Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts

Abstract

1. Introduction

2. Supplementary Cementitious Materials

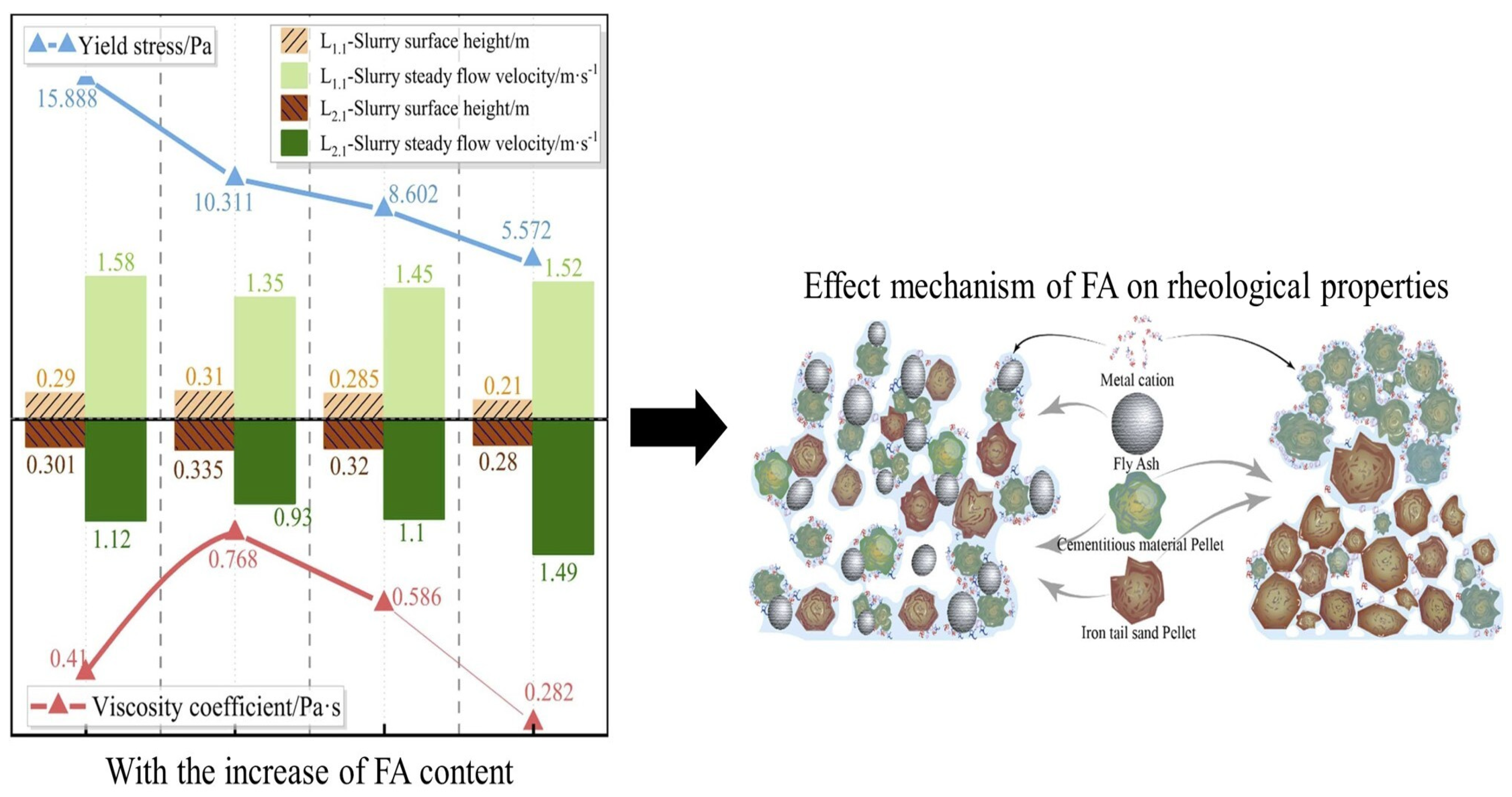

2.1. Fly Ash

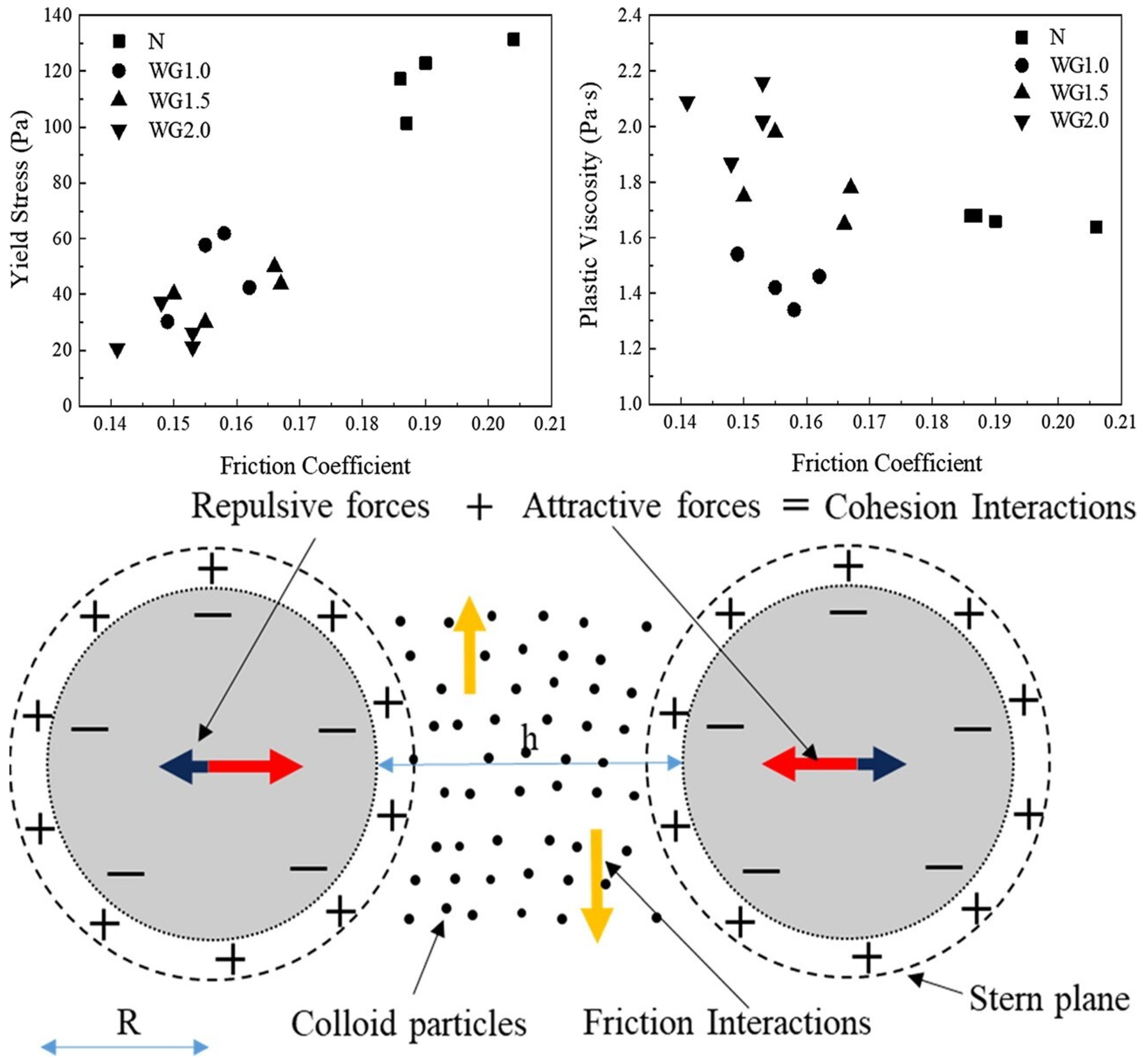

2.2. Ground Granulated Blast Furnace Slag

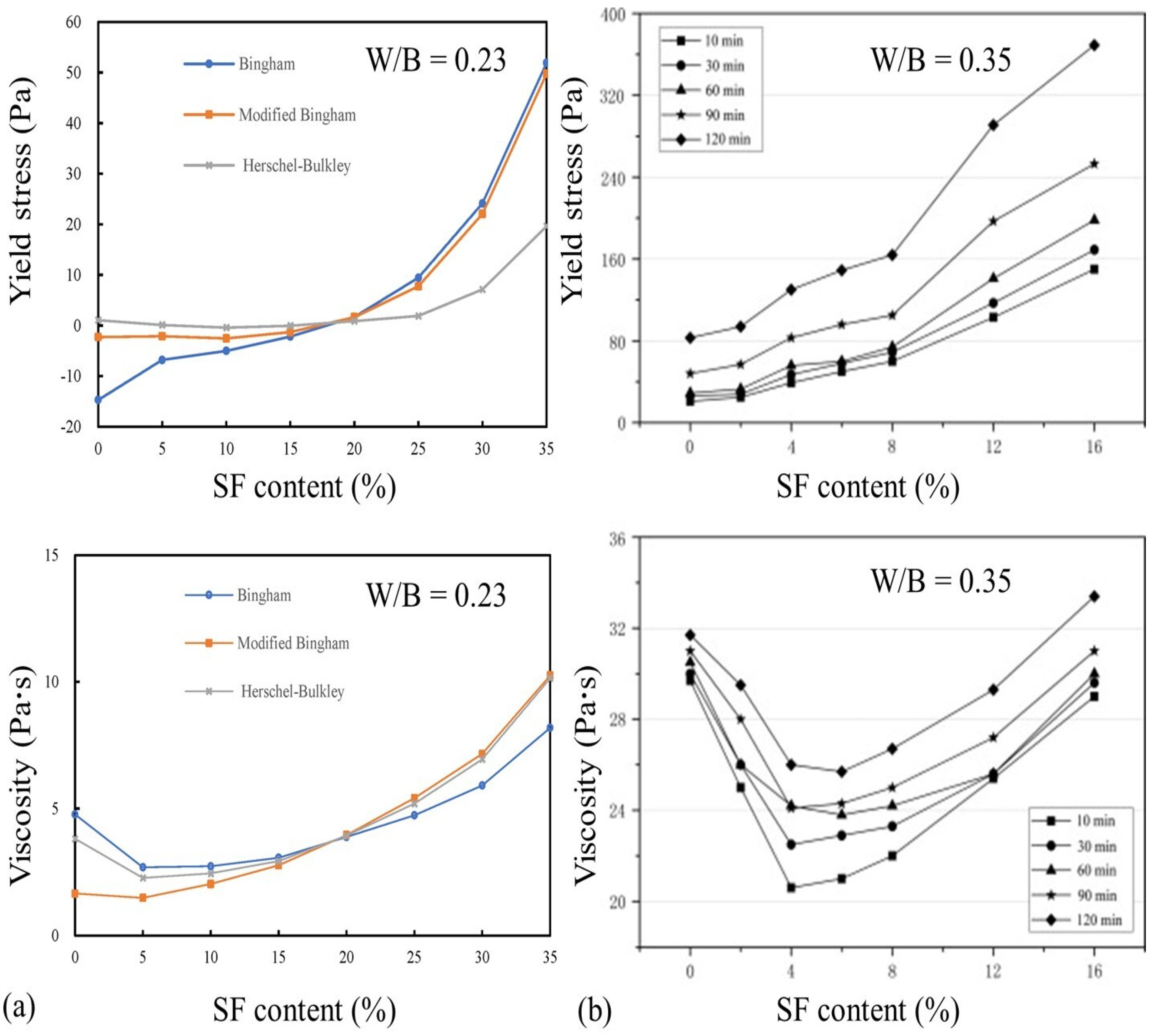

2.3. Silica Fume

| Type | Dosage (%) | Plastic Viscosity (mPa·s) | Yield Stress (Pa) | Thixotropy (Δ) | Remarks | Reference |

|---|---|---|---|---|---|---|

| FA | 5–25 | As FA substitution increases, the shear-thickening effect and slurry viscosity grow. | Yield stress demonstrates a proportional relationship with the FA content. | - | The large specific surface area of SF increases water wetting, leading to larger flocculated structures, higher yield stress, and poor fluidity in pastes. | [54] |

| 8–12 | The plastic viscosity of the mortar was 0.768 Pa·s by adding 8% fly ash. | Adding 8–12% FA reduced the yield stress of the mortar by 35–65%. | - | FA effectively improved mortar segregation and precipitation. | [23] | |

| 10 and 20 | Slurries mixed with 10% and 20% FA increased the early plastic viscosity by 0.11 and 0.17 Pa·s, respectively, compared to that of the control cement-based material without FA. | After 57 min of hydration, the dynamic yield stresses were 75.1, 87.0, 190.8, and 132.0 Pa. The Paste with 20% FA consistently exhibited the highest dynamic yield stresses. | Using 20% FA reduced the static yield stress and thixotropic by 31.9 Pa and 971.1 Pa·s−1. The appropriate FA content reduced the yield stress and enhanced the thixotropy. | FA increased the plastic viscosity of the cement-based material by promoting early hydration and consuming more free water. | [55] | |

| GGBFS | 0–50 | As the GGBFS content increased from 0% to 50%, the plastic viscosity increased from 7.13 Pa·s to 16.46 Pa·s. | As the GGBFS content increased from 0% to 50%, the yield stress of the cement-based material increased from 36.6 Pa to 239.1 Pa. | As the GGBFS amount increased, the thixotropy of the cement-based materials increased over the resting time. | Low GGBFS contents (≤30%) mainly affected the plastic viscosity of the geopolymer, while high GGBFS contents (40–50%) had a remarkable effect on the yield stress. | [56] |

| 10–40 | An increase in the slag content led to a decrease in the plastic viscosity compared to that of the control mortar. | Using slag reduced the yield stress of the paste, with reductions of 10% to 55% for pastes with 10% to 35% slag. | - | The increase in the slag content increased the yield stress and plastic viscosity of fresh mortars. | [57] | |

| SF | 0–35 | The plastic viscosity and hysteresis loop area decreased slightly with the addition of a small amount of SF but increased significantly with the continuous increase in SF. | When the SF content was less than 15%, the yield stress was close to 0. With increasing SF content, the yield stress increased rapidly. | - | As the SF content increased from 0% to 35%, the shear-thickening effect of the cement-based materials decreased, transitioning from dilatant to Newtonian and then to pseudoplastic behaviors. | [40] |

| 0–50 | Adding SF increased the plastic viscosity by 6.7–24.7%. The nucleation and filling of the SF promoted the hydration reaction and significantly increased the plastic viscosity of the paste. | The SF addition increased the yield stress by 2.6–18.4%, with its small particle size enhancing nucleation sites and accelerating hydration. | - | The SF increased the rheological parameters and reduced the fluidity attenuation, with a stronger effect during accelerated hydration, enhancing the reaction through nucleation and releasing more heat. | [58] | |

| SF and FA | 0–20 | SF and FA significantly reduced the plastic viscosity of the cement-based materials, with reductions of 110% and 175%, respectively. | The yield stress decreased to 57 Pa with 10% SF then increased as the SF content rose further. The yield stresses of the pastes with 10% and 20% FA decreased by 104% and 315% compared to that of the reference. | - | SF and FA significantly improved the fluidity of cement-based materials. | [59] |

