Experimental Analysis of Magnetic Focusing of the Plasma Arc of a Cutting Torch

Abstract

1. Introduction

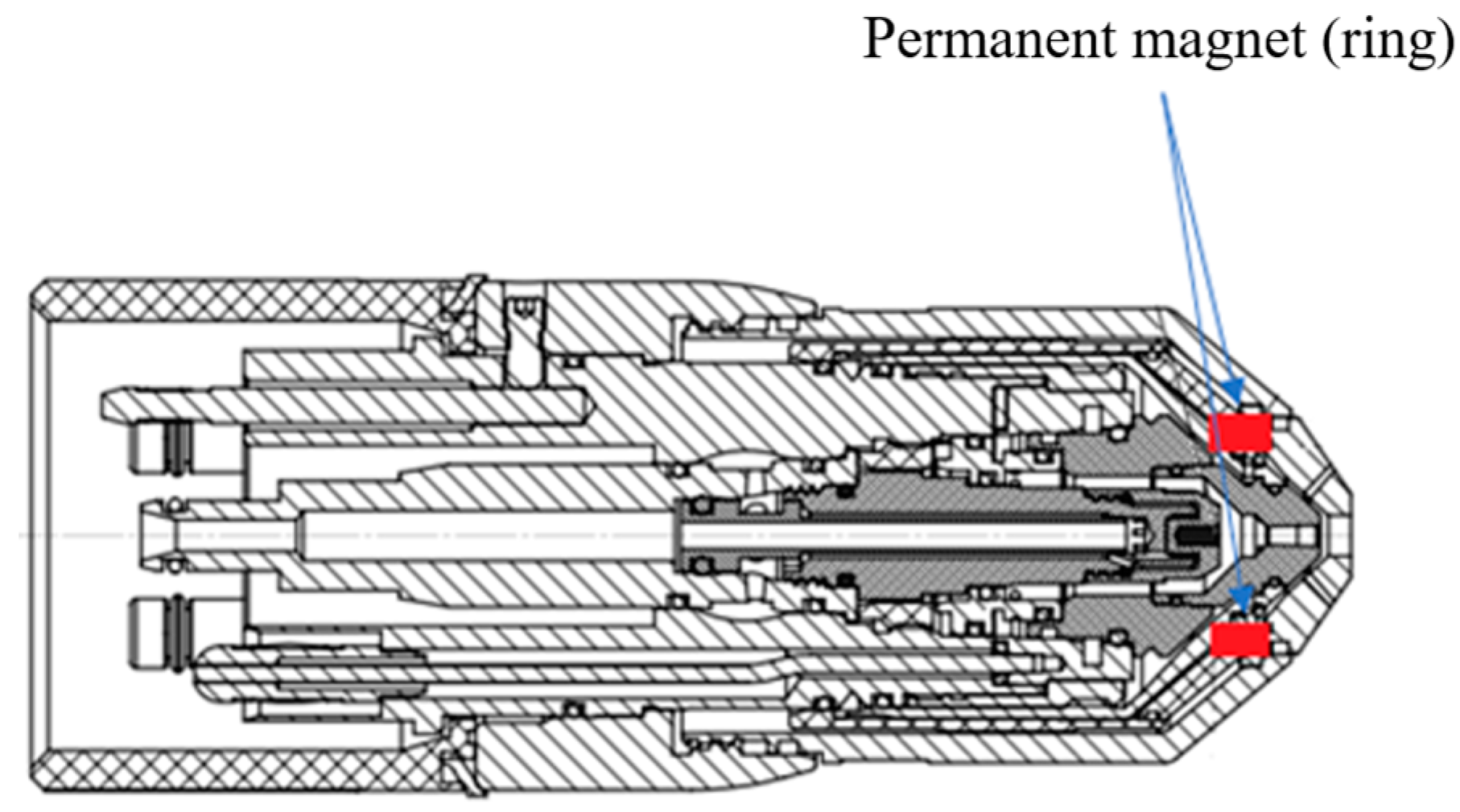

2. Fundamental Principles of Lens and Plasma Arcs Used for Cutting

2.1. Electromagnetic Lens

2.2. Physics of the Cutting Arc

- The high temperature of the cathode spot (or the cathode in general) sufficient for the thermal emission of electrons;

- The current density of the cathode spot is of the order of tens of MA/m2;

- Small electrode losses;

- The small voltage between the electrodes (relative to the voltage of the source);

- Large current passing through the arc (greater than 1 A);

- Intense light emission from the discharge plasma and the electrodes.

