Mechanical Response and Microstructure Evolution of TA1 Titanium Under Normal Ultrasonic Vibration Processing

Abstract

:1. Introduction

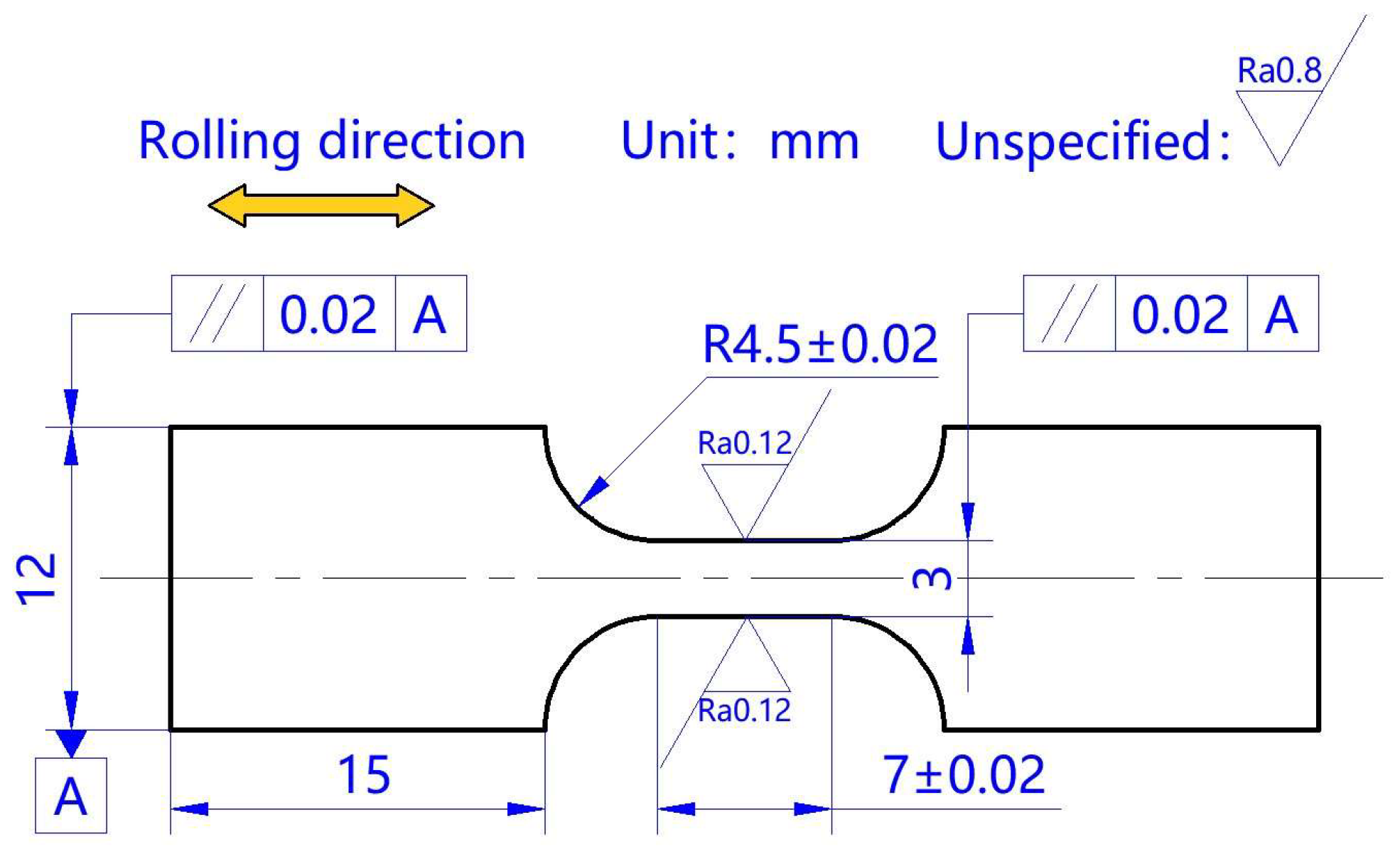

2. Materials and Methods

2.1. Material Preparation

2.2. Experimental Setup