| Metakaolin (MK) | 5–20 | As the MK replacement increased from 5% to 20%, the plastic viscosity increased in the range 1.2–661.3%. The incorporation of MK can increase the plastic viscosity. | As the MK replacement increased from 5% to 20%, the yield stress increased in the range 5.1–234.2%. The incorporation of MK can increase the yield stress. | As the MK replacement increased from 5% to 20%, the thixotropy increased in the range 1.8–146.69%. The incorporation of MK can increase the thixotropy. | Adding MK can reduce flow rate and flow spread. Using MK reduced the film thickness of the particles, explaining its effects on both microscopic rheological parameters and macroscopic flow properties. | [45] |

| 5 and 10 | When MK is used in cement-based materials, if attractive forces dominate the system, flocculation occurs, leading to increases in rheological parameters. This effect has been observed in studies involving MK. | The static yield stresses of the 5% and 10% MK mixtures were 522 and 764 Pa, respectively, showing a content-dependent increase. MK’s absorbent laminar structure reduced the requirement of the free water and increased the flow resistance. | The thixotropic behaviors of mixtures are favored by MK. | The incorporation of MK increases the flow resistance of the cementitious mixes, requiring greater force to flow, with the effect being proportional to the additional content. | [60] | |

| Coral Powder (CP) | 0–15 | With the addition of the coral powder, the plastic viscosity (μ) also increased from 0.21 to 0.74, a rise of 243.3%. | With the addition of the coral powder, the yield stress (τ0) gradually increased from 1.20 to 3.71 Pa, a rise of 208.1%. | - | The addition of CP increased the yield stress and plastic viscosity of the paste, which affects the rheological properties of pastes. | [61] |

| MK and CP | 10 CP 5–30 MK | The paste with 10% CP showed higher consistency and plastic viscosity. The reduction in the rheological index indicated pronounced shear thinning, except when adding 30% MK. | The cement paste with 10% CP showed higher dynamic shear stress, which was further increased by adding MK, indicating greater yield stress. | - | The ternary system showed significant shear thinning, with the Herschel–Bulkley model fitting well. Up to 20% MK enhanced the rheology and workability. | [62] |

| Limestone Fines (LFs) | 0–60 | - | The rheological properties of the paste made with LFs showed viscoplastic fluids with shear thinning behavior. | - | Incorporating LFs into cement suspensions increased the yield stress, viscosity, and flow time, reducing the fluidity. | [51] |

| 30, 60 vol. | Using 30% LF1 increased the torque of the mortar at higher speeds, resulting in a 16% increase in the plastic viscosity. At 60% replacement by LF2, the plastic viscosity was reduced by 8%. | Using 30% LF1 did not affect the yield stress. Adding LF2 reduced the yield stress, with an 11% decrease at a low rpm for the composition; 60% replacement decreased the yield stress by 18%. | - | Limestone type and the use of a dispersant affected the rheological parameter yield torque. | [52] | |

| LFs and Rice Husk Ash (RHA) | 10 RHA 5–20 LFs | When 10% RHA was adopted, the consistency (plastic viscosity) decreased by 28.17%, 40.85%, and 73.24% compared to those of the cement pastes without LFs. | With 10% RHA, adding 5%, 10%, and 20% LFs reduced the cement paste’s dynamic yield stress by 43.86%, 69.64%, and 87.11%, respectively. | LFs and RHA have the opposite effects on the static yield stress and structural build-up rate. RHA boosts the initial static yield stress and accelerates structural recovery. | LFs effectively eliminated the adverse effect of the RHA on the rheological properties. The pastes with a combination of 10% RHA and 10% or 20% LFs had had suitable rheological properties. | [63] |