2.2.1. Arc Temperature

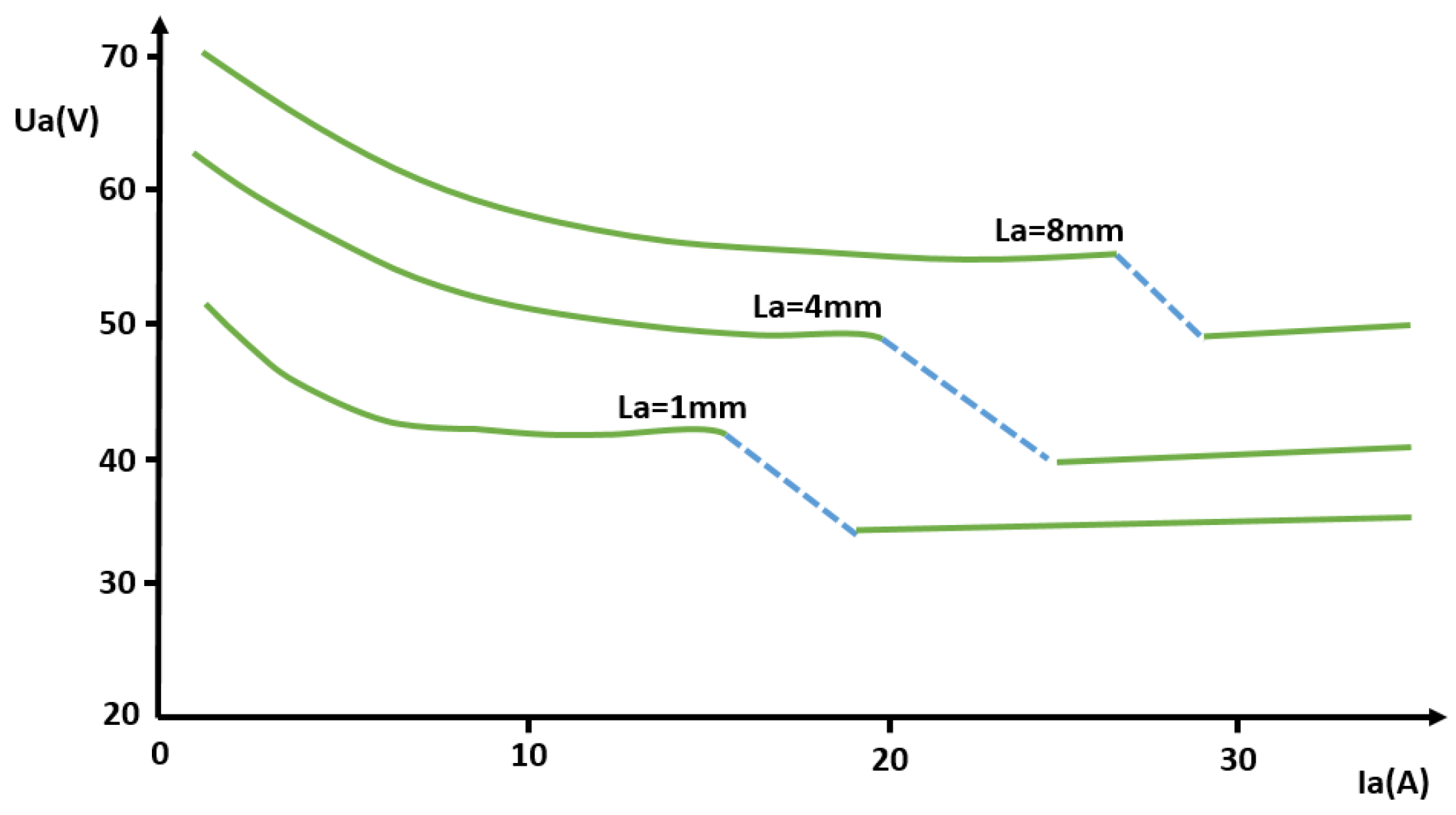

2.2.2. Discharge Characteristic of the Arc

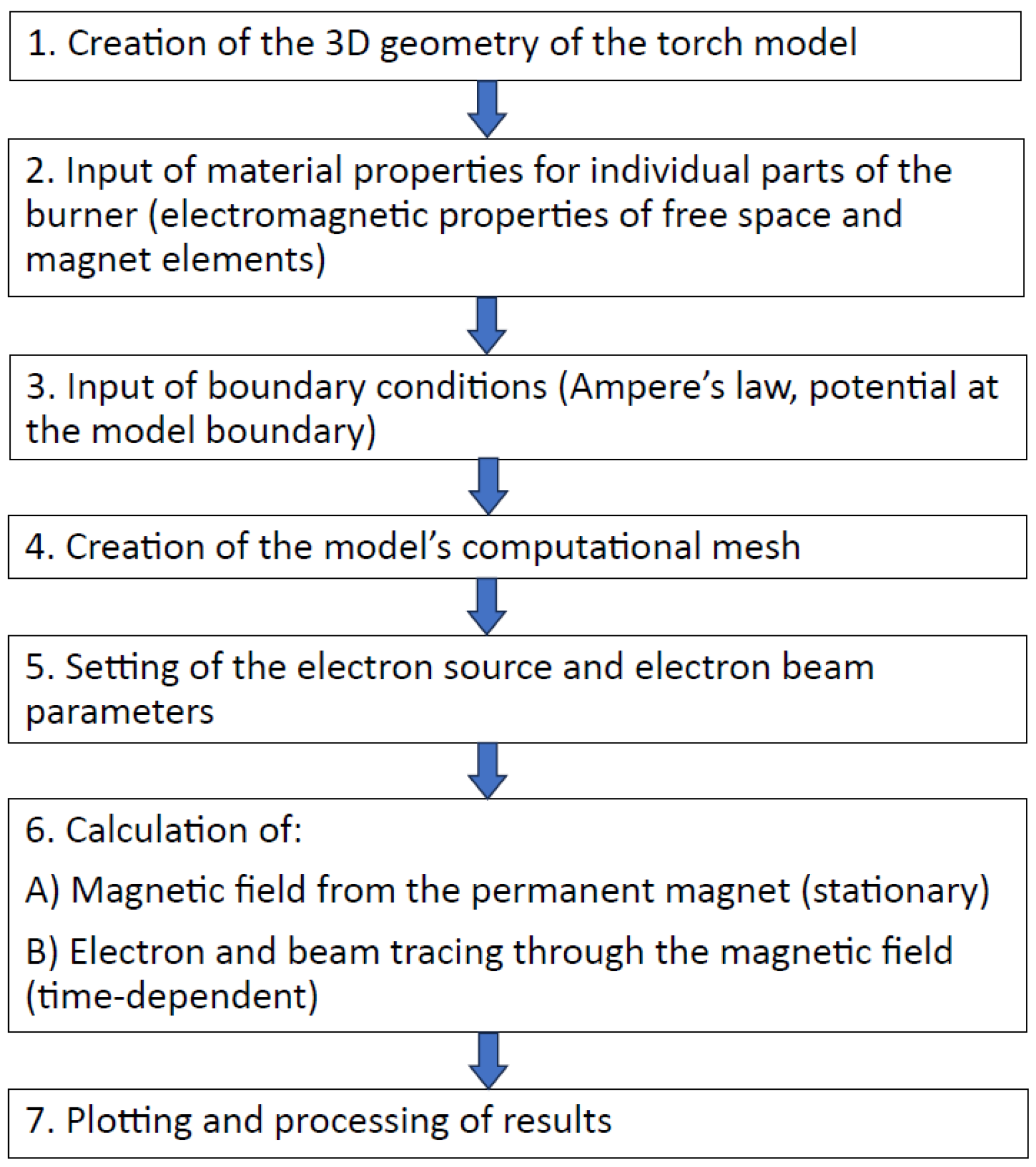

3. Experiments and Simulation Results

- Basic simulation with a permanent magnet alone and with a 3D torch together with a magnet;

- Main simulation with a reduced 3D burner model (with geometric and energy variations).