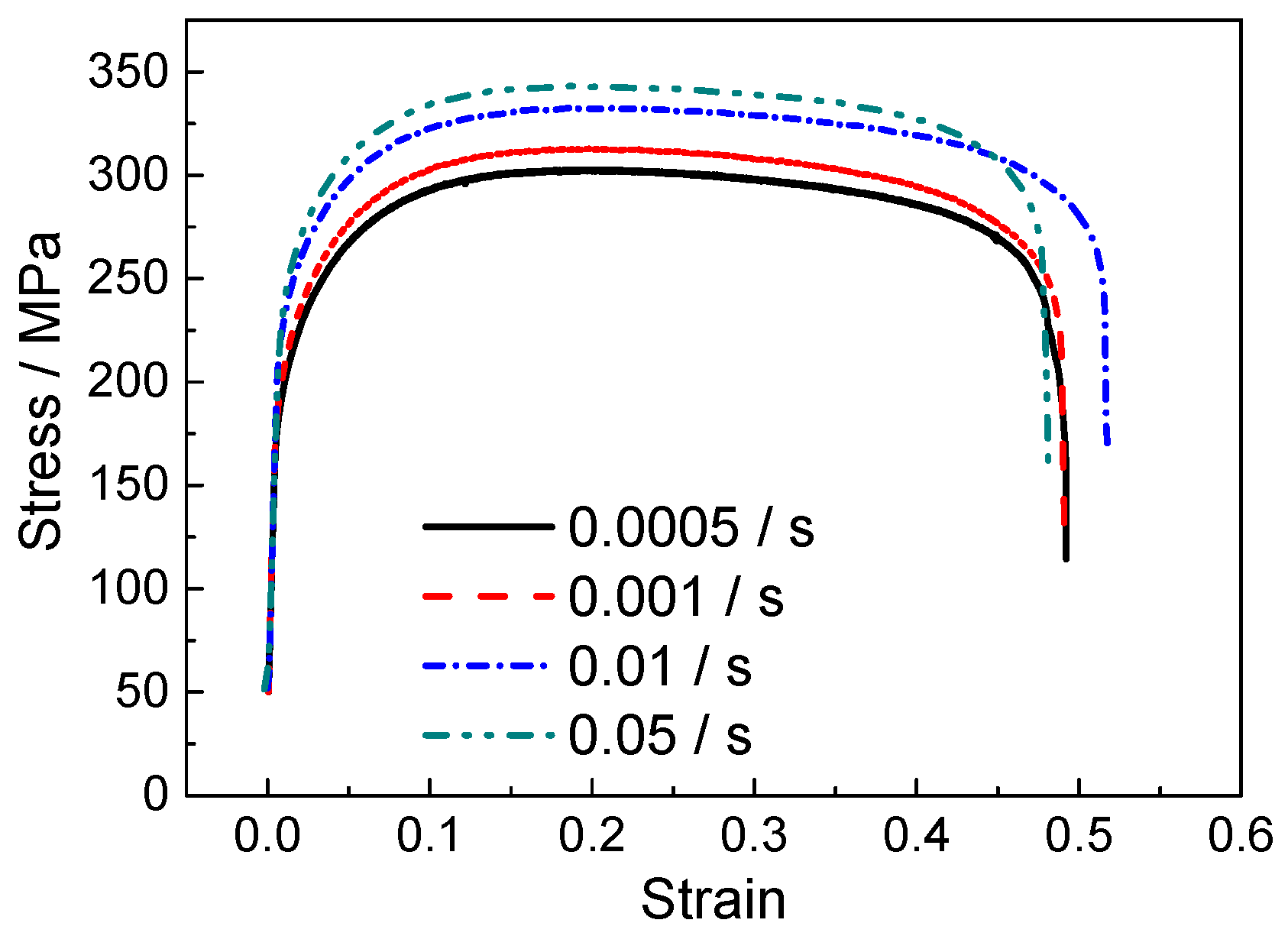

2.3. Experimental Scheme

3. Results and Discussion

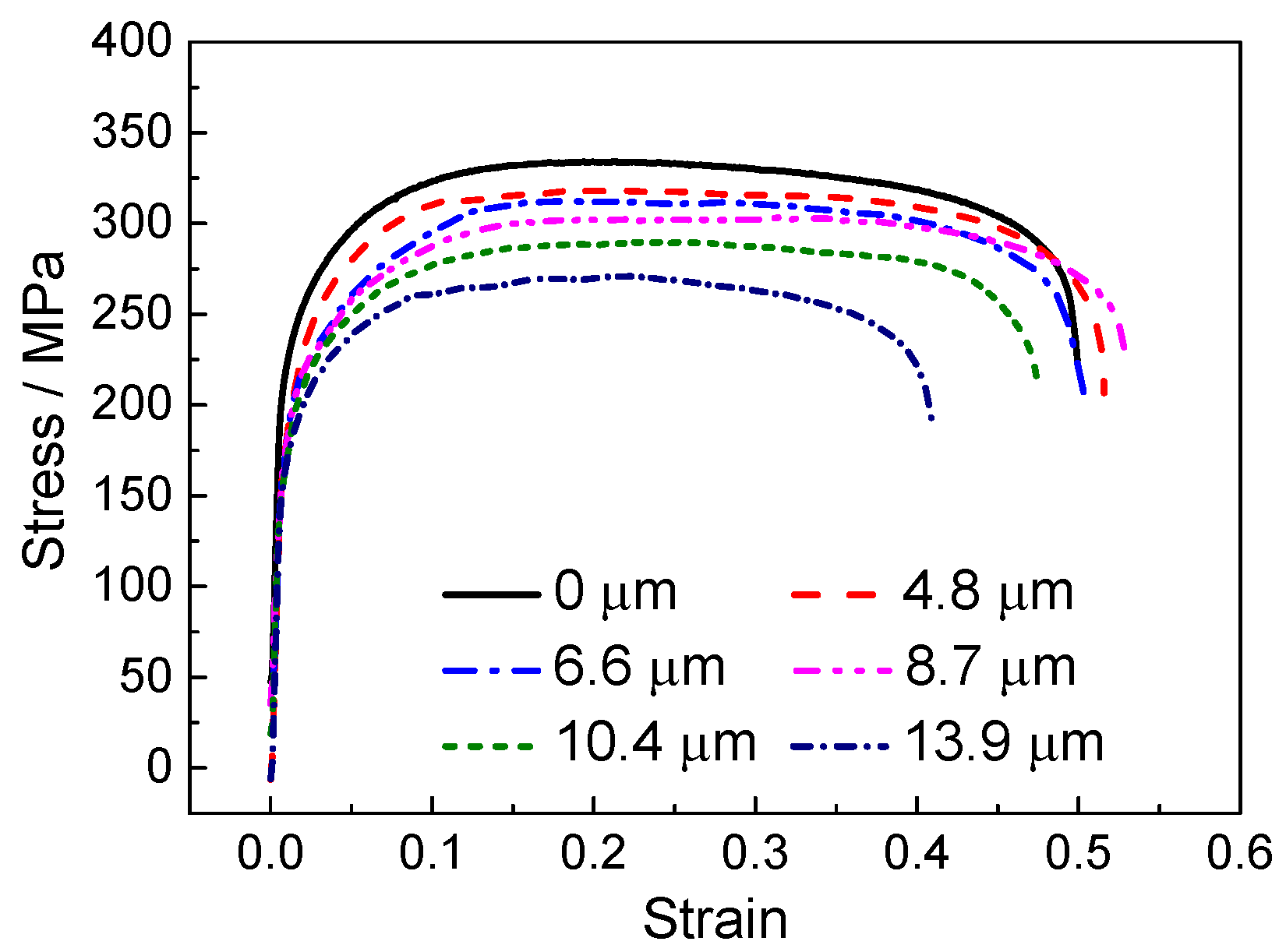

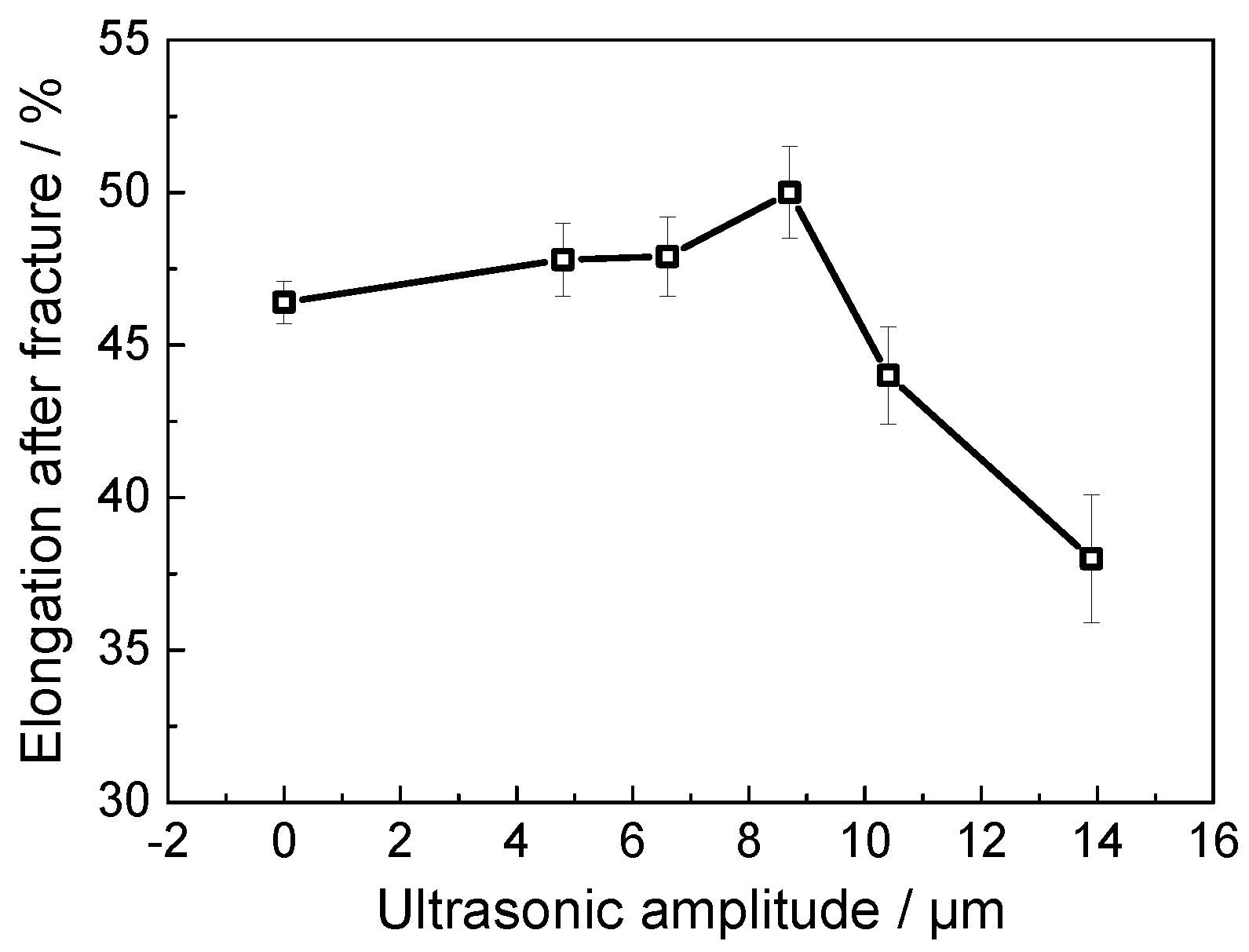

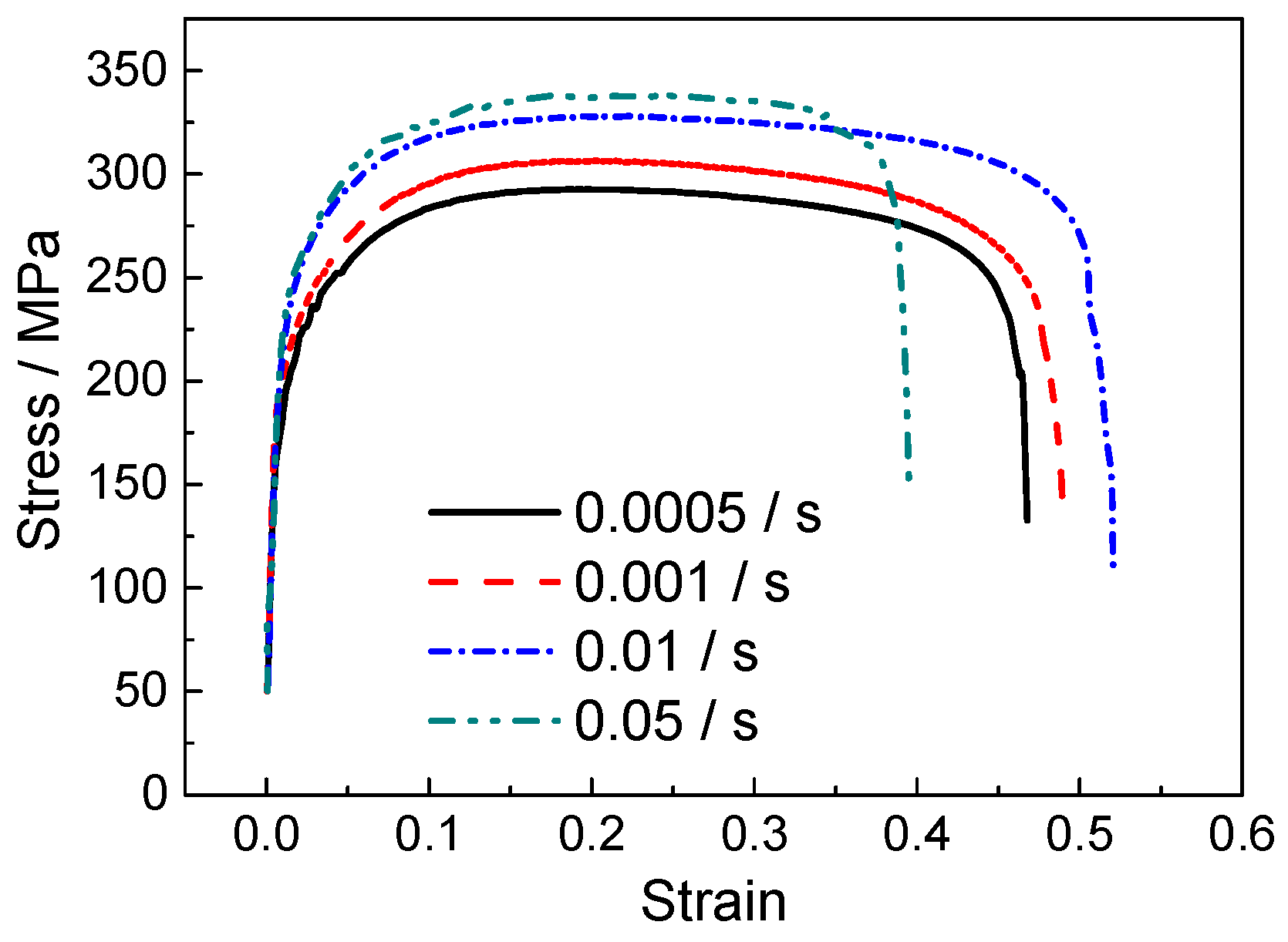

3.1. Acoustic Softening Effect

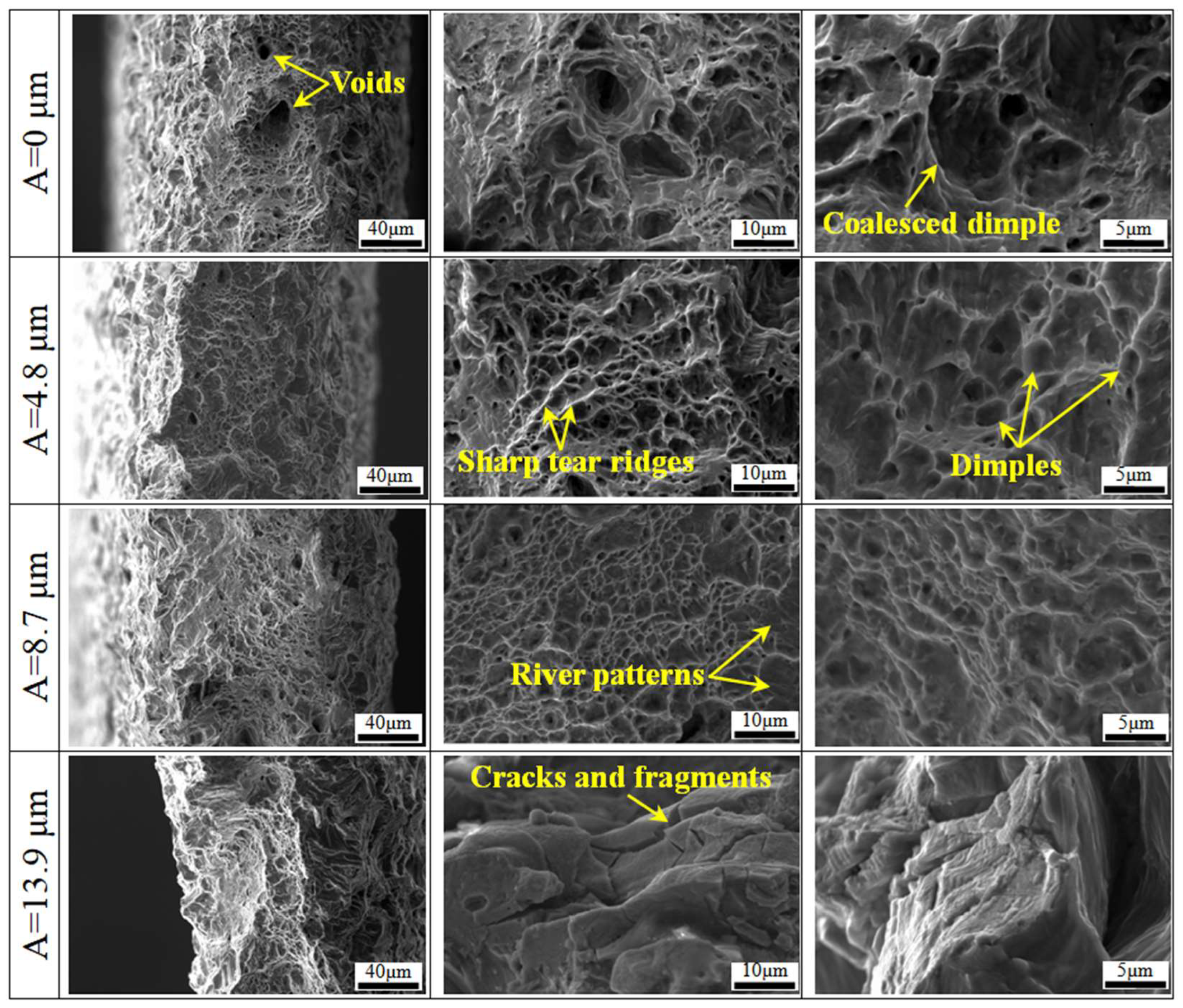

