Cost-Effective Inorganic Multilayer Film for High-Performance Daytime Radiative Cooling

Abstract

1. Introduction

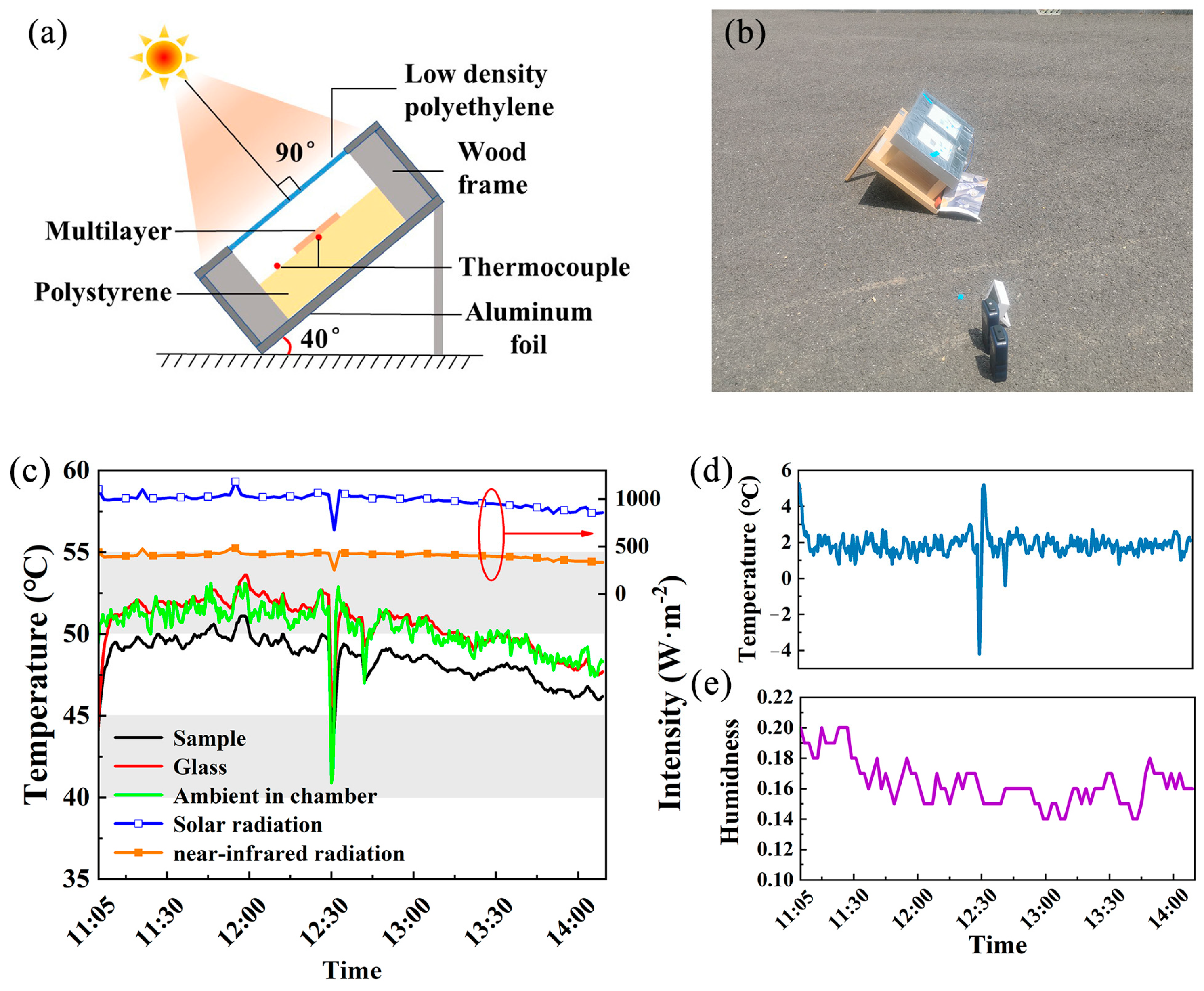

2. Materials and Methods

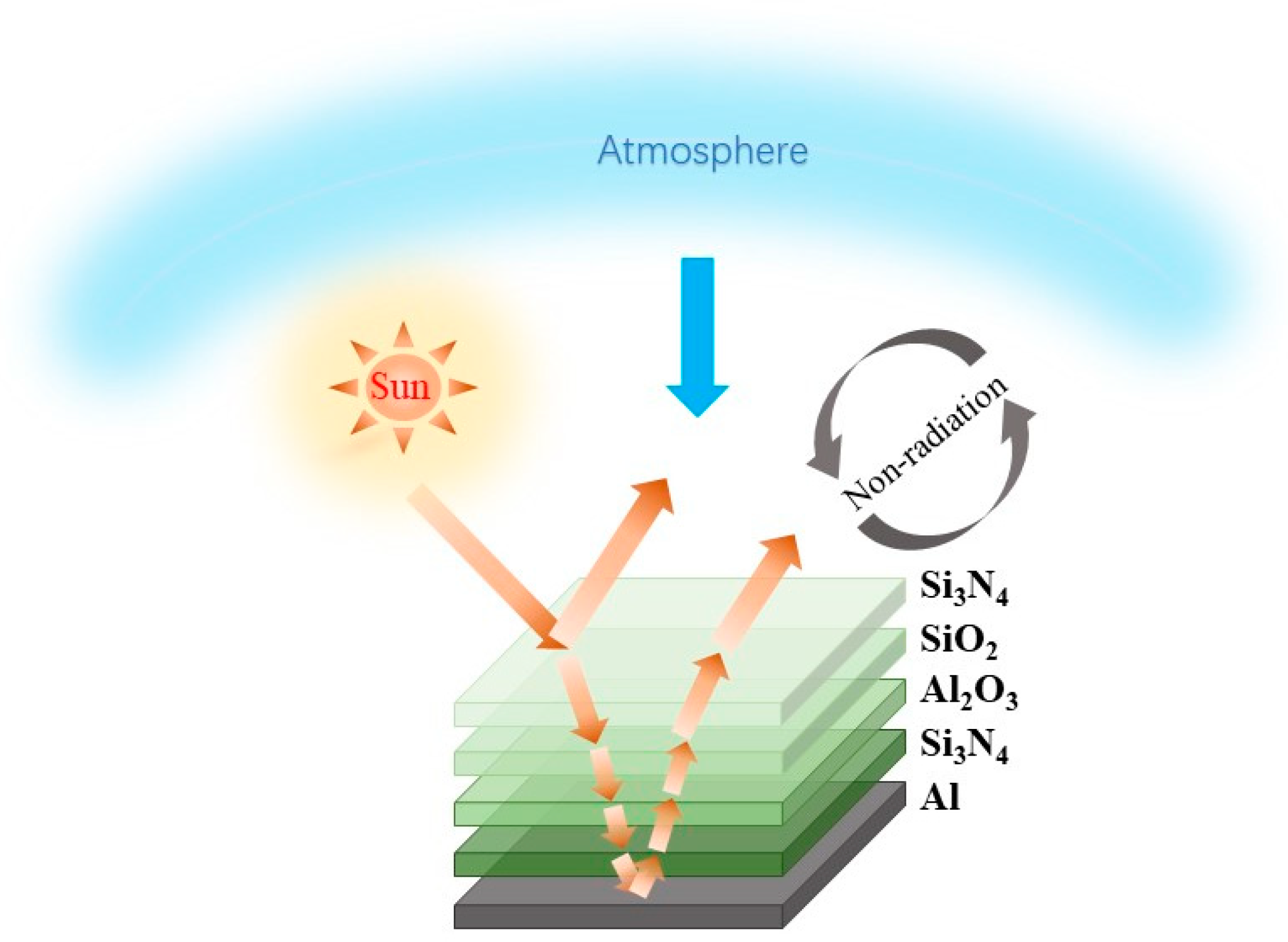

