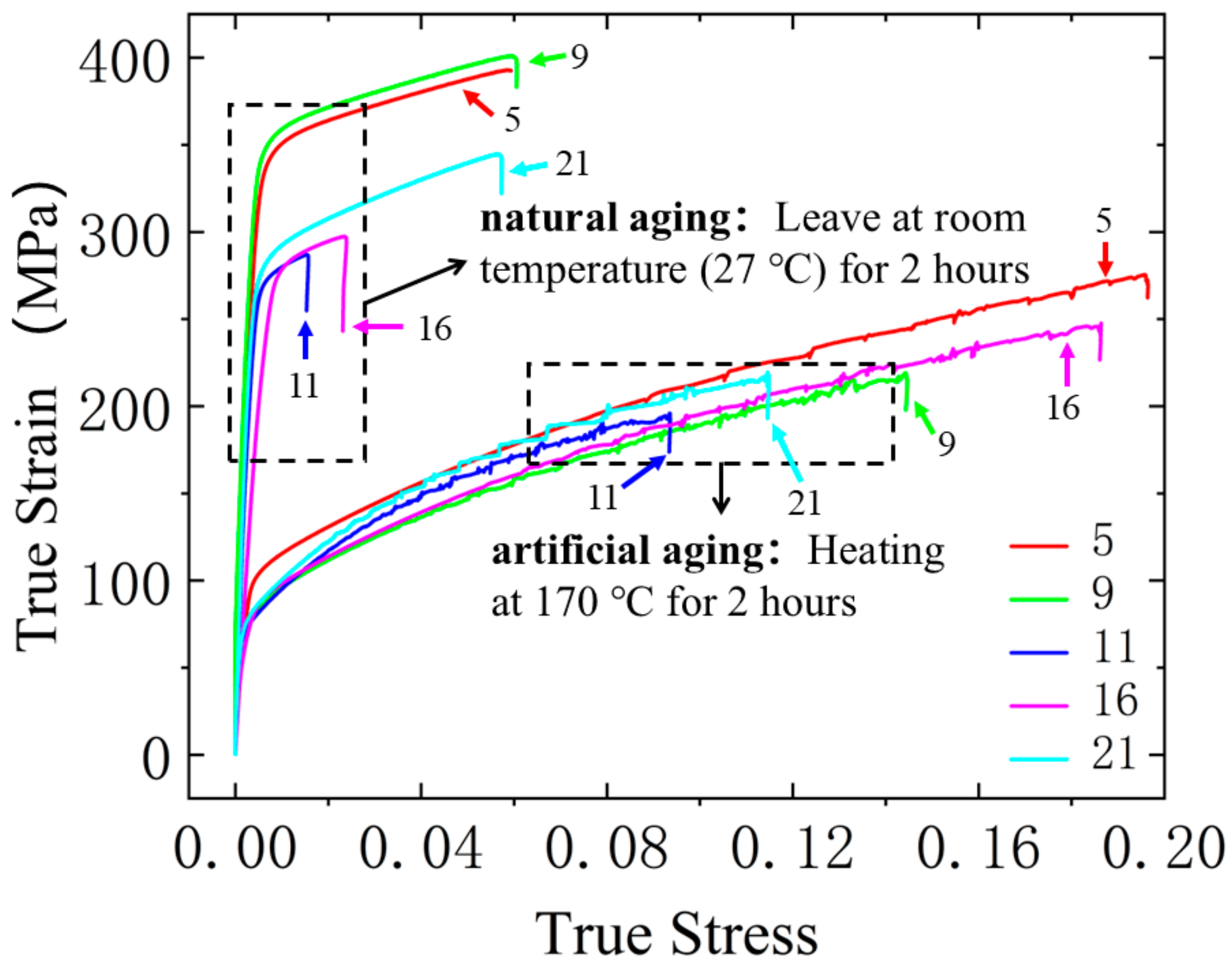

3.1. The Effect of Strain Rate on Performance

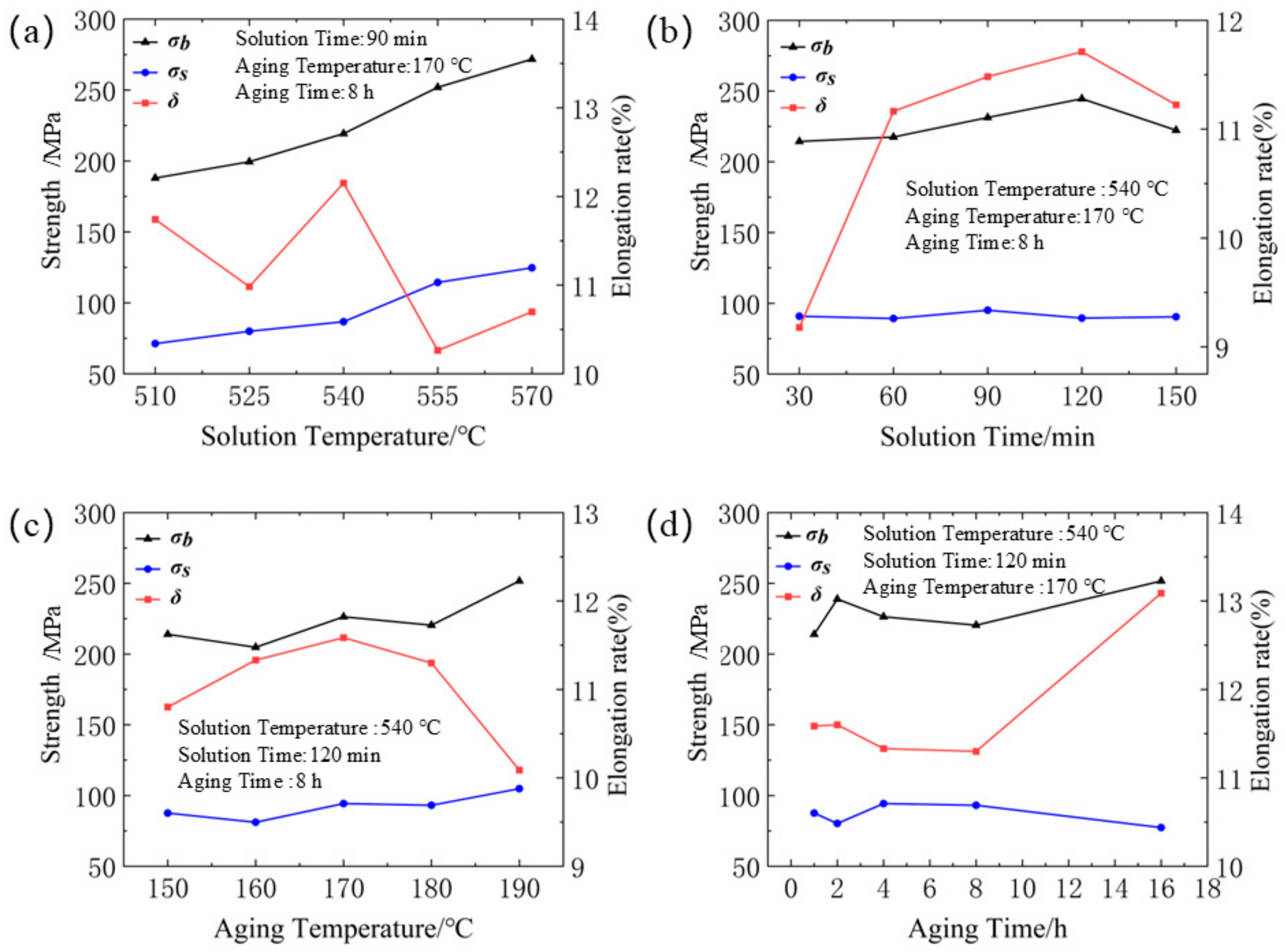

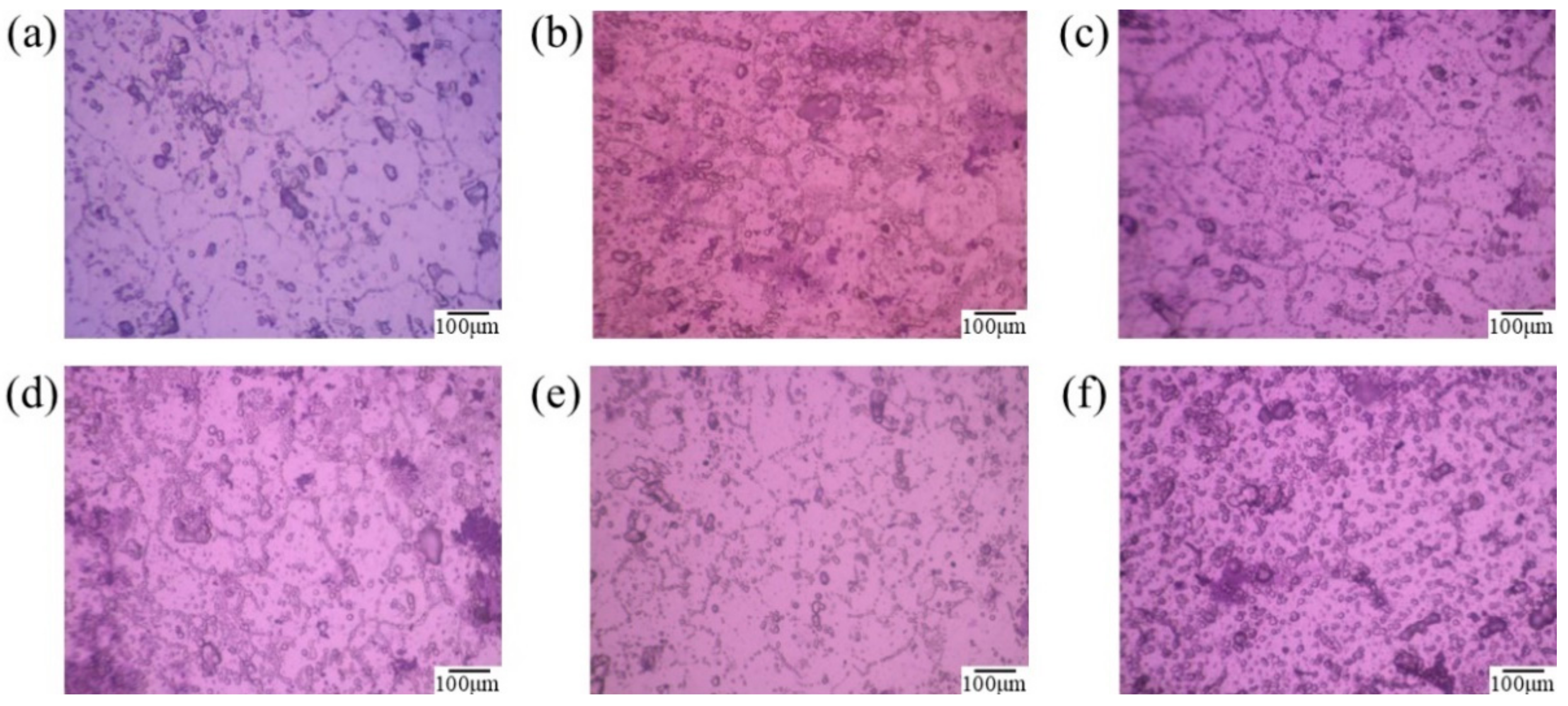

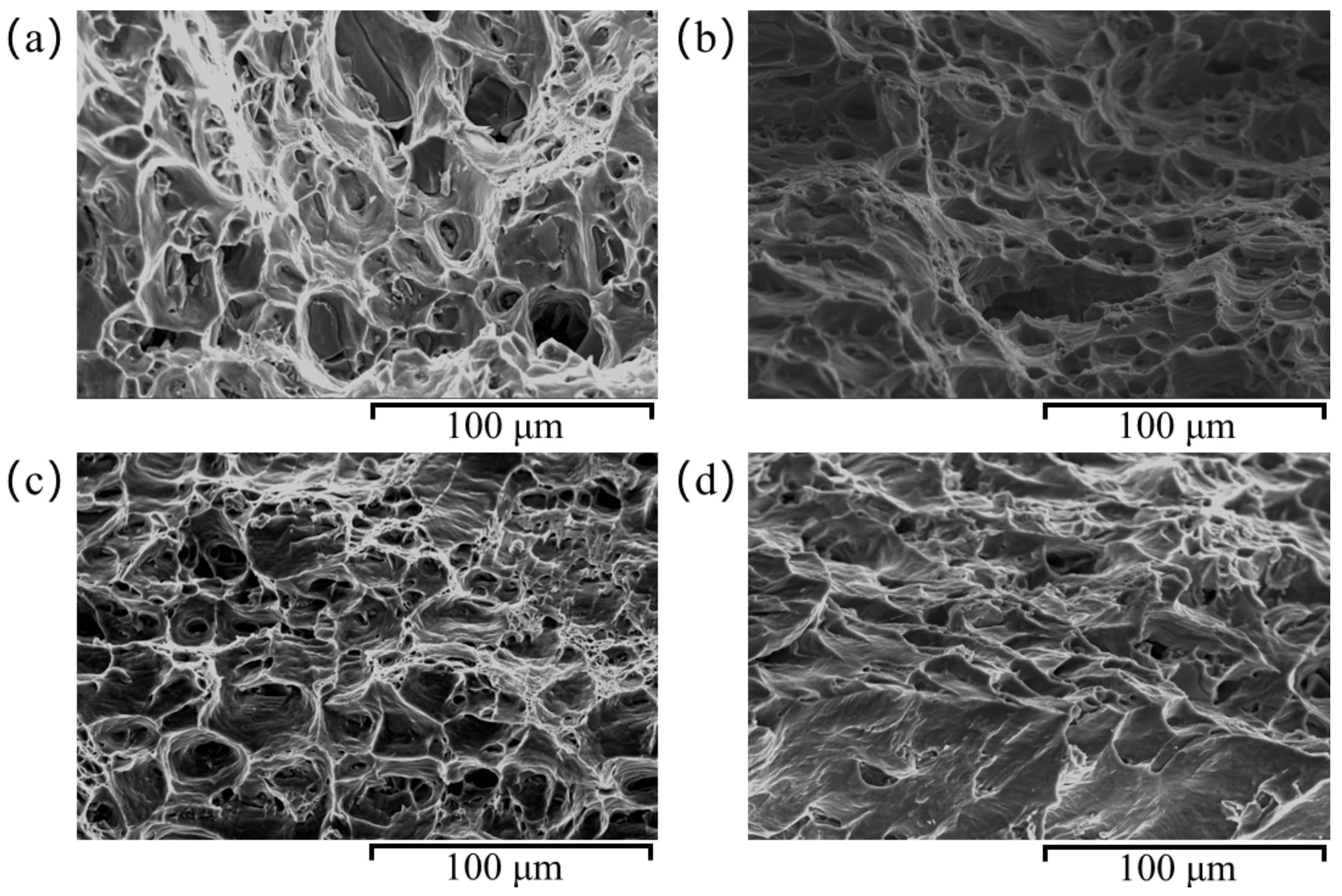

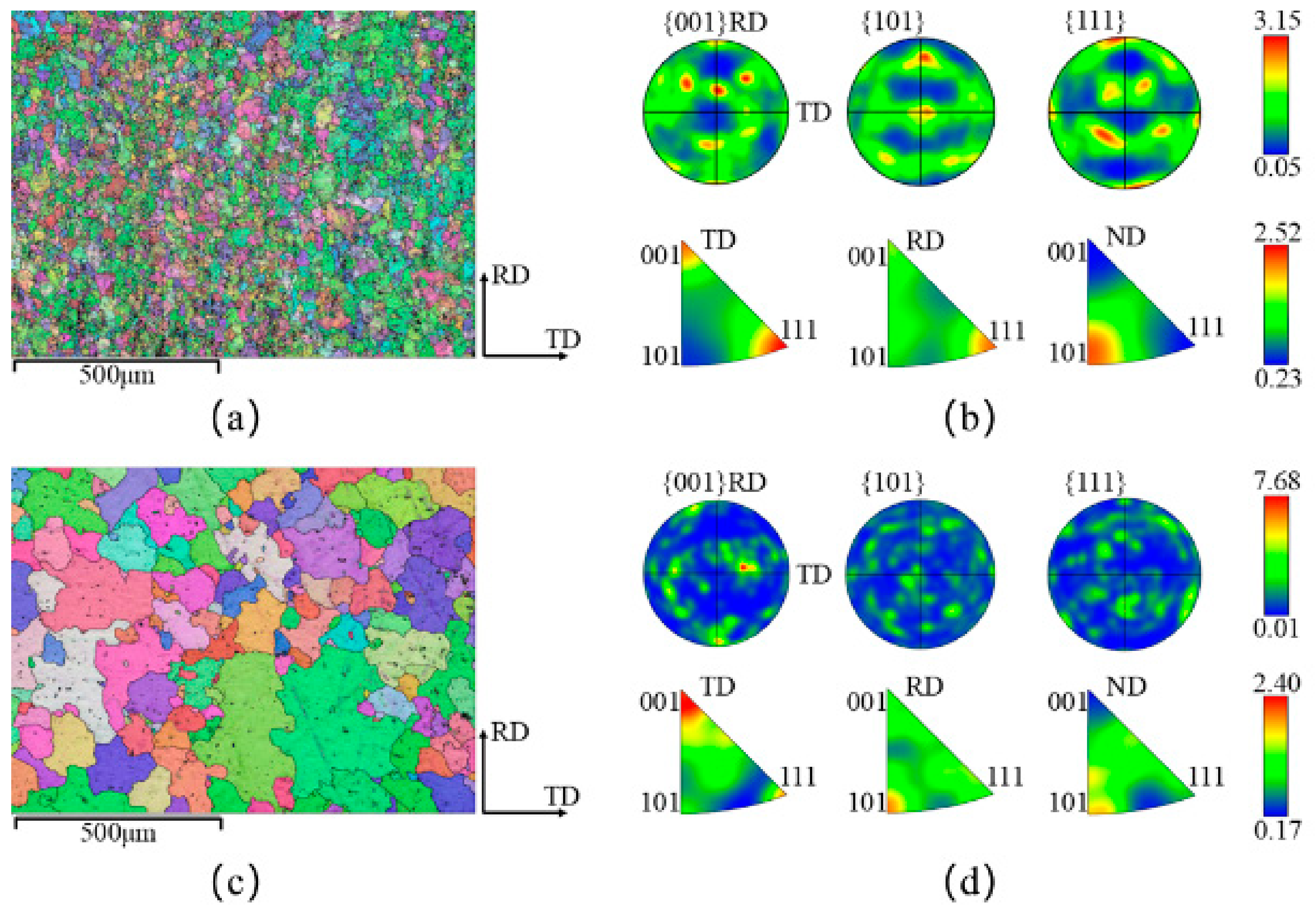

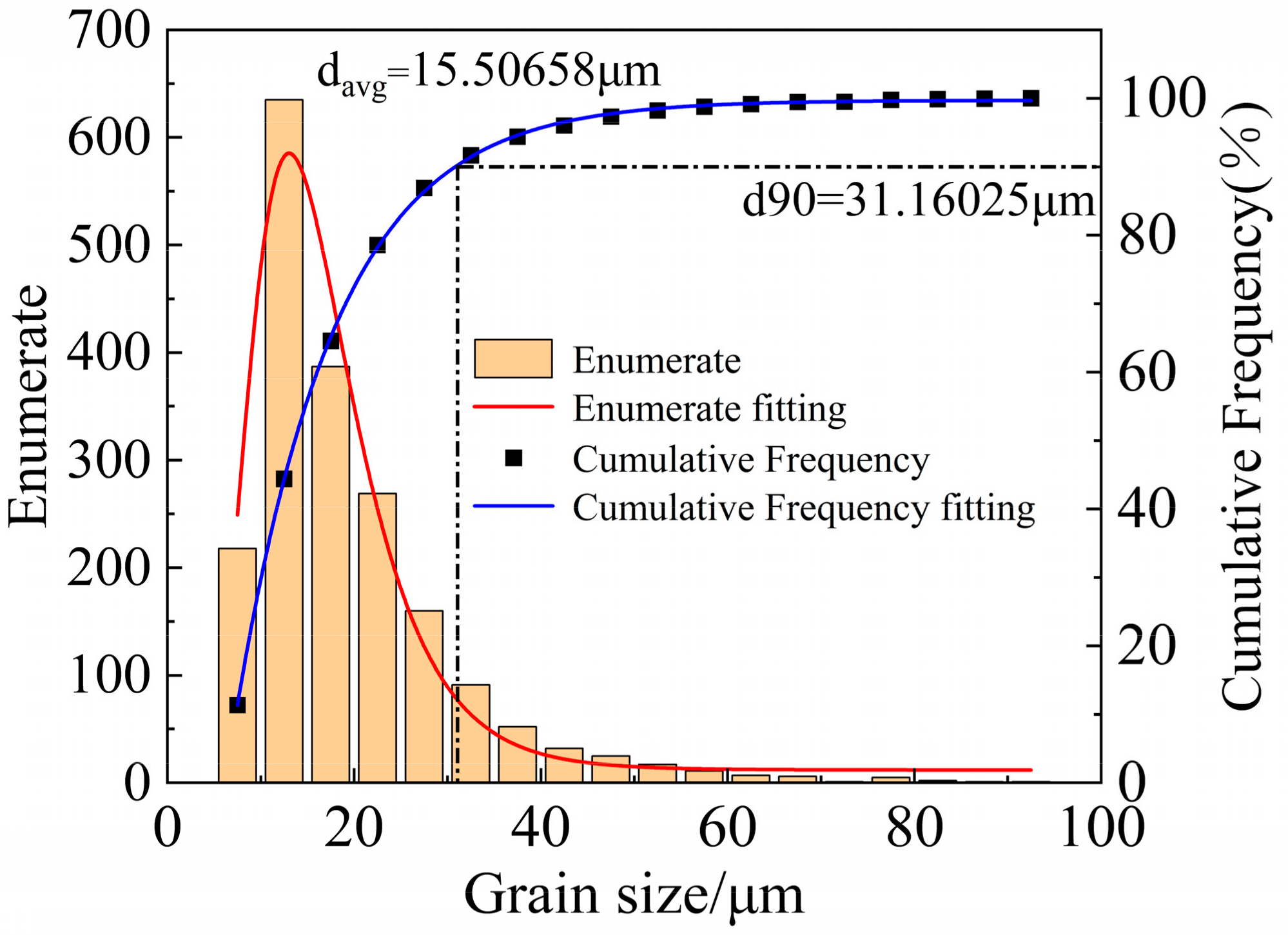

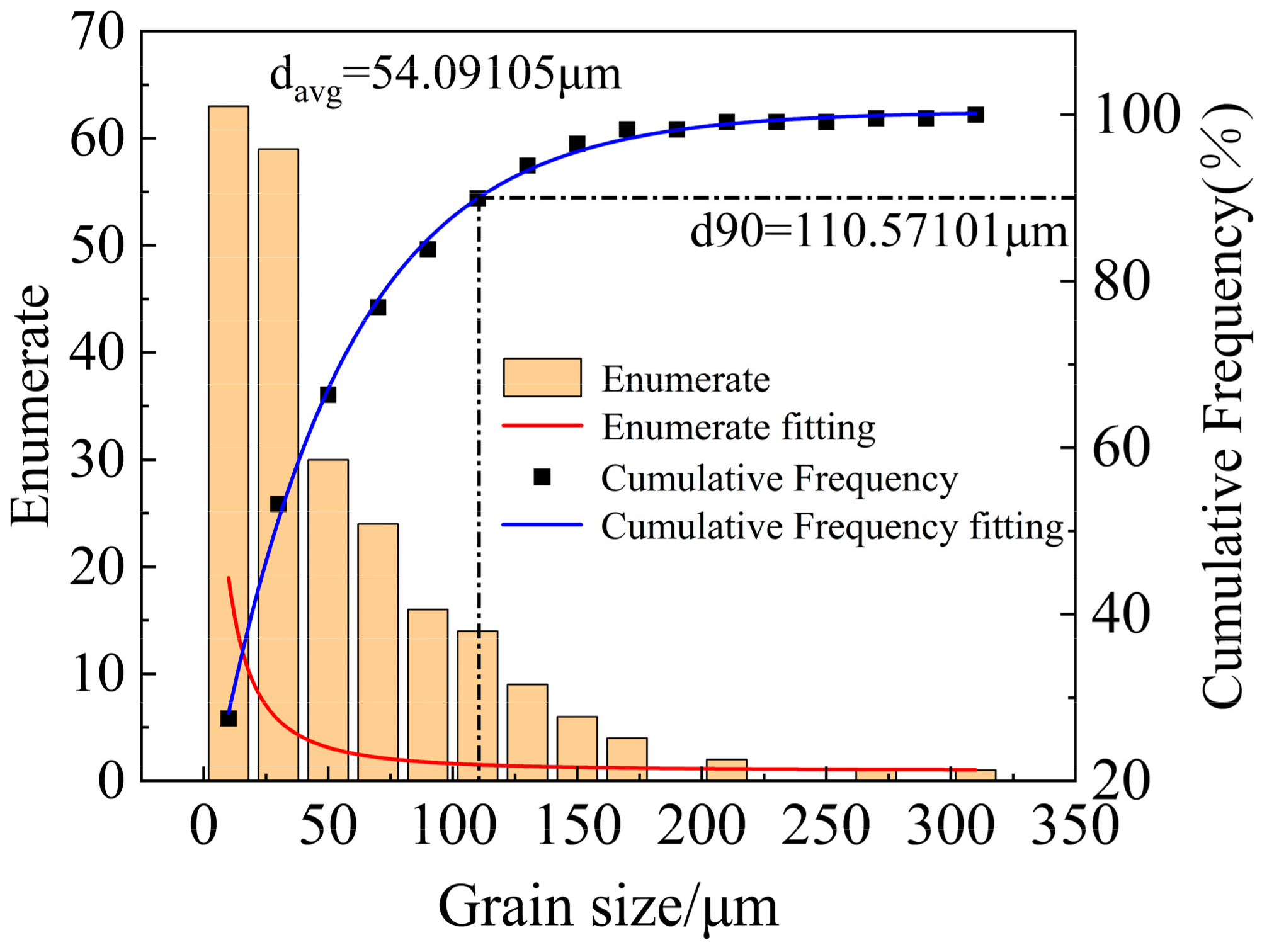

3.2. The Effect of Heat Treatment on Performance

4. Constitutive Model

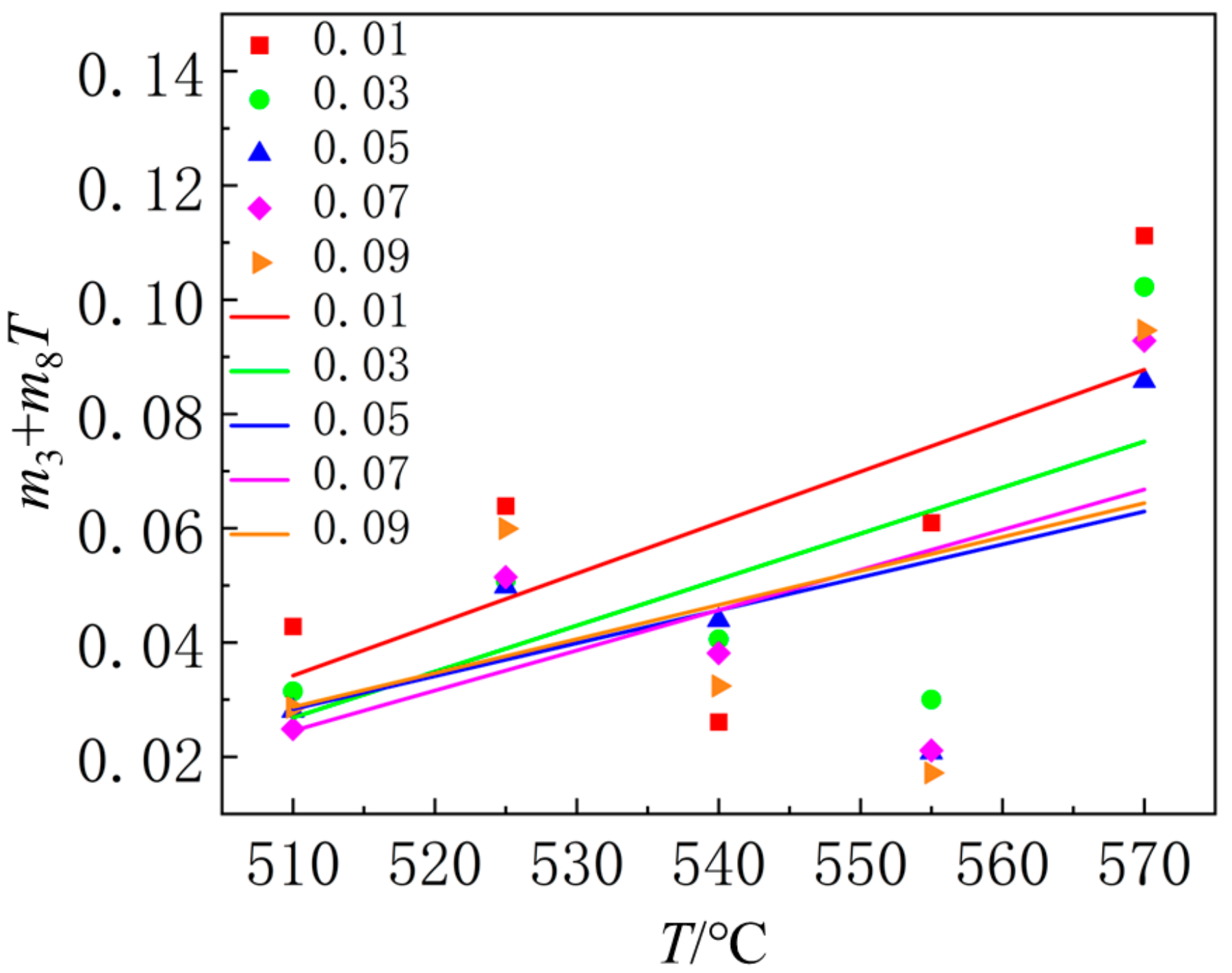

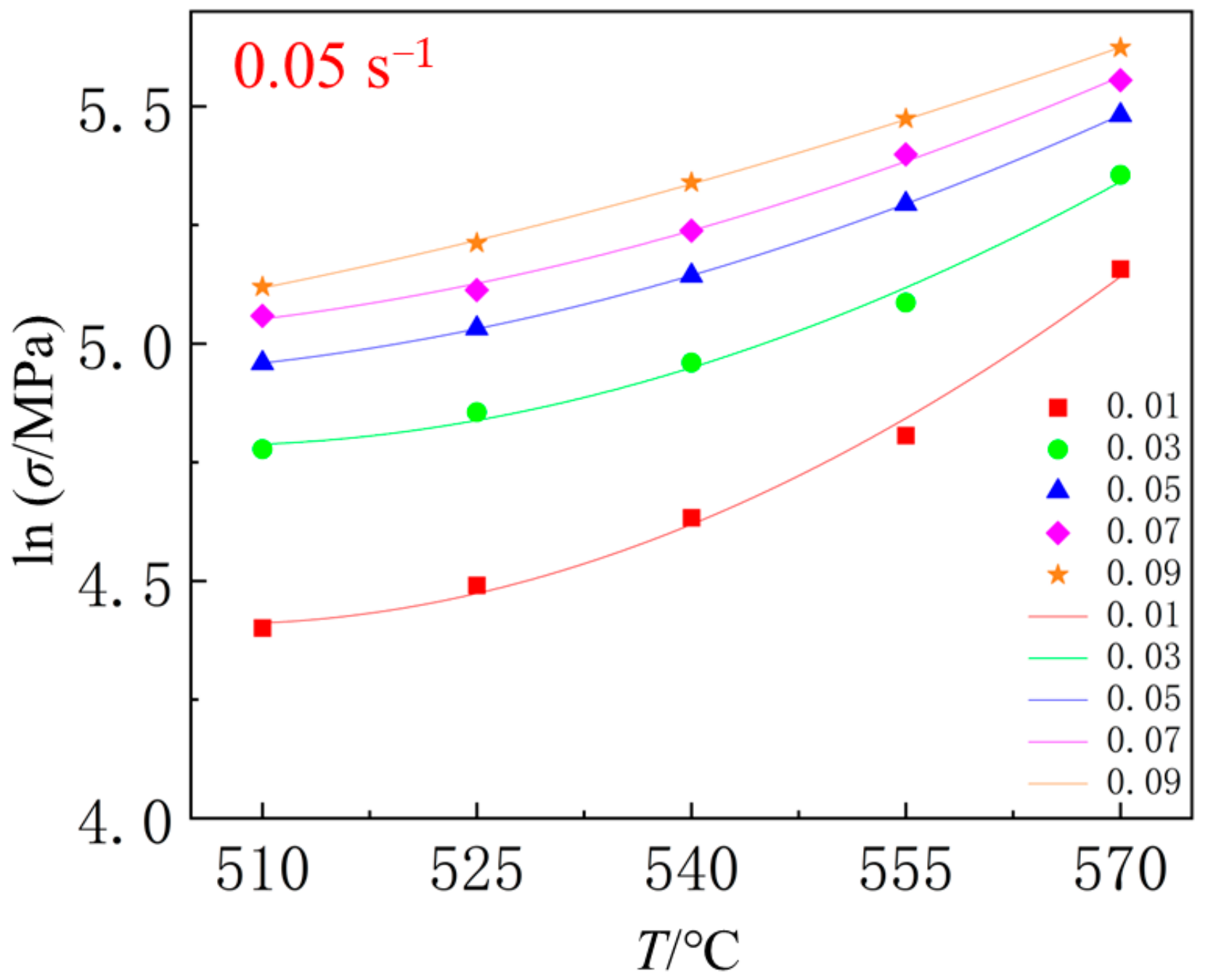

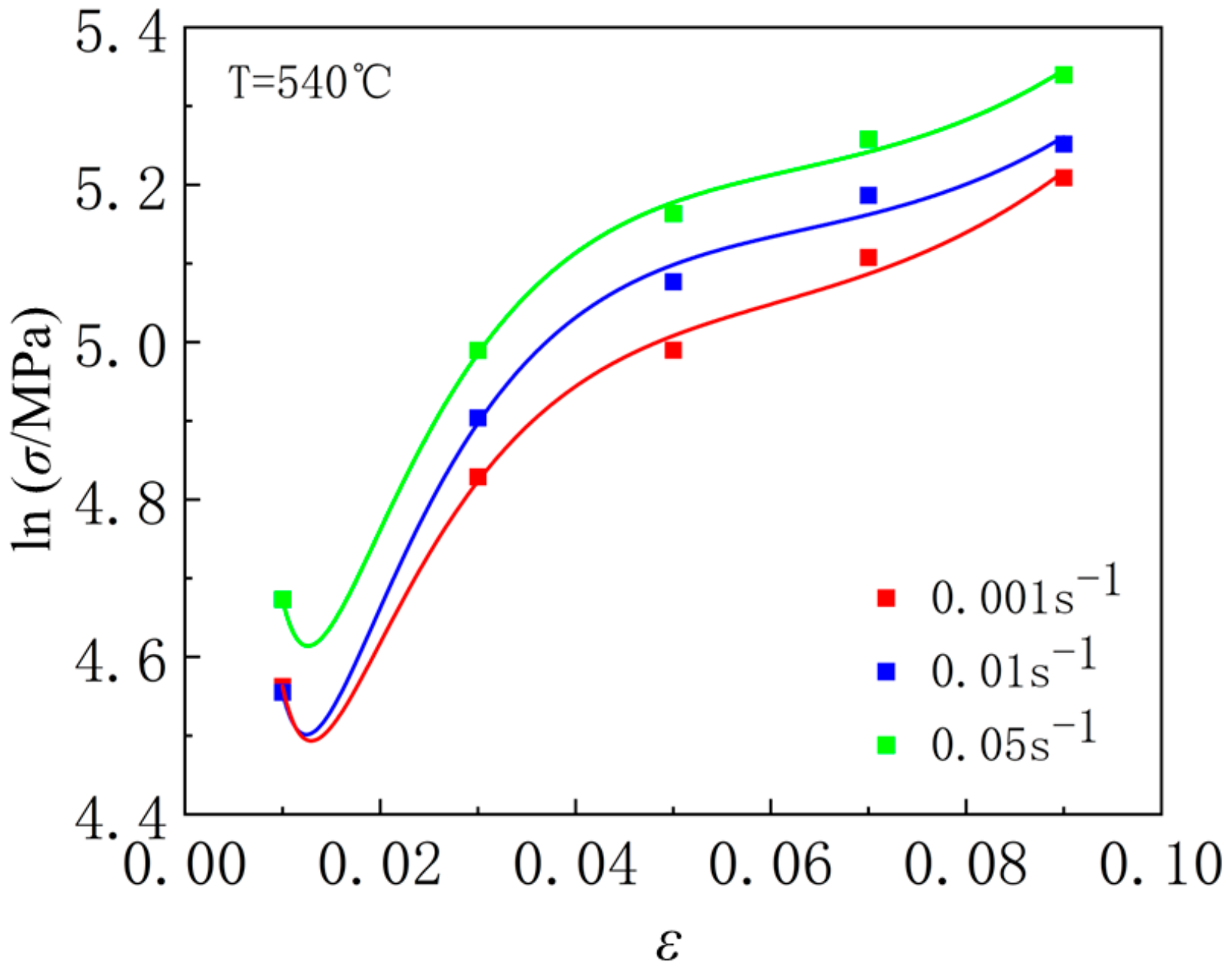

4.1. Fitting of m3 and m8 Values

4.2. Fitting of m1, m5, m9 Values

4.3. Fitting of m2, m4, m7 Values

4.4. Calculate the Value of A

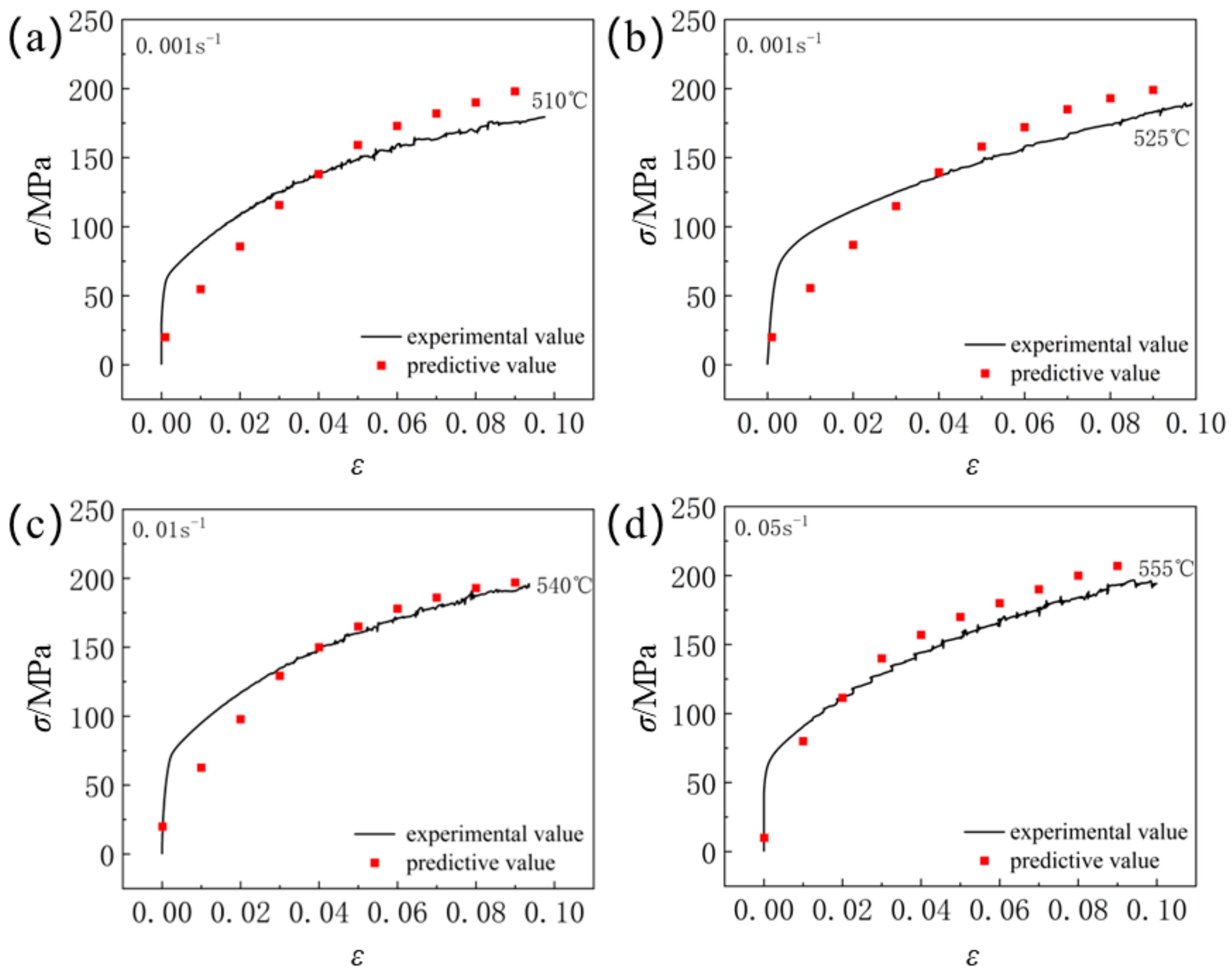

4.5. Verification of Constitutive Equation