3. Chemical Admixtures

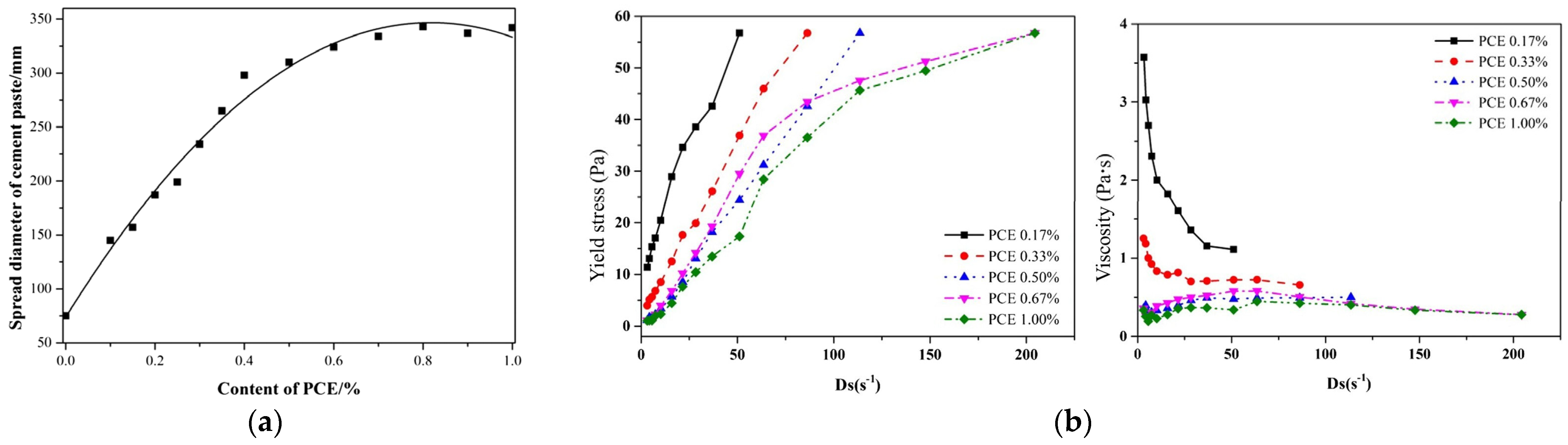

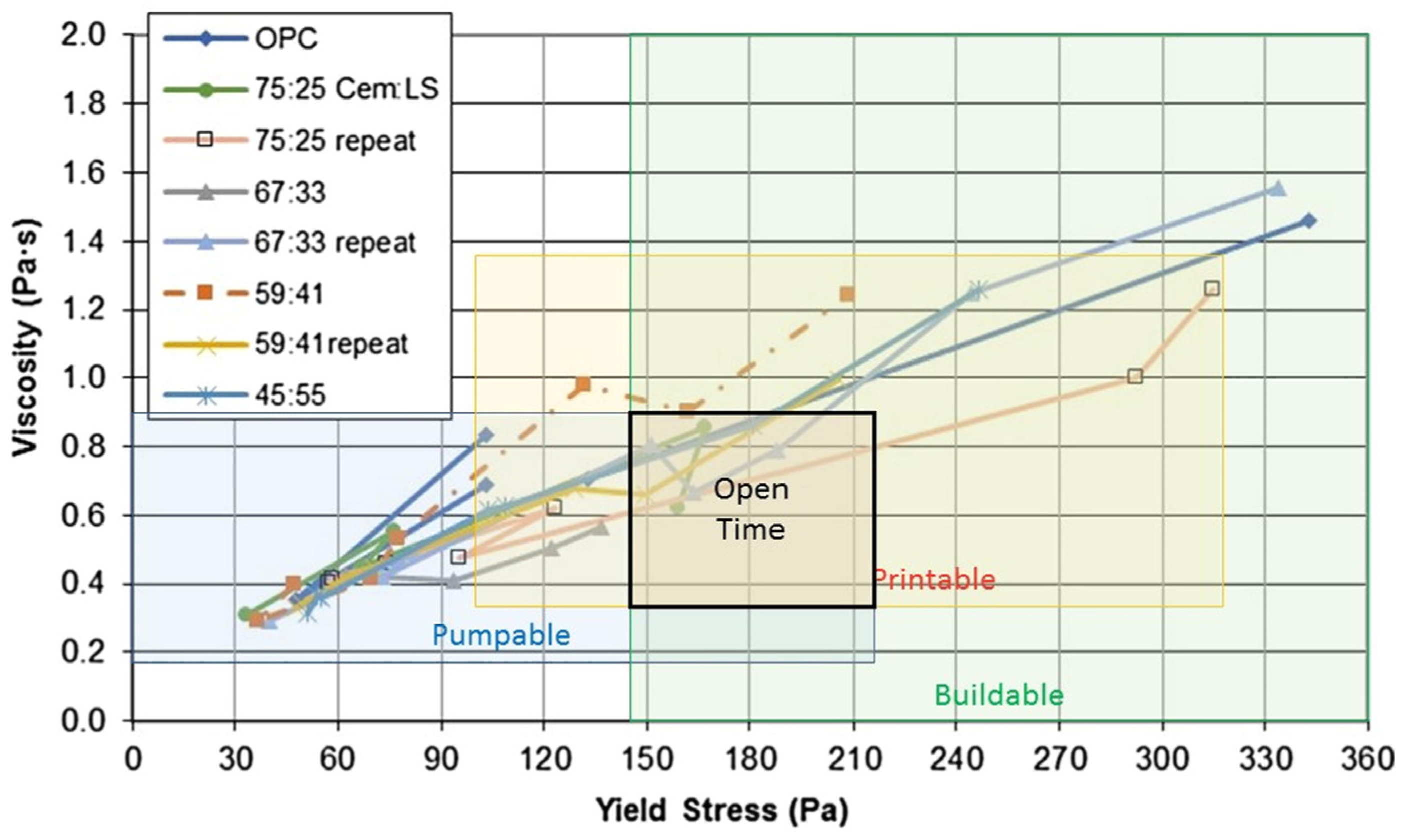

3.1. Superplasticizers

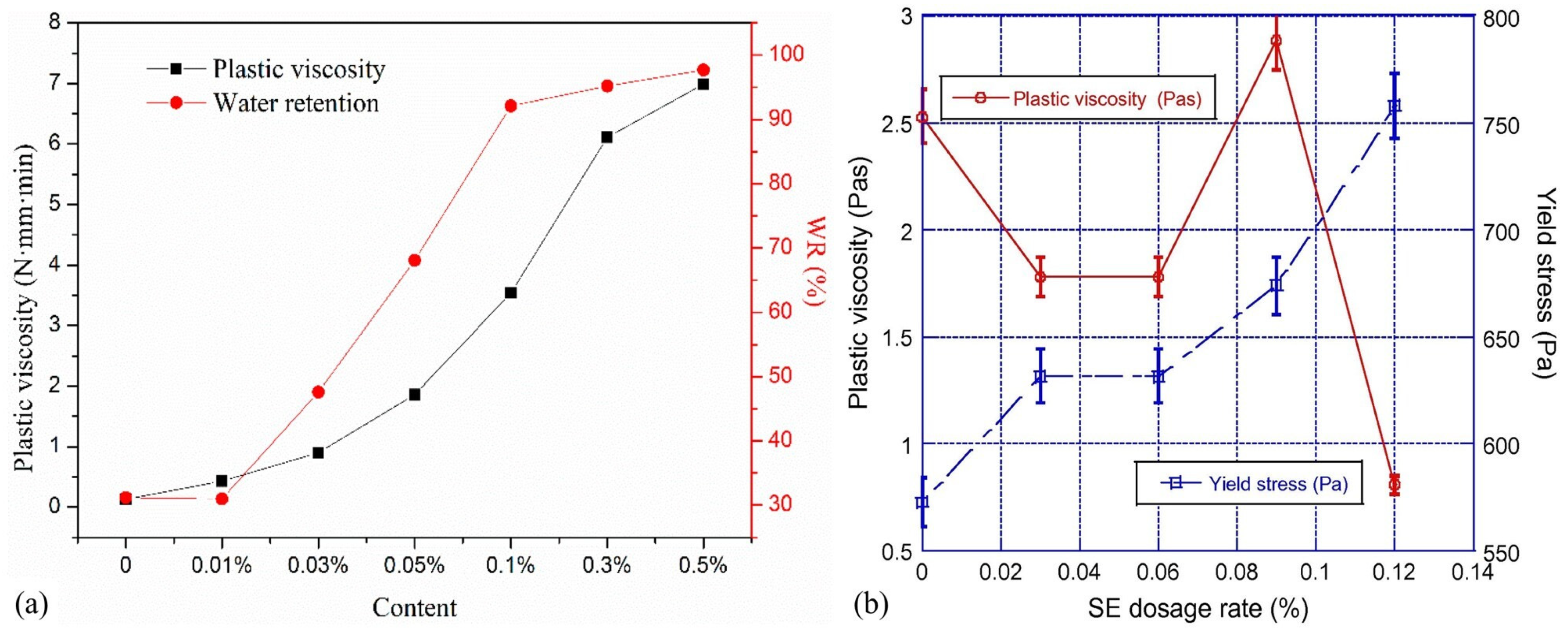

3.2. Viscosity-Modifying Agents

3.3. Setting-Time Control Agents

3.4. Superabsorbent Polymers

4. Nanomaterials and Fibers

4.1. Synthesized Nanomaterials

4.2. Nanomaterials Produced from Industrial Byproducts

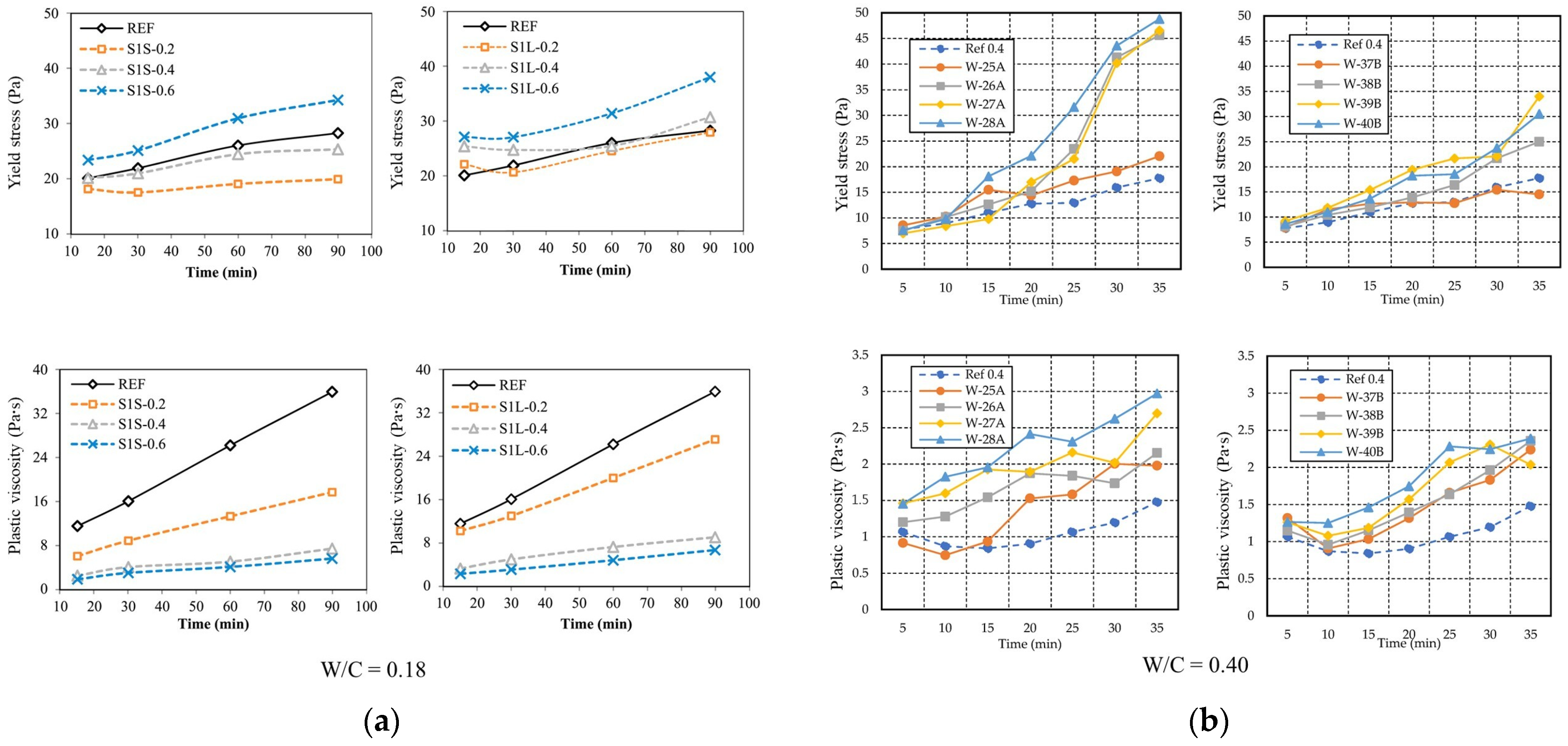

4.3. Fibers

5. Recommendations for Future Research

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, C.; Liu, J.; Liu, L.; Chen, Z.; Shi, C. Interactions between coral sand and polycarboxylate superplasticizer and their effects on rheological properties of cement-based materials—A review. Constr. Build. Mater. 2023, 389, 131607. [Google Scholar] [CrossRef]

- Franco-Luján, V.A.; Montejo-Alvaro, F.; Ramírez-Arellanes, S.; Cruz-Martínez, H.; Medina, D.I. Nanomaterial-Reinforced Portland-Cement-Based Materials: A Review. Nanomaterials 2023, 13, 1383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Chen, J.; Zhu, J.; Yang, Y.; Zhou, D.; Wang, T.; Shu, X.; Qiao, M. Advances in Organic Rheology-Modifiers (Chemical Admixtures) and Their Effects on the Rheological Properties of Cement-Based Materials. Materials 2022, 15, 8730. [Google Scholar] [CrossRef] [PubMed]

- Ley-Hernández, A.M.; Feys, D. Effect of sedimentation on the rheological properties of cement pastes. Mater. Struct. 2021, 54, 47. [Google Scholar] [CrossRef]

- Li, H.; Huang, F.; Yi, Z.; Wang, Z.; Zhang, Y.; Yang, Z. Investigations of Mixing Technique on the Rheological Properties of Self-Compacting Concrete. Appl. Sci. 2020, 10, 5189. [Google Scholar] [CrossRef]

- Ouédraogo, N.P.; Becquart, F.; Benzerzour, M.; Abriak, N.-E. Influence of fine sediments on rheology properties of self-compacting concretes. Powder Technol. 2021, 392, 544–557. [Google Scholar] [CrossRef]