3. Results and Discussion

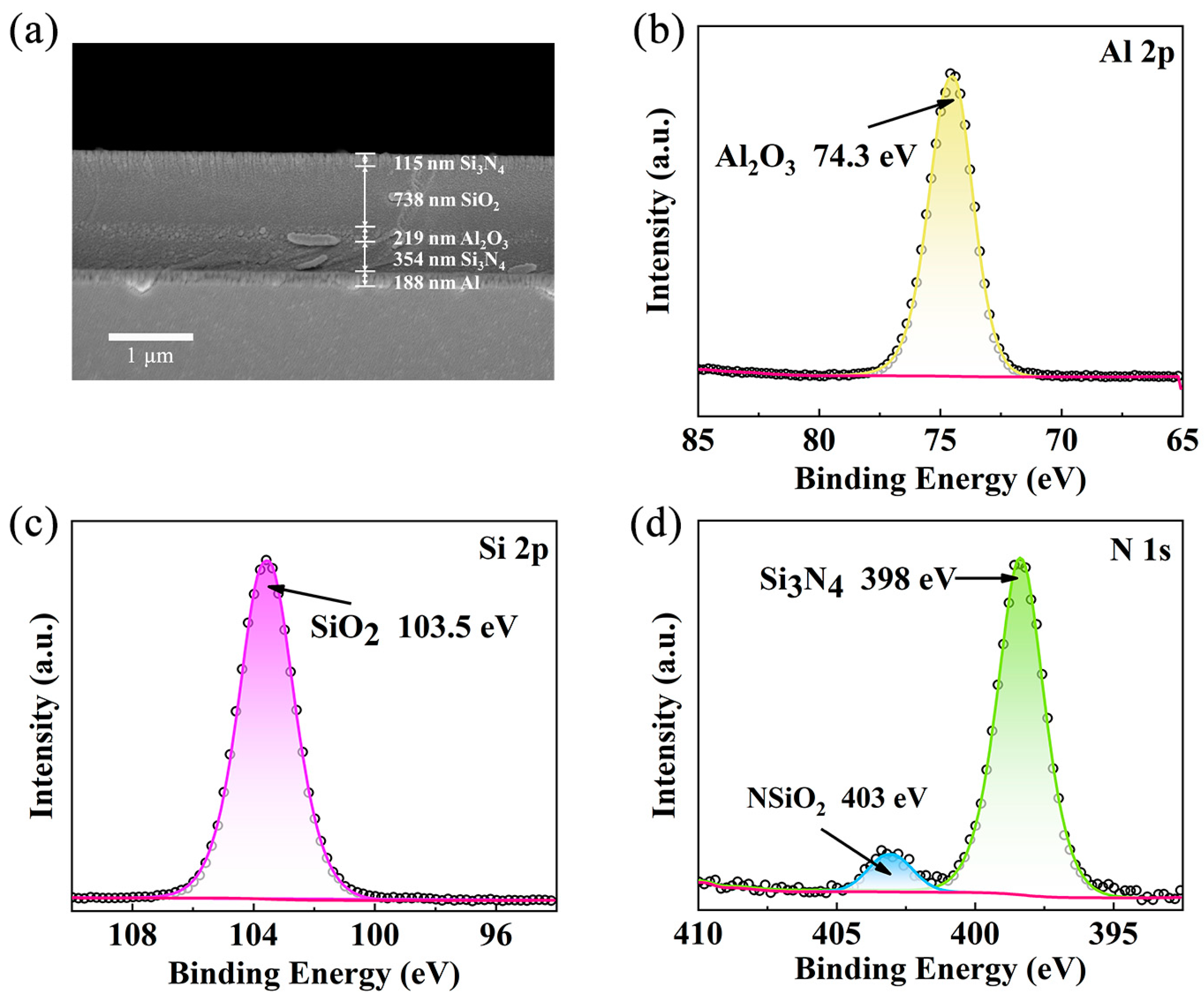

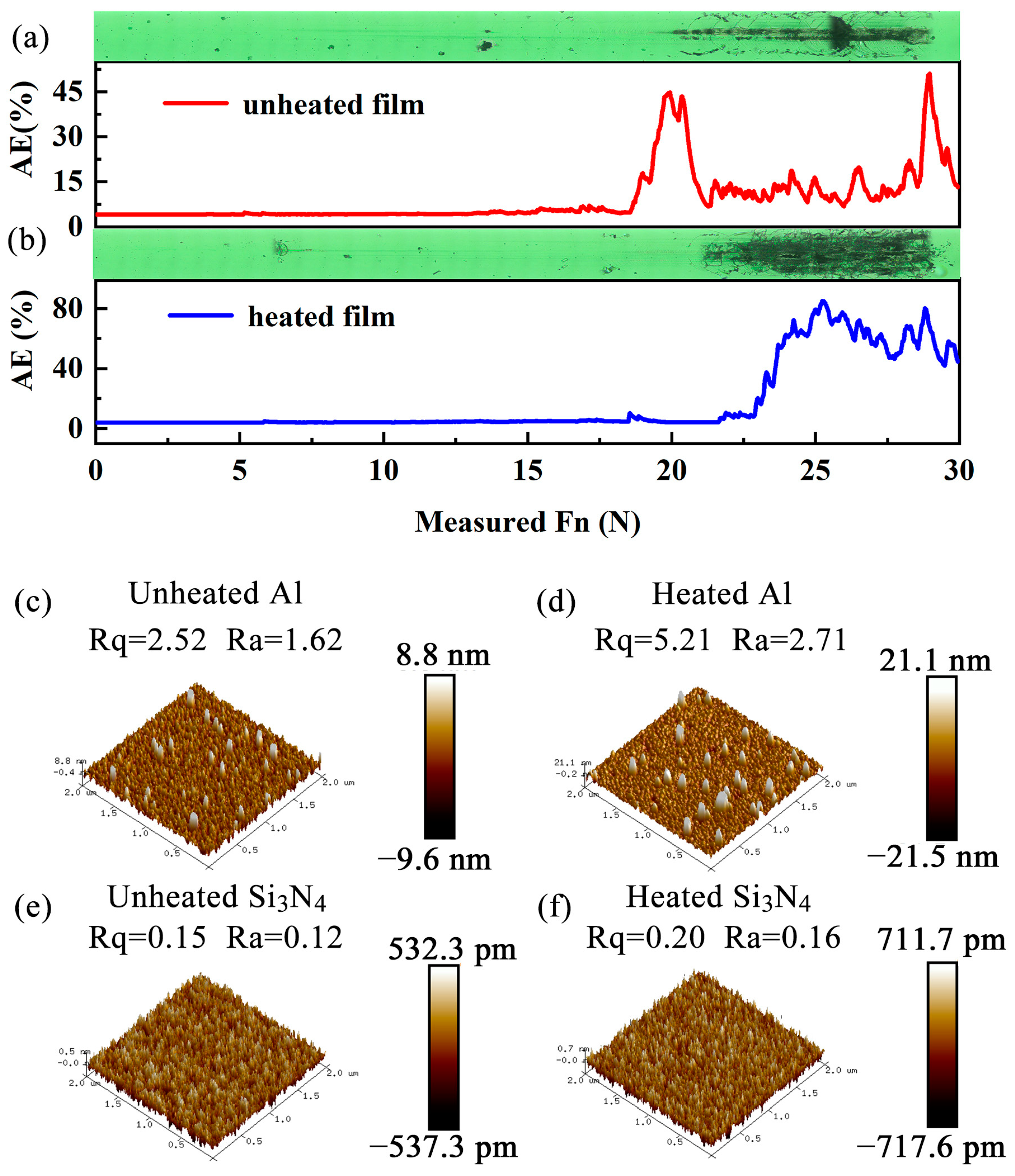

3.1. Structural Characterization

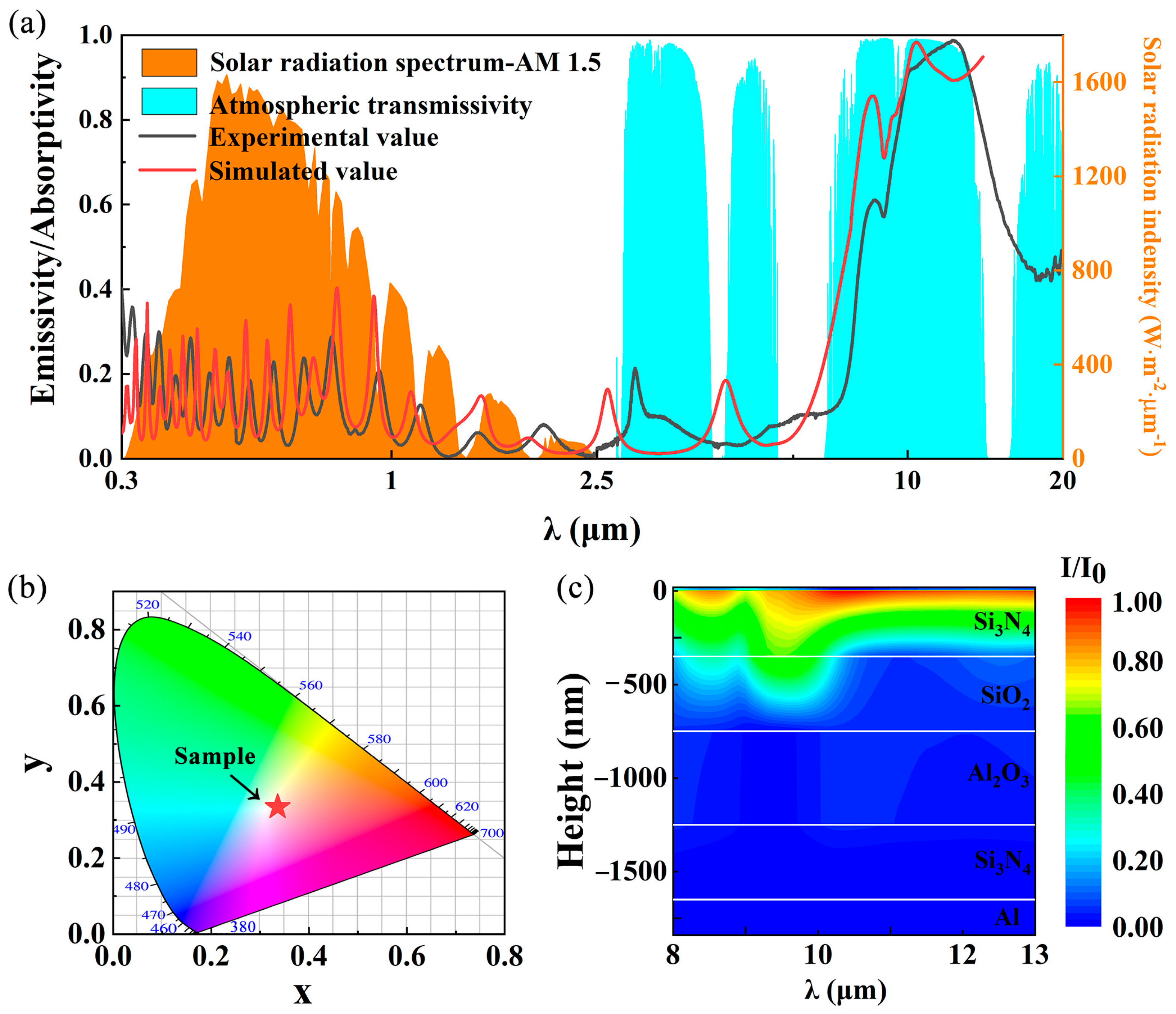