5. Conclusions

- (1)

- Commercial cold-rolled 6061 aluminum plates exhibit significant anisotropy. The mechanical properties along the rolling direction (RD) and in the direction 90° to the rolling direction (LT) are significantly superior to those in the 45° direction relative to the rolling direction. During the plastic deformation process, both the yield strength and tensile strength of 6061 aluminum alloy decrease with increasing strain rate, while the plastic elongation shows a decreasing trend as the strain rate increases.

- (2)

- Within the temperature range of 510 °C to 540 °C, the plasticity of 6061 aluminum alloy gradually increases while the hardness decreases. When the solution treatment temperature is raised to 570 °C, the grain size of the 6061 aluminum alloy significantly increases, the brittleness of the grain boundaries rises, and the plasticity decreases. The effect of solution treatment time on the material’s strength is relatively small. As the aging temperature increases, the overall strength of the material shows a rising trend. The elongation of the 6061 aluminum alloy first decreases and then increases with the aging time.

- (3)

- Based on the experimental results, a Hansel–Spittel rheological stress model for 6061 aluminum alloy was constructed. The correlation coefficient (R) between the predicted results of the model and the experimental measurements is 0.9991, indicating a strong linear correlation. The Average Absolute Relative Error (AARE) is 13.42%, demonstrating that