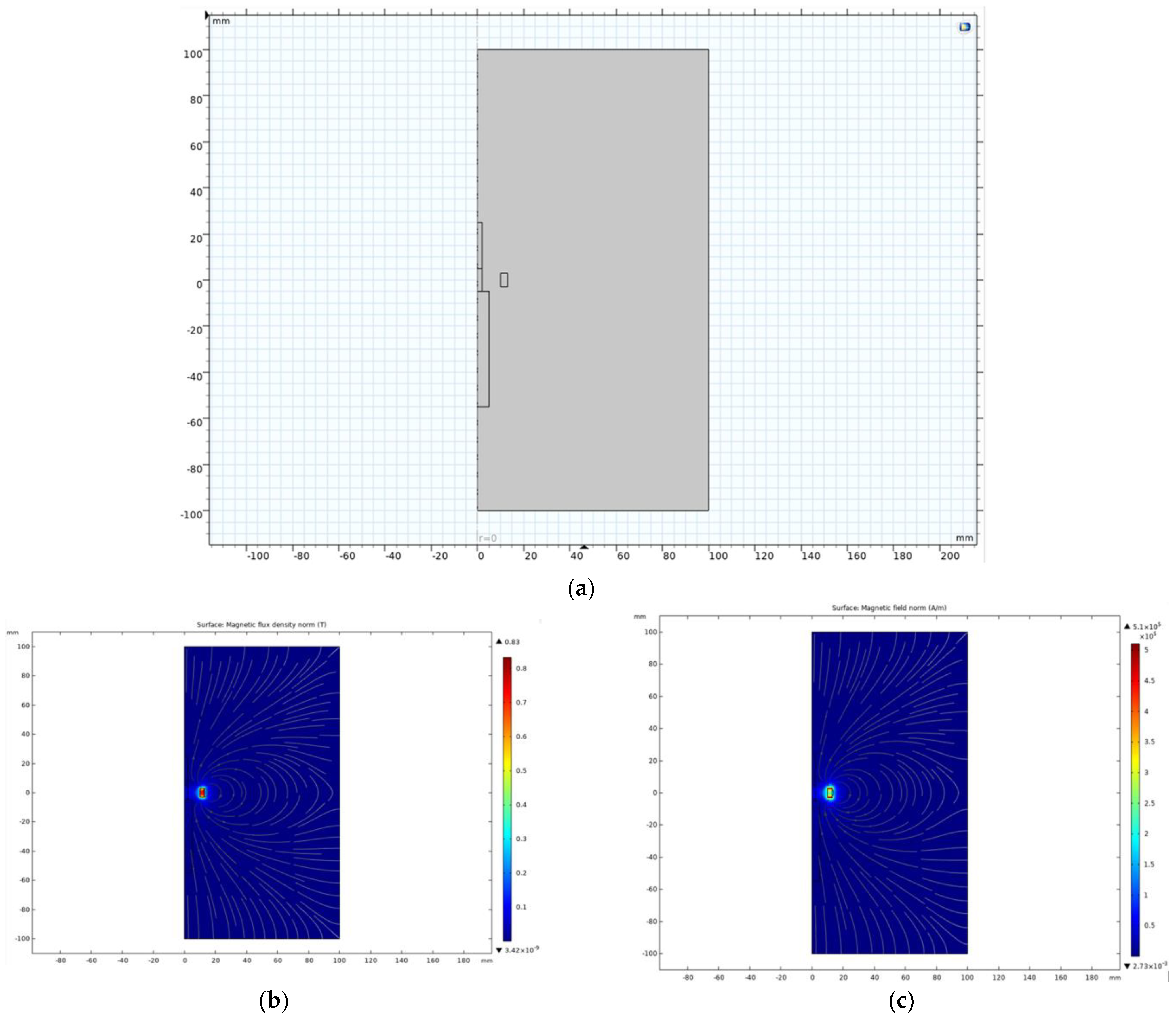

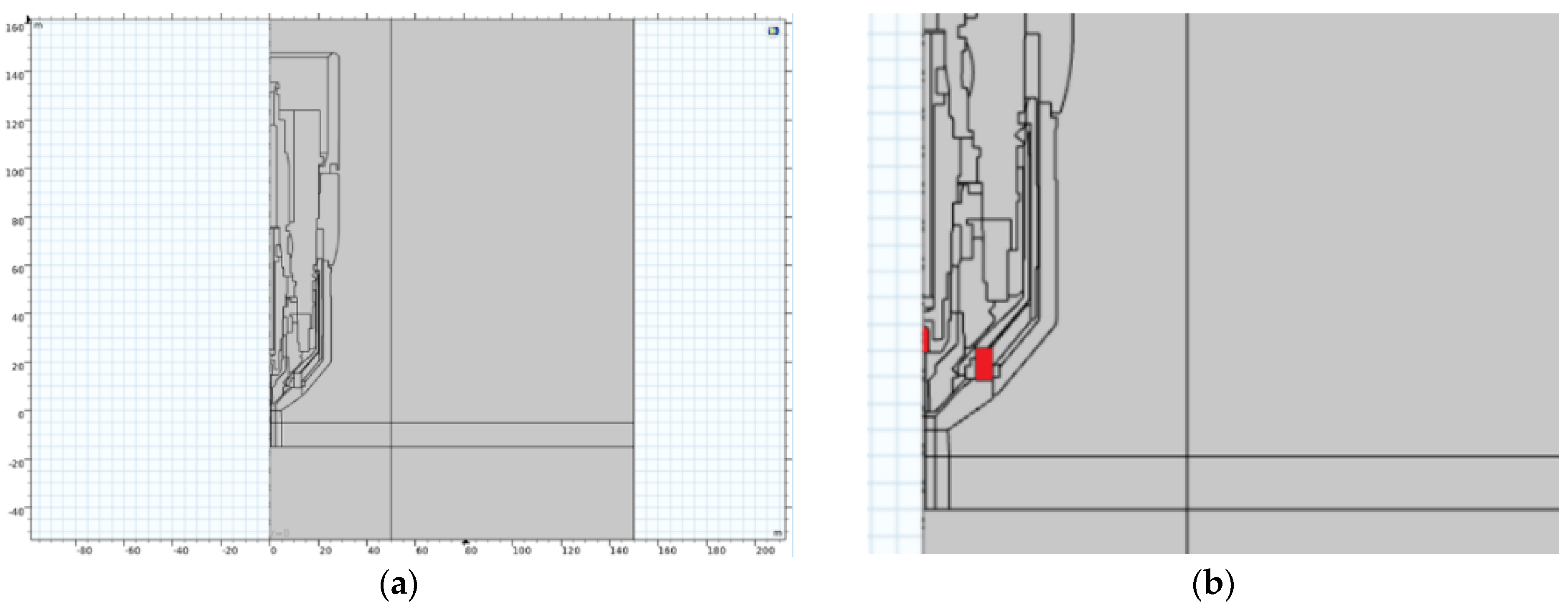

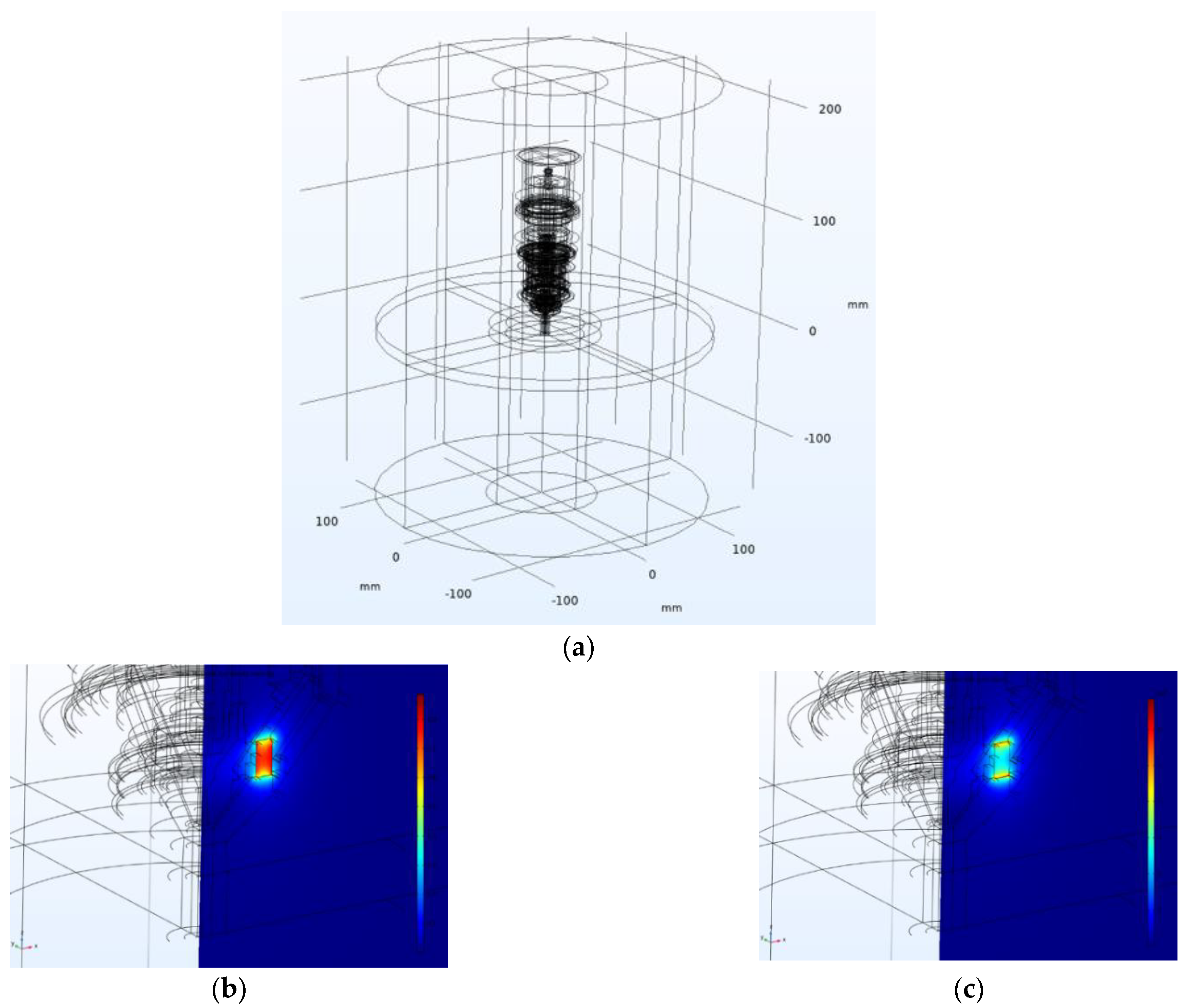

3.1. Basic Simulation

3.1.1. Permanent Magnet Alone

3.1.2. 3D Torch with Magnet

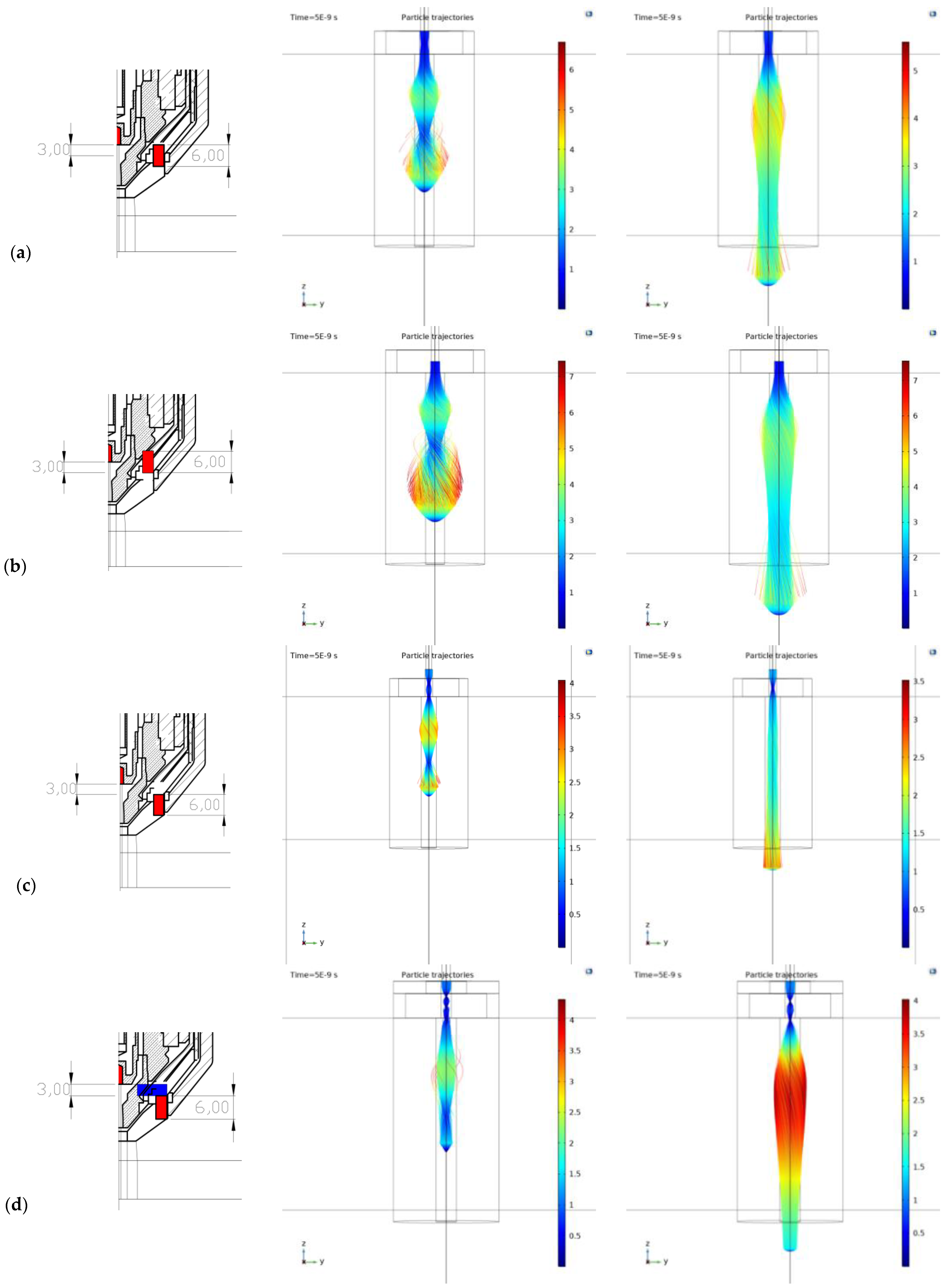

3.2. Main Simulation-Reduced 3D Burner Model for Different Geometric and Energy Variations

- Version 1—the magnet itself, the electrode together with the top of the magnet—Figure 9a;

- Version 2—the magnet itself, the electrode in the middle of the magnet +3 mm down—Figure 9b;

- Version 3—the magnet itself, the electrode having moved up +3 mm—Figure 9c;

- Version 4—pole attachment only on top—Figure 9d;

- Version 5—two pole extensions (top and bottom)—Figure 9e;

- Version 6—pole attachment only below—Figure 9f;

- Version 7—the magnet itself, with the Fe plate 1 cm away from the magnet/1 cm thick—Figure 9g;

- Version 8—top and bottom pole extensions, with the Fe plate 1 cm away from magnet/1 cm thick—Figure 9h.

4. Discussion

- The results demonstrate the impact of the magnet, along with the nozzle placement and configuration, providing a clear understanding of their influence and suitability. These findings, combined with the employed method, offer insights into approximating the plasma discharge focus from a cutting torch by converting the plasma current into an electron beam. This approach is applicable to specific configurations of magnet position and torch energy and can be extended to general plasma and electron beams in various applications, such as plasma welding [39], coating [40], etc.