- Chen, M.; Jin, Y.; Sun, K.; Wang, S.; Zhao, P.; Wang, L.; Liu, J.; Yue, G.; Li, Q.; Lu, L. Study on the durability of 3D printed calcium sulphoaluminate cement-based materials related to rheology control. J. Mater. Res. Technol. 2023, 26, 2481–2494. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, Q.; Dai, X.; Tao, Y.; Zhang, Y.; Jiang, Z.; Van Tittelboom, K.; De Schutter, G. A potential active rheology control approach for 3D printable cement-based materials: Coupling of temperature and viscosity modifiers. Cem. Concr. Compos. 2024, 149, 105496. [Google Scholar] [CrossRef]

- Liu, G.; Cheng, W.; Chen, L.; Pan, G.; Liu, Z. Rheological properties of fresh concrete and its application on shotcrete. Constr. Build. Mater. 2020, 243, 118180. [Google Scholar] [CrossRef]

- Pan, G.; Li, P.; Chen, L.; Liu, G. A study of the effect of rheological properties of fresh concrete on shotcrete-rebound based on different additive components. Constr. Build. Mater. 2019, 224, 1069–1080. [Google Scholar] [CrossRef]

- Saleh Ahari, R.; Kemal Erdem, T.; Ramyar, K. Effect of various supplementary cementitious materials on rheological properties of self-consolidating concrete. Constr. Build. Mater. 2015, 75, 89–98. [Google Scholar] [CrossRef]

- Iqbal Khan, M.; Mourad, S.M.; Charif, A. Utilization of Supplementary Cementitious Materials in HPC: From rheology to pore structure. KSCE J. Civ. Civil. Eng. 2017, 21, 889–899. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J.; Xiong, G. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar] [CrossRef]

- Lamine Zeggar, M.; Azline, N.; Azizi Safiee, N. Fly ash as supplementry material in concrete: A review. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012025. [Google Scholar] [CrossRef]