3.2. Optical Properties

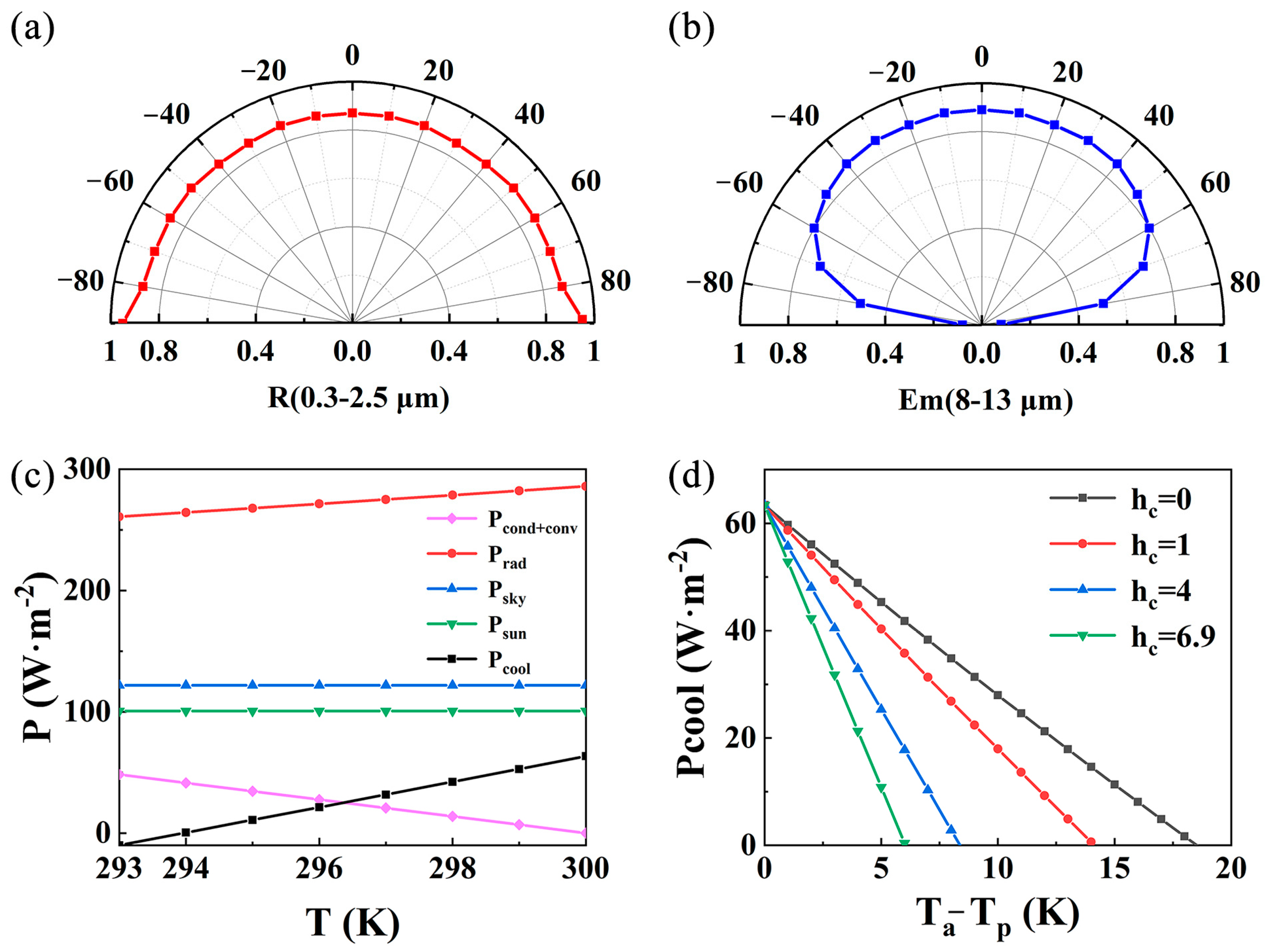

3.3. Radiative Cooling Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| H | High refractive indices |

| L | Low refractive indices |

| DC | Direct current |

| RF | Radio frequency |

| sccm | Standard cubic centimeters per minute |

| I/I0 | Normalized energy flux density |

| AM1.5 | Air mass 1.5 |

References

- Kim, M.; Seo, J.; Yoon, S.; Lee, H.; Lee, J.; Lee, B.J. Optimization and performance analysis of a multilayer structure for daytime radiative cooling. J. Quant. Spectrosc. Radiat. Transf. 2021, 260, 107475. [Google Scholar] [CrossRef]