3.2. Fracture Morphologies

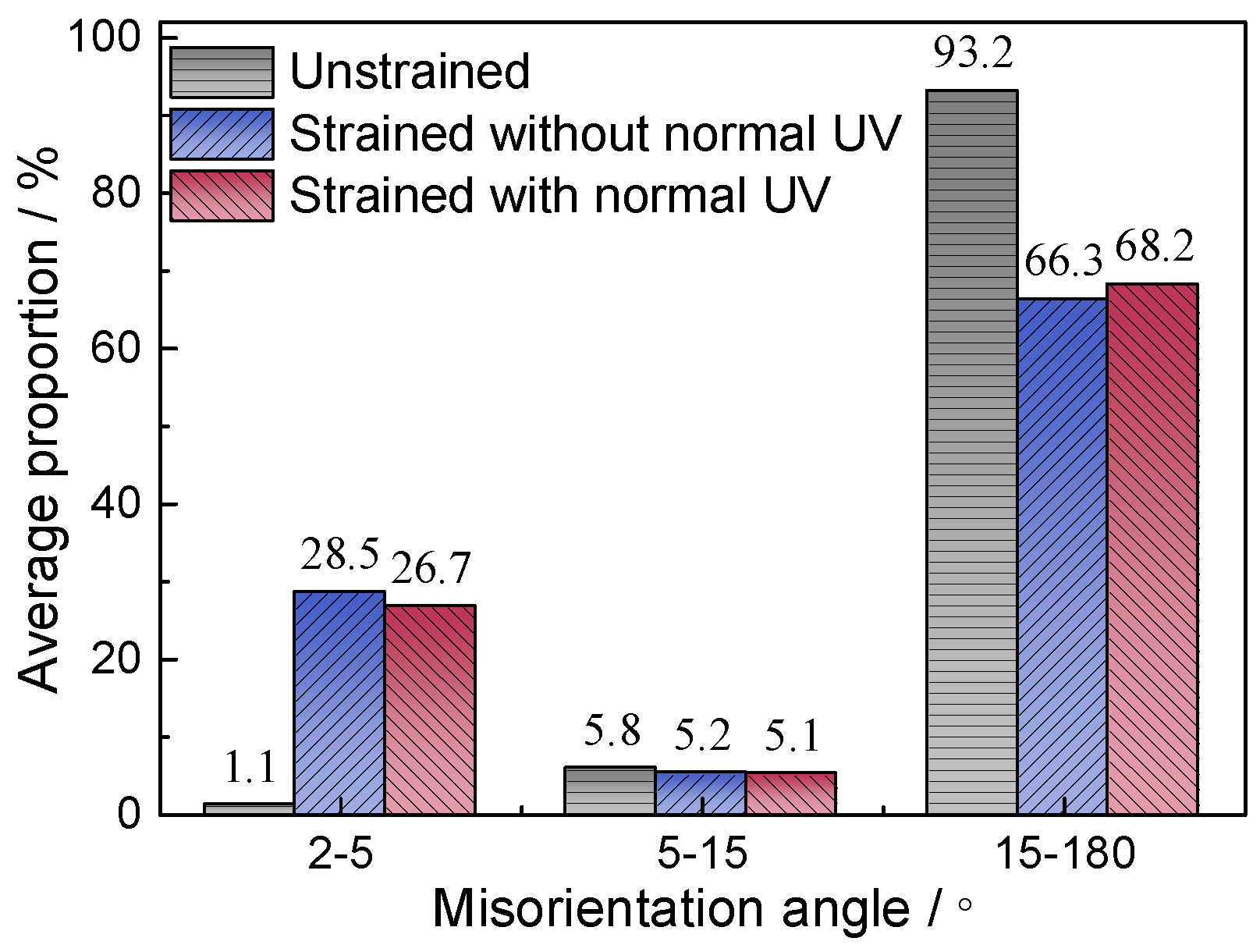

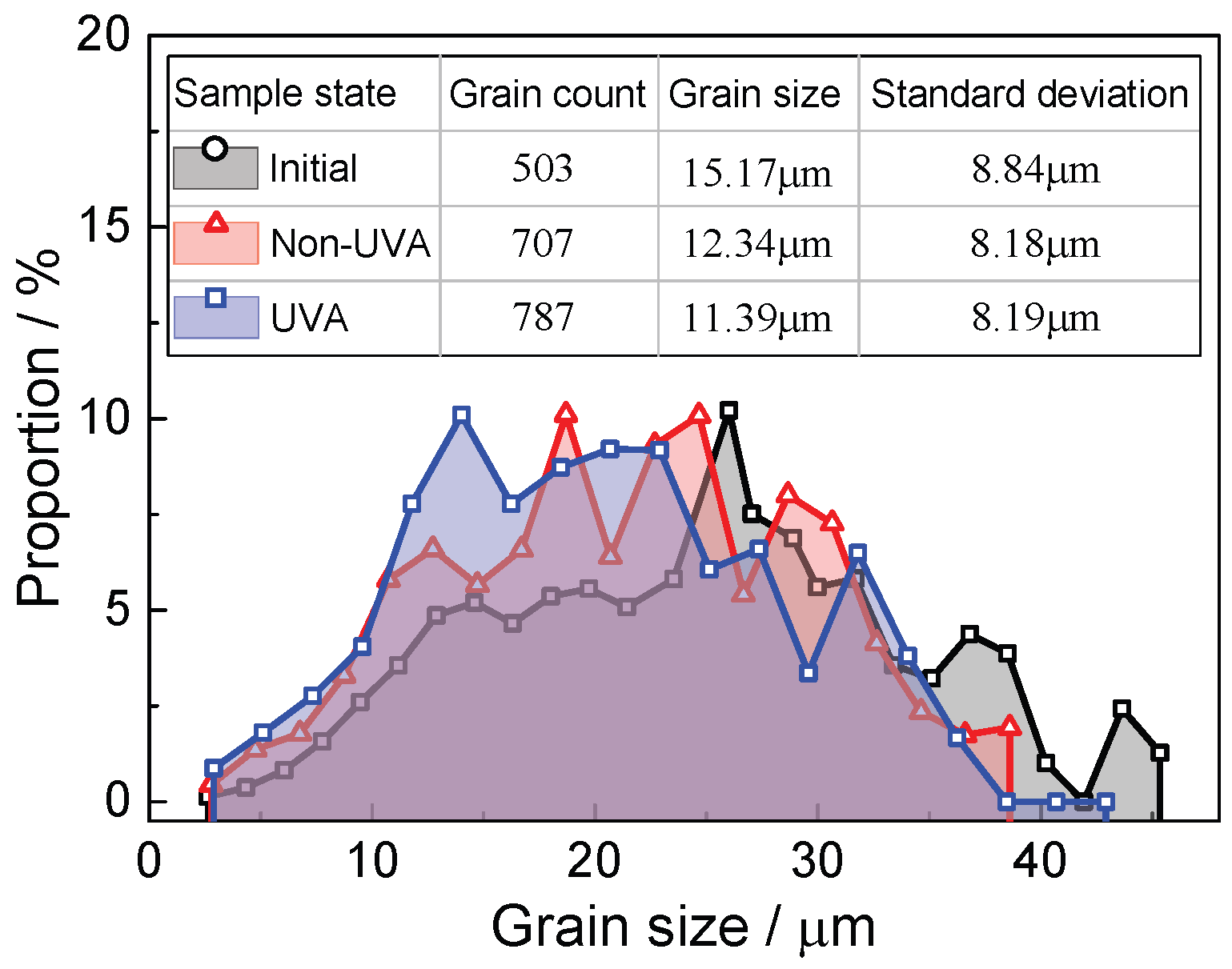

3.3. Microstructure Characterization

4. Conclusions

- Based on normal UV-assisted uniaxial tensile testing, the acoustic softening effect increases