- Khayat, K.H.; Meng, W.; Vallurupalli, K.; Teng, L. Rheological properties of ultra-high-performance concrete—An overview. Cem. Concr. Res. 2019, 124, 105828. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A. A review on eminent application and performance of nano based silica and silica fume in the cement concrete. Sustain. Energy Technol. Assess. 2023, 56, 103105. [Google Scholar] [CrossRef]

- Feng, K.; Ma, K.; Yang, H.; Long, G.; Xie, Y.; Zeng, X.; Tang, Z.; Usman, I.U. Influence of cellulose ethers on rheological properties of cementitious materials: A review. J. Build. Eng. 2024, 95, 110347. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y.; Shah, S.P. Rheological Properties and Structural Build-Up of Cement Based Materials with Addition of Nanoparticles: A Review. Buildings 2022, 12, 2219. [Google Scholar] [CrossRef]

- Han, F.; Wang, Q.; Feng, J. The differences among the roles of ground fly ash in the paste, mortar and concrete. Constr. Build. Mater. 2015, 93, 172–179. [Google Scholar] [CrossRef]

- Nassar, R.-U.-D.; Room, S. Comparison of the performance of class-C and class-F fly ash concrete mixtures produced with crushed stone sand. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Thiyagarajan, H.; Mapa, M.; Kushwaha, R. Investigation on the Rheological Behavior of Fly Ash Cement Composites at Paste and Concrete Level. J. Inst. Eng. (India) Ser. A 2018, 99, 295–301. [Google Scholar] [CrossRef]

- Luo, X.; Gao, J.; Guo, Z.; Li, S.; Liu, C.; Zhao, Y. Experimental study on the rheological property of cement paste with fly ash and brick powder. Powder Technol. 2023, 426, 118635. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, C.; Wang, B.; Han, J.; Guo, L.; Tang, N. Study on the micro-rheological properties of fly ash-based cement mortar. Constr. Build. Mater. 2024, 442, 137664. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Z.; Deng, Y.; Hu, J.; Yu, Q.; Shi, C. Effects of silica fume/ultrafine fly ash on the rheology and hardening of alkali-activated slag-waste ceramic powder paste. Constr. Build. Mater. 2024, 438, 137265. [Google Scholar] [CrossRef]

- Ghafoor, M.T.; Fujiyama, C. Effect of Fly Ash Content on Rheological Properties of Self-Compacting Geopolymer Mortar. J. Adv. Concr. Technol. 2024, 22, 103–114. [Google Scholar] [CrossRef]

- Wei, J.; Farzadnia, N.; Khayat, K.H. Synergistic effect of macro synthetic fiber and shrinkage-reducing admixture on engineering properties of fiber-reinforced super-workable concrete. Constr. Build. Mater. 2024, 414, 134566. [Google Scholar] [CrossRef]

- Gómez Nemocón, S.A.; Lizarazo Marriaga, J.M.; Puerto Suárez, J.D. Rheological and hardened properties of self-compacting concrete using hollow glass microspheres as a partial replacement of cement. Constr. Build. Mater. 2022, 342, 128012. [Google Scholar] [CrossRef]

- Lu, B.; Qian, Y.; Li, M.Y.; Weng, Y.W.; Leong, K.F.; Tan, M.J.; Qian, S.Z. Designing spray-based 3D printable cementitious materials with fly ash cenosphere and air entraining agent. Constr. Build. Mater. 2019, 211, 1073–1084. [Google Scholar] [CrossRef]

- Lu, B.; Zhu, W.P.; Weng, Y.W.; Liu, Z.X.; Yang, E.H.; Leong, K.F.; Tan, M.J.; Wong, T.N.; Qian, S.Z. Study of MgO-activated slag as a cementless material for sustainable spray-based 3D printing. J. Clean. Prod. 2020, 258, 10. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Zhou, Y.; Pu, S.; Han, F.; Zhang, H.; Zhang, Z. Effect of ultrafine slag on hydration heat and rheology properties of Portland cement paste. Powder Technol. 2022, 405, 117549. [Google Scholar] [CrossRef]

- Megat Johari, M.A.; Brooks, J.J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Maameri, N.E.; Bensaci, H.; Kenai, S. The effect of treated recycled steel fibers and slag on the properties of recycled self-compacting concrete. MRS Adv. 2023, 8, 613–617. [Google Scholar] [CrossRef]

- Luo, T.; Wang, Q.; Zhuang, S. Effects of ultra-fine ground granulated blast-furnace slag on initial setting time, fluidity and rheological properties of cement pastes. Powder Technol. 2019, 345, 54–63. [Google Scholar] [CrossRef]

- Harashima, A.; Ito, K. The Conditions of Ettringite Formation by the Reaction of a Blast Furnace Slag with Aqueous Alkaline Solutions. ISIJ Int. 2016, 56, 1738–1745. [Google Scholar] [CrossRef]

- Park, C.K.; Noh, M.H.; Park, T.H. Rheological properties of cementitious materials containing mineral admixtures. Cem. Concr. Res. 2005, 35, 842–849. [Google Scholar] [CrossRef]

- Long, W.J.; Wu, Z.; Khayat, K.H.; Wei, J.; Dong, B.; Xing, F.; Zhang, J. Design, dynamic performance and ecological efficiency of fiber-reinforced mortars with different binder systems: Ordinary Portland cement, limestone calcined clay cement and alkali-activated slag. J. Clean. Prod. 2022, 337, 130478. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, C.; Yuan, S.; Yuan, H.; Yang, K.; Yu, L.; Zhang, M.; Zhu, X. Understanding the rheological properties of alkali-activated slag pastes from the cohesion and friction interactions. Constr. Build. Mater. 2021, 291, 123311. [Google Scholar] [CrossRef]

- Smirnov, A.O.; Dobshits, L.M.; Anisimov, S.N. Effect of superplasticizer and silica fume on the properties of self-compacting mortars. IOP Conf. Ser. Mater. Sci. Eng. 2020, 896, 012095. [Google Scholar] [CrossRef]

- He, J.; Cheng, C.; Zhu, X.; Li, X. Effect of Silica Fume on the Rheological Properties of Cement Paste with Ultra-Low Water Binder Ratio. Materials 2022, 15, 554. [Google Scholar] [CrossRef]

- Lu, C.; Yang, H.; Mei, G. Relationship between slump flow and rheological properties of self compacting concrete with silica fume and its permeability. Constr. Build. Mater. 2015, 75, 157–162. [Google Scholar] [CrossRef]

- Barkat, A.; Kenai, S.; Menadi, B.; Kadri, E.; Soualhi, H. Effects of local metakaolin addition on rheological and mechanical performance of self-compacting limestone cement concrete. J. Adhes. Sci. Technol. 2019, 33, 963–985. [Google Scholar] [CrossRef]

- Rojo-López, G.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Rheology, durability, and mechanical performance of sustainable self-compacting concrete with metakaolin and limestone filler. Case Stud. Constr. Mater. 2022, 17, e01143. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, Y.; Sun, J.; Han, F. Effect of Ultrafine Metakaolin on the Properties of Mortar and Concrete. Crystals 2021, 11, 665. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Tian, Z.; Bu, J.; Qiu, J. Effect and Mechanism of Metakaolin Powder (MP) on Rheological and Mechanical Properties of Cementitious Suspension. Materials 2022, 15, 5797. [Google Scholar] [CrossRef]

- Janotka, I.; Puertas, F.; Palacios, M.; Kuliffayová, M.; Varga, C. Metakaolin sand–blended-cement pastes: Rheology, hydration process and mechanical properties. Constr. Build. Mater. 2010, 24, 791–802. [Google Scholar] [CrossRef]

- Santos, F.N.; de Sousa, S.R.; Bombard, A.J.; Vieira, S.L. Rheological study of cement paste with metakaolin and/or limestone filler using Mixture Design of Experiments. Constr. Build. Mater. 2017, 143, 92–103. [Google Scholar] [CrossRef]

- Muzenda, T.R.; Hou, P.; Kawashima, S.; Sui, T.; Cheng, X. The role of limestone and calcined clay on the rheological properties of LC3. Cem. Concr. Compos. 2020, 107, 103516. [Google Scholar] [CrossRef]

- Vance, K.; Kumar, A.; Sant, G.; Neithalath, N. The rheological properties of ternary binders containing Portland cement, limestone, and metakaolin or fly ash. Cem. Concr. Res. 2013, 52, 196–207. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Safiddine, S.; Amokrane, K.; Debieb, F.; Soualhi, H.; Benabed, B.; Kadri, E.-H. How quarry waste limestone filler affects the rheological behavior of cement-based materials. Appl. Rheol. 2021, 31, 63–75. [Google Scholar] [CrossRef]

- Costa, E.B.C.; Cardoso, F.A.; John, V.M. Influence of high contents of limestone fines on rheological behaviour and bond strength of cement-based mortars. Constr. Build. Mater. 2017, 156, 1114–1126. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Xing, J.; Sun, X.; Ma, Z. Flowability of ultrafine-tailings cemented paste backfill incorporating superplasticizer: Insight from water film thickness theory. Powder Technol. 2021, 381, 509–517. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Q.; Tang, S.; Pei, Y.; Skoczylas, F. Effects of fly ash and silica fume on the rheological properties of magnesium phosphate cement-emulsified asphalt (MPC-EA) composite repair materials. Constr. Build. Mater. 2024, 433, 136708. [Google Scholar] [CrossRef]