- Chae, D.; Kim, M.; Jung, P.-H.; Son, S.; Seo, J.; Liu, Y.; Lee, B.J.; Lee, H. Spectrally selective inorganic-based multilayer emitter for daytime radiative cooling. ACS Appl. Mater. Interfaces 2020, 12, 8073–8081. [Google Scholar] [CrossRef]

- Tso, C.Y.; Chan, K.C.; Chao, C.Y.H. A field investigation of passive radiative cooling under Hong Kong’s climate. Renew. Energy 2017, 106, 52–61. [Google Scholar] [CrossRef]

- Xi, W.; Liu, Y.; Zhao, W.; Hu, R.; Luo, X. Colored radiative cooling: How to balance color display and radiative cooling performance. Int. J. Therm. Sci. 2021, 170, 107172. [Google Scholar] [CrossRef]

- Li, Y.; Lin, C.; Huang, J.; Chi, C.; Huang, B. Spectrally selective absorbers/emitters for solar steam generation and radiative cooling-enabled atmospheric water harvesting. Glob. Chall. 2021, 5, 2000058. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Zhang, J.; Feng, W.; Zuo, J. Advances and challenges in commercializing radiative cooling. Mater. Today Phys. 2019, 11, 100161. [Google Scholar] [CrossRef]

- Sun, X.; Sun, Y.; Zhou, Z.; Alam, M.A.; Bermel, P. Radiative sky cooling: Fundamental physics, materials, structures, and applications. Nanophotonics 2017, 6, 997–1015. [Google Scholar] [CrossRef]

- Vila, R.; Martorell, I.; Medrano, M.; Castell, A. Adaptive covers for combined radiative cooling and solar heating. A review of existing technology and materials. Sol. Energy Mater. Sol. Cells 2021, 230, 111275. [Google Scholar] [CrossRef]

- Yu, X.; Chan, J.; Chen, C. Review of radiative cooling materials: Performance evaluation and design approaches. Nano Energy 2021, 88, 106259. [Google Scholar] [CrossRef]

- Li, M.; Coimbra, C.F.M. On the effective spectral emissivity of clear skies and the radiative cooling potential of selectively designed materials. Int. J. Heat Mass Transf. 2019, 135, 1053–1062. [Google Scholar] [CrossRef]

- Vall, S.; Castell, A. Radiative cooling as low-grade energy source: A literature review. Renew. Sust. Energy Rev. 2017, 77, 803–820. [Google Scholar] [CrossRef]

- Cai, L.; Song, A.Y.; Li, W.; Hsu, P.C.; Lin, D.; Catrysse, P.B.; Liu, Y.; Peng, Y.; Chen, J.; Wang, H.; et al. Spectrally selective nanocomposite textile for outdoor personal cooling. Adv. Mater. 2018, 30, 1802152. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Liang, Z.; Qin, Z.; Hou, E.; Shi, X.; Zhang, Y.; Xiong, Y.; Tang, Y.; Fan, Y.; Yang, F.; et al. Small–sized long wavelength infrared absorber with perfect ultra–broadband absorptivity. Opt. Express 2020, 28, 1279. [Google Scholar] [CrossRef] [PubMed]

- Üstün, K.; Turhan-Sayan, G. Ultra-broadband long-wavelength infrared metamaterial absorber based on a double-layer metasurface structure. J. Opt. Soc. Am. B 2017, 34, 456. [Google Scholar] [CrossRef]

- Sajjad, U.; Hamid, K.; Tauseef ur, R.; Sultan, M.; Abbas, N.; Ali, H.M.; Imran, M.; Muneeshwaran, M.; Chang, J.-Y.; Wang, C.-C. Personal thermal management—A review on strategies, progress, and prospects. Int. Commun. Heat Mass 2022, 130, 105739. [Google Scholar] [CrossRef]

- Hu, Z.; Yang, X.; Qiu, Y. Tandem radiative cooling with latent thermal energy storage for enhanced passive cooling and thermal shock resistance. Sol. Energy Mater. Sol. Cells 2025, 286, 113565. [Google Scholar] [CrossRef]

- Yoon, S.; Seo, J.; Jung, J.; Choi, M.; Lee, B.J.; Kim, J.B. Improving radiative cooling performance via strong solar reflection by dense Al2O3 particles in a polymeric film. Int. J. Heat Mass Transf. 2024, 227, 125574. [Google Scholar] [CrossRef]

- Jung, J.; Yoon, S.; Kim, B.; Kim, J.B. Development of high-performance flexible radiative cooling film using PDMS/TiO2 Microparticles. Micromachines 2023, 14, 2223. [Google Scholar] [CrossRef]