with increasing the ultrasonic amplitude from 4.8 μm to 13.9 μm, while the elongation shows a maximum value of 50% at an ultrasonic amplitude of 8.7 μm.

- Combined with the elongation results, fracture morphologies obtained from SEM show that the fracture mode of the TA1 changes from ductile fracture to brittle fracture with increasing ultrasonic amplitude.

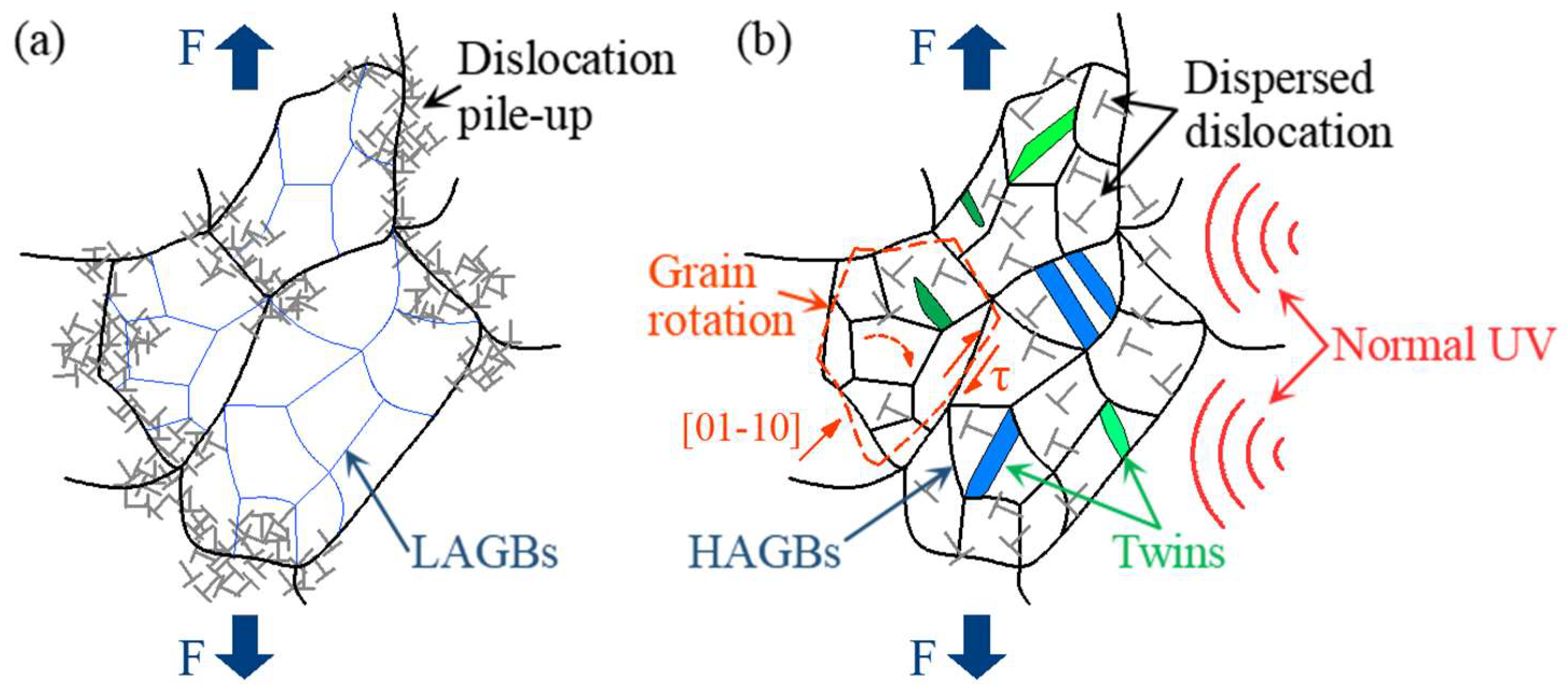

- Instead of stress superposition, acoustoplasticity is considered the only deformation mechanism for the TA1 titanium sheet under normal UV.