- The initial energy and velocity of the electrons affect the curvature of their path. Higher energy results in a more evenly focused beam. Practically, lower arc currents with higher arc voltages are recommended. Additionally, the insertion height of the cathode into the top plane of the permanent magnet significantly impacts the electron beam characteristics. These conclusions are supported by the trajectory maps for each configuration.

- The beam is most uniformly focused for variant (c), where the magnet is positioned 3 mm below the cathode with a higher accelerating voltage. The deflection at the nozzle mouth here is approximately 3 mm, resulting in a parallel linear beam. In contrast, variants (e), (f), and (h), which involve specific configurations of the pole extensions, exhibit significant defocusing of the electron beam. In variant (h), the beam is deflected up to 14 mm at the nozzle mouth, with magnetic focusing having an opposite effect, causing substantial blurring and broadening of the electron beam. Other variants without pole extensions show similar behavior, with the magnitude of the effect varying due to the displacement of the beam with the magnetic field of the magnet. The key to evaluation and the overall effect lies in adjusting the initial position of the electron beam relative to the magnetic field of the magnet.

- The final configuration of the electron beam is primarily determined by the entry and exit points of the beam within the magnet’s magnetic field. Additionally, the initial energy imparted to the electrons by the accelerating voltage plays a crucial role, with significantly influence from the specific accelerating voltage applied to the electron beam and lens setup.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liziakin, G.D.; Gavrikov, A.V.; Kuzmichev, S.D.; Smirnov, V.P.; Usmanov, R.A. Generation of a radial electric field in a cylindrical plasma column with an axial magnetic field. Uspekhi Fiz. Nauk 2024, 194, 495–519. [Google Scholar] [CrossRef]

- El Khalloufi, M.; Soucy, G. Oxide Reduction Treatment with a Thermal Plasma Torch: A Case Study. Minerals 2024, 14, 443. [Google Scholar] [CrossRef]

- Boulos, M.I.; Fauchais, P.L.; Pfender, E. Plasma torches for cutting, welding, and PTA coating. In Handbook of Thermal Plasmas, 1st ed.; Boulos, M.I., Fauchais, P.L., Pfender, E., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Venkatramani, N. Industrial plasma torches and applications. Curr. Sci. 2002, 83, 254–262. Available online: https://www.currentscience.ac.in/Volumes/83/03/0254.pdf (accessed on 3 June 2024).

- Ophus, C. Quantitative scanning transmission electron microscopy for materials science: Imaging, diffraction, spectroscopy, and tomography. Annu. Rev. Mater. Res. 2023, 53, 105–141. [Google Scholar] [CrossRef]

- COMSOL Multiphysics®, Simulation Software, Understand, Predict, and Optimize Real-World Designs, Devices, and Processes with Simulation. Available online: https://www.comsol.com/comsol-multiphysics (accessed on 17 June 2024).

- Vajdi, M.; Moghanlou, F.S.; Sharifianjazi, F.; Asl, M.S.; Shokouhimehr, M. A review on the Comsol Multiphysics studies of heat transfer in advanced ceramics. J. Compos. Compd. 2020, 2, 35–43. [Google Scholar] [CrossRef]

- Wu, J.; Meng, Z.; Zhang, X.; Mi, W.; Yan, Y. Capacitive angle sensor research using COMSOL Multiphysics. Appl. Sci. 2023, 13, 2937. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, W.; Chen, X.; Xiao, J. A frequency-domain micromagnetic simulation module based on COMSOL Multiphysics. AIP Adv. 2023, 13, 055108. [Google Scholar] [CrossRef]

- Bergs, T.; Biermann, D.; Erkorkmaz, K.; M’Saoubi, R. Digital twins for cutting processes. CIRP Ann. 2023, 72, 541–567. [Google Scholar] [CrossRef]

- Harničárová, M.; Valíček, J.; Zajac, J.; Hloch, S.; Čep, R.; Džubáková, I.; Tofil, S.; Hlaváček, P.; Klich, J.; Čepová, L. Techno-economical comparison of cutting material by laser, plasma and oxygen. Teh. Vjesn. 2012, 19, 813–817. Available online: http://hrcak.srce.hr/file/137703 (accessed on 3 June 2024).

- Tanaka, M.; Lowke, J.J. Predictions of weld pool profiles using plasma physics. J. Phys. D Appl. Phys. 2006, 40, R1. [Google Scholar] [CrossRef]

- Duplák, J.; Hatala, M.; Dupláková, D.; Botko, F. Prediction model of surface roughness parameters of structural steel created by plasma arc cutting via full factor experiment. Mater. Werkstofftechnik (Mater. Sci. Eng. Technol.) 2019, 50, 1207–1220. [Google Scholar] [CrossRef]

- Rohan, P.; Lukáč, F.; Kolaříková, M.; Krum, S.; Horník, J.; Lukeš, J.; Šepitka, J.; Kuchař, J. Pulsed Plasma Surfacing of Titanium Matrix Cermet Based on B4C. J. Therm. Spray Technol. 2022, 31, 1975–1984. [Google Scholar] [CrossRef]

- Caron, D.; John, R.; Scime, E.E.; Steinberger, T.E. Ion velocity distribution functions across a plasma meniscus. J. Vac. Sci. Technol. A 2023, 41, 033001. [Google Scholar] [CrossRef]

- Cantoro, G.; Colombo, V.; Concetti, A.; Ghedini, E.; Sanibondi, P.; Zinzani, F.; Rotundo, F.; Dallavalle, S.; Vancini, M. Plasma arc cutting technology: Simulation and experiments. J. Phys. Conf. Ser. 2011, 275, 012008. [Google Scholar] [CrossRef]

- Lazarevic, A.; Lazarevic, D. Effects of plasma arc cutting process parameters on the cutting speed optimization based on the required cut quality. CIRP J. Manuf. Sci. Technol. 2022, 38, 836–843. [Google Scholar] [CrossRef]

- Lazarević, A.; Ćojbašić, Ž.; Lazarević, D. Computationally intelligent modelling of the plasma cutting process. Int. J. Comput. Integr. Manuf. 2020, 33, 252–264. [Google Scholar] [CrossRef]

- Nedić, B.; Janković, M.; Radovanović, M. Kvalitet obrade kod sečenja plazma. IMK-14-Istraživanje i Razvoj 2013, 19, 7–14. Available online: https://scindeks-clanci.ceon.rs/data/pdf/0354-6829/2013/0354-68291301007N.pdf (accessed on 3 June 2024). (In Serbian).