- Lin, K.-T.; Han, J.; Li, K.; Guo, C.; Lin, H.; Jia, B. Radiative cooling: Fundamental physics, atmospheric influences, materials and structural engineering, applications and beyond. Nano Energy 2021, 80, 105517. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540. [Google Scholar] [CrossRef]

- Pirouzfam, N.; Menguc, M.P.; Sendur, K. Colorization of passive radiative cooling coatings using plasmonic effects. Sol. Energy Mater. Sol. Cells 2023, 253, 112225. [Google Scholar] [CrossRef]

- Ma, H.; Yao, K.; Dou, S.; Xiao, M.; Dai, M.; Wang, L.; Zhao, H.; Zhao, J.; Li, Y.; Zhan, Y. Multilayered SiO2/Si3N4 photonic emitter to achieve high-performance all-day radiative cooling. Sol. Energy Mater. Sol. Cells 2020, 212, 110584. [Google Scholar] [CrossRef]

- Cunha, N.F.; Al-Rjoub, A.; Rebouta, L.; Vieira, L.G.; Lanceros-Mendez, S. Multilayer passive radiative selective cooling coating based on Al/SiO2/SiNx/SiO2/TiO2/SiO2 prepared by dc magnetron sputtering. Thin Solid Films 2020, 694, 137736. [Google Scholar] [CrossRef]

- Ren, J.; Liang, D.; Liu, H.; Yang, Y.; Li, A.; Sun, Y.; Wang, C. High-temperature thermal stable solar selective absorbing coating based on the dielectric-metal-dielectric structure. Mater. Today Phys. 2023, 34, 101092. [Google Scholar] [CrossRef]

- Tsai, W.; Delfino, M.; Fair, J.A.; Hodul, D. Temperature dependence of the electrical resistivity of reactively sputtered TiN films. J. Appl. Phys. 1993, 73, 4462–4467. [Google Scholar] [CrossRef]

- Yao, K.; Ma, H.; Huang, M.; Zhao, H.; Zhao, J.; Li, Y.; Dou, S.; Zhan, Y. Near-perfect selective photonic crystal emitter with nanoscale layers for daytime radiative cooling. ACS Appl. Nano Mater. 2019, 2, 5512–5519. [Google Scholar] [CrossRef]

- Chae, D.; Son, S.; Lim, H.; Jung, P.H.; Ha, J.; Lee, H. Scalable and paint-format microparticle–polymer composite enabling high-performance daytime radiative cooling. Mater. Today Phys. 2021, 18, 100389. [Google Scholar] [CrossRef]

- Zhanga, J.-M.; Xu, K.-W.; Ji, V. Dependence of strain energy on the grain orientations in an FCC-polycrystalline film on rigid substrate. Appl. Surf. Sci. 2002, 185, 177–182. [Google Scholar] [CrossRef]

- Chen, M.; Wang, X.; Yu, Y.H.; Pei, Z.L.; Bai, X.D.; Sun, C.; Huang, R.F.; Wen, L.S. X-ray photoelectron spectroscopy and auger electron spectroscopy studies of Al-doped ZnO films. Appl. Surf. Sci. 2000, 158, 134–140. [Google Scholar] [CrossRef]

- Han, L.; Jeurgens, L.P.H.; Cancellieri, C.; Wang, J.; Xu, Y.; Huang, Y.; Liu, Y.; Wang, Z. Anomalous texture development induced by grain yielding anisotropy in Ni and Ni-Mo alloys. Acta Mater. 2020, 200, 857–868. [Google Scholar] [CrossRef]

- Carel, R.; Thompson, C.V.; Frost, H.J. Computer simulation of strain energy effects vs surface and interface energy effects on grain growth in thin films. Acta Mater. 1996, 44, 2479–2494. [Google Scholar] [CrossRef]

- Dong, R.; Du, T.; Dong, S.; Zhao, X.; Ma, R.; Du, A.; Fan, Y.; Cao, X. A weather-resistant daytime radiative cooler based on fluorocarbon resin. Sol. Energy Mater. Sol. Cells 2022, 235, 111486. [Google Scholar] [CrossRef]

- Patsalas, P.; Charitidis, C.; Logothetidis, S. The effect of substrate temperature and biasing on the mechanical properties and structure of sputtered titanium nitride thin films. Surf. Coat. Technol. 2000, 125, 335–340. [Google Scholar] [CrossRef]

- Pandey, S.K.; Thakur, O.P.; Raman, R.; Goyal, A.; Gupta, A. Structural and optical properties of YSZ thin films grown by PLD technique. Appl. Surf. Sci. 2011, 257, 6833–6836. [Google Scholar] [CrossRef]

- Atmospheric Transmittance Under AM1.5 Conditions. Available online: https://www.gemini.edu/observing/telescopes-and-sites/sites#Transmission (accessed on 1 December 2024).