the established Hansel–Spittel rheological stress model can accurately predict the rheological stress characteristics of 6061 aluminum alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, M.; Yang, X.; Zhang, Z.; Gu, Y.; Li, K.; Liu, Y.; Ma, J. Research status of laser cladding technology on aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2025, 137, 1–21. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Bai, J.; Xue, H.; Tian, N.; Zhao, Z.; Qin, G. Research progress on microstructure tuning of heat-resistant cast aluminum alloys. J. Mater. Sci. 2024, 59, 10035–10057. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Sun, P.; Huang, R.; Zheng, S.; Duan, Y.; Li, M. Effect of Aging Time on Precipitation of MgZn2 and Microstructure and Properties of 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2023, 33, 6601–6611. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, S.; Gu, R.; Wang, W.; Wei, X. Effect of Heat Treatment Conditions on Mechanical Properties and Precipitates in Sheet Metal Hot Stamping of 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2018, 27, 4423–4436. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, J.; He, D. Effects of contact body temperature and holding time on the microstructure and mechanical properties of 7075 aluminum alloy in contact solid solution treatment. J. Alloys Compd. 2020, 823, 153919. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Z.; Liu, M.; Bao, E.; Liang, C.; Zhao, G. Effects of single- and multi-stage solid solution treatments on microstructure and properties of as-extruded AA7055 helical profile. Trans. Nonferrous Met. Soc. China 2021, 31, 1885–1901. [Google Scholar] [CrossRef]

- Lu, J.; Huang, H.; Wu, H.; Wen, S.; Gao, K.; Nie, Z. Effect of Solution Treatment on the Properties and Microstructural Evolution of Al-Zn-Mg-Cu-Er-Zr Alloy. Mater. Sci. Forum 2016, 877, 303–309. [Google Scholar] [CrossRef]

- Jia, S.F.; Zhan, L.H.; Zhang, J. Influence of solid solution treatment on microstructure and mechanical properties of 2219 aluminium alloy. Mater. Res. Innov. 2014, 18, 52–58. [Google Scholar] [CrossRef]

- Gomes, R.; Soares, G.; Madureira, R.; Silva, R.P.; Silva, J.; Neto, R.; Reis, A.; Fernandes, C. Development of Heat Treatments for Structural Parts in Aluminium Alloys Produced by High-Pressure Die Casting (HPDC). Metals 2024, 14, 1059. [Google Scholar] [CrossRef]

- Peng, X.; Li, Y.; Liang, X.; Guo, Q.; Xu, G.; Peng, Y.; Yin, Z. Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing. J. Alloys Compd. 2018, 735, 964–974. [Google Scholar] [CrossRef]

- Fan, Y.Q.; Wen, K.; Li, Z.H.; Li, X.W.; Zhang, Y.A.; Xiong, B.Q.; Xie, J.X. Microstructure of as-extruded 7136 aluminum alloy and its evolution during solution treatment. Rare Met. 2017, 36, 256–262. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, L.; Dong, Q.; Song, X.; Yang, B. Microstructure and tensile properties of 6061 aluminum alloy prepared by friction rolling additive manufacturing. J. Mater. Res. Technol. 2025, 35, 5464–5474. [Google Scholar] [CrossRef]