- Li, T.; Xu, X.; Yang, J.; Hu, X.; Xue, J.; He, Y.; Tang, Y. Effect of fly ash on the rheological properties of potassium magnesium phosphate cement paste. Case Stud. Constr. Mater. 2022, 17, e01650. [Google Scholar] [CrossRef]

- Zhang, D.; Zhu, T.; Yang, Q.; Vandeginste, V.; Li, J. Influence of ground granulated blast furnace slag on recycled concrete powder-based geopolymer cured at ambient temperature: Rheology, mechanical properties, reaction kinetics and air-void characteristics. Constr. Build. Mater. 2024, 438, 137190. [Google Scholar] [CrossRef]

- Kouider Djelloul, O.; Menadi, B.; Kenai, S. The effect of slag and natural pozzolan on the rheological and compressive strength properties of recycled self-compacting mortar. Eur. J. Environ. Civ. Civil. Eng. 2024, 28, 3793–3810. [Google Scholar] [CrossRef]

- Liu, H.; Sun, X.; Wang, Y.; Lu, X.; Du, H.; Tian, Z. Study on the Influence of Silica Fume (SF) on the Rheology, Fluidity, Stability, Time-Varying Characteristics, and Mechanism of Cement Paste. Materials 2022, 15, 90. [Google Scholar] [CrossRef]

- Dong, D.; Huang, Y.; Pei, Y.; Zhang, X.; Cui, N.; Zhao, P.; Hou, P.; Lu, L. Effect of spherical silica fume and fly ash on the rheological property, fluidity, setting time, compressive strength, water resistance and drying shrinkage of magnesium ammonium phosphate cement. J. Build. Eng. 2023, 63, 105484. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Muñoz, M.A.; Vargas, A.; Mejía de Gutiérrez, R. Effects of incorporating bentonite, metakaolin, microsilica, and calcium carbonate on the rheological properties of portland cement-based 3D printing inks. Constr. Build. Mater. 2024, 445, 137857. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, L.; Wu, H.; Wang, Z.; Yao, Y. Effect and Mechanism of Coral Powder on the Rheological Properties of Cementitious Materials. J. Phys. Conf. Ser. 2020, 1622, 012084. [Google Scholar] [CrossRef]

- Qin, Q.; Meng, Q.; Gan, M.; Zhang, J.; Yi, P. Synergistic effects of waste coral powder and metakaolin in cement pastes: Hydration, pore structure, rheology, and strength. J. Build. Eng. 2024, 97, 111001. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, F.; Wang, R. Study on the interaction between limestone filler and rice husk ash on the rheological properties of cement composite pastes. Constr. Build. Mater. 2024, 456, 139247. [Google Scholar] [CrossRef]

- Jiang, S.; Shan, B.H.; Ouyang, J.; Zhang, W.; Yu, X.; Li, P.G.; Han, B.G. Rheological properties of cementitious composites with nano/fiber fillers. Constr. Build. Mater. 2018, 158, 786–800. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Wang, H.; Yang, X.; Xiong, W.; Liu, X.; Zhang, Z. Synthesis and the Effects of New Melamine Superplasticizer on the Properties of Concrete. ISRN Chem. Eng. 2013, 2013, 708063. [Google Scholar] [CrossRef]

- Marchon, D.; Flatt, R.J. 12—Impact of chemical admixtures on cement hydration. In Reviews in Science and Technology of Concrete Admixtures; Aïtcin, P.-C., Flatt, R.J., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 279–304. [Google Scholar]

- He, Y.; Zhang, X.; Hooton, R.D.; Wang, Y.T.; Kong, Y.N.; Wang, X.F.; Wang, H.R. Influence of PCE on Rheological and Hydration Performances of Cement Paste. J. Mater. Civ. Civil. Eng. 2020, 32, 04020002. [Google Scholar] [CrossRef]

- Xu, H.; Tian, H.; Deng, J.; Zhuo, Q.; Cui, J.; Wang, J.; Yin, Y.; Yu, P. Review of influence of steric effect on aggregation behavior of fine particles. Miner. Eng. 2023, 203, 108304. [Google Scholar] [CrossRef]

- Pott, U.; Jakob, C.; Jansen, D.; Neubauer, J.; Stephan, D. Investigation of the Incompatibilities of Cement and Superplasticizers and Their Influence on the Rheological Behavior. Materials 2020, 13, 977. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Zhang, Y.; Zhang, G.; Zhu, H. Composite application of naphthalene and melamine-based superplasticizers in alkali activated fly ash (AAFA). Constr. Build. Mater. 2021, 297, 123651. [Google Scholar] [CrossRef]

- Stecher, J.; Plank, J. Novel concrete superplasticizers based on phosphate esters. Cem. Concr. Res. 2019, 119, 36–43. [Google Scholar] [CrossRef]

- Chen, S.L.; Sun, S.M.; Chen, X.L.; Zhong, K.H.; Shao, Q.; Xu, H.J.; Wei, J.X. Effects of core-shell polycarboxylate superplasticizer on the fluidity and hydration behavior of cement paste. Colloids Surf. A-Physicochem. Eng. Asp. 2020, 590, 124464. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Xie, Y.; Liu, Y.; Tao, J.; Liu, R.; Li, Z.; Liu, F.; Li, M. The effect of alkyl acrylate ester side chain length of polycarboxylate superplasticizer on the flow behaviour of concrete. Constr. Build. Mater. 2024, 443, 137691. [Google Scholar] [CrossRef]

- Phan, T.H.; Chaouche, M.; Moranville, M. Influence of organic admixtures on the rheological behaviour of cement pastes. Cem. Concr. Res. 2006, 36, 1807–1813. [Google Scholar] [CrossRef]

- Lachemi, M.; Hossain, K.M.A.; Lambros, V.; Nkinamubanzi, P.C.; Bouzoubaa, N. Performance of new viscosity modifying admixtures in enhancing the rheological properties of cement paste. Cem. Concr. Res. 2004, 34, 185–193. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F. The effect of viscosity modifying agents on mortar and concrete. Cem. Concr. Compos. 2007, 29, 341–349. [Google Scholar] [CrossRef]

- Azima, M.; Bundur, Z.B. Influence of Sporasarcina pasteurii cells on rheological properties of cement paste. Constr. Build. Mater. 2019, 225, 1086–1097. [Google Scholar] [CrossRef]

- Pei, R.; Liu, J.; Wang, S. Use of bacterial cell walls as a viscosity-modifying admixture of concrete. Cem. Concr. Compos. 2015, 55, 186–195. [Google Scholar] [CrossRef]

- Ortiz-Álvarez, N.; Lizarazo-Marriaga, J.; Brandão, P.F.B.; Santos-Panqueva, Y.; Carrillo, J. Rheological properties of cement-based materials using a biopolymer viscosity modifying admixture (BVMA) under different dispersion conditions. Cem. Concr. Compos. 2021, 124, 104224. [Google Scholar] [CrossRef]

- Teng, L.; Wei, J.; Khayat, K.H.; Assaad, J.J. Effect of competitive adsorption between specialty admixtures and superplasticizer on structural build-up and hardened property of mortar phase of ultra-high-performance concrete. Cem. Concr. Compos. 2023, 141, 105130. [Google Scholar] [CrossRef]

- Castellanos, R.; Gálvez, J.C.; Alberti, M.G.; Vera-Agulló, J.; Pina-Zapardiel, R. Rheological analysis of wet-mix shotcrete with various viscosity-modifiying admixtures. Tunn. Undergr. Space Technol. 2023, 142, 105269. [Google Scholar] [CrossRef]

- Chen, N.; Wang, P.M.; Zhao, L.Q.; Zhang, G.F. Water Retention Mechanism of HPMC in Cement Mortar. Materials 2020, 13, 2918. [Google Scholar] [CrossRef] [PubMed]

- Cappellari, M.; Daubresse, A.; Chaouche, M. Influence of organic thickening admixtures on the rheological properties of mortars: Relationship with water-retention. Constr. Build. Mater. 2013, 38, 950–961. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jones, S.Z.; Bentz, I.R.; Peltz, M.A. Towards the formulation of robust and sustainable cementitious binders for 3-D additive construction by extrusion. Constr. Build. Mater. 2018, 175, 215–224. [Google Scholar] [CrossRef]

- Brough, A.R.; Holloway, M.; Sykes, J.; Atkinson, A. Sodium silicate-based alkali-activated slag mortars Part II. The retarding effect of additions of sodium chloride or malic acid. Cem. Concr. Res. 2000, 30, 1375–1379. [Google Scholar] [CrossRef]