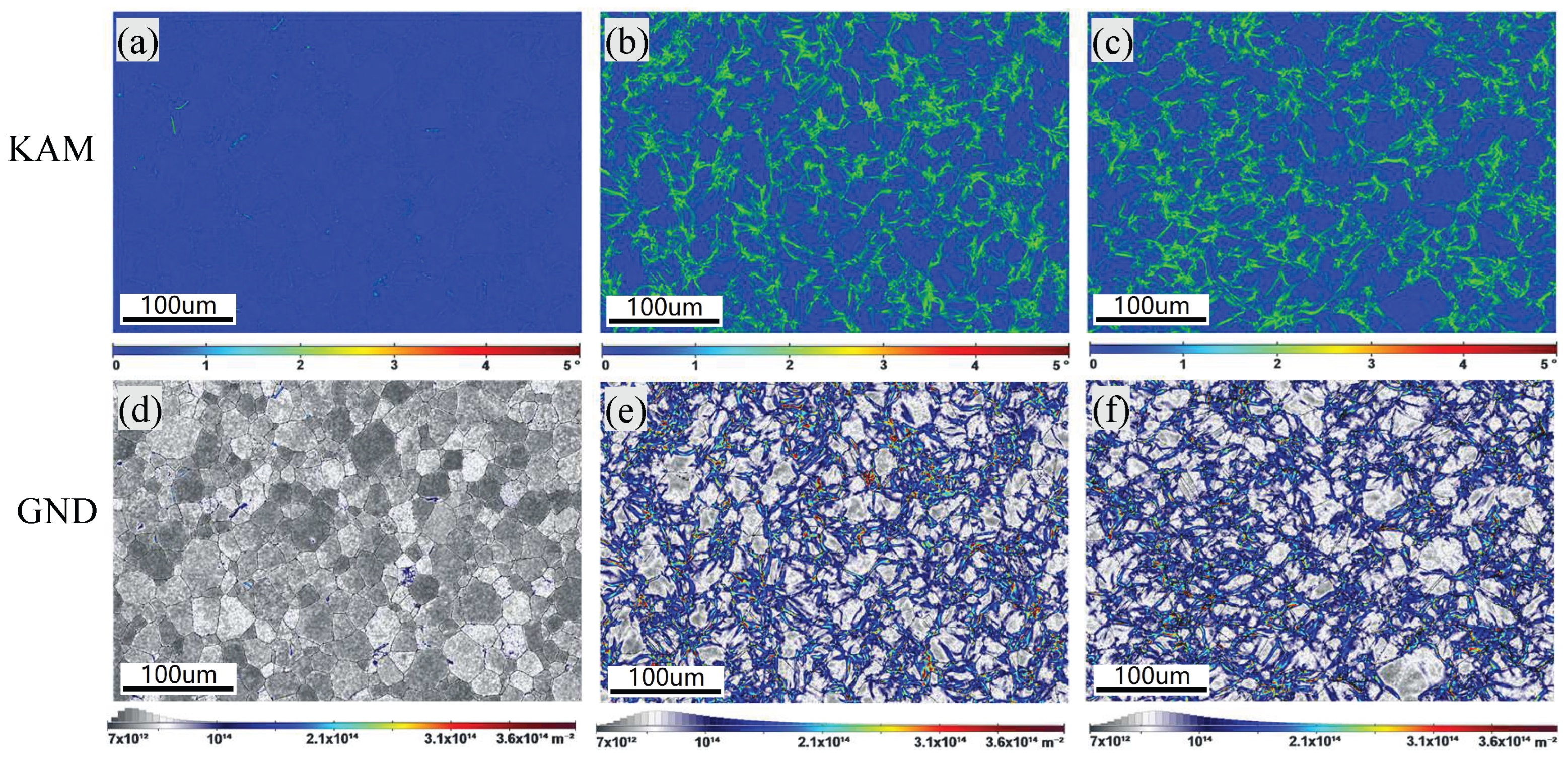

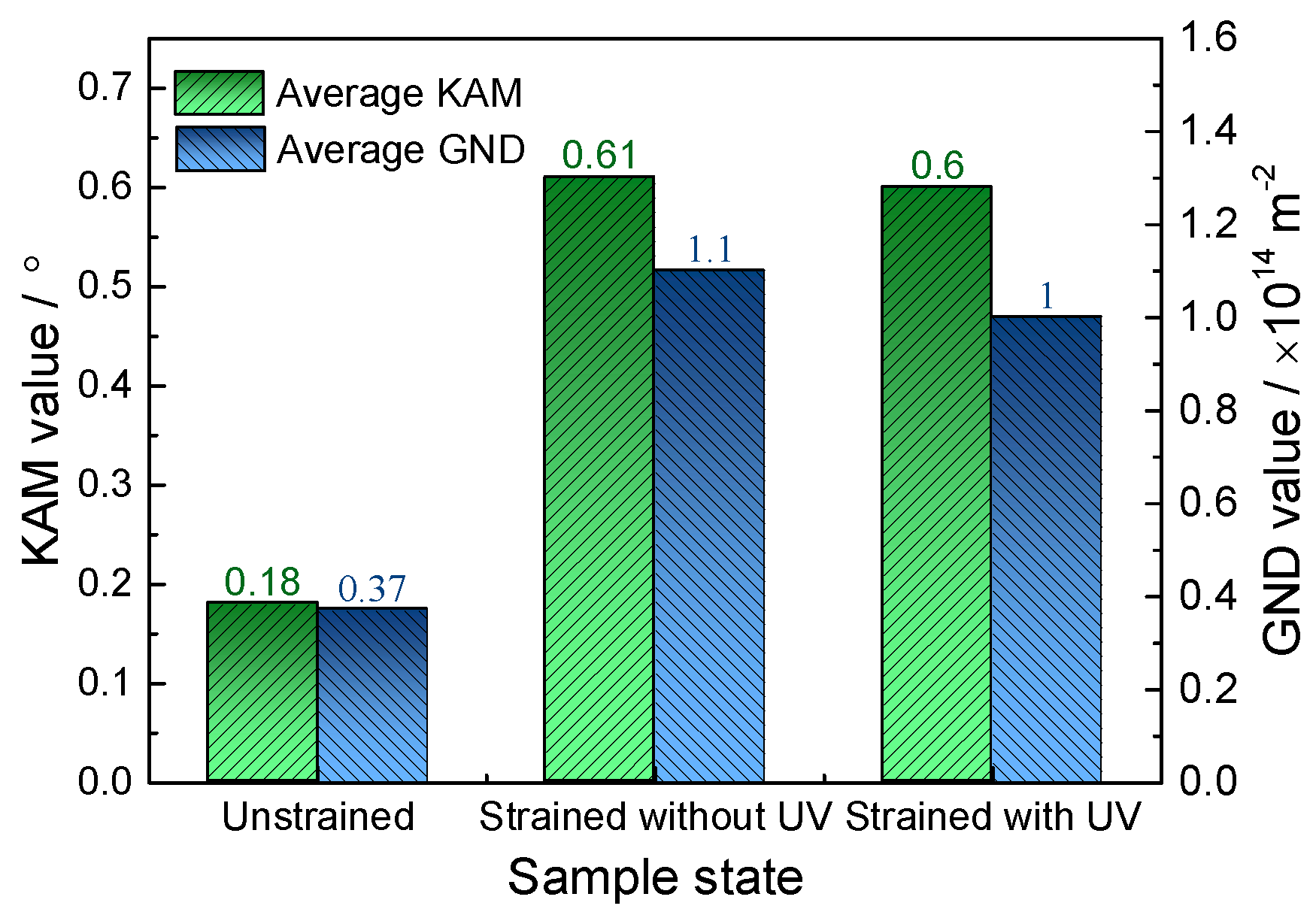

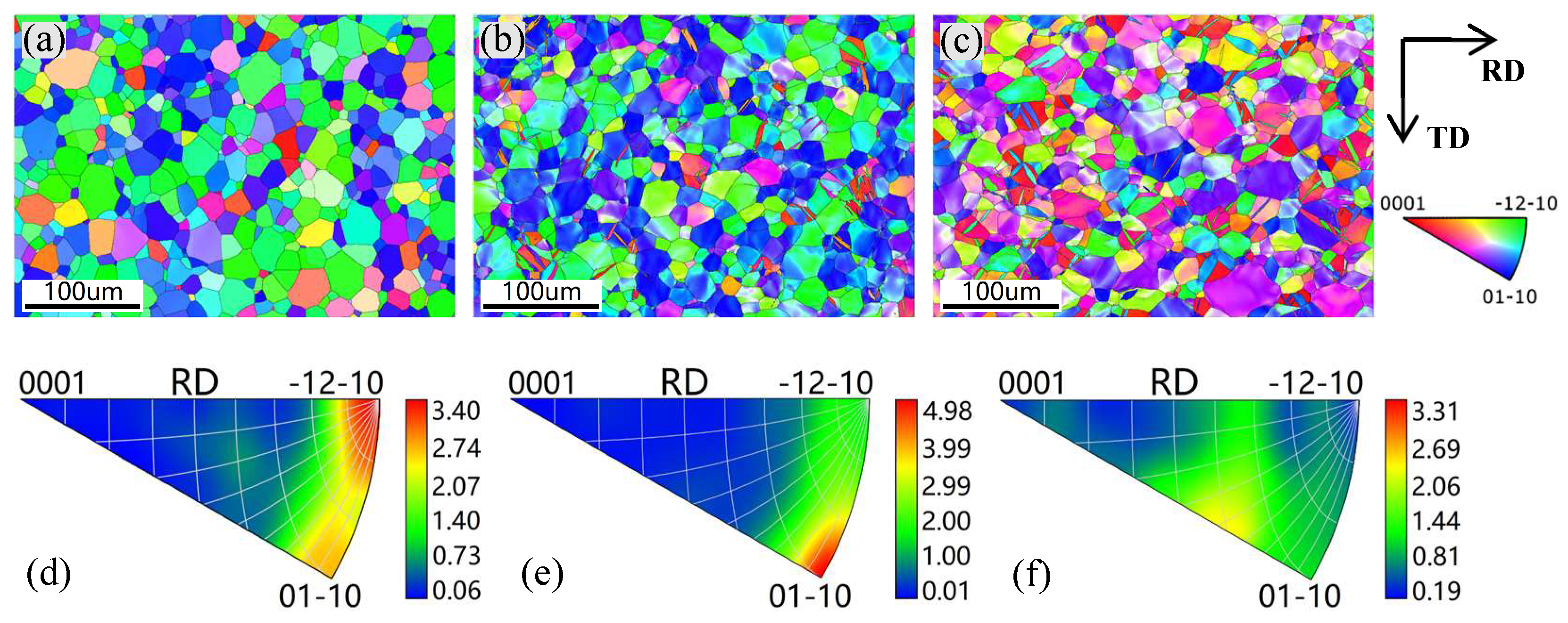

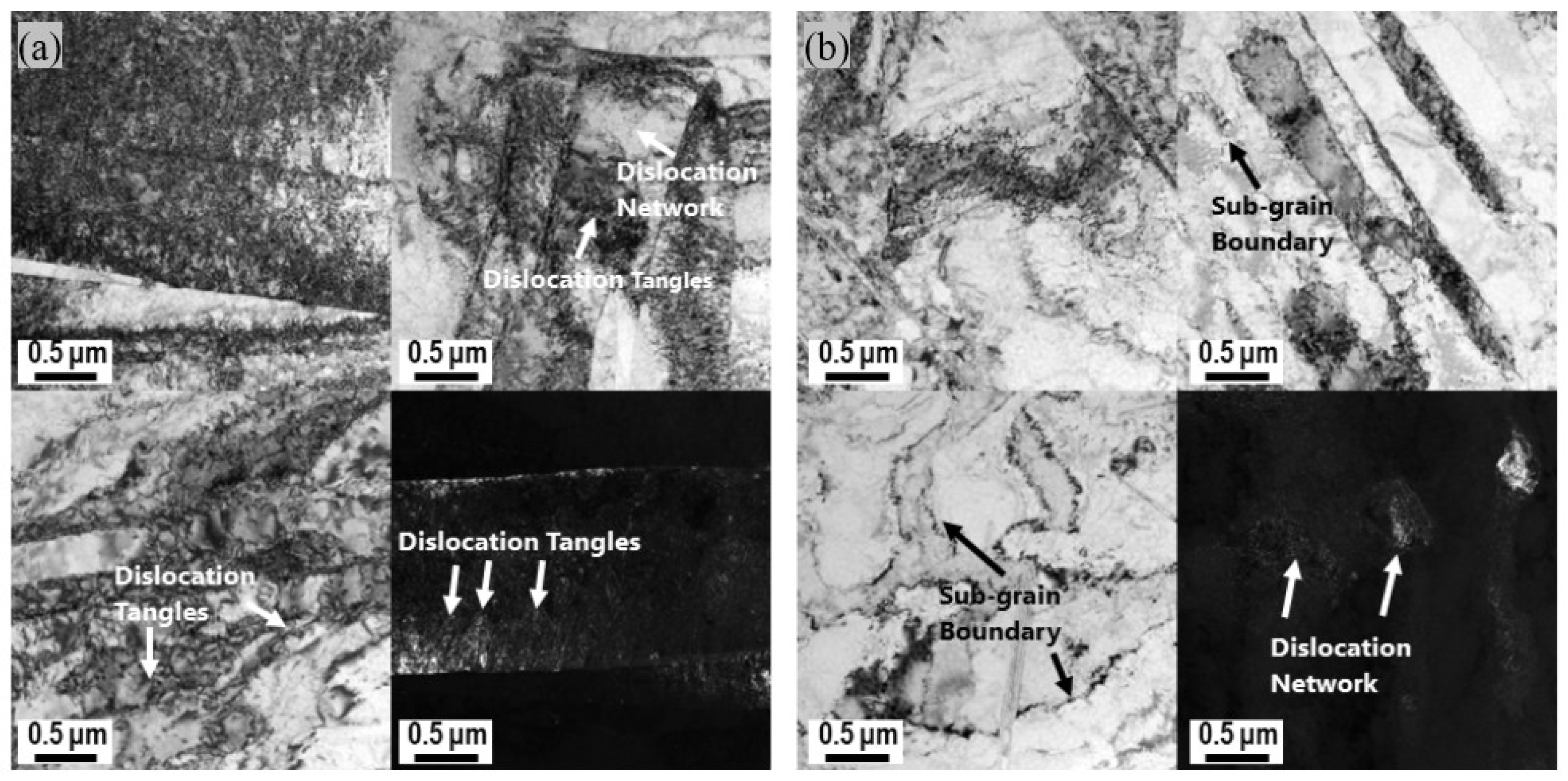

- EBSD and TEM observations show that superimposed normal UV can lead to grain refinement and a decrease in LAGB proportion and KAM and GND density, resulting in homogeneous plastic deformation and flow stress reduction.

- The IPFs reveal that the texture intensity decreases from 4.98 to 3.31 when normal UV is superimposed. Concurrently, the proportion of Σ3 twin boundaries significantly increases from 5.75% to 25.1%, suggesting enhanced activation of multiple slip systems and additional plastic deformation mechanisms, such as twinning and grain rotation, contributing to improved deformation uniformity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meng, B.; Cao, B.N.; Wan, M.; Xu, J.; Shan, D.B. Ultrasonic-assisted microforming of superalloy capillary: Modeling and experimental investigation. J. Manuf. Process. 2020, 57, 589–599. [Google Scholar] [CrossRef]

- Wang, C.J.; Cheng, L.D.; Liu, Y.; Zhu, C.Q. Ultrasonic flexible bulging process of spherical caps array as surface texturing using aluminum alloy 5052 ultra-thin sheet. J. Mater. Process. Technol. 2020, 284, 116725. [Google Scholar] [CrossRef]