- Salonitis, K.; Vatousianos, S. Experimental investigation of the plasma arc cutting process. Procedia CIRP 2012, 3, 287–292. [Google Scholar] [CrossRef]

- Peko, I.; Marić, D.; Nedić, B.; Samardžić, I. Modeling and Optimization of Cut Quality Responses in Plasma Jet Cutting of Aluminium Alloy EN AW-5083. Materials 2021, 14, 5559. [Google Scholar] [CrossRef]

- Abouzaid, A.; Mousa, S. Influence of the Cutting Feed Rate on the Hardness and Microstructure of Copper Using Plasma Arc Machining (PAM). Metals 2023, 13, 208. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Melnik, Y.A.; Volosova, M.A. Equipment and Technology for Combined Ion–Plasma Strengthening of Cutting Tools. Machines 2018, 6, 58. [Google Scholar] [CrossRef]

- Praks, P.; Lampart, M.; Praksová, R.; Brkić, D.; Kozubek, T.; Najser, J. Selection of appropriate symbolic regression models using statistical and dynamic system criteria: Example of waste gasification. Axioms 2022, 11, 463. [Google Scholar] [CrossRef]

- Montiel-Bohórquez, N.D.; Saldarriaga-Loaiza, J.D.; Pérez, J.F. Analysis of investment incentives for power generation based on an integrated plasma gasification combined cycle power plant using municipal solid waste. Case Stud. Therm. Eng. 2022, 30, 101748. [Google Scholar] [CrossRef]

- Kusano, R.; Kusano, Y. Applications of Plasma Technologies in Recycling Processes. Materials 2024, 17, 1687. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, B.; Wang, X.; Zhang, C.; Meng, X. Modelling, Linearity Analysis and Optimization of an Inductive Angular Displacement Sensor Based on Magnetic Focusing in Ships. J. Mar. Sci. Eng. 2023, 11, 1028. [Google Scholar] [CrossRef]

- Holcakova, R.; Marek, M. Innovative research in electron microscopes, analysis of magnetic field distribution of some types of magnetic lenses by FEM. In Proceedings of the 10th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 8–11 May 2011. [Google Scholar] [CrossRef]

- Abdelrahman, M.M. Factors enhancing production, extraction and focusing of positive ion beams. Ain Shams Eng. J. 2012, 3, 71–78. [Google Scholar] [CrossRef]

- Druyvesteyn, M.J.; Penning, F.M. The mechanism of electrical discharges in gases of low pressure. Rev. Mod. Phys. 1940, 12, 87–176. [Google Scholar] [CrossRef]

- Radmilovic-Radjenovic, M.; Radjenovic, B.; Bojarov, A.; Klas, M.; Matejcik, S. The breakdown mechanisms in electrical discharges: The role of the field emission effect in direct current discharges in micro gaps. Acta Phys. Slovaca 2013, 63, 105–205. Available online: http://www.physics.sk/aps/pubs/2013/aps-13-03/aps-13-03.pdf (accessed on 28 January 2025).

- Havelka, O.; Dubravec, B.; Gross, B.; Homa, V.; Novotný, V. Elektrické Přístroje; SNTL: Prague, Czech Republic, 1985. [Google Scholar]

- Ayrton, H. The Electric Arc; Cambridge University Press: Cambridge, UK, 1902. [Google Scholar] [CrossRef]

- Deng, R.; Cao, Q.; Gong, G.; Yang, H.; Shinshi, T.; Han, D. Multi-pole magnetization of NdFeB magnetic elastomers via a programmable magnetic stamp inspired by movable type printing. Sens. Actuat. A-Phys. 2024, 366, 114945. [Google Scholar] [CrossRef]

- Radwan-Pragłowska, N.; Radwan-Pragłowska, J.; Łysiak, K.; Janus, Ł.; Galek, T. Effect of laser-assisted surface modification of NdFeB permanent magnets applicable in high-demand working environment. Opt. Laser Technol. 2024, 174, 110611. [Google Scholar] [CrossRef]

- Liu, S.Q.; Xiu, S.X.; Qu, C.C.; Guo, M.Q.; Zhu, D.J.; Shen, Y.T. Study on structural parameters of cup-type axial magnetic contacts on gap magnetic field and arc characteristics. Vacuum 2024, 221, 112859. [Google Scholar] [CrossRef]

- Yoon, T.W.; Choi, M.; Hong, S.J. Thermal and electrical analysis of the electrostatic chuck for the etch equipment. IEEE Trans. Semicond. Manuf. 2023, 36, 653–665. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Y.; Li, Z.; Wang, Q.; Li, Y.; Chen, X.; Chen, P.; Lu, Z.; Su, B. On-demand 3D spatial distribution of magnetic permeability based on Fe3O4 nanoparticle liquid toward micro-cavity detectors. Small 2023, 20, 2306340. [Google Scholar] [CrossRef]

- Tashiro, S. Interaction Mechanism of Arc, Keyhole, and Weld Pool in Keyhole Plasma Arc Welding: A Review. Materials 2024, 17, 1348. [Google Scholar] [CrossRef]