- Baskoca, A.; Ozkul, M.H.; Artirma, S. Effect of chemical admixtures on workability and strength properties of prolonged agitated concrete. Cem. Concr. Res. 1998, 28, 737–747. [Google Scholar] [CrossRef]

- Yildirim, H.; Altun, B. Usage of molasses in concrete as a water reducing and retarding admixture. Indian J. Eng. Mater. Sci. 2012, 19, 421–426. [Google Scholar]

- Emoto, T.; Bier, T.A. Rheological behavior as influenced by plasticizers and hydration kinetics. Cem. Concr. Res. 2007, 37, 647–654. [Google Scholar] [CrossRef]

- Lu, H.; Wang, J.; Zhan, X.; Zhao, P.; Xie, Z.; Wang, S.; Yue, Z. Effects of retarders on the rheological properties of coal fly ash/superfine iron tailings-based 3D printing geopolymer: Insight into the early retarding mechanism. Constr. Build. Mater. 2024, 411, 134445. [Google Scholar] [CrossRef]

- Chen, M.X.; Li, L.B.; Wang, J.A.; Huang, Y.B.; Wang, S.D.; Zhao, P.Q.; Lu, L.C.; Cheng, X. Rheological parameters and building time of 3D printing sulphoaluminate cement paste modified by retarder and diatomite. Constr. Build. Mater. 2020, 234, 117391. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, Y.; Liu, X.; Tian, C.; Wang, Y.; Mu, Y.; Zhang, M.; Hao, Y. Comparative Investigation of Effect of Borax and Sodium Gluconate Retarders on Properties of Magnesium Phosphate Cement. Arab. J. Sci. Eng. 2022, 47, 13187–13198. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Kanagasuntharam, S.; Sanjayan, J. In-line activation of cementitious materials for 3D concrete printing. Cem. Concr. Compos. 2022, 131, 104598. [Google Scholar] [CrossRef]

- Prevedello Rubin, A.; Hasse, J.A.; Longuini Repette, W. The evaluation of rheological parameters of 3D printable concretes and the effect of accelerating admixture. Constr. Build. Mater. 2021, 276, 122221. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Wang, F.; Zhang, J.; Guo, L.; Zhang, Y.; Li, Y.; Lin, J.; Lu, Z.; Jiang, J. Deciphering the influence of superabsorbent polymers on cement hydration and portlandite formation. Constr. Build. Mater. 2024, 418, 135455. [Google Scholar] [CrossRef]

- Qin, X.; Lin, Y.; Mao, J.; Sun, X.; Xie, Z.; Huang, Q. Research of Water Absorption and Release Mechanism of Superabsorbent Polymer in Cement Paste. Polymers 2023, 15, 3062. [Google Scholar] [CrossRef] [PubMed]

- Bessaies-Bey, H.; Baumann, R.; Schmitz, M.; Radler, M.; Roussel, N. Effect of polyacrylamide on rheology of fresh cement pastes. Cem. Concr. Res. 2015, 76, 98–106. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Secrieru, E.; Schrofl, C. Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—Development of yield stress and plastic viscosity over time. Cem. Concr. Res. 2015, 67, 52–65. [Google Scholar] [CrossRef]

- Liu, J.H.; Khayat, K.H.; Shi, C.J. Effect of superabsorbent polymer characteristics on rheology of ultra-high performance concrete. Cem. Concr. Compos. 2020, 112, 103636. [Google Scholar] [CrossRef]

- Kuruva, V.; Deo, S.V.; Murmu, M. Effect of dosage of super absorbent polymer on self-consolidating concrete: Correlation between compressive strength and rheological properties. Mater. Today Proc. 2023, 93, 29–34. [Google Scholar] [CrossRef]

- Paiva, H.; Esteves, L.P.; Cachim, P.B.; Ferreira, V.M. Rheology and hardened properties of single-coat render mortars with different types of water retaining agents. Constr. Build. Mater. 2009, 23, 1141–1146. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Fakoorpoor, S.M.; Hosseini, P.; Khaloo, A. Interactions between superabsorbent polymers and cement-based composites incorporating colloidal silica nanoparticles. Cem. Concr. Compos. 2013, 37, 196–204. [Google Scholar] [CrossRef]

- Secrieru, E.; Mechtcherine, V.; Schrofl, C.; Bonin, D. Rheological characterisation and prediction of pumpability of strain hardening cement-based-composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr. Build. Mater. 2016, 112, 581–594. [Google Scholar] [CrossRef]

- Geng, J.; He, L.; Chen, M.; Niu, Y. Applicability of rheological properties of superabsorbent polymer cement-based materials using apparent viscosity. Mater. Struct. 2022, 55, 79. [Google Scholar] [CrossRef]

- Adsul, N.; Lee, J.-W.; Kang, S.-T. Investigating the Impact of Superabsorbent Polymer Sizes on Absorption and Cement Paste Rheology. Materials 2024, 17, 3115. [Google Scholar] [CrossRef] [PubMed]

- Dilbas, H. Effect of Cement Type and Water-to-Cement Ratio on Fresh Properties of Superabsorbent Polymer-Modified Cement Paste. Materials 2023, 16, 2614. [Google Scholar] [CrossRef]

- Gu, Y.-C.; Khayat, K.H. Effect of superabsorbent polymer on 3D printing characteristics as rheology-modified agent. Constr. Build. Mater. 2024, 438, 137140. [Google Scholar] [CrossRef]

- Gu, Y.-c.; Zheng, S.; Ma, H.; Long, W.-J.; Khayat, K.H. Effect of absorption kinetics of superabsorbent polymers on printability and interlayer bond of 3D printing concrete. Cem. Concr. Compos. 2024, 151, 105609. [Google Scholar] [CrossRef]

- Li, B.; Ding, T.; Qu, C.; Liu, W. Modification of fresh and hardened properties of 3D-printed recycled mortar by superabsorbent polymers. J. Build. Eng. 2024, 95, 110189. [Google Scholar] [CrossRef]

- Luo, Q.-L.; Yu, K.-K.; Long, W.-J.; Zheng, S.-Y.; Geng, S.-Y.; Feng, G.-L.; Wang, H.-L.; Qiu, Z.-H. Influence of different types of superabsorbent polymers on fresh mechanical properties and interlayer adhesion of 3D printed concrete. Case Stud. Constr. Mater. 2024, 21, e03517. [Google Scholar] [CrossRef]

- Oh, S.; Choi, S. Effects of superabsorbent polymers (SAP) on the rheological behavior of cement mortars: A rheological study on performance requirements for 3D printable cementitious materials. Constr. Build. Mater. 2023, 392, 131856. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, M.; Zhang, Y.; Li, Z.; Šavija, B.; Schlangen, E.; Çopuroğlu, O. Can superabsorbent polymers be used as rheology modifiers for cementitious materials in the context of 3D concrete printing? Constr. Build. Mater. 2023, 371, 130777. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Ben Fraj, A. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Yang, H.B.; Yang, Q.; Du, X.H.; Li, C.S.; Cheng, X. Effects of particle size of colloidal nanosilica on hydration of Portland cement at early age. Adv. Mech. Eng. 2019, 11, 1687814019828948. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Mahmood, W.; Noaman, R.; Ghafor, K.; Qadir, W.; Kadhum, Q. Characterization and modeling the flow behavior and compression strength of the cement paste modified with silica nano-size at different temperature conditions. Constr. Build. Mater. 2020, 257, 119590. [Google Scholar] [CrossRef]

- Qian, Y.; Ma, S.W.; Kawashima, S.; De Schutter, G. Rheological characterization of the viscoelastic solid-like properties of fresh cement pastes with nanoclay addition. Theor. Appl. Fract. Mech. 2019, 103, 7. [Google Scholar] [CrossRef]

- Varela, H.; Barluenga, G.; Palomar, I. Influence of nanoclays on flowability and rheology of SCC pastes. Constr. Build. Mater. 2020, 243, 118285. [Google Scholar] [CrossRef]

- Qian, Y.; De Schutter, G. Enhancing thixotropy of fresh cement pastes with nanoclay in presence of polycarboxylate ether superplasticizer (PCE). Cem. Concr. Res. 2018, 111, 15–22. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Tan, M.J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. Part. B-Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.Q.; Unluer, C.; Tan, M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part. B-Eng. 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.S.; Liu, G.J.; Yang, Y.G.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Liu, J.Z.; Wang, K.J.; Zhang, Q.Q.; Lomboy, G.R.; Zhang, L.H.; Liu, J.P. Effects of Ultrafine Powders on the Properties of the Lubrication Layer and Highly Flowable Concrete. J. Mater. Civ. Civil. Eng. 2020, 32, 10. [Google Scholar] [CrossRef]

- Sun, H.; Que, Z.; Wei, H.; Zhou, A.; Peng, X.; Cui, W.; Wang, X. Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers. Nanotechnol. Rev. 2022, 11, 1570–1582. [Google Scholar] [CrossRef]

- Wang, B.M.; Fan, C.C. Effect of carbon nanofibers on rheological and mechanical properties of cement composites. Mater. Res. Express 2018, 5, 065058. [Google Scholar] [CrossRef]