- Ngaile, G.; Bunget, C. Influence of ultrasonic vibration on micro extrusion. Ultrasonics 2011, 5, 606–616. [Google Scholar]

- Liu, Y.; Wang, C.J.; Han, H.B.; Shan, D.B.; Guo, B. Investigation on effect of ultrasonic vibration on micro-blanking process of copper foil. Int. J. Adv. Manuf. Technol. 2017, 93, 2243–2249. [Google Scholar] [CrossRef]

- Yin, Z.D.; Wan, W.Q.; Yang, M. An evaluation of the impact effect on the surface microstructure and its induced temperature changes during ultrasonic-assisted micro-forging. Materials 2024, 17, 4123. [Google Scholar] [CrossRef]

- Qu, Y.Y.; Fang, Q.Y.; Zhao, L.; Guo, Z.X. Microstructure and properties of ultrasonic-assisted gallium-based alloys for room-temperature bonding of Cu/Cu. Phil. Mag. Lett. 2023, 103, 2230955. [Google Scholar]

- Yu, M.R.; Nan, X.C.; Zhou, L.; Xu, F.; Zhao, H.Y.; Song, X.G. Ultrasonic-induced amorphization and strengthening mechanisms of ultrasonic vibrations assisted friction stir Al/Ti welds. Mater. Des. 2024, 246, 113313. [Google Scholar] [CrossRef]

- Ji, F.L.; Hu, Z.Q.; Qin, X.P.; Ni, M.; Xiong, X.C.; Liu, G.C. Improving microstructure and mechanical properties of thin-wall part fabricated by wire arc additive manufacturing assisted with high-intensity ultrasound. J. Mater. Sci. 2023, 58, 2381–2395. [Google Scholar] [CrossRef]