- Yue, J.-Y.; Jiao, P.-C.; Sui, Y.; Lu, F.; Zhang, R.-Y.; Chen, W.-D.; Zhao, L.-S. Dispersed CeO2 Nanorods with Low-Speed Mixing for Mechanical Properties Promotion of PTA Steel Coatings. Coatings 2024, 14, 713. [Google Scholar] [CrossRef]

- Prommesberger, C.; Dams, F.; Langer, C.; Schreiner, R.; Rutkowski, S.; Bornmann, B.; Müller, G. Simulation of electron trajectories of a field emission electron source in triode configuration by using finite element methods. In Proceedings of the 2011 24th International Vacuum Nanoelectronics Conference, Wuppertal, Germany, 18–22 July 2011; pp. 115–116. Available online: https://ieeexplore.ieee.org/abstract/document/6004589 (accessed on 28 January 2025).

- Basu, A.; Velásquez-García, L. An electrostatic ion pump with nanostructured Si field emission electron source and Ti particle collectors for supporting an ultra-high vacuum in miniaturized atom interferometry systems. J. Micromech. Microeng. 2016, 26, 124003. [Google Scholar] [CrossRef]

- Datta, S.; Han, J.G.; Kumar, R.; Sahu, B.B. Experimental studies and COMSOL 1-D simulation in Ar capacitively coupled plasmas. AIP Adv. 2024, 14, 015046. [Google Scholar] [CrossRef]

- Colmenares, J.; Ghazi, D. Plasma Burner: Numerical Modeling of Plasma Generation and Flow; Luleå University of Technology, Department of Computer Science, Electrical and Space Engineering: Luleå, Sweden, 2021; Available online: https://www.diva-portal.org/smash/get/diva2:1595885/FULLTEXT01.pdf (accessed on 28 January 2025).

- Tao, J.; Li, C.; Cao, X.; Li, S.; Wang, J.; Hu, G. Modeling of the Arc Characteristics inside a Thermal Laminar Plasma Torch with Different Gas Components. Processes 2024, 12, 1207. [Google Scholar] [CrossRef]

- Uscila, R.; Grigaitienė, V.; Valinčius, V.; Kėželis, R.; Gimžauskaitė, D.; Kavaliauskas, Ž. Research on the Energy Characteristics of a Transferred Arc Plasma-Chemical Reactor for Waste Treatment. Appl. Sci. 2023, 13, 4221. [Google Scholar] [CrossRef]

- Elaissi, S.; Alsaif, N.A.M. Modeling and Performance Analysis of Municipal Solid Waste Treatment in Plasma Torch Reactor. Symmetry 2023, 15, 692. [Google Scholar] [CrossRef]

- Marinova, P.; Benova, E.; Topalova, Y.; Todorova, Y.; Bogdanov, T.; Zhekova, M.; Yotinov, I.; Krcma, F. Effects of Surface-Wave-Sustained Argon Plasma Torch Interaction with Liquids. Processes 2023, 11, 3313. [Google Scholar] [CrossRef]

- Onggar, T.; Frankenbach, L.A.; Cherif, C. Investigations of the Interface Design of Polyetheretherketone Filament Yarn Considering Plasma Torch Treatment. Coatings 2024, 14, 1424. [Google Scholar] [CrossRef]

- Praks, P.; Rasmussen, A.; Lye, K.O.; Martinovič, J.; Praksová, R.; Watson, F.; Brkić, D. Sensitivity analysis of parameters for carbon sequestration: Symbolic regression models based on open porous media reservoir simulators predictions. Heliyon 2024, 10, e40044. [Google Scholar] [CrossRef] [PubMed]

- Brzobohatý, T.; Říha, L.; Karásek, T.; Kozubek, T. Performance evaluation of OpenFOAM on many-core architectures. In AIP Conference Proceedings, Proceedings of the International Conference on Numerical Analysis and Applied Mathematics 2014 (ICNAAM-2014); AIP Publishing LLC.: Melville, NY, USA, 2015; Volume 1648, p. 830004. [Google Scholar] [CrossRef]

- Faltýnková, M.; Meca, O.; Brzobohatý, T.; Říha, L.; Jaroš, M.; Strakoš, P. Workflow for high-quality visualisation of large-scale CFD simulations by volume rendering. Adv. Eng. Softw. 2025, 200, 103822. [Google Scholar] [CrossRef]

| α [V] | β [V/m] 1 | γ [W] | δ [W/m] | |

|---|---|---|---|---|

| Cu–air | 17 | 2000 | 22 | 18,000 |

| C–air | 40 | 1200 | 20 | 10,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marek, M.; Brkić, D.; Praks, P.; Kozubek, T.; Frantík, J. Experimental Analysis of Magnetic Focusing of the Plasma Arc of a Cutting Torch. Materials 2025, 18, 1811. https://doi.org/10.3390/ma18081811

Marek M, Brkić D, Praks P, Kozubek T, Frantík J. Experimental Analysis of Magnetic Focusing of the Plasma Arc of a Cutting Torch. Materials. 2025; 18(8):1811. https://doi.org/10.3390/ma18081811

Chicago/Turabian StyleMarek, Martin, Dejan Brkić, Pavel Praks, Tomáš Kozubek, and Jaroslav Frantík. 2025. "Experimental Analysis of Magnetic Focusing of the Plasma Arc of a Cutting Torch" Materials 18, no. 8: 1811. https://doi.org/10.3390/ma18081811

APA StyleMarek, M., Brkić, D., Praks, P., Kozubek, T., & Frantík, J. (2025). Experimental Analysis of Magnetic Focusing of the Plasma Arc of a Cutting Torch. Materials, 18(8), 1811. https://doi.org/10.3390/ma18081811