- Liu, H.; Sun, Y.; Ren, J.; Liang, D.; Yang, Y.; Fan, Z.; Wang, C. Inorganic multilayer film with high infrared selective emission enhanced by SiNx for daytime radiative cooling. ACS Appl. Energy Mater. 2024, 7, 2478–2486. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Q.; Tao, C.; Hong, Y.; Xu, Z.; Shen, W.; Kaur, S.; Ghosh, P.; Qiu, M. Multispectral camouflage for infrared, visible, lasers and microwave with radiative cooling. Nat. Commun. 2021, 12, 1805. [Google Scholar] [CrossRef]

- Liang, D.; Ren, J.; Liu, H.; Yang, Y.; Ambar, A.; Sun, Y.; Wang, C. High-performance radiative cooling film with excellent thermostability and mechanical property realized by self-assembled nanoparticles. Mater. Today Phys. 2024, 44, 101425. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Huang, Z.; Zhao, Z.; Qiu, J.; Ruan, X. Full daytime sub-ambient radiative cooling with high figure of merit in commercial-like paints. Cell Rep. Phys. Sci. 2020, 1, 100221. [Google Scholar] [CrossRef]

- Huang, W.; Chen, Y.; Luo, Y.; Mandal, J.; Li, W.; Chen, M.; Tsai, C.C.; Shan, Z.; Yu, N.; Yang, Y. Scalable aqueous processing-based passive daytime radiative cooling coatings. Adv. Funct. Mater. 2021, 31, 2010334. [Google Scholar] [CrossRef]

- You, P.; Li, X.; Huang, Y.; Ma, X.; Pu, M.; Guo, Y.; Luo, X. High-performance multilayer radiative cooling films designed with flexible hybrid optimization strategy. Materials 2020, 13, 2885. [Google Scholar] [CrossRef]

- Li, P.; Wang, A.; Fan, J.; Kang, Q.; Jiang, P.; Bao, H.; Huang, X. Thermo-optically designed scalable photonic films with high thermal conductivity for subambient and above-ambient radiative cooling. Adv. Funct. Mater. 2021, 32, 2109542. [Google Scholar] [CrossRef]

- Fan, J.; Fu, C.; Fu, T. Yttria-stabilized zirconia coating for passive daytime radiative cooling in humid environment. Appl. Therm. Eng. 2020, 165, 114585. [Google Scholar] [CrossRef]

- Bao, H.; Yan, C.; Wang, B.; Fang, X.; Zhao, C.Y.; Ruan, X. Double-layer nanoparticle-based coatings for efficient terrestrial radiative cooling. Sol. Energy Mater. Sol. Cells 2017, 168, 78–84. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Zhang, T.; Chen, Y.; Zhang, S.; Yu, D.; Wang, W. Radiative cooling materials prepared by SiO2 aerogel microspheres@PVDF-HFP nanofilm for building cooling and thermal insulation. Ceram. Int. 2024, 50, 48031–48040. [Google Scholar] [CrossRef]

- China Meteorological Administration (CMA). Available online: https://weather.cma.cn/ (accessed on 9 November 2023).

| R (0.3~2.5 μm) (%) | Εm (8~13 μm) (%) | Pnet-cooling (W·m−2) | Prad (W·m−2) | Psky (W·m−2) | Psun (W·m−2) | Pcond+conv (W·m−2) | ΔT(h = 6.9) (K) |

|---|---|---|---|---|---|---|---|

| 89.57 | 83.41 | 63.38 | 285.88 | 121.81 | 100.69 | 0 | 6.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Yang, Y.; Ambar, A.; Fan, Z.; Sun, Y.; Wang, C. Cost-Effective Inorganic Multilayer Film for High-Performance Daytime Radiative Cooling. Materials 2025, 18, 1729. https://doi.org/10.3390/ma18081729

Liu H, Yang Y, Ambar A, Fan Z, Sun Y, Wang C. Cost-Effective Inorganic Multilayer Film for High-Performance Daytime Radiative Cooling. Materials. 2025; 18(8):1729. https://doi.org/10.3390/ma18081729

Chicago/Turabian StyleLiu, Huan, Yingxin Yang, Atsha Ambar, Zhiqiang Fan, Ying Sun, and Cong Wang. 2025. "Cost-Effective Inorganic Multilayer Film for High-Performance Daytime Radiative Cooling" Materials 18, no. 8: 1729. https://doi.org/10.3390/ma18081729

APA StyleLiu, H., Yang, Y., Ambar, A., Fan, Z., Sun, Y., & Wang, C. (2025). Cost-Effective Inorganic Multilayer Film for High-Performance Daytime Radiative Cooling. Materials, 18(8), 1729. https://doi.org/10.3390/ma18081729