- Gao, T.J.; Wang, X.; Yang, Y.; Lu, H.T.; Wang, K.X. Effect of compound energy-field with temperature and ultrasonic vibration on bending properties of 2195 Al-Li alloy. Rare Met. Mater. Eng. 2022, 4, 1226–1230. [Google Scholar]

- Daud, Y.; Lucas, M.; Huang, Z. Modelling the effects of superimposed ultrasonic vibrations on tension and compression tests of aluminium. J. Mater. Process. Technol. 2007, 186, 179–190. [Google Scholar] [CrossRef]

- Yao, Z.H.; Kim, G.Y.; Wang, Z.H.; Faidley, L.A.; Zou, Q.Z.; Mei, D.Q.; Chen, Z.C. Acoustic softening and residual hardening in aluminum: Modeling and experiments. Int. J. Plast. 2012, 39, 75–87. [Google Scholar] [CrossRef]

- Wang, C.J.; Liu, Y.; Guo, B.; Shan, D.B.; Zhang, B. Acoustic softening and stress superposition in ultrasonic vibration assisted uniaxial tension of copper foil: Experiments and modeling. Mater. Des. 2016, 112, 246–253. [Google Scholar] [CrossRef]

- Wang, X.W.; Wang, C.J.; Liu, Y.; Liu, C.; Wang, Z.L.; Guo, B.; Shan, D.B. An energy based modeling for the acoustic softening effect on the Hall-Petch behavior of pure titanium in ultrasonic vibration assisted micro-tension. Int. J. Plast. 2021, 136, 102879. [Google Scholar] [CrossRef]

- Siddiq, A.; Sayed, T.E. A thermomechanical crystal plasticity constitutive model for ultrasonic consolidation. Comp. Mater. Sci. 2012, 51, 241–251. [Google Scholar] [CrossRef]

- Kelly, G.S.; Advani, S.G.; Gillespie, J.W., Jr.; Bogetti, T.A. A model to characterize acoustic softening during ultrasonic consolidation. J. Mater. Process. Technol. 2013, 213, 1835–1845. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, C.J.; Bi, R.G. Acoustic residual softening and microstructure evolution of T2 copper foil in ultrasonic vibration assisted micro-tension. Mater. Sci. Eng. A 2022, 841, 143044. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Cui, H.Z.; Qin, Q.H. Influence of ultrasonic vibration on the plasticity of metals during compression process. J. Mater. Process. Technol. 2018, 251, 146–159. [Google Scholar] [CrossRef]

- Lum, I.; Huang, H.; Chang, B.H.; Mayer, M.; Du, D.; Zhou, Y. Effects of superimposed ultrasound on deformation of gold. J. Appl. Phys. 2009, 105, 024905. [Google Scholar] [CrossRef]

- Dutta, R.K.; Petrov, R.H.; Delhez, R.; Hermans, M.J.M.; Richardson, I.M.; Böttger, A.J. The effect of tensile deformation by in situ ultrasonic treatment on the microstructure of low-carbon steel. Acta Mater. 2013, 61, 1592–1602. [Google Scholar] [CrossRef]

- Siu, K.W.; Ngan, A.H.W. Oscillation-induced softening in copper and molybdenum from nano-to micro-length scales. Mater. Sci. Eng. A 2013, 572, 56–64. [Google Scholar] [CrossRef]

- Cheng, B.; Leung, H.S.; Ngan, A.H.W. Strength of metals under vibrations dislocation-density-function dynamics simulations. Philos. Mag. 2015, 95, 1845–1865. [Google Scholar] [CrossRef]

- ASTM E112; Standard Test Methods for Determining Average Grain Size. ASTM: West Conshehoken, PA, USA, 2021.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

- GB/T 3620.1-2016; Standardization Administration of China. Titanium and Titanium Alloys—Designation and Chemical Composition. China Standards Press: Beijing, China, 2016.

- Meng, B.; Cao, B.N.; Wan, M.; Wang, C.J.; Shan, D.B. Constitutive behavior and microstructural evolution in ultrasonic vibration assisted deformation of ultrathin superalloy sheet. Int. J. Mech. Sci. 2019, 157–158, 609–618. [Google Scholar] [CrossRef]

- Beausir, B.; Fundenberger, J.J. ATEX-Software; Université de Lorraine: Metz, France, 2017; Available online: www.atex-software.eu (accessed on 28 November 2023).

- Siu, K.W.; Ngan, A.H.W.; Jones, I. New insight on acoustoplasticity-ultrasonic irradiation enhances sub-grain formation during deformation. Int. J. Plast. 2011, 5, 788–800. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y.T.; Chen, M.W.; Ma, E. Twinning and stacking fault formation during tensile deformation of nanocrystalline Ni. Scr. Mater. 2006, 54, 1685–1690. [Google Scholar] [CrossRef]

- Li, Y.X.; Wang, L.; An, R.; Zhao, P.L.; Yan, Z.W.; Cheng, H.W.; Cheng, X.W. Deformation behavior of Ti-6Al-3Nb-2Zr-1Mo titanium alloy at low temperatures and high strain rates. Rare Met. Mater. Eng. 2022, 51, 4369–4375. [Google Scholar]

- Das, A. Ultrasonic-assisted fracture appearance of titanium. J. Mater. Eng. Perform. 2024, 33, 1485–1494. [Google Scholar] [CrossRef]

| Ti | Fe | C | N | H | O |

|---|---|---|---|---|---|

| ≥99.50 | ≤0.25 | ≤0.10 | ≤0.03 | ≤0.015 | ≤0.20 |

| Group | Amplitude (μm) | Duration (s) | Tensile Speed (mm·min−1) | Strain Rate (s−1) |

|---|---|---|---|---|

| 1 (Amplitude) | 4.8 | Throughout | 5 | 0.012 |

| 6.6 | ||||

| 8.7 | ||||

| 10.4 | ||||

| 13.9 | ||||

| 2 (Strain rate) | 4.8 | Throughout/ None | 0.21 | 0.0005 |

| 0.42 | 0.001 | |||

| 4.2 | 0.01 | |||

| 21 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, C.; Zeng, H.; Liu, X.; Song, X.; Zhang, Z.; Liu, S.; Li, J. Mechanical Response and Microstructure Evolution of TA1 Titanium Under Normal Ultrasonic Vibration Processing. Materials 2025, 18, 1712. https://doi.org/10.3390/ma18081712

Liu Y, Wang C, Zeng H, Liu X, Song X, Zhang Z, Liu S, Li J. Mechanical Response and Microstructure Evolution of TA1 Titanium Under Normal Ultrasonic Vibration Processing. Materials. 2025; 18(8):1712. https://doi.org/10.3390/ma18081712

Chicago/Turabian StyleLiu, Yang, Chunju Wang, Haolan Zeng, Xiaoye Liu, Xinhua Song, Zhifang Zhang, Siyuan Liu, and Jian Li. 2025. "Mechanical Response and Microstructure Evolution of TA1 Titanium Under Normal Ultrasonic Vibration Processing" Materials 18, no. 8: 1712. https://doi.org/10.3390/ma18081712

APA StyleLiu, Y., Wang, C., Zeng, H., Liu, X., Song, X., Zhang, Z., Liu, S., & Li, J. (2025). Mechanical Response and Microstructure Evolution of TA1 Titanium Under Normal Ultrasonic Vibration Processing. Materials, 18(8), 1712. https://doi.org/10.3390/ma18081712