- Yadav, R.; Meena, A.; Lee, S.Y.; Park, S.J. Experimental tribological and mechanical behavior of aluminium alloy 6061 composites incorporated ceramic particulates using Taguchi analysis. Tribol. Int. 2024, 192, 109243. [Google Scholar] [CrossRef]

- Sana, M.; Asad, M.; Farooq, M.U.; Anwar, S.; Talha, M. Machine learning for multi-dimensional performance optimization and predictive modelling of nanopowder-mixed electric discharge machining (EDM). Int. J. Adv. Manuf. Technol. 2024, 130, 5641–5664. [Google Scholar] [CrossRef]

- Yang, J.; Peng, J.; Fan, C.; Zhang, Z.; Li, J.; Liu, D.; Tao, T.; Zhang, W.; Ghali, E.; Chen, L.; et al. The effect of deposition voltage on microstructure and properties of silver-containing porous Al alloy. Surf. Coat. Technol. 2025, 502, 131982. [Google Scholar] [CrossRef]

- Zhu, M.; Cao, S.X.; Yang, L.J.; Yuan, Y.F.; Guo, S.Y. The Anti-corrosion Property of 6061 Aluminum Alloy Subjected to Direct Current Interference in Marine Environment. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, R.; Chen, K.; Li, Q.H.; Yin, Y. Effect of Temperature Treatment on Microstructure and Electrochemical Properties of 6061 Aluminum Alloy. Int. J. Electrochem. Sci. 2021, 16, 210410. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, W.; Xu, S.; Sun, K.; Hu, X.; Ren, G.; Li, J.; Zhao, X.; Gao, F. Effect of Ultrasonic Surface Rolling Process on Surface Properties and Microstructure of 6061 Aluminum Alloy. Mater. Res. 2023, 26, e20230322. [Google Scholar] [CrossRef]

- Yang, J.; Ni, Y.; Li, H.; Fang, X.; Lu, B. Heat Treatment Optimization of 2219 Aluminum Alloy Fabricated by Wire-Arc Additive Manufacturing. Coatings 2023, 13, 610. [Google Scholar] [CrossRef]

- Qi, Q.; Li, M.; Duan, Y.; Bu, H.; Li, M. Effect of Solution Heat Treatment on the Microstructure and Microhardness of 7050 Aluminum Alloy. Metals 2023, 13, 1819. [Google Scholar] [CrossRef]

- Arslankaya, S. Estimating the effects of heat treatment on aluminum alloy with artificial neural networks. Emerg. Mater. Res. 2020, 9, 540–549. [Google Scholar]

- Niu, X.; Chen, Z.; Jing, L.; Huang, Y.; Liu, Y. Effect of Cryogenic Treatment on Residual Stress and Microstructure of 6061 Aluminum Alloy and Optimization of Parameters. Materials 2024, 17, 4873. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.X.; Qu, S.M. Influence of overburning on microstructure and property of 6061 aluminum alloy. In New Materials and Processes, 2nd ed.; Chen, W.Z., Li, Q., Chen, Y.L., Dai, P.Q., Jiang, Z.Y., Eds.; Trans Tech Publications Inc.: Zurich, Switzerland, 2012; Volume 476–478, pp. 118–121. [Google Scholar]

- Chen, W.; Guan, Y.; Wang, Z. Modeling of Flow Stress of High Titanium Content 6061 Aluminum Alloy Under Hot Compression. J. Mater. Eng. Perform. 2016, 25, 4081–4088. [Google Scholar] [CrossRef]

- Khamei, A.A.; Dehghani, K. Effects of strain rate and temperature on hot tensile deformation of severe plastic deformed 6061 aluminum alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 627, 1–9. [Google Scholar] [CrossRef]

- Rudnytskyj, A.; Simon, P.; Jech, M.; Gachot, C. Constitutive modelling of the 6061 aluminium alloy under hot rolling conditions and large strain ranges. Mater. Des. 2020, 190, 108568. [Google Scholar] [CrossRef]

- Yan, J.B.; Kong, G.B.; Zhang, L.X. Low-temperature tensile behaviours of 6061-T6 aluminium alloy: Tests, analysis, and numerical simulation. Structures 2023, 56, 105054. [Google Scholar] [CrossRef]

| Mg | Si | Mn | Fe | Cu | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.97 | 0.13 | 0.12 | 0.56 | 0.27 | 0.12 | 0.08 | 0.023 | Balance |

| Level | A. Solution Temperature /°C | B. Solution Time /min | C. Aging Temperature /°C | D. Aging Time /h |

|---|---|---|---|---|

| 1 | 510 | 30 | 150 | 1 |

| 2 | 525 | 60 | 160 | 2 |

| 3 | 540 | 90 | 170 | 4 |

| 4 | 555 | 120 | 180 | 8 |

| 5 | 570 | 150 | 190 | 16 |

| Strain Rate (s−1) | Direction | Yield Strength σs (MPa) | Tensile Strength σb (MPa) | Elongation Rate Δ (%) |

|---|---|---|---|---|

| 0.05 | RD | 347 | 395 | 9.0 |

| ST | 306 | 355 | 7.9 | |

| LT | 321 | 378 | 9.8 | |

| 0.01 | RD | 346 | 395 | 10.9 |

| ST | 312 | 357 | 7.4 | |

| LT | 334 | 378 | 10.5 | |

| 0.001 | RD | 345 | 391 | 10.4 |

| ST | 345 | 355 | 7.4 | |

| LT | 310 | 367 | 8.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Fan, Z.; Luo, Z.; Hu, G.; Zhang, H. Impact of Heat Treatment Parameters on the Plastic Properties of 6061 Aluminum Alloy. Materials 2025, 18, 1705. https://doi.org/10.3390/ma18081705

Jia X, Fan Z, Luo Z, Hu G, Zhang H. Impact of Heat Treatment Parameters on the Plastic Properties of 6061 Aluminum Alloy. Materials. 2025; 18(8):1705. https://doi.org/10.3390/ma18081705

Chicago/Turabian StyleJia, Xiangdong, Zhenyu Fan, Zhan Luo, Gang Hu, and Hongyao Zhang. 2025. "Impact of Heat Treatment Parameters on the Plastic Properties of 6061 Aluminum Alloy" Materials 18, no. 8: 1705. https://doi.org/10.3390/ma18081705

APA StyleJia, X., Fan, Z., Luo, Z., Hu, G., & Zhang, H. (2025). Impact of Heat Treatment Parameters on the Plastic Properties of 6061 Aluminum Alloy. Materials, 18(8), 1705. https://doi.org/10.3390/ma18081705