- Kilic, U.; Soliman, N.; Omran, A.; Ozbulut, O.E. Effects of cellulose nanofibrils on rheological and mechanical properties of 3D printable cement composites. Cem. Concr. Compos. 2024, 152, 105617. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstandinidis, A.; Koltsou, P.; Papadopoulos, S. 24—Rheological properties of biofibers in cementitious composite matrix. In Reviews in Advances in Bio-Based Fiber; Rangappa, S.M., Puttegowda, M., Parameswaranpillai, J., Siengchin, S., Gorbatyuk, S., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 553–573. [Google Scholar]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lu, C.-X.; Cui, X.-Y.; Li, S.-Y.; Wang, X. Rheological behavior of fresh cement pastes with a graphene oxide additive. New Carbon. Mater. 2016, 31, 574–584. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Aunkor, M.T.H.; Javed, M.F.; Mehmood, K.; Shah, S.M.A. Influence of Graphene Nanosheets on Rheology, Microstructure, Strength Development and Self-Sensing Properties of Cement Based Composites. Sustainability 2018, 10, 822. [Google Scholar] [CrossRef]

- Hulagabali, M.M.; Vesmawala, G.R.; Patil, Y.D. Synthesis, characterization, and application of graphene oxide and reduced graphene oxide and its influence on rheology, microstructure, and mechanical strength of cement paste. J. Build. Eng. 2023, 71, 106586. [Google Scholar] [CrossRef]

- Alatawna, A.; Birenboim, M.; Nadiv, R.; Buzaglo, M.; Peretz-Damari, S.; Peled, A.; Regev, O.; Sripada, R. The effect of compatibility and dimensionality of carbon nanofillers on cement composites. Constr. Build. Mater. 2020, 232, 117141. [Google Scholar] [CrossRef]

- Gunnelius, K.R.; Lundin, T.C.; Rosenholm, J.B.; Peltonen, J. Rheological characterization of cement pastes with functional filler particles. Cem. Concr. Res. 2014, 65, 1–7. [Google Scholar] [CrossRef]

- Li, H.Y.; Ding, S.Q.; Zhang, L.Q.; Ouyang, J.; Han, B.G. Effects of particle size, crystal phase and surface treatment of nano-TiO2 on the rheological parameters of cement paste. Constr. Build. Mater. 2020, 239, 10. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Peng, Y.M.; Ma, K.L.; Long, G.C.; Xie, Y.J. Influence of Nano-SiO2, Nano-CaCO3 and Nano-Al2O3 on Rheological Properties of Cement-Fly Ash Paste. Materials 2019, 12, 2598. [Google Scholar] [CrossRef] [PubMed]

- Montes, F.; Fu, T.F.; Youngblood, J.P.; Weiss, J. Rheological impact of using cellulose nanocrystals (CNC) in cement pastes. Constr. Build. Mater. 2020, 235, 117497. [Google Scholar] [CrossRef]

- Chu, S.H.; Li, L.G.; Kwan, A.K.H. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Le, N.; Khuong, M.U.; Thong, M.P. Generative artificial intelligence and optimisation framework for concrete mixture design with low cost and embodied carbon dioxide. Constr. Build. Mater. 2024, 451, 138836. [Google Scholar]

- Barbhuiya, S.; Mhd, S.S. Artificial Intelligence in Concrete Mix Design: Advances, Applications and Challenges. In Proceedings of the International Conference on Innovation and Intelligence for Informatics, Computing, and Technologies (3ICT), Manama, Bahrein, 20–21 November 2023. [Google Scholar]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Long, W.J.; Li, H.D.; Wei, J.J.; Xing, F.; Han, N. Sustainable use of recycled crumb rubbers in eco-friendly alkali activated slag mortar: Dynamic mechanical properties. J. Clean. Prod. 2018, 204, 1004–1015. [Google Scholar] [CrossRef]

- Long, W.J.; Zhang, X.; Xie, J.; Kou, S.; Luo, Q.; Wei, J.; Feng, G.L. Recycling of waste cathode ray tube glass through fly ash-slag geopolymer mortar. Constr. Build. Mater. 2022, 322, 126454. [Google Scholar] [CrossRef]

- Wei, J.J.; Wu, Z.; Fang, C.; Dong, B.; Long, W.J. Effect of calcined clay content on dynamic mechanical properties of ultra-high performance concrete. J. Chin. Ceram. Soc. 2021, 49, 2355. [Google Scholar]

- Li, H.; Wei, J.; Khayat, K.H. 3D printing of fiber-reinforced calcined clay-limestone-based cementitious materials: From mixture design to printability evaluation. Buildings 2024, 14, 1666. [Google Scholar] [CrossRef]

- Du, J.; Guo, P.; Liu, Z.; Meng, W. Highly thixotropic ultra-high-performance concrete (UHPC) as an overlay. Constr. Build. Mater. 2023, 366, 130130. [Google Scholar] [CrossRef]

| Type | Dosage | Rheological Impact(s) | Key Finding(s) | Study |

|---|---|---|---|---|

| NS | 1.5%, 3%, and 5% by the weight of the binder | Acts as a thickening agent, reducing the slump and potentially affecting the fluidity. | It is an effective thickening agent but reduces the fluidity, emphasizing the need for the proper dosage. | [113] |

| A mass fraction of 5% of the cement | The yield stress increases by 82.6%, 62.1%, and 38.2%, while the plastic viscosity rises by 53.0%, 55.1%, and 57.3%. | Nanoparticles increase the yield stress significantly because of flocculation, affecting free water’s mobility. | [114] | |

| 1% NS | The shear stress limit increased from 15% to 52.7%. | The percentage of the NS strongly impacts the shear stress and plastic viscosity. | [115] | |

| NCs | 0, 0.1, 0.3, and 0.5% by the mass of the binder | With a 0.5% NC addition, the static yield stress increased from 19 Pa to 58.2 Pa. | The cohesion and static yield stress increased with increasing NC addition. | [116] |

| 2% by the cement weight for the four NCs (attapulgite, bentonite, and sepiolite) | The yield stress and viscosity increased, particularly with the sepiolite addition. | They enhanced the static yield stress and thixotropy and were ideal for pumpability and buildability. | [117] | |

| 0.5% NCs | Increased the static yield stress without affecting the apparent viscosity. | Effective in 3DPC, providing high yield stress and low viscosity for improving the layer stability. | [119] | |

| Nano-CaCO3 | 1% replacement of the cement | Increased the yield stress, plastic viscosity, and thixotropic behavior | Improved flow characteristics while maintaining stability | [122] |

| Replaced 0%, 2%, and 4% by mass of the cement | Using nano-CaCO3 increased the shape retention factor from 0.87 to 0.97. | The addition of nano-CaCO3 improved the rheology. | [137] | |

| NT | 0, 0.1%, 0.3%, 0.5%, 0.7%, and 1.4 vol% of the cement | Increased the cohesive energy and rheological parameters (yield stress and viscosity) depending on the particle size and crystal phase (rutile > anatase) | Rutile NT increased the rheological parameters because of its higher surface energy, highlighting the impacts of the particle size and structure. | [133] |

| 0–12 wt.% | The addition of the NT significantly increased the values of the torque and yield stress, corresponding to a decrease in the open testing time. | Using SP at varying levels, depending on the concentration of the NT, resulted in additional performance improvements and distinct variations in hydration kinetics. | [134] | |

| CNCs | Addition rates from 0.023 vol% to 3.311 vol% relative to the dry cement | Low dosages reduced the yield stress by 54%; high dosages increased the yield stress by over 10 times the original value. | Versatile behavior, with water-reducing properties at low dosages, making CNCs adaptable to varied rheological requirements. | [136] |

| CNFs | Variable CNF dosages (0, 0.05%, 0.1%, 0.2%, 0.3%, 0.4%, and 0.5%) | Higher viscosity, yield stress, and flow resistance with increased CNF content; the increased rate of the yield stress ranged from 167% to 11,867%. | Strong interfacial bonds and nucleation sites from CNFs increased the yield stress, which is ideal for high-performance applications. | [124] |

| GO | 0.01, 0.03, and 0.05 wt.% of the cement | The effects of the GO increased the yield stress and plastic viscosity and enhanced thixotropy and flocculation. | GO promotes microstructural flocculation, with significant effect on fresh and long-term performance | [128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, K.; Yang, J.; He, H.; Wei, J.; Zhu, Y. Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Materials 2025, 18, 1753. https://doi.org/10.3390/ma18081753

Xu K, Yang J, He H, Wei J, Zhu Y. Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Materials. 2025; 18(8):1753. https://doi.org/10.3390/ma18081753

Chicago/Turabian StyleXu, Ke, Jie Yang, Haijie He, Jingjie Wei, and Yanping Zhu. 2025. "Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts" Materials 18, no. 8: 1753. https://doi.org/10.3390/ma18081753

APA StyleXu, K., Yang, J., He, H., Wei, J., & Zhu, Y. (2025). Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Materials, 18(8), 1753. https://doi.org/10.3390/ma18081753